#Grain Based Ethanol

Explore tagged Tumblr posts

Text

Maximize productivity and quality in your grain-based distillery with Sona Machinery's advanced solutions for unloading and milling. Discover the difference expertise makes!

#Sona Machinery#Grain Based Distillery#Grain Based Ethanol#Grain Processing Machines#Rice Mill Machinery#Ethanol Plant Manufacturer

0 notes

Note

So I was re-reading the Fish meta just now trying to figure out where taramasalata would go in all that, when the thought occurred -- I don't know if there are many sushi restaurants in the South Downs, so A. and/or C. might get into doing home-made stuff (e.g. from 'Sushi For Dummies or smth); do you think Ineffable Husbands speak would make a distinction between restaurant vs home-made sushi?

Hi, love! Your Asks always make me hungry lol. 💕 What I think your ask has to do with bacon, Hamlet, coffee, the "fomenting" of 597 AD, The British Museum Cafe, the kimchi that Brenda so desperately needed to bitch about to Her Ron in S1, and a hidden language joke related to Crowley's 1941 hat under the cut. (Sorry this one took a minute-- your Ask got my brain percolating a bit. 😊)

One of the reasons why I think it's sushi that Crowley & Aziraphale chose to go out for on their sneaky dinners circa 2008 is that sushi is predominantly made up of fish (usually raw but not always) wrapped up in fermented rice. I'm not an expert in the history of sushi but one thing I have learned about it is that it was originally invented as a way to preserve fish for longer back in ancient times when there wasn't a way to keep fish chilled. Then, it was called narezushi.

Narezushi involved salting fish after skinning and gutting it, then letting it ferment for a few months in the salt, before then removing the salt and stuffing and covering it with rice, and fermenting for even longer. Fish would be stored in rice for the better part of the year and, much of the time, the rice wouldn't actually be eaten afterwards-- just the fish. Over time, it evolved into the sushi that we know today, which is still made with a kind of fermented rice. Fermentation is the same process used to make alcohol and several different kinds of bread-- including black bread and sourdough, the two Crowley and Aziraphale are coded as being.

In bread, the yeast in the fermenting process is what causes the dough to rise and in alcohol, it's the ethanol fermentation that turns the sugars in the fruit or grain into alcohol. We know that bread, fish, and alcohol are all common sex euphemisms in different ways in their speak so what's with the focus on fermentation?

I think it's a couple of things at once. One is that fermentation is an analogy for arousal. Another is that, in talking about sushi and fish-- things like pickled herring, etc., as well that also are about preserving fish-- there's also a romantic sense to it. They've been together a long time. Food that can be made to age-- wine, cheese, pickled and preserved fish and other food, etc..-- is food that lasts a long time, if not as long as they do. It's bits of the past carrying into the present. Still another aspect to it would be a nod to delayed gratification. If a food involves fermentation and can last longer than most other food, it's analogous to aspects of things like edging that are alluded to in a half-dozen or so different scenes.

The last reason, though, could be because it reminds them of 597 AD and the brief bit of ferment/foment/frumenty wordplay confusion.

I wrote about this at one point I think already but the jokes in this scene are based around the fact that they both keep saying or thinking of words that sound like "ferment." Crowley says he's "spreading foment"-- a word that does mean spreading discord but also is used to describe oils/potions applied with warm water. Foment is bath soaks and Crowley is super uncomfortable in that suits and knows Aziraphale is too so he's all let's quit and go take a bath.

Aziraphale gets that Crowley is wordplay-flirting with him (showing up and posing with "and you have found your [little] death" made that a bit clear) but he is confused by what the hell foment is because they usually flirt in food terms. Aziraphale thinks Crowley is going for a food euphemism-- "is that some kind of porridge?"-- because there was a new porridge called frumenty that had come up around the same time and that sounds like a word that Aziraphale could see Crowley using-- it's food, it's phonetically linked to fruit, even!-- but Crowley clarifies that, no, he was using foment. What is extra-confusing is that both words link to ferment and the process of fermentation, which is already a thing for them.

Crowley makes his meaning more clear and they figure out what each other is saying but it's a fun scene because Aziraphale just assuming that Crowley was trying to food-flirt with him then makes this one of the scenes in the series that make it more obvious that they are, in fact, doing just that. (Otherwise, you have to think that Aziraphale thought Crowley got dressed in a knight's outfit and schlepped around a damp woods spreading actual porridge and why on Earth would Aziraphale think that was an actual answer to what Crowley was up to? lol)

Later scenes suggest that it's in 597 AD as a result of the ferment/foment/frumenty conversation that Crowley and Aziraphale experimented and figured out the truth about their ability to do miracles and this is suggested in a few places, like we looked at in other metas, as to be how they figured out they could have all the sex without killing each other. That... seems like it would place fermentation in a pretty revered position in Ineffable Husbands Speak lol so whether they're getting sushi from a restaurant or making it at home, fish with a history related to fermentation seems like it would be top of the list for sexy dinner night.

One of the other jokes about fermented food in the series is about one of the most famous examples of it-- kimchi-- and it's the one in the scene where Aziraphale possesses Madame Tracy during one of her "psychic sessions." Crowley and Aziraphale refer to possession in highly-sexualized terms, to the point that when Aziraphale appeared to Crowley after being discorporated and they started talking about Aziraphale needing to possess someone to get back to Earth, the "receptive body", etc. innuendo is just blatant and not at all coded.

Brenda chose to take the time Aziraphale gave her to speak to her husband to go on to Ron about how scandalized she was to be served Korean food at the wedding she recently attended and it's when she starts to talk about "the kimchi" being brought out, that is when Ron finally flips out and loses it at her from beyond the grave, right? Poor Ron never got any fermentation in life and he's not about to keep being tormented in death. 😂 Not exactly an example of true passion, Brenda and Her Ron were...

After the whole interlude is over, we hear King of All Fermenting Aziraphale pause and then dryly remark: "Wasn't that touching?" Hilarious in its own right and a comment that Crowley would have found even funnier, since neither touching sentiment nor physical touching seemed to be very prevalent in the sad marriage of Brenda and Ron. They could have done with eating a bit more kimchi.

I do think Crowley & Aziraphale would differentiate between homemade and restaurant sushi, if only for the fun with messing with the words-- because I think they subtly actually already are from some other scenes in the series.

We heard in S2 that one of their alternate rendezvous spots is The British Museum Cafe, which is pretty hilarious from an euphemistic standpoint. They had to pick a place that they could be said to have just been in at the same time should they get caught and also museums are the indoor versions of public parks in spycraft stories but we've also seen them use restaurant/cafe/place that provides food euphemistically for a lover. The two of them meeting each other in secret in the cafe of The British Museum when they are literally older than dirt is just very funny. What kind of cafes are they to each other? The kind related to the stuff that's been here forever-- the ones that provide coffee and lunch and snacks amongst all the fossils and ancient art.

Cafe and restaurant-- like rendezvous-- are also obviously French loaner words in English; they are French words that have been absorbed into common use in English. When you say them in a sentence, you are, technically, speaking two languages at once. There is a technical name for that and it's related to something that lives in plain sight in the bookshop so we'll come back to that in a second...

Cafe is also obviously the French word for coffee. Coffee, in GO, seems to live at the symbolic intersection of sex and America. (A very complicated intersection lol.) There are other posts around these parts about coffee and its role in the American Revolution and all the American symbolism in Give Me Coffee or Give Me Death in S2. Coffee as a beverage in the whole food-and-drink thing, though, is a drink produced by grinding together coffee beans, which are actually seeds, which really feels like another meta at this point so getting to that Seeds of Destruction post soon...

Crowley and Aziraphale are actually also drinking coffee after wine at The Ritz in S1 and Crowley is being pouty about Aziraphale having put him on half-rations of late while in his angel feelings and not talking to him about those feelings as much as Crowley would like when he tells Nina this is what he wants to drink:

Share them frozen peas, Aziraphale... Anyway, if that's restaurants and cafes, then do they also already have a concept of home? I think they do and we can see it in some of the words they're using.

