#Global CONVEYOR SYSTEM MARKET

Explore tagged Tumblr posts

Text

CONVEYOR SYSTEM MARKET Growth, Industry Size-Share, Global Trends, Key Players Strategies and Upcoming Demand

Data Bridge Market Research analyses that the CONVEYOR SYSTEM MARKET will project a compound annual growth rate (CAGR) of 4.20% during the forecast period of 2022-2028.

A world class CONVEYOR SYSTEM MARKET research report is formulated with the finest and advanced tools of collecting, recording, estimating and analysing market data. With the systematic and comprehensive market research study, this market research report offers the facts associated with any subject in the field of marketing for Automotive industry. It gives superior ideas and solutions in terms of product trends, marketing strategy, future products, new geographical markets, future events, sales strategies, customer actions or behaviours. This CONVEYOR SYSTEM MARKET report has been prepared by considering several fragments of the present and upcoming market scenario.

CONVEYOR SYSTEM MARKET Scope and Market Size

Conveyor system market is segmented on the basis of industry and type. The growth among segments helps you analyse niche pockets of growth and strategies to approach the market and determine your core application areas and the difference in your target markets.

On the basis of industry, conveyor system market is segmented into warehouse & distribution, food & beverage, automotive, electronics, mining, and airport. Food & beverage has been further segmented into meat and poultry & dairy among others.

The conveyor system market is also segmented on the basis of type into belt, roller, overhead, floor, pallet, crescent, cable and bucket.

Get the Free sample copy of the report here:

Some of the key questions answered in this report:

How has the CONVEYOR SYSTEM MARKET performed so far and how will it perform in the coming years?

What has been the impact of COVID-19 on the CONVEYOR SYSTEM MARKET?

What are the key regional markets?

What are the key driving factors and challenges in the industry?

What is the structure of the CONVEYOR SYSTEM MARKET and who are the key players?

Market Analysis and Insights: CONVEYOR SYSTEM MARKET

Conveyor system market will reach at an estimated value of USD 10.86 billion and grow at a CAGR of 4.20% in the forecast period of 2021 to 2028. Rising demand for handling larger volumes of goods and improving productivity is an essential factor driving the conveyor system market.

Conveyor system is a type of automated machine handling operation that involves transportation of equipment, materials, product from one position to another. They are majorly utilized in transferring and transportation of heavy-weighted items, as they can perform this task with ease and high effectiveness. It is also used in production lines, as well as in sorting procedures in a number of warehouses, manufacturing facilities and factories.

CONVEYOR SYSTEM MARKET - Regional Level Analysis

The countries covered in the conveyor system market report are U.S., Canada and Mexico in North America, Brazil, Argentina and Rest of South America as part of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe in Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA).

CONVEYOR SYSTEM MARKET - Share Analysis:

Conveyor system market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, regional presence, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies’ focus related to conveyor system market.

Key player - CONVEYOR SYSTEM MARKET

Some of the major players operating in the CONVEYOR SYSTEM MARKET are WESTFALIA TECHNOLOGIES INC., Schaefer Systems International Inc., Emerson Electric Co., Dematic, Continental AG, Bastian Solutions Inc., Somi Conveyor Beltings Ltd., TGW Logistics Group, Fives, Siemens, Honeywell Intelligrated, Vanderlande Industries B.V., Invata Intralogisitcs, Taikisha Ltd., Daifuku Co. Ltd., Swisslog Holding Ltd., Conveyor Systems Ltd, PHOENIX CBS GmbH and Khare Agromech Industries Pvt.Ltd.

Get Full Access of Report@

MAJOR TOC OF THE REPORT

Chapter One: Introduction

Chapter Two: Scope and Market Size

Chapter Three: Analysis and Insights

Chapter Four: Country Level Analysis

Chapter Five: Share Analysis

Chapter Six: Key player

Get TOC Details:

Top Trending Reports:

Global Sealed Lead Acid Battery Market

Global Ride Sharing Market

Global Weigh-In-Motion System Market

Global Convertible Roof System Market

Global Conveyor System Market

Global Electronic Logging Device Market

Global Gasoline Direct Injection Market

Global Hybrid Train Market

Global Industrial Crane Market

Global Trailer Assist System Market

Global Train Signalling System Market

Global V2X for Automotive Market

Global Rolling Stock Market

Asia-Pacific Rolling Stock Market

Europe Rolling Stock Market

Middle East and Africa Rolling Stock Market

North America Rolling Stock Market

Europe Remote Diagnostics Systems for Heavy Commercial Vehicles Market

India Passenger Vehicle Interior Market

North America LPG Vehicles Market

Global Automotive In-Cabin Air Quality Improvement Solutions Market

Global Commercial Aircraft Wings Market

Global Electric Glider Market

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-386.8-2818

Email: [email protected]

