#Inconel 718 supplier

Explore tagged Tumblr posts

Text

Inconel 718 Scrap Suppliers in Mumbai

Inconel 718, an alloy renowned for its strength and resistance to corrosion, holds pivotal importance in aerospace and other rigorous industries. As components and structures approach the end of their lifecycle or undergo manufacturing processes, the production of Inconel 718 scrap becomes inevitable. However, rather than considering it mere waste, astute industries recognize its intrinsic value and prioritize recycling and repurposing this exceptional material. Resource Preservation: Recycling Inconel 718 scrap aids in preserving valuable resources by reutilizing this high-performance alloy, thus reducing the reliance on primary production.

#industrial#manufacturing#metal#business#Inconel 718 Scrap#Inconel 718 Scrap Suppliers#Inconel 718 Scrap Suppliers in India#Inconel 718 Scrap Suppliers in Mumbai

0 notes

Text

Sankalp Alloys Overseas is a leading Manufacturer, Supplier, Stockist and Exporter of Incoloy 800HT Flanges, also known as UNS N08811. Incoloy 800HT is a nickel-based superalloy that has the basic chemical composition of Incoloy 800 but with controlled element chemistry so as to have significantly higher creep-rupture strength.

This high-temperature annealing provides enhanced strength to Alloy 800H Flanges, making them suitable for demanding industries like processing of chemicals and petrochemicals, industrial furnaces, heat-treating equipment, and fabrication of superheater and reheater tubing of power plants.

#Incoloy 800HT Flanges Exporters in India#Incoloy 800HT Flanges Exporters#Incoloy 800HT Flanges Manufacturers in India#Incoloy 800HT Flanges Manufacturers#Flanges#india#industrial tools#tools#equipments#expert#exporters#stockists#metalwork#innovation#suppliers#manufacturers#business#sankalpalloys#inconel 718 flanges manufacturers#incoloy flanges#sankalp alloys overseas

1 note

·

View note

Text

Qatargas Approved Flanges in KSA

Meraki Star Metals Oil and Gas Hardware Exchanging L.L.C offers an extensive variety of Inconel 718 Spines to its clients, known for their strong development, sturdiness, and predominant execution. The addition of niobium to Inconel 718 Slip-On Flanges (UNS N07718) is a key feature that enables age hardening and prevents spontaneous hardening during heat treatment and welding.

These Inconel 718 Ribs are generally utilized in aviation, gas turbines, rocket motors, space vehicles, space transports, atomic reactors, siphons, super siphon seals, and tooling. Hot dealing with Inconel 718 Ostensibly Debilitated Show Ribs is completed at a greatest heater temperature of 2050°F (1121°C). Inconel 718 Weld Neck Ribs are solidified by heat treatment and can be welded in a completely solidified condition. These Inconel 718 Apparently Debilitated Spines are additionally accessible in different sizes and shapes to address client issues. Jet engines, pump bodies and parts, rocket motors and thrust reversers, spacers for nuclear fuel elements, and hot extrusion tooling all make use of Inconel 718 Connection Weld Flanges.

Inconel 718 Lap Joint Ribs are about a portion of the heaviness of different spines and are viewed as a recalcitrant super-combination, fit for working ceaselessly above 600°C. The expansion of niobium works with molybdenum to fortify the network of Inconel 718 Ring Type Joint Ribs, giving high strength without requiring an optional intensity therapy.

Inconel 718 Pipe Flanges Specifications

Specifications: ASTM B564 / ASME SB564

Size: 1/2″NB TO 60″NB

Standards: ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Class / Pressure: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Standard: ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

#Inconel 718 Flanges Manufacturers in UAE#Inconel 718 Flanges Suppliers in UAE#Inconel 718 Flanges Stockists in UAE#Inconel 718 Flanges Exporters in UAE#Qatar Petroleum Approved Flanges in UAE#Qatargas Approved Flanges in UAE#Qchem Approved Flanges in UAE#Reliance in Industries Approved Flanges in UAE#Repsol YPF Approved Flanges in UAE#Qatar Petroleum Approved Flanges In UAE

0 notes

Text

Inconel 718 Sheets & Plates Exporters In India

Navneet Metal Corporation is a prominent supplier and stockist of Inconel 718 sheets and plates in India. Inconel 718 is a high-strength, nickel-chromium alloy that is well-regarded for its outstanding resistance to corrosion, oxidation, and extreme temperatures. It is widely used in aerospace, power generation, and various industrial applications due to its excellent mechanical properties, including high tensile and yield strength.