The word home itself has a rather interesting history, especially from a GO-related perspective. It's related to the root words of ham and hem (food/seamstressing.) You can see some of that linguistic history still remaining to this day in what we call a little human settlement that isn't quite as big as a full-on town-- a hamlet.

Yes, really lol. Of all the plays for them to have attended, eh? Yet another reason for it having been Hamlet, in addition to the content of the play itself. (My favorite being that Burbage is mixed in louder around them at The pangs of despised love/the law's delay/the insolence of office and the spurns... Yep.) Whickber Street could also be described as a hamlet within London Soho and Aziraphale is largely responsible for having developed it. But what about the bookshop itself? Is it a home for both of them within the hamlet?

You've undoubtedly heard the idiom "home is where you hang your hat" and we've seen in several scenes that the in-universe explanation for Terry Pratchett's hat hanging on Aziraphale's hatstand in the bookshop is that it's Crowley's hat from 1941. This isn't just a visual, literal execution of that idiom but also a different joke related to the hatstand, not the hat, and wordplay.

One, old-time-y word for a coat rack/hat stand like Aziraphale has in the bookshop is a portmanteau. This word means a half-dozen different things, including also a large, old-fashioned trunk that would have been used as a suitcase. While these are literal things-- physical objects-- the word portmanteau also has meanings when it comes to languages.

In linguistics, the word portmanteau can be used to refer to two different kinds of language things, both of which involve words that are blended together.

When we use words from more than one language in a sentence together, the sentence could be defined as a portmanteau. Most of us make these kinds of sentences without consciously intending to do so and fairly often-- especially with relation to food. Like the use of the words restaurant and cafe in sentences spoken in English that we mentioned above.

Aziraphale is actually making a pun about portmanteaus in S2 when he uses jardiniere in his French sentence because the word jardiniere exists in French but is also a loaner word in English, where it has come to mean a garden box/flower planter. It's French that was adopted into English, which altered its meaning a bit, and then Aziraphale puts it back into the sentence he's speaking-- which is all otherwise in French-- but using its English-language-derived meaning to form the innuendo. He's made a portmanteau in the process.

This isn't the only linguistic meaning of portmanteau, though. The other is actually the even more commonly used one and it's a word that is created out of mashing up two or more words together. One example is popsicle (pop, as in soda pop + icicle = popsicle) which is the American word for one of the desserts they buy during the body swap scene in the park. Another relevant to Crowley and Aziraphale is breakfast (break + fast, the meal they're getting-- no matter the time of day lol-- when it's been a minute since they were together but which, ironically, it doesn't seem they actually have a lot when it comes to literal food itself, since there's suggestion that they're not usually together in the mornings.)

A portmanteau-the-hat-stand is also an umbrella stand... The S2 posters with the umbrellas... Frou frou cocktails with little umbrellas... All of these things-- hats, umbrellas, wings, etc..-- provide the same function as another word we've heard recently:

They're all canopies... and so is the bookshop, really, as it's a form of shelter that keeps them safe and under the roof of which they've probably had their share of vavoomy kisses... The portmanteau where Crowley hangs his hat in the bookshop-- a place full of words in books and wordplay with his partner-- is a physical representation of wordplay that relates to the word used to describe different words and languages blended together, like how they're trying to do together as best as they can through the bonkers circumstances we've seen them in.

But we're not quite done with a concept of home yet because let's go back to ham for a minute... So, we talk about fish a lot in these here parts but not so much about jokes related to meat and since ham is now home, let's get into the meat and potatoes of it. (*groan* I know... that one was beneath me lol.)

In S2, meat became a whole damn thing after we had the ox ribs scene, right? The first food Aziraphale ever ate was (a lot of) meat, which feels right and just for the self-proclaimed The Southern Pansy... but meat had been lingering around in the wordplay already for a bit-- including in God's intro to Crowley & Aziraphale in S1.

The word meat is, of course, a homophone for the word meet.

Just as God uses "quarter" twice in her opening monologue in 1.01 and encourages us to look at multiple meanings of words in doing so, She uses "meeting" twice in her intro to the St. James' Park scene that serves as a paragraph of language lessons in Ineffable Husbands Speak. The word is used in the first and last sentences and with relation to the multiple meanings of clandestine meetings that are happening on and under the surface-- secret agents, secret lovers, and secret language within the world of both of those.

While there's the secret agent comparison happening, there's also the other connotation of a secret meeting and God encourages us to bring in historical context to what's happening on the surface by saying that St. James' Park "is and always has been" the best place in London for a clandestine meeting. It doesn't take more than a brief Google search to learn that St. James' Park was originally one of the most notorious hookup parks of history-- making it then already amusing in S1 when God then finishes her intro by saying that Crowley and Aziraphale "have been meeting here" in St. James' Park "for quite some time." After S2, though, this is even funnier.

Meeting here, did you say, God?

Probably also worth mentioning that another way to have said that sentence is "Crowley and Aziraphale have been coming here for quite some time" since you go to a meeting and... yeah lol.

Or, in S2, when Aziraphale flirts with Crowley during the party they're having in their home by telling him that he was hosting a business meeting and then holds out a tray of vol-au-vents in a knowing imitation of how Crowley once did with the ox ribs.

As we all know, ham is meat that comes from a pig. When you crisp that meat up, it's called something else-- bacon. The word bacon comes from the same root words as that of the word back-- a word with two meanings that cross together when it comes to a sense of home made with a romantic partner.

We have bacon coming from the word back as a noun-- referring to a part of the body-- but the word back is also a verb that refers to returning to a place. This is referred to more frequently as coming back and now we've, well, come back to wordplay around the verb to come... not unexpectedly lol. Your home is the place where you hang your hat and to which you keep returning.

Crowley leaves the house during the 2.01 argument and then returns and dramatically announces: "I'm back."

The bacon has come back home, should Aziraphale wish for any makeup meating at any time. Glasses off and everything.

Aziraphale drolly replies: "Yes. I can see that."

"I can (container, often for food) see (homophone: sea) that (contains hat)." Welcome home, dear. Guess who will be doing a dance?

Remember Muriel in the tie-in notes describing Crowley as "grumpy + nice" and musing that this new word could be called "grice"?

As we looked at in another meta, the word already exists and a grice is a pig. And Harmony describing Crowley as "a swine" in 1941? It's from pigs that we get ham (home) and bacon (coming back, returning to that home) and Crowley and Aziraphale keep being tied to pigs... which is a word that can also be used to refer to those with a dirty sense of humor.

Furthering that, there is the other, non-pig definition of grice, which refers to being someone who is very enthusiastic about trains.

Within grice though is also, of course, the word rice...

...and ice, which replaced fermentation in fish preservation...

...and, so, back at the sushi we arrive. 🐠

Meta the Ask references for anyone who is wondering what we're on about regarding fish:

#ineffable husbands#good omens#crowley#aziraphale#aziracrow#good omens meta#good omens 2#ineffable husbands speak#etymology

28 notes

·

View notes

Text

India Ethanol Market

India Ethanol Market Size, Share, Trends: Bajaj Hindusthan Sugar Ltd. Lead

Rapid Expansion of Grain-based Ethanol Production Capacity

Market Overview:

The India ethanol market is projected to grow at a CAGR of 8.5% from 2024 to 2031, reaching a value of INR YY billion by 2031. North India dominates the market, accounting for 35% of the national share. Key metrics include rising demand for biofuels, increasing government support for ethanol blending, and growing applications in the pharmaceutical and personal care industries.

The Indian ethanol market is expanding rapidly, owing to the government's ambitious ethanol blending program and an increased emphasis on reducing reliance on fossil fuels. As a critical component of the country's plan to attain energy security and reduce carbon emissions, ethanol production and use are expanding rapidly across multiple industries.

DOWNLOAD FREE SAMPLE

Market Trends:

One significant trend in the Indian ethanol market is the rapid expansion of grain-based ethanol production capacity, primarily from maize and rice. This shift is driven by the government's focus on diversifying feedstock sources and reducing reliance on molasses-based ethanol. According to the Indian Sugar Mills Association (ISMA), grain-based ethanol production capacity grew by 40% in the 2022-23 season compared to the previous year. This rapid rise is fueled by government incentives and policies encouraging the establishment of grain-based distilleries.

