Photo

A letter that requires a certain “suspension” of disbelief (not in the sense of “that didn’t happen”, more in a “I can’t believe I just read that entire story,” sort of way)

#Daily Mail#Cambridge#Suspension#Chaos#Really David?#Chaos?#Really?#Engineering#Astronauts#Hydrolastic Suspension#My landlady#MG1100#Dr Moulton#I won’t call him Alex#He didn’t go to Suspension School for all those years to be called Alex#Chequebook#Scholastic calm

5 notes

·

View notes

Photo

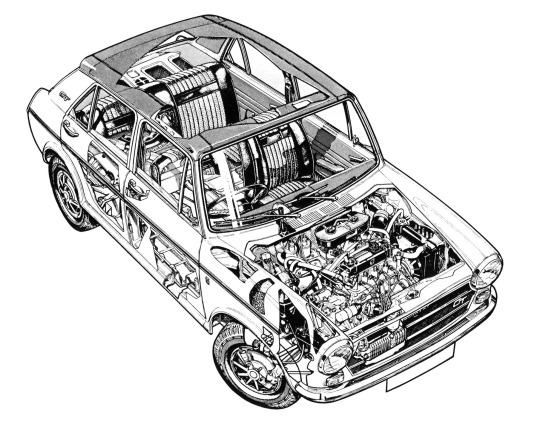

BMC ADO16, 1963-1974. The ADO16 (Amalgamated Drawing Office project no. 16) was engineered by Alec Issigonis. Following up his success with the Mini, BMC needed a larger and more sophisticated car using the same transverse engine, front wheel drive configuration but appealing to a broader market. Pininfarina was commissioned to design the car. They also featured a Hydrolastic interconnected fluid suspension system designed by Alex Moulton. They were sold under multiple brands and in 3 configurations, 2 & 4 door saloons and 3 door estate. From the top: Morris 1100, Austin 1100/1300/1300GT, Austin 1300 Countryman, MG 1300, Wolseley 1300, Riley Kestrel, Vanden Plas Princess 1300, Morris 1500 Nomad (bottom pic). The Austin/Morris versions were the UK’s best selling cars from 1963-1971 (except in 1967). The vast majority were powered by BMC’s A-series OHV engine in 1.1 and 1.3 litre versions. They were built and sold internationally including the US (marketed as the Austin America). For the Australian market (where they were manufactured) a 1500cc version using BMC’s OHC E-series engine was developed and in 1969 the Nomad 1500 5 door hatchback was introduced. The ADO16 is significant because it popularised the concept of a transverse engine driving the front wheels as a way of liberating more interior space within a compact overall package. BMC became BLMC and then British Leyland but they completely failed to capitalise on the success of the ADO16, replacing the Morris version with the rear wheel drive Marina and the Austin with the weirdly designed Allegro

#BMC#BMC ADO16#Morris 1100#Austin 1300#MG 1300#Riley Kestrel#Wolseley 1300#Vanden Plas Princess 1300#Morris 1500 Nomad#front wheel drive#transverse engine#Pininfarina#Alec Issigonis#badge engineering#auto history#dead brands#Austin America

132 notes

·

View notes

Text

This Is The Only MG EX234 Prototype Roadster Ever Made

This Is The Only MG EX234 Prototype Roadster Ever Made

This is the original MG EX234 prototype roadster – the car that had been designed to replace both the MGB and the MG Midget. Just a single example of the EX234 was built, it’s now an interesting historic “what if.” The EX234 was an advanced design for the mid-1960s, it has four-wheel independent Hydrolastic suspension, four-wheel disc brakes, rack and pinion steering, and according to period test…

View On WordPress

0 notes

Photo

2012 Alex Moulton folding bike #hydrolastic and full rubber cone suspension F-frame design. Founded in 1962 in England #MoultonBicycles continues production of these iconic bicycles today. Sell your bicycles & parts on the Sprocket app. Link in bio www.sprocket.bike/app #moulton #alexmoulton #alexmoultonbike #rubberconesuspension (at The Cow Palace.) https://www.instagram.com/p/Caf7Ab8vsfc/?utm_medium=tumblr

0 notes

Photo

The #ADO16 cars became famous for the rather cynical badge engineering that had the same basic car on sale as an #Austin, Morris, MG, Riley, Wolseley, and a Vanden Plas (to say nothing of Authi, Innocenti, and other global versions), but they were good cars and hugely successful. The technologically sophisticated ADO16s were the best selling cars in the U.K. for all but one year from 1963-1971, losing out to the Ford Cortina in 1967, probably because of serious strikes in late 1966. - ADO16 (the car’s development code) was basically an enlarged version of the Mini, both coming from the mind of Alec Issigonis, which meant a transverse A-series engine driving the front wheels with the ‘box in the sump. This saved lots of room - the smallish 1100/1300 was as roomy as the much larger Cortina. The suspension was Alex Moulton’s #Hydrolastic fluid system which gave sharp handling and a supple ride (but proved very alien to many stateside mechanics). Overall, the ADO16 was way ahead of the curve. Aside from the gearbox, the circa-1962 car was not so different from later competitors like the Simca 1100 and Fiat 128. - The U.S. (barely) remembers this car best as the #AustinAmerica, sold here from 1968-72, but in actuality it first came over as an MG - the MG “sports sedan” for 1963, sold primarily as a 2-door. But the MG 1100/1300 was never a strong seller and BMC dealers wanted a VW Beetle fighter. In 1967, they got the same car as an Austin while a new dedicated North American version was prepared - the 1968 America. - The America was a 2-door only version of the MkII ADO16 Austin 1300 with a number of changes for federalization - lights and safety/emissions equipment. Power came from the 1,275-cc A-series in smogged form with 60hp. An optional Automatic gave North American dealers something VW didn’t have. Strangely, the America was also sold in Switzerland. The America sold better than the MG, but not by much, and BMC/BL supposedly lost money on every unit. A surprisingly high number of them survive, but usually in states of disrepair or as parts cars due to rust. This one was sold new by Castle Ford, a Herkimer, New York, dealer that briefly dabbled in imports. https://www.instagram.com/p/BtWU1e6Aj8c/?utm_source=ig_tumblr_share&igshid=1a328rtaztwvs

