#Heat Shrink Cable Joints

Explore tagged Tumblr posts

Text

More than 22 years Manufacturer of High Stable Quality Heat Shrink Tubing and Braided Sleeve for all your wire and cable management solutions, Insulation ,Sealing, Connection, Bundling, Identification, Color-coding, Stress Control, Anti-tracking, Heat resistance,Weather resistance, UV resistance... Welcome to Visit us at Korea Electronics Show (KES Korea), Dates: 22~25th Oct. 2024, Location: COEX Booth No. Hall A- 512 Welcome to Visit us at Electronica 2024 Dates: November 12–15, 2024 Location: Messe München, Munich, Germany Booth No. Hall C6-540/8 Contact [email protected] or [email protected] to customized your heat shrink tubing and braided sleeve.

#KES Korea#Electronica Germany#upmheatshrink#shrink tubing#shrinkable sleeve#wire insulation#cable joint kit#cable termination#electronics wire protection#thin wall heat shrink tubing#high shrink ratio

1 note

·

View note

Text

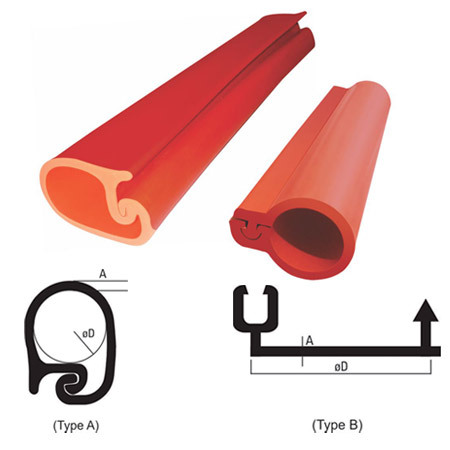

Is this a Dumbbell?

No,It is high shrink ratio (up to 6:1) medium and heavy wall heat shrink tubing,Insulation mechanical protection and sealing of low voltage power cable joint and terminations.

#cable protection#shrink sleeve#heat shrink#shrink tube#upmheat shrink#wire insulation#cable joint#cable termination#high shrink ratio

0 notes

Text

Get Better Connections with Yamuna Densons Copper Braids

We are one of the leading manufacturers and suppliers of copper braid. If you are looking for the best Copper Braid Manufacturers and Suppliers in India, So you have come to the right location. Please visit Yamuna Denson. Yamuna Denson Copper braid construction varies depending on the desired flexibility and application. A copper braid can be made with different wire diameters, with a smaller diameter resulting in greater flexibility. The degree of flexibility offered by various weaves, such as flat, round, and rope braids, can be selected by the particular needs of the application.

To know more information about our products, you can directly contact us at (91) 11 - 47025670.

#connector front & rear#cold shrink cable joints & terminations#conductor cover#heat shrinkable end caps#medium voltage cable jointing kit#low voltage cable jointing kit#bus bar connector#cable repair sleeve#shrinkable anti tracking#copper braid#Cable Repair Sleeve#Bus Bar Connector

0 notes

Text

Repair

In 2018 I purchased an electric adjustable bed frame from a brick and mortar. It included delivery and assembly. They delivered, they assembled, and I really liked it. In my head I was of course extremely skeptical about how long it would last, how long it would continue to move under weight.

And because of my suspicions, because of my experience as an extremely heavy person for whom furniture breaking had become a norm, when it started not erratically not working 6 months later I didn't try very hard to figure it out. I did all the normal troubleshooting I could think of, but eventually it stopped working and never worked again.

Now, five years later, I still have and use the bed frame it just... became a normal bed frame. And I wanted to see if I could adjust the height, so I turned it over, and lo and behold there's a whole other box and section of the electrical part that controls the movement. So I unscrew it all from the frame to sort out which wires go where, and then I find the problem.

The IDIOTS who installed it somehow threaded the POWER cable through the joint in the middle of the bed that allows it to go up and down. So every single time I was moving the bed up and down that metal joint was crimping down on the power cable, and eventually completed severed it.

It turned out that I didn't break the bed! THEY DID! But of course now 5 years later there's no way in hell I can get anything from the manufacturer or the store that sold it to me. But now I'm excited, because I know what the problem is, and that means I can fix it!

It's just a cable that goes from the power brick to the control box, it's got two plugs on each end, SURELY I'll be able to find a replacement cable or maybe an entire replacement control box SOMEWHERE on the internet.