Market Segmentation:

The fuel and fuel additives segment dominates the India ethanol market, accounting for over YY% of the total demand. This segment has grown exponentially due to the government's ethanol blending scheme. According to the Ministry of Petroleum and Natural Gas, ethanol use for blending with petrol reached 4.5 billion litres in the 2022-23 supply year, up 35% over the previous year.

The industrial solvents industry is also expanding rapidly, especially in the pharmaceutical and personal care sectors. Ethanol's use in hand sanitizers and disinfectants surged by 200% in 2020-21 due to the COVID-19 pandemic, and demand remains high.

Market Key Players:

Bajaj Hindusthan Sugar Ltd.

Shree Renuka Sugars Limited

Balrampur Chini Mills Limited

India Glycols Limited

Dhampur Sugar Mills Limited

Triveni Engineering & Industries Ltd.

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

Harnessing the potential of agriculture for a sustainable future!

Halder Group has built a strong reputation for itself based on trust and commitment for over 100 years. Despite facing various economic fluctuations and industrial challenges, we have successfully managed to stand the test of time. During global trade, we have skillfully managed changes within the market for raw materials. The key to our success has always been resilience and strategically adapting to change for the better.

We are proudly committed to our journey of excellence in the agro-industry and the growth we have experienced for generations. Pursuit of innovation and seeking new ways to adopt sustainable practices has helped us to stay ahead of our competitors in the industry. One of the such sustainable practices we adhere to in our production process is our commitment to minimising waste through our "zero wastage policy". We ensure that every by-product generated during product processing is utilised efficiently, thus minimising waste to the maximum extent possible.

By-Products of Rice Processing: Types and Multiple Usages

Rice processing yields several valuable by-products, each serving multiple purposes. Dive into the types of by-products and their multiple usages:

Rice Husk Ashes: Engineering Excellence from Agricultural Residue

In our constant search for efficient and environmentally friendly resource utilisation, rice husk ashes are now considered revolutionary. At Halder Group, we have developed a complex process of converting rice husk ash into a better pozzolanic material. When this pozzolanic material reacts with calcium hydroxide, it contributes to the formation of cement.

Rice Husk: Elevating Waste to Renewable Energy

The sustainability of rice processing is profoundly affected by the efficient use of the by-products, especially the rice husk. At Halder Group, we are pioneers in transforming rice husk into densified pellets and bricks, which is a process of converting rice husk into a valuable biofuel feedstock.

This knowledge helps the company fine-tune the production process and obtain biofuel that is both effective and environmentally friendly. Thus, the utilisation of rice husk in the production of renewable energy solves the problem of waste management and is a great contribution to the solution of the energy crisis.

Indian Broken Rice: Revolutionising Ethanol Production

The process of making ethanol from agricultural crops like Indian broken rice is an example of a progressive innovation in resource utilisation. Thus, at Halder Group, we have improved the traditional ethanol production process, which includes the steps of liquefaction and simultaneous saccharification and fermentation.

Rice Bran: Nutrient-Rich and Versatile

Rice bran, the rich source of nutrients that is the outer layer of the rice grain, has numerous uses in different fields. Source of essential fatty acids, antioxidants, and vitamins, rice bran is widely used in the extraction of rice bran oil, which is known for its nutritional values and uses in cooking. Aside from its application in the production of oil, rice bran is utilised in animal feed as it is a good source of nutrients for livestock. Due to the high fibre content, rice bran can be incorporated into dietary supplements and functional foods to improve digestion and general health.

Rejected Rice: Turning Waste into Worth

Milling process rejects or what is commonly referred to as rice, can be a source for new products. The rejected rice can be processed using more sophisticated techniques to produce rice flour, which is used in gluten-free products and in many other recipes. Moreover, rejected rice can be used in the manufacturing of bio-based products which can help in the creation of sustainable packaging and biodegradable products.

Heralding a New Era of Sustainability

The history of Halder Group is a century-old story of survival, creativity, and a focus on sustainable development. Thus, by converting by-products like rice husk and rice husk ash into valuable products, and enhancing the process of ethanol production from broken rice, it is possible to show the way towards efficient resource management in the future.

0 notes

Text

Distillery Enzymes Manufacturer

Innovative Enzyme Solutions for the Distillery Industry by Pharmabiz.World (PBW)

In the heart of the modern distillery industry, where precision and efficiency are paramount, enzymes play a crucial role in optimizing production processes. From improving fermentation rates to enhancing the quality of the final product, enzymes are indispensable in the production of spirits, biofuels, and other fermented products. Pharmabiz.World (PBW), a leader in enzyme manufacturing, stands at the forefront of this revolution, offering cutting-edge enzymatic solutions designed to meet the unique needs of distillery operations worldwide.

Who is Pharmabiz.World (PBW)?

Pharmabiz.World (PBW) is a pioneering enzyme manufacturer with a dedicated focus on providing high-quality enzyme products tailored for industries like distillery, pharmaceuticals, food and beverage, biofuels, and more. With years of expertise and state-of-the-art production facilities, PBW has positioned itself as a trusted partner for distillery manufacturers looking to improve their fermentation processes, increase yield, and reduce costs.

Enzymes: The Backbone of Distillery Production

Distilleries rely heavily on enzymes for their core processes. In particular, enzymes break down starches into fermentable sugars, enabling the fermentation process that is essential to producing ethanol, alcohol, and various bio-based products. The role of enzymes is indispensable in ensuring efficiency and consistency in these processes. By utilizing specific enzyme formulations, distilleries can:

1. Increase Fermentation Efficiency: Enzymes like amylases break down complex carbohydrates into simpler sugars, facilitating faster and more efficient fermentation. This results in higher ethanol yields, reduced fermentation times, and better overall efficiency.

2. Improve Distillation Yields: PBW’s enzyme solutions help increase the yield during the distillation process by optimizing the sugar conversion and fermentation phases, reducing waste, and maximizing output from raw materials.

3. Enhance Product Quality: PBW’s enzymes also help distilleries produce cleaner, more refined spirits by breaking down unwanted compounds that could affect the taste and quality of the final product.

4. Reduce Operational Costs: By improving fermentation efficiency and reducing the need for additives or extended fermentation periods, PBW's enzyme products help distilleries lower operational costs. They reduce energy consumption, waste, and the need for additional raw materials.

PBW’s Distillery-Specific Enzyme Solutions

Pharmabiz.World offers a comprehensive range of enzyme products formulated specifically for the distillery industry. These enzymes are designed to cater to various raw materials, including grains (corn, barley, wheat), fruits, and other starch-rich sources. Some of PBW’s most popular enzyme solutions include:

1. Amylase Enzymes: Amylases break down starches into fermentable sugars, a critical step for the fermentation process. PBW’s highly efficient amylase solutions are formulated to work across a wide range of raw materials, ensuring consistent fermentation and high ethanol yield.

2. Cellulase Enzymes: Cellulases are used to break down cellulose and hemicellulose in plant-based raw materials, helping to release fermentable sugars and improve the overall efficiency of the fermentation process.

3. Protease Enzymes: Proteases are important for breaking down proteins in raw materials, leading to improved fermentation and smoother distillation. These enzymes help reduce foaming issues and create a cleaner distillate.

4. Xylanase Enzymes: Xylanase is effective in breaking down complex sugars in lignocellulosic materials, making it ideal for bioethanol production from non-traditional feedstocks such as wood chips and agricultural residues.

Why Choose PBW for Your Distillery Needs?

Tailored Solutions: PBW understands that every distillery has unique requirements. That’s why our enzyme products are customized to meet specific production processes, ensuring maximum efficiency and cost-effectiveness.

Proven Expertise: With years of experience in the enzyme manufacturing industry, PBW brings a deep understanding of the challenges faced by distilleries and offers scientifically-backed enzyme solutions that address those challenges.