0 notes

Photo

Moulton Bicycle Company

"The Moulton Bicycle is a unique, full-suspension, small wheeled, performance bicycle, designed and built for speed, efficiency, durability and comfort. Expertly engineered and hand crafted since 1962 in Bradford-on-Avon, Somerset."

Moultons are often misunderstood as folding cycles which they are not. They have small wheels to further add rigidity to the already stiff frame rather than to allow for compact folding, although they *are* separable for transportation and stowage. The comfort is designed back in through hydrolastic suspension, a throw back to Moulton’s heritage in the automotive industry providing similar suspension for the BMC Mini and others.

Moulton’s workshops are in the grounds of The Hall, an imposing Grade I listed building built in 1620 and, for over 100 years, was the site of a major rubber vulcanising plant employing 600 people. The Hall passed to Alex Moulton and the rubber company to Avon. Alex set up Moulton Developments and invented Hydrolastic Car Suspension and subsequently the Moulton Bicycle, transferring much of his automotive suspension knowledge to the bike; the combination of rigid frame, high pressure tyres and suspension goes to make a bike that is lighter, stronger, faster and more comfortable than many other bikes.

On my tour of the workshops, I was struck by the intensity of the labour required to hand craft the Moulton frame. Consequently the bikes are not the cheapest on the market but they will last for decades, retaining their good looks, condition and much of their value.

Today, Moultons are still produced in large numbers, 80% of which are exported, Japan being a major market. The bike range is extensive and caters for many kinds of cycling and cyclist and aims to give value for money and pleasure of ownership. British light engineering at its best.

#365project#handmadeintheuk#handbuilt#cycling#touringbike#roadbike#cyclestyle#cycleculture#cyclelife

1 note

·

View note

Text

1967 Austin Cooper Mk I Mini - $16,495.00

This MK I mini is receiving a rebuilt 1275 engine and a rebuilt rod change gearbox. It has a clean title and low miles. The current owners are unsure of what exactly this Mk I is as there is no VIN to decode, just titled of the body tag. By decoding these tags, they have determined it is in fact a Cooper. It is fitted with an original looking 130mph speedometer and fitted with hydrolastic suspension. The outside is finished in an iris blue and white roof. The current owners almost want to claim the paint as original as it has some modest fading on the boot and looking at the hinges, some rust has shown through without any primer or filler. The body has some areas with rust poking through, but for the cars age, it is not abnormal. Replacement of the hinges and some panels can refresh everything. The glass is all intact without issues. The wheels are a chrome minilite style with newer Falken FK-07E tires. The interior is a little mixed up. The dash is utilizing an ash-wood bezel and is fitted with a red motolita racing wheel. The rear seat appears to be a later type basic seat, with the fronts being older cloth cobras. The fabric does have some tears in it. The cream colored door cards and headliner are in great shape. Under the bonnet will be one of two things, if you opt for the roller, it will have nothing! If you would like the owners to fit their fully rebuilt power unit, this mini will be powered by a 1275 Pre A-Plus engine, utilizing a twin HS2 set up just as a Cooper would have. Coupled that to an A-Plus Rod Change gearbox, and you have one good powerplant! It will be painted MOWOG green and made to look relatively standard, unless requested differently ahead of time. They can also build the engine to your standards before it is installed. Please Note The Following **Vehicle Location is at our clients home and Not In Cadillac, Michigan. **We do have a showroom with about 25 cars that is by appointment only from Cardaddy.com https://www.cardaddy.com/vehicles/vehicle/1967-austin-cooper-mk-i-mini-cadillac-michigan-19959376

0 notes

Photo

MG 1100, 1962. The MG version of the ADO16 used a twin carburettor version of the BMC A-series engine that produced 55hp. It was available with 2 or 4 doors and was remarkably advanced for its time with hydrolastic suspension, a transverse engine and front wheel drive. From 1967 it was upgraded to a 70hp 1275cc version of the A-series engine. It was discontinued in 1971 after 116,827 had been built

#MG#MG 1100#BMC ADO 16#transverse engine#front wheel drive#1962#badge engineering#twin carb#1960s#safety fast

115 notes

·

View notes

Text

The Incredible Story Of The Africar – The Wooden-Bodied Car For Africa

The story of the Africar is worthy of a Hollywood film, it involves millions of dollars, a Cambridge-educated engineering genius, a film crew, a global adventure, a wildly unusual automobile, and ultimately, a controversial prison sentence.

Tony Howarth, and A Dream of a Car for Africa

The Africar was the vision of Englishman Tony Howarth. Howarth’s vision was for an inexpensive yet adaptable vehicle, able to negotiate the tracks that form most of Africa’s road networks, able to be fixed and maintained by people with only moderate skills and training, easy to drive, and that would last at least thirty years or more. In short, the Africar was to be exactly what the established automotive industry would not be likely to create.

