#sankalp alloys overseas

Explore tagged Tumblr posts

Text

Duplex Steel S32750 Fasteners Manufacturers

In today's industrial landscape, choosing the right fasteners can make all the difference between seamless operations and unexpected failures. As industries push boundaries with extreme temperatures, pressures, and corrosive environments, the demand for high-performance materials continues to grow. This is where Duplex Steel S32750 Fasteners stand out, offering unparalleled strength and resistance. But what exactly makes these fasteners exceptional? Let’s dive into their properties, benefits, and why they are the preferred choice for many sectors worldwide.

What are Duplex Steel S32750 Fasteners?

Duplex Steel S32750, often referred to as Super Duplex, is a highly durable and corrosion-resistant alloy that combines the best characteristics of both austenitic and ferritic stainless steels. The alloy features a blend of chromium, molybdenum, and nitrogen, offering enhanced mechanical strength and superior resistance to pitting, crevice corrosion, and stress corrosion cracking.

Duplex Steel S32750 Fasteners are industrial-grade components, including bolts, nuts, screws, and washers, designed to endure harsh conditions. They are widely used across industries such as oil and gas, petrochemical, marine, and construction due to their robust performance.

Key Properties of Duplex Steel S32750 Fasteners

The exceptional properties of Duplex Steel S32750 Fasteners make them ideal for demanding applications:

High Corrosion Resistance: The alloy’s high chromium and molybdenum content provide superior resistance to corrosion in both oxidizing and reducing environments. This makes the fasteners perfect for use in chloride-rich environments, such as seawater and chemical processing industries.

Exceptional Strength: With nearly twice the yield strength of conventional austenitic stainless steels, Duplex Steel S32750 offers outstanding mechanical strength. This enables the use of thinner, lighter fasteners without compromising performance.

Excellent Thermal Conductivity: Compared to austenitic grades, Duplex Steel S32750 exhibits better thermal conductivity, making it suitable for high-temperature applications.

Low Thermal Expansion: The alloy’s reduced thermal expansion minimizes distortion in fasteners during temperature changes, ensuring stability and reliability.

Resistance to Stress Corrosion Cracking (SCC): The combination of ferritic and austenitic properties reduces susceptibility to SCC, particularly in environments containing chlorides and sulfides.

Specifications of Duplex Steel S32750 Fasteners

When it comes to selecting the right fasteners, the following specifications are essential:

Specification: ASTM A479, A182 / ASME SA479, SA182

Dimension Standards: DIN, ISO, ASTM, JIS, BS, GB, IS, and other international standards

Size Range: M3 - M56 | 3/6" to 2" | Custom sizes available

Length: 3 mm to 200 mm

Types Available: Nuts, bolts, screws, sockets, studs, hex set screws, socket screws, cap screws, pan head screws, machine screws, socket head cap screws, Allen cap screws, wing screws, washers, spring washers, anchor bolts, marine anchors, J bolts, U bolts, and many more

Benefits of Using Duplex Steel S32750 Fasteners

Longer Lifespan: Due to their high corrosion resistance, these fasteners exhibit an extended service life, even in challenging conditions.

Cost-Effective: The increased strength of Duplex Steel S32750 allows for the use of smaller, lighter fasteners, reducing material costs.

Enhanced Safety: Their superior resistance to environmental factors ensures minimal maintenance, reducing the risk of unexpected failures and enhancing overall safety.

Versatility: Available in a wide range of sizes and types, Duplex Steel S32750 Fasteners can be customized for specific industrial applications.

Applications of Duplex Steel S32750 Fasteners

Due to their remarkable properties, Duplex Steel S32750 Fasteners find applications in a wide array of industries:

Oil and Gas Industry: Used in offshore platforms, pipelines, and subsea equipment where resistance to chlorides is critical.

Chemical Processing: Ideal for fasteners in chemical tanks, reactors, and other equipment exposed to corrosive substances.

Marine Environments: Commonly used in shipbuilding, desalination plants, and other marine structures due to their resistance to seawater corrosion.

Construction: Suitable for infrastructure projects requiring high-strength and corrosion-resistant fasteners.

Pulp and Paper Industry: Used in equipment subjected to high temperatures and chemicals.

Why Choose Sankalp Alloys Overseas for Duplex Steel S32750 Fasteners?

Sankalp Alloys Overseas is a trusted name in the field of industrial fasteners, recognized as a leading manufacturer, exporter, stockist, and supplier of Duplex Steel S32750 Fasteners in India and abroad. With years of experience and a commitment to quality, Sankalp Alloys Overseas has established itself as an expert in providing top-notch solutions for various industrial needs.

1. Expertise in Manufacturing and Exporting: Sankalp Alloys Overseas boasts an advanced manufacturing facility equipped with state-of-the-art technology. The company adheres to stringent quality standards to ensure that every fastener meets or exceeds industry specifications.

2. Extensive Product Range: With a comprehensive selection of fasteners, including custom sizes, Sankalp Alloys Overseas caters to diverse industrial requirements. Whether you need bolts, screws, washers, or specialty fasteners, they have it all.

3. Global Reach: As leading Duplex Steel S32750 Fasteners exporters, Sankalp Alloys Overseas serves clients across the globe, offering reliable and timely delivery.

4. Quality Assurance: The company conducts rigorous testing on all products to guarantee durability and performance. Certifications like ASTM and ASME are a testament to their dedication to quality.

5. Customer-Centric Approach: Sankalp Alloys Overseas places a high priority on customer satisfaction, providing technical support, competitive pricing, and prompt service.

Conclusion

Duplex Steel S32750 Fasteners are indispensable components for industries that demand high-strength, corrosion-resistant, and reliable fastening solutions. With their outstanding properties, these fasteners ensure long-term performance in challenging environments. For industries seeking the best in quality and durability, partnering with a reputable manufacturer like Sankalp Alloys Overseas is essential.

Contact Sankalp Alloys Overseas Today

To learn more about Duplex Steel S32750 Fasteners or to place an order, reach out to Sankalp Alloys Overseas:

Contact Number: +91-8828369483

Email: [email protected]

Website: https://www.sankalpalloys.com

Choosing Sankalp Alloys Overseas means choosing quality, reliability, and industry expertise. Make the right choice for your industrial fastening needs today!