Quality Assurance: Every enzyme product produced by PBW undergoes rigorous testing to ensure it meets the highest quality standards. Our enzymes are highly active, stable, and reliable, giving distilleries the consistency they need for their operations.

Sustainability Focus: PBW is committed to sustainable practices. By optimizing fermentation and distillation processes, our enzyme solutions help distilleries reduce energy consumption, waste, and environmental impact.

Global Reach: As a trusted supplier, PBW serves distillery clients around the world, providing technical support, training, and guidance to ensure that our enzyme products deliver the best possible results.

Partner with PBW for Your Distillery’s Success

In today’s competitive distillery market, it’s essential to adopt innovative solutions that can improve production efficiency, enhance product quality, and reduce costs. Pharmabiz.World (PBW) is your go-to partner for all your enzyme needs, offering the highest quality, most effective enzyme products available. Whether you’re producing spirits, biofuels, or other fermented products, PBW’s advanced enzyme solutions are here to support your growth and success.

For more information about PBW’s enzyme solutions or to request a consultation, visit our website: https://pharmabiz.world/distillery | Email Us Your Requirements: [email protected] OR Call / WhatsApp Now for Order: 01169310523.

and take the first step toward optimizing your distillery’s production process today!

0 notes

Text

Bee products (honey, royal jelly, freeze-dried powder, bee pollen) testing

There are many different testing methods for bee products (honey, royal jelly, freeze-dried powder, bee pollen), and each product has its own specific testing items and corresponding testing methods. The following is a detailed summary of these testing methods:

Testing methods for honey

Appearance quality inspection: Through visual observation, check whether the appearance of the honey is intact, whether the color is normal, whether there is no odor, mildew, etc.

Water solubility test method: Put a spoonful of honey into a cup of water, stir gently, and observe the dissolution of the honey. Real honey will form a certain amount of suspended matter and sediment.

Fire test method: Drop honey on the lit cotton and observe the burning of the flame and cotton. Real honey will make crackling sounds and the cotton will not burn.

Refrigeration test method: After putting the honey in the refrigerator for a period of time, observe whether it becomes thick and has signs of crystallization.

Sugar content test method: Use a saccharimeter to measure the sugar content of honey. The sugar content of real honey is usually around 75%.

Bee pollen content test method: The authenticity of honey can be determined by testing the bee pollen content in honey. Real honey usually contains a certain amount of bee pollen.

Microbial detection: Including total colony count detection, coliform detection, and mold detection to evaluate the hygiene of honey.

Pesticide residue and heavy metal residue detection: Use gas chromatography, liquid chromatography and other technologies to determine the content of pesticide residues and heavy metal residues in honey to determine the safety of honey.

Royal jelly detection method

Moisture detection: Observe the consistency and moisture content of royal jelly through methods such as bamboo chopstick pulling method.

PH detection: Use test paper or PH meter to determine the PH value of royal jelly to determine its storage time and quality.

Refractive index detection: Use Abbe refractometer to determine the refractive index of royal jelly to determine whether it is mixed with other refractive substances.

Microscope detection: Use a microscope to check whether there are impurities such as wax flakes and insect body fragments in royal jelly.

Surface tension test: Measure the surface tension of royal jelly to determine whether it is aged or deteriorated.

Adulteration test: Including tests such as adulteration with talcum powder, milk, starch or dextrin to determine whether the royal jelly is pure.

Freeze-dried powder detection method

Ingredient detection: Qualitative and quantitative analysis of the active ingredients in the freeze-dried powder to ensure that its main ingredients remain active and meet the content indicated on the label. Common methods include high performance liquid chromatography (HPLC), gas chromatography (GC) and mass spectrometry (MS).

Moisture content determination: Karl Fischer titration or weight loss method is used to accurately determine the moisture content in freeze-dried powder.

Residual solvent detection: Use gas chromatography (GC) to detect residual organic solvents in freeze-dried powder, such as ethanol, methanol, acetone, etc.

Microbial limit detection: Including total colony count detection, mold , yeast detection and sterility inspection to ensure the safety of freeze-dried powder.

Physical property testing: including particle size, appearance, solubility, density and thermogravimetric analysis to evaluate the stability and use effect of freeze-dried powder.

Bee pollen testing methods

Microscope testing: can visually observe the morphological characteristics of pollen grains, which is the basic means to identify bee pollen from different plant sources.

Chemical method: based on the chemical properties of the substance, the content of the target component in the sample is determined through a specific chemical reaction. For example, spectrophotometry can quickly determine the protein concentration in bee pollen; titration rules are often used to detect indicators such as acidity or alkalinity.

Biological identification method: use biological characteristics to identify the authenticity and quality of bee pollen. Immunological detection rules use the principle of specific binding of antibodies and antigens to achieve high-sensitivity detection of specific components.

Spectroscopy and mass spectrometry: obtain information by measuring the absorption or emission spectrum and molecular weight distribution of substances. Advanced equipment such as spectrometers and mass spectrometers not only improve detection efficiency, but also greatly expand the detection range.

In summary, the detection methods of bee products cover multiple aspects, including appearance quality, physical and chemical properties, microbial indicators, nutritional components, and safety. These testing methods together constitute a complete system for bee product quality control, providing strong protection for consumer health and market regulations.

0 notes

Text

Effect of pressure treatment on the extraction rate of rice protein

Abstract: In this experiment, we used Jinjianxing No.2 rice (indica rice) as raw material, pressurized the rice, soaked it in distilled water to isolate the rice protein, and determined the protein content of the extracted rice by Kjeldahl method. The reaction conditions were optimized by orthogonal test to select the rice with low protein content. The experimental results showed that, under the condition that the treatment pressure was not greater than 0.2MPa, the pressure treatment conditions had no significant effect on the extraction rate of rice protein.

Rice is one of the staple foods of Chinese people, according to modern nutritional analysis, rice consists of protein, fat, vitamin B1, vitamin A, vitamin E and a variety of minerals. In terms of varieties, rice can be divided into round-grained rice, indica rice and glutinous rice. The distribution of various chemical components in the rice, directly determines its physiological characteristics. Only by understanding and mastering the chemical composition, nutritional value and physiological effects of various parts of rice, can we carry out rational development and research and utilization of rice. Protein content in rice is about 7.8% [1], although protein is not a rich material component in rice, but its role is the most important.

Rice protein has a high nutritional value and is a widely recognized cereal-based plant protein[2] . According to Osborne's classification[3] , rice proteins are divided into four types: glutelin, which can be dissolved in dilute acid and alkali, accounting for more than 80% of the total rice protein; globulins, which can be dissolved in a l0.5mol/L solution of NaC, accounting for 2%~10% of the total rice protein; albumins, which can be dissolved in water, accounting for 2%~5% of the total rice protein; alcohol-soluble protein, which can be dissolved in water, accounting for 2%~5% of the total rice protein; and alcohol-soluble protein, accounting for 2%~5% of the total rice protein. albumins, soluble in water, accounting for 2%~5% of total rice protein; alcohol soluble proteins (prola- mins), soluble in 70%~80% solution of ethanol, accounting for 1%~5% of total rice protein. Among them, storage proteins including gluten and alcohol-soluble proteins account for most of the rice protein, while the relatively low content of albumin and globulin are active proteins with physiological functions.

Low-protein rice is produced by reducing the protein content of rice, i.e., extracting the excess protein from the rice by a better process, while high pressure can to some extent improve the solubility characteristics of rice proteins. High pressure has a direct effect on increasing the solubility of rice proteins by changing the structure of the protein molecules or their state of existence. Compared with the process without autoclaving, autoclaving results in the gradual dissolution of rice protein molecules with higher molecular weights, and in the process produces rice protein molecules with smaller molecular weights[4] .

1 Experimental materials and equipment

1.1 Experimental materials

Raw material: Jinjianxing No. 2 rice (purchased from supermarkets, indica rice).

Reagents: anhydrous ether, concentrated sulfuric acid, distilled water, potassium sulfate, copper sulfate, sodium hydroxide, boric acid, mixed indicator (1 part of methyl red ethanol solution mixed with 5 parts of bromocresol green ethanol solution), hydrochloric acid, sodium hydrogen carbonate, and methyl red ethanol solution.