#CONVEYOR SYSTEM MARKET#Global CONVEYOR SYSTEM MARKET#CONVEYOR SYSTEM MARKET size#CONVEYOR SYSTEM MARKET share#CONVEYOR SYSTEM MARKET analysis#CONVEYOR SYSTEM MARKET growth#CONVEYOR SYSTEM MARKET demand#CONVEYOR SYSTEM MARKET research#CONVEYOR SYSTEM MARKET research report#CONVEYOR SYSTEM MARKET report#CONVEYOR SYSTEM MARKET overview#CONVEYOR SYSTEM MARKET opportunity#CONVEYOR SYSTEM MARKET segmentation#CONVEYOR SYSTEM MARKET value#CONVEYOR SYSTEM MARKET insight

0 notes

Text

Supply and Demand: Asia’s Mining Market at a Glance

The times of clear outline between the creating and created universes are a distant memory. Prospering, self-assured youthful economies from all continents have entered the world stage as shippers of labor and products for infrastructure projects, as well as conspicuous exporters and global financial backers.

South and East Asia, drove by new economic forces to be reckoned with India and China, is a locale that is rich with an open door for the mining and metals sector. Be that as it may, more than essentially being a hotbed of mining activity and new projects, Asian companies are quickly catching up with North America and Europe in worldwide mining venture, and consolidations and acquisitions.

This quick ascent, particularly prominent in China, is even more clear in the mining scene as Asian countries try to secure present and future material resources. Notwithstanding China, projects and arrangements in Asia and all around the world are being driven by India, Singapore, Indonesia, Japan and South Korea.

In this preview of Asia's mining market, we investigate the Asian mining companies venturing into the spotlight, as well as recent speculations made to take advantage of the continent's own crude resources. We likewise inquire as to whether unfortunate security systems mean this noteworthy extension comes at too high an exorbitant cost in certain countries.

Vale puts resources into China

Numerous Asian countries are areas of strength for attracting from the world's significant mining companies. Vale, the world's biggest iron metal mining company, which last year outperformed Petrobras as Brazil's greatest exporter with outside deals worth $24bn, has been proactively increasing its presence in China. In December 2010, the company started exchanging on the Hong Kong Stock Exchange (HKSE), the biggest non-financial company ever to exchange publicly in Hong Kong. This clear sign of the company's aim to expand activities in China and Asia is being borne out, as Asia is presently Vale's greatest commodity market.

For more mining market commodity insights, download a free report sample

The Brazilian company is likewise starting to put resources into iron metal projects in China. One of the most conspicuous of these is a joint endeavor organization with Henan-based steelmaker Anyang Iron and Steel on a 1.2-million-ton iron mineral pellet plant. Vale and Anyang are expecting the plant to begin production toward the finish of March 2011.

Vale has additionally collaborated with two Chinese companies to give hardware to its $2.5bn CLN iron metal project in the Brazilian province of Maranhão, with contracts endorsed in Shanghai among Vale and Chinese manufacturers Keda Machinery Manufacturing and Zoomlion in November 2010. Keda will produce five conveyor belts for the project, while Zoomlion will give a reclaimer and two iron metal stackers. The companies will create probably the most elevated capacity hardware in their respective fields at any point worked in China.

Endless supply of the contracts, Vale CEO Roger Agnelli talked confidently about the company's future endeavors in China and with Chinese companies. "Vale will put a great deal in China before very long and we are completely confident that China brings a ton to the table," he said. "We will become together."

However, not just Vale is cooperating with Asian companies, and not just China is welcoming significant interests into mining projects, Merukh Ventures auxiliary PT Merukh Iron and Steel announced in February 2011 that it would contribute $48bn to fabricate two new iron metal plants in the Indonesian province of East Nusa Tenggara to assist with fulfilling the country's skyrocketing demand for steel.

2 notes

·

View notes

Text

Industrial Oven Manufacturers in Bangalore: Pioneering Industrial Solutions

Bangalore, known as India’s Silicon Valley, is a hub for technological advancements and industrial innovation. Among its many industrial offerings, industrial oven manufacturers in Bangalore stand out for their precision engineering and cutting-edge solutions. These manufacturers play a pivotal role in catering to diverse industries, ranging from automotive and aerospace to food processing and electronics.

The Role of Industrial Ovens

Industrial ovens are indispensable in manufacturing processes where controlled heat treatment is required. These robust machines serve functions such as curing, baking, drying, and annealing. Their applications span multiple sectors:

Aerospace and Automotive: Heat treatment of components ensures durability and performance.

Electronics: Precision drying of circuit boards enhances reliability.

Food Processing: Ovens are used for baking and dehydration processes, adhering to strict food safety standards.

Metal and Glass Industries: Annealing and tempering are crucial for material strengthening.

The demand for high-quality industrial ovens in Bangalore is driven by the city’s thriving industrial base, making it a strategic location for manufacturers specializing in these systems.

Customization: Meeting Industry-Specific Needs

One of the hallmarks of industrial oven manufacturers in Bangalore is their ability to provide customized solutions. Depending on the industry and application, ovens can vary significantly in design, size, and functionality.

