#INCONEL

Explore tagged Tumblr posts

Text

Système d'échappement KLINE : Donnez à votre véhicule d'exception une puissance accrue, un son élégant et une fiabilité inégalée pour optimiser ses performances, tout en profitant d'une qualité premium

En commandant chez AD-RACINGWORLD MOTORSPORT®, vous bénéficiez de notre expérience et de nos connaissances sur les produits que nous vendons

Nous proposons une gamme d'échappement sport de haute qualité, de nombreux clients en France et dans le monde nous font confiance depuis des années, nous sommes situés à coté de Lyon, à 450kms de Paris ou de Nice et 150kms de Genève en Suisse, nous livrons dans toute la France et à l'international, également en collaboration avec des partenaires pour la pose

►Contact : [email protected]

►Boutique : https://www.ad-racingworld.com/fr/

#ferrari#lamborghini#bugatti#mclaren#porsche#audi#bmw#mercedesamg#nissangtr#klineinnovation#echappementkline#exhaustkline#klineexhaust#inconel#adracingworld#france#suisse#belgique#espagne#portugal#hollande#italie#allemagne#voituredesport#voituredeluxe#echappement#exhaust#luxe#luxury

13 notes

·

View notes

Text

Researchers zero in on the underlying mechanism that causes alloys to crack when exposed to hydrogen-rich environments

When deciding what material to use for infrastructure projects, metals are often selected for their durability. However, if placed in a hydrogen-rich environment, like water, metals can become brittle and fail. Since the mid-19th century, this phenomenon, known as hydrogen embrittlement, has puzzled researchers with its unpredictable nature. Now, a study published in Science Advances brings us a step closer to predicting it with confidence. The work is led by Dr. Mengying Liu from Washington and Lee University in collaboration with researchers at Texas A&M University. The team investigated formation of cracks in initially flawless, crack-free samples of a nickel-base alloy (Inconel 725), which is primarily known for its strength and corrosion resistance. There are currently several working hypotheses that attempt to explain hydrogen embrittlement. The results of this study show that one of the more well-known hypotheses—hydrogen enhanced localized plasticity (HELP)—is not applicable in the case of this alloy.

Read more.

19 notes

·

View notes

Text

Manilaxmi Industrial Announcing New Blog Site

Our blog provides Insights, industry updates, and in-depth information on industrial products, including pipes, fittings, and flanges, tailored to help businesses stay informed and succeed.

#Blog#Blogging#ManilaxmiIndustrial#IndustrialProducts#IndustrialSupplies#IndustrialEquipment#PipesAndFittings#PipeFittings#Flanges#SteelProducts#MetalProducts#AlloySteel#ForgedFittings#StainlessSteel#NickelAlloys#Hastelloy#Monel#Inconel#DuplexSteel#PipeManufacturers#SteelSuppliers#IndustrialManufacturers#Manufacturing#Engineering#Fabrication#SteelIndustry#FAQ#FrequentlyAskedQuestions#ProductFAQs#TechnicalSupport

3 notes

·

View notes

Text

Inconel 625: Properties, Applications, and Advantages

Introduction

Inconel 625 is a superalloy nickel-based metal created by Special Metals Corporation that is highly prized for its exceptional mechanical strength, corrosion resistance, and stability in harsh environments. No matter how it is exposed to high temperatures, aggressive chemicals, or sea environments, Inconel 625 always produces a worthwhile outcome. Its broad scope of properties has made it a favorite in top industries such as aerospace, chemical processing, marine engineering, oil & gas, and nuclear power.

In this comprehensive guide, we will explore:

The chemical composition of Inconel 625

Its key properties and benefits

Industrial applications

A comparative analysis with other materials

Considerations for machining and welding

Chemical Composition of Inconel 625

The high performance of the alloy results from its carefully designed chemical composition. Inconel 625 is mainly made up of Nickel, Chromium, Molybdenum, and Niobium, supplemented by trace elements that enhance its performance in adverse conditions.

Key Properties and Characteristics of Inconel 625

1. High-Temperature Strength

Maintains structural integrity up to 1800°F (982°C)

Excellent creep resistance and stress rupture strength in prolonged high-heat conditions

2. Superior Corrosion Resistance

Withstands oxidation and corrosion in aggressive environments such as:

Seawater

Acids (sulfuric, nitric, hydrochloric)

Chloride-containing environments

Ideal for offshore and chemical processing environments

3. Fatigue and Wear Resistance

High fatigue strength under cyclic loading

Outstanding erosion and abrasion resistance, even in turbulent or corrosive flow environments

4. Excellent Weldability and Fabrication

Welds readily using TIG, MIG, and laser techniques

Post-weld heat treatment is usually not necessary

Maintains mechanical properties across the welded zone

Applications of Inconel 625

Inconel 625’s ability to handle extreme stress, heat, and corrosion makes it a staple in various industries:

Aerospace Industry

Jet engine parts including exhaust ducts, turbine blades, and seals.

