#heat shrinkable end caps

Explore tagged Tumblr posts

Text

Heat Shrink

A member of Gala Group of Industries with its establishments in the year 1979. entered into the business of Cable management products with specialization in the field of PVC and Heat Shrinkable range of products like Heat Shrink, Cable Joints, Cable Terminations, cable end sealing caps, Spreader caps, heat shrink end caps, heat shrink tubes, heat shrink sleeve, Cable Accessories, PVC Caps, Cable Splicing Kit, Branch Joint, heat shrinkable four way cable breakout, Heat Shrink Tape, Transition Joint, Electrical Insulating tubes, Strain relief Tubs, MV Cable Joints, Cable Splice, Bus bar Insulation Product, Low Voltage Splices, LV Cable Joint, etc.

0 notes

Text

Electrical Maintenance Power Cable Joint Kits

Power Cable Joint Kits are indispensable in the realm of electrical engineering and maintenance. These kits are designed to facilitate the safe and efficient connection of power cables, ensuring continuity and reliability in electrical systems.

Electrical systems are the backbone of modern infrastructure, powering everything from residential homes to industrial complexes. A critical aspect of maintaining these systems is the ability to connect and repair power cables effectively. Power Cable Joint Kits are specially designed to address this need, providing a comprehensive set of tools and materials for creating secure and durable cable connections.

A typical power cable joint kit includes a variety of components, each serving a specific purpose in the jointing process:

1. Cable Jointing Compound: A specialized adhesive that ensures a watertight and airtight seal, protecting the connection from environmental factors.

2. Insulating Tape: Used to provide additional insulation and protection to the joint, preventing short circuits and electrical leakage.

3. Shrink Tubing: A heat-sensitive material that, when applied and heated, shrinks to form a tight, protective layer around the joint.

4. Cable Jointing Tools: Includes cable cutting tools, stripping tools, and crimping tools, essential for preparing the cables for jointing.

5. Crimping Sleeves: Metal or plastic sleeves that are crimped onto the cable ends to secure the connection.

6. Heat Shrinkable End Caps: Used to cover the ends of the joint, providing a neat finish and additional protection.

7. Safety Equipment: Gloves, goggles, and other protective gear to ensure the safety of the person performing the jointing.

0 notes

Text

How End Caps Improve Indoor Termination Kits

End caps are integral components of indoor termination kits, playing a significant role in enhancing their performance and reliability. This article explores how end caps contribute to the effectiveness of indoor termination kits, emphasizing their functions, benefits, and impact on electrical installations.

Understanding End Caps in Indoor Termination Kits

End caps are protective covers or sleeves that are used to seal and insulate the ends of cables within termination kits. They are typically made from durable and insulating materials such as rubber, silicone, or heat-shrinkable polymers. End caps are designed to provide mechanical protection, environmental sealing, and electrical insulation for cable terminations, ensuring the long-term integrity and reliability of electrical connections.

Key Functions of End Caps in Indoor Termination Kits

The importance of end caps in indoor termination kits lies in their essential functions:

Environmental Sealing: End caps seal the ends of cables to prevent the ingress of moisture, dust, and other contaminants that could degrade insulation and compromise the electrical integrity of the termination.

Mechanical Protection: End caps provide mechanical protection for cable terminations, shielding them from physical damage, abrasion, and impact during handling, installation, and operation.

Electrical Insulation: End caps insulate the exposed cable ends, reducing the risk of electrical faults, short circuits, and flashovers caused by accidental contact with conductive materials or foreign objects.

Stress Relief: End caps help to relieve mechanical stress and strain on cable terminations by distributing forces evenly and preventing sharp bends or kinks that could weaken the cables or connections.

Corrosion Prevention: End caps protect cable terminations from corrosion and oxidation, particularly in harsh or corrosive environments, extending the service life of the termination and associated equipment.

Advantages of End Caps in Indoor Termination Kits

The use of end caps in indoor termination kits offers several advantages:

Enhanced Reliability: End caps enhance the reliability and longevity of cable terminations by providing comprehensive protection against environmental, mechanical, and electrical hazards.

Simplified Installation: Indoor termination kits with pre-molded or heat-shrinkable end caps offer easy and straightforward installation, reducing labor costs and ensuring consistent and professional results.

Versatility: End caps are available in various sizes, shapes, and materials to accommodate different cable types, sizes, and termination configurations, making them suitable for a wide range of applications.