Batch Ovens: Ideal for small-scale operations or specialized treatments, these ovens handle one batch of material at a time.

Continuous Ovens: Suitable for high-volume operations, they allow materials to move through the oven in a steady flow.

Vacuum Ovens: Used for applications requiring a moisture-free or low-oxygen environment, common in electronics and medical industries.

Conveyor Ovens: Perfect for assembly lines, offering consistent heat treatment.

These manufacturers understand that no two businesses are alike, and customization ensures optimal performance, energy efficiency, and cost-effectiveness.

Advancements in Technology

Bangalore’s reputation as a technology-driven city is reflected in the innovations introduced by its industrial oven manufacturers. Modern industrial ovens incorporate advanced features such as:

Digital Controls: Touchscreen interfaces and IoT integration provide precise temperature control and real-time monitoring.

Energy Efficiency: Innovations in insulation and heating systems reduce energy consumption while maintaining performance.

Safety Features: Over-temperature protection, auto-shutdown mechanisms, and robust construction ensure safe operations.

Remote Monitoring: Manufacturers are leveraging smart technology to enable remote access, ensuring operational efficiency and reducing downtime.

These technological advancements not only improve the efficiency of manufacturing processes but also align with global sustainability goals by minimizing the environmental footprint.

Importance of Quality Standards

Quality assurance is a priority for industrial oven manufacturers in Bangalore. They adhere to national and international standards to ensure reliability and safety. Certifications such as ISO and compliance with government regulations underscore their commitment to excellence.

Regular quality checks during manufacturing, coupled with post-installation support, help businesses maintain seamless operations. Bangalore’s manufacturers also provide comprehensive training to operators, ensuring the effective and safe use of the equipment.

Export Opportunities

Bangalore’s strategic position as an industrial hub has enabled its oven manufacturers to reach international markets. Their ability to produce ovens that meet global standards has positioned them as reliable exporters. Industries across Europe, the Middle East, and Southeast Asia source high-quality industrial ovens from Bangalore, further boosting the city’s reputation as a manufacturing powerhouse.

Why Choose Bangalore for Industrial Ovens?

Several factors make Bangalore a preferred destination for sourcing industrial ovens:

Skilled Workforce: The city boasts a pool of skilled engineers and technicians who excel in precision manufacturing.

Proximity to Key Industries: Bangalore’s ecosystem includes industries that demand high-quality ovens, ensuring a consistent market.

Innovation-Driven Culture: The emphasis on research and development leads to continuous product improvement.

After-Sales Support: Manufacturers in Bangalore prioritize long-term client relationships by offering reliable maintenance and servicing solutions.

Future Outlook

As industries continue to expand, the need for efficient and advanced heat treatment solutions will rise. Industrial oven manufacturers in Bangalore are well-positioned to meet this growing demand. With a focus on innovation, quality, and sustainability, they are likely to remain at the forefront of the industry, catering to both domestic and international markets.

In conclusion, Bangalore’s industrial oven manufacturers are vital contributors to the city’s industrial landscape. Their commitment to quality, technological advancements, and customer-centric solutions makes them leaders in the field, ensuring that businesses across industries achieve precision and efficiency in their operations.

#industrial oven manufacturers in Bangalore#industrial oven manufacturers#industrial oven manufacturers in India

0 notes

Text

0 notes

Text

Digital Innovations in Coal Import Services: Enhancing Efficiency

Introduction

The global coal import industry is a vital component of energy supply chains, serving industries such as power generation, steel production, and cement manufacturing. However, the complexities of coal import logistics, including supply chain disruptions, fluctuating demand, and stringent regulations, call for innovative solutions. Digital technologies are emerging as transformative tools, enhancing efficiency and streamlining coal import processes.

1. AI-Driven Demand Forecasting

Artificial Intelligence (AI) has revolutionized demand forecasting for coal imports. Using historical data, market trends, and predictive analytics, AI models can accurately forecast demand, helping importers optimize purchase quantities and avoid overstocking. This not only minimizes costs but also ensures a steady supply for end-users.

2. Blockchain for Transparent Transactions

Blockchain technology enhances transparency and trust in coal trade transactions. By creating a decentralized and immutable ledger, blockchain allows stakeholders to track every stage of coal shipments—from mine to port to final delivery. This ensures accountability, reduces the chances of fraud, and improves trust among importers, exporters, and intermediaries.

3. Automated Port Operations

The adoption of automation in port operations has significantly improved coal handling efficiency. Automated cranes, conveyors, and loaders expedite the unloading and storage of coal shipments, reducing turnaround times. Coupled with AI-based scheduling systems, ports can optimize docking and loading schedules, minimizing delays.

