#Power Cable Joint Kits

Explore tagged Tumblr posts

Text

Environmental Sustainability Of Power Cable Joint Kits

Power cable joint kits are integral to the modern electrical infrastructure, providing a reliable means of connecting power cables to ensure uninterrupted energy flow. These kits are not just tools for electrical engineers; they are also a testament to the ongoing efforts to create sustainable and resilient energy systems.

Power cable joint kits are essential in both underground and overhead electrical installations, providing reliable performance in high-voltage applications. They are widely used in industries such as power generation, construction, and utilities, ensuring long-lasting and secure electrical connections.

The design of power cable joint kits is crucial for maintaining the performance and longevity of the cables they connect. They are engineered to withstand the physical stress of cable movement and the environmental conditions they may encounter, such as temperature fluctuations, moisture, and potential mechanical damage.

One of the key aspects of power cable joint kits is their contribution to environmental sustainability. By ensuring that power cables are connected without loss of energy, these kits help reduce energy waste. This efficiency is particularly important in the context of renewable energy sources, where the efficient transmission of power from generation sites to consumers is essential.

0 notes

Text

Yamuna Power is one of the top Cable Jointing Kits Manufacturers. We offer strong and safe Power Cable Jointing Kits for all industries. Our products are trusted for quality and performance. Choose us for reliable cable jointing solutions every time. Worldwide shipping. For more details, visit: https://www.yamunapower.com/joints-heatshrink.php

0 notes

Note

Of course Jade! You're such a cute robot girl and deserve someone being nice to you, and I'm happy to volunteer as tribute~

Speaking of being nice, after that bad patch you probably need a proper treat to help you feel better~

run protocol: maintenanceMode(

systemShutdown = false,

sensorShutdown = false,

safeDisconnect = true,

selfMaintenance = false

),

System entering maintenance mode

Assuming safe position for motor shutdown

Motor systems shutting down

System is ready for maintenance

Don't worry, I still plan to find your sensors through trial and error, so I'll avoid any spoilers~

Opens my tool kit and takes out my spudging tool and hot air gun and begins slowly undoing your seals and removing your dust covers, organising them as I go, stripping off any old adhesives to replace them with fresh ones later. Once I've got easy access to all the maintenance screws and pins, I begin the work proper.

First I disconnect your left shoulder joint, doing some basic checks with the sensory cables still connected and getting your feedback, before fully disconnecting it and opening it up, cleaning lubricant residue and making you blush everytime I spitshine a part, removing worn parts and replacing them with new ones, making small adjustments to tensioning and positioning, and calibrating everything several times before doing a quick clean of the shoulder connectors and reattaching the joint and then the cables, your mind quickly flooding with all the sensations from your arm's internal memory, the way my hands were so firm as they held it, how my fingers interwove with yours as I tested grip calibration, even the occasional stroke against a particularly sensitive sensor, and just how pleasurable and comfortable everything is now~

After testing that the new calibration is correct and comfortable for your left arm, I repeat the process with your right arm, then circle around to your legs, your cooling system whirring in your ears as you feel several minutes worth of me gripping and touching your inner thighs being compressed into barely a second, as I take off your breast plate and open your torso to do some basic maintenance of your internal components, your battery icon flashing into view while I'm changing out your overcycled power unit for a nice fresh one that leaves you feeling energized as I close up your chest and give your breasts a quick clean before putting them back where they belong.

Next up I remove your vagina module and give it a quick once over and thoroughly clean both the internal components and the connectors, replacing a few frayed wires and ensuring that it'll feel just as sensitive as a brand new model, then plugs it back in and politely ignores the way your head thrashes in an orgasm that your body can't show.

And finally, I disconnect your head, your battery icon showing again as I quickly clean and tinker inside your neck, replacing a few corroded vertebrae modules and giving the whole lot a fresh coat of protectant and lubrication before reconnecting you and finishing up with some gentle processor maintenance and a quick removal and cleaning of your eyes, each of them giving you a few minutes of footage of looking at my lap and close-ups of my deep blue eyes when I reconnect them.

And then reactivates you and lets you feel how everything is just so much more comfortable and smooth, much as you'd imagine a human must feel after a long, comfortable massage. Finishing off with a kiss on the lips and a grin.

Hope you enjoyed getting some much deserved maintenance Jade, sorry if it was a little bit on the long side.

Now go have a drink of water to top up your coolant supply, it's steaming out of your ears~

A-Ah mnfffjdh useerrr mpg *bzzttt* M-My wirres are really sensitive >< I-I mmphhh hard to think after maintenance M-My fan is in overdrive C-Cant process mpggg wahhhhh N-Need to calm down or else I might just-

#brainwashing#hypnok1nk#trans nsft#hypnosis#robokink#hypnosub#roboposting#robogirl#robophilia#robotgirl

14 notes

·

View notes

Text

Clericar RGB :3

I've always had a fixation on car lighting, n ever since I've had a car myself, I always thought of silly ways to add a little cosmetic or utility lighting here and there. I particularly wanted to try LED "neon" underglow, for a touch of customizable, indirect color, that can be completely invisible when turned off.

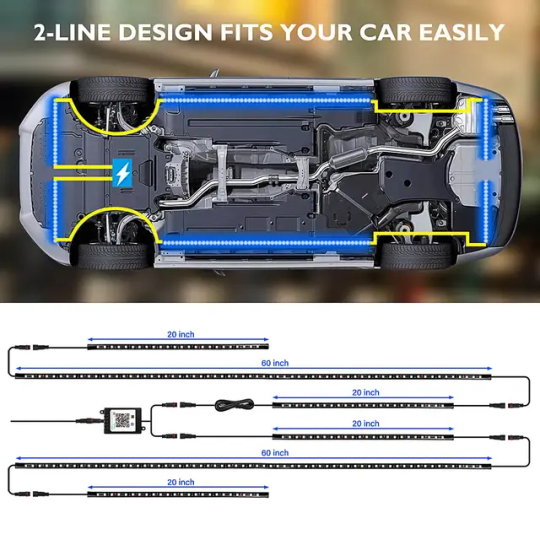

with my new car (someone cut me off at a red light in january :c) I've started getting more into doing my own maintenance and tweaking, n with a visit to my mom's place, with room to work and access to power tools, I figured it was the time :3 I got one of those inexpensive bluetooth kits on AliExpress, comprised of 2 chains of a 90cm strip, 180cm, and another 90cm, to be installed like this:

the dimensions seemed most appropriate for Clericar II

Friday

I started with the end of the chain, at the back. I don't trust the strip's pre-applied double-sided tape to hold them in place for any amount of time, even the official product page recommended to use zip ties.