Cost-Effectiveness: End caps are cost-effective solutions for cable termination protection, minimizing the need for costly repairs, replacements, or maintenance due to premature failure or damage.

Compliance: End caps comply with industry standards and regulations for cable termination and insulation, ensuring adherence to safety and quality requirements in electrical installations.

Impact on Indoor Termination Kits

The impact of end caps on indoor termination kits is significant:

Improved Performance: End caps improve the performance and reliability of indoor termination kits, ensuring the integrity of cable terminations and minimizing the risk of electrical faults or failures.

Enhanced Safety: By providing comprehensive protection against environmental and mechanical hazards, end caps contribute to a safer working environment for personnel and equipment.

Increased Durability: End caps extend the service life of cable terminations and associated equipment by preventing damage, corrosion, and degradation, reducing downtime and maintenance costs.

Seamless Integration: End caps seamlessly integrate with indoor termination kits, complementing other components such as insulation, splices, and connectors to provide a complete and effective termination solution.

Future-Proofing: End caps support future expansion and upgrades of indoor termination kits, providing a flexible and scalable solution for evolving power requirements and infrastructure needs.

Conclusion: Enhancing Protection and Reliability

In conclusion, end caps play a crucial role in improving the performance and reliability of indoor termination kits. Their environmental sealing, mechanical protection, electrical insulation, and other functions make them indispensable components of modern electrical installations. By incorporating high-quality end caps into indoor termination kits, electrical utilities and operators can ensure efficient, safe, and dependable termination of cables in indoor environments.

0 notes

Text

Angle Boot

Cable management products like cable end sealing caps,heat shrink end caps,heat shrinkable moulded shapes,heat shrinkable tubes,busbar insulation shrouds, heat shrinkable wrap around sleeve

0 notes

Text

Components of an LV AB Cables Distribution Line

Low Voltage Aerial Bundled Cables, which have an insulating layer of XLPE, are an innovative concept for the distribution of electricity to households, street lights or other low voltage applications. These electrical distribution systems are practical not only in congested cities where the insulation provides safety and manoeuvrability but are also useful in rural areas where live line maintenance is much easier than using bare conductors. You can read more about this in our article on the “Advantages of Low Voltage Aerial Bundled Cables for Overhead Power Distribution”.

According to research published in 2017, “XLPE cables are expected to last or service well beyond the 40-year design life under normal circumstances”. However, this long lifespan can be severely reduced if improper clamps and connectors are used along with the AB Cable. According to the research, the most influential factor in ageing ABC cables is the use of non-standard cable connectors, accessories and clamps because they allow water ingress which slowly damages the cable.

The appropriate components to be used along with the AB Cable system are listed below.

1. Aerial Bundled Cable (ABC)

a. Insulated Messenger System: An insulated messenger system (also called the French system) consists of 3 black, weather-resistant XLPE or PE insulated phase conductors twisted along with an insulated messenger conductor made of a high strength Aluminum alloy which serves as a dual purpose earthing and/or neutral messenger wire.

b. Self-Supporting System (Two Core or Four Core System): The self-supporting cable system consists of 2 or 4 PE or XLPE black, weather-resistant insulated conductors. The mechanical strength of all the cables is equal such that, when strained, all the cables will equally bear the load of the system.

c. Uninsulated Messenger System: An uninsulated messenger system (also called the Finnish system) consists of 1-4 black, weather-resistant PE insulated phase conductors twisted around a messenger conductor made of a high strength Aluminum alloy.

2. Poles

a. Wooden Poles

b. Cement (RCC – Reinforced Cement Concrete, PCC – Plain Cement Concrete Poles)

c. Steel Tubular Pole (Stepped pole, Swaged pole).

d. Rail Pole.

3. Suspension System:

a. Suspension Clamps for LV AB Cables are used along with a bracket or other supporting hardware to suspend and grip, without damaging, the insulated or uninsulated messenger or the self-supporting system of a LV ABC system by means of an adjustable lock that accommodates a range of cable sizes.

4. Anchoring System:

a. Anchoring Clamps for LV AB Cables are used along with a bracket or other supporting hardware and are used to strain the insulated or uninsulated neutral messenger or the self-supported system to terminate into transformer leads or mains for industrial/residential supply. They are also used to provide angles to a LV ABC system without damaging the cable’s insulation.

