#wastewater storage tanks in india

Explore tagged Tumblr posts

Text

Top Water Storage Tank Supplier in India | Industrial, Agricultural & Firefighting Solutions

Reliable Water Storage Solutions in India – Commercial, Industrial & Agricultural Tanks

Water storage is essential for industries, agriculture, and municipal applications. Our high-quality commercial, industrial, and agricultural water storage tanks are designed for durability, efficiency, and long-term performance.

Our Storage Tank Solutions:

✔ Commercial & Industrial Storage Tanks – Ideal for manufacturing, processing, and raw water storage. ✔ Agricultural & Rainwater Tanks – Sustainable storage for irrigation and farming. ✔ Firefighting & Wastewater Tanks – FM-approved and corrosion-resistant solutions.

As a leading water storage tank supplier in India, we offer GFS tanks, FM-approved tanks, and zinc aluminium steel tanks.

#Commercial water storage tanks#Commercial water storage tanks in India#Agricultural water storage tanks#Agricultural water storage tanks in india#industrial storage tanks#industrial storage tanks in india#wastewater storage tanks#wastewater storage tanks in india#raw water storage tank#raw water storage tanks in india#firefighting storage tanks#firefighting storage tanks in india#rain water storage tanks#rain water storage tanks in india#process water storage tanks#process water storage tank in india#water storage tank supplier in india#GFS tank in india#FM approved tank#FM approved tank supplier in india#GFS tank supplier in india#Zinc aluminium steel tanks supplier#zinc aluminium steel tank supplier in india

0 notes

Text

💧 Efficient Wastewater Storage Solutions in Pune & India 🌍

Looking for wastewater storage tanks in Pune? 🌊 COEP Prefab Water Tanks offers high-quality wastewater containment tanks in Pune designed for safe and efficient wastewater management. Our wastewater storage tanks in India are engineered to handle industrial and municipal wastewater, ensuring compliance with environmental regulations.

🌐 Visit Now: Wastewater Storage Tanks in Pune

✅ Why Choose Our Wastewater Storage Tanks?

🔹 Durable & Corrosion-Resistant – Our COEP wastewater storage solutions in India are built from top-quality materials for long-lasting performance. 🔹 Leak-Proof & Secure – Our wastewater storage tanks in Pune provide a robust containment system to prevent leakage and contamination. 🔹 Customizable for Various Needs – Available in different capacities, our wastewater containment tanks in Pune cater to industrial, commercial, and municipal applications. 🔹 Sustainable & Eco-Friendly – Designed for Effluent Treatment Plants tanks, these storage solutions support wastewater recycling and treatment.

🚀 Applications of Wastewater Storage Tanks

✔️ Industrial wastewater management 🏭 ✔️ Municipal sewage treatment systems 🌱 ✔️ Effluent storage in treatment plants 🏢 ✔️ Environmental and sustainability projects 🌎

As leading COEP wastewater tanks suppliers in Pune, we specialize in wastewater treatment storage tanks in Pune, ensuring efficiency and reliability in water treatment systems. Our efficient wastewater tanks in India are an essential part of sustainable water management strategies for industries across the country.

📞 Contact us today for high-performance wastewater storage tanks in India! 💧

🔗 Explore More

#WastewaterStorage #WastewaterTanks #EffluentTreatmentTanks #COEPPrefabWaterTanks #WaterManagement #EcoFriendlySolutions #StorageTanksIndia #WastewaterSolutions 🚰

#Waste water storage tanks#Wastewater storage tanks in Pune#Wastewater storage tanks in India#coepprefabwatertanks storage tanks in India#Wastewater containment tanks Pune#COEP wastewater tanks suppliers Pune#COEP wastewater storage solutions India#Wastewater treatment storage tanks Pune#Efficient wastewater tanks in India#Effluent Treatment Plants tank

0 notes

Text

High-Quality Water Storage Solutions in Pune | Glass Fused Steel Tanks

When it comes to reliable water storage solutions in Pune, our glass-fused steel tanks stand out as the top choice for various industrial and domestic needs. Whether you're looking for raw water storage tanks in Pune or advanced systems like industrial fire-fighting tanks in India, we provide robust and durable storage options tailored to your requirements.

Glass Fused Steel Tanks: Superior Storage Technology

Glass fused steel (GFS) tanks are known for their strength, longevity, and corrosion resistance. These tanks offer a highly effective solution for storing liquids in a range of industries, from potable water to hazardous materials. Our glass fused steel tank manufacturing facility ensures that every tank is produced to the highest standards, providing unmatched durability and safety.

DM Water Storage Tanks in India

Demineralized (DM) water is essential in various industrial processes, and proper storage is critical for maintaining its quality. We offer top-tier DM water storage tanks in India, designed to preserve the purity and integrity of demineralized water for industrial applications.

FM Global Tanks and Industrial Fire Fighting Tanks in Pune

In fire-prone industries, FM Global tanks in Pune provide an extra layer of protection. These tanks are FM-approved, ensuring the highest level of safety and compliance. Our industrial fire-fighting tanks in Pune are built to store large volumes of water, providing an immediate and reliable source in emergency situations.

Wastewater and Potable Water Storage Tanks

We also specialize in wastewater storage tanks in India, ideal for efficiently handling and storing wastewater before treatment. Additionally, our potable and domestic water storage tanks in Pune provide safe and hygienic storage solutions for residential and commercial uses.

Zinc Aluminium Steel and Bolted Steel Tanks

Our range extends to zinc aluminium steel tanks in Pune, which combine strength with corrosion resistance, making them suitable for a variety of industrial applications. We also offer steel bolted water tanks, providing a versatile and modular option for your water storage needs.

Choose our advanced, durable, and cost-effective storage solutions to meet your industrial and domestic water storage requirements in Pune and across India.

#Raw water storage tanks in Pune#Industrial fire fighting tanks in Pune#Industrial fire fighting tanks India#DM water storage tanks in India#FM global tanks in Pune#Wastewater storage tanks in India#Potable & domestic water storage tanks in Pune#Zinc aluminium steel tanks in Pune#Glass fused steel tanks#Glass fused steel tank manufacturer near#Gfs Tank in India#Steel bolted water tanks

0 notes

Text

Preserving Assets: The Role of Corrosion Inhibitors in Industrial Maintenance

Corrosion is a persistent threat to industrial assets, causing billions of dollars in damages annually across various sectors. From oil and gas facilities to manufacturing plants, the impact of corrosion can be devastating, leading to equipment failures, production downtime, and costly repairs. However, with the right preventive measures in place, such as corrosion inhibitors, industrial facilities can effectively mitigate the risk of corrosion and prolong the lifespan of their assets. As a leading chemical company in Vadodara, Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) understands the critical role of corrosion inhibitors in industrial maintenance. In this blog post, we'll explore the importance of corrosion inhibitors, their applications, and the expertise of ICPL as a corrosion inhibitor manufacturer and exporter in India.