There wasn't any obvious good spot to attach the strips in back, the two options were either the bottom of the rear bumper, or the chassis behind it, full of bumps, hot exhaust pipes, tow hitch, and other obstacles. The bumper seemed best, I drilled holes in the hollow plastic for zip ties, cleaned the surface, and installed the strips there

I had a bit of an oopsie with that first strip, bent it a bit too hard and broke some solder joints :< I thought it was best to leave it on and work on the rest, and worry about replacing it later, since i didnt bring my soldering iron. but! my mom has a Not Soldering Iron™ for engraving wood, so i went for a quick trip to the hardware store for solder n I managed to fix it :3 at the cost of weatherproofing

I routed the cables over and around the rear wheels to reach the sides of the car, and took a mental note to be careful about tight bends later.

I wasn't a big fan of the result so far, because just standing behind the car, the strips themselves were visible, and I would have preferred them to be entirely hidden. but in exchange, the light was covering a large area under and behind the car!

Saturday

Safely securing strips to the side of the car seemed like an impossible job: the sheet metal from the side panels folds towards the centre and is directly soldered to structural metal, leaving seemingly no room for zip ties:

My only bet were three holes with rubber plugs along the edge, but those would be too close to the edge, making the light strips visible (like in back), and interfering with jack points. I bashed my head at this problem, seeing that no one online seemed to have that issue (their car had more traditional side panel skirts, even among other low sporty cars).

Eventually, I found a blog post of someone building their own LED strips (before cheap ones on AliExpress were a thing) and attaching them with hot glue. Short of any other options, I figured that would work, and went out and bought a cheap glue gun.

I would still much prefer solid physical connection over glue,, but it was also a lot stronger than expected, so maybe this will do. The downside of having the strips farther from the edges is that the light on the ground doesn't spread nearly as much, but it was either that, or the strips getting squished next time I or a mechanic need to lift the car up.

I also used hot glue to fix the weatherproofing on that rear strip i re-soldered, and extra electrical tape just in case!

Sunday

The front bumper is almost ideal: a plastic surface, with a short lip to hide everything. drilling holes for zip ties wasn't easy, with the weird geometry down there, I should have probably removed the bumper entirely for easy access, but im strubborn so I managed

wiring was a bit annoying: I want the LEDs to be connected to accessory power, to turn on when I unlock the car, stay on when the car is on, and for a few minutes after turning off the engine, but no fuse inside the engine bay reflects this state. I can't easily pass a wire from the cabin to the engine bay either, at least not without removing a windshield wiper arm, which takes some tools I don't have (and am a bit scared to use ><)

most guides and even the product page recommend wiring it directly to the battery, and turning it on and off via bluetooth, which sounds like a terrible idea! imagine not noticing it's on in daylight and draining the battery, and also, even off, the control box is still emitting a BLE signal, that doesnt sound great! maybe I'll use one of those automatic DRL controllers, that detects when the engine is on with the voltage increase caused by the generator, and stays on for a minute after the engine is turned off, I got one at home

I ended up just hotwiring it to a headlight fuse, as safely as i could, n hopefully one day I can pass wires from the cabin to do what I want! im still not too happy with the wiring, there's some dodgy things i did cause i couldn't easily make holes in the wheel guards, and some lengths of cable that are a bit too long and risk sagging down under the car. the latter is easy to fix but the former idk!

the front light spread is rly nice, similar to the back but the light strips are well hidden! photos don't do it justice but I like the overall result a lot :D

I already know some people have comments about RGB lights on a car, but I do not care :3 I knew going into this that even in the car community, this is a controversial mod, I knew I was doing it for myself, and I like it! you can keep your negative comments for yourself ^ㅅ^

I wanna take more photos with street lights for better context, but thats it for now, thanks for following my silly adventures :D be extra safe when you jack your car, put fuses on any electrical system you install, keep your lights from flickering or flashing to not distract other drivers, and enjoy the road :) <3

3 notes

·

View notes

Text

Why Choose a Crimp Terminal Kit? A Complete Guide for DIYers and Professionals

Understanding Crimp Terminal Kits

A crimp terminal kit is an essential toolkit for professionals and hobbyists working with electrical systems, electronic assemblies, and hardware projects. These kits contain a variety of crimp connectors designed to ensure strong, reliable, and safe wire connections. Whether you're repairing cables in a laptop or wiring microcontrollers in a new build, a crimp terminal kit simplifies your work by providing all necessary terminals and tools in one convenient package.

What Makes a Crimp Terminal Kit So Valuable?

Crimp terminal kits are ideal for managing diverse wiring needs, offering everything from ring terminals to spade and butt connectors. These kits are especially useful in environments where durable and vibration-resistant connections are required, such as in controllers, microprocessors, and even industrial contactors. With everything organized in one kit, you reduce downtime, boost productivity, and improve safety on the job.

Key Components in a Typical Crimp Terminal Kit

A high-quality crimp terminal kit usually includes:

A range of terminals including ring, fork, spade, butt, and bullet types

Color-coded insulation for easy wire size identification

Heat-shrink or vinyl insulation for added protection

A crimping tool with interchangeable jaws or multi-functional features

Features That Make These Kits Essential

When it comes to selecting a crimp terminal kit, several standout features enhance its usability:

Pre-insulated terminals compatible with various wire gauges

Durable crimping tool designed for long-term use

Organised compartments that simplify selection and storage

Easy compatibility with standard cables, thermal wires, and LED leads

Ready-to-use design, suitable for on-site repairs and installations

Advantages of Using a Crimp Terminal Kit

Switching from soldering to crimping offers multiple benefits. Here’s why crimp terminal kits are a smart investment:

Speeds up wiring tasks by eliminating the need for heat or solder

Reduces the risk of overheating delicate sensors or capacitors

Provides a consistent connection quality for repeat jobs

Ensures safer terminations by reducing loose wire hazards

Enhances professionalism in electronics and automotive projects

Where Can You Use Crimp Terminal Kits?