NOPE! I somehow managed to purchase an extremely special snowflake unicorn adjustable bed frame, because even with all of the model numbers and every general kind of search I can think of, I could not find even a picture of a cable with a plug the same as mine that's cut, let alone a place to buy a replacement.

So the only choice was to REPAIR the cable. And I just finished. And it was a lot of work, and I had to buy a lot of tools and junk, but I did it! Well, that is to say, I soldered the two tiny wires that were inside the larger cable sheath together and then re-sheethed all of it with heat shrink sheets with a small layer of non-conductive silicone gunk between the wires and the sheets, and it LOOKS like a repaired cable. I have yet to reassemble the control box and test it.

9 notes

·

View notes

Text

Heat Shrink

A member of Gala Group of Industries with its establishments in the year 1979. entered into the business of Cable management products with specialization in the field of PVC and Heat Shrinkable range of products like Heat Shrink, Cable Joints, Cable Terminations, cable end sealing caps, Spreader caps, heat shrink end caps, heat shrink tubes, heat shrink sleeve, Cable Accessories, PVC Caps, Cable Splicing Kit, Branch Joint, heat shrinkable four way cable breakout, Heat Shrink Tape, Transition Joint, Electrical Insulating tubes, Strain relief Tubs, MV Cable Joints, Cable Splice, Bus bar Insulation Product, Low Voltage Splices, LV Cable Joint, etc.

0 notes

Text

Enhancing Electrical Connectivity with Electrical Lugs: A Comprehensive Overview

Electrical lugs are essential components in electrical systems used for connecting cables or wires to electrical equipment, devices, or other cables. These lugs play a crucial role in ensuring secure and reliable electrical connections, enabling efficient power transmission and distribution in various applications. This article delves into the functionality, types, applications, advantages, and installation methods of electrical lugs, highlighting their significance in modern electrical systems.

Functionality of Electrical Lugs:

Electrical lugs, also known as cable lugs or wire lugs, serve as interface connectors between cables or wires and electrical equipment. These lugs are typically made of conductive materials such as copper or aluminum and are designed to provide a secure and stable connection that facilitates the flow of electrical current. Electrical lugs come in various shapes and sizes to accommodate different wire gauges and types, ensuring compatibility with a wide range of electrical applications.

Types of Electrical Lugs:

Copper Lugs: Copper lugs are widely used for their excellent conductivity and corrosion resistance, making them ideal for applications requiring high electrical performance.

Aluminum Lugs: Aluminum lugs are lightweight and cost-effective alternatives to copper lugs, suitable for applications where weight and cost considerations are important.

Mechanical Lugs: Mechanical lugs feature a screw or compression mechanism for securing wires, offering a reliable and reusable connection that can withstand mechanical stress.

Solder Lugs: Solder lugs require soldering to create a permanent connection between the lug and the wire, providing a secure and low-resistance electrical joint.

Applications of Electrical Lugs:

Power Distribution Networks: Electrical lugs are commonly used in power distribution networks to connect cables to transformers, switchgear, and distribution panels, ensuring efficient power transmission.

Renewable Energy Systems: In solar power installations and wind turbines, electrical lugs are utilized to connect solar panels, inverters, and battery banks, facilitating the flow of renewable energy.

Industrial Equipment: Electrical lugs are essential in industrial machinery and equipment, providing secure connections for motors, control systems, and electrical enclosures.

Automotive Industry: In automotive applications, electrical lugs are used to connect electrical components, batteries, and wiring harnesses, ensuring reliable performance in vehicles.

Advantages of Electrical Lugs:

Reliable Connectivity: Electrical lugs offer a secure and stable connection between cables and electrical equipment, minimizing the risk of electrical faults and interruptions in power transmission.

Versatility: With a wide range of types and sizes available, electrical lugs are versatile components that can be used in various electrical applications, providing flexibility and adaptability.

Corrosion Resistance: Copper and aluminum lugs are resistant to corrosion, ensuring long-term performance and durability in diverse environmental conditions.

Ease of Installation: Electrical lugs are designed for easy installation, reducing downtime and labor costs associated with connecting cables to electrical equipment.

Installation Methods for Electrical Lugs:

Cable Preparation: Ensure that the cables are stripped, cleaned, and prepared properly before attaching the lugs.

