#Industrial Water Storage Tank

Explore tagged Tumblr posts

Text

Modular Water Tanks | Water Tank Manufacturers – Frontier Polymers

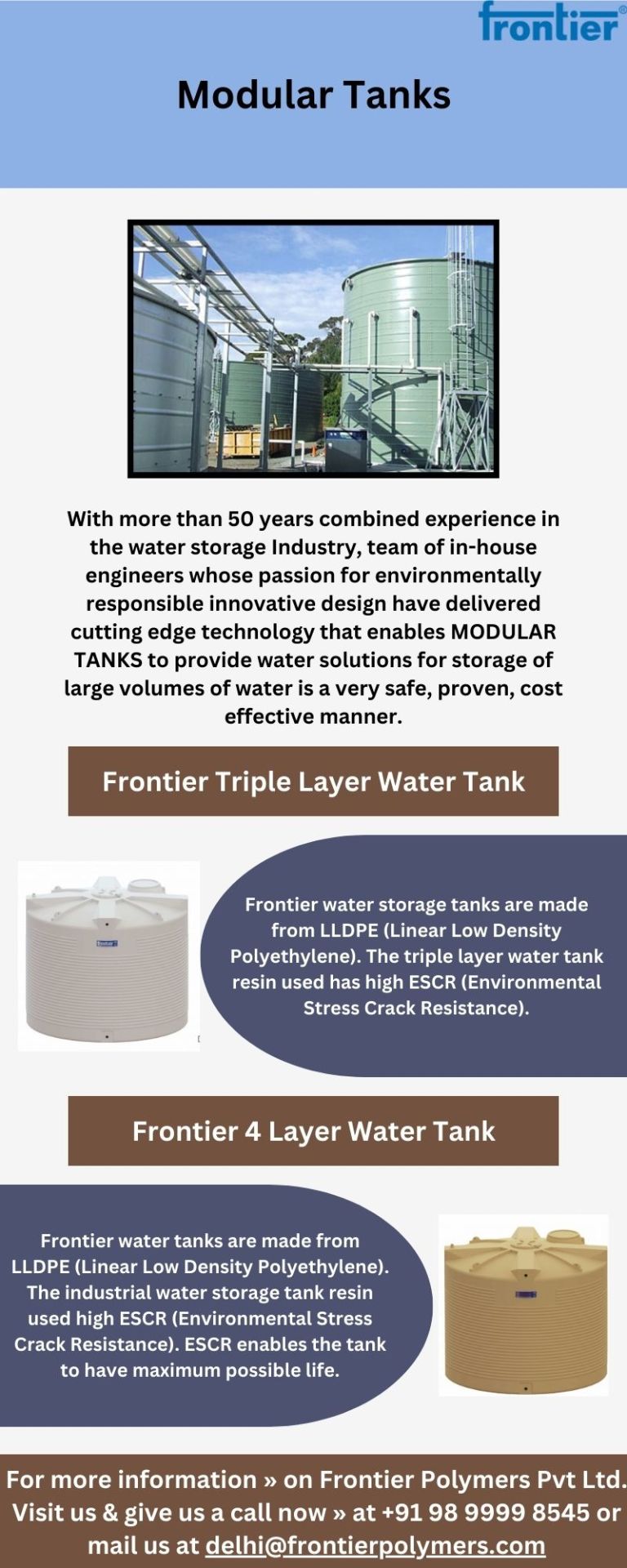

With over 50 years of expertise in the water storage industry. Frontier Polymers proudly presents modular water tanks. Our team of dedicated engineers, driven by their passion for environmentally responsible design, has developed cutting-edge technology that allows us to offer safe and cost-effective solutions for storing large volumes of water.

Modular water tanks are designed with your convenience in mind. Our innovative modular system enables easy installation and customization according to your specific needs. Whether you require a water storage solution for residential, commercial, or industrial use, our tanks provide reliable and efficient performance.

For more information » on Frontier Polymers Pvt Ltd. Visit us & give us a call now » at +91 98 9999 8545 or mail us at [email protected]

#Water Tank Manufacturers#Water Tanks India#Loft Tanks#Water Storage Tanks#Industrial Water Storage Tank

0 notes

Text

Steel Bolted Water Tanks in Australia – Reliable Water Storage Solutions

Water storage is a crucial requirement for industries, commercial establishments, and rural areas across Australia. Steel bolted water tanks in Australia offer a durable, cost-effective, and customizable solution for various applications. Prefab Tanks specializes in manufacturing high-quality bolted steel tanks, ensuring reliability and efficiency for all your water storage needs.