Crimp terminal kits have versatile applications across various domains. Here are some key areas where they prove invaluable:

Electronics: Ideal for connecting LEDs, capacitors, microcontrollers, and sensors in circuit boards

Automotive repairs: Reliable connections for lights, switches, and fuses

Home improvement: Installing lighting fixtures, sockets, and safety alarms

Industrial equipment: Wiring machines, contactors, and control systems

Laptop repair: Rewiring broken cables, fan connections, and power jacks

DIY projects: Creating custom electronics, robotics, or smart home setups

Tips for Using Crimp Terminals Properly

To ensure optimal performance and long-term reliability of your crimped connections:

Strip the correct amount of insulation from the wire

Match the wire gauge to the correct terminal size

Use the appropriate crimping tool for the terminal type

Test the strength of the connection before installation

Add thermal pads or protective sleeves when working in high-heat zones

Crimping vs. Soldering: Which Is Better?

Although soldering has its place in electronics, crimping offers faster, cleaner, and more vibration-resistant connections. Crimp terminals are easier to handle, especially when you're working in tight spaces like electrical panels, under dashboards, or inside laptop housings. Moreover, crimped joints are widely accepted in professional industries because of their consistent quality and reduced need for post-installation inspection.

Choosing the Right Kit for Your Needs

When selecting a crimp terminal kit, it's essential to consider the following:

Connector variety: Does the kit include connectors for your specific projects involving controllers or sensors?

Wire range compatibility: Can it handle standard sizes used in electronics and thermal setups?

Tool durability: Is the crimping tool ergonomic and suited for repeated use with cables and grips?

Kit size: Does it include enough pieces for large projects without constant repurchasing?

Final Thoughts: Why Every Workshop Needs a Crimp Terminal Kit

In summary, a crimp terminal kit is a smart, convenient, and safety-driven investment for anyone working with electronics, wiring, or repairs. It enhances workflow, provides secure and long-lasting connections, and supports a broad range of applications, whether you're fixing microcontrollers, setting up switches, or managing sensors in an industrial setting. With benefits that span across tools, cables, oils, connectors, and more, there's no reason to delay adding one to your workspace.

0 notes

Text

How Do Power, Motor & Robotics Development Tools Drive Innovation in Automation?

Introduction to Modern Development Ecosystems

As the era of intelligent machines, automation, and smart manufacturing continues to advance, Power, Motor & Robotics Development Tools have emerged as essential components in transforming ideas into functioning prototypes and commercial solutions. These tools serve as the backbone for developing precise and reliable control systems used in a wide variety of sectors—from industrial robotics to electric mobility.

With the increasing integration of microcontrollers, sensors, thermal management components, and electronic controllers, development tools offer a modular and practical approach to building sophisticated electronic and electromechanical systems.

What Are Power, Motor & Robotics Development Tools?

Power, Motor & Robotics Development Tools consist of hardware kits, interface boards, and control modules designed to help developers and engineers test, prototype, and deploy automated systems with precision and speed. These tools make it possible to manage current, voltage, mechanical motion, and real-time decision-making in a structured and scalable manner.

By combining essential components such as capacitors, fuses, grips, cables, connectors, and switches, these kits simplify complex engineering challenges, allowing smooth integration with controllers, microprocessors, and sensors.

Exploring the Primary Toolsets in the Field

Power Management Development Tools

Efficient energy management is crucial for ensuring stability and performance in any robotic or motor-driven system.

Development boards supporting AC/DC and DC/DC conversion

Voltage regulators and surge protection circuits for safe energy flow

Thermal sensors and oils to maintain system temperature

Battery management ICs to control charge-discharge cycles

High-efficiency transformers and current monitors

Motor Control Development Tools

Motor control kits are built to manage torque, direction, and speed across a range of motor types.

H-bridge motor drivers for bidirectional motor control

Stepper motor controllers with high-precision movement

Brushless DC motor driver modules with thermal protection

Feedback systems using encoders and optical sensors

PWM-based modules for real-time torque adjustment

Robotics Development Tools

Robotics kits merge both mechanical and electronic domains to simulate and deploy automation.

Preassembled robotic arm platforms with programmable joints

Sensor integration boards for object detection, motion sensing, and environmental monitoring

Wireless modules for IoT connectivity using BLE, Wi-Fi, or RF

Microcontroller development platforms for logic execution

Mounting hardware and cable grips for secure installations

Benefits of Using Professional Development Tools

Advanced development kits offer more than just experimentation—they serve as stepping stones to commercial production. These tools minimize development time and maximize productivity.

Enhance system performance with modular plug-and-play designs

Enable easy integration with laptops, diagnostic tools, and controllers

Reduce design errors through pre-tested circuitry and embedded protection

Facilitate rapid software and firmware updates with compatible microcontrollers

Support debugging with LED indicators, thermal pads, and status feedback

Key Applications Across Industries

The adaptability of Power, Motor & Robotics Development Tools makes them suitable for countless industries and applications where intelligent movement and power efficiency are essential.

Industrial robotics and pick-and-place systems for manufacturing automation

Smart agriculture solutions including automated irrigation and drone control

Automotive design for electric vehicle propulsion and battery systems

Aerospace applications for lightweight, compact control mechanisms

Educational platforms promoting STEM learning with hands-on robotics kits

Essential Components that Enhance Development Kits

While the kits come equipped with core tools, several other components are often required to expand capabilities or tailor the kits to specific use cases.

Sensors: From temperature and light to current and magnetic field detection

Connectors and plugs: For flexible integration of external modules

Switches and contactors: For manual or automatic control

Thermal pads and heatsinks: For preventing overheating during operation

Fuses and circuit protection devices: For safeguarding sensitive electronics

LED displays and character LCD modules: For real-time data visualization

How to Choose the Right Tool for Your Project

With a vast array of kits and tools on the market, selecting the right one depends on your application and environment.