Rocket motor casings and fuel line systems

Heat shielding for high-temperature zones

Chemical Processing

Heat exchangers, transfer piping, and reactor vessels

Handling of acidic or oxidizing chemicals in process equipment

Marine & Offshore Engineering

Subsea valves, pumps, and fasteners

Propeller shafts, risers, and seawater handling components

Oil & Gas Sector

Downhole tubing, wellhead parts, and separation systems

High-pressure, high-temperature (HPHT) equipment

Nuclear Power Plants

Core containment, steam lines, and radiation shielding

Long-lasting reliability in radioactive and high-temperature environments

Advantages Over Other Materials

When comparing Inconel 625 to popular alternatives like Stainless Steel (316L) and Titanium (Grade 5), it consistently outshines in extreme environments:

Inconel 625 is superior where strength, corrosion resistance, and temperature stability cannot be compromised. Although more costly, it reduces long-term maintenance and enhances system life.

Machining and Welding Considerations

Machining Tips

Use carbide or ceramic tools to handle its abrasiveness

Adopt low cutting speeds and high feed rates to reduce work hardening

Apply high-pressure coolant systems to prevent overheating

Welding Guidelines

TIG welding is ideal for precision and strength

Inconel 625 filler material should always be used to preserve optimal corrosion resistance.

Post-weld heat treatment is optional but may be beneficial in stress-relief applications

Conclusion

Inconel 625 is a robust superalloy specifically designed for high-demand environments that push regular material to its limits. Its strong resistance to corrosion, heat, and fatigue makes it an indispensable material in industries where performance and reliability are paramount. Though its initial price tag is higher, its longer lifespan, minimal maintenance, and higher performance easily offset the cost.

Final Thoughts

If your application demands a material that can endure high stress, resist corrosive chemicals, or perform at extreme temperatures, Inconel 625 is one of the most dependable choices available. Its properties allow engineers and designers to push the boundaries of innovation and safety.

#ananka#anankafasteners#inconel#inconelfasteners#fasteners#fastenersmanufacturer#manufacturing#articles#blog#advantages#inconel625#inconelbolts#inconelnut#manufacturer#supplier#mumbai#blog tumblr#tumblr

0 notes

Text

Why Engineers Choose Inconel 600?

In high-stress environments, only a few alloys hold up. Inconel 600 is one of the most reliable choices for engineers.

Nickel-chromium alloy with high thermal stability

Resists chloride stress corrosion cracking

Used in turbines, reactors & aerospace components

Durable in extreme environments

Ensures long-term performance & safety

🔩 Trusted by engineers across industries. Explore premium Inconel 600 at Riyaarth Overseas

0 notes

Text

Special forging utilizes high-performance materials like Super Duplex, Inconel, and Titanium to create durable, corrosion-resistant, and high-strength components for industries such as oil & gas, power plants, and aerospace. These materials ensure long-term reliability in extreme environments, making them essential for critical piping applications. Explore the full article to learn more about the key materials and their advantages in special forging

#inconel and incoloy fittings#india#Industrial Solutions#You said:#without#ChatGPT said:#Special Forging#Super Duplex#Inconel#Titanium#Industrial Forging#High-Performance Materials#Pipe Fittings#O-LETs#Power Plants#Oil and Gas Industry#Aerospace Materials#Chemical Processing#Metal Forging#china

0 notes

Text

Why Inconel 718 Round Bars Are Preferred for High-Stress Applications

Amardeep Steel Centre LLP is a leading supplier and exporter of Inconel 718 Round Bars, renowned for their outstanding performance in high-stress and high-temperature applications. These round bars are manufactured using a nickel-chromium-based superalloy, which includes essential elements like molybdenum, niobium, iron, and titanium. This unique composition enhances the strength, durability, and corrosion resistance of Inconel 718 round bars, making them a preferred choice in critical industrial applications.

🔹 Why Inconel 718 Round Bars Excel in High-Stress Applications:

✅ High Tensile and Yield Strength: Inconel 718 round bars exhibit remarkable tensile and yield strength, even under extreme load and pressure conditions. This high-strength property makes them ideal for applications where mechanical stress is a major concern.

✅ Superior Fatigue and Creep Resistance: These bars are specifically designed to withstand fatigue and creep deformation over prolonged exposure to high temperatures. They maintain their structural integrity, preventing cracks and deformation, even after long-term service in elevated temperature environments.

✅ Corrosion and Oxidation Resistance: Inconel 718 round bars provide excellent resistance to oxidation and corrosion in various aggressive environments, including acidic, alkaline, and seawater conditions. This property makes them suitable for offshore, chemical, and marine applications.