5. Taking service lines or tap connections:

a. Service Clamps are used along with a bracket or other supporting hardware and is used to strain the insulated service conductor of an LV-ABC system without damaging the cable’s insulation. The main application of Service Clamps is to bring service connections to households or street lights.

b. Insulation Piercing Connectors are used on all AB cable systems (messenger wire as well as self-supporting system) to take tap connections. This tap can be used to continue the line, distribute the line, be used in street lighting or in-service connections to households.

6. Service line distribution

a. Distribution Boxes are used to take multiple connections from a single enclosure. These connections can be used for distribution to households.

7. Other Hardware

a. Midspan Joints are used for insulated ABC cables on stranded phase and neutral to join two cables.

b. Insulated BM Lugs are used for insulated ABC cables on stranded phase and neutral to terminate the cables.

c. Elastomeric or Heat Shrinkable End Caps are used to safely terminate the ends of the AB Cable. Elastomeric End Caps are usually supplied with insulation piercing connectors.

d. Fixing Nails are used to support Aerial bundled cable on façades.

e. Stainless Steel straps are used along with the Fixing Nails to accommodate an additional bundle if required. Stainless Steel Cable ties are also used to fix brackets and distribution boxes onto the electric pole.

f. Tensioner is used to tension the steel straps which are mounted on the poles to hold the brackets or distribution boxes in place.

To learn more about AB Cable Accessories, please watch our videos on how to install the components.

To see our range of Accessories for Aerial Bundled Cables, please visit our website. You can also find our other products, including Lightning Protection Systems, Earthing/Grounding Systems, Brass Cable Glands, Cable Lugs and more on our website.

Please email us at [email protected] or [email protected] if you have any enquiries.

Thank you for reading the blog, Axis is a leading manufacturer and supplier of Electrical Components to over 80+ Countries. Talk to our industry expert by visiting our contact us section. You can also watch our videos by our experts – click here.

Follow us on LinkedIn for regular updates on our Products!

0 notes

Text

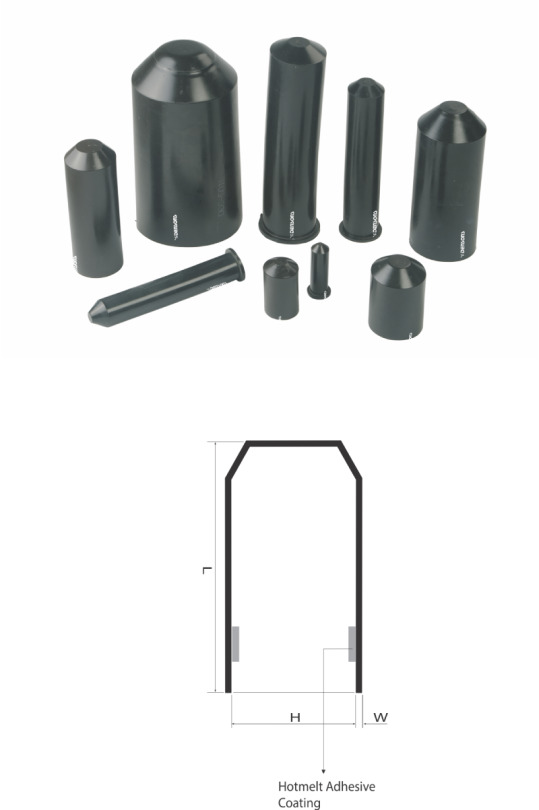

Protect Your Equipment with Yamuna Denson's Heat Shrinkable End Caps

Yamuna Denson Heat Shrinkable End Caps provide optimum waterproofing and environmental protection for underwater, underground, and outdoor applications. Our heat-shrink end caps are highly resistant to moisture, fungus, and weathering. We also offer electrical end caps with pre-coat sealants. The heat-shrink end caps are available in several sizes to accommodate varying cable diameters due to their large range-taking ability.

Contact Us Today.

#connector front & rear#cold shrink cable joints & terminations#conductor cover#heat shrinkable end caps#medium voltage cable jointing kit#low voltage cable jointing kit#bus bar connector#cable repair sleeve#shrinkable anti tracking#copper braid

0 notes

Text

Cable End Sealing Caps

Heat shrink tubes is one of the most effective tools you can have for organizing and protecting electrical cables. It is manufactured from cross linked polyolefin material. This type of tubing is often used in military, industrial, and commercial settings. By fitting around your electrical cables and then heating the tubed area with a hot air gun, the tubing shrinks to fit your cables. This protects them from environmental hazards like moisture and shock while making them easier to identify. Additionally, its a very adaptable tool, allowing for a number of applications that aren't readily apparent.