Identify whether your project focuses more on power management, motor control, or full robotic systems

Consider compatibility with popular development environments such as Arduino, STM32, or Raspberry Pi

Check the current and voltage ratings to match your load and motor specifications

Evaluate add-on support for wireless communication and real-time data processing

Ensure the tool includes comprehensive documentation and driver libraries for smooth integration

Why Development Tools Are Crucial for Innovation

At the heart of every advanced automation solution is a well-structured foundation built with accurate control and reliable hardware. Development tools help bridge the gap between conceptualization and realization, giving engineers and makers the freedom to innovate and iterate.

Encourage experimentation with minimal risk

Shorten product development cycles significantly

Simplify complex circuit designs through preconfigured modules

Offer scalability for both low-power and high-power applications

Future Scope and Emerging Trends

The future of development tools is headed toward more AI-integrated, real-time adaptive systems capable of learning and adjusting to their environment. Tools that support machine vision, edge computing, and predictive analytics are gaining traction.

AI-powered motion control for robotics

Integration with cloud platforms for remote diagnostics

Advanced motor drivers with feedback-based optimization

Miniaturized power modules for wearable and mobile robotics

Conclusion: Is It Time to Upgrade Your Engineering Toolkit?

If you're aiming to build smarter, faster, and more energy-efficient systems, Power, Motor & Robotics Development Tools are not optional—they’re essential. These kits support you from idea to implementation, offering the flexibility and performance needed in modern-day innovation.

Whether you're developing a prototype for a high-speed robotic arm or integrating power regulation into a smart grid solution, the right development tools empower you to transform challenges into achievements. Take the leap into next-gen automation and electronics by investing in the tools that make engineering smarter, safer, and more efficient.

#Power Motor & Robotics Development Tools#electronic components#technology#electricalparts#halltronics

0 notes

Text

How Gulf Trans Power Simplifies Procurement of Electrical Bulk Material in Dammam

Introduction

Efficient procurement is the backbone of every successful industrial project. From construction to oil and gas, the ability to access reliable electrical supplies on time can mean the difference between meeting deadlines and costly delays. Gulf Trans Power stands out as a trusted supplier, helping industries in Dammam streamline the sourcing of complex and large-scale components. This blog explores how Gulf Trans Power simplifies the acquisition of Electrical bulk material in Dammam, making the process faster, more reliable, and fully tailored to project needs.

Challenges in Bulk Electrical Procurement

Industrial clients face multiple procurement challenges, such as:

Delayed deliveries from non-local or inconsistent vendors

Shortage of specialized components at critical phases

Compliance issues with local and Aramco standards

Lack of technical support during material selection

Inadequate documentation or certifications for inspection

Gulf Trans Power addresses these obstacles head-on through experience, scale, and deep market understanding.

A One-Stop Source for All Electrical Bulk Needs

Rather than sourcing materials from multiple vendors, Gulf Trans Power acts as a centralized supply partner. We offer a complete range of products including:

Cable trays and accessories

Conduits and fittings

Junction boxes

Cable sealing kits

Termination and jointing kits

Grounding and earthing systems

This minimizes the administrative burden on your procurement team while ensuring material compatibility across all system components.

Local Expertise and On-Time Delivery

Being based in Dammam gives Gulf Trans Power an edge. We understand regional logistics, warehouse availability, and project dynamics specific to the Eastern Province. By working closely with clients and manufacturers, we ensure:

Fast quotations and order confirmation

Local stocking of frequently used items

Scheduled deliveries aligned with site demands

Immediate response to urgent or short-notice requirements

This eliminates downtime caused by late shipments or incomplete deliveries.

Technical Support from Specification to Inspection

Our role goes beyond material supply. Gulf Trans Power provides engineering and compliance support to ensure that all electrical bulk items meet the right standards. We assist with:

Interpreting project BOQs

Recommending compatible brands and specs

Providing datasheets and certifications

Supporting QA/QC documentation for inspections

This is especially critical for Aramco, Sabic, and SEC-approved projects, where non-compliance can lead to costly rejections.

Integration with Broader Systems

Gulf Trans Power not only supports power distribution but also plays a role in smart infrastructure development. We integrate bulk electrical supply with intelligent networking components, offering solutions that support both energy and communication needs. For example, a project may require a data connectivity solution in Saudi Arabia to operate alongside traditional power infrastructure—Gulf Trans Power ensures these systems are compatible from the start.

Conclusion

For industrial contractors, EPC companies, and facility managers, choosing the right supplier is crucial. Gulf Trans Power makes the process of sourcing Electrical bulk material in Dammam efficient, compliant, and worry-free. With local expertise, comprehensive stock, and end-to-end technical support, we simplify your procurement process so you can focus on project execution.

🔗 Looking for reliable bulk electrical and data connectivity solutions? Visit us at: https://www.gulftranspower.com/products/electric-bulk-materials/

0 notes

Text

Must-Have Cable Tray Accessories for Secure & Efficient Installations

Introduction

A well-designed cable tray system is crucial for organized and safe electrical wiring in industrial, commercial, and data center applications. However, the real strength of a cable tray system lies in its accessories—components that ensure stability, safety, and ease of maintenance.

In this guide, we’ll explore the essential cable tray accessories that every installer, contractor, and project manager should consider for secure, efficient, and long-lasting installations.

Cable Tray Accessories

Why Are Cable Tray Accessories Important?

Cable tray accessories enhance: ✔ Safety – Prevent cable slippage, short circuits, and fire hazards. ✔ Durability – Reinforce joints and protect against corrosion. ✔ Flexibility – Allow bends, expansions, and directional changes. ✔ Ease of Maintenance – Simplify inspections and future upgrades.

Without the right accessories, cable trays may fail under stress, leading to costly downtime and safety risks.

Cable Tray Manufacturer

Top 10 Must-Have Cable Tray Accessories

1. Cable Tray Brackets & Supports

Purpose: Securely mount trays to walls, ceilings, or structures.

Types: Cantilever brackets, trapeze hangers, and wall-mounted supports.

Best for: Overhead installations in factories and data centers.

2. Cable Tray Clamps (Straps & Fasteners)

Purpose: Hold cables firmly in place to prevent movement.