There are a few easily understandable strategies that the automotive industry use to keep their factories profitable and key among these is the idea of planned obsolescence. A modern motor car is made with an intentionally short life expectancy. In order to ensure that a vehicle will not last for thirty years or more vehicles are made from materials that will rot or rust: Australians used to joke that the Australian Holden was “the only car in the world that came rust free, they gave you the rust for nothing”.

Despite the fact that rustproofing of Holdens and various other brands is nowadays vastly better than it was yet the cars are fitted with electronics that ensure they are not owner fixable and therefore by definition totally unsuited to third world countries, especially the wild places of the African continent where if something fails you can’t just call up a mobile mechanic to come and fix it.

youtube

Another strategy to ensure planned obsolescence is providing a plethora of models and constantly “updating” those models, thus ensuring that finding spare parts for a car will become increasingly difficult and then impossible because it has become “obsolete”. None of us need lots of different models to choose from, and neither the people in Africa, nor anywhere else in the world want to invest money in a vehicle only to have it become obsolete or unusable before we’ve managed to pay out the loan we took out to buy it.

Cars don’t have to be made so they have a short life expectancy and one of the good examples of this are the Toyota Crown Comfort taxis used in Hong Kong and Japan. I lived in Hong Kong for over twenty years and when I first went there they were mostly using Toyota Crown Comfort cars for taxis, many of them old looking when I got there. Two decades later the most common Hong Kong taxi was still the Toyota Crown Comfort, some of them new, many of them the old cars with their tell-tale tropical roof looking like they still had another twenty years of service left in them. So the world’s auto makers can make cars that will last if they choose to.

Tony Howarth understood what was needed for a vehicle that would be uncomplicated, easy to build, easy to fix, and perfectly suited to the rough tracks that are the roads of much of the third world.

This was in part because he had taken an engineering degree at Cambridge University, having before that been engaged in such activities as building his own fuel injection system for his motorcycle back when he’d been a sweet young lad of ten. But the more important thing that equipped him to truly understand what was needed in a car for Africa was his passion for filmmaking and photography: something that had taken him driving through and sometimes living in 130 countries, traveling on all sorts of roads and tracks, and in all weather conditions.

The Africar Concept

Tony Howarth had great respect for Henry Ford and his Model T. It had been designed and built for an America which back at that time had a road system much like that found in Africa in modern times. The roads were dirt tracks which got washed out and rutted when it rained, and the Model T was created to negotiate them. Not only that but the Model T was made to be easy to drive for someone who’d never driven a car before, it was owner fixable, and they were built to last for decades, as evidenced by the sheer number that still survive and have been restored into running order.

In a sense Tony Howarth had something like the Model T in mind when he put together the concept that was to become the Africar. It was to be two wheel drive to avoid the expense and complication of four wheel drive (although four wheel drive versions were also planned), it was to be built around an extruded frame made using a CNC tube bender. The suspension, engine and transmission would then be attached to that tube frame. Howarth’s material of choice was stainless steel so that the vehicle would be truly “rust free”. That stainless steel would be sand-blasted so it did not need painting or powder coating.

The body panels for the Africar could be made from a variety of materials and it is most likely that sheet aluminium, stainless steel or some sort of plastic would have been chosen, but resin impregnated plywood would also be usable.

The Channel 4 Documentary

Tony Howarth had long been passionate about filmmaking, with photography secondary to that. He had attempted to break into film, to no avail, but he got the opportunity to go to Africa with a group of students and when he returned Life magazine featured six pages of his photographs. However, once he’d gotten started on the Africar project he was not initially willing when Channel 4 expressed an interest in his Africar with a view to including it in a series to be called “The Car Designers”. For the Channel 4 film they were interested in the lightweight angle of doing something about a guy who was “messing about building a funny car”.

Despite understanding that the Channel 4 film would provide a great vehicle for publicizing the Africar and thereby potentially attracting significant investment Tony remained reluctant to do the film.

Although he had the concept for the Africar pretty well established in his mind at that point it still had a long way to go. The tipping point was an article written by a journalist friend about the Africar and published in the “African Business”. Prior to that the Africar had been kept quite secret, but with the idea out in the open Tony decided he would agree to do the film and see what interest it might garner.

The Channel 4 film needed an interesting plot and what could be better than a “Boys Own Adventure” driving a convoy of Africars from the Arctic Circle down to the Equator in Africa. It was something like a “Top Gear” adventure but with different personalities.

Channel 4 would not provide a crew support vehicle so Tony Howarth finished up building no less than three Africars for the journey. These comprised a six wheel and a four wheel station wagon, and a pick-up. Also along for the journey was a Series III Land Rover which would spend much of the journey being pulled out of difficult situations by one of the Africars.

The Africar vehicles made for the Channel 4 film expedition were not made using the methods Tony Howarth intended for production vehicles. Instead they were made using Tony’s expertise in boat building, both chassis and body being made of resin impregnated marine plywood. This led to people thinking that the Africar was to be a wooden car, which it was not.

The three vehicles for the Channel 4 expedition were built using Citroën GS engines mated to a Citroën 2CV manual gearbox and driving the front wheels. The GS engine was an air cooled horizontally opposed four cylinder similar to the Volkswagen boxer engine. Given the time when the expedition cars were built it is probable that the 1,222 cc 60hp version was used to benefit from the improved torque of that engine.