Understanding Corrosion Inhibitors

Corrosion inhibitors are chemical compounds designed to protect metal surfaces from the damaging effects of corrosion. By forming a protective barrier on the metal surface or altering the corrosion process, inhibitors prevent or slow down the oxidation and deterioration of metals in corrosive environments. Corrosion inhibitors are widely used in various industries, including oil and gas, petrochemicals, power generation, water treatment, and manufacturing, to safeguard critical assets and infrastructure from corrosion-related failures.

The Importance of Corrosion Inhibitors in Industrial Maintenance

1. Asset Protection: Industrial facilities rely heavily on equipment and infrastructure made of metal, such as pipelines, tanks, vessels, and machinery. Corrosion inhibitors play a crucial role in protecting these assets from corrosion, extending their service life and reducing the need for frequent repairs or replacements.

2. Cost Savings: Corrosion-related failures can result in significant financial losses due to equipment downtime, production disruptions, and repair expenses. By incorporating corrosion inhibitors into maintenance programs, industries can minimize the risk of corrosion-related failures and realize substantial cost savings in the long run.

3. Safety and Reliability: Corrosion compromises the structural integrity of industrial assets, posing safety hazards to personnel and the surrounding environment. Corrosion inhibitors help maintain the reliability and safety of critical infrastructure, reducing the likelihood of accidents, spills, and environmental contamination.

4. Environmental Protection: Corrosion-related leaks and spills can have detrimental environmental consequences, polluting soil, water bodies, and ecosystems. By preventing corrosion and minimizing the risk of leaks and spills, corrosion inhibitors contribute to environmental protection and sustainability efforts.

Applications of Corrosion Inhibitors

Corrosion inhibitors find applications across various industrial sectors, where metal components are exposed to corrosive environments. Some common applications of corrosion inhibitors include:

Oil and Gas Production: In the oil and gas industry, corrosion inhibitors are used to protect pipelines, well casings, and production equipment from corrosion caused by corrosive fluids, gases, and environmental conditions.

Water Treatment: Corrosion inhibitors are added to cooling water systems, boilers, and wastewater treatment facilities to prevent metal corrosion caused by dissolved oxygen, scale formation, and aggressive ions.

Manufacturing: In manufacturing processes involving metal components, such as automotive, aerospace, and electronics manufacturing, corrosion inhibitors are used to protect parts, components, and machinery from corrosion during production, storage, and transportation.

Marine and Offshore Structures: Corrosion inhibitors are applied to marine vessels, offshore platforms, and coastal structures to protect against corrosion in seawater environments.

ICPL: Your Trusted Corrosion Inhibitor Manufacturer and Exporter in India

As the best chemical company in Vadodara, ICPL is dedicated to delivering high-quality corrosion inhibitors tailored to the specific needs of industrial clients. Here's why ICPL is the preferred choice for corrosion inhibitors in India:

Expertise and Experience: With decades of experience in the chemical industry, ICPL possesses the expertise and technical know-how to develop and manufacture corrosion inhibitors that meet the highest quality standards and regulatory requirements.

State-of-the-Art Facilities: ICPL operates state-of-the-art manufacturing facilities equipped with advanced technologies and production processes to ensure the consistent quality and performance of its corrosion inhibitors.

Customized Solutions: ICPL offers customized corrosion inhibitor formulations tailored to the unique requirements and operating conditions of industrial applications. Our team of experts works closely with clients to develop solutions that address specific corrosion challenges and performance objectives.

Global Reach: As a corrosion inhibitor exporter in India, ICPL serves clients worldwide, exporting its products to diverse markets across Asia, Africa, the Middle East, and beyond. With a strong global presence and distribution network, ICPL delivers reliable corrosion protection solutions to industries around the globe.

Conclusion

In conclusion, corrosion inhibitors play a crucial role in industrial maintenance by protecting metal assets from the damaging effects of corrosion. As a leading corrosion inhibitor manufacturer and exporter in India, ICPL is committed to providing high-quality corrosion inhibitors that safeguard critical infrastructure, ensure operational reliability, and promote cost-effective maintenance practices. With ICPL's expertise, customized solutions, and global reach, industries can effectively mitigate the risk of corrosion and preserve the integrity of their assets for years to come. Contact ICPL today to learn more about our corrosion inhibitor products and solutions.

#Corrosion inhibitor Vadodara#Best chemical company in Vadodara#Corrosion Inhibitor exporter in India#Corrosion inhibitors manufacturer in India#Oxygen scavenger Chemical in Vadodara#Oxygen scavenger Chemical supplier in Gujarat#Oxygen scavenger Chemical Manufacture India#Oxygen scavenger Chemical exporter in Gujarat#Oil and gas industry#Oil and gas companies#Oil and gas pipelines#leading Oilfield Chemicals manufacturer and exporter in India