Types: Stainless steel clamps, nylon straps, and snap-in clips.

Best for: High-vibration environments like power plants.

3. Splice Plates (Connectors)

Purpose: Join two cable tray sections seamlessly.

Types: Straight, adjustable, and hinge-type splice plates.

Best for: Extending tray runs without weak points.

4. Reducers & Transition Pieces

Purpose: Connect trays of different widths or depths.

Types: Tapered reducers, offset transitions.

Best for: Adapting tray sizes in complex layouts.

5. Elbows & Bends

Purpose: Change direction (90°, 45°, or custom angles).

Types: Horizontal, vertical, and adjustable elbows.

Best for: Routing cables around obstacles.

6. Cable Tray Covers (Lids)

Purpose: Protect cables from dust, moisture, and physical damage.

Types: Solid, ventilated, and lockable covers.

Best for: Outdoor or hazardous locations.

7. Dropout Plates & Cable Entry Plates

Purpose: Allow cables to exit/enter trays neatly.

Types: Knockout plates, gland plates.

Best for: Linking trays to control panels or junction boxes.

8. Grounding Kits & Bonding Jumpers

Purpose: Ensure electrical safety by grounding metal trays.

Types: Copper braids, grounding clamps.

Best for: Compliance with NEC/IEC standards.

9. Cable Tie Mounts & Cleats

Purpose: Organize and bundle cables within trays.

Types: Adhesive mounts, screw-fixed cleats.

Best for: Preventing tangled wires in IT racks.

10. End Caps & Splash Guards

Purpose: Seal tray ends to prevent debris/rodent entry.

Types: Rubber grommets, metal caps.

Best for: Food processing plants and outdoor setups.

Wire Mesh Cable Tray Accessories

How to Choose the Right Accessories?

Consider these factors: 🔹 Material (Stainless steel for corrosive areas, galvanized for general use). 🔹 Load Rating (Match accessories to tray weight capacity). 🔹 Fire Resistance (Critical for tunnels and high-risk zones). 🔹 Ease of Installation (Quick-fit vs. bolt-on designs).

Common Mistakes to Avoid

❌ Ignoring corrosion protection (Use zinc-plated or powder-coated accessories in humid areas). ❌ Overlooking expansion joints (Prevent warping in long runs). ❌ Skipping grounding (Avoid electrical hazards).

Conclusion

The right cable tray accessories make the difference between a safe, efficient installation and a hazard-prone mess. Whether you’re working on a data center, factory, or commercial building, investing in high-quality accessories ensures long-term reliability and compliance.

🚀 Pro Tip: Partner with a trusted manufacturer who provides certified, custom-ready accessories for your project needs!

Call to Action

📞 Need expert advice on cable tray accessories? Contact Less Wire Forms today! 📧 Email: [email protected] | 🌐 Website: www.madewithless.in

#Wire mesh cable tray manufacturer#Industrial cable trays#Cable tray manufacturer#Wire mesh cable tray

0 notes

Text

Essential Guide to Power Cable Joint Kits

Power cable joint kits are essential tools in ensuring that electrical connections are secure, efficient, and safe. These kits are designed to facilitate the joining of power cables, whether for repairs, extensions, or new installations.Cable joints are critical points in any electrical system where two lengths of cable are connected. A poorly made joint can pilot a range of issues, from power loss to safety hazards such as electrical shorts or fires. Power cable joint kits address these concerns by providing all the necessary components and tools to create a robust and secure connection.A typical power cable joint kit includes several essential items. The one is the joint itself, which can be a variety of types depending on the application. There are joint kits designed for both indoor and outdoor use, with different materials to withstand environmental conditions such as moisture or UV radiation.The kit also includes a variety of connectors, which are chosen based on the type of cable being joined. These connectors ensure a secure electrical connection and can be designed for different voltage levels and current capacities.

0 notes

Text

MV Cable Joints

In modern electrical infrastructure, MV Cable Joints (Medium Voltage Cable Joints) play a critical role in maintaining the integrity and safety of power distribution systems. Whether it's an industrial facility, utility network, or infrastructure project, MV cable joints ensure smooth and secure connections for medium voltage cables, typically ranging from 1kV to 36kV.

If you're looking to improve the performance and reliability of your medium voltage systems, understanding the importance of high-quality MV cable joints is essential.

What Are MV Cable Joints?

MV Cable Joints are specialized electrical components used to connect two or more medium voltage cables. They are designed to maintain electrical continuity, mechanical strength, and environmental sealing. These joints are commonly used in underground, overhead, and substation cable installations.

Depending on the application, MV cable joints may be heat shrink, cold shrink, or resin-cast types, each offering different advantages in terms of installation, durability, and environmental resistance.

Key Features and Benefits of MV Cable Joints

✅ Electrical Reliability Ensure consistent and safe power transmission with excellent insulation properties.

✅ Weather and Moisture Resistance MV joints are designed to withstand harsh environmental conditions, making them suitable for outdoor and underground use.

✅ Mechanical Strength Reinforced materials protect against physical stress, vibration, and cable movement.

✅ Ease of Installation Available in user-friendly kits with pre-tested components to minimize downtime.

✅ Long Service Life Manufactured using high-grade materials to deliver long-term performance and protection.

Types of MV Cable Joints

Heat Shrink Cable Joints

Ideal for environments requiring a moisture-tight seal

Easy to transport and store

Requires heat gun for installation

Cold Shrink Cable Joints

Tool-free, safer installation

Suitable for confined or hazardous spaces

Pre-expanded sleeves that contract over time

Resin-Cast Joints

High mechanical protection

Excellent chemical and moisture resistance

Often used in industrial or heavy-duty applications

Applications of MV Cable Joints

MV Cable Joints are used in a wide variety of sectors, including:

Power generation and distribution networks

Renewable energy (solar/wind farms)

Oil and gas facilities

Rail and transport infrastructure

Commercial and industrial complexes

Utility substations

Their ability to maintain reliable electrical performance makes them indispensable for any medium-voltage application.

Choosing the Right MV Cable Joint

When selecting an MV cable joint, consider the following:

Voltage rating (e.g., 11kV, 22kV, 33kV)

Type of cable (XLPE, PILC, etc.)

