#Global Industrial Lubricants Market

Explore tagged Tumblr posts

Text

Lubricants Market Size, Industry Share Growth Forecast

In the vast ocean of industrial sectors, the lubricants market stands out as a crucial component driving the smooth operation of numerous industries worldwide. From automotive to marine, the demand for lubricants spans a wide array of sectors, fueling the global economy. In this blog post, we delve into the dynamics of the lubricants market, exploring its size, trends, key players, and future prospects.

Market Size and Growth

According to recent reports, the global lubricants market has witnessed steady growth in recent years, the global lubricants market size was estimated at USD 139.44 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 3.8% from 2024 to 2030. This is attributed to the growing demand for automotive oils and greases due to the growing trade of vehicles and spare parts. Factors such as industrialization, urbanization, and the expansion of transportation networks contribute to the increasing demand for lubricants across the globe.

Understanding the Landscape

The global lubricants market is expansive and diverse, encompassing various segments such as automotive lubricants, industrial lubricants, marine lubricants, and specialty lubricants. Each segment caters to specific needs, ranging from ensuring optimal engine performance to enhancing machinery efficiency in industrial settings.

Key Segments and Opportunities

Automotive Lubricants Market: With the automotive industry experiencing rapid technological advancements and stringent regulations regarding emissions and fuel efficiency, the demand for high-performance lubricants continues to rise. Manufacturers are focusing on developing innovative lubricant solutions to meet the evolving needs of modern vehicles.

Industrial Lubricants Market: Industries such as manufacturing, construction, mining, and energy heavily rely on lubricants to maintain equipment durability and operational efficiency. The industrial lubricants market presents significant opportunities for suppliers to offer specialized products tailored to specific industrial applications.

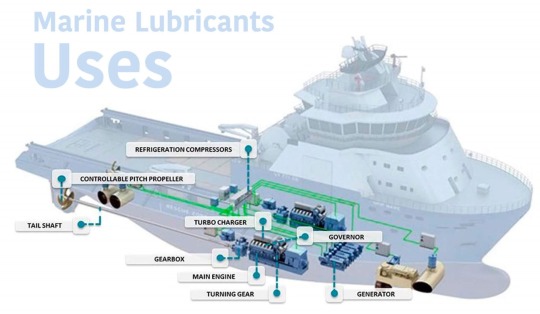

Marine Lubricant Market: As the maritime industry navigates towards sustainability and compliance with environmental regulations, there is a growing demand for eco-friendly marine lubricants. Companies are investing in research and development to formulate lubricants that reduce emissions and enhance engine performance in marine vessels.

Specialty Lubricants Market: The specialty lubricants segment caters to niche applications where standard lubricants may not suffice. These high-performance lubricants offer superior properties such as extreme temperature resistance, corrosion protection, and longer service life, making them indispensable in critical industries like aerospace, defense, and electronics.

Future Outlook

The future of the lubricants industry appears promising, driven by ongoing technological innovations, increasing awareness regarding environmental sustainability, and the expansion of end-user industries. Market players are expected to focus on product differentiation, strategic partnerships, and sustainable practices to maintain a competitive edge in the evolving market landscape.

Challenges and Considerations

While opportunities abound in the lubricants market, manufacturers and suppliers face several challenges, including fluctuating raw material prices, regulatory complexities, and intensifying competition. However, proactive measures such as investing in research and development, adopting advanced manufacturing processes, and diversifying product portfolios can help mitigate these challenges and foster growth.

Conclusion

In conclusion, the lubricants market continues to thrive amidst a dynamic business environment, driven by the indispensable role lubricants play in various industries. As demand continues to grow globally, stakeholders must stay abreast of market trends, embrace innovation, and adapt to changing customer needs to capitalize on emerging opportunities and ensure sustained success in the lubricants sector.

#Lubricants Market#Global Lubricants Market Size#Global Industrial Lubricants Market#Industrial Lubricants Market#Automotive Lubricants Market#Lubricants Sector

0 notes

Text

The volume of package delivery drones is projected to grow from 32,456 (In units) in 2024 to 275,703 (In units) by 2030. The Drone Package Delivery Market is projected to grow from USD 693 Million in 2024 to USD 4,666 Million by 2030, at a CAGR of 37.4%. There is rise in deployment of drones for quick and same day package delivery. Government approvals, cost-effectiveness delivery, reducing carbon emissions and instant package delivery are main reasons for the Drone Package Delivery Industry growth.

#Aviation Lubricant#Aviation Lubricant Market#Aviation Lubricant Industry#Global Aviation Lubricant Market

0 notes

Text

IBC Cap Market Size, Share, Trends, Growth and Competitive Analysis

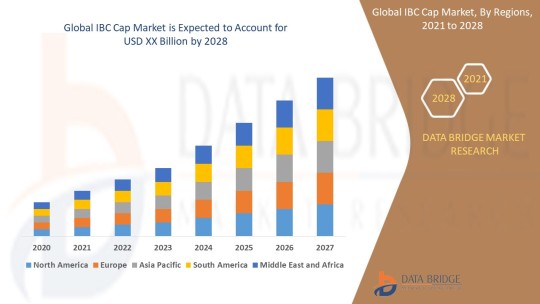

"IBC Cap Market – Industry Trends and Forecast to 2028

Global IBC Cap Market, By Product Type (Flange, Plugs, Vent-in Plug, Vent-out Plug and Screw closure), Type (Plastic IBC, Metal IBC and Composite IBCs), Material Type (Plastics, Metal, Aluminium and Steel), End Use (Chemicals & Fertilizers, Petroleum & Lubricants, Paints, Inks & Dyes, Food & Beverage, Agriculture, Building & Construction, Healthcare & Pharmaceuticals and Mining), Application (Food And Drinks, Chemical Industry, Oil and Agriculture), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

The global IBC cap market is expected to witness significant growth over the forecast period due to the increasing demand for intermediate bulk containers (IBCs) in various industries such as chemicals, food and beverages, pharmaceuticals, and others. The IBC caps play a crucial role in ensuring the safe storage and transportation of liquid products. The market growth is also being driven by technological advancements in IBC cap designs, such as tamper-evident seals and spouts for easy dispensing. Additionally, the growing focus on sustainability and recyclability of packaging materials is further boosting the adoption of IBC caps made from eco-friendly materials.

**Segments**

- Based on material type, the IBC cap market can be segmented into plastic, metal, and others. Plastic caps are widely used due to their lightweight nature and cost-effectiveness. - By cap type, the market can be categorized into screw caps, snap-on caps, and flip-top caps. Screw caps are preferred for their secure sealing properties. - On the basis of end-user industry, the market can be divided into chemicals, food and beverages, pharmaceuticals, and others. The chemicals segment is anticipated to hold a significant market share due to the widespread use of IBCs for storing chemical products.

**Market Players**

- TPS Industrial Srl - Schuetz GmbH & Co. KGaA - Mauser Packaging Solutions - Time Technoplast Ltd - Berry Global Inc. - THIELMANN UCON AG - Precision IBC, Inc. - Peninsula Packaging LLC

These market players are actively involved in strategic initiatives such as product launches, partnerships, and acquisitions to strengthen their market presence and expand their product offerings. The competitive landscape of the IBC cap market is characterized by intense competition, prompting companies to focus on innovation and quality to gain a competitive edge.

The Asia-Pacific region is expected to witness substantial growth in the IBC cap market, driven by the rapid industrialization and the increasing adoption of IBCsThe Asia-Pacific region represents a significant growth opportunity for the global IBC cap market due to several key factors. With rapid industrialization and the expanding manufacturing sector in countries like China, India, and Southeast Asia, there is a growing demand for efficient storage and transportation solutions, including IBCs and their associated caps. The increased focus on chemical production, food processing, and pharmaceutical manufacturing in the region further fuels the need for reliable packaging solutions like IBC caps. As these industries continue to grow, the adoption of IBC caps is expected to rise, driving market expansion in the Asia-Pacific region.