✅ Thermal Stability at High Temperatures: These round bars retain their mechanical properties at temperatures ranging from cryogenic conditions up to 700°C, making them perfect for applications that demand high thermal stability.

✅ Excellent Weldability and Machinability: Inconel 718 bars can be welded and fabricated with ease, offering greater flexibility in complex engineering designs and structures. Their excellent machinability enhances productivity while ensuring precision in various applications.

📌 Key Applications of Inconel 718 Round Bars:

🔸 Aerospace and Aviation: Used extensively in turbine blades, jet engines, afterburners, and exhaust systems due to their high heat and stress resistance.

🔸 Gas Turbines and Power Generation Plants: Ideal for high-temperature components, including turbine disks, heat exchangers, and combustion chambers, ensuring reliability in power plants.

🔸 Oil and Gas Industry: Inconel 718 round bars are utilized in downhole tools, wellhead equipment, and pipeline systems that encounter extreme pressure and corrosive environments.

🔸 Marine and Subsea Applications: Highly resistant to seawater and chloride-induced corrosion, making them suitable for offshore platforms, marine hardware, and subsea components.

🔸 Chemical and Petrochemical Processing: Widely used in heat exchangers, reactors, and pressure vessels that handle corrosive chemicals and operate at high temperatures.

🎯 Why Choose Amardeep Steel Centre LLP for Inconel 718 Round Bars?

✅ ISO-Certified Manufacturer with Over 40 Years of Industry Expertise ✅ Precision Engineering and Strict Quality Control Standards ✅ Wide Range of Sizes and Specifications Available ✅ Quick Turnaround and Global Supply Capability ✅ Trusted Vendor for Industry Giants like KNPC, Alfa Laval, L&T, and Qatar EnergyWith a commitment to quality and precision, Amardeep Steel Centre LLP ensures that Inconel 718 round bars meet international standards and provide unmatched performance in critical applications.

0 notes

Text

Exotic Steel Alloys: The Backbone of High-Performance Engineering

Introduction

In industries where strength, durability, and resistance to extreme conditions are crucial, exotic steel alloys have become indispensable. From aerospace and medical to industrial manufacturing, these specialized materials offer superior performance over conventional metals. But what makes them the preferred choice for critical applications? Let’s explore their unique benefits and why top engineers rely on them.

Why Industries Prefer Exotic Steel Alloys

1. Exceptional Strength & Durability

Exotic steel alloys like 330 stainless steel, Inconel, and Hastelloy boast superior mechanical properties, making them ideal for applications that demand high tensile strength and impact resistance.

2. High Corrosion & Heat Resistance

Industries such as aerospace, marine, and chemical processing rely on exotic steel alloys for their ability to withstand harsh environments, extreme temperatures, and corrosive chemicals.

3. Enhanced Machinability & Weldability

Unlike traditional stainless steel, exotic alloys are engineered to provide better machinability and ease of fabrication, allowing manufacturers to create complex components with precision.

4. Lightweight Yet Strong

Many high-performance sectors require materials that offer strength without excessive weight. Exotic steel alloys strike the perfect balance, particularly in aerospace applications, where weight reduction directly impacts fuel efficiency.

Real-World Applications

Aerospace Engineering

Exotic steel alloys are extensively used in jet engines, spacecraft, and structural components. Their ability to endure high-pressure environments and extreme temperatures makes them indispensable.

Medical Industry

In medical implants and surgical instruments, biocompatible exotic steel alloys like 316L stainless steel and cobalt-chromium alloys are used for their corrosion resistance and durability inside the human body.

Industrial & Chemical Processing

Heat exchangers, boilers, and reactors in chemical plants operate under extreme conditions. Exotic steel alloys such as Hastelloy and Duplex Stainless Steel ensure longevity and efficiency in these demanding environments.

Expert Insights

According to industry experts, the growing demand for high-performance materials is driving innovation in exotic steel alloys. Dr. Michael Carter, a materials engineer, states:

“Exotic steel alloys are no longer niche materials—they are becoming the standard in high-stress applications where reliability is non-negotiable.”

Frequently Asked Questions (FAQs)

1. What makes a steel alloy ‘exotic’?

Exotic steel alloys contain rare or specialized elements like nickel, chromium, molybdenum, and cobalt, giving them superior strength, corrosion resistance, and thermal stability.

2. How do exotic steel alloys compare to titanium?

While titanium is lightweight and corrosion-resistant, exotic steel alloys provide higher strength, better wear resistance, and often lower costs for certain applications.

3. Are exotic steel alloys cost-effective?

Though they may have a higher upfront cost, their long lifespan, reduced maintenance, and superior performance make them cost-effective in the long run.

4. Can exotic steel alloys be customized?

Yes! Many exotic steel alloys can be custom-engineered to meet specific industry requirements, offering tailored solutions for unique challenges.