Why Choose Steel Bolted Water Tanks?

Steel bolted water tanks are widely used due to their strength, versatility, and ease of installation. Unlike traditional welded tanks, bolted steel tanks can be assembled quickly and relocated if necessary.

Key Benefits of Bolted Steel Tanks

✔ High Durability – Made from premium steel, these tanks are resistant to corrosion, harsh weather, and UV exposure. ✔ Customizable Water Tanks – Available in various sizes and configurations to meet specific industrial and commercial requirements. ✔ Quick & Easy Installation – Modular design allows for faster setup compared to conventional storage solutions. ✔ Low Maintenance – Coated with protective layers to prevent rust and contamination. ✔ Eco-Friendly & Cost-Effective – Sustainable water storage with reduced maintenance costs over time.

Industrial Water Tanks in Australia

Prefab Tanks is a trusted provider of industrial water tanks in Australia, serving diverse industries such as:

Agriculture & Irrigation

Mining & Construction

Fire Protection & Emergency Water Storage

Municipal & Drinking Water Supply

Wastewater & Chemical Storage

Customizable Water Tanks for Every Need

Our steel water storage solutions are designed to suit various applications, whether you need water storage tanks in Australia for residential, industrial, or commercial use. We offer customizable water tanks tailored to your specifications.

Prefab Tanks – Your Trusted Water Storage Partner

As one of the leading manufacturers of bolted steel tanks, Prefab Tanks provides high-quality, long-lasting Australia water tanks that meet international standards. Whether you need a large-capacity industrial water tank or a compact water storage solution, we have the perfect product for you.

📞 Contact Us Today! 🌐 Visit: https://prefabtanks.com.au/steel-bolted-water-tanks-in-australia.html

#SteelBoltedWaterTanks #WaterStorageAustralia #PrefabTanks #BoltedSteelTanks #IndustrialWaterTanks #CustomWaterTanks #WaterStorageSolutions

#“”“Steel bolted water tanks in Australia#water storage tanks Australia#Prefab tanks#industrial water tanks Australia#bolted steel tanks#customizable water tanks#steel water storage solutions#Australia water tanks“”

0 notes

Text

Top Water Storage Tank Supplier in India | Industrial, Agricultural & Firefighting Solutions

Reliable Water Storage Solutions in India – Commercial, Industrial & Agricultural Tanks

Water storage is essential for industries, agriculture, and municipal applications. Our high-quality commercial, industrial, and agricultural water storage tanks are designed for durability, efficiency, and long-term performance.

Our Storage Tank Solutions:

✔ Commercial & Industrial Storage Tanks – Ideal for manufacturing, processing, and raw water storage. ✔ Agricultural & Rainwater Tanks – Sustainable storage for irrigation and farming. ✔ Firefighting & Wastewater Tanks – FM-approved and corrosion-resistant solutions.

As a leading water storage tank supplier in India, we offer GFS tanks, FM-approved tanks, and zinc aluminium steel tanks.

#Commercial water storage tanks#Commercial water storage tanks in India#Agricultural water storage tanks#Agricultural water storage tanks in india#industrial storage tanks#industrial storage tanks in india#wastewater storage tanks#wastewater storage tanks in india#raw water storage tank#raw water storage tanks in india#firefighting storage tanks#firefighting storage tanks in india#rain water storage tanks#rain water storage tanks in india#process water storage tanks#process water storage tank in india#water storage tank supplier in india#GFS tank in india#FM approved tank#FM approved tank supplier in india#GFS tank supplier in india#Zinc aluminium steel tanks supplier#zinc aluminium steel tank supplier in india

0 notes

Text

Top-Quality Commercial Water Storage Tanks in India – COEP Prefab Water Tanks 💦🏗️

COEP Prefab Water Tanks is a leading provider of commercial water storage tanks in India, delivering durable and efficient storage solutions for various industries. Whether you need industrial water storage tanks in Pune or custom water storage tanks in India, our expertise ensures high-performance water containment systems tailored to your needs. ✅🌍

Why Choose COEP Prefab Water Storage Tanks? 🔩💧

✔️ Premium Quality & Durability – Our GFS tanks, GFL tanks, and steel bolted tanks are made from corrosion-resistant materials, ensuring long-lasting performance. ✔️ Custom Solutions Available – We specialize in custom water storage tanks in India, offering flexible designs and sizes to meet specific industrial requirements. ✔️ Ideal for Industrial & Commercial Use – Our industrial GFS water tanks in India are perfect for factories, manufacturing plants, commercial buildings, and municipal projects. ✔️ Reliable & Certified – As a trusted name in commercial water storage tanks in Pune, we adhere to global safety and quality standards.