#Duplex Steel S32750 Fasteners Manufacturers#Duplex Steel S32750 Fasteners Exporters#Duplex Steel S32750 Fasteners Manufacturers in India#Duplex Steel S32750 Fasteners Exporters in India#manufacturers#business#suppliers#exporters#stockists#innovation#metalwork#sankalpalloys#fasteners#supplier#india#sankalp alloys overseas#tools#industrial tools#industry#equipments

1 note

·

View note

Text

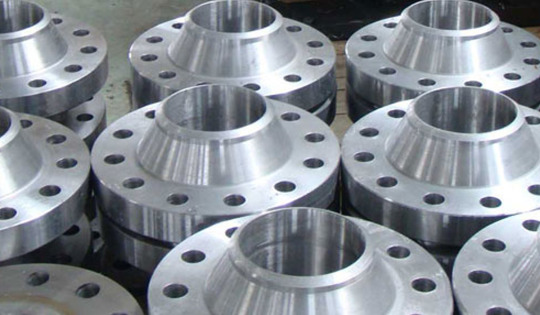

Sankalp Alloys Overseas is a leading Manufacturer, Supplier, Stockist and Exporter of Incoloy 800HT Flanges, also known as UNS N08811. Incoloy 800HT is a nickel-based superalloy that has the basic chemical composition of Incoloy 800 but with controlled element chemistry so as to have significantly higher creep-rupture strength.

This high-temperature annealing provides enhanced strength to Alloy 800H Flanges, making them suitable for demanding industries like processing of chemicals and petrochemicals, industrial furnaces, heat-treating equipment, and fabrication of superheater and reheater tubing of power plants.

#Incoloy 800HT Flanges Exporters in India#Incoloy 800HT Flanges Exporters#Incoloy 800HT Flanges Manufacturers in India#Incoloy 800HT Flanges Manufacturers#Flanges#india#industrial tools#tools#equipments#expert#exporters#stockists#metalwork#innovation#suppliers#manufacturers#business#sankalpalloys#inconel 718 flanges manufacturers#incoloy flanges#sankalp alloys overseas

1 note

·

View note

Text

Copper Nickel 70/30 Flanges Exporters

Copper Nickel 70/30 flanges have emerged as a popular choice in various industries due to their exceptional resistance to corrosion, especially in seawater environments. Sankalp Alloys Overseas stands out as a leading manufacturer, supplier, exporter, and stockist of these flanges in Mumbai, India, and worldwide. This article explores the definition, key properties, specifications, benefits, applications, and reasons to choose Sankalp Alloys Overseas for your Copper Nickel 70/30 flange needs.

What is Copper Nickel 70/30 flanges?

Copper Nickel 70/30 flanges are fittings made from a copper-nickel alloy that contains 70% copper and 30% nickel. This composition provides excellent resistance to pitting and crevice corrosion, making these flanges ideal for marine and industrial applications.

Key Properties

Corrosion Resistance: Exceptional resistance to seawater and other corrosive environments.

Strength: High mechanical strength, ensuring durability and longevity.

Weldability: Good weldability and formability, allowing for ease of installation.

Thermal Conductivity: High thermal conductivity, beneficial in heat exchange applications.

Copper Nickel 70/30 Flanges Exporters Specifications

Standard: ASTM B151 / ASME SB151

Dimension Standards: ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Size: Ranges from 1/2" (15 NB) to 48" (1200 NB)

Class/Pressure Ratings: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64, etc.

Flange Face Type: Flat Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges: Various standards including DIN 2527, 2566, 2573, etc.

JIS Flanges: JIS B2220 5K, 10K, 16K, 20K

BS Flanges: BS4504 PN 6, 10, 16, 25, 40, and more.

Benefits

Durability: The robust composition ensures that these flanges withstand harsh conditions, prolonging the lifespan of installations.

Cost-Effectiveness: Lower maintenance costs due to reduced corrosion rates lead to significant long-term savings.

Versatility: Suitable for various applications, including shipbuilding, oil and gas, and chemical processing.

Reliability: Trusted performance in critical applications where failure is not an option.

Applications

Copper Nickel 70/30 flanges are widely used in:

Marine applications, such as shipbuilding and offshore platforms

Chemical processing industries

Oil and gas extraction

Desalination plants

Heat exchangers and cooling systems

Why Choose Sankalp Alloys Overseas?

Sankalp Alloys Overseas is your trusted partner for Copper Nickel 70/30 flanges for several reasons:

Expertise: Years of experience in manufacturing high-quality flanges.

Quality Assurance: Strict adherence to international standards ensures premium quality products.

Global Reach: Serving clients in India and across the globe, backed by reliable logistics.

Customer Service: Dedicated support team to assist with inquiries and orders.

Comprehensive Product Range: Offering a wide variety of flanges to meet diverse industry needs.

Conclusion

When looking for reliable Copper Nickel 70/30 flanges, Sankalp Alloys Overseas should be your first choice. With a commitment to quality, a wide range of specifications, and a focus on customer satisfaction, they are the leading Copper Nickel 70/30 flanges manufacturers and exporters in India and worldwide.

For more information, feel free to contact us at:

Email: [email protected]

Contact Number: +91-8828369483

Website: Sankalp Alloys Overseas

Explore the benefits of Copper Nickel 70/30 flanges today and enhance your operations with quality and reliability!

#Copper Nickel 70/30 Flanges Exporters#Copper Nickel 70/30 Flanges Exporters in India#Copper Nickel 70/30 Flanges Manufacturers#Copper Nickel 70/30 Flanges Manufacturers in India#manufacturers#business#suppliers#exporters#stockists#innovation#metalwork#flanges#copper flanges#Copper Nickel 70/30 Flanges#Sankalpalloys#Sankalp Alloys Overseas#tools#industrial tools#equipments

1 note

·

View note

Text

Duplex Steel S32760 Fasteners Exporters

When it comes to high-performance fasteners that can withstand extreme conditions, Duplex Steel S32760 Fasteners stand out as a reliable and superior choice. These fasteners offer exceptional resistance to corrosion, immense strength, and are well-suited for various industrial applications. Sankalp Alloys Overseas, a renowned name in the industry, is the leading manufacturer, supplier, exporter, and stockist of Duplex Steel S32760 Fasteners in Mumbai, India, and across the globe.

What is Duplex Steel S32760?

Duplex Steel S32760, also known as Super Duplex, is a highly alloyed stainless steel, known for its high mechanical strength and outstanding resistance to corrosion. With a balanced mix of austenitic and ferritic phases, this grade provides superior performance in environments that demand both high strength and resistance to corrosive chemicals.

Key Properties of Duplex Steel S32760 Fasteners

Excellent Corrosion Resistance: Superior to standard austenitic or ferritic stainless steels, particularly in chloride-containing environments.

High Strength: Combines the mechanical strength of ferritic steel with the corrosion resistance of austenitic steel.

Thermal Conductivity: Higher thermal conductivity than austenitic grades.

Stress Corrosion Cracking Resistance: Designed to resist cracking in high-stress environments.

Good Weldability: Duplex S32760 fasteners can be easily welded without the need for post-weld heat treatments.