Conclusion

With their unmatched strength, corrosion resistance, and adaptability, exotic steel alloys continue to shape high-performance industries. Whether in aerospace, medical, or industrial applications, these materials provide reliability where it matters most.

Looking for High-Quality Exotic Steel Alloys?

At Accromet, we specialize in premium exotic steel alloys for industries that demand excellence. Contact us today to discuss your requirements and find the perfect material for your needs!

📞 Call us at +1 800-543-4755 | 🌐 Visit: https://www.accromet.com/

0 notes

Text

Inconel Flanges Manufacturer in India

Rishabh Steel Industries is a trusted exporter of Inconel Flanges that we carefully package and ship to domestic and global markets only after a thorough, methodical assessment of our outgoing products is conducted to ensure maximum quality maintenance from our side.

A greater Chromium content in DIN 2.4816 Inconel slip on Flanges avoids any fissures at high temperatures, a virtue required in the ship building and steel Construction Industry. We are the leading, premium and largest Inconel Flanges Manufacturer in India with different materials, and finishes and specialize in mass producing quality products for companies involved in heavy equipment, energy, transportation, etc. A pint size of Molybdenum in DIN 2.4856 Inconel Weld Neck Flanges works wonders: it shields the fittings against possible crevice and pitting corrosion besides being impervious to oxidation and non-magnetic.

Inconel flanges are a type of pipe fitting used to connect piping or equipment sections requiring an opening to be sealed or closed. They are made from Inconel, a family of nickel-chromium-based alloys known for their high strength, excellent corrosion resistance & ability to withstand high temperatures and pressures.

Using Inconel flanges includes their high strength, excellent corrosion resistance & ability to withstand high temperatures and pressures. They are also highly resistant to oxidation and scaling at elevated temperatures, ideal for harsh, corrosive environments. Inconel flanges have excellent weldability and can be easily fabricated to meet specific requirements.

Inconel flanges are used in various high-temperature and high-pressure applications, including aerospace, chemical processing, power generation, oil and gas & marine industries. They are commonly used in harsh, corrosive environments where resistance to oxidation and scaling at elevated temperatures is essential. Inconel flanges are used in applications that require excellent weldability and good resistance to cracking and pitting.

Inconel Flanges Manufacturer in India are highly resistant to corrosion. Inconel is a family of nickel-chromium-based alloys known for their excellent corrosion resistance in harsh & corrosive environments, including those with high temperatures and pressures. Inconel flanges are also highly resistant to oxidation and scaling at elevated temperatures, making them ideal for applications where corrosion resistance is essential.

#inconelflangesmanufacturerinindia#inconelflanges#manufacturerinindia#rishabhsteelindustries#inconel#flanges#manufacturer#in#india

0 notes

Text

Aplikasi Inconel dan Hastelloy

Dalam dunia industri, memilih material yang tepat adalah langkah penting untuk memastikan keberhasilan proyek. Dua material paduan berbasis nikel yang sering dipertimbangkan adalah Inconel dan Hastelloy. Kedua material ini terkenal karena daya tahan mereka yang luar biasa terhadap kondisi ekstrem, tetapi masing-masing memiliki karakteristik unik yang membuatnya cocok untuk aplikasi tertentu. Artikel ini akan membahas secara mendalam tentang perbedaan, keunggulan, aplikasi, dan panduan memilih antara Inconel dan Hastelloy untuk proyek Anda.

________________________________________

Apa Itu Inconel dan Hastelloy?

Inconel: Paduan Tahan Suhu Tinggi

Inconel adalah paduan berbasis nikel-kromium yang dirancang untuk tetap stabil dalam suhu ekstrem. Material ini sangat tahan terhadap oksidasi dan korosi, menjadikannya pilihan utama di industri yang membutuhkan ketahanan panas.

Ciri-ciri Utama Inconel:

Ketahanan Suhu: Dapat bertahan hingga suhu lebih dari 1.000°C tanpa kehilangan kekuatan.

Tahan Oksidasi: Tidak mudah terdegradasi meski terus-menerus terkena suhu tinggi.

Kekuatan Mekanis Tinggi: Mempertahankan stabilitas struktural di bawah tekanan besar.

Namun, Inconel tidak terlalu optimal di lingkungan yang sangat korosif, terutama dibandingkan Hastelloy.

________________________________________

Hastelloy: Paduan Tahan Korosi Ekstrem

Hastelloy adalah paduan berbasis nikel dengan tambahan molibdenum, besi, dan elemen lain yang meningkatkan ketahanannya terhadap korosi. Material ini ideal untuk lingkungan yang sangat agresif secara kimia.

Ciri-ciri Utama Hastelloy:

Ketahanan Korosi: Mampu bertahan dalam paparan asam kuat seperti asam klorida dan asam sulfur.