The use of front wheel drive was chosen so that the Africar could pull itself out of a boggy situation whereas a rear wheel drive would tend to dig in. The Africar was designed so that four wheel drive could be fitted as an option.

The use of a horizontally opposed air cooled engine was in part preferred because the vehicle was designed with a very high ground clearance, and so for the sake of stability needed the heavy components such as the engine to have as low a centre of gravity as possible.

The suspension has been likened to the British Leyland “Hydrolastic” type as fitted to the Austin/Morris 1800 and similar cars but it was in fact somewhat different. The suspension comprised leading links at the front and trailing links at the rear. This allowed for very long movement of the wheels without changes to the camber. These leading and trailing links were supported by nitrogen gas spheres with damping provided by lightweight Hydrogas units: in all a simple and easy to maintain system ideal for very rough tracks.

The Channel 4 Expedition began in Norway at the Arctic Circle and the little Africars wound their way south, efficiently traversing sand, mud and all sorts of rough tracks rather more efficiently than the Series III Land Rover with its live axles and leaf springs.

This being in large part because of the Africar’s fully independent long wheel travel suspension and very high ground clearance. The team came close to getting shot or imprisoned in Zaire because they were carrying two-way radios which were forbidden there. But mercifully things were worked out and they were able to proceed to their destination and complete their documentary series after four months on the “road”.

Africar International Limited

After having completed the Channel 4 expedition Tony Howarth founded Africar International Limited (AIL) in Lancaster, England. A public event was put on and investors invited. At that inaugural event an Africar prototype was on display but roped off so that people could not actually touch it let alone climb in and try out the driving position. The prototype was only a show car model without engine, the doors were glued shut, and at the time of the inaugural event the smell of fresh paint permeated the air because the bright orange paint was still wet.

Investment trickled in, but was nowhere near what was needed to move into actual production. It was at this time that Tony Howarth made the mistake that would prove to be the kiss of death for the Africar.

Had he continued to use the Citroën engines and transmissions and begun small scale manufacture of the Africar he may have been able to keep sufficient income coming in and obtained the more significant investment needed for larger scale manufacture. Tony however understood that being dependent on Citroën for engines and transmissions was risky because those engines and transmissions would be made obsolete and he would be faced with jumping onto the planned obsolescence bandwagon.

So he invested the investor’s money into development of an engine for the Africar. There was however too little to see this to completion, and in the meantime investors who had imagined that their invested money would result in them taking delivery of an Africar were disappointed. One frustrated customer quietly went to the factory and drove away an Africar without permission, so he got “delivery” of his car.

Financial and Legal Troubles

Tony Howarth, no doubt very aware of the corner he was painted into, sought to raise the money needed for the survival of the Africar project by turning Africar International Limited into a public limited company. His accountants however refused to value the license to manufacture the Africar at £8 million which torpedoed that hope. Customers who had made down payments were promised delivery of their Africar in two months if they paid the balance owing.

The Commerce Branch of the Lancashire Constabulary intervened in July 1988 and the company ceased trading. The factory premises were returned to the owner and the police seized all company documents.

Tony Howarth was in the United States at that time trying to raise the money needed to save the company. But by 1994 he understood that it was a lost cause and so he returned to Britain where he was arrested and, as he recalls, pressured to sign a confession by the Serious Fraud Office. He maintains that the confession was not a reflection of the truth and so he believes he was effectively pressured into perjuring himself, but that he had no other choice. He finished up receiving fifteen months free board and lodging “at Her Majesty’s pleasure” and said that it was rather like being at a British boarding school.

Epilogue

For Tony Howarth the Africar is sadly dead, and the dream of a car for Africa dead with it. Nowadays he is still achieving things he values including work on his yacht: boat-building has long been one of his passions. But though Tony Howarth is no longer involved others have been inspired by his quest to create a car for Africa and they are embarked on turning the vision into a reality. The Mobius of Kenya is one example.

We hope that the car for Africa turns out to be one with great longevity, great practicality, and is also made available at an affordable price. It needs to be a car that not only provides reliable and affordable transport, but it needs to be a car that spawns an industry, manned by people who develop the skills and knowledge to support their industry, and to help African nations to become manufacturing centres in their own right. What is needed is an African Industrial Revolution that propels her nations from the Third World into the First World with all the benefits in income, health and enjoyment of life that provides.

Tony Howarth’s contribution was to conceive the vision and blaze the trail. Happily others are now picking up that vision to see it through to fulfillment.

Picture Credits: Tony Howarth and Africar International Limited

The post The Incredible Story Of The Africar – The Wooden-Bodied Car For Africa appeared first on Silodrome.

source https://silodrome.com/history-africar/

0 notes

Photo

2012 Alex Moulton folding bike #hydrolastic and full rubber cone suspension F-frame design. Founded in 1962 in England #MoultonBicycles continues production of these iconic bicycles today. Get Sprocket, the bike info app on GooglePlay and App Store #alexmoulton #alexmoultonbike #foldingbicycle #bicycle (at Cow Palace)

1 note

·

View note

Text

How To Get The Best From A Garage Service Center

Making sure the job is done well - at the right price.

The motorist choosing a garage to service and repair his car looks for prompt attention, good workmanship and a reasonable price. If he is wise, he will also foresee that disputes can occasionally arise, so that a garage which belongs to a scheme for settling disputes is better than one which does not.

How does a motorist find out whether a garage does a good job for a fair price? Obviously the recommendations of friends are valuable, especially if they have been going to the garage for some time.