Crimp or Compression: Use crimping tools or compression devices to secure the lug onto the cable, ensuring a tight and reliable connection.

Insulation: Insulate the connection using heat shrink tubing or insulating tape to protect against electrical hazards and ensure safety.

Testing: After installation, conduct testing to verify the integrity of the connection and ensure proper electrical conductivity.

Significance of Electrical Lugs in Electrical Systems:

Electrical lugs play a critical role in ensuring efficient power transmission, reliable connectivity, and safe operation of electrical systems. By providing secure connections between cables and electrical equipment, these components help minimize power losses, reduce downtime, and prevent electrical faults, thereby enhancing the overall performance and reliability of electrical networks.

In conclusion, electrical lugs are indispensable components in the electrical industry, offering secure connectivity, versatility, and ease of installation in various applications. With their importance in facilitating efficient power transmission and safe operation of electrical systems, electrical lugs continue to be essential components in modern power distribution networks, industrial equipment, renewable energy systems, and automotive applications. As the demand for robust and reliable electrical connections grows, the role of electrical lugs in ensuring secure and stable connections remains paramount in maintaining the integrity and efficiency of electrical networks.

0 notes

Text

0 notes

Text

0 notes

Text

Electrical Maintenance Power Cable Joint Kits

Power Cable Joint Kits are indispensable in the realm of electrical engineering and maintenance. These kits are designed to facilitate the safe and efficient connection of power cables, ensuring continuity and reliability in electrical systems.

Electrical systems are the backbone of modern infrastructure, powering everything from residential homes to industrial complexes. A critical aspect of maintaining these systems is the ability to connect and repair power cables effectively. Power Cable Joint Kits are specially designed to address this need, providing a comprehensive set of tools and materials for creating secure and durable cable connections.

A typical power cable joint kit includes a variety of components, each serving a specific purpose in the jointing process:

1. Cable Jointing Compound: A specialized adhesive that ensures a watertight and airtight seal, protecting the connection from environmental factors.

2. Insulating Tape: Used to provide additional insulation and protection to the joint, preventing short circuits and electrical leakage.

3. Shrink Tubing: A heat-sensitive material that, when applied and heated, shrinks to form a tight, protective layer around the joint.

4. Cable Jointing Tools: Includes cable cutting tools, stripping tools, and crimping tools, essential for preparing the cables for jointing.

5. Crimping Sleeves: Metal or plastic sleeves that are crimped onto the cable ends to secure the connection.

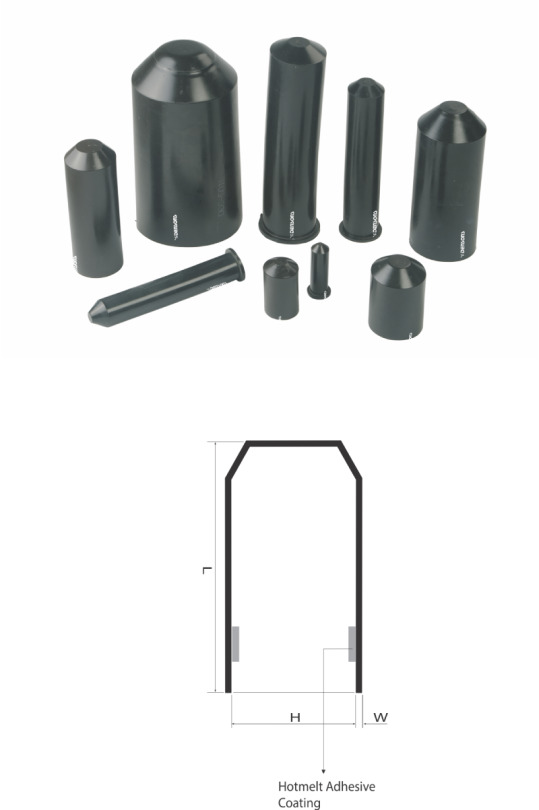

6. Heat Shrinkable End Caps: Used to cover the ends of the joint, providing a neat finish and additional protection.

7. Safety Equipment: Gloves, goggles, and other protective gear to ensure the safety of the person performing the jointing.

0 notes

Text

A Fire Safety Guide to Fire Protection Systems and Fire-Rated Sealant

Fire protection systems are vital for keeping people safe during building fires. Fire-rated sealants are a crucial part of these systems because they stop fire and smoke from spreading. This blog will discuss why firestop sealants are essential and how they help protect buildings during fires.

