#Industrial Lubricants Market size

Explore tagged Tumblr posts

Text

Exploring the UAE Lubricants Industry: Trends, Opportunities, and Challenges

The United Arab Emirates (UAE) is a global hub for trade, commerce, and innovation, and its lubricants market is no exception. With a strategic geographical location, a growing industrial base, and a thriving automotive industry, the UAE's lubricants industry is poised for substantial growth. This blog delves into the key trends, opportunities, and challenges shaping the market.

Overview of the UAE Lubricants Market

The UAE lubricants market is projected to reach a volume of 159.81 million liters in 2024 and is expected to grow to 173 million liters by 2026, reflecting a compound annual growth rate (CAGR) of 4.04% over the forecast period (2024-2026).

The UAE lubricants market is a vital segment of the country’s economy, driven by industrial applications, transportation, and marine activities. The demand for lubricants spans across various sectors, including:

Automotive: The increasing number of vehicles on the road has boosted the demand for engine oils, transmission fluids, and other automotive lubricants.

Industrial Applications: Manufacturing, construction, and energy sectors heavily rely on industrial lubricants for machinery maintenance.

Marine Industry: With bustling ports like Jebel Ali and an expansive shipping industry, marine lubricants play a crucial role.

Market Trends

Several trends are shaping the UAE’s lubricants industry:

Shift Towards Synthetic Lubricants: Synthetic and semi-synthetic lubricants are gaining popularity due to their superior performance and extended oil change intervals.

Focus on Sustainability: The industry is witnessing a growing emphasis on eco-friendly and biodegradable lubricants, aligned with global sustainability goals.

Technological Advancements: Innovations in lubricant formulations to meet the demands of high-performance engines and machinery.

Growth of Electric Vehicles (EVs): While EVs require fewer traditional lubricants, there is an emerging market for specialized EV lubricants and coolants.

Key Players in the Market

The UAE lubricants market is competitive, with a mix of international giants and local manufacturers. Some notable players include:

Shell

ExxonMobil

TotalEnergies

ADNOC (Abu Dhabi National Oil Company)

ENOC (Emirates National Oil Company)

These companies are investing in R&D, expanding distribution networks, and offering tailored solutions to cater to diverse customer needs.

Opportunities in the UAE Lubricants Market

Strategic Location: The UAE’s position as a gateway between Asia, Europe, and Africa provides lucrative export opportunities.

Growing Industrial Base: Rapid industrialization and infrastructure projects fuel the demand for industrial lubricants.

Specialized Lubricants for New Markets: Opportunities exist in sectors like renewable energy, aerospace, and advanced manufacturing.

Government Support: Policies encouraging industrial growth and innovation provide a conducive environment for the lubricant industry.

Challenges in the Market

Volatile Oil Prices: Fluctuations in crude oil prices impact the cost of raw materials for lubricant production.

Competition: The presence of numerous players intensifies competition, pressuring margins.

Shift to EVs: The rise of electric vehicles may reduce the long-term demand for conventional automotive lubricants.

Regulatory Compliance: Stricter environmental regulations require manufacturers to innovate and adapt.

Future Outlook

The UAE lubricants market is expected to grow steadily, driven by advancements in technology, rising industrialization, and increasing vehicle ownership. The shift towards sustainable and specialized lubricants will open new avenues for growth, while challenges like EV adoption and market competition will push companies to innovate.

Conclusion

The UAE’s lubricants market is at an exciting juncture, offering opportunities for growth and innovation. By aligning with global trends, focusing on sustainability, and leveraging its strategic advantages, the UAE can continue to strengthen its position as a leading player in the global lubricants industry. For a detailed overview and more insights, you can refer to the full market research report by Mordor Intelligence: https://www.mordorintelligence.com/industry-reports/uae-lubricants-market-industry

#UAE Lubricants Industry#UAE Lubricants Market#UAE Lubricants Market Size#UAE Lubricants Market Share#UAE Lubricants Market Analysis#UAE Lubricants Market Report

0 notes

Text

Synthetic Lubricants Market Industry Outlook: Forecasting Market Trends and Growth for the Coming Years

Synthetic Lubricants Market Strategies: Taking Advantage of Trends to Drive Growth in 2032

The Synthetic Lubricants Market Report provides essential insights for business strategists, offering a comprehensive overview of industry trends and growth projections. It includes detailed historical and future data on costs, revenues, supply, and demand, where applicable. The report features an in-depth analysis of the value chain and distributor networks.

Employing various analytical techniques such as SWOT analysis, Porter’s Five Forces analysis, and feasibility studies, the report offers a thorough understanding of competitive dynamics, the risk of substitutes and new entrants, and identifies strengths, challenges, and business opportunities. This detailed assessment covers current patterns, driving factors, limitations, emerging developments, and high-growth areas, aiding stakeholders in making informed strategic decisions based on both current and future market trends. Additionally, the report includes an examination of the Automatic Rising Arm Barriers sector and its key opportunities.