0 notes

Text

Unveiling Medium Voltage Cable Accessories and GIS Cable Termination Techniques

Medium voltage cable accessories and GIS (Gas Insulated Switchgear) cable termination techniques play a crucial role in ensuring the efficiency and reliability of electrical networks. From providing insulation to facilitating connections, these components are vital for seamless power distribution. Let's delve into the intricacies of medium voltage cable accessories and GIS cable termination to understand their significance in modern electrical systems.

Medium Voltage Cable Accessories: Enhancing Reliability

Medium voltage cable accessories encompass a variety of components designed to optimize the performance and longevity of medium voltage cables. These accessories provide insulation, protection, and connectivity, thereby ensuring the smooth transmission of electricity in diverse applications.

Types of Medium Voltage Cable Accessories

Cable Terminations: Cable terminations are used to terminate medium voltage cables at switchgear, transformers, or other electrical equipment. They provide a secure connection while maintaining electrical integrity and insulation.

Joints and Splices: Joints and splices are used to connect two or more medium voltage cables together. They are essential for extending cable lengths or repairing damaged sections while preserving electrical continuity and insulation.

Cable Seals and End Caps: Cable seals and end caps are used to seal cable terminations and joints, protecting them from moisture, contaminants, and mechanical stress. These accessories ensure the long-term reliability of cable connections in harsh environments.

Key Features of Medium Voltage Cable Accessories

Insulation Integrity: Medium voltage cable accessories must provide reliable insulation to prevent electrical leakage and breakdown, especially in high-stress environments.

Mechanical Strength: Accessories should possess high mechanical strength to withstand external forces, such as vibration, tension, and impact, ensuring the longevity of cable connections.

Environmental Resistance: Resistance to moisture, chemicals, UV radiation, and other environmental factors is crucial for maintaining the performance of cable accessories in diverse operating conditions.

Ease of Installation: Accessories that are easy to install and maintain help minimize downtime and labor costs, enhancing overall operational efficiency.

GIS Cable Termination: Ensuring Seamless Connectivity

GIS cable termination involves the termination of cables in Gas Insulated Switchgear (GIS) installations, which are compact and space-efficient solutions for high voltage applications. Proper cable termination techniques are essential for maintaining the integrity of GIS systems and ensuring reliable power distribution.

Techniques for GIS Cable Termination

Pre-molded Terminations: Pre-molded cable terminations are factory-made components designed to fit specific cable sizes and types. They offer quick and easy installation, ensuring consistent performance and reliability in GIS applications.

Heat Shrink Terminations: Heat shrink cable terminations use heat shrinkable materials to create a tight seal around cable terminations. These terminations provide excellent insulation and mechanical strength, making them suitable for GIS installations where space is limited.

Cold Shrink Terminations: Cold shrink terminations eliminate the need for heat during installation by using pre-expanded rubber tubes that shrink to form a tight seal when the supporting core is removed. These terminations are ideal for GIS applications where heat may be a concern.

Advantages of GIS Cable Termination

Space Efficiency: GIS cable terminations occupy minimal space compared to conventional air-insulated switchgear, making them suitable for compact installations and urban environments.

Reduced Maintenance: GIS systems require less maintenance compared to traditional switchgear, resulting in lower operational costs and increased reliability.

Enhanced Safety: The encapsulated design of GIS systems reduces the risk of electrical faults and enhances safety for personnel working in close proximity to the equipment.

Conclusion

Medium voltage cable accessories and GIS cable termination techniques are integral components of modern electrical systems, ensuring the efficiency, reliability, and safety of power distribution networks. By selecting the appropriate accessories and employing the right termination techniques, operators can optimize the performance and longevity of their electrical installations while minimizing downtime and maintenance costs. Investing in high-quality components and adhering to best practices in installation and maintenance is key to achieving optimal results in medium voltage applications.