Specifications of Duplex Steel S32760 Fasteners

Specification: ASTM A479, A182 / ASME SA479, SA182

Dimensions: DIN, ISO, ASTM, JIS, BS, GB, IS, and all International Standards

Size Range: M3 - M56 | 3/6" to 2" | Custom Sizes Available

Length: 3 mm to 200 mm

Types: Nuts, Bolts, Screws, Sockets, Studs, Washers, Anchors, U-Bolts, J-Bolts, Hex Bolts, and more.

Benefits of Duplex Steel S32760 Fasteners

Superior Corrosion Resistance: Ideal for use in aggressive environments such as offshore, petrochemical, and chemical processing industries.

High Mechanical Strength: Suitable for applications that demand both strength and durability.

Cost-Effective: Long lifespan reduces the need for frequent replacements, lowering overall maintenance costs.

Versatility: Available in various types and sizes, they can be customized to meet specific application requirements.

Environmentally Friendly: The long-lasting nature of Duplex S32760 fasteners helps reduce waste and promotes sustainable operations.

Applications of Duplex Steel S32760 Fasteners

Oil & Gas Industry: Ideal for subsea components and platforms where corrosion resistance and high strength are essential.

Marine Applications: Used in shipbuilding, marine hardware, and other marine environments due to excellent corrosion resistance to seawater.

Petrochemical Industry: Widely used in chemical plants, reactors, and refineries where both strength and corrosion resistance are necessary.

Power Generation: Essential in the construction of power plants and related equipment.

Desalination Plants: Excellent resistance to brackish water and high chloride environments makes them a popular choice for desalination projects.

Why Choose Sankalp Alloys Overseas?

Sankalp Alloys Overseas is a trusted name in the world of metal fasteners, providing top-quality Duplex Steel S32760 Fasteners to clients in India and worldwide. Here’s why we are the best choice:

Extensive Industry Experience: With years of experience, we understand the technical demands of industrial applications and provide solutions that meet the highest standards.

Global Reach: As leading Duplex Steel S32760 Fasteners Exporters, we cater to international markets with prompt deliveries and quality assurance.

Custom Solutions: We offer a wide range of sizes, types, and dimensions, with the ability to customize fasteners to your specific needs.

Quality Assurance: All our fasteners are manufactured under stringent quality controls, ensuring they meet international standards like ASTM, DIN, and ISO.

Excellent Customer Support: We pride ourselves on providing personalized service, offering expert advice, and ensuring customer satisfaction every step of the way.

Conclusion

For industries requiring high-performance fasteners that can endure harsh environments, Duplex Steel S32760 Fasteners are a perfect choice. They offer exceptional strength, corrosion resistance, and durability, making them ideal for use in sectors like oil & gas, marine, and chemical processing. Sankalp Alloys Overseas is your reliable partner, offering top-quality fasteners, tailored to your specific needs. With global delivery and competitive prices, we are the go-to Duplex Steel S32760 Fasteners manufacturers and exporters in India and beyond.

For inquiries and orders, reach out to us at:

Email: [email protected]

Contact Number: +91-8828369483

Website: https://www.sankalpalloys.com

Optimize your projects with the strength and reliability of Duplex Steel S32760 Fasteners from Sankalp Alloys Overseas!

#Duplex Steel S32760 Fasteners Exporters#Duplex Steel S32760 Fasteners Exporters in India#Duplex Steel S32760 Fasteners Manufacturers#Duplex Steel S32760 Fasteners Manufacturers in India#Duplex Steel S32760 Fasteners#Fasteners#Duplex Steel S32760#manufacturers#business#suppliers#exporters#stockists#innovation#metalwork#sankalp alloys overseas#sankalpalloys#industry

1 note

·

View note

Text

Sankalp Alloys Overseas is one of the prime manufacturers and suppliers of Inconel 718 Flanges. We process ASTM B564 Inconel 718 Flanges with top-class raw materials from our vast inventory. Being well-noted for producing high-quality UNS N07718 Inconel Flanges, Sankalp Alloys Overseas has created a credible position in the industry.

#Inconel 718 Flanges Exporters in India#Inconel 718 Flanges Exporters#inconel 718 flanges#Inconel 718 Flanges Manufacturers in India#Inconel 718 Flanges Manufacturers#Flanges#manufacturers#business#exporters#suppliers#stockists#innovation#metalwork#inconel flanges#manufacturing#Sankalpalloys#Sankalp alloys Overseas#India#Mumbai#maharashtra

1 note

·

View note

Text

Nickel 200 Flanges Exporters

In the world of industrial applications, where corrosion resistance and durability are key, Nickel 200 flanges are a popular choice. When it comes to sourcing top-quality Nickel 200 flanges, Sankalp Alloys Overseas stands out as a global leader in manufacturing, supplying, exporting, and stocking these flanges. Based in Mumbai, India, Sankalp Alloys Overseas is renowned for its commitment to quality, innovation, and customer satisfaction. In this article, we will explore everything you need to know about Nickel 200 flanges and why Sankalp Alloys Overseas should be your go-to supplier.

What Are Nickel 200 Flanges?

Nickel 200 flanges are made from Nickel Alloy 200, a commercially pure wrought nickel with excellent mechanical properties. The flanges serve as essential components in piping systems, connecting pipes, valves, and other equipment. Known for their high corrosion resistance, particularly in alkaline environments, Nickel 200 flanges are widely used in industries like chemical processing, food handling, and marine engineering.

Key Properties of Nickel 200 Flanges

Corrosion Resistance: Nickel 200 offers outstanding resistance to various chemicals, including caustic alkalis, making it ideal for demanding industrial environments.

High Ductility: Nickel 200 is highly ductile, allowing it to withstand extreme mechanical stress without fracturing.

Thermal and Electrical Conductivity: It provides excellent thermal and electrical conductivity, making it a versatile choice for different applications.

Magnetostrictive Properties: Nickel 200 possesses magnetostrictive properties, making it useful in certain magnetic applications.

Nickel 200 Flanges Specifications

Sankalp Alloys Overseas offers Nickel 200 flanges with the following specifications:

Dimensions: ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, and custom drawings.

Standards: ASTM, ASME, ANSI, DIN, EN, and BS Flanges.

Specifications: ASTM B564 / ASME SB 564.

Size Range: From 1/2" NB to 60" NB.

Class: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, ASA 150#, ASA 300# DIN ND 6,10,16,25,40, etc.

Length: 100 mm to 3000 mm and above.

Grade: Nickel Alloy 200 (UNS No. N02200).

Benefits of Nickel 200 Flanges

Superior Corrosion Resistance: Nickel 200 flanges offer unmatched resistance to corrosive environments, especially in alkalis.

Longevity: These flanges have a long service life, even in harsh industrial conditions, reducing the need for frequent replacements.