4. IoT for Real-Time Monitoring

Internet of Things (IoT) devices are enabling real-time monitoring of coal shipments during transit. Sensors installed on cargo containers measure factors such as temperature, humidity, and weight to ensure the coal's quality remains intact. IoT platforms also provide real-time location tracking, offering importers greater visibility into their shipments' progress.

5. Digital Documentation and E-Customs

Traditional coal import documentation is often paper-heavy, leading to delays and inefficiencies. Digital documentation platforms streamline processes by digitizing contracts, invoices, and compliance reports. E-customs systems further expedite the clearance process, ensuring quicker release of shipments and reducing administrative burdens.

6. Big Data Analytics for Strategic Decision-Making

Big data analytics empowers coal importers with actionable insights. By analyzing global trade data, market trends, and competitor strategies, companies can make informed decisions regarding sourcing, pricing, and logistics. This helps businesses remain competitive in an ever-evolving market.

7. Sustainable Solutions Through Digitalization

Digital tools also contribute to sustainability in coal imports. Carbon tracking software calculates the environmental footprint of coal transportation, encouraging importers to adopt greener logistics practices. Additionally, AI-powered optimization tools help reduce fuel consumption in shipping, aligning coal import operations with global sustainability goals.

Conclusion

Digital innovations are redefining the coal import industry by enhancing efficiency, transparency, and sustainability. From AI-driven forecasting to blockchain-based transaction tracking, these technologies streamline processes, reduce costs, and ensure reliable supply chains. As the global coal market becomes increasingly dynamic, embracing digital tools is no longer an option but a necessity for businesses aiming to stay ahead of the curve.

By leveraging these advancements, coal importers can navigate industry challenges, improve operational efficiency, and contribute to a more sustainable future for global energy supply chains.

0 notes

Text

From Air to Action: Supporting Industry Everywhere from Gajjar Compressor

Introduction

Industries worldwide are evolving rapidly, requiring cutting-edge technology to meet growing demands for efficiency, reliability, and sustainability. At the heart of this transformation are industrial air compressors—critical tools powering operations across diverse sectors. Gajjar Compressor, a trusted name in the industry, is leading this revolution with innovative solutions that cater to a wide range of industrial applications.

Understanding the Importance of Air Compressors

Air compressors are integral to various industries, converting power into potential energy stored in pressurized air. This stored energy powers tools, machinery, and processes that form the backbone of industrial production. From manufacturing to healthcare, food processing to automotive, the applications are vast and indispensable.

Key Benefits of Industrial Air Compressors

Versatility: Suitable for various applications, from assembly lines to pneumatic tools.

Cost-Effectiveness: Reduces operational costs by optimizing energy usage.

Enhanced Productivity: Improves workflow efficiency and minimizes downtime.

Environmental Benefits: Modern compressors focus on energy efficiency, reducing carbon footprints.

Gajjar Compressor recognizes these benefits and incorporates them into its product designs, ensuring clients receive maximum value and performance.

Gajjar Compressor: A Legacy of Excellence

With decades of experience, Gajjar Compressor has built a reputation for delivering reliable and innovative air compressor solutions. The company’s commitment to quality, affordability, and customer satisfaction sets it apart in the competitive market.

Why Choose Gajjar Compressor?

Wide Range of Products: From oil-free compressors to high-pressure systems, Gajjar Compressor offers solutions tailored to industry-specific needs.

Innovative Technology: Integrating the latest advancements in energy efficiency and performance.

Global Reach: Trusted by clients worldwide, showcasing its credibility and expertise.

After-Sales Support: Comprehensive maintenance services and spare parts availability ensure uninterrupted operations.

Supporting Industries Across the Spectrum

Gajjar Compressor’s versatile products cater to various industries, ensuring seamless operations and enhanced productivity.

1. Manufacturing and Assembly Lines

In the manufacturing sector, precision and consistency are paramount. Gajjar Compressor provides solutions that power pneumatic tools, conveyor systems, and automation technologies, ensuring high-quality output with minimal downtime.

Applications in Manufacturing:

Operating robotic arms and CNC machines.

Spray painting and coating systems.

Assembly and packaging lines.

2. Healthcare and Pharmaceuticals

Air purity is critical in healthcare and pharmaceutical industries. Gajjar’s oil-free compressors ensure contamination-free air supply, meeting stringent safety and hygiene standards.

Key Benefits for Healthcare:

Reliable operation of ventilators and other medical devices.

Sterile air for pharmaceutical production.

Quiet and efficient systems ideal for hospital environments.

3. Food and Beverage Processing

Food safety regulations demand clean and reliable air systems. Gajjar Compressor delivers compressors that maintain product integrity and quality during food processing, packaging, and storage.

Food Industry Applications:

Packaging and bottling lines.

Mixing and blending systems.

Air-driven cleaning and drying processes.

4. Automotive Industry

From car manufacturing plants to service centers, the automotive industry relies on air compressors for a range of applications, including powering tools and inflating tires.

Automotive Uses:

Painting and finishing.

Operating air tools like wrenches and drills.