0 notes

Text

MASTIC TAPE

Gala Thermo Shrink PVT. LTD. a member of Gala Group of Industries with its establishments in the year 1979. entered into the business of Cable management products with specialization in the field of PVC and Heat Shrinkable range of products like cable end sealing caps,Spreader caps, heat shrink end caps, busbar insulation shrouds, heat shrinkable moulded shapes, polymeric insulators, heat shrinkable tubes

0 notes

Text

Mastic tape - Gala Thermo Shrink Pvt Ltd

Gala Thermo Shrink PVT. LTD. a member of Gala Group of Industries with its establishments in the year 1979. entered into the business of Cable management products with specialization in the field of PVC and Heat Shrinkable range of products like Heat Shrink, Cable Joints, Cable Terminations, cable end sealing caps, Spreader caps, heat shrink end caps, heat shrink tubes, heat shrink sleeve, Cable Accessories, PVC Caps, Cable Splicing Kit, Branch Joint, heat shrinkable four way cable breakout, Heat Shrink Tape, Transition Joint, Electrical Insulating tubes, Strain relief Tubs, MV Cable Joints, Cable Splice, Bus bar Insulation Product, Low Voltage Splices, LV Cable Joint, etc.

http://www.galathermo.com

1 note

·

View note

Photo

Gala Thermo Shrink PVT. LTD. a member of Gala Group of Industries with its establishments in the year 1979. entered into the business of Cable management products with specialization in the field of PVC and Heat Shrink, Heat Shrinkable range of products like cable end sealing caps, Cable End Caps, Spreader caps, heat shrink end caps, busbar insulation shrouds, anti-tracking tubes, MV Cable Joints, Protection Shroud etc.

http://www.galathermo.com

0 notes

Text

Mastic tape - Gala Thermo Shrink Pvt Ltd

http://www.galathermo.com

Gala Thermo Shrink PVT. LTD. a member of Gala Group of Industries with its establishments in the year 1979. entered into the business of Cable management products with specialization in the field of PVC and Heat Shrink, Heat Shrinkable range of products like cable end sealing caps, Cable End Caps, Spreader caps, heat shrink end caps, busbar insulation shrouds, anti-tracking tubes, MV Cable Joints, Protection Shroud etc.

0 notes

Text

Pump mechanical seal leakage cause

There are many types of mechanical seals for diesel trash pump, and the models are different, but there are five main leak points: a, the seal between the sleeve and the shaft; b, the seal between the moving ring and the sleeve; c, Seal between moving and static rings; d sealing between the stationary ring and the stationary ring seat; e, Sealing between the sealed end cap and the pump body. In general, the leakage between the shafts of the bushings, the seal end caps and the engine driven water pump body is easier to find and solve, but it needs to be carefully observed, especially when the working medium is liquefied gas or high pressure, toxic and harmful gas, it is relatively difficult. some. The remaining leaks are difficult to distinguish and judge intuitively. It is necessary to observe, analyze, and judge the leak symptoms on the basis of long-term management and maintenance practices in order to draw correct conclusions.

Dewatering pump

I. Analysis and judgment of leakage causes

1) Leak when installing the static test. After the mechanical seal is installed and debugged, it is generally necessary to perform a static test to observe the amount of leakage. If the leakage is small, there are problems with the moving ring or static ring seal; when the leakage is large, it indicates that there is a problem between the friction pairs of the moving and stationary rings. On the basis of preliminary observation of the leakage amount and judging the leakage location, the vehicle can be manually observed. If there is no obvious change in the leakage amount, the static and dynamic ring seals have problems; if there is a significant change in the leakage amount during the cranking, it can be determined that it is moving. There is a problem with the static ring friction pair; if the leakage medium is sprayed in the axial direction, there are many problems in the moving ring sealing ring, and the leakage medium is sprayed to the periphery or leaks from the water cooling hole, and the static ring sealing ring is mostly invalid. In addition, the leakage channel can also exist at the same time, but there are generally primary and secondary differences. As long as the observation is meticulous and familiar with the structure, it can be judged correctly.