Navneet Metal Corporation provides Inconel 718 sheets and plates that comply with international standards such as ASTM B670, ensuring the products are suitable for high-performance applications. The company offers these materials in a range of thicknesses and dimensions, catering to various industrial needs. Their stock includes thicknesses ranging from 0.1mm to 100mm and sizes up to 2000mm in width and 6000mm in length. This makes them a versatile supplier capable of meeting specific customer requirements for both large and small-scale projects (Navneet Metal Corporation) (Never Brokes).

In addition to providing high-quality products, Navneet Metal Corporation emphasizes their commitment to rigorous quality control and testing. They ensure that their Inconel 718 sheets and plates are thoroughly tested for mechanical and chemical properties before delivery, guaranteeing reliable performance in demanding environments. The company also offers value-added services such as cutting, shaping, and custom fabrication to meet precise specifications, making them a one-stop solution for industrial clients (Navneet Metal Corporation) (Never Brokes).

With a strong presence in Mumbai and a wide distribution network across India, Navneet Metal Corporation is well-positioned to provide timely delivery and excellent customer service. Their experience and expertise in handling specialty alloys like Inconel 718 make them a trusted partner for industries requiring high-performance materials (Navneet Metal Corporation).

For more details on their Inconel 718 products, you can visit their official website.

For more information

Visit our website: https://www.navneetcorp.com/

Call us on: 8369128023

Email us: [email protected]

0 notes

Text

#Inconel 718 Fasteners Manufacturers In India#Inconel 718 Fasteners Suppliers In India#Inconel 718 Fasteners Stockists In India#Inconel 718 Fasteners Exporters In India

0 notes

Text

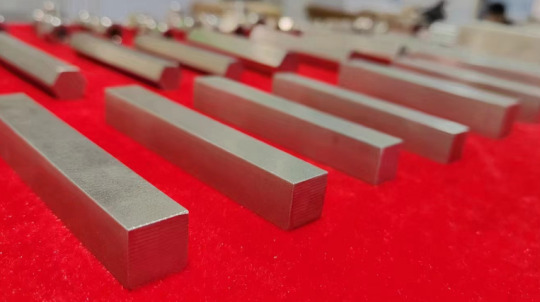

Inconel 718 Round Bar Suppliers: Your Gateway to Premium Quality Alloys

What are Inconel 718 Round Bar Suppliers?

Inconel 718, renowned for its exceptional corrosion resistance and high strength even at elevated temperatures, demands superior handling and sourcing expertise. Inconel 718 round bar suppliers are entities specializing in providing this specific alloy in the form of round bars. These suppliers serve as crucial links in the supply chain, ensuring that industries requiring this high-performance material receive it reliably and in accordance with their specifications.

Applications of Inconel 718 Round Bar Suppliers

Inconel 718 round bars find extensive use across various industries, including aerospace, automotive, oil and gas, and marine sectors. The bars are utilized in critical components such as turbine discs, rocket motors, nuclear reactors, and gas turbines. Their exceptional properties make them indispensable in environments where extreme temperature, pressure, and corrosive elements are prevalent. Inconel 718 round bar suppliers play a vital role in catering to the diverse application needs of these industries.

Advantages of Using Inconel 718 Round Bar Suppliers

Collaborating with reputable Inconel 718 round bar suppliers offers several advantages. Firstly, suppliers ensure the authenticity and quality of the material, adhering to industry standards and specifications. Additionally, they provide a wide range of sizes and customization options to suit specific project requirements. Moreover, established suppliers offer reliability in terms of on-time delivery and consistent supply, crucial for maintaining seamless operations in industries relying on this alloy.