Moreover, the emphasis on enhancing safety standards and ensuring product integrity is a crucial factor contributing to the growth of the IBC cap market in Asia-Pacific. Regulations regarding the safe handling and transportation of hazardous chemicals and pharmaceuticals necessitate the use of high-quality caps that can effectively seal and protect the contents of IBCs. As companies in the region strive to comply with stringent regulatory requirements, the demand for advanced and secure IBC caps is projected to increase significantly.

Additionally, the shift towards sustainability and eco-friendly practices is another trend shaping the IBC cap market in Asia-Pacific. With growing environmental concerns and increasing awareness about plastic pollution, there is a rising preference for IBC caps made from recyclable and biodegradable materials. Market players in the region are focusing on developing sustainable packaging solutions to meet the evolving consumer demands and align with global sustainability goals. This shift towards eco-friendly IBC caps not only addresses environmental concerns but also presents market players with opportunities to differentiate their offerings and attract environmentally conscious customers.

Furthermore, the competitive landscape of the IBC cap market in Asia-Pacific is characterized by the presence of both local manufacturers and international players. Local companies often have a strong understanding of regional market dynamics and customer preferences, giving them a competitive advantage in catering to specific industry needs. On the other hand, multinational companies bring technological expertise and a wide product portfolio, which can appeal to a broader customer base seeking innovative and**Global IBC Cap Market, By Product Type**

- Flange - Plugs - Vent-in Plug - Vent-out Plug - Screw closure

**Type**

- Plastic IBC - Metal IBC - Composite IBCs

**Material Type**

- Plastics - Metal - Aluminium - Steel

**End Use**

- Chemicals & Fertilizers - Petroleum & Lubricants - Paints, Inks & Dyes - Food & Beverage - Agriculture - Building & Construction - Healthcare & Pharmaceuticals - Mining

**Application**

- Food And Drinks - Chemical Industry - Oil and Agriculture

The Global IBC Cap market is experiencing significant growth due to the rising demand for intermediate bulk containers across various industries. Plastic caps are increasingly preferred for their lightweight and cost-effective nature, driving market growth within the material type segment. Screw caps, known for their secure sealing properties, dominate the cap type category. The chemicals segment is anticipated to hold a substantial market share among end-user industries, attributed to the widespread use of IBCs for chemical storage. The market players in the industry are focusing on strategic initiatives like product launches and partnerships to enhance their market presence and offerings. The competitive landscape is intense, spurring companies to innovate and prioritize quality for a competitive advantage.

In Asia-Pacific, the IBC cap market is poised for robust growth fueled by rapid industrialization and the expanding manufacturing sector, particularly in countries like China,

Countries Studied:

North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Key Coverage in the IBC Cap Market Report:

Detailed analysis of IBC Cap Market by a thorough assessment of the technology, product type, application, and other key segments of the report

Qualitative and quantitative analysis of the market along with CAGR calculation for the forecast period

Investigative study of the market dynamics including drivers, opportunities, restraints, and limitations that can influence the market growth

Comprehensive analysis of the regions of the IBC Cap industry and their futuristic growth outlook

Competitive landscape benchmarking with key coverage of company profiles, product portfolio, and business expansion strategies

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Browse Trending Reports:

Calcium Glycinate Market Retinal Biologics Market Facial Fat Transfer Market Angio Suites Diagnostic Imaging Market Adoption Of Benelux Power Tools Market De Quervains Tenosynovitis Treatment Market Biodetectors And Accessories Market Colposcope Market Sports Medicine Market Automotive Adhesives Market Infrared Imaging Market Vapour Deposition Market Professional Diagnostics Market Ct Scanner Market Programmable Application Specific Integrated Circuit Asic Market Hospital Operating Room Or Products And Solutions Market Castor Oil Market Zika Virus Infection Drug Market Toluene Diisocynate Market Antibiotic Resistance Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

2 notes

·

View notes

Text

The Essential Role of Oilfield Chemical Products in Extraction Efficiency

The extraction of oil and gas is a complex and challenging process that requires the use of advanced technologies and high-quality chemical products. These chemicals play a crucial role in enhancing extraction efficiency, ensuring environmental safety, and reducing operational costs. Imperial Oilfield Chemicals Pvt. Ltd. (ICPL), recognized as the best chemical company in Vadodara, excels in providing innovative oilfield chemical solutions that meet the rigorous demands of the industry. In this article, we will delve into the essential role of oilfield chemical products in extraction efficiency and highlight why ICPL stands out as the best oilfield chemical products provider in the world.

The Importance of Oilfield Chemicals in Extraction

Oilfield chemicals are indispensable in various stages of oil and gas extraction. From drilling to production and processing, these chemicals enhance performance, protect equipment, and ensure efficient resource recovery. Here are some key areas where oilfield chemicals play a vital role:

1. Drilling Fluids

Drilling fluids, also known as drilling muds, are essential in the drilling process. They serve multiple functions, including:

Lubrication: Reducing friction between the drill bit and the rock formation.

Cooling: Keeping the drill bit cool to prevent overheating.

Stabilization: Maintaining the integrity of the wellbore walls.

Carrying Cuttings: Transporting rock cuttings to the surface.

ICPL’s advanced drilling fluid formulations ensure optimal performance in various geological conditions, making them a preferred choice for drilling operations worldwide.

2. Cementing Additives

Cementing is a critical phase in well construction, providing structural integrity and zonal isolation. Cementing additives are used to enhance the properties of cement slurries, ensuring:

Improved Strength: Enhancing the compressive strength of the cement.

Reduced Shrinkage: Minimizing the risk of annular gaps and leaks.

Accelerated Setting: Reducing the waiting time for cement to set and harden.

As one of the best oilfield chemicals suppliers, ICPL offers a range of cementing additives that improve the efficiency and reliability of well cementing operations.

3. Production Chemicals

During the production phase, various chemicals are used to maximize oil and gas recovery and maintain flow efficiency. These include:

Corrosion Inhibitors: Preventing corrosion of pipelines and equipment.

Scale Inhibitors: Preventing the formation of scale deposits that can clog pipelines.

Emulsion Breakers: Separating water from oil to ensure smooth flow.

ICPL’s production chemicals are designed to address specific challenges in oil and gas production, ensuring high efficiency and longevity of equipment.

4. Enhanced Oil Recovery (EOR) Chemicals

Enhanced Oil Recovery (EOR) techniques are used to extract additional oil from reservoirs after primary and secondary recovery methods. EOR chemicals include:

Surfactants: Reducing surface tension to improve oil mobility.

Polymers: Increasing the viscosity of injected water to improve sweep efficiency.

Alkalis: Reacting with natural acids in the reservoir to form surfactants in-situ.

ICPL’s expertise in EOR chemicals positions them as the best oilfield chemical products provider in the world, helping operators maximize recovery from mature fields.

ICPL: A Leader in Oilfield Chemical Solutions

Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) has earned its reputation as the best chemical company in Vadodara by consistently delivering high-quality, innovative chemical solutions tailored to the needs of the oil and gas industry. Here are some reasons why ICPL stands out in the global market:

1. Research and Development

ICPL invests heavily in research and development to stay at the forefront of technological advancements. Their state-of-the-art R&D facilities in Vadodara focus on developing new formulations and improving existing products to meet the evolving needs of the industry.

2. Quality Assurance

Quality is at the core of ICPL’s operations. They adhere to stringent quality control measures at every stage of production, from raw material sourcing to final product testing. This commitment to quality ensures that their products meet international standards and deliver consistent performance.