But not all garages are equally suited to deal with each type of car. The complexity of modern motor vehicles makes it essential that major repairs should be carried out with specialized tools and equipment, by trained mechanics experienced in dealing with your make of car. In practice, this means using a garage which is the manufacturer's authorized franchise-holder.

These garages are the specialists. They should have a comprehensive stock of essential spare parts and a staff of mechanics with the relevant experience. In addition, they will be kept informed by bulletins from the manufacturer about modifications and defects affecting the models they sell and service.

Motoring organizations experienced in dealing with complaints about garages have found that the greatest single cause of dispute is repair work carried out by garages which are not the appropriate franchise-holders (for instance, the replacement of the clutch or the hydrolastic suspension unit of a BMC Mini by a garage which is not a BMC franchise-holder).

Garages and their facilities vary considerably - from the normal petrol station type, mainly interested in selling petrol, oil and possibly a few accessories, to the larger garage which deals with insurance, car hire, new and used car sales and major body repairs. It is unreasonable to expect the same type of service from both these types of garage.

A detailed guide to the size, facilities and equipment of garages is provided by the spanner gradings of the Automobile Association's Garage Plan. Under this scheme, garages are allowed to display a one, two or three-spanner sign, according to the range of services they are equipped to provide to the public.

A garage displaying any one of the spanner signs has been inspected and found to be well equipped and staffed by trained mechanics.

A good way of ensuring reliable service is to become a regular customer. The motorist who goes to a garage for petrol, spares and routine work is valued - someone who is more likely to get extra assistance when he is in difficulties.

What will it cost?

Garage charges for repair work are made up of two elements: the retail cost of any parts supplied, and the cost of labour, charged at an hourly rate.

Labour charges vary from one part of the country to another, but there is usually little or no difference between rates charged by franchise and non-franchise garages in the same area, or by garages with one, two or three-spanner gradings.

Experience shows that most customers ideas of what a repair will cost are wide of the mark. To avoid unpleasant surprises, always ask for an estimate before authonsing garage to go ahead. If the price quoted is quite high, ask to have the quote in writing.

The garage may say that it is not possible to give a reliable estimate without first dismantling parts and investigating the cause of the trouble.

In this case it should give an estimate of the cost of this exploratory work, and a second estimate of what the repair itself is likely to cost.

If either estimate appears to be unreasonably high, there may be another franchise-holder nearby whom you can ask to estimate for the same job. But beware of giving the job to a non-franchise garage, even if it quotes a substantially lower price. This could easily turn out to be a false economy.

If the work is eventually done by a second garage, expect to pay a fair charge, be to the first garage for investigating the cause of a breakdown. i.e., An estimate which appears to be too high can also be checked with your motoring organisation. If a repair is going to be too costly and you are unsure whether you can afford it, ask for an estimate giving the upper and lower limits of the cost.

Many disputes over bills are caused by the variation between estimates and bills. Usually this variation arises because the garage has found additional repair work urgently needing attention, and has gone ahead without consulting the car owner.

A good garage will not proceed with these extra jobs without authority. But to be on the safe side, the motorist can set a cash limit on repairs when leaving the car, and ask the garage manager to get in touch with him before this limit is exceeded. He should also give a telephone number where he can be reached during the day. He will then be liable to pay only for the work he has authorised.

Article Source: http://EzineArticles.com/7605740

0 notes

Text

My father used to change cars as often as he changed his undies, or so it seemed.

He was always bringing home his latest find, having off-loaded the previous one at some tiny car yard somewhere.

Standouts included a Fiat 500 Bambino, Morris Woody wagon, Mini panel van, VW Microbus with the hinged side doors, and an EH Holden wagon with mags — the list goes on. I guess that’s where my interest in cars stems from?

Going right back to the beginning, however, readers might remember our story about Kev’s first ever car — you guessed it — a Riley sports car.

The woman pictured with my father in that photo spotted it 60 odd years after it was taken in a newspaper in Queensland, back when I worked for newspapers.

One of the many treasures my father brought home for the “family” in our years together as a family was the ubiquitous Austin 1800.

Known affectionately as the “Landcrab”, the 1800 was hailed the ‘‘Car of the Century’’ on its release in 1964.

Released here just over a year later in November 1965, it was famous among other things for its flat, wide-bodied stance and cavernous interior, with bench seats that accommodated up to six people.

Designed by Alec lssigonis (the bloke who penned the Mini), the Austin 1800 followed the basic design concepts pioneered by the Mini and 1100 models (we had both of those cars too).

It had a transversely-mounted engine and transmission, front-wheel drive and ‘Hydrolastic’ suspension with ‘‘a wheel at each corner’’.

Like many of the models from the company from the time — it floats on fluid — with a teardrop transfer (that’s what they used to call them) on the rear window attesting to the fact.

The system replaced the springs and dampers of a conventional suspension.

The 1800 was a new car from the British Motor Corporation (BMC) and did not replace any model in the existing Austin range.

The water-cooled, overhead-valve, four-cylinder engine produced 63kW of power at 5300rpm and maximum torque of 134Nm of torque at 2100rpm.

With four on the floor, the 1800 was able to reach a top speed of 145km/h and could accelerate from 0-80km/h in 11 seconds.

Under favourable conditions, petrol consumption was rated at about 9.4L/100km.