Vehicle assembly processes.

5. Energy and Power Generation

Energy-intensive industries require robust and efficient compressors. Gajjar Compressor’s high-pressure systems are designed to withstand demanding environments, ensuring optimal performance.

Examples of Use:

Gas and oil extraction processes.

Power plant maintenance.

Operating turbines and pneumatic systems.

Sustainability: A Core Focus of Gajjar Compressor

As industries shift towards sustainable practices, Gajjar Compressor remains at the forefront, developing energy-efficient compressors that reduce carbon emissions and operational costs.

Green Initiatives by Gajjar Compressor:

Energy-Efficient Designs: Compressors that consume less energy without compromising performance.

Eco-Friendly Manufacturing: Minimizing waste and using sustainable materials in production.

Recycling Programs: Encouraging clients to adopt responsible disposal and recycling of old equipment.

Customer-Centric Approach

Gajjar Compressor’s success stems from its unwavering commitment to customer satisfaction. The company goes beyond selling products by providing tailored solutions, technical support, and training to clients.

Highlights of Gajjar’s Customer Service:

Customizable Solutions: Understanding unique requirements and delivering customized compressors.

24/7 Support: Ensuring clients receive assistance whenever needed.

Comprehensive Training: Educating clients on the proper use and maintenance of equipment.

Future Innovations from Gajjar Compressor

The company’s focus on research and development ensures it stays ahead of industry trends. From IoT-enabled compressors to AI-driven predictive maintenance systems, Gajjar Compressor is pioneering the future of industrial air solutions.

Upcoming Advancements:

Smart compressors with remote monitoring capabilities.

Advanced filtration systems for ultra-clean air.

Enhanced durability for extreme operating conditions.

Conclusion

Gajjar Compressor continues to redefine industry standards by delivering innovative, efficient, and sustainable air compressor solutions. By empowering industries with reliable technology, Gajjar is not just providing compressors but enabling growth, efficiency, and success.

From air to action, Gajjar Compressor is a trusted partner in powering industries worldwide, ensuring they thrive in an ever-evolving landscape.

Explore the possibilities with Gajjar Compressor today and experience the difference in quality, performance, and support!

0 notes

Text

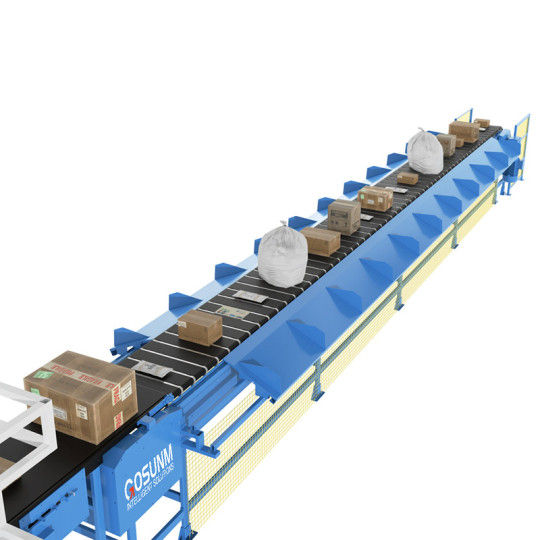

Small And Medium-sized Express Parcel Sorting Solutions

At present, the popularization of automated parcel sorting equipment has driven the rapid development of the global logistics and express delivery industry. However, there is currently no targeted equipment to meet the sorting needs of regional express headquarters, direct-operated centers, and first- and second-level large outlets with large inbound and outbound sorting volumes. For this reason, Gosunm has provided a solution that can complete the sorting tasks efficiently and accurately.

With the basic completion of the layout of front-end automation equipment, the number of inbound deliveries at express delivery terminals has increased year by year, resulting in a large number of deliveries and high labor costs. In order to solve the automation development of small and medium-sized express delivery terminals around the world, gosunm has created an automated sorting equipment for small and medium-sized express delivery centers - a linear narrow-band sorter.

The linear narrow belt sorter is a linear express cross belt sorter. Different from the circular cross belt sorting system, the linear sorter system is mainly a new type of general-purpose automated sorting equipment for sorting goods or parcels at the end of the express and logistics industries.

The main components include the feeding system, sorting trolley, grid system and control system.

It has the characteristics of small footprint, high sorting efficiency, labor saving, energy saving, and easy operation.

Linear sorting equipment solves the problem of existing cross-belt sorting machines being tall and occupying a lot of space.

The working principle of the equipment is that the parcel is loaded on the supply table, the code is read by the scanner, the position of the grid is determined, and the goods are unloaded to the designated grid smoothly through the trolley belt conveyor. The linear sorting machine has the following advantages:

Small footprint: Straight-line shape, minimum footprint of only about 300 square meters, can greatly save site area and rent.

Fast sorting speed: Line running speed 1.2m/s-1.8m/s multi-band adjustable, achieve sorting efficiency of 8000-13000 pieces/hour.