According to Straits Research, the global Synthetic Lubricants Market market size was valued at USD 17.2 Billion in 2022. It is projected to reach from USD XX Billion in 2023 to USD 22.9 Billion by 2031, growing at a CAGR of 3.28% during the forecast period (2023–2031).

Get Free Request Sample Report @ https://straitsresearch.com/report/synthetic-lubricants-market/request-sample

TOP Key Industry Players of the Synthetic Lubricants Market

Royal Dutch Shell

ExxonMobil

Sasol

Valvoline

British Petroleum

Chevron

Morris Lubricants

Dow

Indian Oil

Petronas

Lukoil

Idemitsu Kosan

Fuchs

Total Energies

Sinopec

Global Synthetic Lubricants Market: Segmentation

As a result of the Synthetic Lubricants market segmentation, the market is divided into sub-segments based on product type, application, as well as regional and country-level forecasts.

By Applications

Engine Oil

Transmission Fluids and Hydraulic Fluids

Metalworking Fluids

Greases

Others

By End-User

Power Generation

Automotive and Transportation

Heavy Equipment

Food and Beverage

Others

By Type

Polyalphaolefin

Esters

Polyalkylene Glycol

Browse Full Report and TOC @ https://straitsresearch.com/report/synthetic-lubricants-market/request-sample

Reasons for Buying This Report:

Provides an analysis of the evolving competitive landscape of the Automatic Rising Arm Barriers market.

Offers analytical insights and strategic planning guidance to support informed business decisions.

Highlights key market dynamics, including drivers, restraints, emerging trends, developments, and opportunities.

Includes market estimates by region and profiles of various industry stakeholders.

Aids in understanding critical market segments.

Delivers extensive data on trends that could impact market growth.

Research Methodology:

Utilizes a robust methodology involving data triangulation with top-down and bottom-up approaches.

Validates market estimates through primary research with key stakeholders.

Estimates market size and forecasts for different segments at global, regional, and country levels using reliable published sources and stakeholder interviews.

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Synthetic Lubricants Market#Synthetic Lubricants Market Share#Synthetic Lubricants Market Size#Synthetic Lubricants Market Research#Synthetic Lubricants Industry#What is Synthetic Lubricants?

0 notes

Text

Lubricant Market: Trends, Size & Key Industry Players

The global lubricant market is a vital component of the automotive, industrial, and machinery sectors, serving as a critical factor in ensuring the smooth functioning and longevity of equipment. Lubricants reduce friction, wear, and tear, leading to improved efficiency and performance in various applications. This market has shown robust growth over the years, driven by the increasing demand from end-use industries, technological advancements, and the expansion of the automotive sector. In this blog, we will explore the market size, share, and growth of the lubricant market, analyze current market trends, identify key players, discuss the challenges facing the market, and conclude with insights into its future trajectory.

Market Size, Share, and Growth

As of 2023, the global lubricant market was valued at approximately USD 163 billion. This market is expected to grow at a compound annual growth rate (CAGR) of 3.2% from 2024 to 2030, reaching a value of around USD 205 billion by the end of the forecast period. The growth of this market can be attributed to the rising demand for lubricants in emerging economies, the expansion of the automotive industry, and the increasing industrialization and mechanization of various sectors.

The automotive sector accounts for the largest share of the lubricant market, holding nearly 50% of the market revenue. This dominance is primarily due to the extensive use of lubricants in engine oils, gear oils, and transmission fluids, which are essential for the maintenance and efficiency of vehicles. The industrial segment follows closely, with significant demand from manufacturing, power generation, and other heavy machinery sectors.

Market Trends

Several key trends are shaping the growth and evolution of the lubricant market:

Shift Towards Synthetic and Bio-Based Lubricants: Environmental concerns and the need for sustainability have led to a significant shift from conventional mineral-based lubricants to synthetic and bio-based alternatives. Synthetic lubricants, known for their superior performance, longer life, and better thermal stability, are gaining traction, especially in developed markets. Bio-based lubricants, derived from renewable resources, are also seeing increased adoption due to their biodegradable nature and lower environmental impact.

Rising Demand from Emerging Markets: Emerging economies in Asia-Pacific, particularly China and India, are driving the demand for lubricants. Rapid industrialization, increasing automotive sales, and infrastructure development in these regions are key factors contributing to market growth. The Asia-Pacific region holds the largest market share, accounting for nearly 40% of the global lubricant consumption.

Technological Advancements: Innovation in lubricant formulation and production processes is a significant trend in the market. Companies are focusing on developing high-performance lubricants that offer better fuel efficiency, reduced emissions, and extended service intervals. Additionally, advancements in additive technology are enhancing the overall quality and functionality of lubricants.