Stabilitas Kimia: Tetap kokoh meski digunakan di lingkungan dengan bahan kimia agresif.

Durabilitas Tinggi: Tidak mudah rusak meski digunakan dalam jangka waktu lama.

Namun, Hastelloy biasanya tidak seefisien Inconel dalam menangani suhu ekstrem.

________________________________________

Perbedaan Utama Antara Inconel dan Hastelloy

Komposisi Material

Inconel: Berbasis nikel-kromium, fokus pada ketahanan panas dan oksidasi.

Hastelloy: Berbasis nikel-molibdenum, unggul dalam ketahanan terhadap korosi kimia.

Ketahanan Suhu

Inconel: Pilihan utama untuk aplikasi suhu tinggi.

Hastelloy: Cocok untuk suhu sedang di lingkungan kimia yang agresif.

Ketahanan Korosi

Inconel: Tahan terhadap oksidasi dan korosi umum.

Hastelloy: Luar biasa dalam menghadapi bahan kimia agresif.

Biaya

Hastelloy: Cenderung lebih mahal karena sifat anti-korosinya yang superior.

________________________________________

Aplikasi Inconel dan Hastelloy

Penggunaan Inconel

Karakteristik tahan panas Inconel membuatnya cocok untuk aplikasi yang membutuhkan stabilitas suhu tinggi, seperti:

Industri Dirgantara: Komponen mesin jet, turbin, dan bagian pesawat lainnya.

Industri Energi: Boiler dan turbin gas di pembangkit listrik.

Industri Kelautan: Struktur bawah laut yang terkena paparan air asin.

Penggunaan Hastelloy

Ketahanan Hastelloy terhadap bahan kimia agresif menjadikannya ideal untuk aplikasi berikut:

Industri Kimia: Reaktor, pipa, dan heat exchanger yang menangani asam kuat.

Minyak dan Gas: Sistem perpipaan untuk transportasi bahan bakar.

Farmasi: Peralatan pengolahan bahan kimia untuk pembuatan obat-obatan.

________________________________________

Cara Memilih Material yang Tepat

Pemilihan antara Inconel dan Hastelloy tergantung pada kebutuhan spesifik proyek Anda. Berikut beberapa tips untuk membantu Anda membuat keputusan:

Evaluasi Lingkungan Operasional

Pilih Inconel jika proyek Anda melibatkan suhu sangat tinggi.

Pilih Hastelloy jika Anda bekerja di lingkungan kimia yang sangat korosif.

Perhitungan Anggaran

Inconel lebih ekonomis dibandingkan Hastelloy, tetapi biaya tambahan Hastelloy sering terbayar dengan ketahanannya terhadap korosi.

Durasi Penggunaan

Jika proyek Anda membutuhkan material yang tahan lama terhadap lingkungan ekstrem, pertimbangkan sifat unik dari masing-masing paduan.

Aplikasi Khusus

Konsultasikan dengan ahli untuk memastikan pilihan Anda sesuai dengan kebutuhan teknis proyek Anda.

________________________________________

Tips Memilih Supplier Inconel dan Hastelloy

Memilih supplier yang tepat adalah langkah penting untuk memastikan kualitas material. Berikut beberapa hal yang perlu diperhatikan:

Reputasi Supplier

Cari tahu ulasan pelanggan sebelumnya untuk menilai pengalaman dan kualitas layanan.

Sertifikasi

Pastikan supplier memiliki sertifikasi industri seperti ISO 9001 untuk menjamin keandalan produk.

Stok dan Ketersediaan

Pilih supplier yang dapat menyediakan material sesuai kebutuhan Anda dalam waktu singkat.

Layanan Purna Jual

Pastikan supplier menawarkan dukungan teknis dan jaminan untuk produk yang Anda beli.

Harga Transparan

Bandingkan harga dari beberapa supplier untuk mendapatkan penawaran terbaik tanpa mengabaikan kualitas.

________________________________________

Kesimpulan

Memutuskan antara Inconel dan Hastelloy memerlukan pemahaman mendalam tentang kebutuhan spesifik proyek Anda. Jika Anda memprioritaskan ketahanan suhu tinggi, Inconel adalah pilihan yang tepat. Namun, jika lingkungan kerja Anda melibatkan bahan kimia agresif, Hastelloy adalah solusi terbaik.

Dengan mempertimbangkan karakteristik material, anggaran, dan aplikasi proyek, serta memilih supplier yang terpercaya, Anda dapat memastikan keberhasilan proyek Anda.

0 notes

Text

Inconel Prices, News, Trend, Graph, Chart, Forecast and Historical

Inconel, a high-performance alloy primarily composed of nickel and chromium, is a critical material in industries such as aerospace, automotive, marine, and energy. Its exceptional resistance to corrosion, oxidation, and extreme temperatures makes it indispensable for applications where reliability under harsh conditions is paramount. The market for Inconel is influenced by various factors, including demand from end-use industries, raw material availability, production costs, and global economic trends. Over recent years, fluctuations in Inconel prices have been shaped by these dynamics, as well as by geopolitical factors and technological advancements.