Conclusion

Inconel 718 round bar suppliers serve as indispensable partners for industries requiring high-quality, high-performance alloys. Their expertise in sourcing, handling, and delivering this specific material ensures that critical applications across various sectors meet stringent quality and performance standards. By collaborating with trusted suppliers, industries can access reliable sources of Inconel 718 round bars tailored to their specific needs, thereby driving innovation and progress in their respective fields.

0 notes

Text

Nickel Alloy 718: Properties and Applications

Nickel Alloy 718, typically referred to as Inconel 718, boasts a extremely good composition, mixing numerous elements to gain its first rate houses and wide applicability throughout industries. Recognized for Inconel 718 hardness and adherence to stringent specifications, this alloy stands as a cornerstone in aerospace, marine engineering, and beyond. As the foremost Inconel 718 stockist and Inconel 718 suppliers in Mumbai, we proudly function the top-quality source for this sought-after fabric. Our comprehensive stock encompasses pipes, tubes, spherical bars, coils, shims, strips, wires, sheets, and plates, making sure we meet diverse commercial needs with precision and reliability. Whether you seek for inconel 718 compositions or require specific Inconel 718 hardness stages in keeping with Inconel 718 specifications.

In this weblog put up, we delve into the residences and packages of Nickel Alloy 718, losing mild on why it’s a desired desire for plenty vital applications.

Inconel 718 Alloy

This Inconel 718 Alloy famous extraordinary power, sturdiness, and oxidation resistance at prolonged temperatures, making it ideal for use in aerospace, chemical processing, and marine environments. Its versatility and reliability have made it a desired material for important components in gasoline mills, rocket engines, and different annoying applications.

Properties of Nickel Alloy 718 Alloy:

High Temperature Resistance:

Nickel Alloy 718 famous remarkable resistance to high temperatures, making it quality for programs in which publicity to excessive warmth is not unusual. With a melting aspect of around 1300°C (2372°F), this alloy maintains its energy and structural integrity even under extended exposure to expanded temperatures.

Corrosion Resistance:

One of the standout talents of Nickel Alloy 718 is its fantastic resistance to corrosion and oxidation. This belongings makes it appropriate to be used in harsh environments in which publicity to corrosive materials or atmospheric conditions should compromise the integrity of various substances.

High Strength:

Nickel Alloy 718 gives immoderate tensile and yield energy, coupled with tremendous fatigue resistance. This combination of properties makes it appropriate for applications requiring power and sturdiness, in conjunction with internal aerospace and oil Industries.

Product Designations and Standards of Inconel 718 Alloys

Our Inconel 718 specifications conform to international standards and are available in a variety of forms.

Product Form - Sheet, Plate

ASTM - B 670 B 906

ASME - SB 670 SB 906

DIN - 17744

Product Form - Strips

ASTM - B 670

ASME - SB 670 SB 906

DIN - 17744 17750

Product Form - Pipe & Tubes

ASTM -

ASME -

DIN - 17751

Product Form - Rod, Bar, Forging stock & Wire

ASTM - B 637

ASME - SB 637

DIN - 17744 17752

Inconel 718 Chemical Composition

Element -Percentage

Carbon -0.08 max

Manganese-0.35 max

Phosphorus -0.015 max

Sulfur -0.015 max

Silicon -0.35 max

Chromium -17-21

Nickel -50-55

Molybdenum -2.80-3.30

Columbium -4.75 - 5.50

Titanium -0.65 -1.15

Aluminium -0.20 - 0.80

Cobalt -1.00 max

Boron -0.006 max

Tantalum -0.05 max

Iron -Balance

Inconel 718 Alloy Equivalent

Standard - Inconel 718

WERKSTOFF Nr. - 2.4668

UNS - N07718

JIS - NCF 718

Mechanical Properties of WR.Nr 2.4668 Alloys

Element - Inconel 718

Density - 8.2 g/cm3

Melting Point - 1350 °C (2460 °F)

Tensile Strength - Psi – 1,35,000 , MPa – 930

Yield Strength - Psi – 75,000 , MPa – 482

Elongation - 45%

Applications of Nickel Alloy 718:

Gas Turbines and Power Generation: The alloy's excessive temperature resistance makes it perfect for components in gas generators, where it is able to face up to the tough conditions of combustion environments. It is likewise utilized in power era packages for additives like turbine wheels and bolts.