Growing Focus on Energy Efficiency: Energy efficiency has become a critical factor in industrial operations and automotive applications. Lubricants that reduce friction and energy losses are in high demand, as they contribute to lower operating costs and improved sustainability. This trend is particularly evident in the manufacturing and transportation sectors, where energy efficiency is directly linked to profitability and environmental impact.

Key Market Players and Their Market Share

The global lubricant market is highly competitive, with several key players dominating the industry. These companies are involved in extensive research and development activities, mergers and acquisitions, and strategic partnerships to maintain their market positions. Some of the leading players in the lubricant market include:

Royal Dutch Shell Plc: Shell is a global leader in the lubricant market, holding a market share of approximately 12%. The company offers a wide range of lubricants under its Shell Helix, Shell Rimula, and Shell Tellus brands. Shell’s strong global presence, innovative product portfolio, and commitment to sustainability have helped it maintain a leading position in the market.

ExxonMobil Corporation: ExxonMobil is another major player in the lubricant industry, with a market share of around 10%. The company’s Mobil 1, Mobil Delvac, and Mobil SHC brands are well-known for their high performance and reliability. ExxonMobil’s focus on technological innovation and its extensive distribution network contribute to its strong market presence.

BP Plc (Castrol): BP, through its Castrol brand, holds a significant share of the lubricant market, estimated at 8%. Castrol’s lubricants are widely used in automotive, industrial, and marine applications. The company’s focus on developing environmentally friendly products and its strong brand reputation have been key factors in its success.

TotalEnergies SE: TotalEnergies is a prominent player in the global lubricant market, with a market share of approximately 7%. The company offers a diverse range of lubricants under its Total Quartz, Total Rubia, and Total Azolla brands. TotalEnergies’ commitment to sustainability and its extensive presence in emerging markets are driving its growth in the industry.

Chevron Corporation: Chevron, with its Havoline and Delo brands, holds a market share of around 6%. The company is known for its high-quality lubricants, which are used in a wide range of applications, including automotive, industrial, and marine sectors. Chevron’s focus on innovation and customer satisfaction has helped it maintain a strong position in the market.

Market Challenges

Despite the positive growth outlook, the lubricant market faces several challenges that could impact its development:

Environmental Regulations: Stringent environmental regulations regarding emissions and waste disposal are a significant challenge for the lubricant industry. Governments worldwide are implementing stricter standards to reduce environmental impact, which is driving the shift towards synthetic and bio-based lubricants. However, the high cost of these alternatives can be a barrier to their widespread adoption, particularly in price-sensitive markets.

Fluctuating Raw Material Prices: The lubricant industry is highly dependent on the availability and cost of raw materials, particularly crude oil. Fluctuations in crude oil prices can significantly impact the profitability of lubricant manufacturers. Additionally, the increasing demand for synthetic and bio-based lubricants is putting pressure on the supply of raw materials, leading to potential supply chain disruptions.

Technological Disruption: The rapid pace of technological advancement in the automotive and industrial sectors poses a challenge to the lubricant market. The development of electric vehicles (EVs), for example, requires less lubrication compared to traditional internal combustion engine vehicles. This shift could reduce the demand for automotive lubricants in the long term.

Market Fragmentation: The lubricant market is highly fragmented, with numerous small and medium-sized players competing with established giants. This fragmentation can lead to intense price competition, which can erode profit margins and hinder market growth. Additionally, the presence of counterfeit products in certain regions poses a challenge to maintaining product quality and brand reputation.

Conclusion

The global lubricant market is poised for steady growth in the coming years, driven by increasing demand from emerging economies, technological advancements, and the ongoing shift towards synthetic and bio-based products. However, the market faces significant challenges, including stringent environmental regulations, fluctuating raw material prices, and technological disruption. To navigate these challenges, industry players must focus on innovation, sustainability, and strategic partnerships. Companies that can adapt to changing market dynamics and meet the evolving needs of consumers will be well-positioned to succeed in this competitive landscape. In conclusion, the lubricant market remains a critical component of the global economy, supporting a wide range of industries and applications. While challenges exist, the market's resilience and adaptability suggest a promising future, with continued opportunities for growth and development.

#Lubricant Sector#Marine Lubricant Market#Global Lubricant Industry#Top 20 Lubricants Companies#Lubricant Market Players#Lubricant Market Revenue#Lubricant Market Size

0 notes

Text

Industrial Lubricants Market Forecasted to Hit $74.3 Billion by 2029: Regional Insights and Sectorial Demands

The report “Industrial Lubricants Market by Base Oil (Mineral Oil, Synthetic Oil, Bio-based Oil), Product Type (Hydraulic Fluid, Metalworking Fluid, Grease), End-use Industry (Construction, Power Generation, Food Processing), Region – Global Forecast to 2029″, size was USD 63.9 billion in 2024 and is projected to reach USD 74.3 billion by 2029, at a CAGR of 3.1%, between 2024 and 2029. The…

#automotive lubricants industry#automotive lubricants market#automotive motor oil market#bio-lubricants market#construction lubricants market#Industrial Lubricants#Industrial Lubricants Market#Industrial Lubricants Market 2024#Industrial Lubricants Market Opportunities#Industrial Lubricants Market Overview#Industrial Lubricants Price#lubricants market size#marine lubricants market

0 notes

Text

Global Agricultural Lubricant Market | BIS Research

According to BIS Research Analyst, the global Agricultural Lubricant Market was valued at $6.93 billion in 2024, and it is expected to grow with a CAGR of 4.15% during the forecast period 2023-2028 to reach $10.40 billion by 2034.