One of the primary drivers of Inconel prices is the cost of its raw materials, particularly nickel. Nickel is a key component of Inconel alloys, and its price volatility on the global market has a direct impact on the pricing of Inconel products. Nickel prices can fluctuate due to factors such as supply disruptions, changes in mining output, and shifts in demand from other industries like stainless steel production. Furthermore, geopolitical tensions in major nickel-producing regions can exacerbate supply chain challenges, influencing Inconel prices. Similarly, the price of chromium, another critical element in Inconel alloys, plays a role in determining the overall cost structure of these materials.

Get Real time Prices for Inconel: https://www.chemanalyst.com/Pricing-data/inconel-1365

The demand for Inconel is closely tied to the health of the industries that rely on its unique properties. For example, the aerospace industry, a major consumer of Inconel, heavily influences market dynamics. The ongoing push for fuel efficiency and lightweight materials in aviation has increased the demand for high-temperature-resistant alloys like Inconel. Any slowdown in aerospace manufacturing or global travel can dampen demand, exerting downward pressure on prices. Conversely, periods of strong growth in aerospace activity tend to drive prices higher as manufacturers ramp up their procurement of Inconel components.

The energy sector is another significant driver of Inconel demand, particularly in applications involving extreme environments such as gas turbines and oil and gas extraction. The global transition towards cleaner energy sources and the development of advanced energy systems have also spurred the need for materials like Inconel, which can withstand demanding operational conditions. Additionally, innovations in nuclear energy and hydrogen production are expected to further enhance the demand for Inconel alloys, potentially impacting prices over the long term.

Technological advancements in manufacturing processes and recycling capabilities are also influencing Inconel prices. Improved production techniques can lead to cost efficiencies, making Inconel more accessible to a broader range of applications. At the same time, the recycling of nickel-based alloys has emerged as a viable option to reduce dependency on primary raw materials. This recycling trend has the potential to stabilize Inconel prices by alleviating some of the pressure on raw material supply chains.

The regional distribution of production and consumption further adds complexity to the Inconel market. Major producers of Inconel alloys are concentrated in regions with advanced metallurgical capabilities, such as North America, Europe, and parts of Asia. However, the demand is global, driven by industries operating in both developed and developing economies. Emerging markets in Asia-Pacific, particularly China and India, are witnessing increased industrial activity, which is expected to bolster the demand for Inconel. This regional demand-supply interplay can create disparities in pricing across different markets.

The environmental impact of Inconel production is gaining attention, as sustainability becomes a growing concern across industries. The energy-intensive processes involved in producing nickel and chromium raise questions about the carbon footprint of Inconel alloys. As industries strive to meet stricter environmental regulations and adopt greener practices, the cost of compliance may influence Inconel pricing. Additionally, the development of alternative alloys and materials with comparable properties may introduce competition, potentially affecting market dynamics.

Market speculation and investor sentiment also play a role in influencing Inconel prices. The commodity nature of its key components, especially nickel, makes the Inconel market susceptible to price swings driven by speculative trading. This speculative activity can sometimes amplify the effects of underlying supply and demand factors, creating volatility in pricing.

In conclusion, the Inconel market is shaped by a complex interplay of raw material costs, industrial demand, technological innovations, and global economic trends. As industries continue to evolve and new applications for high-performance alloys emerge, the demand for Inconel is expected to remain robust. However, challenges such as raw material price volatility, geopolitical uncertainties, and environmental concerns will continue to influence pricing. Stakeholders in the Inconel market must navigate these factors strategically to ensure stability and capitalize on emerging opportunities. Maintaining a balance between supply chain resilience, sustainable practices, and technological advancements will be key to fostering growth in this vital market.

Get Real time Prices for Inconel: https://www.chemanalyst.com/Pricing-data/inconel-1365

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Inconel#Inconel Price#Inconel Prices#Inconel Pricing#Inconel News#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

1 note

·

View note

Text

AD-RACINGWORLD MOTORSPORT® est une entreprise dédiée à la personnalisation de voitures de sport, qu'elles soient modernes ou classiques, notre domaine de spécialisation concerne les systèmes d'échappement en Inconel F1 et les accessoires en carbone pour des marques prestigieuses telles que : BUGATTI, FERRARI, LAMBORGHINI, MASERATI, McLAREN, PORSCHE

Depuis 2004, nous sommes distributeurs des échappements KLINE, des échappements NOVITEC ainsi que des échappements IPE, CAPRISTO et TUBISTYLE, notre sélection de ces marques renommées témoigne de notre engagement envers l'excellence et la performance pour les automobiles de luxe