7 notes

·

View notes

Text

Turnkey Projects Solution in Andhra Pradesh

Amma En-fab Is a leading Turnkey Projects Solution in Andhra Pradesh, India. Our Registered Office and Manufacturing Unit is in Ahmedabad, Gujarat, India. We specialize in crafting high-quality Ribbon Blenders, Vessels, Chimneys, Ball Mills, Storage Tanks, Steel Structure Projects, and Turnkey Projects. Each of our products is designed with precision to meet the diverse needs of our clients. We offer comprehensive turnkey services, which include project manufacturing and supply, detailed engineering design, procurement, erection, and on-time project delivery. We prioritize a flexible, customer-focused approach in all our turnkey projects, ensuring that your operations work with maximum energy, efficiency, and profitability. Our experienced team successfully realizes turnkey projects, ensuring that your manufacturing plant achieves the highest industry standards in quality, productivity, and efficiency. Applications of Turnkey Projects: Manufacturing Water and Wastewater Treatment Construction and Infrastructure Energy and Power Pharmaceuticals and Food Processing Environmental Solutions What industries do you offer Turnkey Projects for? We offer turnkey solutions across a wide range of industries, including manufacturing, pharmaceuticals, food processing, construction, water treatment, energy, and more. What are the benefits of opting for a Turnkey Project solution? Opting for a turnkey project allows you to benefit from a single point of responsibility, cost savings, reduced risk, timely completion, and high-quality results. How long does it take to complete a Turnkey Project? The duration of a turnkey project depends on the project’s scope and complexity. We provide realistic timelines and ensure that the project is delivered on time. Amma En-fab Is a leading Turnkey Projects Solution in Andhra Pradesh, India Including Anantapur, Chittoor, East Godavari, Guntur, Krishna, Kurnool, Prakasam, Srikakulam, Sri Potti Sriramulu Nellore, Visakhapatnam, Vizianagaram, West Godavari, Kadapa, Visakhapatnam, Vijayawada, Nellore, Kurnool, Rajamahendravaram, Tirupati, Kakinada, Srikakulam, Yemmiganur, Nagarjunakoṇḍa, Rajahmundry, Adoni, Amaravati, Chandragiri, Dowlaiswaram, Eluru, Guntur, Kadapa, Kakinada. Contact us today for more information or to request a quote. View Product: Click Here Read the full article

#Adoni#Ahmedabad#Amaravati#AmmaEn-fab#Anantapur#AndhraPradesh#Chandragiri#Chittoor#Dowlaiswaram#EastGodavari#Eluru#Exporter#Gujarat#Guntur#Kadapa#Kakinada#Krishna#Kurnool#Manufacturer#Nagarjunakoṇḍa#Nellore#Prakasam#Rajahmundry#Rajamahendravaram#SriPottiSriramuluNellore#Srikakulam#Supplier#Tirupati#TurnkeyProjectsSolution#TurnkeyProjectsSolutioninAhmedabad

0 notes

Text

Supplier of HDPE Spiral Tank in Rajasthan

Sunfiber is a Manufacturer and Supplier of HDPE Spiral Tank in Rajasthan, India. Our Manufacturing Unit is in Ahmedabad, Gujarat, India. Sunfiber specialize in providing HDPE Spiral Tanks that offer advanced storage solutions for a wide variety of industries. We craft our HDPE (High-Density Polyethylene) Spiral Tanks using cutting-edge technology to deliver superior strength, chemical resistance, and reliability. We design these tanks to meet the most demanding storage requirements, providing a long-lasting and eco-friendly alternative to traditional storage solutions. Why Choose Sunfiber for HDPE Spiral Tanks? Unmatched Durability: Sunfiber HDPE Spiral Tanks are built for extreme durability. They resist corrosion, UV damage, and physical wear, making them perfect for harsh environments. Cost-Effective Solution: Our tanks offer great value. With low maintenance and a long lifespan, they reduce the need for frequent replacements, saving you money over time. Customized Solutions: We provide fully customizable options. We tailor our tanks from size to material grade to meet the specific needs of your industry. Chemical Resistance: HDPE is highly resistant to chemicals. It safely stores a wide range of liquids, including acids, alkalis, oils, and solvents. Excellent Customer Support: Sunfiber offers outstanding customer service. Our experts assist you from selection to installation, ensuring your tank performs at its best. Applications: Chemical Industry Agriculture Food and Beverage Water and Wastewater Treatment Pharmaceuticals Construction FAQs: What is the maximum capacity of your HDPE Spiral Tanks? We can manufacture our HDPE Spiral Tanks in capacities ranging from 100 liters to over 100,000 liters, depending on your specific storage needs. Do HDPE Spiral Tanks require maintenance? HDPE Spiral Tanks are low-maintenance. We recommend regular cleaning and inspection for any physical damage, but the tanks require minimal upkeep. Are Sunfiber HDPE Spiral Tanks suitable for storing chemicals? Yes, our HDPE Spiral Tanks are specifically designed for chemical storage. They offer excellent resistance to a wide range of chemicals, including acids, bases, oils, and solvents. Sunfiber is a Manufacturer and Supplier of HDPE Spiral Tank in Rajasthan, India Including Ajmer, Alwar, Barmer, Bhilwara, Bundi, Chittaurgarh, Churu, Dausa, Dhaulpur, Dungarpur, Ganganagar, Hanumangarh, Jaipur, Jaisalmer, Jalor, Jhalawar, Jhunjhunu, Jodhpur, Karauli, Kota, Nagaur, Pali, Pratapgarh, Rajsamand, Sawai Madhopur, Sikar, Sirohi, Tonk, Udaipur, Bhiwadi, Bikaner, Beawar, Kishangarh, Bharatpur, Sri Ganganagar. For detailed information or inquiries, please feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#Ajmer#Alwar#Barmer#Beawar#Bharatpur#Bhilwara#Bhiwadi#Bikaner#Bundi#Chittaurgarh#Churu#Dausa#Dhaulpur#Dungarpur#Ganganagar#Gujarat#Hanumangarh#HDPESpiralTank#HDPESpiralTankinRajasthan#India#Jaipur#Jaisalmer#Jalor#Jhalawar#Jhunjhunu#Jodhpur#Karauli#Kishangarh#Kota

0 notes

Text

Side Entry Mixer Manufacturer in Pune, India

The Side Entry Mixer Manufacturer in Pune, India by Galaxy Industrial Equipment is a compact and efficient solution for mixing applications in large storage tanks across industries such as petrochemicals, food and beverage, and wastewater treatment. With a high-performance impeller for even mixing, solid construction for challenging conditions, and dependable mechanical joints to stop leaks, it is made for side-mounted installation, which saves space. This mixer is a reliable and affordable alternative for industrial mixing needs since it offers adjustable choices to fit individual process requirements and guarantees good blending, temperature control, and equalization.

#manufacturer#process equipment manufacturers in pune#industrial equipment#galaxyindustrial#side entry mixer

0 notes

Text

Understanding FRP Pipes: A Comprehensive Guide to Benefits and Applications

D Chel Oil & Gas is a recognised FRP pipe manufacturer in India. FRP pipes are well-known for their exceptional durability, corrosion resistance, and lightweight construction. These pipes are utilised in a variety of sectors, including chemical processing, water treatment, and oil and gas, where they must withstand high pressures and extreme environmental conditions. FRP pipes' non-corrosive nature makes them perfect for long-term applications, lowering maintenance costs and assuring consistent performance.