Best Commercial Water Storage Tanks in Pune & India 🌎💦

Our coepprefabwatertanks storage tanks in India are widely used across various industries, including agriculture, food processing, pharmaceuticals, and fire protection systems. Whether you need a GFS tank in India for bulk water storage or a GFL tank for industrial use, we offer high-quality solutions designed for efficiency and sustainability.

Leading Industrial Water Storage Tanks Supplier in Pune 🔥🏭

As a recognized provider of industrial water storage tanks in Pune, COEP Prefab Water Tanks ensures optimal water management solutions for industries requiring large-scale and reliable water storage. Our GFS tanks, GFL tanks, and custom-built storage solutions meet diverse commercial and industrial demands.

💡 Discover More: 👉 COEP Prefab Water Tanks

🔹 Hashtags: #CommercialWaterStorageTanks #IndustrialWaterStorage #COEPPrefabWaterTanks #GFS #GFLTanks #StorageSolutions #WaterStorageIndia 🚀💧

#Commercial water storage tanks#Commercial water storage tanks in Pune#Commercial water storage tanks in India#coepprefabwatertanks storage tanks in India#GFS tank in India#GFL tank#Gfs tank#Industrial GFS water tanks India#Custom water storage tanks India#Industrial water storage tanks Pune

0 notes

Text

Mixing Vessels for Pharmaceutical Industry

In the pharmaceutical industry, precision and consistency are crucial for ensuring product quality and compliance. Mixing vessels play a vital role in the production of liquid formulations, emulsions, and suspensions, enabling uniform blending under controlled conditions. These vessels are designed to meet stringent regulatory standards, making them essential for pharmaceutical manufacturing.

Key Features of Pharmaceutical Mixing Vessels

Hygienic Design – Constructed from stainless steel (SS 316L/SS 304) with electropolished surfaces to prevent contamination.

Advanced Mixing Technology – Equipped with agitators, stirrers, and homogenizers for precise and uniform blending.

Temperature & Pressure Control – Features jacketed designs for heating, cooling, and maintaining optimal processing conditions.

Regulatory Compliance – Meets cGMP, FDA, and ASME BPE standards, ensuring adherence to industry regulations.

Customizable Capacities – Available in various sizes and configurations to suit different production requirements.

Applications of Mixing Vessels in Pharmaceuticals

Syrup & Suspension Manufacturing – Ensures homogeneity and stability in liquid formulations.

Emulsions & Creams – Facilitates the production of ointments, lotions, and topical solutions.

Biopharmaceutical Processing – Used in buffer preparation and culture media mixing.

Sterile Solutions & Injections – Maintains aseptic conditions for injectable drug manufacturing.

Benefits of Using High-Quality Mixing Vessels

Consistent Product Quality – Ensures uniform blending for reliable pharmaceutical formulations.

Enhanced Efficiency – Optimized mixing processes reduce production time and improve batch consistency.

Minimal Contamination Risk – Sanitary designs prevent microbial growth and cross-contamination.

Cost-Effective Production – Reduces material wastage and improves process efficiency.

Why Choose Swjal Process Pvt. Ltd.?

Swjal Process Pvt. Ltd. specializes in manufacturing high-quality pharmaceutical Stainless Steel mixing vessels, designed to meet the highest industry standards. With expertise in customized solutions, automation, and regulatory compliance, Swjal provides reliable, GMP-compliant equipment tailored to pharmaceutical needs. Partner with Swjal for innovative and efficient pharmaceutical mixing solutions.

#SS Mixing Vessle with Agiators#Stainless Steel Vessels#SS Tank#Pharmacutical Industry Vessles#Mixing Tank#Manufacturers#inudstrial storage vessles#pharmaceutical water treatment

0 notes

Text

Custom Metal Design and Manufacturing Services

Our platework steel fabrication methods utilize state-of-the-art machinery to ensure precision and consistency. Contact us now!