Versatility: Nickel 200 is suitable for use in a wide range of temperatures, making it ideal for various applications.

High Strength: Even at extreme temperatures, Nickel 200 retains its mechanical strength, ensuring reliable performance.

Applications of Nickel 200 Flanges

Nickel 200 flanges are utilized in several industries due to their unique properties:

Chemical Processing: Highly resistant to caustic soda and other chemicals.

Food Processing: Safe for food handling and resistant to corrosion from organic acids.

Marine Engineering: Performs well in saline environments, making it ideal for shipbuilding and marine applications.

Electronics: Used in electrical and electronic components due to its high conductivity.

Pharmaceuticals: Employed in medical devices and equipment manufacturing because of its non-reactive nature.

Why Choose Sankalp Alloys Overseas?

When it comes to Nickel 200 flanges, Sankalp Alloys Overseas is a name you can trust. Here's why:

Unmatched Quality: Each product undergoes rigorous quality checks to meet international standards.

Global Reach: Sankalp Alloys Overseas serves clients worldwide, offering fast and reliable shipping.

Custom Solutions: They provide customized flanges based on your specific requirements and industry needs.

Expertise: With years of experience, Sankalp Alloys Overseas has established itself as a leading authority in nickel alloy products.

Customer-Centric Approach: The team at Sankalp Alloys Overseas is dedicated to delivering unparalleled customer service, ensuring satisfaction at every step.

Conclusion

Nickel 200 flanges are an essential component in various industrial applications, offering high durability and resistance to corrosive environments. For those seeking top-quality Nickel 200 flanges, Sankalp Alloys Overseas is the leading manufacturer, supplier, exporter, and stockist in Mumbai, India, and worldwide. With a commitment to quality, innovation, and customer satisfaction, Sankalp Alloys Overseas ensures that their Nickel 200 flanges exceed expectations in both performance and reliability.

For more information, contact Sankalp Alloys Overseas at [email protected] or +91-8828369483, or visit their website at sankalpalloys.com.

#Nickel 200 Flanges Exporters#Nickel 200 Flanges Exporters in India#Nickel 200 Flanges Manufacturers#Nickel 200 Flanges Manufacturers in India#Nickel 200 Flanges#Sankalpalloys#Sankalp Alloys Overseas#manufacturers#suppliers#exporters#stockists#innovation#flanges#nickel 200#tools

1 note

·

View note

Text

Super Duplex S32760 Flanges Manufacturers in India

The manufacturer and supplier of Very Duplex Steel Flanges made their products in a variety of sizes and forms for the customer in response to interest. The manufacturer, stockist, and supplier of the entire stainless steel item, including this, is Sankalp Alloys Overseas. They provide everything and deliver the product while maintaining excellent quality and price as well.

Super Duplex Steel Flanges are regarded as the best in the series of steel Flanges based on their characteristics and strong points. The austenitic toughened steel is offered in Very Choice with a few components like copper, zinc, and chromium. The majority of businesses use a lot of Duplex steel products since they provide high strength when they come into touch.

There are many kinds of Flanges accessible, for example, Welding Neck Wall It is by and large utilized in low-temperature and high-pressure applications since they required the unhindered liquid stream conveyed by the line framework. Long welding Neck-They is equivalent to a weld neck just contrast in a lengthy welding neck the tightened center point (neck) is expanded and performs like an exhausting expansion. Slip-on Spine It is appended to the fittings or the line by two filet welds, one external the hole and the other one executed inside the rib. They are handily perceived by their minimal and thin shape.

Strung Rib This is attached by screwing the line into the spine rather than using a crease weld. They are typically used in small, low-temperature, low-stress applications like utility and water management. They are legally required in dangerous areas like petrol stations and industries. Since welding associations could be dangerous in this type of environment. Spine Attachment Weld To connect this type of rib to the lines, a single fillet weld is performed on the exterior of the rib. Joint-joint ribs This spine frequently uses an alloy with a stub end and a component with a level spacing. Dark Spine Due to the necessary catapulting forces and the structure pressure, these Flanges reduce outstanding mechanical forces.

A few other exceptional sorts of rib are Nipo rib, Weldo rib, Turn Rib, Elbo Rib, Lactro Rib, Growing spine, and Lessening Rib.

Specification of Super Duplex Stainless Steel S32750/S32760 Flanges

Super Duplex Stainless Steel Flanges Specification: ASTM A182 / ASME SA182 Dimension Standard : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. Standard: ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. Size: 1/2" (15 NB) to 48" (1200NB) Class / Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. Flange Face Type: Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) DIN Flanges : DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673. JIS Flanges : JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K BS Flanges: BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

12 notes

·

View notes

Text

Incoloy 825 Flanges

Sankalp Alloys Overseas are Manufacturers, Provider, and Exporters of Incoloy 825 Flanges that is Produced using Phenomenal Unrefined parts. Incoloy 825 Flanges are Accessible in various grades and sizes, shapes. we offer these things at additional reasonable costs and these Flanges have a stunning income in the neighborhood as well as the overall market.

INCOLOY 825 ANSI B16.5 / B16.47 FLANGES SPECIFICATION :

Standard: ASTM, ASME, ANSI, JIS, DIN, BSNA 11, EN Ni 99.2, JIS NW 2200, GOST-НП-2

Dimensions: ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Designation: ASTM / ASME B 564 / SB 564

Class: Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500 & Class 2500

Size: 1/2″NB TO 60″NB

Grades: Incoloy 825 (UNS N08825) Flanges, 2.4858

Pressure: DIN PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160

7 notes

·

View notes

Text

Hastelloy C22 Flanges Exporters

Sankalp Alloys Overseas is one of the prime manufacturers, suppliers, stockists, and exporters of Hastelloy C22, also referred to as Alloy C22. Austenitic alloy stabilized with molybdenum, tungsten, nickel, and chromium is offered extensively and highly in demand due to their improved resistance to stress corrosion cracking, pitting, and crevice corrosion. The high chromium content provides excellent resistance to Hastelloy C-22 in oxidizing environments.

#Hastelloy C22 Flanges Exporters#Hastelloy C22 Flanges Exporters in India#Hastelloy C22 Flanges Manufacturers#Hastelloy C22 Flanges#Hastelloy C22 Flanges Manufacturers in India#flanges#metal#manufacturers#business#suppliers#exporters#stockists#innovation#sankalpalloys#metalwork#india#mumbai#uae#tools#industrial tools

0 notes

Text

Incoloy 825 Fasteners Exporters

In the realm of industrial fasteners, one name stands out for its remarkable resilience and dependability—Incoloy 825. Used across a variety of sectors, from chemical processing to marine engineering, these fasteners are known for their unmatched performance in demanding environments. But what exactly makes Incoloy 825 fasteners so special, and why should you consider them for your projects? Let’s dive into the unique features and benefits of these high-performance fasteners.