The 1800 was a medium-sized family car that offered silent, high-speed cruising, unsurpassed road holding and cornering, excellent luggage space, and built-in safety and longevity from what was then probably the strongest body shell ever planned for quantity production.

Three-point seatbelts were fitted as standard for the driver and front passenger, with seatbelt mounting points at the rear.

The disc/drum brakes were power assisted with a ‘‘G-conscious’’ valve to prevent rear-wheel locking.

Radial ply tyres were fitted for better safety, performance and longer tyre life.

The east-west engine meant more interior room in a car that is only 4.17m long, with 70 per cent of the overall length devoted to passenger or luggage space.

There was no air conditioning in those days but a heater demister was fitted, with fresh air vents for driver and passenger.

The car also had what BMC described as a ‘‘Camping body’’ with a split-fold front bench and a slide and recline rear seat that formed a makeshift bed.

It was a good idea to watch out for the floor mounted gear shift though.

A three-speed auto version of the 1800 was released in February, 1968, and a ute that was unique to Australia followed in July that year.

The much improved Mark ll version of the Aussie Landcrab was released on October 25, 1968.

In Australia there were at least three panel vans produced for the Navy, that were used as ambulances, and an Austin 1800 campervan conversion.

The Australian model was built at BMC’s Sydney plant in Zetland.

Production ceased in 1970 with the introduction of the replacement Tasman and Kimberley cars, with a total 56,918 examples produced over its five-year run.

Testing for local conditions resulted in several changes for the Australian model.

The wheels were also replaced with locally designed and made units as the original units were considered not strong enough for our deplorable roads.

CHECKOUT: Do you share a name with a car?

CHECKOUT: British cars keep disappearing into the mist

Dad changed cars like his undies #1800 #Austin #BLMC #cars #cars4start My father used to change cars as often as he changed his undies, or so it seemed.

0 notes

Photo

At first, the plan was to greatly update the best-selling, Pininfarina-styled BMC #ADO16 cars - the Austin/Morris 1100/1300 - with new styling and features. Alec Issigonis’ circa-1963 design looked like the 60s but even in 1970 it still compared well to much newer designs like the Fiat 128. But the update plan’s fate was sealed with the #BritishLeyland merger and chief Donald Stokes’ vision of a wholly-new replacement. That car became #ADO67 - the #AustinAllegro. - Harris Mann’s styling was meant to be avant-garde - everything about the Austin make was, in the context of Stokes’ plans, designed to be forward thinking and high-tech, like Citroëns. The initial sketches for the #Allegro were very sleek, but as BL added things to it - notably the E-series engine from the #Austin Maxi, the hood line had to change, and then lots of things started changing, which fundamentally changed the styling. - The altered styling clothed a car similar to the ADO16 but with more space and a wider range of engines. It also had the new Hydragas suspension, an improvement on the old Hydrolastic system. Getting the car into production took ages - styling was finished in September, 1969 but the car didn’t go on sale until May of ’73. - The Allegro famously bombed - a situation blamed largely on the styling and quality. Within a year as many quick fixes as could be engineered were in the works - interiors were upgraded, the infamous “quartic” steering wheel was binned, and the engine given new mounts to reduce NVH. It was too little, too late, and the Allegro became an AMC Pacer-like poster child for BL’s problems. - In 1979, a revised Allegro appeared called the #Allegro3. Many of the criticisms leveled at the early cars were addressed with the 3 - a higher quality, better driving, better equipped car than the earlier examples; but it didn’t revive sales and Allegro production ended in May, 1982. - This is one of the very last Allegro 3’s, and one of probably less than a half dozen Allegros in the United States (where it was never sold). It was privately imported by a friend a few years ago and is now with caring new owner Mike H. The U.S. plate matches the original #British reg. https://www.instagram.com/p/BozKatQl5vA/?utm_source=ig_tumblr_share&igshid=1xcq4c4crfnlg

0 notes

Text

VotW - BMC's Hydrolastic Suspension

VotW – BMC’s Hydrolastic Suspension

Let’s get bumpy this week! Our Video of the Week this time is going to be a Morris 1100 television commercial from New Zealand featuring the car’s hydrolastic suspension. Made for the New Zealand British Motor Corporation (BMC) distributor Dominion Motors.

If you don’t know, hydrolastic suspension was used on early Minis and the…

View On WordPress

0 notes

Text

Minis auctioned off at Historics @ Brooklands

All photos: Historics@Brooklands

There were a fair few classic Minis auctioned off last weekend at Brooklands with the new season whetting the appetite for new investment or treat. Let's see what went down. 1999 Rover Mini Cooper Sportspack

Registration T90 BHP Chassis Number SAXXNNAZEXD1781885 Engine Number 12A2LK70 381693 Odometer reading 28,752 miles Estimate £11,000 - £14,000 Result Sold - £12,600 The Mini was manufactured by the British Motor Corporation (BMC) and its successors from 1959 until 2000. The original is considered a British icon of the 1960's and its space-saving front-wheel drive layout allowing 80% of the car's floorpan to be used for passengers and luggage, influenced a generation of car makers. In 1999, the Mini was voted the second most influential car of the 20th century behind the Ford Model T. Initially, Minis were marketed under the Austin and Morris names until Mini became a marque in its own right in 1969. The Mini was again marketed under the Austin name in the 1980's and was offered in a number of limited editions that usually included a special combination of trim and badging. This Mini Cooper was originally registered on 28th July, 1999 and has only covered 28,752 miles from new. However the first owner won a competition for the car to be sent to John Cooper Works in West Sussex for the car to be upgraded to a 90bhp example and included changing the cylinder head which is now stamped and numbered by John Cooper Works. This low mileage example is in exceptional condition and has clearly been lovingly cherished by the previous keeper; the current vendor has recently fitted new brakes, new shock absorbers, new exhaust and four new Yokohama tyres. The British Racing Green paintwork is virtually unmarked as is the cream leather interior. The car is supplied with a V5C registration document, a full years MoT test certificate, the original service books with eight service stamps recorded together with the confirmation of the work carried out by John Cooper Works and an article from MiniWorld magazine featuring T90 BHP. Classic shape, limited edition, Mini's are becoming increasingly desirable, examples such as this, with an interesting history, will attract shrewd investors. 1999 Rover Mini 40th Anniversary Edition