1.2 Instruments and equipment

Portable semi-automatic autoclave : Shanghai Yichuan Instrumentation Co.

JXFM110 Hammer Cyclone Mill : Shanghai Jiading Grain & Oil Instrument Co.

GZX-9070 MBE Digital Display Blast Drying Oven : Shanghai Boxun Industry Co.

DL-1 Universal Electric Furnace : Beijing Yong Guangming Medical Instrument Factory Co.

SRJX- 4 - 13 High Temperature Chamber Resistance Furnace : Qianjin Furnace Co.

FW80 High-speed Universal Pulverizer : Tianjin Tester Instrument Co.

LD5002 Electronic Balance : Longteng Electronics Co.

FA2104N Analytical Balance : Shanghai Minqiao Precision Scientific Instrument Co.

KDN-04A Digestion Oven : Shanghai Jinglong Scientific Instrument Co.

SKD-2000 Automatic Kjeldahl Nitrogen Determination Instrument : Shanghai Peio Analyzer Instrument Company, etc.

2 Experimental Methods

2.1 Determination of the basic composition of rice

2.1.1 Determination of moisture content of rice

Completed with reference to GB 5009.3-2010 National Standard for Food Safety Determination of Moisture in Food.

2.1.2 Determination of protein content of rice

Refer to the first method of Kjeldahl nitrogen determination in GB 5009.5-2010 Determination of Proteins in Foods.

2.1.3 Determination of fat content of rice

Refer to the Soxhlet extraction method in GB∕T 5009.6-2003 "Determination of fat in food".

2.1.4 Determination of the ash content of rice

Refer to the method in GB∕T 5009.4-2010 "Determination of Ash in Foods".

2.2 Rice protein extraction process

2.2.1 Rice protein extraction process route

Raw rice (dry basis) → pressure treatment → soaking in distilled water → draining → drying → milling → protein content measurement.

2.2.2 One-way experiment on rice protein extraction process

2.2.2.1 Effect of different pressures on the rate of protein reduction in rice

From the data found in the pressure does not exceed 0.25MPa conditions, rice protein at a temperature greater than 90 ℃ will not be completely denatured. Weighing the same mass of rice, respectively, placed in the pressure: 0.05MPa, 0.1MPa, 0.15MPa, 0.20MPa autoclave for 1h, remove the samples for protein content determination.

2.2.2.2 Effect of atmospheric soaking temperature on the rate of protein reduction in rice

The weighed rice was put into the temperature environment of 20℃, 40℃, 60℃, 80℃ and 100℃ respectively, and kept warm for 1h. Take out the sample for soaking for 24h, and then carry out the Kjeldahl method to determine the protein content of the test, the method is the same as above. Three parallel experiments were compared with the blank samples to take the average value. 2.2.2.3 Effect of soaking time on the rate of protein reduction in rice

An equal amount of rice samples were taken, stirred with distilled water and placed at room temperature of 25℃ for 1h, 12h, 24h, 36h and 48h, respectively, and then removed for protein content analysis, and the average of three parallel experiments was compared with that of the blank samples.

2.2.3 Orthogonal experiments

The main factors and levels affecting the extraction rate of rice protein were obtained through one-way experiments, and orthogonal experiments were carried out with orthogonal tables to finally obtain the optimal extraction process of rice protein.

2.3 Determination of rice protein content and calculation of extraction rate

2.3.1 Determination of protein content

In this paper, the protein content of rice was determined as an index, and the extraction rate of protein was calculated. The protein content was determined by Kjeldahl method (GB 5009.5-2010 National Standard for Food Safety "Determination of Protein in Food").

2.3.2 Reduction rate of rice protein

where A is the rate of protein reduction in rice, a0 is the percentage of protein in the raw rice, and a1 is the percentage of protein in the pressure-treated sample rice.

3 Results and analysis

3.1 Determination of the content of rice components

The basic composition of Jinjianxing No. 2 rice (indica) on a dry basis is shown in Table 1. 3.2 Results of one-way experiments

3.2.1 Effect of soaking temperature on the reduction of rice protein

With a fixed steam pressure of 0.1MPa and a soaking time of 12h, the effect of different soaking temperatures on the extraction rate of rice protein is shown in Fig. 1.

Fig. 1 Effect of soaking temperature on the rate of protein reduction

It can be seen from Fig. 1 that, as the temperature increases, the reduction rate of rice protein slightly increases, because in a certain temperature range, as the temperature increases, gluten can better dissolve in alkali, which is conducive to the extraction of proteins. However, from the data, the temperature has very little effect on the extraction rate of rice protein, at the same time, too high a temperature will denature the protein, causing aggregation and precipitation of proteins, so that its solubility decreases, thus reducing the rate of protein extraction. Therefore, the extraction temperature should not be too high, but too low will affect the extraction effect, so choose 25 ℃ as the optimal temperature for the removal of rice protein.

3.2.2 Effect of soaking time on protein reduction in rice

Fig. 2 Effect of soaking time on the rate of protein reduction

From Fig. 2, it can be seen that the reduction rate of rice protein increases with the increase of soaking time. When the extraction time was extended from 1h to 36h, the rate of protein reduction increased significantly, but when the extraction time was greater than 36h, the rate of reduction increased slowly without change, probably because the alkali-soluble proteins in the rice have been basically dissolved, so to extend the soaking time, the rate of reduction increased slowly, so the choice of 36h is the best soaking time.

3.2.3 Effect of pressure treatment on protein reduction in rice

Fig. 3 Effect of vapor pressure on the rate of protein reduction

Fixed soaking time of 12h, soaking temperature of 25℃, under the condition of steam pressure not more than 0.2MPa, the effect of different steam pressures on the reduction of rice protein is shown in Fig. 3.

It can be seen from Fig. 3 that the reduction of rice protein tends to increase with the increase of steam pressure. This is because high pressure treatment affects the molecular structure of protein and increases its solubility. However, at steam pressures less than 0.2MPa, the increasing trend is not significant.

4 Conclusion

Under the condition of pressure less than 0.2MPa, when using a certain steam pressure to treat rice to produce low-protein rice, the factors that affect the protein content of rice in descending order are soaking time, treatment pressure and soaking temperature. The rice protein extraction process was optimized through one-way and orthogonal experiments, i.e., the raw material rice was soaked at 25℃ under 0.2MPa pressure for 36h, and the reduction rate of rice protein was 15.92% under this process; under the condition of pressure not greater than 0.2MPa, the effect of pressure treatment on the extraction rate of rice protein was not significant.

References:

[1] Zhan Yi-Pu. The significance of low-protein diet in slowing down the progression of chronic kidney damage-MDRD test [ J] . China Medical Journal , 2001 (2) : 128- 130.

[2] Yao Huiyuan. Deep processing of rice [ M]. Beijing : Chemical Industry Publishing House , 2004 : 137- 141.

[3] Department of Personnel, State Grain Administration. Grain and oil quality inspector [ M ]. Beijing : China Light Industry Press , 2010 : 38-39.

[4] LIU Ying , HU Zhongze , FAN Lei , DING Xiaojuan . Optimization of production process parameters for low protein rice [ J] . Food and Feed Industry , 2004 (10) : 23-25.

0 notes

Text

Ethanol Market: Role in Blending Mandates and Energy Security

The Ethanol Market size was valued at USD 99.68 billion in 2022 and is expected to grow to USD 150.67 billion by 2030 with a growing CAGR of 5.3% over the forecast period of 2023–2030.

Ethanol is an alcohol-based compound commonly used as a biofuel and in industrial, pharmaceutical, and consumer goods applications. With a key role in fuel blending, ethanol reduces emissions when mixed with gasoline, contributing to global sustainability goals. This market is witnessing growth from innovations in bioethanol production, including second-generation ethanol derived from non-food biomass, which increases feedstock flexibility and reduces environmental impact.

The ethanol market, segmented by type, source, purity, and application, is shaped by supportive government policies, advancements in biofuel technology, and growing demand for sustainable chemicals in everyday products.