What is a Fire Sealant?

A fire-stopping sealant is a specialized construction material designed to prevent the spread of fire, smoke, and toxic gases through joints, gaps, and penetrations in building assemblies. It is applied to seal gaps and joints in walls, floors, and ceilings, forming a barrier that helps contain fires and protect occupants. Fire-rated sealants are formulated to withstand high temperatures and meet stringent fire safety standards. They play a crucial role in maintaining the integrity of fire-rated assemblies, enhancing fire resistance, and ensuring compliance with building codes and regulations, thereby contributing to overall fire safety in buildings.

Why are Fire-Rated Sealants Important?

Fire-stopping sealants are crucial for maintaining the integrity of fire-rated assemblies in buildings. They prevent the spread of fire, smoke, and toxic gases through joints and gaps in construction materials, helping to contain fires and protect occupants. By sealing penetrations and gaps in walls, floors, and ceilings, fire-rated sealants ensure that fire-rated barriers remain effective, allowing occupants more time to evacuate safely and reducing property damage. These sealants are critical in enhancing fire safety and compliance with building codes and regulations, making them essential components of fire protection systems in residential and commercial buildings.

Types of Fire-Rated Sealants

Silicone-Based Sealants: Silicone sealants are known for their flexibility and durability. They can withstand high temperatures and are often used where movement or expansion is expected, such as expansion joints in concrete or metal substrates. Silicone-based fire-rated sealants are also resistant to UV radiation and weathering, making them suitable for interior and exterior applications.

Acrylic-Based Sealants: This fire sealant is cost-effective and easy to apply. They offer good adhesion to various substrates and are commonly used in interior applications requiring fire resistance, such as sealing gaps around doors, windows, and electrical penetrations. However, acrylic sealants are less flexible than silicone sealants and may shrink over time, reducing their effectiveness in dynamic joint applications.

Intumescent Sealants: Intumescent sealants contain special additives that expand during heat exposure, forming a char layer that seals off joints and prevents fire spread. These sealants are typically used in fire-rated walls, floors, and ceilings to maintain the assembly's fire resistance rating. An intumescent sealant provides excellent fire-stopping properties but may require careful installation to ensure proper activation during a fire.

Choosing the Right Fire Sealant

Choosing the proper fire sealant involves considering several factors. First, assess the project's specific requirements, including fire rating, flexibility, and adhesion properties. Ensure the sealant complies with relevant building codes and standards. Consider the substrate material and the expected movement in the joint. Evaluate the sealant's durability, weather resistance, and compatibility with other building materials. Review the manufacturer's reputation, product warranties, and technical support. Ultimately, select a fire sealant that best meets the project's needs, balancing performance, cost-effectiveness, and compliance with safety regulations.

The Bottom Line

A fire-rated sealant is usually a water-based, eco-friendly acrylic sealant. It's great for stopping fires from spreading through cable and metal pipe holes in fireproof walls. For more info on intumescent sealant, visit Vijay Systems engineers official page today.

0 notes

Text

Where to find your heat shrinkable parts of reliable cable joint and termination? Power Cable Joint and Termination Heat Shrinkable Tubing provide excellent environmental protection, electrical insulation, and mechanical support, ensuring reliable connections and longevity in various applications. Product range: S3(n) Medium Wall Halogen Free Heat Shrink Tubing S3(nh) Heavy Wall Haogen Free Heat Shrink Tubing S4 6:1 High Shrink Ratio Shrink Tubing C101 Non-tracking Heat Shrink Tubing C102 6~24,36KV Stress Control Shrink Tube C105 Semi-conductive/Insulation Double Layer Heat Shrink Tubing C06 Semi-conductive/insulation/elastomeric Insulation Triple Layer Heat Shrink Tubing C107 Plastic Insulation/Elastomeric Insulation Double layer Heat Shrink Tube Y1 Heat Shrink Breakout Boot Y2 Shrinkable Cable End Cap Y3 Non-tracking Heat Shrink Rain Shed 0.6~1kV 26/35kV Heat Shrinkable Accessories

#heat shrink#manufacturer#upmheatshrink#factory#shrinkage#shrink sleeve#heat shrinkable#shrink tube#cable joint#cable termination#cable accessories#rain shed#cable end cap#breakout boot#triple layer shrink tubing#high shrink ratio#stress control