#Agricultural Lubricant Market#Agricultural Lubricant Industry#Agricultural Lubricant Market Report#Agriculture#BIS Research#Agricultural Lubricant Market Size

1 note

·

View note

Text

#Saudi Arabia Bio lubricants Market#Market Size#Market Share#Market Trends#Market Analysis#Industry Survey#Market Demand#Top Major Key Player#Market Estimate#Market Segments#Industry Data

0 notes

Text

Engine Oil Additives Market - Forecast (2023 - 2028)

Global engine oil additives market is valued 10,853$ million in the year 2017 and is anticipated to grow at a CAGR of 3.2% during the forecast period 2018-2023.

#Engine Oil Additives market#Engine Oil Additives market size#Engine Oil Additives industry#Engine Oil Additives market share#Engine Oil Additives top 10 companies#Engine Oil Additives market report#Engine Oil Additives industry outlook#lubricant additives#anti-wear additives#corrosion inhibitors#friction modifiers#anti-foam agent#polymer additives

0 notes

Text

According to MarkNtel Advisors, the Global Fluid and Lubricants for Electric Vehicle Market is anticipated to grow at around 17.5% CAGR during the forecast period, i.e., 2021-26. The market growth primarily attributes to the rising inclination of consumers toward EVs as they are eco-friendly, sustainable, & help curb CO2 emissions, coupled with the burgeoning need for durable fluids for EVs and the introduction of various types of coolants & lubricants.

#Fluid and Lubricants for Electric Vehicle Market#Fluid and Lubricants for Electric Vehicle Market growth#Fluid and Lubricants for Electric Vehicle Market size#Fluid and Lubricants for Electric Vehicle Market industry

0 notes

Link

#marketsandmarkets research pvt. ltd.#lubricity improver market#lubricity improver market size#lubricity improver industry

0 notes

Text

Mining Lubricants Market Segment Analysis By Product, Application, Region And Forecast Till 2030 : Grand View Research Inc.

Mining Lubricants Market Segment Analysis By Product, Application, Region And Forecast Till 2030 : Grand View Research Inc.

San Francisco, 12 Jan 2023: The Report Mining Lubricants Market Size, Share & Trends Analysis Report By Product (Mineral Oil, Synthetic, Bio-based), By Application (Coal Mining, Iron Ore Mining), By Region, And Segment Forecasts, 2022 – 2030 The global mining lubricants market size is estimated to reach USD 8.96 billion by 2030, growing at 3.8% CAGR, according to a new report by Grand View…

View On WordPress

#Mining Lubricants Industry#Mining Lubricants Market#Mining Lubricants Market 2030#Mining Lubricants Market Revenue#Mining Lubricants Market Share#Mining Lubricants Market Size

0 notes

Text

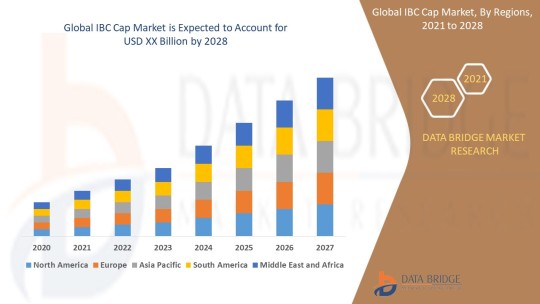

IBC Cap Market Size, Share, Trends, Growth and Competitive Analysis

"IBC Cap Market – Industry Trends and Forecast to 2028

Global IBC Cap Market, By Product Type (Flange, Plugs, Vent-in Plug, Vent-out Plug and Screw closure), Type (Plastic IBC, Metal IBC and Composite IBCs), Material Type (Plastics, Metal, Aluminium and Steel), End Use (Chemicals & Fertilizers, Petroleum & Lubricants, Paints, Inks & Dyes, Food & Beverage, Agriculture, Building & Construction, Healthcare & Pharmaceuticals and Mining), Application (Food And Drinks, Chemical Industry, Oil and Agriculture), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

The global IBC cap market is expected to witness significant growth over the forecast period due to the increasing demand for intermediate bulk containers (IBCs) in various industries such as chemicals, food and beverages, pharmaceuticals, and others. The IBC caps play a crucial role in ensuring the safe storage and transportation of liquid products. The market growth is also being driven by technological advancements in IBC cap designs, such as tamper-evident seals and spouts for easy dispensing. Additionally, the growing focus on sustainability and recyclability of packaging materials is further boosting the adoption of IBC caps made from eco-friendly materials.