Registration T40 JEB Chassis Number SAXXNWAZEXD173839 Engine Number 12A2LK70 385075 Odometer reading 21,130 miles Estimate £11,000 - £14,000 Result Sold - £12,040 Produced in limited numbers, the Mini 40 is based on the Cooper S and is fitted with a 1275cc fuel injected engine. Chrome bumpers, grille and door handles together with an aluminium engine turned dashboard are all standard equipment. Finished in Mulberry Red with matching leather interior and contrasting seat piping, this delightful Mini 40 has covered only 21,130 miles since new and comes with all of the original equipment including a service book with 18 stamps, every MoT test certificates and invoices that have been carried out on the car and the commemorative case, still in its cardboard box. The condition of this Mini is certainly commensurate with such a low mileage and clearly, this car has been lovingly looked after by the two registered keepers. Supplied with a V5C registration document and a current MoT test certificate valid until 24th August 2017, this 40th Anniversary Mini is exceptional and is sure to attract the attention of shrewd investors. 1969 Morris Mini Traveller 'Woody'

Registration WPE979G Chassis Number MAW61256221A Engine Number 99H-143-H6039 Odometer reading 68,030 miles Estimate £9,000 - £14,000 Result Sold - £14,560 The first Morris Mini Traveller was built on 29th March 1960 but not despatched until 27th July 1960 to Welder Ltd. Unlike Morris Mini saloons, which came out of the Cowley plant, all Travellers were built at Longbridge. The first cars were available in the same paint colours as the Mini Saloons of the time. The interior also matched that of the saloon with a white speedometer housed in a single round cowling and two-tone seats. Costing £623, the estates were available only in a De Luxe trim level which included a recirculating heater, bumper overriders, silver insert round the screen and chrome sill edging, filler cap and wheel trims. Two wing mirrors were fitted as standard, since this was a legal requirement at the time for estate cars, but a rear view mirror was an optional extra, as were seatbelts! The rear floor pressing of the early estates resembled that of an extended saloon with the battery being retained in its traditional Mini location in the boot. One of the most interesting things about the very early Traveller and Countryman cars was the internal fuel tank. It was positioned on the lefthand side in the rear of the car and was trimmed to match the boot. These so-called internal tank cars are easily recognisable by the filler cap being just underneath the rear window on the lefthand side of the car. Production of the internal tank cars was so limited that these have become the most sought after of all Mini estates. This 'Woody' has had single family ownership from new and in 2014 was subject to a full body restoration by renowned Mini specialists, Super Mini Ltd. of Weybridge, which included powder coating the sub frames. It is important to note that this example has all its original wood and is one of only 17 automatic examples thought to be left in existence. Offered in splendid deep red with matching interior, this example has recently been on display with a modern Mini dealership in Guildford and is including an MoT test certificate until January 2018. Offered in pristine condition, this rare car 1000cc Traveller is a treat for all Mini enthusiasts. 1965 Morris Mini Cooper S (970cc)

Registration CBK 99C Chassis Number KA254550919 Engine Number 9F-5A-X/29883 Odometer reading 29,281 miles Estimate £50,000 - £58,000 Result Sold - £56,000 Designed by Alex Issigonis in 1959, a new concept in car design was born. With a monocoque shell, transversely mounted engine and front wheel drive, the new 'Mini', as it was commonly known, soon became popular across a broad spectrum of the population. The potential for competition use was soon seen by John Cooper and although Alex Issigonis was less keen, BMC were finally persuaded by John Cooper and the two worked together in culminating the birth of the Austin Mini Cooper and the Morris Mini Cooper in 1961. Victories in the 1964, 1965 and 1967 Monte Carlo Rallies set the Mini on the road to fame but probably the greatest publicity was gained from their (somewhat unfair) disqualification for lighting irregularities in the 1966 event after coming in 1st, 2nd and 3rd. A more powerful Mini Cooper, dubbed the 'S', was developed in tandem and released in 1963. Featuring a 1071cc engine and larger servo-assisted disc brakes, 4,030 Cooper S cars were produced and sold until the model was updated in August 1964. Cooper also produced two S models specifically for circuit racing in the under 1,000 cc and under 1,300 cc classes respectively, rated at 970cc and a 1,275cc. The smaller-engine model was not well received, and only 963 had been built when the model was discontinued in 1965. The 1,275 cc Cooper S models continued in production until 1971. This Morris Mini Cooper S has been restored by the vendor to a superb standard. Leaving no stone unturned, the engine was removed and stripped down along with the gearbox while the bodywork was being attended to. In addition to this the suspension, brakes and steering were all rebuilt or replaced as necessary. The quality of paintwork is excellent and clearly many hours were spent on preparing the bodywork correctly by the exceedingly fastidious vendor. The mileage of 29,281 appears genuine although not warranted and the interior of this delightful Mini is completely original apart from the steering wheel. Without doubt Morris Mini Coopers are exceedingly rare, as is a restoration project of this quality. With an engine that runs like a sewing machine and a gearbox that is almost perfect in operation this Cooper S has performance and styling in abundance. Supplied with a V5C registration document and a current MoT test certificate, this Mini has the original 970cc engine AEG 151 block and 12G 190 gearbox, one of the best Mini Coopers S's we have seen. 1965 Austin Mini Cooper Mk.1