What are Incoloy 825 Fasteners? Incoloy 825 fasteners are made from a nickel-iron-chromium alloy known for its exceptional resistance to various corrosive elements. The alloy is further enriched with molybdenum, copper, and titanium, which enhance its resistance to pitting, crevice corrosion, and stress-corrosion cracking. These fasteners are designed to perform in highly aggressive environments, such as chemical processing plants, offshore oil and gas facilities, and seawater applications.

Key Properties of Incoloy 825 Fasteners Corrosion Resistance: Incoloy 825 exhibits outstanding resistance to both reducing and oxidizing acids, making it ideal for use in environments with sulfuric acid, phosphoric acid, and other corrosive chemicals. High Temperature Tolerance: The alloy maintains its mechanical strength and corrosion-resistant properties even at elevated temperatures, which makes it suitable for heat-exposed applications. Durability and Strength: Incoloy 825 fasteners provide high mechanical strength and are known for their long lifespan, reducing the need for frequent replacements. Resistance to Pitting and Crevice Corrosion: Thanks to the molybdenum content, these fasteners can withstand pitting and crevice corrosion in chloride-containing environments.

Specifications of Incoloy 825 Fasteners Standards: DIN, ASTM, BS, and all international standards Size Range: 3 mm to 200 mm Bolt/Screw Size: M3 - M56 | 3/6" to 2" | Custom sizes available Nut Size: M3 - M56 | 3/6" to 2" | Custom sizes available Washer Size: M1 - M64 | #4 to 3" | Custom sizes available Length: M02 to M33 Types: Includes nuts, bolts, screws, sockets, studs, hex head bolts, machine screws, marine anchors, eye bolts, foundation bolts, structural bolts, and more. Benefits of Incoloy 825 Fasteners Long-Term Cost Savings: Their durability and resistance to harsh chemicals reduce the frequency of replacements, leading to long-term savings. High Corrosion Resistance: Ideal for applications exposed to saltwater, acidic, and alkaline environments. Wide Range of Applications: Used in multiple industries, from chemical processing and oil & gas to marine engineering. Easy Customization: Available in various sizes and shapes, with custom sizes upon request to meet specific project requirements. Consistency and Reliability: Conforms to international standards ensuring dependable performance across diverse applications.

Applications of Incoloy 825 Fasteners Incoloy 825 fasteners are utilized in various industries due to their remarkable properties. Some of the key applications include:

Chemical Processing: Used in processing plants dealing with sulfuric, phosphoric, and other aggressive acids. Oil & Gas Industry: Suitable for offshore drilling, oil refining, and gas extraction, where exposure to corrosive environments is common. Marine Engineering: Employed in shipbuilding, marine hardware, and seawater desalination plants due to their resistance to saltwater corrosion. Pollution Control Equipment: Ideal for use in components exposed to polluted or contaminated environments. Heat Exchangers: These fasteners hold up well in heat exchangers and other equipment that operates at high temperatures.

Why Choose Sankalp Alloys Overseas for Incoloy 825 Fasteners? Sankalp Alloys Overseas is a trusted leader in the manufacturing, exporting, stocking, and supply of Incoloy 825 fasteners in India and internationally. Here’s why you should consider partnering with them:

Expertise and Experience: With years of experience in the industry, Sankalp Alloys Overseas has developed a reputation for delivering high-quality fasteners that meet the stringent requirements of various industrial applications. Wide Range of Products: They offer an extensive selection of Incoloy 825 fasteners, including custom sizes and configurations to suit specific needs. Quality Assurance: Sankalp Alloys Overseas adheres to international quality standards such as DIN, ASTM, and BS, ensuring that their products consistently deliver exceptional performance. Competitive Pricing: They provide cost-effective solutions without compromising on quality, ensuring that you get the best value for your investment. Global Reach: As exporters, they serve clients not only in India but around the world, ensuring prompt and efficient delivery regardless of location. Customer-Centric Approach: Committed to customer satisfaction, they offer personalized services, including technical support and product recommendations tailored to your specific requirements.

Conclusion When it comes to industrial fasteners, Incoloy 825 fasteners stand out for their superior corrosion resistance, high strength, and versatility across a range of applications. Whether you are dealing with harsh chemicals, high temperatures, or seawater environments, these fasteners offer unmatched performance. For the best quality and service, Sankalp Alloys Overseas is your go-to partner. With their expertise, comprehensive product range, and commitment to quality, you can trust them to meet all your fastening needs.

Contact Details For inquiries, quotations, or more information, get in touch with Sankalp Alloys Overseas:

Contact Number: +91-8828369483 Email: [email protected] Website: https://www.sankalpalloys.com

Sankalp Alloys Overseas is your reliable source for top-quality Incoloy 825 fasteners—delivering excellence and precision for all your industrial requirements.

#Incoloy 825 Fasteners Exporters#Incoloy 825 Fasteners Exporters in India#Incoloy 825 Fasteners Manufacturers#Incoloy 825 Fasteners Manufacturers in India#Incoloy 825 Fasteners#Fasteners#exporter#suppliers#business#exporters#innovation#stockists#manufacturers#metalwork#sankalpalloys#india#mumbai#uae

1 note

·

View note

Text

Duplex Steel S32750 Fasteners Exporters

Duplex Steel S32750 Fasteners Manufacturers

In the world of fasteners, the choice of material is crucial to ensure performance, durability, and resistance to various environmental conditions. Among the many options available, Duplex Steel S32750 has emerged as a top choice for many industries. Sankalp Alloys Overseas, located in Mumbai, India, stands as a leading manufacturer, supplier, exporter, and stockist of Duplex Steel S32750 fasteners, catering to a global clientele.

Duplex Steel S32750 Flanges

Duplex Steel S32750, also known as Super Duplex Stainless Steel, is a high-performance alloy that combines the beneficial properties of both austenitic and ferritic stainless steels. This unique blend offers excellent mechanical strength, corrosion resistance, and improved weldability, making it ideal for various demanding applications.

Key Properties

Duplex Steel S32750 boasts several impressive properties:

High Strength: It has a yield strength that is approximately twice that of standard austenitic stainless steel.

Corrosion Resistance: Excellent resistance to pitting, crevice corrosion, and stress corrosion cracking.

Thermal Stability: Retains strength and toughness even at elevated temperatures.

Weldability: Good weldability without the need for post-weld heat treatment.

Specification of Duplex Steel S32750 Fasteners

Standard Specifications: ASTM A182 / ASME SA182

Dimension Standards: ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Sizes: Ranges from 1/2" (15 NB) to 48" (1200 NB)

Class/Pressure Ratings: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64, etc.