#custom steel tanks fabricator#chemical process tanks#fabricated tanks#settling tank wastewater treatment#custom industrial tanks#constructed steel process tanks#custom steel process tanks#platework steel fabrication#field erected storage tanks#stainless steel mixing tanks#stainless steel water tanks#stainless steel tank#stainless steel tanks

0 notes

Text

Reliable FRP Water Tank Manufacturer – Sagar FRP Industries

As a leading FRP water tank manufacturer, Sagar FRP Industries specializes in producing high-quality, corrosion-resistant fiberglass tanks. Our tanks are designed for maximum durability and safe, efficient water storage in any environment.

#FRP tank manufacturers#FRP chemical storage tank manufacturer#FRP anti corrosive chemical tank manufacturer in Gurgaon#FRP fire fighting water tank manufacturer industry#FRP bottom storage tank manufacturer in Gurgaon#FRP feedwell manufacturers

0 notes

Text

Ensuring Durability and Strength: Why MKV Tech Solutions is Your Trusted Water Storage Tank Partner

In today’s rapidly evolving industrial landscape, businesses demand innovative and reliable solutions for their water storage needs. MKV Tech Solutions stands at the forefront, offering top-notch water storage tanks that combine durability, strength, and advanced technology. Whether you’re in need of a Zincalume water storage tank or an industrial-grade demineralized water tank, We delivers unparalleled quality and service.

Zincalume Water Storage Tank Manufacturers

When it comes to water storage, Zincalume tanks have become a popular choice due to their excellent corrosion resistance and long-lasting durability. As leading Zincalume Water Storage Tank Manufacturers, We ensures that each tank is engineered with precision, utilizing cutting-edge Zincalume steel technology. These tanks are ideal for industrial use, providing longevity and reliable performance in a variety of challenging environments.

Zinc Aluminium Water Storage Tank Manufacturers

We also recognized as a premier Zinc Aluminium Water Storage Tank Manufacturers, offering tanks that leverage the unique properties of zinc and aluminum alloys. The combination of these metals enhances the tank’s strength and corrosion resistance, making them a perfect fit for both industrial and commercial applications. With our expert craftsmanship, each tank meets the highest industry standards, ensuring safety and efficiency for our clients.

Industrial Water Storage Tank Service Provider

At MKV Tech Solutions, we take pride in being a leading Industrial Water Storage Tank Service Provider. Our commitment goes beyond just manufacturing; we provide comprehensive services that include consultation, installation, and maintenance. Our expert team is equipped to handle the most complex storage needs, ensuring that your industrial water systems operate smoothly and efficiently, no matter the scale of your project.

Demineralized Water Tank Suppliers

For industries that require ultra-pure water, such as pharmaceuticals, power generation, and food processing, we are trusted Demineralized Water Tank Suppliers. Our demineralized water tanks are designed to prevent contamination and preserve water purity. These tanks are built to withstand rigorous industrial environments while maintaining the high standards required for demineralized water storage.

Zincalume Steel Storage Tank Suppliers

As reputable Zincalume Steel Storage Tank Suppliers, we ensure that all our storage solutions meet the evolving needs of modern industries. The Zincalume steel we use combines the best properties of zinc and aluminum, resulting in tanks that are not only robust but also offer superior corrosion protection. These tanks are perfect for long-term use, ensuring that your investment is safeguarded for years to come.

Why Choose MKV Tech Solutions?

MKV Tech Solutions is dedicated to providing reliable, cost-effective, and innovative water storage solutions to clients across various industries. Our products, backed by exceptional customer service, stand as a testament to our commitment to quality. Whether you’re looking for Zincalume water storage tanks or demineralized water tanks, we deliver customized solutions tailored to meet your unique needs.

By choosing us you’re investing in superior water storage systems that are built to last. Trust us to deliver the quality and performance your business deserves.

#Zincalume Water Storage Tank Manufacturers#Zinc Aluminium Water Storage Tank Manufacturers#Industrial Water Storage Tank Service Provider#Demineralized Water Tank Suppliers#Zincalume Steel Storage Tank Suppliers

0 notes

Text

Looking for high-quality Industrial Storage Tanks in Ahmedabad? We offer various durable and reliable storage solutions for various industries, including chemical, petroleum, food processing, water treatment, and more. Our tanks are engineered to meet the most demanding specifications and ensure safe liquids, chemicals, and gases storage.