Oil and Gas Industry: Nickel Alloy 718 is hired in numerous oil and gasoline applications, which include downhole system, including valves, mandrels, and crowning glory gear. Its resistance to corrosion and potential to preserve mechanical homes at high temperatures make it suitable for those traumatic environments.

Medical Devices: Some scientific gadgets, specifically those requiring high strength and corrosion resistance, utilize Nickel Alloy 718. It is frequently used in implants, surgical instruments, and clinical equipment subjected to harsh sterilization techniques.

Nuclear Industry: Nickel Alloy 718 reveals packages within the nuclear industry for additives together with reactor core additives, gasoline element spacers, and manage rod power mechanisms. Its resistance to radiation-brought on damage and high-temperature balance are beneficial in those environments.

Industrial Machinery: Various business equipment and system, together with pumps, compressors, and heat exchangers, utilize Nickel Alloy 718 due to its aggregate of power, corrosion resistance, and thermal stability, especially in excessive-temperature and corrosive environments.

Additive Manufacturing: With the arrival of additive production technologies, Nickel Alloy 718 is more and more being utilized in 3-D printing packages, especially in industries requiring complicated geometries, consisting of aerospace and car.

Electronics: In sure electronics applications, mainly the ones requiring high temperature and corrosion resistance, Nickel Alloy 718 may be utilized in additives like connectors, springs, and electronic packaging.

Final Words!

At MV Super Alloys, we deal with supplying top charge Nickel Alloy 718 merchandise meticulously crafted with an maximum useful Inconel 718 composition. Our inventory caters to numerous commercial needs at some stage in India, together with Hyderabad, Gujarat, Chennai, Bangalore, Mumbai, Telangana, Rajasthan, Delhi, Punjab, and Himachal Pradesh. As authentic Inconel 718 suppliers in Mumbai, we make certain that our merchandise meet stringent Inconel 718 specifications, making sure outstanding Inconel 718 hardnes and usual overall performance. Trust MV Super Alloys as your dependable partner for all your Nickel Alloy 718 necessities, sponsored through Material Test Certificates (MTC) and competitive pricing. Experience the distinction of MV Super Alloys Today!

#inconel 718 composition#inconel 718 hardness#inconel 718 specification#inconel 718 suppliers in Mumbai#inconel 718 Stockist

0 notes

Text

MSS SP44 Incoloy Alloy BLRF Flanges Stockist

Slip-On flanges or SO flanges are commonly lower in price than weld-neck flanges, and to this effect are a popular choice for our customers. Slip on pipe flanges in stock include AWWA slip on pipe flanges, ANSI slip on pipe flanges, Pressure Vessel slip on pipe flanges and slip on pipe flanges that match the OD and drilling of ASME flanges.

Incoloy Slip-On Pipe Flanges, As made obvious by their name, these pipe flanges slip over the pipe. They're manufactured with an inside diameter that is slightly bigger than the pipe's outside diameter. These attachments are connected to the pipe via fillet weld at the top and bottom of the flange.

However, customers should bear in mind that this initial cost saving may be diminished by the additional cost of the two fillet welds required for proper installation. Moreover, weld-neck flanges have a higher life expentancy than slip-on flanges under duress. It is fabricated with an inside diameter that is bigger than the pipe’s outside distance across. These connections are associated with the pipe by means of filet weld at the top and base of the flange.

Incoloy Slip-on flanges are all bored slightly larger than the O.D. of the pipe. They are preferred over welding neck flanges bu many users due to their lower intial cost, but final intallation cost is probably not much less than that of the welding neck flange because of the additional welding involved.