Key Market Drivers

Rising Demand for Bioethanol: Bioethanol, derived from renewable sources, is increasingly used as a cleaner alternative to traditional fossil fuels.

Government Policies and Incentives: Policies supporting renewable energy and biofuel blending mandates are accelerating ethanol adoption.

Diverse Applications in Consumer Products: Ethanol’s uses in personal care, disinfectants, and industrial solvents fuel demand beyond the energy sector.

Technological Innovations: Advances in second-generation bioethanol from waste and non-food feedstocks are making production more sustainable.

Environmental Benefits: Ethanol’s role in reducing emissions and reliance on fossil fuels aligns with global sustainability objectives.

Market Segmentation

The ethanol market is segmented as follows:

By Type

Synthetic Ethanol: Produced from petrochemical processes, commonly used in industrial applications.

Bioethanol: Made from renewable biomass sources and widely used in fuel and eco-friendly applications.

By Source

Grain-Based: Primarily derived from corn and wheat, grain-based ethanol is a common form of bioethanol.

Second Generation: Produced from non-food biomass such as agricultural residues and waste, offering greater sustainability.

Sugar & Molasses-Based: Commonly produced in regions with high sugarcane production, such as Brazil.

By Purity

Denatured Ethanol: Ethanol treated with additives to make it unfit for consumption, primarily used as fuel and in industrial applications.

Undenatured Ethanol: Used in consumable products such as alcoholic beverages and certain pharmaceutical formulations.

By Application

Industrial Solvents: Ethanol’s solvent properties make it valuable for use in paints, coatings, and other industrial products.

Beverages: Ethanol is the active ingredient in alcoholic drinks and is carefully regulated for safe consumption.

Disinfectants and Personal Care: Ethanol’s antiseptic properties are widely used in sanitizers, cleaners, and personal care products.

Fuel & Fuel Additives: Ethanol is blended with gasoline to create cleaner-burning fuels that reduce carbon emissions.

Regional Analysis

North America: The U.S. leads in ethanol production, primarily from corn. Government mandates for ethanol blending in fuels and increasing biofuel adoption drive demand.

Europe: Ethanol’s role in achieving EU emissions reduction targets is vital, with strong demand for bioethanol in transportation and industry.

Asia-Pacific: With rapid urbanization and a growing focus on renewable energy, Asia-Pacific nations like China and India are expanding bioethanol production.

Latin America: Brazil is a major producer of sugarcane-based ethanol, and ethanol serves as a primary fuel source in the country’s transportation sector.

Middle East & Africa: While the market is nascent, the region is beginning to explore ethanol as a cleaner energy source.

Current Market Trends

Second-Generation Bioethanol Growth: With a focus on reducing reliance on food-based feedstocks, second-generation bioethanol production from waste biomass is increasing.

Increased Adoption in Personal Care: Ethanol’s antimicrobial properties are driving its use in sanitizers, personal care, and household products.

Government Support for Biofuel Blending: Global policies aimed at reducing carbon emissions are encouraging the use of ethanol in fuel.

Circular Economy Initiatives: Efforts to reduce waste are aligning with the growth of second-generation ethanol production, creating sustainable value chains.

R&D Investments in Sustainable Production: Continued investment in research for eco-friendly ethanol production technologies is a key trend shaping the market.

Conclusion

The global ethanol market is positioned for strong growth over the forecast period as it meets increasing demands for renewable energy, sustainable industrial solutions, and eco-friendly consumer products. With the advantages of reduced emissions and diverse applications, ethanol will continue to play a critical role in the energy transition and in supporting sustainable practices across industries.

Read Complete Report Details of Ethanol Market: https://www.snsinsider.com/reports/ethanol-market-2902

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions.

Contact Us: Akash Anand — Head of Business Development & Strategy [email protected] Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)

0 notes

Text

Exploring the Industrial Potential of Bacillus megaterium: From Enzyme Production to Bioplastics

Exploring the Industrial Potential of Bacillus megaterium: From Enzyme Production to Bioplastics

Introduction In an era of rising environmental concerns and a shift towards sustainable industrial practices, Bacillus megaterium has emerged as a key player in biotechnology. Known for its exceptionally large cell size and diverse metabolic capabilities, this bacterium has captured attention for its ability to produce a wide range of enzymes, vitamins, and biodegradable plastics.

The versatility of Bacillus megaterium makes it an ideal candidate for applications across industries such as food production, pharmaceuticals, paper manufacturing, and eco-friendly packaging. Its role in enzyme production and bioplastics manufacturing highlights how microorganisms can transform traditional processes, offering more sustainable alternatives for industrial development.

Enzyme Production Capabilities of Bacillus megaterium

Bacillus megaterium is widely regarded as an enzyme powerhouse due to its ability to efficiently produce enzymes that play critical roles in multiple industries. These enzymes drive innovations in food processing, detergents, paper manufacturing, and pharmaceuticals, paving the way for eco-friendly solutions.

1. Amylase and Protease Production

Amylases are essential for breaking down starch into simpler sugars, making them a key component in the brewing, baking, and food processing industries. In brewing, for example, amylase helps convert starch from grains into fermentable sugars, improving efficiency and flavor profiles.

Proteases, on the other hand, are commonly used in the detergent industry to break down protein stains, such as those from food or sweat. Detergents containing protease enzymes offer superior cleaning performance while reducing the need for harsh chemicals.

2. Xylanase: A Green Solution for the Paper and Biofuel Industries

Xylanase plays an important role in the pulp and paper industry by breaking down hemicellulose, facilitating the production of high-quality paper without the use of harsh chemicals. This eco-friendly process minimizes the release of pollutants, contributing to cleaner production.

In the biofuel industry, xylanase is crucial in the production of cellulosic ethanol, a sustainable alternative to fossil fuels. By breaking down plant biomass, it increases the efficiency of biofuel extraction, supporting the transition to renewable energy.

3. Vitamin B12 Synthesis: Addressing Nutritional Deficiencies

Bacillus megaterium naturally produces vitamin B12, an essential nutrient that supports red blood cell formation, nerve function, and DNA synthesis. Vitamin B12 supplements are critical in addressing deficiencies, particularly in vegetarian and vegan populations.

Industrial production of vitamin B12 using B. megaterium offers a sustainable and cost-effective way to meet the growing demand for supplements without relying on animal-derived sources.

Bioplastic Production: A Sustainable Shift in Manufacturing

In addition to enzyme production, Bacillus megaterium holds immense potential in the field of bioplastics, providing a greener alternative to conventional petroleum-based plastics. With increasing environmental regulations and the demand for sustainable materials, bioplastics represent the future of packaging and manufacturing.

1. Polyhydroxyalkanoates (PHA) Production

Bacillus megaterium is capable of producing Polyhydroxyalkanoates (PHA), a class of biodegradable plastics that break down naturally in the environment. PHAs are seen as a promising solution to the global plastic pollution crisis, offering a zero-waste alternative to synthetic plastics.

Unlike conventional plastics, which can persist in the environment for centuries, PHAs degrade harmlessly in soil or marine ecosystems, making them ideal for eco-friendly products and packaging.

2. Supporting the Packaging Industry’s Transition to Sustainable Materials

With industries around the world shifting towards sustainable packaging, PHAs produced by B. megaterium are increasingly used in the manufacture of biodegradable food containers, cutlery, and films.

These materials provide excellent durability and flexibility while being non-toxic and compostable, helping companies meet environmental goals and regulatory standards. The adoption of bioplastics not only reduces the carbon footprint of packaging but also appeals to environmentally conscious consumers.

Environmental and Economic Impact

The utilization of Bacillus megaterium in industrial processes brings multiple economic and environmental benefits:

Reduction of Chemical Waste: Enzyme-based processes, such as using xylanase in paper bleaching, minimize the need for toxic chemicals, reducing environmental pollution.

Lower Energy Consumption: The production of enzymes and bioplastics using microbial fermentation consumes less energy compared to traditional manufacturing processes.