6 inch trash pump

2). Leakage that occurs during commissioning. After the static test of the mechanical seal of the pump, the centrifugal force generated by the high-speed rotation during operation will suppress the leakage of the medium. Therefore, the leakage of the mechanical seal during the test run is basically caused by the failure of the friction pairs of the moving and stationary rings after the failure of the seal between the shafts and the end caps. The main factors causing the failure of the friction pair seal are: 1, During operation, due to abnormal phenomena such as evacuation, cavitation, and rolling, a large axial force is caused to separate the moving and static ring contact surfaces; 2, The amount of compression is too large when installing the mechanical seal, resulting in severe wear and abrasion of the end face of the friction pair; 3, The moving ring seal ring is too tight, and the spring cannot adjust the axial floating amount of the moving ring; 4, The static ring seal ring is too loose, when the moving ring is axially floating, the static ring is separated from the static ring seat; 5, There are granular materials in the working medium, and the friction pair is in operation during operation, and the end face of the moving and static ring seal is detected;6, The design selection is wrong, the sealing end face is lower than the pressure deviation or the sealing material is more cold-shrinkable. The above phenomenon often occurs during trial operation, and can sometimes be eliminated by appropriately adjusting the static ring seat, etc., but most of them need to be reassembled and replaced.

3). Sudden leakage during normal operation. The sudden leakage of the centrifugal pump during operation is due to normal wear or has reached the service life, and most of them are caused by large changes in working conditions or improper operation and maintenance. evacuation, cavitation or rolling for a long time, resulting in seal damage; The actual output of the pump is too small, a large number of medium trailer mounted pump circulate, heat accumulates, causing gasification of the medium, resulting in seal failure; The return flow is too large, causing the sediment at the bottom of the suction side container (tower, kettle, tank, pool) to rise and damage the seal; For a longer period of time, there is no manual turning when restarting, and the friction pair tears the sealing surface due to adhesion; Increased corrosive, polymerizable, and gelatinous substances in the medium; The ambient temperature changes drastically; Frequent changes or adjustments in working conditions;

Sudden power outage or downtime. The diesel engine irrigation pump suddenly leaks during normal operation. If it cannot be found in time, it will often cause a big accident or loss. It must be taken seriously and effective measures taken.

Secondly, several misunderstandings in the mechanical seal inspection of dewatering pump. The greater the amount of spring compression, the better the sealing effect. In fact, if the spring compression amount is too large, the friction pair may be sharply worn and burned instantaneously; excessive compression causes the spring to lose the ability to adjust the end face of the moving ring, resulting in seal failure. The tighter the seal diagram of the moving ring, the better. In fact, the dynamic ring seal is too tight and harmful. First, the wear between the seal ring and the bushing is intensified, and the leakage is premature. Secondly, the resistance of the axial adjustment and movement of the moving ring is increased. When the working condition changes frequently, the adjustment cannot be timely; thirdly, the spring is excessively fatigued and easily damaged; It is to deform the moving ring seal and affect the sealing effect. The tighter the seal ring of the static ring, the better. The static ring seal is basically at rest, and the relatively tight seal will be better, but too tight is also harmful. First, the static ring seal is caused by excessive deformation, which affects the sealing effect. Secondly, the static ring material is mostly graphite, which is generally brittle. Excessive force is easy to cause fragmentation. Third, it is difficult to install and disassemble, and it is easy to damage the static ring. The tighter the impeller lock is, the better. In mechanical seal leakage, leakage between the bushing and the shaft (interaxial leakage) is relatively common. It is generally believed that the leakage between the shafts is that the impeller locks are not locked. In fact, there are many factors causing leakage between the shafts, such as the failure of the inter-axis pads, the offset, the impurities between the shafts, and the larger shape of the shaft and the sleeve. The position error, the contact surface is broken, there is a gap between the components on the shaft, and the shaft thread is too long, which causes leakage between the shafts. Excessive locking of the lock nut will only lead to premature failure of the inter-axis pad. On the contrary, the lock nut is moderately locked, so that the inter-shaft pad always maintains a certain compression elasticity. During operation, the lock nut will automatically lock in time, so that the shaft is always in good condition. Sealed state. The new one is better than the old one. Relatively speaking, the effect of using a new mechanical seal is better than that of the old one, but the quality or material selection of the new mechanical seal is not appropriate. The large dimensional error will affect the sealing effect; in the polymerizable and permeable medium, the static ring is not excessive. Wear or not replace it as well. Because the static ring is in a static state for a long time in the static ring seat, the polymer and impurities are deposited as one body, which has a good sealing effect. The repair is better than not. In the event of a mechanical seal leak, it is rushed to be repaired. In fact, sometimes the seal is not damaged. It is only necessary to adjust the working condition or properly adjust the seal to eliminate the leak. In this way, it avoids waste and can verify its own fault judgment ability, and accumulates maintenance experience to improve the quality of maintenance.