Améliorez les performances de votre véhicule d'exception en lui apportant une puissance supérieure, un son élégant et une fiabilité inégalée, tout en garantissant une qualité de premier ordre

PRÉPARATEUR AUTOMOBILE : Expert en accessoires pour véhicules de sport de grandes marques, notamment des modèles italiens, allemands et britanniques, nous proposons des lignes d'échappement en Inconel Kline-Innovation, des kits de télécommande des valves d'échappement Capristo, ainsi que des pièces en carbone et des silencieux d'échappement Novitec

Une gamme d'échappements sport de qualité supérieure, faisant l’objet de la confiance de nombreux clients en France et dans le monde depuis plusieurs années. Situés à proximité de Lyon, à 450 km de Paris ou de Nice et à 150 km de Genève, en Suisse, nous offrons des services de livraison en France, en Corse, à Genève, ainsi qu'en Belgique, en Suisse, Monaco, Andorre, Luxembourg, Espagne et Portugal, en partenariat avec des spécialistes pour l'installation

►Contact : [email protected]

►Boutique : https://www.ad-racingworld.com/fr/

#ferrari#lamborghini#bugatti#mclaren#porsche#audi#bmw#mercedesamg#nissangtr#klineinnovation#echappementkline#exhaustkline#klineexhaust#inconel#adracingworld#france#suisse#belgique#espagne#portugal#hollande#italie#allemagne#voituredesport#voituredeluxe#echappement#exhaust#luxe#luxury

2 notes

·

View notes

Text

-👑

0 notes

Text

Nickel 201 vs. Other Alloys: What Sets It Apart in Forged Fittings

In industries where durability, reliability, and resistance to extreme conditions are most important forged fittings play a critical role. Among the all materials available for manufacturing these essential components, Nickel 201 stands out as a superior choice. But what makes Nickel 201 unique compared to other alloys commonly used for forged fittings? In this blog, we’ll dive into its properties, advantages, and why it’s often the preferred material in demanding applications.

Comparing Nickel 201 with Other Alloys

1. Nickel 201 vs. Stainless Steel

Corrosion Resistance: While stainless steel is a popular choice for forged fittings, it can struggle in environments with high levels of halides, such as chlorides. Nickel 201 offers exceptional resistance to a wide range of corrosive chemicals, including strong acids and alkalis, making it ideal for chemical processing plants.

Thermal Stability: Nickel 201 outperforms stainless steel in high-temperature environments. Its resistance to oxidation and thermal cracking makes it the go-to material for applications requiring prolonged exposure to extreme heat.

2. Nickel 201 vs. Inconel (Nickel-Chromium Alloys)

Chemical Purity: Inconel alloys, while robust, are designed for specific high-stress environments like jet engines or nuclear reactors. Nickel 201, on the other hand, offers the advantage of higher chemical purity, making it more suitable for processes requiring inert and contamination-free materials.

Cost-Effectiveness: Nickel 201 is often more cost-effective than Inconel for applications where pure nickel properties are sufficient, such as in caustic soda production or food-grade equipment.

3. Nickel 201 vs. Brass and Copper Alloys

Durability: While brass and copper alloys are known for their conductivity, they lack the mechanical strength and durability of Nickel 201. In industrial settings with high mechanical stress, Nickel 201 forged fittings excel due to their superior tensile strength.

Corrosion in Alkaline Environments: Brass and copper alloys are prone to dezincification and corrosion in alkaline conditions. Nickel 201’s exceptional resistance to strong alkalis ensures a longer lifespan in such applications.

4. Nickel 201 vs. Titanium Alloys

Chemical Compatibility: Titanium alloys are lightweight and highly corrosion-resistant but can be cost-prohibitive. In cases where extreme lightweight properties are not necessary, Nickel 201 provides an equally corrosion-resistant but more economical solution, especially in highly acidic or caustic environments.

Ease of Fabrication: Nickel 201 is easier to forge and weld compared to titanium, reducing manufacturing complexity and costs for custom fittings.

Conclusion

Nickel 201 forged fittings are a testament to how advanced materials engineering can solve industrial challenges. When compared to other alloys, its combination of durability, thermal stability, and chemical resistance makes it an unmatched choice for applications requiring reliable and long-lasting performance.

If your project demands materials that can withstand the toughest conditions, Nickel 201 should undoubtedly be at the top of your list.