Circular Economy Practices: By using renewable raw materials for PHA production, industries can adopt a circular approach to manufacturing, where materials are continuously reused and recycled.

New Market Opportunities: With growing consumer demand for eco-friendly products, companies utilizing bioplastics and microbial enzymes can gain a competitive edge in the global market.

Challenges and Future Research

While Bacillus megaterium offers exciting opportunities, some challenges remain in scaling up the production of bioplastics and enzymes. Researchers are actively working on improving fermentation efficiency and reducing production costs to make microbial-based processes more commercially viable.

Additionally, advances in genetic engineering are opening new doors for enhancing the productivity of Bacillus megaterium. By modifying its metabolic pathways, scientists aim to develop strains with optimized enzyme yields and increased PHA production capacity.

Collaborative research efforts between industry and academia are essential to unlock the full potential of this bacterium, ensuring that its applications continue to grow across various sectors.

Conclusion

Bacillus megaterium stands out as a model microorganism in the pursuit of sustainable industrial solutions. Its ability to produce essential enzymes, such as amylases and xylanases, along with vitamin B12 and biodegradable plastics, demonstrates its versatility and value in multiple industries. As companies transition toward greener alternatives, the role of B. megaterium in eco-friendly manufacturing processes will become even more significant.

By driving innovation in enzyme production and bioplastics manufacturing, Bacillus megaterium is paving the way for a greener and more sustainable future. As research advances and production methods improve, this remarkable bacterium will continue to play a vital role in reducing environmental impact and promoting sustainable industrial practices across the globe.

0 notes

Text

Top Trends in DDGS and Dryee Suppliers

The demand for dried distillers grains with solubles (DDGS) has surged in recent years, primarily due to its growing application in animal feed, particularly in livestock and poultry industries. This high-protein byproduct of ethanol production has proven to be a cost-effective alternative to traditional feed grains, offering both nutritional benefits and sustainability. As the market for DDGS expands, the role of DDGS and Dryee suppliers becomes increasingly significant, with trends shaping the industry and driving innovation. In this article, we will explore some of the key trends in the DDGS market and the evolving role of DDGS Dryee suppliers.

1. Increased Demand for Sustainable Animal Feed

With rising concerns over climate change and environmental sustainability, there is a noticeable shift towards more sustainable feed options in the agriculture industry. DDGS, a byproduct of the ethanol production process, is often considered a more environmentally friendly alternative to traditional feed grains, as it is produced from renewable resources. Its inclusion in animal diets helps reduce feed costs while promoting a more circular economy. This demand is expected to increase as more countries push for sustainable agricultural practices, creating opportunities for DDGS Dryee suppliers to expand their offerings.

2. Expansion of DDGS in Livestock and Poultry Feed

The versatility of DDGS makes it suitable for a wide range of animals, including cattle, swine, poultry, and even fish. Over the past few years, there has been a growing acceptance of DDGS in poultry and swine rations due to its high nutritional value. It is rich in protein, fiber, and essential amino acids, which makes it an attractive option for feed manufacturers. As the demand for protein-rich animal products increases globally, DDGS is likely to play an even larger role in animal feed formulations, offering DDGS Dryee suppliers an opportunity to diversify their client base and increase market share.

3. Advancements in Drying Technology

Drying is a critical part of the DDGS production process, as it ensures the moisture content is reduced to levels that are optimal for storage and transportation. Recent advancements in drying technology, such as the development of more energy-efficient dryers and innovative drying techniques, are helping DDGS producers improve their product quality while reducing operational costs. These innovations also enable DDGS Dryee suppliers to meet growing demand while maintaining high standards of consistency and quality in the dried products they supply.

4. Rising Global Demand for Ethanol and Biofuels

The increasing global demand for biofuels, especially ethanol, is directly influencing the growth of the DDGS market. As more countries transition to renewable energy sources, the production of ethanol as a biofuel has expanded, resulting in larger quantities of DDGS as a byproduct. This trend has not only created a more sustainable feed resource but also contributed to the growth of DDGS Dryee suppliers. As ethanol production ramps up, suppliers in countries like India, Brazil, and the United States are seeing greater opportunities for exporting DDGS products to feed markets worldwide.

5. Focus on Nutritional Enhancements

To meet the evolving needs of the animal feed industry, DDGS producers and suppliers are focusing on enhancing the nutritional profile of their products. Through the use of advanced processing techniques, they are able to improve the amino acid composition and digestibility of DDGS. Additionally, suppliers are experimenting with different forms of DDGS, such as high-oil DDGS, which offer even greater nutritional benefits. This trend is expected to continue as suppliers aim to offer more tailored solutions to their clients.

Conclusion

As the demand for sustainable, cost-effective, and nutritionally-rich animal feed continues to rise, DDGS is poised to play an even larger role in the global feed market. The evolving trends in DDGS production, including advancements in drying technology, the expansion of DDGS in various animal feed markets, and the increasing importance of sustainability, present ample opportunities for growth in the industry. In India, where the agriculture and livestock sectors are rapidly growing, there is a rising demand for quality DDGS. As a result, working with a reliable DDGS Dryee Supplier in india is becoming increasingly essential for businesses looking to tap into this expanding market. With the right supplier, stakeholders in the feed industry can meet both their nutritional and environmental goals, contributing to a more sustainable agricultural future.

0 notes

Text

NuLifeLineCare Rehab — Alcohol De-addiction and Rehabilitaion Centre in Delhi

Alcohol De-addiction Centre in Delhi

NuLifeLineCare Rehab stands out among the best when it comes to alcohol addiction treatment and de-addiction centers. With their expert team of professionals and comprehensive approach, they provide a holistic and effective solution for those struggling with alcohol addiction or alcoholism.

At NuLifeLineCare Rehab, they understand the challenges that come with alcohol addiction and offer specialized programs tailored to meet each individual’s unique needs. Their evidence-based treatment methods, combined with compassionate care, create a supportive environment for recovery.

The centre is equipped with state-of-the-art facilities and amenities designed to ensure comfort during the rehabilitation process. From detoxification to counseling sessions and aftercare support, NuLifeLineCare Rehab Centre in Delhi focuses on addressing both the physical and psychological aspects of alcohol addiction.

With a team of experienced doctors, therapists, and counselors, NuLifeLineCare Rehab provides personalized treatment plans that encompass medical intervention, therapy sessions, mindfulness exercises, and educational workshops. They aim not only to help individuals overcome their dependence on alcohol but also to empower them with coping mechanisms for long-term sobriety.

Whether someone is seeking treatment for themselves or a loved one battling with alcohol addiction, NuLifeLineCare Rehabilitation Centre in Delhi offers a safe haven where individuals can rebuild their lives free from the chains of substance abuse.

In summary, NuLifeLineCare Rehab is undoubtedly one of the leading deaddiction centers for alcohol addiction treatment. With their comprehensive approach and unwavering commitment to recovery, they offer hope and healing for those struggling with alcohol dependence.

As we know alcohol is a hard drink that contains ethanol which is prepared by the fermentation of grains, fruits, or any other materials that contain sugar. This drink is consumed widely in the world. It acts as a depressant and helps to reduce anxiety and shyness if taken in small doses.

Harmful effects of high consumption of alcohol

But this drink is harmful to health if it will be consumed in large amounts or on a daily basis because it is a kind of drug that can cause drunkenness, unconsciousness, or even death. After all, it affects majorly the liver. But despite all this due to its seductive nature, the persons that are become addicted to this can’t get rid in their complete life. But the persons who are determined enough can leave this and there are many alcohol treatments in India that can help you to get out of its vicious circle.

Alcohol Rehabilitation Centers in India

There are many rehab centers along with treatments that can prop you to get away from this drink as early as possible. We purely recommend going to the NuLifeLineCare Rehab to get aid or treatment because it is one of the best rehabs in India. You can avail the facilities of professional and experienced staff there in the capital city of India, Delhi. At this place, the patients are treated with a strategic approach as well and it is one of the most cost-effective rehabs in India. You can call, email, or browse the official website to get all the details about this center. There are also frequently asked questions available on the website so that any visitor can’t hassle in case of any confusion. One more interesting point that should be noted is that the therapies that are available here also consist of game therapies along with hypnotherapy and autogenic.