1 note

·

View note

Text

Steel cables,wires and ropes anti-corrosion,wear resistance protection heat shrink tubing

The heat shrink tubing is applied in outdoor amusement facilities, providing waterproof sealing at the connection points of steel cables, wires, and ropes, offering corrosion and rust protection, weld joint protection, reinforcement of connections, wear resistance, and noise reduction. It is easy to install, and subsequent maintenance and replacement are simple. [email protected] or [email protected] at your service. #upmheatshrink @upmheatshrink #heat shrink application

#heat shrink#sealing#steel cable protection#weld joint protection#upm heat shrink specialist#cable protection#shrink sleeve#shrink tubing#upmheat shrink#upmheatshrink#wire insulation#shrink tube#heat shrink tubing

0 notes

Text

Protect Your Equipment with Yamuna Denson's Heat Shrinkable End Caps

Yamuna Denson Heat Shrinkable End Caps provide optimum waterproofing and environmental protection for underwater, underground, and outdoor applications. Our heat-shrink end caps are highly resistant to moisture, fungus, and weathering. We also offer electrical end caps with pre-coat sealants. The heat-shrink end caps are available in several sizes to accommodate varying cable diameters due to their large range-taking ability.

Contact Us Today.

#connector front & rear#cold shrink cable joints & terminations#conductor cover#heat shrinkable end caps#medium voltage cable jointing kit#low voltage cable jointing kit#bus bar connector#cable repair sleeve#shrinkable anti tracking#copper braid

0 notes

Text

Raychem Termination kits

What should we know about the Raychem Termination Kit?

Raychem offers a comprehensive splice kit for a variety of cables. The company's bonding kits are designed to withstand extreme climates and pollution, ideal for underground and overhead installation reliability. Transeletric provide quality-guaranteed products, timely delivery, and an affordable pricing policy.

About Raychem Termination Kit

Get the correct industry standard wire connector from Transeletric's wide selection of wholesale termination kits. Each terminal connection is made of 99.9% pure copper, efficiently preventing corrosion, electrical sparks and oxidation. After heating evenly, this adhesive-coated heat shrink connector releases hot melt adhesive and instantly shrinks and bonds to the wire insulation. In this way, a totally water-resistant and wear-proof environmental closure can be created. This unit can be used for terminal wiring of specialist equipment such as batteries, power distribution boxes and cables.

The feat rate of joining wires be contingent on the average of the terminal. There is no need to worry. Depending on your needs, choose wire or screw terminals from Transeletric's range of termination kits. This Termination Kit will save you time. It would support if you had a high temperature gun to blast the joints, and you're virtuous to go. In particular, spade connectors track the universal size, which makes them adaptable. Furthermore, an elegant, high-standard widening opening helps wire insertion and laid-back operation even in demanding applications. All these benefits are found in Transeletric's bulk Raychem termination kits.

Get the Raychem Termination Kit online.

The terminals are designed to fit into tight, confined spaces and can be bent after connection, eliminating the need for soldering or crimping in tight areas. Control the temperature with the heat gun. Each lug also has specification markings to help you quickly find the correct terminal and make the connection faster and easier. This electrical terminal kit can knob almost any wiring prerequisite, from simple wire acquaintances to rigorous shuddering applications. We also have a team of experienced and dedicated marketing experts, quality inspection experts and other support staff overseeing the production process. Additionally, our approach towards ethical business practices helps us stay ahead of our competitors in this industry. Furthermore, we are committed to building long-term relationships with our customers by providing quality Raychem Termination Kit per their specifications. Furthermore, during this period, our company has partnered with various domestic and international players to offer products that are authentic and value for money. To further our objectives and provide the best service in the industry, we have set up a wholly-owned branch office in Chennai. Building infrastructure closer to the customer's front door reduces response and delivery times. Browse Rechem Termination Kits at Transeletric and choose from various options today.

1 note

·

View note

Text

Heat Shrink

A member of Gala Group of Industries with its establishments in the year 1979. entered into the business of Cable management products with specialization in the field of PVC and Heat Shrinkable range of products like Heat Shrink, Cable Joints, Cable Terminations, cable end sealing caps, Spreader caps, heat shrink end caps, heat shrink tubes, heat shrink sleeve, Cable Accessories, PVC Caps, Cable Splicing Kit, Branch Joint, heat shrinkable four way cable breakout, Heat Shrink Tape, Transition Joint, Electrical Insulating tubes, Strain relief Tubs, MV Cable Joints, Cable Splice, Bus bar Insulation Product, Low Voltage Splices, LV Cable Joint, etc.