**Segments**

- Based on material type, the IBC cap market can be segmented into plastic, metal, and others. Plastic caps are widely used due to their lightweight nature and cost-effectiveness. - By cap type, the market can be categorized into screw caps, snap-on caps, and flip-top caps. Screw caps are preferred for their secure sealing properties. - On the basis of end-user industry, the market can be divided into chemicals, food and beverages, pharmaceuticals, and others. The chemicals segment is anticipated to hold a significant market share due to the widespread use of IBCs for storing chemical products.

**Market Players**

- TPS Industrial Srl - Schuetz GmbH & Co. KGaA - Mauser Packaging Solutions - Time Technoplast Ltd - Berry Global Inc. - THIELMANN UCON AG - Precision IBC, Inc. - Peninsula Packaging LLC

These market players are actively involved in strategic initiatives such as product launches, partnerships, and acquisitions to strengthen their market presence and expand their product offerings. The competitive landscape of the IBC cap market is characterized by intense competition, prompting companies to focus on innovation and quality to gain a competitive edge.

The Asia-Pacific region is expected to witness substantial growth in the IBC cap market, driven by the rapid industrialization and the increasing adoption of IBCsThe Asia-Pacific region represents a significant growth opportunity for the global IBC cap market due to several key factors. With rapid industrialization and the expanding manufacturing sector in countries like China, India, and Southeast Asia, there is a growing demand for efficient storage and transportation solutions, including IBCs and their associated caps. The increased focus on chemical production, food processing, and pharmaceutical manufacturing in the region further fuels the need for reliable packaging solutions like IBC caps. As these industries continue to grow, the adoption of IBC caps is expected to rise, driving market expansion in the Asia-Pacific region.

Moreover, the emphasis on enhancing safety standards and ensuring product integrity is a crucial factor contributing to the growth of the IBC cap market in Asia-Pacific. Regulations regarding the safe handling and transportation of hazardous chemicals and pharmaceuticals necessitate the use of high-quality caps that can effectively seal and protect the contents of IBCs. As companies in the region strive to comply with stringent regulatory requirements, the demand for advanced and secure IBC caps is projected to increase significantly.

Additionally, the shift towards sustainability and eco-friendly practices is another trend shaping the IBC cap market in Asia-Pacific. With growing environmental concerns and increasing awareness about plastic pollution, there is a rising preference for IBC caps made from recyclable and biodegradable materials. Market players in the region are focusing on developing sustainable packaging solutions to meet the evolving consumer demands and align with global sustainability goals. This shift towards eco-friendly IBC caps not only addresses environmental concerns but also presents market players with opportunities to differentiate their offerings and attract environmentally conscious customers.

Furthermore, the competitive landscape of the IBC cap market in Asia-Pacific is characterized by the presence of both local manufacturers and international players. Local companies often have a strong understanding of regional market dynamics and customer preferences, giving them a competitive advantage in catering to specific industry needs. On the other hand, multinational companies bring technological expertise and a wide product portfolio, which can appeal to a broader customer base seeking innovative and**Global IBC Cap Market, By Product Type**

- Flange - Plugs - Vent-in Plug - Vent-out Plug - Screw closure

**Type**

- Plastic IBC - Metal IBC - Composite IBCs

**Material Type**

- Plastics - Metal - Aluminium - Steel

**End Use**

- Chemicals & Fertilizers - Petroleum & Lubricants - Paints, Inks & Dyes - Food & Beverage - Agriculture - Building & Construction - Healthcare & Pharmaceuticals - Mining

**Application**

- Food And Drinks - Chemical Industry - Oil and Agriculture

The Global IBC Cap market is experiencing significant growth due to the rising demand for intermediate bulk containers across various industries. Plastic caps are increasingly preferred for their lightweight and cost-effective nature, driving market growth within the material type segment. Screw caps, known for their secure sealing properties, dominate the cap type category. The chemicals segment is anticipated to hold a substantial market share among end-user industries, attributed to the widespread use of IBCs for chemical storage. The market players in the industry are focusing on strategic initiatives like product launches and partnerships to enhance their market presence and offerings. The competitive landscape is intense, spurring companies to innovate and prioritize quality for a competitive advantage.