1 note

·

View note

Text

Water Storage Systems Market to Surge: Steel, Fiberglass, Concrete, and Plastic Solutions Lead the Way

The global Water Storage Systems market is poised for significant expansion in 2024, driven by increasing demand for efficient water management solutions, climate change concerns, and rapid urbanization. The Water Storage Systems Market size is projected to reach USD 25.1 billion by 2027 from USD 16.5 billion in 2022 growing at a CAGR of 8.7%. The market encompasses various technologies designed…

#Concrete Water Storage Systems#plastic water storage tanks#potable water storage tanks#underground water storage tanks#water cistern systems#water reservoir tanks#Water Storage Systems#Water Storage Systems Industry#Water Storage Systems Industry Trends#Water Storage Systems manufacturers#Water Storage Systems market#Water Storage Systems Market Analysis#Water Storage Systems Market Growth#Water Storage Systems Market Share#water storage tanks

0 notes

Text

Unveiling the Advantages of Hot Press GRP Panel Tanks for Potable Water Storage

Introduction

Choosing the right material for potable water storage involves evaluating various factors, such as hygiene, durability, environmental impact, and customization. Among the options available, hot press GRP (Glass Reinforced Plastic) panel tanks excel due to their superior attributes. Here’s a closer look at why hot press GRP tanks surpass other materials in providing safe and effective water storage solutions.

Optimal Hygiene and Chemical Purity

Conventional GRP Tanks: Standard GRP tanks, composed of fiberglass and resin, can retain volatile chemicals that might leach into the water if the resin is not fully cured. This poses risks to water quality and safety.

Concrete Tanks: Concrete’s porous nature can lead to the leaching of minerals such as lime, which can alter the water’s taste and quality. Regular maintenance is necessary to avoid contamination from cracks and leaks.

Steel Tanks: Steel tanks often need protective coatings to prevent rust and corrosion, which can deteriorate over time and potentially introduce harmful chemicals into the water. They also have a higher rust risk if the coating is damaged.

In contrast, hot press GRP tanks are manufactured at high temperatures, which evaporates any residual chemicals from the material, resulting in a stable and inert composite. This ensures that no harmful substances leach into the water, thereby maintaining its purity.

Exceptional Durability and Longevity

Conventional GRP Tanks: Although reasonably strong, standard GRP tanks can suffer from inconsistent strength and surface finish, leading to potential damage and deterioration over time, especially in harsh conditions.

Concrete Tanks: While concrete tanks are durable, they are prone to cracking and erosion and require regular inspections and maintenance to maintain their integrity.

Steel Tanks: Steel tanks are vulnerable to corrosion, particularly in humid or saline environments, and require ongoing maintenance and protective coatings to prevent rust.

Hot press GRP tanks, made from Sheet Molding Compound (SMC) and subjected to high pressure, feature a dense and uniform structure that offers superior resistance to physical damage, environmental stress, and chemical corrosion. This ensures a longer-lasting and more reliable storage solution.

Environmental Benefits and Efficiency

Conventional GRP Tanks: While an improvement over some alternatives, standard GRP tanks still involve resins that may have environmental impacts during production.

Concrete Tanks: Concrete production is highly energy-intensive and contributes significantly to CO2 emissions. Additionally, concrete tanks are heavy and resource-demanding in terms of transport and installation.

Steel Tanks: Steel production is resource-heavy and involves mining and processing that contribute to environmental degradation. Steel tanks also have a larger carbon footprint due to their weight and the need for protective coatings.

Hot press GRP tanks are manufactured with minimal environmental impact. The high-temperature process eliminates excess chemicals, and their lightweight nature reduces transportation emissions. Their durability also means fewer replacements and less overall waste.

Flexibility and Customization

Conventional GRP Tanks: While versatile, standard GRP tanks may lack the precise customization and finish that hot press tanks offer.

Concrete Tanks: Customizing concrete tanks can be challenging, often requiring significant on-site adjustments, and they are cumbersome to transport and install.

Steel Tanks: While customizable, steel tanks often need additional coatings and treatments, and their heavy weight can complicate installation.