For more information

+91-9819523999

http://kobsindia.in/incoloy-blind-flange.html

#Inconel Blind Flange#Inconel 601/718H Blind Flange#Inconel 601/718 Blind Flanges#ANSI B16.5 BLRF Flanges Supplier#Inconel Raised Face Blind Flanges

1 note

·

View note

Text

Is Monel similar to Inconel?

Many of our customers have such a question: Is Monel similar to Inconel? As a matter of fact, both Monel and Inconel are nickel-based alloys with exceptional corrosion resistance and high-temperature performance, but they differ significantly in composition, properties, and applications. In this article, let’s delve into the key aspects of these two alloys to understand their similarities and differences.

Is Monel similar to Inconel?

Composition:

Monel, also known as Monel alloy, is primarily a nickel-copper alloy, typically containing up to 67% nickel and 28% copper, with the remaining portion composed of iron, manganese, carbon, and silicon. This composition gives Monel its excellent corrosion resistance, particularly against acids and alkalies.

On the other hand, Inconel is a nickel-chromium alloy, with chromium content ranging from 15% to 25%, depending on the specific grade. Inconel alloys also contain significant amounts of other elements like iron, molybdenum, and titanium, which contribute to their high-temperature strength and oxidation resistance.

Properties:

Both Monel and Inconel exhibit excellent corrosion resistance, but the specific environments they thrive in differ. Monel’s corrosion resistance is particularly noteworthy in marine and chemical processing applications, where it can withstand the corrosive effects of saltwater and various acids.

Inconel, on the other hand, is renowned for its ability to maintain its mechanical properties at extremely high temperatures. It is often used in aerospace and power generation applications where materials must withstand extreme heat and pressure. Inconel’s chromium content also gives it superior resistance to oxidation and sulfidation at high temperatures.

When it comes to mechanical properties, Inconel generally offers higher strength and hardness compared to Monel. However, Monel has better formability and weldability, making it easier to shape and join into complex structures.

Applications:

The differences in composition and properties lead to distinct applications for Monel and Inconel. Monel is commonly used in the chemical processing, marine, and food processing industries due to its resistance to corrosion and ease of fabrication. Its ability to withstand the corrosive effects of saltwater makes it a popular choice for marine applications like shipbuilding and offshore drilling.

Inconel, on the other hand, finds its niche in high-temperature applications where strength and oxidation resistance are paramount. Aerospace, power generation, and petrochemical industries rely on Inconel alloys for components that must operate in extreme environments.

Conclusion:

While Monel and Inconel are both nickel-based alloys with exceptional corrosion resistance, they are not interchangeable. Each alloy has its unique composition, properties, and applications. Monel excels in corrosive environments and offers good formability and weldability, while Inconel is renowned for its high-temperature performance and oxidation resistance.

Thank you for reading our article and we hope it can help you to find the answer to the question: Is Monel similar to Inconel? If you are looking for Monel and Inconel suppliers and manufacturers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Monel and Inconel Alloys from Shanghai China, Huaxiao Alloy offers customers high-quality products such as Monel 400, Monel K500, Inconel 600, Inconel 601, Inconel 625, and Inconel 718 at a very competitive price.

2 notes

·

View notes

Text

Inconel 600/601/625/718 Pipes & Tubes | Top Supplier & Manufacturer

Discover premium Inconel 600/601/625/ 718 pipes and tubes from a trusted supplier. Ideal for high-temperature applications, our corrosion-resistant Inconel products ensure durability and performance in demanding industries. Explore our range now!

0 notes

Text

Inconel 718 Round Bars Supplier, Stockist in Saudi Arabia | Anand steels

Anand steel Inconel 718 round bars are high-performance nickel-chromium alloy products, renowned for their exceptional strength and corrosion resistance. These bars are ideal for applications in extreme environments, including aerospace, oil and gas, and chemical processing industries. Exported from Saudi Arabia, they meet stringent quality standards and are available in various sizes to accommodate diverse engineering requirements. The unique properties of Inconel 718 ensure reliability and durability, making it a preferred choice for critical components and structures.

0 notes

Text

What Are the Key Usages of Stainless Steel 420 Round Bar?