In Asia-Pacific, the IBC cap market is poised for robust growth fueled by rapid industrialization and the expanding manufacturing sector, particularly in countries like China,

Countries Studied:

North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Key Coverage in the IBC Cap Market Report:

Detailed analysis of IBC Cap Market by a thorough assessment of the technology, product type, application, and other key segments of the report

Qualitative and quantitative analysis of the market along with CAGR calculation for the forecast period

Investigative study of the market dynamics including drivers, opportunities, restraints, and limitations that can influence the market growth

Comprehensive analysis of the regions of the IBC Cap industry and their futuristic growth outlook

Competitive landscape benchmarking with key coverage of company profiles, product portfolio, and business expansion strategies

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Browse Trending Reports:

Calcium Glycinate Market Retinal Biologics Market Facial Fat Transfer Market Angio Suites Diagnostic Imaging Market Adoption Of Benelux Power Tools Market De Quervains Tenosynovitis Treatment Market Biodetectors And Accessories Market Colposcope Market Sports Medicine Market Automotive Adhesives Market Infrared Imaging Market Vapour Deposition Market Professional Diagnostics Market Ct Scanner Market Programmable Application Specific Integrated Circuit Asic Market Hospital Operating Room Or Products And Solutions Market Castor Oil Market Zika Virus Infection Drug Market Toluene Diisocynate Market Antibiotic Resistance Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

2 notes

·

View notes

Text

Zero Friction Coatings Market: Charting the Course for Enhanced Performance and Sustainable Solutions

The global zero friction coatings market size is estimated to reach USD 1,346.00 million by 2030 according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.6% from 2022 to 2030. Growth can be attributed to the fact that these coatings reduce friction and wear resulting in low fuel consumption and less heat generation. According to the European Automobile Manufacturers' Association, 79.1 million motor vehicles were produced across the globe in 2021 which was up by 1.3% as compared to 2020. Zero friction coatings can extend the time between component maintenance and replacement, especially for machine parts that are expensive to manufacture.

Zero Friction Coatings Market Report Highlights

In 2021, molybdenum disulfide emerged as the dominant type segment by contributing around 50% of the revenue share. This is attributed to its properties such as low coefficient of friction at high loads, electrical insulation, and wide temperature range

The automobile & transportation was the dominating end-use segment accounting for a revenue share of more than 35% in 2021 due to the rapid growth of the automotive industry across the globe

The energy end-use segment is anticipated to grow at a CAGR of 5.7% in terms of revenue by 2030, owing to the excessive wear on the drill stem assembly and the well casing during the drilling operations in the oil and gas sector

In Asia Pacific, the market is projected to witness the highest CAGR of 5.8% over the predicted years owing to the presence of car manufacturing industries in the countries such as Japan, South Korea, and China

For More Details or Sample Copy please visit link @: Zero Friction Coatings Market Report

Several applications in the automobile industry use wear-resistant plastic seals that require zero tolerance for failure and lifetime service confidence. Increasing demand for the product from the automotive industry across the globe for various applications including fuel pumps, automatic transmissions, oil pumps, braking systems, and others is expected to drive its demand over the forecast period.

Low friction coatings can be used in extreme environments comprising high pressure, temperatures, and vacuums. These coatings can provide improved service life and performance thereby eliminating the need for wet lubricants in environments that require chemicals, heat, or clean room conditions. The product containing molybdenum disulfide (MoS2) are suitable for reinforced plastics while those free from MoS2 are suitable for non-reinforced plastics.

Zero friction coatings are paint-like products containing submicron-sized particles of solid lubricants dispersed through resin blends and solvents. The product can be applied using conventional painting techniques such as dipping, spraying, or brushing. The thickness of the film has a considerable influence on the anti-corrosion properties, coefficient of friction, and service life of the product. Its thickness should be greater than the surface roughness of the mating surfaces.

ZeroFrictionCoatingsMarket #FrictionlessTechnology #CoatingInnovations #IndustrialEfficiency #ZeroFrictionSolutions #AdvancedMaterials #SurfaceCoatings #ManufacturingAdvancements #GlobalIndustryTrends #InnovativeCoatings #PerformanceOptimization #MechanicalSystems #SustainableTechnology #IndustrialApplications #FutureTech #InnovationInMaterials #EfficiencySolutions #ZeroFrictionMarket #TechnologyInnovation #EngineeringMaterials

#Zero Friction Coatings Market#Frictionless Technology#Coating Innovations#Industrial Efficiency#Zero Friction Solutions#Advanced Materials#Surface Coatings#Manufacturing Advancements#Global Industry Trends#Innovative Coatings#Performance Optimization#Mechanical Systems#Sustainable Technology#Industrial Applications#Future Tech#Innovation In Materials#Efficiency Solutions#Zero Friction Market#Technology Innovation#Engineering Materials

2 notes

·

View notes

Text

Automotive Lubricants Market: Trends, Market Key Players and Market Share

The automotive lubricants market has been experiencing significant growth in recent years, driven by factors such as increasing vehicle production, rising consumer demand, and advancements in technology. This blog will delve into the current state of the market, including its size, share, growth, trends, key players, and challenges.