Hot press GRP tanks offer outstanding flexibility in terms of size, shape, and features. The precision of the hot pressing process allows for exact specifications and customization, making them suitable for a wide range of applications.

In summary, hot press GRP panel water tanks provide unparalleled benefits over other materials for potable water storage. Their superior hygiene, durability, environmental efficiency, and customization options make them the optimal choice for safe and effective water storage.

#tanks#business#water tank#water industry#grp water tanks#architecture#water treatment#watertreatment#construction#water storage tanks#civil engineering#mechanical engineering#mep design

1 note

·

View note

Text

Water Storage Tanks | Industrial Water Storage Tank - Frontier Polymers

Frontier water tanks are expertly manufactured using LLDPE linear low-density polyethylene to ensure durability and reliability. Our industrial water storage tank resin is specifically chosen for its high ESCR environmental stress crack resistance. guaranteeing a long lifespan for the tank.

We take pride in producing 4-layer UV-stabilized water storage tanks that effectively prevent degradation and cracking. .With our commitment to quality, you can trust that our tanks will meet your needs and provide reliable water storage solutions.

For more information » on Frontier Polymers Pvt Ltd. Visit us & give us a call now » at +91 98 9999 8545 or mail us at [email protected]

#Water Storage Tanks#Water Tank Manufacturers#Triple Layer Water Tank#Industrial Water Storage Tank#Plastic Pickling Tanks

0 notes

Text

Industrial Water Storage Tanks and Firefighting Tanks Supplier in India

Prefabtanks provides reliable and durable industrial water storage tanks and firefighting tanks for businesses across India. Our tanks are designed to meet the toughest requirements for water storage and firefighting, offering high performance, longevity, and low maintenance. We specialize in industrial fire fighting storage tanks and industrial water tanks, ensuring that your facility is always prepared for emergencies and efficient water management.

As a leading industrial water tanks supplier in India, Prefabtanks offers customized solutions that meet diverse industrial needs, from large-scale factories to small businesses. Our tanks are built to last, with robust materials that withstand extreme conditions, ensuring both safety and functionality.

Whether you're looking for industrial fire fighting tanks or other industrial water storage solutions, Prefabtanks is your trusted partner for sustainable and reliable water storage. Visit our website to explore our full range of industrial tanks and discover how we can help safeguard your operations.

For more details, visit our Industrial Water Tanks page.

#Industrial fire fighting tanks#Industrial fire fighting tanks in India#Industrial fire fighting tanks India#Industrial fire fighting tanks near me#Prefab tanks storage tank#Industrial water storage tanks#industrial tanks#industrial storage tanks#industrial water tanks supplier in india#industrial fire fighting storage tanks supplier#industrial fire fighting storage tanks supplier in india#industrial water tanks#industrial water tanks in india

0 notes

Text

COEP Prefab Overseas Projects – Global Water Tank Suppliers 🌍💧

COEP Prefab Water Tanks is a trusted name in industrial water storage tanks worldwide, providing high-quality storage solutions for various industries. As global water tank suppliers, we specialize in steel bolted tanks, GFS tanks, GLS tanks, ETP tanks, STP tanks, and bio digester tanks, ensuring efficient and long-lasting water storage solutions across multiple sectors. 🏗️💦

Why Choose COEP Prefab for Global Water Storage Solutions? 🌎🔩

✔️ Expertise in Overseas Projects – With successful COEP Prefab overseas projects, we have delivered storage tanks for industrial, commercial, and municipal applications worldwide. ✔️ Premium Quality Tanks – Our GFS tanks, GLS tanks, and steel bolted tanks are designed to withstand extreme weather conditions and provide superior durability. ✔️ Wide Range of Applications – We manufacture ETP tanks, STP tanks, SWRO storage tanks, and UASB system tanks for wastewater treatment, industrial storage, and bio digestion processes. ✔️ Customizable & Reliable – Our storage tanks are available in various sizes and specifications to meet global industry standards.

Industrial Water Storage Tanks Worldwide 🌎💧

From Asia to Europe, Africa to the Middle East, COEP Prefab Water Tanks is committed to delivering top-notch storage solutions. Our bio digester tanks and UASB system tanks are widely used for wastewater treatment and bio-energy generation. Whether you need STP tanks for sewage treatment or SWRO storage tanks for desalination plants, we offer high-performance storage solutions tailored to your needs.