Simple loading operation: The configuration can be manually loaded or automatically supplied, and unloading can be directly connected to the telescopic belt conveyor to avoid manual handling in space.

High sorting accuracy: The top scanning barcode recognition rate reaches 99.97%, automatic recognition, automatic grid drop, high accuracy, avoid fatigue of manual operation, error caused by misclassification;

High cost performance: The investment cost of linear equipment is lower than that of circular line, and it can greatly alleviate the efficiency pressure brought by the increase in operation volume, optimize manpower allocation, and achieve more efficient completion of sorting and delivery tasks.

Personalized customization: Different linear cross-belt sorters can be customized according to the specific needs of customers, including customized size, number of smart carts, package supply platforms, and customized grid size for automatic package drop, to support inbound and outbound express delivery and e-commerce warehousing sorting and transportation, etc.

Linear sorting machine application scenarios

Express delivery industry

With the development of the market, the sorting volume of small and medium-sized outlets mainly for port entry has increased, and the labor cost has become increasingly high. The linear cross-belt sorting equipment, with its unique advantages, can better meet its automated sorting needs.

Cross-border e-commerce/e-commerce industry

With the surge in demand for e-commerce, the number of packages at major activity nodes has increased exponentially. The high-efficiency sorting of the linear cross-belt sorting machine has enabled the logistics sorting efficiency to meet the requirements of major markets and industries.

Its application areas include tobacco, clothing, maternal and child products, supermarkets, medicine and other industries. In the future, with the development of the express delivery and e-commerce industries, automated sorting equipment will become the "standard configuration" of express delivery outlets, improve the sorting efficiency of outlets, solve the problem of outlets coping with rising labor costs, and truly achieve the development goal of helping small and medium-sized outlets to automate and be efficient.

#gosunm#large inbound and outbound sorting#linear express cross belt sorter#linear narrow-band sorter

0 notes

Text

Discover Powerplay: The New Game Combining Strategy and Base Building

Powerplay RTS is a brand-new game but also a base builder coming to Linux with Mac and Windows PC. Developer Frantic’s creativity shines through in every detail. Due to make its way onto Steam in 2025. Get ready to dive into Powerplay, a brand-new title from Frantic Software, a Montreal-based indie studio that knows how to mix classic strategy with industrial base builder. This isn’t your average strategy — since it puts you in charge of an industrial nation, balancing military power with a deep economic and resource management system. Sounds intense? It is, but in the best way, with native support.

So yes, as of now, we are planning to ship on Linux :) We are using Unity for this game.

Frantic just confirmed in their reply that they’re using Unity for development. Seeing the rise in Linux market share on Steam, they’re now planning to roll out a native build now.

Build, Equip, Conquer

In Powerplay, you’re not just commanding troops; you’re building the very machines and weapons they’ll use. You’ll start by gathering resources, then work your way up to creating massive armies equipped with the tech you’ve developed. Whether you’re expanding your territory or bunkering down to defend your strongholds, every decision you make counts. Will you prioritize heavy artillery or speedy tanks? It’s all up to you.

Supply Chains: The Heart of the Game

Here’s the twist that sets Powerplay apart: supply chains. Forget about that magic “global inventory” some games rely on—this game keeps things real. You’ll need to design conveyor belts to move raw materials to your factories, which churn out intermediate resources and eventually weapons. Balancing your resources and managing space efficiently is key to staying ahead. Trust me, watching your supply lines in action is as satisfying as landing that perfect RTS rush. But it’s not just about building. Protecting your supply lines is just as critical. Lose those, and your armies will grind to a halt. You’ll need strategy, smarts, and maybe a little luck to keep things running smoothly.

Powerplay RTS | Announcement Trailer

youtube

Military Might

When it’s time to bring the heat, gameplay has you covered. From basic guns to tanks and even nukes, you’ll craft the ultimate war machines using the resources you’ve worked so hard to manage. Want to go all out with long-range strategies? Build trains to transport supplies across your growing empire and keep your troops fueled for battle.

Game Modes for Every Mood

Whether you’re in it for domination or just want to mess around, Powerplay has you covered with three main game modes:

Global Dominance (PvE): Build your empire and crush AI foes.

Deathmatch (PvE): A classic face-off where only one survives.

Sandbox: Let your creativity run wild.

What Makes Powerplay Shine

With features like fog of war, an isometric camera, and even a terrain editor for custom maps. Powerplay gives you endless ways to keep the action fresh. If you’re a fan of classic RTS games but crave a base builder with something deeper, Powerplay is due to be your focus. Get ready to master supply chains, crush enemies, and prove you’ve got what it takes to dominate the battlefield. Due to arrive on Steam in Q2 2025 for Linux, Mac, and Windows PC.

0 notes

Text

CONVEYOR SYSTEM MARKET Growth, Industry Size-Share, Global Trends, Key Players Strategies and Upcoming Demand

Data Bridge Market Research analyses that the CONVEYOR SYSTEM MARKET will project a compound annual growth rate (CAGR) of 4.20% during the forecast period of 2022-2028.