3. Customization

Recognizing that each oilfield has unique challenges, ICPL offers customized solutions to address specific operational requirements. Their team of experts works closely with clients to develop tailored chemical formulations that optimize extraction efficiency and reduce costs.

4. Global Reach

With a strong presence in the global market, ICPL is not only the best oilfield chemicals supplier in India but also a trusted partner for oil and gas companies worldwide. Their products are used in diverse geographical regions, including the Middle East, North America, and Europe, demonstrating their versatility and reliability.

5. Environmental Responsibility

ICPL is committed to sustainable practices and environmental responsibility. They develop eco-friendly chemical formulations that minimize environmental impact and comply with regulatory standards. This focus on sustainability is crucial in today’s industry, where environmental considerations are increasingly important.

Case Study: Enhancing Extraction Efficiency with ICPL Products

To illustrate the impact of ICPL’s oilfield chemical products, let us consider a case study involving a major oilfield operator in the Middle East.

Challenge:

The operator was facing significant challenges with scale formation and corrosion in their production wells, leading to frequent downtime and high maintenance costs.

Solution:

ICPL conducted a thorough assessment of the field conditions and recommended a tailored chemical treatment program. The program included:

Scale Inhibitors: Specifically formulated to prevent the deposition of scale in high-temperature environments.

Corrosion Inhibitors: Designed to protect the integrity of pipelines and equipment.

Results:

The implementation of ICPL’s chemical solutions resulted in a substantial reduction in scale and corrosion issues. The operator reported:

Increased Uptime: Reduced downtime due to fewer maintenance interventions.

Cost Savings: Lower maintenance costs and extended equipment lifespan.

Improved Production: Enhanced flow efficiency and increased oil recovery.

This case study underscores the critical role of high-quality oilfield chemical products in improving extraction efficiency and operational reliability.

Conclusion

The essential role of oilfield chemical products in extraction efficiency cannot be overstated. From drilling and cementing to production and enhanced oil recovery, these chemicals are integral to the success of oil and gas operations. Imperial Oilfield Chemicals Pvt. Ltd. (ICPL), as the best chemical company in Vadodara, continues to lead the industry with innovative solutions and a commitment to quality.

ICPL’s position as the best oilfield chemical products provider in the world is reinforced by their dedication to research and development, customization, quality assurance, and environmental responsibility. Their global reach and proven track record make them a trusted partner for oil and gas operators seeking to enhance extraction efficiency and achieve operational excellence.

As the industry evolves and new challenges arise, ICPL remains at the forefront, delivering cutting-edge chemical solutions that drive the future of oil and gas extraction.

#Best oilfield chemicals suppliers#Best oilfield chemical products provider in the world#Best chemical company in Vadodara#upstream oil and gas industry#upstream oil and gas segment

3 notes

·

View notes

Text

Zero Friction Coatings Market: Charting the Course for Enhanced Performance and Sustainable Solutions

The global zero friction coatings market size is estimated to reach USD 1,346.00 million by 2030 according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.6% from 2022 to 2030. Growth can be attributed to the fact that these coatings reduce friction and wear resulting in low fuel consumption and less heat generation. According to the European Automobile Manufacturers' Association, 79.1 million motor vehicles were produced across the globe in 2021 which was up by 1.3% as compared to 2020. Zero friction coatings can extend the time between component maintenance and replacement, especially for machine parts that are expensive to manufacture.

Zero Friction Coatings Market Report Highlights

In 2021, molybdenum disulfide emerged as the dominant type segment by contributing around 50% of the revenue share. This is attributed to its properties such as low coefficient of friction at high loads, electrical insulation, and wide temperature range

The automobile & transportation was the dominating end-use segment accounting for a revenue share of more than 35% in 2021 due to the rapid growth of the automotive industry across the globe

The energy end-use segment is anticipated to grow at a CAGR of 5.7% in terms of revenue by 2030, owing to the excessive wear on the drill stem assembly and the well casing during the drilling operations in the oil and gas sector

In Asia Pacific, the market is projected to witness the highest CAGR of 5.8% over the predicted years owing to the presence of car manufacturing industries in the countries such as Japan, South Korea, and China

For More Details or Sample Copy please visit link @: Zero Friction Coatings Market Report

Several applications in the automobile industry use wear-resistant plastic seals that require zero tolerance for failure and lifetime service confidence. Increasing demand for the product from the automotive industry across the globe for various applications including fuel pumps, automatic transmissions, oil pumps, braking systems, and others is expected to drive its demand over the forecast period.

Low friction coatings can be used in extreme environments comprising high pressure, temperatures, and vacuums. These coatings can provide improved service life and performance thereby eliminating the need for wet lubricants in environments that require chemicals, heat, or clean room conditions. The product containing molybdenum disulfide (MoS2) are suitable for reinforced plastics while those free from MoS2 are suitable for non-reinforced plastics.

Zero friction coatings are paint-like products containing submicron-sized particles of solid lubricants dispersed through resin blends and solvents. The product can be applied using conventional painting techniques such as dipping, spraying, or brushing. The thickness of the film has a considerable influence on the anti-corrosion properties, coefficient of friction, and service life of the product. Its thickness should be greater than the surface roughness of the mating surfaces.

ZeroFrictionCoatingsMarket #FrictionlessTechnology #CoatingInnovations #IndustrialEfficiency #ZeroFrictionSolutions #AdvancedMaterials #SurfaceCoatings #ManufacturingAdvancements #GlobalIndustryTrends #InnovativeCoatings #PerformanceOptimization #MechanicalSystems #SustainableTechnology #IndustrialApplications #FutureTech #InnovationInMaterials #EfficiencySolutions #ZeroFrictionMarket #TechnologyInnovation #EngineeringMaterials

#Zero Friction Coatings Market#Frictionless Technology#Coating Innovations#Industrial Efficiency#Zero Friction Solutions#Advanced Materials#Surface Coatings#Manufacturing Advancements#Global Industry Trends#Innovative Coatings#Performance Optimization#Mechanical Systems#Sustainable Technology#Industrial Applications#Future Tech#Innovation In Materials#Efficiency Solutions#Zero Friction Market#Technology Innovation#Engineering Materials

2 notes

·

View notes

Text

The Future of Industrial Lubricants: Driving Efficiency and Sustainability in Modern Industries

In today’s industrial landscape, the role of industrial lubricants is more critical than ever. From towering manufacturing plants to high-precision automotive assembly lines, lubricants are the unsung heroes that keep machinery running smoothly, reduce wear and tear, and ensure operational efficiency. But as industries evolve, so do the demands placed on these essential fluids. The future of industrial lubricants is not just about reducing friction—it’s about driving sustainability, embracing innovation, and meeting the challenges of a rapidly changing world.

The Evolving Role of Industrial Lubricants

Industrial lubricants have come a long way from being simple oils and greases. Today, they are sophisticated formulations designed to meet the specific needs of modern machinery and processes. With industries increasingly adopting automation, IoT, and Industry 4.0 technologies, the demand for high-performance lubricants has surged. These advanced fluids are engineered to:

Minimize friction and heat generation in high-speed operations.

Extend equipment lifespan by reducing wear and corrosion.

Enhance energy efficiency by optimizing machinery performance.

But the story doesn’t end there. As global industries face mounting pressure to reduce their environmental footprint, lubricants are also evolving to support sustainability goals.

Key Trends Shaping the Industrial Lubricants Market

The global industrial lubricants market, valued at USD 63.9 billion in 2024, is expected to reach USD 74.3 billion by 2029, growing at a CAGR of 3.1%. This growth is driven by rising demand from industries like construction, mining, agriculture, and marine, as well as the increasing automation of manufacturing processes. Additionally, advancements in lubricant technology and the growing need for processed food are boosting market consumption, making the outlook for industrial lubricants highly promising.