Reliable Global Water Tank Suppliers 🌏🏗️

We take pride in being one of the leading global water tank suppliers, offering cutting-edge storage technology that ensures efficiency, sustainability, and durability. With a track record of successful COEP Prefab overseas projects, we continue to expand our reach, delivering industrial water storage tanks worldwide.

💡 Explore More: 👉 COEP Prefab Water Tanks - Overseas Projects

🔹 Hashtags: #GlobalWaterTankSuppliers #COEPPrefabOverseasProjects #IndustrialWaterStorage #SteelBoltedTanks #GFS #GLSTanks #ETPTanks #STPTanks #StorageTanks #BioDigesterTanks #UASBSystem 🚀💦

#Global water tank suppliers#Coepprefab overseas projects#Industrial water storage tanks worldwide#steel bolted tanks#GFS tank#GLS tank#ETP Tank#Storage tanks#bio digester tank#UASB system#STP tanks#SWRO storage tank

0 notes

Text

Industrial Vessels in Different Industries

Industrial vessels are integral to numerous industries, providing crucial functions that enhance productivity, safety, and efficiency.

1. Pharmaceutical Industry

In the pharmaceutical sector, industrial vessels must adhere to stringent regulatory standards to ensure product quality and safety. Stainless steel is a common material for these vessels, as it resists corrosion and can withstand sterilization processes. Pharmaceutical-grade vessels include mixing tanks for compounding ingredients, reactor vessels for synthesizing active pharmaceutical ingredients (APIs), and storage tanks for purified water. Cleanability is a top priority, with vessels often equipped with CIP (Clean-in-Place) systems to maintain sterile conditions. By maintaining high standards of hygiene and precision, industrial vessels in this industry contribute to the safe production of medicines and other healthcare products.

2. Chemical Industry

The chemical industry heavily relies on industrial vessels for storing and processing volatile or hazardous substances. Reactor vessels enable controlled chemical reactions, while separation vessels play a role in refining raw materials. Materials like carbon steel and stainless steel are preferred due to their durability and resistance to chemicals. Tanks with advanced coatings are often used to handle corrosive chemicals, enhancing the lifespan of the equipment. Safety features, such as pressure-relief valves and fire-resistant designs, are crucial in this industry to prevent accidents and ensure compliance with safety regulations.

3. Food and Beverage Industry

Industrial vessels are essential in the food and beverage sector, where they are used to mix, process, and store ingredients under sanitary conditions. Stainless steel vessels are commonly employed, as they resist corrosion, are easy to clean, and do not react with food-grade ingredients. Mixing vessels help ensure uniformity in products like sauces, dairy, and beverages, while storage tanks are used to maintain the freshness of ingredients such as oils, syrups, and flavorings. Temperature-controlled tanks are often employed to keep perishable items fresh. Industrial vessels in this industry meet regulatory standards to maintain product quality and prevent contamination.

4. Oil and Gas Industry

Industrial vessels in the oil and gas sector must be robust and capable of withstanding harsh conditions. Storage tanks are essential for holding crude oil, refined fuels, and other hydrocarbons, while separation vessels are used in refining processes to separate oil, water, and gas. Spherical and cylindrical tanks are typical in this sector, with materials such as carbon steel and alloys used to handle high pressures and temperatures. Corrosion resistance and fire safety are critical in these vessels, as the materials stored are often flammable and subject to regulatory oversight. Industrial vessels in this industry are engineered to ensure safe handling and storage, protecting both personnel and the environment.

5. Water Treatment and Wastewater Management

In water treatment facilities, industrial vessels are used to store and process water at various stages of treatment. Stainless steel and fiberglass-reinforced plastic (FRP) are common materials, as they resist corrosion from chemicals used in purification processes. Storage tanks hold raw water, while mixing vessels add treatment chemicals. Clarifiers and sedimentation tanks remove solids, while holding tanks store treated water before distribution. Industrial vessels in this industry contribute to efficient water management, ensuring that clean, potable water is available for communities and industries.

Key Considerations for Selecting Industrial Vessels

When selecting industrial vessels, several factors are considered to ensure safety, compatibility, and efficiency.

Material Compatibility: Vessels must be made of materials compatible with the substances they will contain. For example, stainless steel is ideal for pharmaceutical and food applications, while FRP works well in water treatment.