A world class CONVEYOR SYSTEM MARKET research report is formulated with the finest and advanced tools of collecting, recording, estimating and analysing market data. With the systematic and comprehensive market research study, this market research report offers the facts associated with any subject in the field of marketing for Automotive industry. It gives superior ideas and solutions in terms of product trends, marketing strategy, future products, new geographical markets, future events, sales strategies, customer actions or behaviours. This CONVEYOR SYSTEM MARKET report has been prepared by considering several fragments of the present and upcoming market scenario.

CONVEYOR SYSTEM MARKET Scope and Market Size

Conveyor system market is segmented on the basis of industry and type. The growth among segments helps you analyse niche pockets of growth and strategies to approach the market and determine your core application areas and the difference in your target markets.

On the basis of industry, conveyor system market is segmented into warehouse & distribution, food & beverage, automotive, electronics, mining, and airport. Food & beverage has been further segmented into meat and poultry & dairy among others.

The conveyor system market is also segmented on the basis of type into belt, roller, overhead, floor, pallet, crescent, cable and bucket.

Get the Free sample copy of the report here:

Some of the key questions answered in this report:

How has the CONVEYOR SYSTEM MARKET performed so far and how will it perform in the coming years?

What has been the impact of COVID-19 on the CONVEYOR SYSTEM MARKET?

What are the key regional markets?

What are the key driving factors and challenges in the industry?

What is the structure of the CONVEYOR SYSTEM MARKET and who are the key players?

Market Analysis and Insights: CONVEYOR SYSTEM MARKET

Conveyor system market will reach at an estimated value of USD 10.86 billion and grow at a CAGR of 4.20% in the forecast period of 2021 to 2028. Rising demand for handling larger volumes of goods and improving productivity is an essential factor driving the conveyor system market.

Conveyor system is a type of automated machine handling operation that involves transportation of equipment, materials, product from one position to another. They are majorly utilized in transferring and transportation of heavy-weighted items, as they can perform this task with ease and high effectiveness. It is also used in production lines, as well as in sorting procedures in a number of warehouses, manufacturing facilities and factories.

CONVEYOR SYSTEM MARKET - Regional Level Analysis

The countries covered in the conveyor system market report are U.S., Canada and Mexico in North America, Brazil, Argentina and Rest of South America as part of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe in Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA).

CONVEYOR SYSTEM MARKET - Share Analysis:

Conveyor system market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, regional presence, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies’ focus related to conveyor system market.

Key player - CONVEYOR SYSTEM MARKET

Some of the major players operating in the CONVEYOR SYSTEM MARKET are WESTFALIA TECHNOLOGIES INC., Schaefer Systems International Inc., Emerson Electric Co., Dematic, Continental AG, Bastian Solutions Inc., Somi Conveyor Beltings Ltd., TGW Logistics Group, Fives, Siemens, Honeywell Intelligrated, Vanderlande Industries B.V., Invata Intralogisitcs, Taikisha Ltd., Daifuku Co. Ltd., Swisslog Holding Ltd., Conveyor Systems Ltd, PHOENIX CBS GmbH and Khare Agromech Industries Pvt.Ltd.

Get Full Access of Report@

MAJOR TOC OF THE REPORT

Chapter One: Introduction

Chapter Two: Scope and Market Size

Chapter Three: Analysis and Insights

Chapter Four: Country Level Analysis

Chapter Five: Share Analysis

Chapter Six: Key player

Get TOC Details:

Top Trending Reports:

Global Sealed Lead Acid Battery Market

Global Ride Sharing Market

Global Weigh-In-Motion System Market

Global Convertible Roof System Market

Global Conveyor System Market

Global Electronic Logging Device Market

Global Gasoline Direct Injection Market

Global Hybrid Train Market

Global Industrial Crane Market

Global Trailer Assist System Market

Global Train Signalling System Market

Global V2X for Automotive Market

Global Rolling Stock Market

Asia-Pacific Rolling Stock Market

Europe Rolling Stock Market

Middle East and Africa Rolling Stock Market

North America Rolling Stock Market

Europe Remote Diagnostics Systems for Heavy Commercial Vehicles Market

India Passenger Vehicle Interior Market

North America LPG Vehicles Market

Global Automotive In-Cabin Air Quality Improvement Solutions Market

Global Commercial Aircraft Wings Market

Global Electric Glider Market

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-386.8-2818

Email: [email protected]

#CONVEYOR SYSTEM MARKET#Global CONVEYOR SYSTEM MARKET#CONVEYOR SYSTEM MARKET size#CONVEYOR SYSTEM MARKET share#CONVEYOR SYSTEM MARKET analysis#CONVEYOR SYSTEM MARKET growth#CONVEYOR SYSTEM MARKET demand#CONVEYOR SYSTEM MARKET research#CONVEYOR SYSTEM MARKET research report#CONVEYOR SYSTEM MARKET report#CONVEYOR SYSTEM MARKET overview#CONVEYOR SYSTEM MARKET opportunity#CONVEYOR SYSTEM MARKET segmentation#CONVEYOR SYSTEM MARKET value#CONVEYOR SYSTEM MARKET insight

0 notes

Text

Essential Techniques for Optimizing Your Distribution and Fulfillment

The developed technology and evolving market landscape through digitalization calls for efficient supply chain management. Most audiences and consumers prefer the comfort of virtual shopping and to fulfill their demand and achieve optimal consumer satisfaction hiring efficient distribution and fulfillment services would give you a competitive edge.