Flange Face Types: Flat Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

JIS Flanges: JIS B2220 5K, 10K, 16K, 20K

BS Flanges: BS4504 PN 6, PN 10, PN 16, PN 25, PN 40, PN 64, PN 100, PN 160, PN 250, BS 10, BS Table D, E, F, H.

Benefits of Duplex Steel S32750 Fasteners

Longevity: The exceptional corrosion resistance ensures a longer lifespan in harsh environments.

Cost-Effectiveness: Although initially more expensive than standard materials, the durability reduces the need for replacements, providing long-term savings.

Versatility: Suitable for various industries, including oil and gas, marine, chemical processing, and more.

Applications

Duplex Steel S32750 fasteners are widely used in:

Oil and Gas Industry: For pipelines, valves, and fittings.

Marine Applications: In shipbuilding and offshore structures.

Chemical Processing: In reactors, heat exchangers, and storage tanks.

Power Generation: For components in nuclear and conventional power plants.

Why Choose Sankalp Alloys Overseas?

Sankalp Alloys Overseas is renowned for its commitment to quality and excellence. As a leading manufacturer and supplier of Duplex Steel S32750 fasteners, we prioritize:

Quality Assurance: Stringent quality control measures to ensure compliance with international standards.

Customization: Ability to provide tailored solutions to meet specific project requirements.

Expertise: A team of skilled professionals with extensive knowledge in alloy manufacturing and applications.

Global Reach: Supplying fasteners to clients across the globe, backed by reliable logistics.

Conclusion

When it comes to choosing fasteners that offer superior strength, corrosion resistance, and longevity, Duplex Steel S32750 is the material of choice. Sankalp Alloys Overseas is your trusted partner for high-quality fasteners, ensuring you get the best products for your industrial needs.

For more information or inquiries, contact us at:

Email: [email protected]

Contact Number: +91-8828369483

Website: Sankalp Alloys Overseas

#Duplex Steel S32750 Fasteners Exporters in India#Duplex Steel S32750 Fasteners Exporters#Duplex Steel S32750 Fasteners#Duplex Steel S32750#Fasteners#Duplex Steel S32750 Fasteners Manufacturers in India#Duplex Steel S32750 Fasteners Manufacturers#suppliers#stockists#exporters#manufacturers#business#innovation#metalwork

1 note

·

View note

Text

Sankalp Alloys Overseas is one of the renowned ISO 9001:2000 manufacturers, suppliers, stockists, and exporters of Incoloy 800 Flanges, available in various sizes, shapes, thicknesses, and dimensions as per the requirements of customers. Slip-on flanges, weld neck flanges, blind flanges, socket weld flanges, threaded flanges, and long weld neck flanges are part of the forged flanges that fit into domestic and global markets.

#Incoloy 800 Flanges Manufacturers#Incoloy 800 Flanges Manufacturers in India#Incoloy 800 Flanges Exporters#Incoloy 800 Flanges Exporters in India#mumbai#india#maharashtra#suppliers#business#manufacturers#Sankalpalloys

0 notes

Text

Incoloy 825 Flanges Manufacturers in India

When it comes to high-performance applications in aggressive environments, Incoloy 825 stands as one of the most reliable and robust alloys available. Known for its exceptional resistance to corrosion and oxidation, this alloy has found widespread usage across a variety of industries. One of the key components where Incoloy 825 plays a critical role is in the manufacturing of flanges. In this blog, we delve into what makes Incoloy 825 flanges special, their features, benefits, and applications.

What is Incoloy 825?

Incoloy 825 is a nickel-iron-chromium alloy with the addition of molybdenum, copper, and titanium. Its chemical composition offers a unique combination of high tensile strength and exceptional corrosion resistance, making it ideal for a variety of demanding environments. The alloy is specifically designed to resist sulfuric and phosphoric acids, seawater, and other harsh chemical environments.

Sankalp Alloys Overseas produces Incoloy 825 Flanges from nickel-chromium alloy containing high portions of 38% nickel and 19% chromium, besides minor additions such as carbon, manganese, silicon, sulfur, copper, iron, aluminum, and titanium combined for purposes of stabilization. These UNS N08825 Pipe Flanges come in different dimensions, sizes, and specifications conforming to the ASTM B564 norms and expediently meet various ASME B16.5, ASME B16.47 series A and B, and other international requirements. We can offer a wide array of flange types: slip-on, weld neck, socket weld, blind flanges.

Incoloy 825 Flanges: Key Features

Flanges are vital components used to connect pipes, valves, pumps, and other equipment, forming a secure and leak-proof system. Incoloy 825 flanges offer the following distinct features that make them a top choice in critical industries:

Superior Corrosion Resistance: One of the most noteworthy features of Incoloy 825 flanges is their excellent resistance to a variety of corrosive elements, including sulfuric acid, phosphoric acid, and even seawater. This makes them ideal for use in marine, chemical processing, and oil and gas industries.

Oxidation Resistance: Thanks to its nickel and chromium content, Incoloy 825 offers impressive resistance to oxidation in both aqueous and high-temperature environments. This prevents the flange from weakening or deteriorating when exposed to extreme conditions.

High Tensile Strength and Durability: Incoloy 825 flanges are designed to withstand high pressure and temperature, ensuring durability and long-lasting performance. The alloy's structural integrity remains intact even under harsh conditions, making it ideal for high-stress applications.

Thermal Stability: The alloy's composition allows it to maintain its mechanical properties at elevated temperatures, making it suitable for environments where heat resistance is a critical factor.

Stress-Corrosion Cracking Resistance: Incoloy 825 flanges offer excellent resistance to stress-corrosion cracking, which is a common issue in environments that combine high tensile stress with corrosive elements.

Benefits of Using Incoloy 825 Flanges

Long Service Life: Due to its excellent corrosion resistance and structural integrity, Incoloy 825 flanges have a long service life, reducing the need for frequent replacements or repairs.

Low Maintenance: The material's durability and resistance to environmental wear make these flanges low-maintenance, which is a significant cost-saver in the long run.

Versatility: Incoloy 825 flanges are suitable for a wide range of applications, from chemical processing to offshore and marine environments.

Economic Efficiency: Although Incoloy 825 may have a higher upfront cost than other materials, its long lifespan and reduced need for maintenance make it an economical choice over time.

INCOLOY 825 ANSI B16.5 / B16.47 FLANGES SPECIFICATION :

Standard : ASTM, ASME, ANSI, JIS, DIN, BSNA 11, EN Ni 99.2, JIS NW 2200, GOST-НП-2

Dimensions : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Designation : ASTM / ASME B 564 / SB 564

Class : Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500 & Class 2500

Size : 1/2″NB TO 60″NB

Grades : Incoloy 825 (UNS N08825) Flanges, 2.4858

Pressure : DIN PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160

Conclusion

Incoloy 825 flanges are a prime choice for industries that require reliable, corrosion-resistant, and durable solutions for their piping systems. With a wide range of types available, these flanges offer versatility and strength in applications exposed to harsh environments, from chemical processing to offshore oil and gas. While the initial investment may be higher, the long-term benefits of reduced maintenance and extended service life make Incoloy 825 flanges a cost-effective solution for many critical applications.