What Are FRP Pipes?

FRP pipes are composite structures composed of thermosetting resins, such as polyester, vinyl ester, or epoxy, reinforced with fiberglass. These materials are layered to form a robust yet lightweight structure, creating pipes with superior mechanical and chemical properties. The use of advanced manufacturing techniques, such as filament winding and centrifugal casting, ensures consistent quality and performance.

Key Features and Advantages of FRP Pipes

Corrosion Resistance One of the standout properties of FRP pipes is their excellent resistance to corrosion. Unlike steel, which is prone to rusting, or concrete, which degrades over time when exposed to harsh chemicals, FRP pipes maintain their integrity in aggressive environments. They are ideal for transporting corrosive fluids in chemical plants, wastewater treatment facilities, and marine applications.

Lightweight and High Strength Despite their lightweight nature, FRP pipes are incredibly strong. Their high strength-to-weight ratio makes them easier to handle, transport, and install compared to heavier materials like steel or concrete. This reduces labor costs and minimizes the need for heavy equipment during installation.

Longevity and Low Maintenance FRP pipes have an impressive lifespan, often exceeding 50 years when properly maintained. Their resistance to wear and tear, combined with their immunity to chemical attacks, means they require minimal maintenance, saving costs over time.

Thermal and Electrical Insulation FRP pipes are excellent insulators, both thermally and electrically. This makes them suitable for applications where temperature fluctuations or electrical conductivity pose challenges.

Customization and Versatility FRP pipes can be customized in terms of size, shape, and resin composition to suit specific industrial needs. Their adaptability ensures they can be tailored to meet the exact requirements of various applications.

We Supply In Various Countries Llike :

FRP Supplier in Qatar

FRP Supplier in Saudi Arabia

FRP Supplier in Bangladesh

FRP Supplier in Oman

FRP Supplier in Malaysia

Applications of FRP Pipes

FRP pipes have found applications in diverse industries, thanks to their unique properties. Some of the key sectors where they are widely used include:

Chemical and Petrochemical Industries FRP pipes are extensively used for transporting corrosive chemicals, acids, and alkalis in chemical and petrochemical plants. Their ability to withstand extreme pH levels and high temperatures makes them a preferred choice.

Water and Wastewater Management Municipalities and industries use FRP pipes for sewage systems, desalination plants, and water treatment facilities. Their corrosion resistance ensures long-term performance in handling potable and non-potable water.

Oil and Gas Industry In oil and gas operations, FRP pipes are used for offshore platforms, pipelines, and storage tanks. Their lightweight nature and resistance to saltwater and hydrocarbons make them indispensable in this sector.

Power Plants FRP pipes are commonly employed in cooling water systems, flue gas desulfurization (FGD) units, and other power plant infrastructure due to their durability and thermal insulation properties.

Marine and Offshore Applications FRP pipes are well-suited for marine environments, where exposure to salt water can corrode traditional materials. They are used in shipbuilding, docks, and offshore platforms.

FRP Pipe Manufacturers in India

India is home to numerous famous FRP pipe manufacturers who provide high-quality goods that match international specifications.FRP Pipe Suppliers in India provide a wide range of solutions tailored to specific industrial requirements, ensuring that clients receive long-lasting and efficient pipe systems. These producers are well-known across the world for their long-lasting and cost-effective FRP pipe solutions, which are the result of modern manufacturing procedures and strict quality control. We are also one of the leading FRP grating manufacturers in India.

0 notes

Text

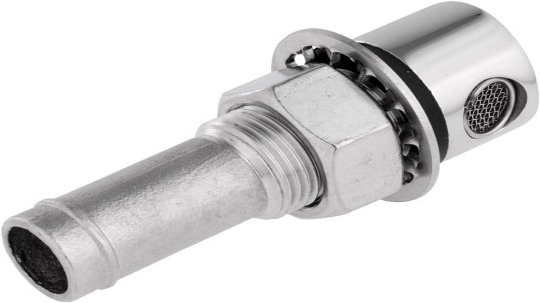

Breather Vent Market Size, Share, Analysis and Opportunities by 2024-2032

The Reports and Insights, a leading market research company, has recently releases report titled “Breather Vent Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Breather Vent Market, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Breather Vent Market?

The breather vent market is expected to grow at a CAGR of 7.8% during the forecast period of 2024 to 2032.

What are Breather Vent?

A breather vent is a specialized device designed to allow air to flow in and out of a sealed container or system, such as tanks, vessels, or pipelines, while keeping out contaminants, dust, and moisture. Its primary function is to equalize pressure changes that occur due to temperature variations, liquid transfers, or operational activities, thereby safeguarding the integrity of the container and its contents. Breather vents may include filters or check valves to enhance their effectiveness, ensuring that only clean air enters while allowing gases to escape safely. By maintaining proper pressure and preventing vacuum conditions, breather vents play a crucial role in the safe and efficient functioning of various industrial applications, including chemical storage, fuel tanks, and wastewater treatment systems.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1927

What are the growth prospects and trends in the Breather Vent industry?

The breather vent market growth is driven by various factors and trends. The breather vent market is witnessing consistent growth, propelled by the rising demand for effective pressure management solutions across various sectors, including oil and gas, chemical processing, and wastewater treatment. As regulations concerning safety and environmental protection tighten, companies are increasingly utilizing breather vents to maintain the integrity of their storage systems and prevent contamination. The market features a diverse range of products, including vents equipped with advanced functionalities such as filters, check valves, and automated monitoring systems that enhance both performance and reliability. Additionally, the growing emphasis on sustainable practices and the need for efficient resource management are contributing to market expansion. With ongoing technological innovations and heightened awareness of air quality and safety, the breather vent market is well-positioned for further growth, serving a variety of applications across multiple industries. Hence, all these factors contribute to breather vent market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type:

Inline Breather Vent

Threaded Breather Vent

Bayonet Breather Vent

Customized Breather Vent

By Material:

Metal Breather Vent

Plastic Breather Vent

Composite Breather Vent

By End-Use Industry:

Automotive

Aerospace and Defense

Manufacturing

Oil and Gas

Chemicals and Pharmaceuticals

Electronics

Food and Beverage

Others

By Sales Channel:

Direct Sales

Distributor Sales

Market Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Parker Hannifin Corporation

Donaldson Company, Inc.