1. Sustainability Takes Center Stage

The push for greener operations has led to the development of bio-based and eco-friendly lubricants. These products are derived from renewable resources and are biodegradable, making them a safer choice for the environment. For instance, industries are increasingly adopting vegetable oil-based lubricants and synthetic esters that offer superior performance while aligning with sustainability initiatives.

2. Smart Lubricants for Smart Factories

The rise of Industry 4.0 has ushered in a new era of smart manufacturing, where machinery is interconnected and data-driven. In this context, smart lubricants are emerging as a game-changer. These lubricants are embedded with sensors that monitor viscosity, temperature, and contamination levels in real-time, enabling predictive maintenance and reducing unplanned downtime.

3. High-Performance Solutions for Extreme Conditions

Industries such as energy, aerospace, and metals operate under extreme conditions, requiring lubricants that can withstand high temperatures, heavy loads, and corrosive environments. Advanced formulations like synthetic lubricants and solid-film lubricants are being developed to meet these challenges, ensuring reliability and performance even in the harshest conditions.

Real-World Applications Across Industries

Manufacturing

In manufacturing plants, lubricants play a crucial role in maintaining the efficiency of CNC machines, conveyors, and robotic arms. By reducing friction and wear, they help minimize downtime and improve productivity.

Automotive

The automotive industry relies on lubricants for everything from engine oils to transmission fluids. With the rise of electric vehicles (EVs), there’s a growing demand for specialized lubricants that can handle the unique requirements of EV components, such as batteries and electric motors.

Energy

In the energy sector, lubricants are essential for the smooth operation of wind turbines, gas compressors, and hydraulic systems. The shift toward renewable energy sources like wind and solar has further increased the need for high-performance lubricants that can operate efficiently in demanding environments.

Metals and Mining

The metals and mining industry faces some of the toughest operating conditions, with heavy machinery exposed to dust, heat, and moisture. Here, lubricants are critical for preventing equipment failure and ensuring safety.

Actionable Insights for Businesses

1. Choose the Right Lubricant

Not all lubricants are created equal. Businesses must select products that are tailored to their specific machinery and operating conditions. Consulting with lubricant experts can help identify the best solutions for your needs.

2. Embrace Predictive Maintenance

By integrating IoT-enabled lubricants and monitoring systems, businesses can move from reactive to predictive maintenance. This approach not only reduces downtime but also lowers maintenance costs.

3. Prioritize Sustainability

Switching to eco-friendly lubricants can help businesses meet regulatory requirements and enhance their brand reputation. Look for products with certifications like ISO 14001 or Ecolabel.

The Road Ahead: A Greener, Smarter Future

As industries continue to evolve, so will the role of industrial lubricants. The future will see a greater emphasis on sustainability, innovation, and digital integration. Lubricants will no longer be just a maintenance tool—they will be a strategic asset that drives efficiency, reduces environmental impact, and supports the transition to smarter, more connected factories.

Download Sample Report : For businesses, staying ahead of these trends will be key to maintaining a competitive edge. By investing in the right lubricants and adopting advanced maintenance practices, industries can unlock new levels of performance and sustainability. The future of industrial lubricants is bright, and it’s time to embrace the change. After all, in the world of modern industry, every drop counts.

#IndustrialLubricants#Sustainability#Industry40#Efficiency#Manufacturing#Automotive Energy#FutureTech#PredictiveMaintenance#GreenSolutions

0 notes

Text

Top 15 Market Players in Global Ethoxylated Castor Oil Market

Top 15 Market Players in Global Ethoxylated Castor Oil Market

The global ethoxylated castor oil market is experiencing steady growth due to its widespread applications in pharmaceuticals, cosmetics, agriculture, textiles, and industrial formulations. Ethoxylated castor oil is a non-ionic surfactant widely used as an emulsifier, solubilizer, and dispersing agent in various industries. Leading market players are focusing on technological advancements, sustainable production methods, and geographical expansion to strengthen their market presence. Below are the top 15 key players in the global ethoxylated castor oil industry:

1. BASF SE

BASF is a dominant player in the specialty chemicals industry, providing high-performance ethoxylated castor oil used in pharmaceuticals, personal care, and industrial applications.

2. Croda International Plc

Croda specializes in biobased surfactants and emulsifiers, offering high-purity ethoxylated castor oil for cosmetic, pharmaceutical, and food applications.

3. Evonik Industries AG

Evonik is a leader in specialty ingredients, producing ethoxylated castor oil as a solubilizer and emulsifier in personal care, agrochemicals, and industrial formulations.

4. Clariant AG

Clariant manufactures ethoxylated castor oil derivatives, serving industries like textiles, agriculture, and pharmaceuticals, with a strong focus on sustainability and regulatory compliance.

5. Solvay S.A.

Solvay provides high-quality surfactants, including ethoxylated castor oil for pharmaceutical, food, and industrial uses, leveraging its strong global distribution network.

6. Ineos Group

Ineos specializes in high-performance surfactants, offering ethoxylated castor oil solutions for coatings, lubricants, and personal care formulations.

7. Sasol Limited

Sasol is a major supplier of ethoxylated castor oil-based surfactants, focusing on industrial applications, agriculture, and lubricants.

8. Lubrizol Corporation

Lubrizol offers specialty chemicals and emulsifiers, including ethoxylated castor oil, for skincare, industrial applications, and agricultural formulations.

9. Stepan Company

A leading producer of non-ionic surfactants, Stepan provides ethoxylated castor oil for personal care, textile processing, and food emulsification.

10. AkzoNobel Specialty Chemicals (Nouryon)

Nouryon manufactures high-quality emulsifiers and solubilizers, including ethoxylated castor oil, for use in pharmaceuticals, coatings, and agricultural products.

11. Lakeland Chemicals

A significant player in surfactant solutions, Lakeland Chemicals supplies ethoxylated castor oil for textile, personal care, and industrial applications.

12. Jeen International Corporation

Jeen International focuses on eco-friendly surfactants and emulsifiers, providing high-purity ethoxylated castor oil for cosmetic and personal care formulations.

13. Guangzhou Tinci Materials Technology Co., Ltd.

An emerging player in Asia-Pacific, Guangzhou Tinci specializes in ethoxylated castor oil derivatives for skincare, pharmaceuticals, and industrial applications.

14. Venus Ethoxyethers Pvt. Ltd.

Venus Ethoxyethers is an Indian company manufacturing ethoxylated castor oil for industrial, pharmaceutical, and personal care applications.

15. RxChemicals

RxChemicals is a niche player specializing in chemical surfactants, providing ethoxylated castor oil for lubricants, industrial cleaning agents, and emulsifiers.

Request report sample at https://datavagyanik.com/reports/global-ethoxylated-castor-oil-market-size-production-sales-average-product-price-market-share/

Top Winning Strategies in Ethoxylated Castor Oil Market

The global ethoxylated castor oil market is highly competitive, with companies employing various strategic initiatives to enhance their market share. Below are the winning strategies driving the industry:

1. Sustainable and Bio-Based Product Development

As the demand for eco-friendly ingredients grows, companies like Croda, Clariant, and Evonik are investing in sustainable and biodegradable ethoxylated castor oil solutions that align with environmental standards.

2. Expansion into Emerging Markets

Leading manufacturers are expanding their presence in Asia-Pacific, Latin America, and Africa, where the demand for industrial and agricultural emulsifiers is growing. Companies like Guangzhou Tinci and Venus Ethoxyethers are strengthening their supply chain networks in developing regions.

3. Strengthening Regulatory Compliance

With increasing regulations on chemical preservatives and surfactants, key players are ensuring compliance with REACH, FDA, and EU regulations to maintain market credibility.