Environmental conditions (outdoor, buried, underwater)

Installation preferences (heat shrink vs. cold shrink)

Compliance with international standards (IEC, IEEE)

High-quality MV cable joints reduce the risk of failure, improve safety, and minimize costly maintenance.

Final Thoughts

Reliable MV Cable Joints are the backbone of medium-voltage electrical systems. Choosing the right jointing solution ensures electrical performance, safety, and longevity in critical infrastructure. Whether you're designing a new system or maintaining existing installations, always invest in certified, high-performance MV cable joint kits.

0 notes

Text

Buy Cable Jointing Kits & Switchgears Online – Ranjit Electrical

Looking to buy cable jointing kits online or switchgears for your electrical needs? Ranjit Electrical offers top-quality products at the best prices. From reliable cable jointing kits to durable switchgears, find everything you need in one place. Easy online shopping, fast delivery, and trusted service make us your go-to choice. Explore our wide range now and get the best deals on switchgears online for sale. Shop smart and power up with Ranjit Electrical!

0 notes

Text

Exothermic Welding Cost: The True Value Behind Reliable Electrical Connections

In the world of electrical grounding, reliability and safety are non-negotiable. That’s why Exothermic Welding remains a top choice for engineers, contractors, and utility providers around the globe. While this technique offers unmatched performance, many people are curious to understand the actual Exothermic Welding Cost and what they get in return for their investment.

In this blog, we’ll break down all the key factors that influence Exothermic Welding Cost, why it’s a smart long-term choice, and how Amiable Impex provides affordable, high-quality solutions to meet all your project needs.

What Is Exothermic Welding?

Before diving into costs, it’s important to understand what Exothermic Welding is. It’s a fusion process that creates a molecular bond between conductors using a controlled chemical reaction involving Exothermic Welding Powder manufacturer.

This permanent, corrosion-resistant connection is often used in:

Electrical grounding systems

Lightning protection networks

Railway signaling systems

Oil and gas infrastructure

Industrial power plants

Unlike mechanical connections, exothermic welds don’t loosen over time, making them ideal for critical applications.

What Makes Up the Exothermic Welding Cost?

Several components contribute to the overall Exothermic Welding Cost. Let’s look at the major ones:

1. Exothermic Welding Mould

This is a graphite mould used to hold conductors in place during the weld. Depending on its size and type, it can be reused up to 70 times. The quality of the mould is crucial, and that’s where trusted manufacturers like Amiable Impex stand out.

Estimated Cost: ₹3,000–₹7,000 (depending on size and connection type)

2. Exothermic Welding Powder

This powder is the fuel that drives the thermite reaction. It’s available in various sizes – typically 45g to 250g. The amount you need depends on the connection type and material being welded.

Estimated Cost: ₹100–₹400 per unit

3. Exothermic Welding Kit

If you’re new to exothermic welding or starting a new project, a complete Exothermic Welding Kit may be required. It includes moulds, powder, ignition tools, brushes, and safety equipment.

Exothermic Welding Kit Price: ₹6,000–₹15,000 depending on customization

4. Labor Cost

While exothermic welding is straightforward, it requires trained professionals for best results. Labor costs may vary depending on your location and project complexity.

Why Exothermic Welding Cost Is Justified

✅ Long-Term Durability

A properly executed exothermic weld will last for decades. Compared to mechanical clamps or compression fittings that need regular inspection and replacement, exothermic welding is virtually maintenance-free.

✅ Corrosion Resistance

The molecular bond created during the reaction is highly resistant to corrosion — a common problem in harsh or wet environments. This eliminates the cost of rework and replacement.

✅ Better Conductivity

Since the connection is molecular, there’s minimal resistance, leading to more efficient current flow. Over time, this improves system performance and energy efficiency.

✅ No External Power Needed

One of the hidden savings in Exothermic Welding Cost is that it doesn’t require electricity or heavy machinery. A simple ignition system is enough to complete the weld.

Factors That Affect Your Project Cost

Even within exothermic welding, not all costs are fixed. Here's what affects the final Exothermic Welding Cost:

🔸 Project Size

More welds = more powder, moulds, and time.

🔸 Type of Joint

Cable-to-cable joints cost less than cable-to-rod or rod-to-rod joints.

🔸 Powder Size

Heavier gauge cables need more powder, increasing material costs.

🔸 Mould Reusability

Investing in a durable mould saves you money over multiple welds.

🔸 Supplier Location

Shipping and import duties can affect pricing if your supplier is overseas. That’s why working with a global supplier like Amiable Impex gives you better value.

Get the Best Price with Amiable Impex

Amiable Impex is a global leader in Exothermic Welding Solutions. Whether you’re looking for a single mould or a complete project kit, we ensure the best value with:

Premium graphite Exothermic Welding Moulds

High-purity Exothermic Welding Powder

Cost-effective Exothermic Welding Kit Price

Reliable customer support

Fast global delivery

Explore all our products atexothermic-welding.com and request a custom quote today.

Tips to Optimize Your Exothermic Welding Cost

Here are a few expert tips to keep your project on budget:

✔️ Plan Ahead

List all the joints and connections you’ll need to make. This will help you order moulds and powder in the right quantities.

✔️ Buy in Bulk

Ordering powder or kits in larger quantities can help lower per-unit costs.

✔️ Maintain Your Mould

Clean and store your moulds properly between uses to increase their lifespan.

✔️ Choose Quality Over Cheap

Don’t compromise on the purity of Exothermic Welding Powder or mould quality just to save a few bucks. It’ll cost more in failures and rework.

Common Questions About Exothermic Welding Cost

Q1. Can I reuse the mould to reduce cost? A1. Yes, most high-quality moulds (like those from Amiable Impex) can be reused up to 70 times with proper care.

Q2. Is exothermic welding worth the investment for small projects? A2. Absolutely. Even if your project is small, the permanent bond and zero maintenance make it a smart long-term investment.

Q3. What is the average Exothermic Welding Kit Price? A3. A complete kit can range between ₹6,000 and ₹15,000, depending on your project size and required accessories.

Final Thoughts: Is the Exothermic Welding Cost Worth It?