Capacity and Size: Determining the right size and capacity is essential for optimizing production processes. Larger operations may require custom-sized vessels, while small-scale processes may benefit from compact designs.

Pressure and Temperature Resistance: High-pressure applications require reinforced vessels, while those exposed to varying temperatures must be designed to prevent structural damage. In chemical industries, vessels may be lined or coated to withstand corrosive environments.

Safety and Compliance: Industries dealing with hazardous or flammable substances must follow strict safety regulations. Pressure-relief valves, explosion-proof designs, and automated monitoring systems are often implemented to meet regulatory standards and protect workers.

Maintenance and Cleaning Requirements: Some applications, like pharmaceuticals and food processing, require frequent cleaning. CIP (Clean-in-Place) systems are integrated to allow for thorough cleaning without disassembling the vessel, ensuring hygiene and minimizing downtime.

Conclusion

Industrial vessels serve as the backbone of multiple industries, enabling efficient, safe, and compliant operations. Each industry relies on specialized vessels, tailored to meet specific needs while adhering to safety and regulatory standards. With innovations in materials and design, these vessels continue to evolve, offering increased durability, efficiency, and environmental sustainability.

#Industrial Vessels#storage vessels#inudstrial storage vessles#storage tanks#water treatment#chemical#cosmetic#food and beverage#paper and pulp industry#pharmaceutical water treatment#water solution#swjalprocess

0 notes

Text

What is the Role of Fire Water Storage Tank?

The Role of Fire Water Storage Tanks:

Fire water storage tanks are specifically designed reservoirs that store large quantities of water for firefighting purposes. They are strategically placed in industrial facilities, commercial complexes, and even residential areas where the risk of fire is significant. These tanks act as a critical resource, providing immediate access to water during emergencies when a rapid response is essential to control and extinguish fires effectively.

Design and Construction

The design of fire water storage tanks is meticulous and adheres to stringent safety standards and regulations. Key considerations include capacity, location, accessibility, and the materials used for construction. Tanks are typically constructed from materials like steel, concrete, or fiberglass, chosen for their durability and ability to withstand fire-related stress and environmental factors.

Capacity and Sizing

The size and capacity of fire water storage tanks vary widely based on the specific needs of the site they serve. Facilities with higher fire risk, such as petrochemical plants or large industrial complexes, require larger tanks capable of holding thousands to millions of gallons of water. Sizing calculations take into account factors such as potential fire hazard, water demand for firefighting equipment, and regulatory requirements.

Emergency Response Readiness

The primary function of fire water storage tanks is to ensure readiness for emergency response. In the event of a fire, rapid access to a large volume of water can make the critical difference in containing the blaze before it spreads uncontrollably. Firefighters rely on these tanks to supply water to firefighting systems like hydrants, sprinkler systems, and fire hoses, enabling them to quickly and efficiently combat fires and protect lives and property.

Maintenance and Compliance

Regular maintenance and compliance with safety standards are essential aspects of managing fire water storage tanks. Inspections, testing of water quality, and upkeep of tank integrity are routine tasks that ensure the tanks remain operational and reliable. Compliance with regulatory requirements also ensures that the tanks meet environmental standards and are equipped to handle emergencies effectively.

Conclusion

Fire water storage tanks are not merely passive installations; they are critical assets in the proactive defense against fire hazards. Their presence and functionality can mean the difference between a contained fire incident and a catastrophic disaster. As technologies and safety protocols evolve, so too does the design and implementation of these essential structures, ensuring that they continue to play a pivotal role in safeguarding communities and industries worldwide.

Top Fire Water Storage Tank Manufacturer in India

Are you looking for Fire Water Storage Tank Manufacturer in India. look no further than Orison Industries, we are a leading manufacturer and supplier of Fire Water Storage Tank in India.

For more details, please contact us!

Website :- www.orisonindustries.in

Contact No. :- +91-8860602980

Email :- [email protected]

#Fire Water Storage Tank Manufacturer in India#Fire Water Storage Tank Supplier in India#Fire Water Storage Tank Manufacturer in Delhi#Fire Water Storage Tank Manufacturer in Ghaziabad#Fire Water Storage Tank Manufacturer in Noida#Fire Water Storage Tank Manufacturer in Faridabad#Fire Water Storage Tank Manufacturer in Gurugram#Orison industries

0 notes