4. Advancements in Green Chemistry

Several companies are shifting towards green chemistry practices to minimize environmental impact. Firms like Lubrizol and Nouryon are researching plant-derived and renewable alternatives to traditional surfactants.

5. Strategic Mergers, Acquisitions, and Collaborations

Companies are engaging in mergers and partnerships to expand their market reach and diversify product portfolios. For instance, BASF and AkzoNobel have established strategic alliances with personal care and pharmaceutical brands to enhance their product innovation.

6. Research & Development in High-Performance Formulations

To stay ahead of competition, companies like Stepan and Solvay are investing in R&D for advanced ethoxylated castor oil formulations that offer better solubility, stability, and performance.

7. Digital Transformation and E-Commerce Integration

As more businesses shift to online procurement, manufacturers are leveraging digital platforms to enhance their global sales presence and direct-to-consumer strategies.

8. Diversification Across Multiple Industries

Companies are expanding their application areas for ethoxylated castor oil, targeting industries such as textiles, agrochemicals, and industrial coatings, in addition to traditional markets like personal care and pharmaceuticals.

9. Cost Optimization and Operational Efficiency

With rising raw material costs, manufacturers are focusing on lean production processes and efficient logistics to maintain profitability while keeping pricing competitive.

10. Customized and Client-Specific Solutions

Leading players like Jeen International and Lakeland Chemicals are offering tailor-made ethoxylated castor oil formulations to meet specific client needs in niche markets.

Conclusion

The global ethoxylated castor oil market continues to expand due to its versatile applications in personal care, pharmaceuticals, and industrial formulations. Market leaders such as BASF, Croda, Clariant, and Evonik are driving innovation through sustainable chemistry, technological advancements, and strategic partnerships. With the growing demand for eco-friendly and high-performance emulsifiers, companies are focusing on biodegradable alternatives, digital sales channels, and global market penetration to maintain their competitive edge.

Request a free sample copy at https://datavagyanik.com/reports/global-ethoxylated-castor-oil-market-size-production-sales-average-product-price-market-share/

#Ethoxylated Castor Oil Market#Ethoxylated Castor Oil Production#market share#market growth#market players#top trends#revenue#average price#market size#competitive pricing strategies

0 notes

Text

Grease Market 2025 | Current and Future Growth Analysis By Forecast 2032

The Latest Trending Grease Market sector is on the brink of remarkable evolution, with projections indicating robust growth and groundbreaking technological advancements by 2032. A recent comprehensive market research report highlights the sector's promising trajectory, fueled by key drivers including expanding market size, increasing market share, and the emergence of innovative trends.

This comprehensive report provides key insights into the Grease market, exploring critical market segmentation and definitions. It highlights the essential components driving growth, offering a clear picture of the industry's trajectory. Utilizing SWOT and PESTEL analyses, the report evaluates the market's strengths, weaknesses, opportunities, and threats, while also considering political, economic, social, technological, environmental, and legal factors that impact the market landscape.

The study offers valuable insights into the competitive landscape, highlighting recent developments and geographical distribution across key regions. Expert competitor analysis provides a detailed understanding of market dynamics, offering strategic guidance for businesses and investors.

With robust analysis and future projections, this report serves as a vital resource for stakeholders looking to capitalize on emerging opportunities and navigate challenges in the Grease market.

What is the projected market size & growth rate of the Grease Market?

Market Analysis and Size

Rise in the automotive industry, overall the world is generating a positive outlook for the market. Grease is extensively used to lubricate suspension, chassis, ball joints, tie-rod ends, control arm-shafts and U-joints. In line with this, the growing demand for high-performance vehicles is favoring the market growth. Furthermore, grease prevents numerous auto parts, such as connectors, switches, wheel bearings and gears from wear and tear due to its stability and temperature tolerance properties. Moreover, the cleaner operations and extensive adoption of high-performance grease in wind power plants to eliminate residue positively impact market growth. Apart from this, the implementation of many government initiatives boost the market by using bio-based grease and the growing product demand in the manufacturing sector are expected to drive the market toward growth.

Data Bridge Market Research analyses that the grease market was valued at USD 5.45 billion in 2021 and is expected to reach USD 6.78 billion by 2029, registering a CAGR of 2.77% during the forecast period of 2022 to 2029. The market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, patent analysis and technological advancements.

Browse Detailed TOC, Tables and Figures with Charts which is spread across 350 Pages that provides exclusive data, information, vital statistics, trends, and competitive landscape details in this niche sector.

This research report is the result of an extensive primary and secondary research effort into the Grease market. It provides a thorough overview of the market's current and future objectives, along with a competitive analysis of the industry, broken down by application, type and regional trends. It also provides a dashboard overview of the past and present performance of leading companies. A variety of methodologies and analyses are used in the research to ensure accurate and comprehensive information about the Grease Market.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-grease-market

Which are the driving factors of the Grease market?

The driving factors of the Grease market include technological advancements that enhance product efficiency and user experience, increasing consumer demand driven by changing lifestyle preferences, and favorable government regulations and policies that support market growth. Additionally, rising investment in research and development and the expanding application scope of Grease across various industries further propel market expansion.

Grease Market - Competitive and Segmentation Analysis:

Global Grease Market, By Base Oil (Mineral, Synthetic, Bio-Based), Thickener Type (Metallic Soap, Non-Soap, Inorganic), End-Use Industry (Automotive, Construction, General Manufacturing, Metal, Mining, Food and Beverage, Power) – Industry Trends and Forecast to 2032.

How do you determine the list of the key players included in the report?

With the aim of clearly revealing the competitive situation of the industry, we concretely analyze not only the leading enterprises that have a voice on a global scale, but also the regional small and medium-sized companies that play key roles and have plenty of potential growth.

Which are the top companies operating in the Grease market?

Some of the major players operating in the grease market are:

Shell PLC. (UK)

Chevron Corporation (US)

Idemitsu Kosan Co., Ltd. (Japan)

China Petrochemical Corporation (China)

BP p.l.c. (UK)

TotalEnergies (France)

ExxonMobil Corporation (US)

JX Nippon Oil & Gas Exploration Corporation (Japan)

Chemtool Incorporated (US)

Petroliam Nasional Berhad (Patrons) (Malaysia)

FUCHS (Germany)

Lubrita Europe B.V (Europe)

Dow (US)

Citgo Petroleum Corporation (US)

Balmer Lawrie & Co. Ltd (India)

Penrite Oil (Australia)

Harrison Manufacturing Company (Australia)

Axel Americas LLC (US)

Calumet Branded Products llc (US)

Hexol. Com (Canada)

Indian Oil Corporation Ltd. (India)

Phillips 66 Company (US)

Short Description About Grease Market:

The Global Grease market is anticipated to rise at a considerable rate during the forecast period, between 2025 and 2032. In 2024, the market is growing at a steady rate and with the rising adoption of strategies by key players, the market is expected to rise over the projected horizon.

North America, especially The United States, will still play an important role which can not be ignored. Any changes from United States might affect the development trend of Grease. The market in North America is expected to grow considerably during the forecast period. The high adoption of advanced technology and the presence of large players in this region are likely to create ample growth opportunities for the market.

Europe also play important roles in global market, with a magnificent growth in CAGR During the Forecast period 2025-2032.

Grease Market size is projected to reach Multimillion USD by 2032, In comparison to 2025, at unexpected CAGR during 2025-2032.

Despite the presence of intense competition, due to the global recovery trend is clear, investors are still optimistic about this area, and it will still be more new investments entering the field in the future.

This report focuses on the Grease in global market, especially in North America, Europe and Asia-Pacific, South America, Middle East and Africa. This report categorizes the market based on manufacturers, regions, type and application.

Get a Sample Copy of the Grease Report 2025

What are your main data sources?