#Incoloy 825 Flanges Manufacturers in India#Incoloy 825 Flanges#Incoloy 825 Flanges Manufacturers#Incoloy 825 Flanges Exporters#Incoloy 825 Flanges Exporters in India#Sankalpalloys

1 note

·

View note

Text

Incoloy 800HT Flanges Manufacturers in India

Incoloy 800HT, part of the Incoloy 800 series, is a high-performance nickel-iron-chromium alloy designed to excel in extreme environments. This alloy's unique combination of mechanical strength, resistance to oxidation, and outstanding stability at elevated temperatures makes it an ideal material for various industries. Among the many products made from this alloy, Incoloy 800HT flanges stand out due to their durability, versatility, and reliability. In this blog, we will dive deep into the properties, applications, and advantages of Incoloy 800HT flanges.

What is Incoloy 800HT?

Incoloy 800HT is a high-temperature alloy made primarily of nickel (30-35%), iron (39.5% minimum), and chromium (19-23%). It also contains small amounts of aluminium and titanium, which enhance its creep and rupture strength at elevated temperatures.

Sankalp Alloys Overseas is a leading Manufacturer, Supplier, Stockist and Exporter of Incoloy 800HT Flanges, also known as UNS N08811. Incoloy 800HT is a nickel-based superalloy that has the basic chemical composition of Incoloy 800 but with controlled element chemistry so as to have significantly higher creep-rupture strength.

This high-temperature annealing provides enhanced strength to Alloy 800H Flanges, making them suitable for demanding industries like processing of chemicals and petrochemicals, industrial furnaces, heat-treating equipment, and fabrication of superheater and reheater tubing of power plants.

Properties of Incoloy 800HT Flanges

Flanges made from Incoloy 800HT are widely known for their excellent thermal properties, high resistance to corrosion, and mechanical strength. Below are some key features of this material:

High-Temperature Strength: Incoloy 800HT maintains its strength and structural integrity at temperatures ranging between 700°C to 1100°C, making it suitable for high-heat environments.

Oxidation and Corrosion Resistance: This alloy provides excellent resistance to oxidation, sulfidation, and carburization, even in the presence of fluctuating temperatures and corrosive environments.

Creep and Stress Rupture Resistance: Incoloy 800HT exhibits remarkable resistance to creep deformation and stress rupture, making it suitable for long-term applications in extreme conditions.

Enhanced Metallurgical Stability: With its balanced chemical composition, Incoloy 800HT is designed for superior stability, reducing the risk of embrittlement at high temperatures.

Applications of Incoloy 800HT Flanges

Due to its exceptional mechanical properties and high-temperature stability, Incoloy 800HT flanges are widely used in a variety of industrial applications. Some common industries and uses include:

Petrochemical and Refining: Incoloy 800HT flanges are ideal for heat exchangers, reactors, and piping systems in chemical processing and refining due to their resistance to chemical corrosion and high temperatures.

Power Generation: In power plants, particularly those using fossil fuels, Incoloy 800HT flanges are used in boiler components, heat exchangers, and gas turbines due to their ability to withstand high heat and pressure.

Heat Treating Equipment: Furnaces, radiant tubes, and other heat-treating equipment benefit from the alloy's high-temperature resistance, making Incoloy 800HT flanges suitable for this application.

Nuclear Engineering: Withstanding harsh environmental conditions and high radiation exposure, these flanges are commonly used in nuclear reactors, especially in high-temperature, high-pressure systems.

Aerospace: The aerospace industry often requires materials that maintain structural integrity at extreme temperatures. Incoloy 800HT flanges are a reliable choice for jet engines, exhaust systems, and high-temperature ducting.

INCOLOY 800HT ANSI B16.5 / B16.47 FLANGES SPECIFICATION:

Standard: ASTM, ASME, ANSI, JIS, DIN, BSNA 11, EN Ni 99.2, JIS NW 2200, GOST-НП-2

Dimensions: ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Designation: ASTM / ASME B 564 / SB 564

Class: Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500 & Class 2500

Size: 1/2″NB TO 60″NB

Grades: Incoloy 800 (UNS N08800) Flanges, 2.4876

Pressure: DIN PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160

Conclusion

Incoloy 800HT flanges offer a perfect balance of high-temperature stability, corrosion resistance, and mechanical strength. They are a superior choice for applications in industries like petrochemical processing, power generation, and aerospace, where extreme conditions are the norm. With their exceptional performance and long-lasting durability, Incoloy 800HT flanges ensure operational efficiency and safety in critical environments.

Choosing the right material for flanges can significantly improve the lifespan and reliability of piping systems. By opting for Incoloy 800HT, industries can achieve the perfect blend of strength, durability, and cost-efficiency in high-temperature applications.

#Incoloy 800HT Flanges Manufacturers in India#Incoloy 800HT Flanges Manufacturers#Incoloy 800HT Flanges Manufacturers in India#Incoloy 800HT Flanges Exporters#Incoloy 800HT Flanges#Flanges#business#exporters#stockists#Incoloy 800HT#Incoloy 800HT Flanges Exporters in India#suppliers#manufacturers

1 note

·

View note

Text

Inconel 600 Flanges Manufacturers

Inconel 600, a nickel-chromium alloy, is renowned for its exceptional resistance to oxidation and corrosion at high temperatures, making it a popular choice in industries that require durability and reliability. One of the key components made from this versatile alloy is flanges, essential in piping systems for connecting pipes, valves, pumps, and other equipment. This article delves into the characteristics of Inconel 600 flanges, their key properties, specifications, and benefits, offering a comprehensive understanding of their significance in various industrial applications.

Introduction

Flanges are integral parts of many industrial piping systems, providing a means to connect pipes, valves, pumps, and other equipment to form a complete system. Among the various materials used to manufacture flanges, Inconel 600 stands out due to its superior performance in challenging environments. Inconel 600 flanges are widely used in industries such as chemical processing, aerospace, power generation, and marine engineering, where resistance to heat, pressure, and corrosive substances is crucial.

Key Properties of Inconel 600

Inconel 600 is an alloy composed primarily of nickel (72%) and chromium (14-17%), with small amounts of iron (6-10%) and other elements. This combination imparts the following key properties to the material:

High Temperature Resistance: Inconel 600 maintains its mechanical strength and stability at temperatures ranging from cryogenic to over 2000°F (1093°C), making it ideal for high-temperature applications.