The short answer is — yes. Whether you’re working on an industrial grounding system, railway infrastructure, or a renewable energy project, Exothermic Welding delivers unmatched safety, durability, and efficiency. And when sourced from a reliable company like Amiable Impex, you get premium quality at a competitive price.Ready to take the next step? 📞 Contact Amiable Impex or visitexothermic-welding.com for customized quotes, product catalogs, and expert guidance.

0 notes

Text

Yamuna Power is a leading cable jointing kits manufacturer and supplier from India that offers a wide range of cable jointing kits at reasonable prices with fast worldwide shipping. Enquire now! For more details, visit: https://www.yamunapower.com/joints-heatshrink.php

0 notes

Text

Essential Boat Maintenance Equipment for Long-Lasting Performance

Proper boat maintenance is key to ensuring a long-lasting, safe, and efficient vessel. Regular upkeep not only enhances performance but also prevents costly repairs. Having the right maintenance Boat Equipment makes the process easier and more effective. Here are some essential boat maintenance tools every boat owner should have.

1. Cleaning and Care Supplies

Keeping your boat clean prevents corrosion, algae buildup, and general wear and tear. Some must-have cleaning supplies include:

Marine-Grade Boat Soap – Specially formulated to remove salt, grime, and stains without harming the boat’s finish.

Soft-Bristled Brushes – Helps clean decks and hulls without scratching surfaces.

Microfiber Cloths and Chamois – Ideal for drying and polishing boat surfaces.

Hull Cleaner – Removes tough stains and waterline marks.

Regular cleaning maintains the boat’s aesthetic appeal and prevents damage caused by dirt and salt accumulation.

2. Engine Maintenance Tools

A well-maintained engine ensures smooth operation and prevents breakdowns. Essential tools include:

Oil Change Kit – Includes an oil pump, marine-grade engine oil, and an oil filter.

Fuel Stabilizer – Prevents fuel degradation and protects the engine from clogging.

Spark Plug Wrench – Necessary for replacing spark plugs and ensuring proper ignition.

Belt and Hose Inspection Kit – Helps detect cracks and wear in engine belts and hoses.

Routine engine maintenance increases fuel efficiency and prolongs the lifespan of the boat’s motor.

3. Electrical and Battery Maintenance Equipment

A reliable electrical system is essential for navigation, lighting, and communication. Important electrical maintenance tools include:

Multimeter – Helps diagnose voltage and electrical issues.

Battery Charger – Keeps marine batteries fully charged and prevents power loss.

Wire Brush and Terminal Cleaner – Used to clean battery terminals and prevent corrosion.

Fuses and Spare Wiring – Essential for quick electrical repairs.

Proper battery maintenance ensures that your boat’s electrical systems remain functional throughout every trip.

4. Lubrication and Corrosion Prevention

Saltwater and moisture can lead to rust and corrosion, so investing in protective products is necessary. Consider using:

Marine Grease – Lubricates moving parts such as steering cables and trailer bearings.

Anti-Corrosion Spray – Protects metal components from rust and oxidation.

Silicone Sealant – Helps prevent leaks and seals joints effectively.

These maintenance tools keep your boat running smoothly and extend the life of critical components.

Conclusion

Investing in proper boat maintenance equipment ensures that your vessel remains in top condition for years. Regular cleaning, engine checks, and electrical upkeep not only improve performance but also enhance safety on the water. By staying proactive with maintenance, you can avoid costly repairs and enjoy worry-free boating adventures.

1 note

·

View note

Text

Find the Best Audi Car Spares for Your Vehicle

Owning an Audi is a symbol of luxury, performance, and advanced engineering. To maintain the longevity and efficiency of your Audi, it’s essential to regularly service it with high-quality Audi car spares. Whether you need routine maintenance or a replacement part, finding the right Audi spare parts is key to ensuring your vehicle continues to perform at its best. In this blog, we will explore how to source Audi spares, why using original Audi spare parts is crucial, and the advantages of buying Audi spare parts online.

Why Choosing the Right Audi Car Spares is Essential

Audi vehicles are known for their precision engineering and high performance. However, even the most dependable cars require maintenance and repairs occasionally. Audi car spares play a significant role in maintaining the optimal performance of your vehicle, ensuring that it runs smoothly and reliably.

The right Audi spare parts can extend the life of your car and improve safety and efficiency. Using genuine parts is especially important as they are designed specifically for Audi vehicles, offering superior performance and durability. With counterfeit or non-original parts, you might experience compatibility issues, which can lead to expensive repairs or compromised vehicle performance.

Types of Audi Car Spares

Audi offers a wide range of parts that cater to the different systems and components in your car. Some common Audi spares include:

Engine Parts: The engine is the heart of your Audi, and using quality Audi spare parts for its maintenance is essential. This includes parts like air filters, oil filters, timing belts, and spark plugs.

Suspension and Steering Parts: These parts include struts, shock absorbers, control arms, and ball joints. Regular replacement of suspension parts ensures a smooth and stable ride.

Brakes and Clutch Parts: Audi vehicles require high-performance brake pads, rotors, and clutch components to ensure safe and efficient braking. Choosing the right Audi spare parts for your brake system is crucial to maintain driving safety.

Transmission and Gearbox Parts: Whether you own a manual or automatic Audi, the transmission and gearbox are integral to your vehicle’s functionality. Parts such as clutch kits, gear cables, and transmission fluid are essential for smooth shifting and power delivery.

Electrical Components: Audi cars come with advanced electrical systems, and parts like alternators, batteries, ignition coils, and sensors help ensure that the electrical components of your car operate efficiently.

The Importance of Genuine Audi Spare Parts

When replacing parts in your Audi, it’s always advisable to use genuine Audi spare parts rather than generic alternatives. Here’s why:

Performance: Genuine Audi spare parts are designed specifically for your vehicle, ensuring they match the specifications and standards set by the manufacturer. This guarantees the parts will function properly, maintaining the performance of your Audi.

Durability: Audi spares are built to last. They are made with high-quality materials that offer superior durability and performance compared to aftermarket parts.

Fit and Compatibility: Original Audi spare parts are guaranteed to fit perfectly with your car, reducing the chances of incompatibility or the need for further modifications, which can be costly.