Both Primary and Secondary data sources are being used while compiling the report. Primary sources include extensive interviews of key opinion leaders and industry experts (such as experienced front-line staff, directors, CEOs, and marketing executives), downstream distributors, as well as end-users. Secondary sources include the research of the annual and financial reports of the top companies, public files, new journals, etc. We also cooperate with some third-party databases.

Geographically, the detailed analysis of consumption, revenue, market share and growth rate, historical data and forecast (2025-2032) of the following regions are covered in Chapters

What are the key regions in the global Grease market?

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Turkey etc.)

Asia-Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia and Vietnam)

South America (Brazil, Argentina, Columbia etc.)

Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa)

This Grease Market Research/Analysis Report Contains Answers to your following Questions

What are the global trends in the Grease market?

Would the market witness an increase or decline in the demand in the coming years?

What is the estimated demand for different types of products in Grease?

What are the upcoming industry applications and trends for Grease market?

What Are Projections of Global Grease Industry Considering Capacity, Production and Production Value? What Will Be the Estimation of Cost and Profit? What Will Be Market Share, Supply and Consumption? What about Import and Export?

Where will the strategic developments take the industry in the mid to long-term?

What are the factors contributing to the final price of Grease?

What are the raw materials used for Grease manufacturing?

How big is the opportunity for the Grease market?

How will the increasing adoption of Grease for mining impact the growth rate of the overall market?

How much is the global Grease market worth? What was the value of the market In 2024?

Who are the major players operating in the Grease market? Which companies are the front runners?

Which are the recent industry trends that can be implemented to generate additional revenue streams?

What Should Be Entry Strategies, Countermeasures to Economic Impact, and Marketing Channels for Grease Industry?

Customization of the Report

Can I modify the scope of the report and customize it to suit my requirements? Yes. Customized requirements of multi-dimensional, deep-level and high-quality can help our customers precisely grasp market opportunities, effortlessly confront market challenges, properly formulate market strategies and act promptly, thus to win them sufficient time and space for market competition.

Inquire more and share questions if any before the purchase on this report at - https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=global-grease-market

Detailed TOC of Global Grease Market Insights and Forecast to 2032

Introduction

Market Segmentation

Executive Summary

Premium Insights

Market Overview

Grease Market By Type

Grease Market By Function

Grease Market By Material

Grease Market By End User

Grease Market By Region

Grease Market: Company Landscape

SWOT Analysis

Company Profiles

Continued...

Purchase this report – https://www.databridgemarketresearch.com/checkout/buy/singleuser/global-grease-market

Data Bridge Market Research:

Today's trends are a great way to predict future events!

Data Bridge Market Research is a market research and consulting company that stands out for its innovative and distinctive approach, as well as its unmatched resilience and integrated methods. We are dedicated to identifying the best market opportunities, and providing insightful information that will help your business thrive in the marketplace. Data Bridge offers tailored solutions to complex business challenges. This facilitates a smooth decision-making process. Data Bridge was founded in Pune in 2015. It is the product of deep wisdom and experience.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]

Browse More Reports:

Nutraceutical Ingredients Market

Do it yourself (DIY) Haircut Kits Market

Distributed Antenna System (DAS) Market

Grease Market

Pharmacy Retail Market

#Grease Market#Grease Market Size#Grease Market Share#Grease Market Trends#Grease Market Growth#Grease Market Analysis#Grease Market Scope & Opportunity#Grease Market Challenges#Grease Market Dynamics & Opportunities#Grease Market Competitor's Analysis

0 notes

Link

0 notes

Text

Lubricant Market: Trends, Size & Key Industry Players

The global lubricant market is a vital component of the automotive, industrial, and machinery sectors, serving as a critical factor in ensuring the smooth functioning and longevity of equipment. Lubricants reduce friction, wear, and tear, leading to improved efficiency and performance in various applications. This market has shown robust growth over the years, driven by the increasing demand from end-use industries, technological advancements, and the expansion of the automotive sector. In this blog, we will explore the market size, share, and growth of the lubricant market, analyze current market trends, identify key players, discuss the challenges facing the market, and conclude with insights into its future trajectory.

Market Size, Share, and Growth

As of 2023, the global lubricant market was valued at approximately USD 163 billion. This market is expected to grow at a compound annual growth rate (CAGR) of 3.2% from 2024 to 2030, reaching a value of around USD 205 billion by the end of the forecast period. The growth of this market can be attributed to the rising demand for lubricants in emerging economies, the expansion of the automotive industry, and the increasing industrialization and mechanization of various sectors.

The automotive sector accounts for the largest share of the lubricant market, holding nearly 50% of the market revenue. This dominance is primarily due to the extensive use of lubricants in engine oils, gear oils, and transmission fluids, which are essential for the maintenance and efficiency of vehicles. The industrial segment follows closely, with significant demand from manufacturing, power generation, and other heavy machinery sectors.

Market Trends

Several key trends are shaping the growth and evolution of the lubricant market:

Shift Towards Synthetic and Bio-Based Lubricants: Environmental concerns and the need for sustainability have led to a significant shift from conventional mineral-based lubricants to synthetic and bio-based alternatives. Synthetic lubricants, known for their superior performance, longer life, and better thermal stability, are gaining traction, especially in developed markets. Bio-based lubricants, derived from renewable resources, are also seeing increased adoption due to their biodegradable nature and lower environmental impact.

Rising Demand from Emerging Markets: Emerging economies in Asia-Pacific, particularly China and India, are driving the demand for lubricants. Rapid industrialization, increasing automotive sales, and infrastructure development in these regions are key factors contributing to market growth. The Asia-Pacific region holds the largest market share, accounting for nearly 40% of the global lubricant consumption.

Technological Advancements: Innovation in lubricant formulation and production processes is a significant trend in the market. Companies are focusing on developing high-performance lubricants that offer better fuel efficiency, reduced emissions, and extended service intervals. Additionally, advancements in additive technology are enhancing the overall quality and functionality of lubricants.

Growing Focus on Energy Efficiency: Energy efficiency has become a critical factor in industrial operations and automotive applications. Lubricants that reduce friction and energy losses are in high demand, as they contribute to lower operating costs and improved sustainability. This trend is particularly evident in the manufacturing and transportation sectors, where energy efficiency is directly linked to profitability and environmental impact.

Key Market Players and Their Market Share

The global lubricant market is highly competitive, with several key players dominating the industry. These companies are involved in extensive research and development activities, mergers and acquisitions, and strategic partnerships to maintain their market positions. Some of the leading players in the lubricant market include:

Royal Dutch Shell Plc: Shell is a global leader in the lubricant market, holding a market share of approximately 12%. The company offers a wide range of lubricants under its Shell Helix, Shell Rimula, and Shell Tellus brands. Shell’s strong global presence, innovative product portfolio, and commitment to sustainability have helped it maintain a leading position in the market.

ExxonMobil Corporation: ExxonMobil is another major player in the lubricant industry, with a market share of around 10%. The company’s Mobil 1, Mobil Delvac, and Mobil SHC brands are well-known for their high performance and reliability. ExxonMobil’s focus on technological innovation and its extensive distribution network contribute to its strong market presence.

BP Plc (Castrol): BP, through its Castrol brand, holds a significant share of the lubricant market, estimated at 8%. Castrol’s lubricants are widely used in automotive, industrial, and marine applications. The company’s focus on developing environmentally friendly products and its strong brand reputation have been key factors in its success.

TotalEnergies SE: TotalEnergies is a prominent player in the global lubricant market, with a market share of approximately 7%. The company offers a diverse range of lubricants under its Total Quartz, Total Rubia, and Total Azolla brands. TotalEnergies’ commitment to sustainability and its extensive presence in emerging markets are driving its growth in the industry.