Corrosion Resistance: The alloy exhibits excellent resistance to a wide range of corrosive environments, including oxidizing and reducing conditions, making it suitable for use in harsh chemical processing environments.

Oxidation Resistance: Inconel 600 is highly resistant to oxidation at high temperatures, which prevents scaling and surface degradation over time.

Good Mechanical Properties: The alloy possesses high tensile strength and good toughness, making it suitable for applications where mechanical stress and pressure are significant factors.

Non-Magnetic: Inconel 600 is non-magnetic, which can be a critical property in certain applications where magnetic interference must be avoided.

What are Inconel 600 Flanges?

Inconel 600 flanges are specialized components designed to connect pipes, valves, and other equipment in a piping system. They are typically used in applications where the system is exposed to high temperatures, corrosive environments, or both. These flanges come in various types, including weld neck, slip-on, socket weld, lap joint, threaded, and blind flanges, each serving a specific purpose in a piping system.

Specification of Inconel 600 Flanges

Inconel 600 flanges are manufactured according to specific standards and specifications to ensure quality, reliability, and compatibility with other system components. Some of the common specifications include:

Standards: ASTM B564, ASME SB564, DIN, EN, and ANSI standards.

Sizes: Typically ranging from ½” to 48” or as per customer requirements.

Pressure Class: Available in various pressure ratings such as 150#, 300#, 600#, 900#, 1500#, and 2500#.

Dimensions: Adhering to standard dimensions for thickness, diameter, and bolt circle as per ASME B16.5, ASME B16.47, and other relevant standards.

Surface Finish: The flanges may come with different surface finishes, including raised face (RF), flat face (FF), and ring-type joint (RTJ).

Sankalp Alloys Overseas is one of the best exporter, creator and provider of Inconel 600 Flanges in India.Inconel boasts excellent qualities compared to most alloys, including stainless steel. Their higher cost compensates with high mechanical strength and excellent corrosion resistance properties. Generally, Inconel Flanges are used to serve in environments of elevated temperatures. Unlike most alloys that lose dimensional stability and mechanical properties at high temperatures, Inconel retains its performance.

Benefits of Inconel 600 Flanges

Inconel 600 flanges offer several advantages that make them suitable for demanding industrial applications:

Durability: The high strength and toughness of Inconel 600 ensure that flanges made from this material can withstand mechanical stress and pressure over extended periods.

Extended Service Life: Due to its resistance to oxidation and corrosion, Inconel 600 flanges have a longer service life compared to flanges made from other materials.

Versatility: The alloy's ability to perform well in both high-temperature and cryogenic environments makes it suitable for a wide range of applications.

Low Maintenance: The excellent corrosion resistance of Inconel 600 reduces the need for frequent maintenance and replacement, lowering overall operational costs.

Safety: Inconel 600 flanges ensure the safe operation of piping systems, particularly in critical environments such as chemical processing plants and power generation facilities.

Conclusion

Inconel 600 flanges are a critical component in various industrial applications, offering unmatched performance in high-temperature, high-pressure, and corrosive environments. Their exceptional properties, such as resistance to oxidation, corrosion, and mechanical stress, make them a reliable choice for industries where safety and durability are paramount. By understanding the specifications and benefits of Inconel 600 flanges, industries can make informed decisions when selecting materials for their piping systems, ensuring long-term performance and reduced maintenance costs.

Whether in chemical processing, power generation, or aerospace engineering, Inconel 600 flanges continue to play a vital role in ensuring the integrity and efficiency of critical systems.

For More Information:

Visit Our Website - https://www.sankalpalloys.com/

Call Us : +91-88283-69483

E-mail - [email protected]

0 notes

Text

Incoloy 800 Flanges Exporters

Introduction

Incoloy 800 flanges are a critical component in various high-temperature and corrosive environments. As a nickel-iron-chromium alloy, Incoloy 800 is renowned for its excellent mechanical properties and resistance to oxidation and carburization. This blog explores the details, specifications, applications, and implications of Incoloy 800 flanges in various industries, with reference to Sankalp Alloys Overseas.

Product Detail

Incoloy 800 flanges are manufactured from a nickel-based alloy that includes chromium and iron, along with small amounts of aluminum and titanium. This composition provides the flanges with exceptional strength and resistance to oxidation at elevated temperatures, making them suitable for applications in harsh environments.

Key Features

Corrosion Resistance: Incoloy 800 flanges exhibit strong resistance to oxidation and carburization, particularly at temperatures up to 1100°F (593°C) .

Mechanical Strength: The alloy maintains impressive tensile and yield strength, ensuring durability even in extreme conditions.

Temperature Tolerance: These flanges can operate effectively in high-temperature applications, making them ideal for industries such as petrochemical and oil refining.

Specifications

The specifications of Incoloy 800 flanges include:

Chemical Composition:

Nickel (Ni): 30.0-35.0%

Chromium (Cr): 19.0-23.0%

Iron (Fe): Minimum 39.5%

Carbon (C): Maximum 0.10%

Aluminum (Al): 0.15-0.60%

Titanium (Ti): 0.15-0.60% .

Physical Properties:

Density: 7.94 g/cm³

Melting Range: 1357 – 1385°C (2475 – 2525°F)

Yield Strength: 13.00–21.00 ksi

Elongation: 18.00–23.00% .

Size Range: Available in various sizes, typically from 0.5 inches to 8 inches .

Applications

Incoloy 800 flanges are widely used across several industries due to their unique properties:

Petrochemical Industry: Ideal for use in heat exchangers, reactors, and piping systems that operate under high temperatures and pressures.

Power Generation: Commonly utilized in steam generation plants, where resistance to thermal cycling is crucial.

Marine Applications: Their corrosion resistance makes them suitable for use in seawater environments.

Nuclear Industry: Employed in components that require high strength and corrosion resistance under extreme conditions .

Implications on Industry

The use of Incoloy 800 flanges has significant implications for various industries:

Enhanced Safety: The high-temperature resistance and mechanical strength contribute to safer operations in critical applications, reducing the risk of failures.

Cost-Effectiveness: While Incoloy 800 may have a higher initial cost compared to other materials, its durability and longevity can lead to lower maintenance and replacement costs over time.

Environmental Resistance: The ability to withstand corrosive environments helps industries comply with safety and environmental regulations, minimizing the risk of leaks and contamination .

Conclusion

Incoloy 800 flanges are a vital component in high-temperature and corrosive applications across various industries. Their unique properties, including excellent mechanical strength and corrosion resistance, make them a preferred choice for demanding environments. As industries continue to evolve, the demand for reliable materials like Incoloy 800 will remain critical, ensuring safety and efficiency in operations.

0 notes