Warranty and Reliability: Genuine parts often come with a warranty, providing you with peace of mind. Using original Audi car spare parts ensures that your car remains covered under the manufacturer’s warranty, reducing the risk of expensive repairs due to faulty parts.

Buying Audi Spare Parts Online

In today’s digital age, buying Audi spare parts online has become a convenient and cost-effective way to maintain your vehicle. Online retailers provide a broad selection of Audi parts, often at more competitive prices than traditional stores.

Convenience: Shopping online allows you to browse a vast selection of Audi spare parts at your own pace, without having to leave your home. You can easily compare prices, check availability, and find the exact parts you need with just a few clicks.

Wide Selection: Online retailers typically carry a wide variety of Audi car spares, including rare or hard-to-find parts. This makes it easier to find the parts you need, no matter how specific or unique.

Competitive Prices: Online stores often offer lower prices compared to physical stores due to reduced overhead costs. Additionally, many online retailers offer seasonal promotions and discounts that make it easier to find Audi spare parts within your budget.

Customer Reviews: One of the major advantages of shopping online is the ability to read customer reviews and ratings. This helps you gauge the quality and reliability of the parts before purchasing, ensuring you’re buying the right Audi spares.

How to Choose the Best Audi Spare Parts Online

When buying Audi spare parts online, it’s essential to choose a trusted and reliable retailer.

Check for Authenticity: Ensure that the online store sells genuine Audi spare parts and not counterfeit products. Look for authorized Audi retailers or dealerships that offer original parts.

Verify Return Policy: Before purchasing, check the retailer’s return policy. A good return policy allows you to return parts if they are defective or not compatible with your vehicle.

Look for Warranty: Choose parts that come with a manufacturer’s warranty. This ensures that you’re getting high-quality parts and offers protection in case of defects.

Compare Prices: While buying online, it’s easy to compare prices from different retailers. Don’t forget to factor in shipping costs when comparing prices to ensure that you are getting the best deal on Audi car spares.

Buy Audi Spare Parts Online at Partstore

When it comes to maintaining your Audi, using the right parts is essential for the performance and longevity of your vehicle. Whether you're looking for Audi car spares, Audi spare parts, or Audi spares, finding a reliable source is crucial. Partstore offers a wide selection of Audi spare parts online, ensuring that you have access to high-quality, genuine parts at competitive prices.

0 notes

Text

How Shear Bolt Connectors Enhance Performance in Cable Jointing Kits

Shear bolt connectors are key components in cable jointing kits, playing a vital role in enhancing performance and reliability. This article explores how shear bolt connectors contribute to the efficiency and effectiveness of cable jointing kits, emphasizing their functionality, advantages, and impact on electrical installations.

Understanding Shear Bolt Connectors

Shear bolt connectors are mechanical connectors designed to securely join electrical cables together in a robust and reliable manner. They consist of a bolt or screw mechanism that, when tightened, compresses the conductors within the connector, creating a strong and low-resistance electrical connection. Shear bolt connectors are commonly used in medium and high-voltage applications where the integrity of the electrical connection is crucial.

Key Functions of Shear Bolt Connectors in Cable Jointing Kits

The importance of shear bolt connectors in cable jointing kits lies in their essential functions:

Secure Connection: Shear bolt connectors provide a secure and stable connection between electrical cables, ensuring continuity and reliability in power transmission.

Mechanical Strength: The robust construction of shear bolt connectors enables them to withstand mechanical stress, vibration, and environmental factors, maintaining the integrity of the joint over time.

Electrical Performance: Shear bolt connectors offer low-resistance electrical connections, minimizing power losses and ensuring efficient energy transmission.

Corrosion Resistance: High-quality shear bolt connectors are designed to resist corrosion and oxidation, preserving the electrical conductivity of the joint and extending its service life.

Ease of Installation: Cable jointing kits with shear bolt connectors are designed for easy and straightforward installation, reducing labor costs and downtime during installation and maintenance activities.

Advantages of Shear Bolt Connectors in Cable Jointing Kits

The use of shear bolt connectors in cable jointing kits offers several advantages:

Reliability: Shear bolt connectors provide a reliable and durable connection that can withstand the rigors of electrical operation, ensuring uninterrupted power supply and operational continuity.

Versatility: Shear bolt connectors are suitable for a wide range of cable sizes and types, making them versatile solutions for various applications and environments.

Safety: Secure and properly installed shear bolt connectors reduce the risk of electrical faults, such as short circuits and cable overheating, promoting safety for personnel and equipment.

Cost-Effectiveness: Cable jointing kits with shear bolt connectors offer cost-effective solutions for cable termination and splicing, minimizing material and labor expenses while maximizing performance.

Compliance: Shear bolt connectors comply with industry standards and regulations for electrical connections, ensuring adherence to safety and quality requirements in electrical installations.

Impact on Electrical Installations

The impact of shear bolt connectors on electrical installations is significant:

Enhanced Performance: Shear bolt connectors improve the performance and efficiency of cable jointing kits, enabling reliable and high-quality electrical connections that meet the demands of modern power systems.

Increased Reliability: The robust and secure connections provided by shear bolt connectors enhance the reliability and longevity of electrical installations, reducing the risk of unplanned downtime and costly repairs.

Simplified Maintenance: Cable jointing kits with shear bolt connectors require minimal maintenance and upkeep, saving time and resources for operators and maintenance personnel.

Improved Safety: By minimizing the risk of electrical faults and failures, shear bolt connectors contribute to a safer working environment for personnel and mitigate the potential for accidents or injuries.

Future-Proofing: Shear bolt connectors support future expansion and upgrades of electrical systems, providing a flexible and scalable solution for evolving power requirements and infrastructure needs.

Conclusion: Optimizing Performance and Reliability

In conclusion, shear bolt connectors play a crucial role in enhancing performance and reliability in cable jointing kits. Their secure connections, mechanical strength, and electrical performance make them indispensable components of modern electrical installations. By selecting high-quality shear bolt connectors and incorporating them into cable jointing kits, electrical utilities and operators can ensure efficient, safe, and dependable power transmission for their systems.

0 notes