Lubricants Market Size, Share, and Growth

The global automotive lubricants market is projected to reach $114.2 billion by 2030, at a CAGR of 7.8% from 2023 to 2030. The market is expected to grow as quick lube centers and vehicle maintenance services have made it more convenient for consumers to maintain their vehicles, leading to increased demand for lubricants. The market size is forecast to reach $80.1 billion by 2026, after growing at a CAGR of 5.3% during 2021-2026.

Market Trends

Shift towards synthetic lubricants: The increasing demand for synthetic lubricants is driven by their superior performance, including better viscosity stability, extended drain intervals, and improved fuel efficiency.

Focus on fuel-efficient formulations: Automotive lubricant manufacturers are developing innovative formulations designed to optimize engine performance and reduce fuel consumption, such as low-viscosity lubricants like 0W-20 and 5W-30 engine oils.

Expansion of electric vehicle (EV) lubricants: The growing need for specialized lubricants tailored to the unique requirements of electric vehicles (EVs) is driving innovation in EV lubricants, which must maintain compatibility with electric motors and battery systems.

Adoption of bio-based lubricants: Bio-based lubricants derived from renewable sources offer environmental benefits like reduced carbon footprint, biodegradability, and lower toxicity, making them a preferred choice amid growing environmental concerns and regulatory pressures.

Lubricants Market Key Players and Market Share

BASF: The German chemical company is a leading player in the automotive lubricants market, with a significant market share due to its extensive product portfolio and strong research and development capabilities.

ExxonMobil: The American multinational oil and gas corporation is another major player in the market, with a strong presence in the production of high-performance lubricants and a significant market share.

Castrol: The British lubricant manufacturer is known for its high-quality lubricants and has a significant market share due to its extensive product portfolio and strong brand recognition.

Chevron: The American multinational energy corporation is a significant player in the market, with a strong presence in the production of lubricants and a significant market share.

Automotive Lubricants Market Challenges

Supply chain disruptions: The COVID-19 pandemic has caused significant disruptions to the global supply chain, leading to shortages and delays in the production and distribution of lubricants.

Regulatory changes: Stricter environmental regulations and emission standards have led to the need for costly investments in research and development to comply with these changes.

Intense competition: The automotive lubricants market is highly competitive, with both global and local players vying for market share, leading to pressure on prices and profit margins.

Skilled labor shortage: The industry is facing a shortage of skilled workers, particularly in areas like advanced manufacturing and software development, which is hindering growth and innovation.

Conclusion The automotive lubricants market is poised for continued growth in the coming years, driven by factors such as increasing vehicle production, rising consumer demand, and advancements in technology. However, the market also faces challenges such as supply chain disruptions, regulatory changes, intense competition, and skilled labor shortages. To succeed in this dynamic market, automotive lubricant manufacturers must focus on innovation, cost-efficiency, and strategic partnerships to stay ahead of the curve.

#Global Lubricants Market Size#lubricants market#industrial lubricants manufacturers#automotive lubricants#Lubricants Sector

0 notes

Text

Increasing Automation and Demand for Eco-friendly Lubricants support the Industrial Lubricants Market Growth| MarketsandMarkets™

Industrial lubricants are special fluids used to reduce friction and wear between two surfaces in contact with each other, such as the mating moving parts of an engine or a machine. They help reduce energy losses, improve machine efficiency, and extend equipment life. Commonly used industrial lubricants include mineral oils and synthetic fluids, greases, and waxes. Industrial lubricants are…

View On WordPress

#automotive lubricants industry#automotive lubricants market#automotive motor oil market#biolubricants market#construction lubricants market#COVID-19 Impact on Industrial Lubricants Market#Global Industrial Lubricants Market#Industrial Lubricants#Industrial Lubricants business research report#Industrial Lubricants Industry Trends#Industrial Lubricants Market#Industrial Lubricants Market Analysis#Industrial Lubricants Market Overview#Industrial Lubricants Market Share#Industrial Lubricants research insights#Industrial Lubricants Research Report#lubricant additives industry#lubricants market size#marine lubricants market

0 notes

Text

A Comprehensive Guide to Hydraulic Paver Block Making Machine

Welcome to "A Comprehensive Guide to Hydraulic Paver Block Making Machine." In the ever-evolving world of construction and infrastructure development, the significance of efficient and eco-friendly building materials cannot be overstated. Paver blocks have emerged as a popular choice due to their durability, versatility, and aesthetic appeal. At the heart of this revolution lies the Hydraulic Paver Block Making Machine – a game-changing technology that has transformed the production of paver blocks.

This article aims to delve into the intricacies of Hydraulic Paver Block Making Machine, providing a detailed exploration of their working principles, key components, and various types available in the market. We will uncover tips and some troubleshooting steps.

Moreover,we will highlight essential considerations for selecting the right machine that aligns with specific project requirements. Whether you are an industry professional seeking to optimize production processes or an enthusiast eager to grasp the mechanics behind paver block manufacturing, this guide will equip you with invaluable insights.