MANN+HUMMEL GmbH

L. Gore & Associates, Inc.

Pall Corporation

Porvair Filtration Group

Eaton Corporation plc

SMC Corporation

Bosch Rexroth AG

Festo AG & Co. KG

Swagelok Company

Emerson Electric Co.

IMI plc

Camfil AB

WAMGROUP S.p.A.

View Full Report: https://www.reportsandinsights.com/report/Breather Vent-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

Fiberglass Tanks Market is valued at USD 2,659.79 million and is projected to grow at a compound annual growth rate (CAGR) of 5.38% over the forecast period, reaching approximately USD 4,044.94 million by 2032.The global fiberglass tanks market has seen significant growth in recent years, driven by its wide-ranging applications across various industries, including chemicals, wastewater treatment, oil & gas, and agriculture. Fiberglass, a reinforced material made from fine glass fibers, has become a preferred material for manufacturing tanks due to its superior strength, corrosion resistance, lightweight, and durability. The market for fiberglass tanks is expanding due to these advantages and is expected to grow steadily in the coming years.

Browse the full report at https://www.credenceresearch.com/report/fiberglass-tanks-market

Market Overview

Fiberglass tanks are widely used for storing liquids, chemicals, and other materials, particularly in industries that require corrosion-resistant solutions. Compared to traditional materials like steel or concrete, fiberglass offers unique benefits that make it suitable for both underground and aboveground storage. As industries increasingly prioritize materials that reduce long-term maintenance costs and improve operational efficiency, fiberglass tanks have emerged as a more viable solution.

In 2023, the global fiberglass tanks market was valued at approximately **$2.5 billion**, and it is projected to grow at a **compound annual growth rate (CAGR)** of 5.7% over the next five years. This growth is driven by a combination of industrial advancements, environmental regulations, and increasing infrastructure development in emerging economies.

Key Growth Drivers

1. Industrial Demand A significant factor driving the fiberglass tanks market is the growing demand from industries such as chemicals, wastewater treatment, oil & gas, and food processing. These industries handle corrosive materials, making fiberglass an ideal choice for tanks due to its superior chemical resistance. The oil & gas sector, in particular, has seen increased use of fiberglass tanks for storing chemicals and wastewater, as they can withstand the harsh environments typical of these applications.

2. Corrosion Resistance Fiberglass tanks offer excellent resistance to corrosion, which is a critical advantage over traditional materials like metal. In industries such as water treatment and agriculture, where tanks are exposed to chemicals and harsh conditions, fiberglass tanks outperform their counterparts. The low susceptibility to rust or degradation leads to longer tank lifespans and reduced maintenance costs, making fiberglass a preferred material choice.

3. Environmental Concerns and Regulations The increasing focus on sustainability and environmental protection has positively impacted the demand for fiberglass tanks. Regulatory bodies are enforcing stringent guidelines on emissions and waste management, particularly in industries like wastewater treatment and chemical processing. Fiberglass tanks, which are non-toxic and recyclable, are seen as eco-friendly options, helping companies meet these regulatory requirements. Additionally, governments worldwide are offering incentives for the adoption of environmentally safe materials, which has accelerated the market's expansion.

4. Growing Infrastructure in Emerging Economies Emerging markets, particularly in Asia-Pacific and Latin America, are witnessing rapid industrialization and urbanization, driving the demand for infrastructure, including water and waste management systems. The growth of these economies has led to increased investments in wastewater treatment plants and chemical storage facilities, boosting the demand for fiberglass tanks. Countries such as India, China, and Brazil are leading this trend, where the need for durable, cost-effective storage solutions is growing rapidly.

Challenges and Opportunities

Despite its growth, the fiberglass tanks market faces challenges, including competition from polyethylene and stainless steel tanks. Additionally, the higher initial cost of fiberglass tanks compared to alternatives can deter smaller businesses from adopting them. However, these challenges are offset by the long-term benefits of fiberglass, such as reduced maintenance and lower operational costs.

There is also significant opportunity for innovation in the fiberglass tanks market. Advancements in resin technology and manufacturing processes are enhancing the strength and durability of fiberglass tanks, allowing them to be used in more demanding applications.

Key Player Analysis:

Containment Solutions, Inc.

ZCL Composites Inc.

Belco Manufacturing Co., Inc.

Augusta Fiberglass

Ershigs, Inc.

Enduro Composites, Inc.

LF Manufacturing, Inc.

Ronco Plastics, Inc.

Hughes Tank Company

Belding Tank Technologies, Inc.

Segmentation:

Based on Product Type:

Aboveground Fiberglass Tanks

Underground Fiberglass Tanks

Fiberglass Septic Tanks

Fiberglass Chemical Storage Tanks

Fiberglass Fuel Storage Tanks

Other Fiberglass Tanks

Based on Design:

Horizontal Fiberglass Tanks

Vertical Fiberglass Tanks

Rectangular Fiberglass Tanks

Cylindrical Fiberglass Tanks

Based on Region:

North America (United States, Canada, Mexico)

Europe (Germany, France, United Kingdom, Italy, Spain)

Asia-Pacific (China, India, Japan, South Korea, Australia)

Latin America (Brazil, Argentina, Chile)

Middle East and Africa (Saudi Arabia, UAE, South Africa, Egypt)

Browse the full report at https://www.credenceresearch.com/report/fiberglass-tanks-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

#Waste water storage tanks#Wastewater storage tanks in Pune#Wastewater storage tanks in India#coepprefabwatertanks storage tanks in India#Wastewater containment tanks Pune#COEP wastewater tanks suppliers Pune#COEP wastewater storage solutions India#Wastewater treatment storage tanks Pune#Efficient wastewater tanks in India#Effluent Treatment Plants tank

0 notes

Text

Wastewater Storage Tanks: Efficient Solutions for Industrial and Municipal Wastewater Management

Wastewater management is a critical aspect of industrial operations and urban infrastructure, ensuring that waste byproducts are treated and stored safely to prevent environmental contamination. COEP Enviro Solutions offers high-quality wastewater storage tanks that are designed to efficiently handle and store wastewater from various sources. As a leading provider of wastewater storage tanks in Pune and across India, we deliver reliable and durable storage solutions tailored to meet the diverse needs of industries and municipalities.