0 notes

Text

Heat Shrink

A member of Gala Group of Industries with its establishments in the year 1979. entered into the business of Cable management products with specialization in the field of PVC and Heat Shrinkable range of products like Heat Shrink, Cable Joints, Cable Terminations, cable end sealing caps, Spreader caps, heat shrink end caps, heat shrink tubes, heat shrink sleeve, Cable Accessories, PVC Caps, Cable Splicing Kit, Branch Joint, heat shrinkable four way cable breakout, Heat Shrink Tape, Transition Joint, Electrical Insulating tubes, Strain relief Tubs, MV Cable Joints, Cable Splice, Bus bar Insulation Product, Low Voltage Splices, LV Cable Joint, etc.

0 notes

Text

Heat Shrinkable Moulded Components

Yamuna Infra & Technology Pvt. Ltd have a complete range of heat shrinkable moulded components such as cable breakout boots, cable end sealing caps, rain sheds and other specialist products.

0 notes

Text

Ensuring Electrical Integrity: Exploring High Voltage Tape and End Caps

In the intricate realm of electrical systems, maintaining the integrity of connections is paramount. This article delves into two essential components that play a pivotal role in safeguarding electrical connections: high voltage tape and end caps. Join us as we uncover the significance, features, applications, and advantages of these critical elements.

Unveiling High Voltage Tape High voltage tape is a vital tool used for insulating and protecting electrical connections in high voltage applications. This specialized tape provides a crucial layer of insulation that shields connections from environmental factors and ensures their longevity.

Key Features of High Voltage Tape Dielectric Strength: High voltage tape is engineered to withstand high electric field strengths, providing robust electrical insulation and preventing arcing and breakdown.

Material Composition: These tapes are often made from materials like rubber, silicone, or ethylene propylene rubber (EPR), which offer excellent electrical and thermal insulation properties.

Weather Resistance: High voltage tape is designed to resist weathering, UV exposure, and moisture, ensuring its effectiveness in outdoor applications.

Exploring End Caps End caps are protective components used to seal the ends of cables, preventing moisture, contaminants, and environmental factors from compromising cable integrity. These caps play a critical role in ensuring the reliability of cable connections.

Key Aspects of End Caps Material Selection: End caps are often crafted from materials such as polyethylene or silicone, providing effective sealing and insulation properties.

Design Variability: End caps come in various designs, including heat shrinkable, cold shrinkable, and push-on types, catering to different application requirements.

Environmental Protection: These caps offer a protective barrier against moisture, chemicals, and other external factors that can degrade cable performance.

Applications and Benefits High Voltage Tape:

Cable Insulation: High voltage tape is used to insulate and protect cable joints, terminations, and splices in high voltage applications, ensuring safe and efficient power transmission. Emergency Repairs: This tape is utilized for emergency repairs on damaged cable insulation, preventing further damage and ensuring continued operation. End Caps:

Cable Termination Protection: End caps are installed on cable terminations to prevent moisture ingress, maintaining the insulation properties of the cable and ensuring a longer lifespan. Connection Sealing: These caps are used to seal the ends of cables, providing protection against environmental factors and maintaining cable integrity. Installation Procedures for Optimal Performance Proper installation is crucial to ensure optimal performance of high voltage tape and end caps. Here's an overview of the installation process for these components:

High Voltage Tape:

Cable Preparation: Ensure the cable is clean and dry before applying the tape to achieve proper adhesion. Wrap and Overlap: Wrap the tape around the cable joint or termination, overlapping the layers to create a secure and effective insulation layer. End Caps:

Cable Preparation: Clean and dry the cable end before installing the end cap to ensure proper adhesion and sealing. Installation: Apply the end cap according to the manufacturer's instructions, ensuring a snug fit and proper sealing. Conclusion High voltage tape and end caps are indispensable components that contribute to the reliability, safety, and longevity of electrical connections. By providing electrical insulation, environmental protection, and sealing capabilities, these components play a significant role in maintaining the integrity of electrical systems.

Investing in premium high voltage tape and end caps is essential for industries seeking robust and dependable electrical infrastructure. With their dielectric strength, weather resistance, and sealing properties, these components ensure the continued and efficient operation of high voltage applications.

0 notes