0 notes

Text

Monel 400: A Comprehensive Guide

Introduction to Monel 400

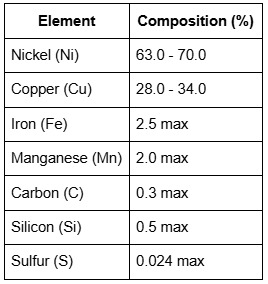

Monel 400 is a durable nickel-copper alloy recognized for its outstanding corrosion resistance and superior strength. It is widely used in marine, chemical, and aerospace industries due to its outstanding properties. The alloy is composed primarily of nickel (around 67%) and copper (about 23%), with trace amounts of iron, manganese, carbon, and silicon. This unique composition gives Monel 400 superior resistance to harsh environments, making it a preferred choice for various applications.

Chemical Composition of Monel 400

The high nickel and copper content makes Monel 400 an excellent choice for extreme environments where high resistance to acids, alkalis, and seawater is required.

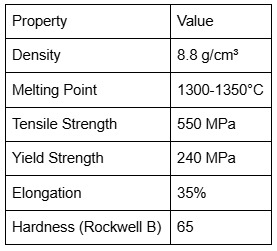

Mechanical Properties of Monel 400

These mechanical properties indicate that Monel 400 offers excellent strength and ductility, making it suitable for both high-temperature and cryogenic applications.

Key Characteristics of Monel 400

Corrosion Resistance: Excellent resistance to seawater, hydrofluoric acid, sulfuric acid, and alkaline solutions.

High Strength: Retains strength across a broad temperature range.

Good Ductility: Can be easily fabricated, machined, and welded.

Thermal Stability: Performs well under extreme temperatures.

Magnetic Properties: Slightly magnetic at room temperature.

Applications of Monel 400

Due to its superior properties, Monel 400 is extensively used in:

1. Marine Industry

Shipbuilding

Submarine parts

Heat exchangers

Seawater piping

2. Aerospace Industry

Aircraft fuel tanks

Engine components

Hydraulic lines

3. Chemical Processing Industry

Pumps and valves

Heat exchangers

Chemical storage tanks

4. Oil and Gas Industry

Offshore drilling components

Pipeline systems

Valves and pumps

5. Power Generation

Nuclear and fossil fuel power plants

Boiler feedwater heaters

Advantages of Monel 400

Exceptional corrosion resistance in harsh environments

High tensile strength and durability

Good machinability and weldability

Superior resistance to high-temperature oxidation

Long lifespan and reliability

Disadvantages of Monel 400

Expensive compared to other alloys

Challenging to machine due to high strength and work-hardening nature

Limited availability in some forms and sizes

Monel 400 vs. Other Alloys

Monel 400 vs. Stainless Steel

Monel 400 has superior corrosion resistance in marine and acidic environments.

Stainless steel is generally more affordable and readily accessible.

Monel 400 exhibits better performance in high-temperature applications.

Monel 400 vs. Inconel

Inconel offers better oxidation resistance at extreme temperatures.

Monel 400 is better suited for seawater and acidic conditions.

Inconel is used for aerospace applications due to its high-temperature performance.

Conclusion

Monel 400 is a premium nickel-copper alloy with remarkable corrosion resistance, high strength, and excellent durability. Its widespread use in marine, chemical, and aerospace industries is a testament to its outstanding properties. While it may be more expensive and challenging to machine than other materials, its long-term performance and reliability make it a valuable choice for demanding applications.

Frequently Asked Questions (FAQ)

1. What makes Monel 400 corrosion-resistant?

Monel 400's high nickel and copper content provide exceptional resistance to seawater, acids, and alkaline solutions.

2. Can Monel 400 be welded?

Yes, Monel 400 can be welded using gas tungsten arc welding (GTAW), shielded metal arc welding (SMAW), and gas metal arc welding (GMAW) methods.

3. Is Monel 400 magnetic?

Monel 400 is slightly magnetic at room temperature due to its nickel content.

4. What is the temperature range of Monel 400?

Monel 400 can operate in temperatures ranging from cryogenic levels up to approximately 1000°F (538°C).

5. Is Monel 400 suitable for seawater applications?

Yes, Monel 400 is widely used in marine environments due to its excellent resistance to seawater corrosion.

#ananka#anankafasteners#monel#monelfasteners#articles#blog#monel400#monel500#inconel#inconelfasteners#inconelbolts#manufacturer#fasteners#supplier#mumbai#bolt#tumblr#blog tumblr

0 notes

Text

Elevate Your Projects with High-Quality Inconel 600

Inconel 600 is a nickel-chromium alloy known for its exceptional resistance to oxidation and corrosion, making it ideal for high-temperature applications. This versatile material is widely used in industries such as aerospace, chemical processing, and power generation, where durability and reliability are crucial.

At Steelco Metal, we offer high-quality Inconel 600 products that meet stringent industry standards, ensuring performance and longevity. Our Inconel 600 is designed to withstand extreme environments while maintaining structural integrity. Whether you need it for heat exchangers, reactors, or other critical applications, we've got you covered.

Explore our range of Inconel 600 products and find the perfect solution for your needs at Steelco Metal.

0 notes