Importance of Wastewater Storage Tanks

Wastewater storage tanks play a vital role in temporarily holding wastewater before it is treated or safely disposed of. These tanks are essential in industries such as manufacturing, power generation, food processing, and municipal wastewater treatment plants. The storage and treatment of wastewater ensure compliance with environmental regulations while protecting water resources.

Features of COEP Enviro Wastewater Storage Tanks

High-Quality Construction: COEP Enviro Solutions manufactures wastewater storage tanks using corrosion-resistant materials like stainless steel, concrete, and high-density polyethylene (HDPE). This ensures long-term durability, even when exposed to harsh industrial chemicals and waste byproducts.

Customizable Designs: Our wastewater storage tanks in Pune come in a range of sizes and configurations to meet specific industry requirements. Whether you need underground or above-ground tanks, we provide solutions tailored to your operations.

Leak-Proof Design: These tanks are built with a leak-proof design to prevent the contamination of surrounding soil and water bodies, ensuring environmental safety.

Easy Maintenance: Our tanks are designed with features that simplify cleaning and maintenance, making it easier for industries to maintain efficient wastewater management practices.

Applications of Wastewater Storage Tanks

Wastewater storage tanks serve a variety of applications across multiple sectors, including:

Industrial Wastewater: Factories and processing plants produce large volumes of wastewater that require temporary storage before treatment. COEP Enviro Solutions provides tanks designed to withstand corrosive and abrasive substances found in industrial wastewater.

Municipal Wastewater: Urban wastewater treatment facilities rely on wastewater storage tanks to store sewage and greywater from residential and commercial sources. These tanks ensure the safe containment of wastewater before it undergoes treatment.

Agriculture: Farms and agricultural businesses use wastewater storage tanks to store and manage runoff and irrigation water, helping to reduce water wastage and prevent contamination of nearby water sources.

Benefits of COEP Enviro Wastewater Storage Tanks

Efficient Water Management: Our tanks allow businesses and municipalities to manage their wastewater efficiently, preventing the release of untreated water into the environment.

Cost-Effective Solutions: Investing in wastewater storage tanks in India provides a long-term solution that reduces the risk of environmental penalties and ensures compliance with wastewater regulations.

Environmentally Friendly: By securely storing and treating wastewater, our tanks help industries reduce their environmental footprint and protect natural water resources from contamination.

Why Choose COEP Enviro Solutions?

At COEP Enviro Solutions, we are committed to delivering state-of-the-art wastewater storage tanks in Pune and throughout India. With a focus on innovation, sustainability, and customer satisfaction, we provide storage solutions that meet the highest industry standards. Our tanks are designed to handle the most demanding wastewater management challenges while offering long-term reliability and performance.

Whether you need storage for industrial, municipal, or agricultural wastewater, COEP Enviro Solutions has the expertise and resources to provide the right solution. Contact us today to learn more about our wastewater storage tanks in India and how we can help improve your wastewater management system.

0 notes

Text

Centrifugal Pump Types Essential for Pharmaceutical Manufacturing

In the pharmaceutical industry, precision and dependability are key. In this industry, the centrifugal pump stands as one of the most critical components that ensure these standards are maintained. These pumps play an essential role in different processes, including liquid transfer to sustain sterile conditions. Differentiating between various types of industrial centrifugal pumps and their applications is helpful for experts when choosing suitable equipment.

In this blog, we discuss about types of centrifugal pumps used in the pharmaceutical industry, their examples, practical uses and the role of centrifugal pump manufacturers in India.

Overview of Centrifugal Pumps

Centrifugal Pumps are mechanical devices designed to move fluids by converting the kinetic energy from rotation into hydrodynamic energy. They are widely used in the pharmaceutical industry due to their high efficiency, reliability, and capability to handle various fluids like corrosive and viscous liquids.

Types Of Centrifugal Pumps In Pharmaceutical Industry

1. Single-Stage Centrifugal Pumps

Single-stage centrifugal pumps usually have one impeller and are typically employed in applications requiring minimum to medium pressure levels. They are simple, economical and best suited for moving liquids from one point to another. Example: A single-stage centrifugal pump used by a pharmaceutical company for transferring purified water from a storage tank to the production line.

2. Multistage Centrifugal Pumps

These include several impellers which increase the fluid pressure at each stage. Such pumps are used where there is a need for high pressure as they could be applied in boiler feed systems or even high-pressure cleaning. Example: In manufacturing sterile injectables, a multistage centrifugal pump ensures that there is a supply of highly pressurized water required during the cleaning and sterilization process.

3. Sanitary Centrifugal Pumps

Sanitary centrifugal pumps are designed with materials and finishes that prevent contamination, making them perfect for handling sensitive pharmaceutical products. They are easy to clean and meet stringent sanitary standards. Example: A pharmaceutical company employs sanitary centrifugal pumps to transfer active pharmaceutical ingredients (APIs) in a sterile environment, ensuring product purity and compliance with regulatory standards.

4. Magnetic Drive Centrifugal Pumps

These centrifugal pumps eliminate the need for mechanical seals by using magnetic couplings to transfer torque. This makes them perfect for handling hazardous liquids or sensitive fluids because it reduces the chances of leaking and contamination. Example: Magnetic drive centrifugal pumps are used by a pharmaceutical plant to handle volatile solvents required in pharmaceutical formulations to make them operate without any danger of leakage.

5. Self-Priming Centrifugal Pumps

Self-priming centrifugal pumps can re-prime themselves even if air enters the system. They are used in applications where the pump may need to start with an empty suction line. Example: Self-priming centrifugal pumps are used by a pharmaceutical company during wastewater treatment operations where there may be different fluid levels that the pump must deal with.

Practical Applications of Centrifugal Pumps in the Pharmaceutical Industry

Fluid transfer: Movement of raw materials, intermediates, and finished products within the facility.

Cleaning systems: These provide necessary pressures for cleaning and sterilization systems.

Filtration processes: This involves circulating fluids through filtration systems to remove impurities.

Cooling systems: These ensure effective cooling of equipment as well as processes being undertaken.

Choosing The Right Centrifugal Pump

Among other factors, the selection of the proper type of centrifuge pump depends on certain fluid properties along with flow rate and pressure requirements coupled with environmental conditions unique to each application. Partnering with reputable centrifugal pump manufacturers in India, like Fristam Pumps, ensures access to high-quality, reliable equipment tailored to the pharmaceutical industry's needs.