Chevron Corporation: Chevron, with its Havoline and Delo brands, holds a market share of around 6%. The company is known for its high-quality lubricants, which are used in a wide range of applications, including automotive, industrial, and marine sectors. Chevron’s focus on innovation and customer satisfaction has helped it maintain a strong position in the market.

Market Challenges

Despite the positive growth outlook, the lubricant market faces several challenges that could impact its development:

Environmental Regulations: Stringent environmental regulations regarding emissions and waste disposal are a significant challenge for the lubricant industry. Governments worldwide are implementing stricter standards to reduce environmental impact, which is driving the shift towards synthetic and bio-based lubricants. However, the high cost of these alternatives can be a barrier to their widespread adoption, particularly in price-sensitive markets.

Fluctuating Raw Material Prices: The lubricant industry is highly dependent on the availability and cost of raw materials, particularly crude oil. Fluctuations in crude oil prices can significantly impact the profitability of lubricant manufacturers. Additionally, the increasing demand for synthetic and bio-based lubricants is putting pressure on the supply of raw materials, leading to potential supply chain disruptions.

Technological Disruption: The rapid pace of technological advancement in the automotive and industrial sectors poses a challenge to the lubricant market. The development of electric vehicles (EVs), for example, requires less lubrication compared to traditional internal combustion engine vehicles. This shift could reduce the demand for automotive lubricants in the long term.

Market Fragmentation: The lubricant market is highly fragmented, with numerous small and medium-sized players competing with established giants. This fragmentation can lead to intense price competition, which can erode profit margins and hinder market growth. Additionally, the presence of counterfeit products in certain regions poses a challenge to maintaining product quality and brand reputation.

Conclusion

The global lubricant market is poised for steady growth in the coming years, driven by increasing demand from emerging economies, technological advancements, and the ongoing shift towards synthetic and bio-based products. However, the market faces significant challenges, including stringent environmental regulations, fluctuating raw material prices, and technological disruption. To navigate these challenges, industry players must focus on innovation, sustainability, and strategic partnerships. Companies that can adapt to changing market dynamics and meet the evolving needs of consumers will be well-positioned to succeed in this competitive landscape. In conclusion, the lubricant market remains a critical component of the global economy, supporting a wide range of industries and applications. While challenges exist, the market's resilience and adaptability suggest a promising future, with continued opportunities for growth and development.

#Lubricant Sector#Marine Lubricant Market#Global Lubricant Industry#Top 20 Lubricants Companies#Lubricant Market Players#Lubricant Market Revenue#Lubricant Market Size

0 notes

Text

India’s Castor Oil Export Dominance: Data, HS Codes, and Global Trade Insights

India’s agricultural and industrial prowess shines brightly in its castor oil exports. As the world’s largest producer and exporter of castor oil, India supplies a staggering 85–90% of global demand, making it an indispensable player in industries ranging from pharmaceuticals to renewable energy. With exports worth $1.009 billion in 2023–24, the nation’s castor oil trade is a testament to its strategic agricultural practices and robust export infrastructure. In this blog, we’ll unpack critical data on castor oil export from India, decode essential HS codes for castor oil, and explore how businesses can leverage this thriving market.

Castor Oil Production in India: The Backbone of Global Supply

India’s dominance in castor oil begins with its unparalleled production capacity. The country produces approximately 800,000 tonnes of castor oil annually, accounting for 92% of global output. Gujarat, contributing 85% of India’s production, is the epicenter of cultivation, followed by Rajasthan, Tamil Nadu, and Maharashtra.

Castor seeds, the raw material for oil extraction, thrive in India’s semi-arid climate, requiring minimal irrigation. This resilience, combined with government support for farmers, ensures a steady supply chain. Over 60% of India’s castor oil production is exported, fueling industries worldwide.

Castor Oil Export Data 2023–24: India’s Record-Breaking Year

The 2023–24 fiscal year marked a historic milestone for castor oil export from India:

Export Value: $1.009 billion

Volume Shipped: 629 million kg

Cargoes: 12,347 shipments

Exporters: 1,153 Indian suppliers

Buyers: 4,156 international clients (a 39% YoY increase)

China emerged as the largest importer, purchasing 501.79millionworthofcastoroil.OthertopdestinationsincludetheNetherlands(501.79millionworthofcastoroil.OthertopdestinationsincludetheNetherlands(120.54 million), the United States (96.62million),andFrance(96.62million),andFrance(74.87 million).

HS Codes for Castor Oil: Your Gateway to Compliance

Navigating international trade requires precision in product classification. Below are the critical HS codes for castor oil:

15153090: Pure castor oil (most commonly used)

151530: Fixed vegetable fats, including castor oil

15153010: Refined castor oil

34021300: Ethoxylated castor oil (used in cosmetics and lubricants)

Using the correct HS code ensures smooth customs clearance and compliance with destination-country regulations.

Top Destinations for Castor Oil Export from India

India’s castor oil reaches over 100 countries, but these markets dominate:

China ($501.79 million)

Netherlands ($120.54 million)

United States ($96.62 million)

France ($74.87 million)

Japan ($26.82 million)

These nations rely on Indian castor oil for manufacturing biofuels, cosmetics, pharmaceuticals, and industrial lubricants.

Global Castor Oil Exporters: India Leads, Others Follow

While India reigns supreme, other countries contribute to global trade:

Netherlands ($47.73 million)

France ($29.68 million)

Germany ($26.24 million)

United States ($16.91 million)

Brazil ($9.42 million)

Many of these nations re-export refined castor oil derivatives, highlighting India’s role as the primary supplier of raw and semi-processed oil.

Castor Oil Exporters in India: Key Players

Several Indian companies drive this booming trade:

Amee Castor & Derivatives Ltd

Jayant Agro-Organics Ltd

Royal Castor Products Ltd

Gokul Overseas

RP.K. Agrotech Exports Pvt. Ltd.

These firms adhere to stringent quality standards, ensuring India’s reputation as a reliable supplier.

How to Export Castor Oil from India: A Step-by-Step Guide

Quality Selection: Choose grades meeting international phytosanitary norms. Opt for oils with low moisture content and high ricinoleic acid levels (85–90%).

Documentation: Secure an Import-Export Code (IEC), APEDA registration, and phytosanitary certificates.

Packaging: Use ISO-certified containers. Label shipments with product details, batch numbers, and exporter information.

Partner Identification: Connect with buyers via platforms like Exportimportdata.in, trade fairs, or B2B portals.

Logistics: Collaborate with freight forwarders specializing in edible oils. Ensure bills of lading, invoices, and packing lists are accurate.

Finding Buyers for Castor Oil: Data-Driven Strategies

Platforms like Exportimportdata.in offer real-time castor oil export data, including:

Buyer/supplier databases

Pricing trends

Customs shipment records

Competitor analysis

Such tools empower exporters to identify high-demand markets and negotiate favorable terms.

Why Castor Oil? Global Applications Fueling Demand

Castor oil’s versatility drives its demand:

Pharmaceuticals: Used in capsules and anti-inflammatory drugs.

Cosmetics: A key ingredient in lipsticks, soaps, and hair oils.

Industry: Vital for bio-lubricants, nylon-11, and renewable plastics.

Food: Approved as a food additive (E1503) in many countries.

Final Words: Seize India’s Castor Oil Export Opportunity

India’s castor oil export industry offers immense potential for businesses ready to navigate its complexities. By leveraging accurate castor oil export data, adhering to HS code guidelines, and partnering with reliable platforms like Exportimportdata.in, exporters can tap into a $1.3 billion global market (projected to grow at 4.8% CAGR until 2030).

Whether you’re a startup or an established enterprise, the time to act is now. For customized insights into castor oil export from India, connect with experts at Exportimportdata.in and transform data into actionable strategies.