Understanding Hydraulic Paver Block Machine Specifications

When it comes to hydraulic paver block machines, understanding their specifications is crucial for making informed decisions. These machines are essential for producing high-quality, durable, and aesthetically pleasing paver blocks used in various construction projects.

Hydraulic paver block machine specifications encompass a range of key features. The capacity, which determines the number of blocks produced per hour, directly impacts productivity. The molding area size affects the dimensions and shapes of the blocks. Additionally, the power and pressure rating influence the machine's efficiency and performance.

Moreover, it's essential to consider the automation level and control system, as advanced automation ensures precision and ease of operation. The type of molds compatible with the machine allows for versatility in block design. Understanding these specifications empowers buyers to select the ideal hydraulic paver block machine that aligns with their specific project requirements, resulting in cost-effective and successful paving solutions.

Choosing the Right Paver Type: Interlocking vs. Non-interlocking

When it comes to selecting the right paver type for your project, the choice between interlocking and non-interlocking pavers plays a crucial role in determining the overall outcome. Here are some key points to consider for each option:

Interlocking Pavers:

Interlocking pavers are designed to fit tightly together, creating a durable and stable surface.

They offer excellent load-bearing capabilities, making them ideal for driveways, walkways, and high-traffic areas.

The interlocking design provides flexibility, allowing them to withstand ground movement without cracking.

These pavers come in various shapes, colors, and patterns, enabling versatile and visually appealing designs.

Installation is relatively easier due to the interlocking system, reducing labor time and costs.

Repairs are simple, as individual pavers can be replaced without affecting the entire surface.

Non-Interlocking Pavers:

Non-interlocking pavers are more affordable compared to their interlocking counterparts.

They are suitable for light to moderate traffic areas like patios, garden pathways, and decorative landscape elements.

Installation may require more precision and skill as they do not have the interlocking mechanism.

Although repairs are possible, they might be more labor-intensive and could involve replacing larger sections.

Pro Tips for Maintaining Your Paver Block Making Machine

Regular Cleaning: Clean the machine daily to remove any residual concrete and debris that can cause blockages or malfunctions.

Lubrication: Keep all moving parts well-lubricated to reduce friction and prevent wear and tear.

Inspection: Conduct routine inspections to identify and address any signs of wear, damage, or misalignment promptly.

Tighten Bolts: Check and tighten all bolts and nuts regularly to maintain stability and prevent vibrations.

Replace Worn Parts: Replace worn-out parts immediately to prevent further damage and ensure optimal performance.

Calibration: Calibrate the machine regularly to ensure accurate and consistent block dimensions.

Electrical Connections: Inspect and secure electrical connections to prevent electrical issues.

Professional Maintenance: Schedule periodic maintenance by qualified technicians to address complex servicing and extend the machine's lifespan.

Operating Guidelines: Train operators on proper machine operation and safety protocols to prevent mishandling or accidents.

Store in Shelter: Store the machine in a sheltered area to protect it from weather conditions and extend its longevity.

Troubleshooting Hydraulic Paver Block Making Machine

Low Block Quality: Adjust the hydraulic pressure and ensure proper alignment of molds to improve block quality.

Block Disintegration: Check the mix proportions of raw materials and the curing process for better block strength.

Oil Leaks: Inspect hydraulic hoses and connections, repair or replace damaged parts, and refill hydraulic oil as needed.

Excessive Noise/Vibrations: Tighten loose components and bolts, and ensure proper leveling of the machine.

Uneven Block Height: Verify uniform material distribution in the mold and calibrate the machine for consistent block height.

Machine Not Starting: Check power supply, fuses, and safety switches; repair or replace faulty electrical components.

Insufficient Block Production: Clean and maintain the machine regularly, and optimize the production process for efficiency.

Irregular Block Shapes: Inspect mold condition, ensure proper vibration, and adjust mold settings to achieve uniform shapes.

Safety Hazards: Implement strict safety protocols, provide training to operators, and display safety guidelines prominently.

Seek Professional Help: If issues persist, consult experienced technicians or manufacturers for advanced troubleshooting and repairs.

Conclusion

A Comprehensive Guide to Hydraulic Paver Block Making Machine highlights the indispensable role of perfect hydraulic machines in revolutionizing paver block production. The detailed exploration of working principles, types, and maintenance underscores their efficiency and eco-friendly advantages. By embracing these cutting-edge technologies, the construction industry gains a competitive edge in creating durable and visually appealing infrastructure. As Perfect Hydraulic Machines continue to shape the future of paver block manufacturing, their impact on sustainable construction practices remains unparalleled.

#Hydraulic Paver Block Making Machine#perfect hydraulic machines#hydraulic machines#Fly Ash Brick Machine

2 notes

·

View notes