Conclusion

Pharmaceutical processes must be optimized by understanding various types of centrifugal pumps and their applications. Depending on the requirements, each form may have several options including multi-stage, single-stage, magnetic drive or even sanitary pumps. By picking out the right category of industrial centrifugal pumps, pharmaceutical companies can ensure efficient, safe and reliable operations.

For top-quality centrifugal pumps manufacturer in India and expert guidance partner with Fristam Pumps, the leading name in industrial centrifugal pumps.

FAQs:

1) What are centrifugal pumps, and why are they used in the pharmaceutical industry?

Centrifugal pumps are mechanical devices that move fluids using rotational kinetic energy. They are used in the pharmaceutical industry for their efficiency, reliability, and ability to handle various fluids, ensuring precise and sterile processes.

2) What types of centrifugal pumps are commonly used in the pharmaceutical industry?

Common types of centrifugal pumps in the pharmaceutical industry include single-stage, multistage, sanitary, magnetic drive, and self-priming pumps.

3) What are the applications of centrifugal pumps in the pharmaceutical industry?

Centrifugal pumps in the pharmaceutical industry are used for fluid transfer, cleaning systems, filtration processes, and cooling systems.

4) What are the benefits of using centrifugal pumps in the pharmaceutical industry?

The benefits of using centrifugal pumps in the pharmaceutical industry include efficiency, reliability, precise fluid handling, and maintaining sterile conditions.

#centrifugal pumps#Pharmaceutical Industry#Pump Types#IndustrialPumps#PumpMaintenance#PharmaceuticalEquipment#PumpSelection

0 notes

Text

HDPE Vessel Supplier in Punjab

Sunfiber is a Manufacturer and Supplier of HDPE Vessel in Punjab, India. Our Manufacturing Unit is in Ahmedabad, Gujarat, India An HDPE vessel is a container or tank made from High-Density Polyethylene (HDPE), a thermoplastic polymer known for its strength-to-density ratio. HDPE is highly resistant to impact, chemicals, and environmental factors, making it ideal for industries that require reliable storage and transportation solutions for various materials. HDPE vessels come in a range of shapes, sizes, and configurations, from small tanks to large industrial vessels, depending on the application. Features of HDPE Vessels: Corrosion Resistance: HDPE vessels are highly resistant to corrosion, making them ideal for storing aggressive chemicals and fluids. Lightweight: HDPE is a lightweight material, which makes vessels easy to transport and handle. Durable: HDPE vessels offer high strength, impact resistance, and a long service life, even in harsh conditions. Non-Toxic: Safe for storing food-grade materials, chemicals, and other sensitive substances. Easy to Clean: The smooth surface makes HDPE vessels easy to clean, reducing contamination risks. UV Resistant: HDPE vessels can withstand exposure to UV light without degrading, making them ideal for outdoor use. Applications of HDPE Vessels: Chemical Industry: For storing corrosive chemicals, solvents, acids, and alkalis. Water Treatment: Used in filtration, mixing, and storage of treated and untreated water. Food and Beverage Industry: For storing and transporting food-grade liquids and materials. Pharmaceuticals: Essential in the safe storage of chemicals and medicines. Wastewater Treatment: Used in bioreactors, septic tanks, and other wastewater treatment applications. Agriculture: For storing pesticides, fertilizers, and other agricultural chemicals. What is an HDPE vessel? An HDPE vessel is a container made from high-density polyethylene, known for its durability, corrosion resistance, and versatility. It is used for storing liquids, chemicals, and other materials in various industrial applications. What are the types of HDPE vessels available? Common types of HDPE vessels include storage tanks, pressure vessels, mixing vessels, chemical vessels, bio-reactor vessels, and HDPE drum vessels. What are the benefits of using HDPE vessels? HDPE vessels offer high chemical resistance, low maintenance, durability, cost-effectiveness, and environmental sustainability. They are lightweight and easy to clean, making them ideal for various industries. Sunfiber is a HDPE Vessel Supplier in Punjab, India Including Hoshiarpur, Faridkot, Amritsar, Bathinda, Batala, Rupnagar, Nawanshahr, Sirhind, Khamanon, Adampur, Ludhiana, Patiala, Khanna, Mansa, Malerkotla, Rajpura, Fatehgarh Sahib, Bassi Pathana, Banga Rural, Kapurthala, Firozpur, Jalandhar, Pathankot, Gurdaspur, Doraha, Phillaur, Sirhind. For detailed information or inquiries, please feel free to contact us. View Product: Click Here Read the full article

#Adampur#Ahmedabad#Amritsar#BangaRural#BassiPathana#Batala#Bathinda#Doraha#ExporterofHDPEVessel#Faridkot#FatehgarhSahib#Firozpur#Gujarat#Gurdaspur#HDPEVessel#HDPEVesselSupplier#HDPEVesselSupplierinGujarat#HDPEVesselSupplierinPunjab#Hoshiarpur#India#Jalandhar#Kapurthala#Khamanon#Khanna#Ludhiana#Malerkotla#Mansa#ManufacturerofHDPEVessel#ManufacturerofHDPEVesselinAhmedabad#Nawanshahr

0 notes

Text

Everything You Need To Know Bolted Tank Manufacturers in India ?

Orison Industries stands out as a leading manufacturer of bolted tanks in India, specializing in the production of robust, customizable storage solutions for various industries. With a commitment to quality, innovation, and customer satisfaction, they have established a strong reputation in the market for their reliable bolted tank systems.

Versatility and Customization: Orison Industries offers a diverse range of bolted tanks that cater to a wide spectrum of applications. From water storage and wastewater treatment to industrial chemicals and food processing, their tanks are designed to meet specific operational needs. They provide customization options in terms of size, material (including stainless steel and epoxy-coated steel), and accessories to ensure optimal performance in various environments.

Engineering Excellence: The bolted tanks manufactured by Orison Industries incorporate advanced engineering techniques and high-quality materials. Each tank is precision-engineered for durability, structural integrity, and resistance to corrosion. This ensures long-term reliability and minimal maintenance, making them a cost-effective storage solution for industries seeking dependable infrastructure.

Quality Assurance and Compliance: Orison Industries adheres to stringent quality assurance protocols throughout the manufacturing process. Their bolted tanks comply with international standards and undergo rigorous testing to ensure they meet or exceed industry requirements for safety, performance, and environmental sustainability. This commitment to quality underscores their dedication to delivering superior products that instill confidence in their customers.