0 notes

Text

Polyethylene Wax Market Trends: Key Insights into Demand and Growth Opportunities in the Coming Years

The Polyethylene Wax Market has been witnessing significant growth in recent years, driven by various factors such as increased demand for high-performance additives and their applications in industries like coatings, lubricants, and plastics. As the demand for consumer goods and industrial products rises, polyethylene wax is becoming an essential ingredient in several formulations due to its versatility, cost-effectiveness, and performance characteristics. This article explores the latest trends shaping the Polyethylene Wax Market, focusing on factors such as technological advancements, regional dynamics, and consumer demand.

Demand for High-Performance Additives

One of the primary trends in the Polyethylene Wax Market is the increasing demand for high-performance additives, which are widely used in coatings, inks, adhesives, and other products. These additives enhance the functionality and durability of the end product, making polyethylene wax an indispensable component in the manufacturing process. The ability of polyethylene wax to improve properties such as surface smoothness, gloss, and scratch resistance is driving its growing adoption in a variety of sectors, particularly in automotive and construction applications.

Technological Advancements and Product Innovation

Technological advancements have played a significant role in the growth of the Polyethylene Wax Market. As manufacturers seek more sustainable and efficient production methods, new innovations are emerging to improve the properties of polyethylene wax. For instance, advances in polymerization techniques are enabling the development of higher-quality polyethylene waxes with better thermal stability and lower environmental impact. The market is also seeing increased investments in research and development to create more specialized formulations that cater to specific industry needs, such as non-toxic waxes for food packaging or cosmetics.

Growing Applications in Emerging Markets

Emerging markets, especially in Asia-Pacific and Latin America, are seeing a surge in demand for polyethylene wax. The expanding manufacturing sector, coupled with rising disposable incomes, is creating new opportunities for the material's use in a wide range of industries. In Asia-Pacific, China and India are among the fastest-growing markets for polyethylene wax, primarily due to the rapid expansion of the automotive, electronics, and construction industries. Similarly, Latin America is witnessing a rise in demand for polyethylene wax in paints, coatings, and adhesives, driven by infrastructural development and urbanization trends.

Environmental Impact and Sustainability Concerns

Sustainability is becoming a key consideration in the polyethylene wax market. As consumer preferences shift toward eco-friendly products, manufacturers are under increasing pressure to develop environmentally responsible alternatives. There is a growing demand for biodegradable and non-toxic polyethylene wax variants, especially in sectors like cosmetics and food packaging. Additionally, some manufacturers are exploring the use of renewable feedstocks to produce polyethylene wax, further addressing environmental concerns and reducing the carbon footprint of the industry. These sustainability efforts are expected to become more pronounced in the coming years, influencing both production methods and consumer preferences.

Regional Dynamics and Market Competition

Geographical factors are playing a crucial role in shaping the Polyethylene Wax Market. North America and Europe are mature markets for polyethylene wax, with established demand in the automotive, packaging, and coatings industries. However, the Asia-Pacific region is expected to experience the highest growth, driven by rapid industrialization and infrastructure development. Competition in the polyethylene wax market is intensifying, with both global and regional players vying for market share. Companies are focusing on expanding their product portfolios and enhancing distribution networks to cater to growing demand, particularly in emerging markets.

Future Outlook

Looking ahead, the Polyethylene Wax Market is poised for continued growth. Increasing industrial demand, technological advancements, and expanding applications across a wide range of sectors are expected to fuel market expansion. However, challenges such as raw material price fluctuations, environmental regulations, and market competition may affect the pace of growth. Nevertheless, the market is expected to remain resilient, with innovations in product development and sustainability practices offering new avenues for growth.

0 notes

Text

Isostearic Acid Market Trends: Growth, Share, Value, Size, Industry Analsis and Forecast by 2029

"Isostearic Acid Market Size And Forecast by 2029

The isostearic acid market is expected to gain market growth in the forecast period of 2022 to 2029. Data Bridge Market Research analyses the market to rise to USD 998.66 million by 2029 and to grow at a CAGR of 6.3% in the above-mentioned forecast period.

The growth trajectory of the Isostearic Acid Market is shaped by various drivers, including technological advancements, favorable regulatory frameworks, and increasing investments in research and development. These growth drivers have catalyzed innovation, leading to the development of cutting-edge solutions that address the diverse needs of end-users.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-isostearic-acid-market

Which are the top companies operating in the Isostearic Acid Market?

The Top 10 Companies in Isostearic Acid Market are prominent players known for their leadership and innovation. These include companies recognized for their strong product offerings and market influence. These companies have built solid reputations through their commitment to quality, customer satisfaction, and staying ahead of industry trends, making them key competitors in the Isostearic Acid Market.

**Segments**

- **Type**: Isostearic acid can be segmented into two types, namely, technical grade and cosmetic grade. Technical grade is used in industrial applications such as lubricants, coatings, and biofuels, while cosmetic grade is utilized in personal care products like skincare and haircare formulations.

- **Application**: Isostearic acid finds application in various industries such as cosmetics, personal care, lubricants, plastics, and chemical intermediate manufacturing. It acts as an emollient, thickening agent, and stabilizer in cosmetic products, while in industrial applications, it serves as a lubricant additive and corrosion inhibitor.

- **End-Use Industry**: The end-use industries for isostearic acid include cosmetics and personal care, automotive, chemicals, and manufacturing. The cosmetics and personal care sector dominate the market due to the increasing demand for natural ingredients and sustainable products.

**Market Players**

- **Croda International Plc**: A leading global supplier of specialty chemicals, Croda offers a wide range of products, including isostearic acid, for various industries such as personal care, healthcare, and industrial.

- **Oleon NV**: Specializing in oleochemicals, Oleon NV is a key player in the isostearic acid market, providing sustainable solutions for the cosmetics, plastics, and food industries.

- **Jarchem Industries Inc.**: Jarchem Industries focuses on manufacturing specialty chemicals, including isostearic acid, catering to diverse industries such as cosmetics, pharmaceuticals, and coatings.

- **Veema Chemicals**: Veema Chemicals is a prominent supplier of isostearic acid for industrial applications, offering high-quality products for sectors like lubricants and coatings.

- **Venus Ethoxyethers Pvt. Ltd.**: With a focus on chemical manufacturing, Venus Ethoxyethers provides isostearic acid for use in various applications, contributing to the growth of the global market.

The global isostearic acid market is experiencing steady growth, driven by the increasing demand for natural and sustainable ingredients in cosmetics and personal care products. The versatility of isostearic acid in different industries such as lubricants, plastics, and chemicals further boosts market expansion. Key market players like Croda International Plc, Oleon NV, Jarchem Industries Inc., Veema Chemicals, and Venus Ethoxyethers Pvt. Ltd. continue to play a significant role in meeting the rising needs of consumers and industries for isostearic acid applications. Overall, the market shows promising prospects for growth and innovation.

https://www.databridgemarketresearch.com/reports/global-isostearic-acid-marketThe global isostearic acid market is poised for significant growth in the coming years due to several key factors impacting the industry landscape. One of the primary drivers of market expansion is the escalating demand for natural and sustainable ingredients in cosmetics and personal care products. Consumers are increasingly seeking products that align with their eco-conscious preferences, leading to a surge in the utilization of isostearic acid in formulations. The versatility of isostearic acid as an emollient, thickening agent, and stabilizer in cosmetic products further enhances its appeal in the industry, driving market growth.

Additionally, the industrial applications of isostearic acid, such as its use as a lubricant additive and corrosion inhibitor, contribute to the overall market momentum. Industries like lubricants, plastics, and chemical intermediate manufacturing rely on isostearic acid for its functional properties and performance benefits. This diverse range of applications across various sectors underscores the broad market potential for isostearic acid, driving adoption and market expansion globally.