0 notes

Text

Enhancing Electrical Connectivity with Electrical Lugs: A Comprehensive Overview

Electrical lugs are essential components in electrical systems used for connecting cables or wires to electrical equipment, devices, or other cables. These lugs play a crucial role in ensuring secure and reliable electrical connections, enabling efficient power transmission and distribution in various applications. This article delves into the functionality, types, applications, advantages, and installation methods of electrical lugs, highlighting their significance in modern electrical systems.

Functionality of Electrical Lugs:

Electrical lugs, also known as cable lugs or wire lugs, serve as interface connectors between cables or wires and electrical equipment. These lugs are typically made of conductive materials such as copper or aluminum and are designed to provide a secure and stable connection that facilitates the flow of electrical current. Electrical lugs come in various shapes and sizes to accommodate different wire gauges and types, ensuring compatibility with a wide range of electrical applications.

Types of Electrical Lugs:

Copper Lugs: Copper lugs are widely used for their excellent conductivity and corrosion resistance, making them ideal for applications requiring high electrical performance.

Aluminum Lugs: Aluminum lugs are lightweight and cost-effective alternatives to copper lugs, suitable for applications where weight and cost considerations are important.

Mechanical Lugs: Mechanical lugs feature a screw or compression mechanism for securing wires, offering a reliable and reusable connection that can withstand mechanical stress.

Solder Lugs: Solder lugs require soldering to create a permanent connection between the lug and the wire, providing a secure and low-resistance electrical joint.

Applications of Electrical Lugs:

Power Distribution Networks: Electrical lugs are commonly used in power distribution networks to connect cables to transformers, switchgear, and distribution panels, ensuring efficient power transmission.

Renewable Energy Systems: In solar power installations and wind turbines, electrical lugs are utilized to connect solar panels, inverters, and battery banks, facilitating the flow of renewable energy.

Industrial Equipment: Electrical lugs are essential in industrial machinery and equipment, providing secure connections for motors, control systems, and electrical enclosures.

Automotive Industry: In automotive applications, electrical lugs are used to connect electrical components, batteries, and wiring harnesses, ensuring reliable performance in vehicles.

Advantages of Electrical Lugs:

Reliable Connectivity: Electrical lugs offer a secure and stable connection between cables and electrical equipment, minimizing the risk of electrical faults and interruptions in power transmission.

Versatility: With a wide range of types and sizes available, electrical lugs are versatile components that can be used in various electrical applications, providing flexibility and adaptability.

Corrosion Resistance: Copper and aluminum lugs are resistant to corrosion, ensuring long-term performance and durability in diverse environmental conditions.

Ease of Installation: Electrical lugs are designed for easy installation, reducing downtime and labor costs associated with connecting cables to electrical equipment.

Installation Methods for Electrical Lugs:

Cable Preparation: Ensure that the cables are stripped, cleaned, and prepared properly before attaching the lugs.

Crimp or Compression: Use crimping tools or compression devices to secure the lug onto the cable, ensuring a tight and reliable connection.

Insulation: Insulate the connection using heat shrink tubing or insulating tape to protect against electrical hazards and ensure safety.

Testing: After installation, conduct testing to verify the integrity of the connection and ensure proper electrical conductivity.

Significance of Electrical Lugs in Electrical Systems:

Electrical lugs play a critical role in ensuring efficient power transmission, reliable connectivity, and safe operation of electrical systems. By providing secure connections between cables and electrical equipment, these components help minimize power losses, reduce downtime, and prevent electrical faults, thereby enhancing the overall performance and reliability of electrical networks.

In conclusion, electrical lugs are indispensable components in the electrical industry, offering secure connectivity, versatility, and ease of installation in various applications. With their importance in facilitating efficient power transmission and safe operation of electrical systems, electrical lugs continue to be essential components in modern power distribution networks, industrial equipment, renewable energy systems, and automotive applications. As the demand for robust and reliable electrical connections grows, the role of electrical lugs in ensuring secure and stable connections remains paramount in maintaining the integrity and efficiency of electrical networks.

0 notes