Innovation and Sustainability: Driven by a culture of innovation, Orison Industries continuously explores new technologies and materials to enhance the efficiency and environmental sustainability of their bolted tanks. They prioritize eco-friendly practices in manufacturing and promote water conservation initiatives through their products, supporting sustainable development goals in India and beyond.

Customer-Centric Approach: Orison Industries places a strong emphasis on customer satisfaction and collaboration. They work closely with clients to understand their specific storage needs and provide tailored solutions that optimize space utilization, operational efficiency, and long-term cost savings. Their dedicated customer support ensures seamless installation, maintenance, and ongoing technical assistance throughout the lifespan of the bolted tanks.

Industry Impact and Future Outlook: As demand grows for reliable storage solutions across diverse sectors in India, Orison Industries remains committed to innovation and excellence. They continue to expand their product offerings and geographical reach, leveraging their expertise to meet the evolving needs of industries while maintaining their reputation as a trusted partner in bolted tank manufacturing.

In conclusion, Orison Industries' leadership in bolted tank manufacturing exemplifies their dedication to quality, innovation, and sustainability in providing essential storage infrastructure for various industries across India. Through their advanced engineering capabilities and customer-centric approach, they continue to shape the future of storage solutions in the region.

For inquiries and consultations, Orison Industries can be reached at +918860602980 or via email at [email protected] (mailto:[email protected]). Whether embarking on a new project or seeking to revitalize existing surfaces, Bolted Tank emerges as the trusted partner for all Bolted Tank Manufacturers in India

1 note

·

View note

Text

The Comprehensive Guide to Stainless Steel Flanges

Riddhi Siddhi Metal Impex is a renowned stainless steel flanges manufacturer in India. The SS flanges have been rigorously designed in accordance with national and international industrial standards, utilising high-quality raw materials and cutting edge technology. Our high-quality stainless steel flanges and other goods are thoroughly tested before being packaged. A stainless steel flanges supplier in India provides stainless steel flanges in various sizes and forms to satisfy our customers' needs. These flanges are vital interior components that support mechanical parts or systems. They can also be used as blind flanges, which operate as plates to cover or seal the end of pipes.

What Are Stainless Steel Flanges?

Stainless steel flanges are mechanical devices used to connect pipes, valves, pumps, and other equipment in piping systems. They provide a secure and leak-proof connection, making them crucial in systems that transport liquids, gases, and other substances.

Types of Stainless Steel Flanges

There are several types of stainless steel flanges, each designed for specific applications and requirements:

Weld Neck Flanges

Weld neck flanges are designed with a long tapered hub that provides reinforcement and is ideal for high-pressure applications. These flanges are welded directly to the pipe, ensuring a strong and leak-proof connection.

Slip-On Flanges

Slip-on flanges are easy to install and require less precision in cutting the pipe to length. They slip over the pipe and are welded in place, making them suitable for low-pressure applications.

Blind Flanges

Blind flanges are used to close off the ends of piping systems or pressure vessel openings. They are essential in systems where expansion or access to the interior is needed.

Socket Weld Flanges

Socket weld flanges are used for smaller-sized, high-pressure piping systems. The pipe is inserted into the socket end and welded, providing a smooth bore and better flow of the fluid.

Lap Joint Flanges

Lap joint flanges are used with stub ends and are ideal for systems requiring frequent dismantling for inspection and maintenance. They are not welded or fixed to the pipe, allowing easy movement.

6. Threaded Flanges

Threaded flanges are screwed onto the pipe, making them suitable for low-pressure and non-critical applications where welding is not feasible.

Orifice Flanges

Orifice flanges are used with orifice meters for measuring the flow rate of liquids and gases in a piping system. They come with special features like pressure taps to measure the pressure drop.

We are Stainless Steel Flanges Supplier In:

SS Flange Supplier in Mumbai

SS Flange Supplier in Chennai

SS Flange Supplier in Ahmedabad

SS Flange Supplier in Coimbatore

SS Flange Supplier in Firozabad

Applications of Stainless Steel Flanges

Stainless steel flanges are used in a wide range of applications, including:

Oil and Gas Industry

In the oil and gas industry, stainless steel flanges are used in pipelines, refineries, and offshore platforms, where they provide reliable connections that can withstand extreme conditions.

Chemical and Petrochemical Industry

The chemical and petrochemical industry relies on stainless steel flanges for their resistance to corrosion and ability to handle aggressive chemicals and high temperatures.

Water Treatment Plants

In water treatment plants, stainless steel flanges are used in piping systems that transport water and wastewater, offering durability and resistance to corrosion.

Food and Beverage Industry

The food and beverage industry uses stainless steel flanges in processing equipment, pipelines, and storage tanks due to their hygienic properties and ease of cleaning.

Power Generation

In power generation, stainless steel flanges are used in various systems, including cooling, steam, and gas turbines, providing reliable and leak-proof connections.

Choosing the Right Stainless Steel Flange

Selecting the right stainless steel flange involves considering several factors:

Application Requirements

Determine the pressure, temperature, and environmental conditions the flange will be exposed to.

Material Grade

Choose the appropriate grade of stainless steel that offers the required corrosion resistance and mechanical properties.

Size and Type

Select the correct size and type of flange that fits the piping system and meets the application's specific requirements.

Standards and Certifications

Ensure the flanges comply with industry standards and certifications to guarantee quality and reliability.

Installation and Maintenance Tips

Proper installation and maintenance are crucial for the performance and longevity of stainless steel flanges:

Proper Alignment

Ensure flanges are aligned correctly to avoid stress and leaks in the piping system.

Use of Gaskets

Use appropriate gaskets to create a leak-proof seal between flanges.

Regular Inspections

Conduct regular inspections to check for any signs of wear, corrosion, or damage.

Tightening Bolts

Follow the recommended torque specifications when tightening bolts to ensure a secure connection without damaging the flange.

Stainless Steel Flanges Manufacturer in India

Stainless steel flanges are machined from solid forgings. We have been India's leading stockholder, manufacturer, supplier, importer, and exporter because of our performance and dependability. Our SS Flanges Manufacturer is well-known across the globe for its dependability and quality. When we give our clients products and services, we consider them partners. We are also renowned as one of Pipe Fittings Manufacturers in India.

#stainless steel flanges manufacturer in India#SS Flanges Manufacturer#stainless steel flanges supplier in India#Pipe Fittings Manufacturers in India

0 notes