Requests requiring high strength, hardness, and reasonable corrosion resistance are the key uses for stainless steel 420 round bar. Since of its fine polishing capacity, it finds wide application in the manufacture of surgical instruments, dental equipment, and cutlery. In addition, it is utilized in the industrial of gears, pumps, and valves, all of which depend on wear resistance. Because it is very robust and effortlessly machined, stainless steel 420 round bar is also used to make shear blades, hand tools, and nozzles. It is a valued material in a diversity of sectors due to its adaptability.

Round Inconel Bar: Superior Alloy

Because of its unresolved performance in corrosive and high-temperature circumstances, Inconel Round Bar is well-known. Its excellent resistance to oxidation and corrosion, subsequent from its typically nickel-chromium composition, renders it a faultless optimal for use in gas turbine components, chemical processing, and aerospace applications. In crucial industrial environments, Chennai providers assuring dependability and endurance, offer a change of Inconel Round Bar in grades like Inconel 600, 625, and 718.

Stainless Steel 420 Round Bar: Adaptable Sturdiness and Power

The excessive strength, hardness, and moderate corrosion resistance of Stainless Steel 420 Round Bar make it extremely valued. It is extensively used in sectors with cutlery, surgical instruments, and industrial equipment mechanisms that demand wear resistance and ease of industrial. Stainless Steel 420 Round Bars that satisfy strict quality standards are available from Chennai vendors guaranteeing top performance in a variety of applications.

Machinability and Corrosion Opposition of Stainless Steel 416 Round Bar

The decent machinability and reasonable corrosion resistance of stainless steel 416 round bar make it extremely observed. Pump shafts, valve components, and automobile portions are among the many areas where it finds recurrent use. These applications require both mechanical qualities and ease of machining. Guaranteeing dependability and consistency in performance across numerous industrial sectors, suppliers in Chennai proposal Stainless Steel 316 Round Bar that satisfy ASTM standards.

Stainless Steel Round Bar 321: Stability at High Temperatures

Because of its strong resistance to intergranular corrosion and oxidation, stainless steel 321 round bar is ideal for requests requiring great temperatures. In gear for chemical processing, furnace parts, and aviation use systems where lengthy exposure to high temperatures is anticipated, it is often employed. With their exceptional mechanical qualities and thermal stability, Chennai suppliers provide a selection of Stainless Steel 321 Round Bars that guarantee dependable performance in demanding conditions.

Multiple Uses for SS Rectangular Bar Suppliers in Chennai

Since of its structural strength and flexibility, SS Rectangular Bar is used for a variety of uses in engineering, manufacturing, and construction. Chennai is home to reliable vendors that offer SS Rectangular Bars in a diversity of grades and sizes. Because of its toughness, resistance to corrosion, and aesthetic appeal, these bars are used in manufacturing gear, machinery supports, and architectural edges.

0 notes

Text

Sankalp Alloys Overseas is one of the prime manufacturers and suppliers of Inconel 718 Flanges. We process ASTM B564 Inconel 718 Flanges with top-class raw materials from our vast inventory. Being well-noted for producing high-quality UNS N07718 Inconel Flanges, Sankalp Alloys Overseas has created a credible position in the industry.

#Inconel 718 Flanges Exporters in India#Inconel 718 Flanges Exporters#inconel 718 flanges#Inconel 718 Flanges Manufacturers in India#Inconel 718 Flanges Manufacturers#Flanges#manufacturers#business#exporters#suppliers#stockists#innovation#metalwork#inconel flanges#manufacturing#Sankalpalloys#Sankalp alloys Overseas#India#Mumbai#maharashtra

1 note

·

View note

Text

#Inconel 718 Flanges Manufacturers in UAE#Inconel 718 Flanges Suppliers in UAE#Inconel 718 Flanges Stockists in UAE#Inconel 718 Flanges Exporters in UAE#Qatar Petroleum Approved Flanges in UAE#Qatargas Approved Flanges in UAE

0 notes

Text

Inconel 718 Roundbars Suppliers in India.

We are top most global distributors, exporter, supplier and traders of Inconel 718 Roundbars in India.