Registration JGU 415C Chassis Number CA2S7L715172 Engine Number 9FD-SA-H7792 Odometer reading 44,850 km Estimate £14,000 - £19,000 Result Not Sold First registered 12th August 1965 this original Mk.1 Austin Mini Cooper is in lovely condition throughout and remarkably original. Recently when taken for an MOT, the mechanic indeed complimented the car on its originality, good body and mechanicals, a credit to the previous ownership. In 2016 this Mk.1 car was subject to an engine rebuild and suspension upgrade to dry suspension, this included correct Hi / Lo kit and a servo was added to improve braking. Invoices totalled £3,700 which can be found in the history file. Other recent maintenance included a new central exit exhaust system and rebuilt brake callipers including new pads and new front wheel bearings attached to the Cooper S reverse rim wheels. Offered with an MoT test certificate until November 2017 and fully serviced with overhauled carburettors, new spark plugs and HT leads, this plucky Cooper is a loved and increasingly rare car that is a sound investment as well as a fun, useable classic. 1964 Austin Mini Cooper S Mk. I

Registration CLU 205B Chassis Number CA257551844 Engine Number 9F-SA-Y/31602 Odometer reading 925 Estimate £37,000 - £46,000 Result Sold - £33,600 Introduced in February 1964, the 1275 Mini Cooper S, with its torquey engine, has long been seen as the ultimate 'S' and is currently still the most sought after version for most buyers and owners. Visually the same as the 1071cc 'S', the 1275cc was fitted with hydrolastic suspension along with the rest of the Mini range in late 1964. From early 1966, the extra fuel tank and oil cooler became standard items. The 1275cc 'S' then remained in production pretty much unchanged until September 1967 when the Mk. II version was launched. Originally delivered on 19th July 1964, this Mk. I version was purchased by the previous owner in the late 90's in need of restoration. This owner had the car until the spring of 2005 when, begrudgingly, he sold it to its current owner, a Mini racer and enthusiast, as an ongoing restoration project. Over the next eight years, a full nut and bolt restoration took place. The shell was stripped and re-painted in the original Old English White by classic specialists; photos in various stages of the process can be found in the history file showing both the condition of the original shell and the extent of the workmanship. Engine, gearbox, drive train and suspension have all been rebuilt, overhauling the original components where possible. It now represents a stunning example; many have been raced and rallied but this is as near to original as possible and has seen no such action. Since finishing the restoration, the vendor has only used the Mini for some 925 miles. Fully serviced and completed with an MoT test certificate until August 2017, a British Motor Industry Heritage Trust certificate and an original green buff logbook, we are informed this Mini drives particularly well; having been involved with Mini's since the 70's our vendor should be a good judge. With correct Cooper S's increasingly hard to find in such standard specification and with this example in this condition, it is a rare find. As collectable as their period Ferrari cousins, the Cooper S is a 'must have' in any serious collection. 2001 Rover Mini Cooper Sport 500

Registration X500 COO Chassis Number SAXXNPAZEID188178 Engine Number 12A2LK70383837 Odometer reading 274 miles Estimate £24,000 - £30,000 Result Not Sold To celebrate the final chapter of the classic shaped Mini that began life in 1959, a limited edition of 500 cars were produced and named the Rover Mini Cooper Sport 500. The classic Mini shape was retained but had the additional benefits of more modern mechanics and trim details. The best quality hides were used within the interior; the alloy dashboard, window winders and door handles were all a tribute to John Cooper. All of these last 500 cars were finished with Platinum silver roofs and stripes; every new owner also received a special gift with the purchase of the car. The most important item, however, is the certificate stating the car is a genuine Cooper Sport 500 which also bears the chassis number and the signatures of John Cooper and Kevin Howe, the chief executive of the MG Rover Group. There is little doubt that the once-humble Mini has developed into something of a collector's item, especially the more specialist and limited edition versions. After the success sale of the Wood & Pickett collection last year and previous Cooper Sport 500s, it is unsurprising that we have been asked to present, what is arguably, the finest and most collectible example of all. With just 500 examples built and #1 recorded as written off, this makes 188178 the earliest Cooper Sport 500 in existence. The first owner was Rover itself, forming part of its fleet stock and registered to an employee in Birmingham, just around the corner from its birthplace at Longbridge. The second and current owner has kept this near-perfect example in a heated garage amongst his other treasures. Upon inspection, the writer could find no fault with the exterior paintwork or interior finish. The paperwork is up to date, complete with certificate of authenticity and there is even the original dealership advertising document and cherished number plate, 'X500 COO'. It currently holds an MoT test certificate valid until September 2017 and the original gift pack. An opportunity to acquire one of the last proper Minis is unusual, but the earliest, best and most unused, is priceless. The next Historics Auction is at Ascot Racecourse in May. http://ift.tt/1sBcqK0 via Blogger http://ift.tt/2mA6k4b

0 notes