The idea behind this article

Consuming alcohol is not a disease but it is a kind of habit that is new at its start and started generally for getting its taste by any age group people. If it is consumed in high doses it can not only destroy the physical or mental health of the individual but can ruin the financial stability and also can ruin the families because then they are getting embarrassed in front of everyone and can’t help to maintain balance to the drunken person.

Review

So it is our first priority that we don’t have to make anything a habit that can’t be avoided and due to which our family can get ruined.

For more details, call us on +91–8958305058

Or visit: https://www.nulifelinecare.org/

#drugsfreeindia#saynotodrugs#nashamuktbharat#nashamuktbharatabhiyaan#nmba#bestrehabcentre#rehabilitation#nashamuktikendra#bestrehabindehradun#uttarakhand#fightagainstdrugs#fightagainstaddiction#nomoredrugs#addictionawareness#addictionrecovery#recovery#nasha_ab_nahi#bandkaronasha#dehradun#addiction#bestnashamuktikendra#nulifelinecarerehab

0 notes

Text

BCL Industries Announces Strategic Acquisition of Goyal Distillery and Expansion of Ethanol Production

On October 3, 2024, BCL Industries Ltd. made an exciting announcement regarding its latest strategic move to strengthen its position in India's ethanol manufacturing sector. The Board of Directors approved the acquisition of Goyal Distillery Private Ltd., marking a pivotal step in the company’s long-term growth plan.

Goyal Distillery, based in Fatehabad, Haryana, will now become a wholly owned subsidiary of BCL Industries. The acquisition comes as part of BCL's efforts to enhance its production capacity and expand its footprint in the ethanol sector, which has become increasingly vital to India’s energy landscape. BCL Industries, already a leader in the grain-based ethanol manufacturing industry, will now be better equipped to meet the growing demand for sustainable energy solutions.

The acquisition holds particular significance for BCL, as Goyal Distillery already possesses the necessary land and regulatory clearances to set up a 250 KLPD (Kilo Liters Per Day) grain-based ethanol unit. This ready-to-go infrastructure means the distillery can be operational in a much shorter timeframe than typical plant setups, giving BCL a significant advantage in terms of speed and efficiency. This rapid commission timeline is particularly critical as the global ethanol market continues to expand.

Once the plant is up and running, BCL Industries’ total distillery capacity will increase from its current level of 700 KLPD to 1100 KLPD. This expansion includes an additional 150 KLPD at BCL’s existing Bathinda unit and the newly added 250 KLPD capacity at the Fatehabad unit. This scale of growth is set to place BCL Industries among the top ethanol producers in India.

Beyond the sheer production increase, the acquisition highlights BCL Industries’ commitment to sustainability. The new plant will include a power generation facility that uses paddy straw as its primary fuel source, making it a prime example of the company’s green energy initiatives. By utilizing this agricultural byproduct, BCL is taking a significant step towards promoting renewable energy sources while supporting the local agricultural economy.

BCL Industries is also making strides in the biogas sector. As part of its expansion plan, the company intends to establish a biogas plant on a 9-acre plot adjacent to the distillery in Fatehabad. The plant will have the capacity to process approximately 250 metric tons of paddy straw daily, converting it into around 20 metric tons of biogas. This initiative not only supports BCL’s green energy ambitions but also addresses environmental concerns associated with the disposal of paddy straw, a common agricultural waste product.

The estimated capital expenditure (Capex) for the combined distillery and biogas projects is projected to be around ₹350 crore. The timeline for the construction and commissioning of these facilities is expected to be around 20 months from the groundbreaking date, making 2026 a pivotal year for BCL Industries’ ethanol and renewable energy operations.

With this acquisition, BCL Industries continues to strengthen its position as an industry leader. By increasing its production capacity and integrating renewable energy solutions into its operations, BCL is setting itself up for sustained growth and success in the ethanol market.

The Board of Directors' meeting, held on October 3, 2024, commenced at 3 PM and concluded at 3:30 PM. Following the meeting, the company expressed confidence in the new acquisition’s ability to contribute significantly to both its financial performance and its sustainability goals.

This acquisition is yet another step in BCL Industries’ ongoing journey towards creating a greener, more energy-efficient future. The move also aligns with the broader national and global trends towards renewable energy, putting the company in an excellent position to capitalize on the growing demand for eco-friendly energy solutions.

For BCL Industries, this is not just an acquisition; it’s a commitment to innovation, growth, and sustainability. The company’s leadership in ethanol production, combined with its focus on renewable energy initiatives, continues to set the standard for the future of energy in India.

0 notes

Text

Revolutionizing Efficiency: The Future of Ethanol Plant Automation

Understanding the Basics: What is Ethanol Plant Automation?

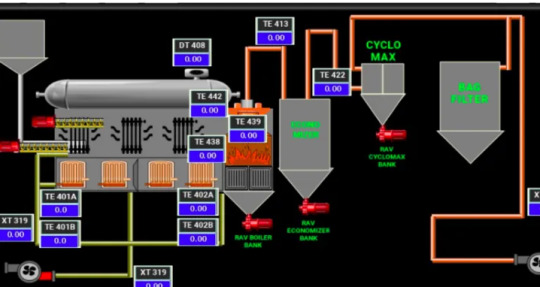

These are the advanced technologies implemented in controlling and monitoring the numerous processes related to ethanol production. This encompasses handling the feedstock, fermentation, distillation, and dehydration. At the heart of this automation are the Electrical Automation Panels and the PLC Automation Panels, which serve as the brains of the plant. This is the panel that is designed and made by Accord Automation; it fronts sensors, actuators, and a rubric of control systems scattered around the plant. They collect real-time data, process it, and make intelligent decisions for the optimization of production efficiency, maintenance of product quality, and, above all, safety. Our working values for ethanol plant automation are founded on respect, professionalism, and perseverance. We treat the needs of every ethanol plant as peculiar; thus, we work as a partner with each of our clients to deliver solutions that are relevant to their requirements.

2. Key Benefits of Implementing Automation in Ethanol Production

a) Increased Productivity: Automation lets it run 24/7 with minimal human intervention, meaning that production capacity can be increased enormously.

b) Improved Quality Control: With automated systems, product quality is ensured to increase by taking tight control over critical parameters such as temperature, pH, and fermentation time.

c) Enhanced Safety: Reducing the number of human operators in high-risk areas would greatly improve safety.

d) Energy Efficiency: The design for optimized energy consumption through sophisticated control algorithms helps reduce operation costs while making a technological shift for damage control of the environment.

e) Real-time Monitoring and Reporting: Real-time access to the data obtained from production is possible through automation, facilitating quick decision-making and strategies with improved troubleshooting.

f) Lower Labor Requirement: It is the reason why industrial production can still be managed with a lesser number of skilled operators, hence significantly reducing the sum total labor requirement for routine tasks. Accord Automation’s automation solutions aim at making ethanol plants more efficient, safer from accidents, and more profitable. Our Electric Automation Panel and PLC Automation Panels are built user-friendly but robust enough to counter harsh working environments and hence maintain steady performance.

3. Top Technologies Driving Ethanol Plant Automation

Several key technologies are driving the automation revolution in ethanol plants:

a) Programmable Logic Controllers (PLCs): These are the core of plant automation. They serve control to many processes based on pre-programmed logic and real-time data. Our PLC Automation Panels are state-of-the-art, modulating this technology with unbeatable control and flexibility.

b) SCADA — Supervisory Control and Data Acquisition Systems: SCADA systems provide the software that is interfaced with our industrial control and automation systems to provide a graphical interface in monitoring basic plant operation. Our Electrical Automation Panels can be fully integrated into a single source of control management.

c) The IIoT devices of the Industrial Internet of Things allow real-time data collection and analysis for predictive maintenance and optimization.

d) Artificial Intelligence and Machine Learning: Technologies allow the predictive modeling and optimization of the plant processes for achieving efficiency that only keeps getting better with time.