Inconel 718 Rods (UNS N07718) are used in pollution-control equipment, nuclear reactors, cryogenic storage tanks, and other high temprature critical applications.

We are inconel 718 round bar suppliers in india

Tripura, Ahmedabad, Kolkata, Lucknow, Andhra Pradesh, Pune, Ambala, Maiduguri, Buxar, Puducherry, Karnataka, Maharashtra, Bhiwadi, Surat, Mizoram, Manipur, Delhi, Bangalore, Kerala, Ballia, Jamalpur, Chennai, Jaipur, Hyderabad, Indore, Patna, Agra, West Bangal, Ranchi, Durg, Bilaspur, Raipur, Satpura, Malwa, Kanpur, Dehradun etc.

Get in touch with us.

We are one of the India's leading suppliers of inconel 718 round bars To discover more about our products and to receive a competitive quotation,

Write to us :[email protected]

#Inconel718#inconelroundbars#aerospaceengineering#oilandgasindustry#refineryproject#cncmachinning#vmcmachinning

0 notes

Text

Inconel 718 Fasteners Suppliers

Inconel 718 Fastener is one of the most adaptable and out-and-out crazy levels of catch that are completely utilised in various present-day applications. These are precipitation-setting joints that are coordinated with chromium-nickel content and a little edge of titanium and aluminium content. These locks ensure uncommon disintegration and oxidation properties that grant astounding performance in high-strain and focused energy conditions. The presence of nickel content confirms critical high malleability, creep break, and creep features at high temperatures. These catches show a lean towards deterrence over the opening and pitting disintegrating. Also, these are by and large resistant to chloride molecule stress, breaking, and liquid decay.

These are preparations at cryogenic temperatures up to the basic length relationship at 1200-degree F. Considering their age, spreading out highlights that these are effectively tempered and welded without unconstrained setting at the hour of warming and cooling.

Deep Steel Centre is a recognizable firm that takes part in parties, giving and conveying a goliath get-together of Inconel 718 Secure, beginning with one side of the planet and then onto the next. As a verifiable substance, we offer a wide range of things in various shapes, perspectives, and sizes as per the needs of our huge partners. To achieve this, taking everything into account, we use an amazing standard substance for its creation cycle. Comprehensively more, we worked with the best new developments and modernized gadgets to achieve shocking size and standard quality.

Specifications:

Standard : DIN, ASTM, BS and all International Standards

Size : 3 mm to 200 mm

Bolt / Screw Size : M3 - M56 | 3/6" to 2" | Custom Sizes

Nuts Size : M3 - M56 | 3/6" to 2" | Custom Sizes

Washers Size : M1 - M64 | #4 to 3" | Custom Sizes

Length : M02 to M33

Types : Nuts, Bolts, Screws, Sockets, Studs, Screw, Hex Set Screw, Socket Screw, Cap Screw, Pan Head Screw, Machine Screw, Socket Head Cap Screw, Allen Cap screw, Wing Screw, Washers, Spring Washers, Studs, Anchors, Marine Anchors, Nut, Hexagon Nut, Hex Nut, Hex Coupling Nut, Hex Domed Cap Nuts, Square Nut, Stud Bolts, Hex Head Bolts, Socket Hexagon Head Screw Anchor Bolt, U-Bolts, J Bolts, Mushroom Head Square Neck Bolts, T-Head Bolts, Wing Screw, Eye Bolt, Foundation Bolts, Structural Bolts.

Visit Website:

Email: [email protected]

#Inconel 718 Fasteners Manufacturers#Inconel 718 Fasteners Suppliers#Inconel 718 Fasteners Stockists#Inconel 718 Fasteners Exporters#Inconel 718 Fasteners Manufacturers in India#Inconel 718 Fasteners Suppliers in India#Inconel 718 Fasteners Stockists in India#Inconel 718 Fasteners Exporters in India#Inconel 718 Fasteners Manufacturers in Mumbai#Inconel 718 Fasteners Suppliers in Mumbai#Inconel 718 Fasteners Stockists in Mumbai#Inconel 718 Fasteners Exporters in Mumbai

0 notes