Companies can optimize these areas, by hiring warehousing and distribution services which can reduce costs, improve delivery times, and enhance customer satisfaction. Yet companies need to understand the process and best implementation to help their business grow and make a profit. So in this blog let’s look at some essential techniques to help streamline and elevate your fulfillment process and run efficient distribution of goods and products.

Techniques to Optimize Supply Chain Management:

Implement Advanced Inventory Management Systems: An effective inventory management system is fundamental to optimizing distribution and fulfillment, the following are some advanced technologies used by fulfillment centers to keep up with high demand, gain a competitive edge, and meet customer expectations without carrying excessive inventory,

Automated systems that track real-time inventory levels across multiple warehouses prevent stockouts, reduce overstock, and ensure products are where they need to be

Tools like barcode scanning, RFID, or cloud-based software help businesses maintain accurate inventory counts, optimize stock levels, and better forecast demand

Utilize Data Analytics for Demand Forecasting: Predicting demand accurately is crucial for efficiency, the packaging and fulfillment services use data analytics tools to analyze historical data, market trends, and customer behavior to forecast future demand more precisely. By understanding when and where demand spikes, companies can plan their inventory and workforce allocation accordingly, reducing waste and enhancing responsiveness. Reliable demand forecasting minimizes storage costs and reduces the likelihood of both stockouts and excess inventory, keeping the distribution chain flowing smoothly and enhancing the supply chain management

Optimize Warehouse Layout and Operations: Optimizing the layout by strategically placing high-demand products near packing and shipping areas minimizes picking and packing time, increasing efficiency in warehousing and distribution. Warehouse automation, such as conveyor belts, robotics, and automated picking systems, can further reduce manual tasks and streamline the order fulfillment process, reducing errors and speeding up deliveries. Implementing a “first in, first out” (FIFO) system can also reduce spoilage for perishable goods

Leverage Multi-Warehouse Strategies: Having multiple fulfillment centers located strategically closer to key markets helps reduce shipping costs and delivery times. This decentralized approach, often referred to as distributed fulfillment, allows for quicker, more affordable delivery by decreasing the distance packages need to travel. Companies can use order management systems (OMS) to route orders to the nearest warehouse with available inventory, reducing shipping costs and enhancing customer satisfaction. For international orders, companies can hire global distribution services that have warehouses in strategic locations making international shipping and order fulfillment easy

Partner with Reliable Shipping Carriers and Optimize Routes: Selecting trustworthy shipping partners is vital for timely deliveries. So try partnering with packaging and fulfillment services that offer tracking services and consistent delivery times to ensure orders reach customers as expected. Route optimization technology can also help companies plan the most efficient delivery paths, reducing fuel costs and delivery times. This technology, which accounts for factors like traffic patterns and delivery windows, is particularly useful for businesses with high volumes of local or regional deliveries

Automate Order Processing and Tracking: Order processing automation in warehousing and distribution speeds up fulfillment and reduces human errors. Automated tracking allows customers to monitor their orders, improving transparency and building trust. In the same way by integrating e-commerce platforms with inventory and fulfillment systems, companies can automatically process orders, generate picking lists, and track inventory status in real-time. In addition, proactive notifications about delivery updates or delays enhance the customer experience by setting realistic expectations and smoothly running the supply chain management

To conclude optimizing logistics is essential for delivering exceptional customer service while controlling costs. Many distribution and fulfillment services implement advanced inventory systems, to significantly enhance their distribution efficiency. These techniques streamline operations, reduce costs, and ultimately improve customer satisfaction, positioning your business for sustained growth in a competitive market.

0 notes

Text

The global indoor farming market size reached USD 22.3 Billion in 2024. IMARC Group expects the market to reach USD 47.2 Billion by 2033, exhibiting a growth rate (CAGR) of 8.63% during 2025-2033. The market is experiencing steady growth driven by rising preferences for sustainable and locally sourced food options, continuous technological advancements in indoor farming practices, and the widespread adoption of automation systems, including robotic arms and conveyor belts.

0 notes

Text

Overhead Conveyor Market Size, Share, Trends, Growth and Competitive Analysis

"Overhead Conveyor Market – Industry Trends and Forecast to 2028

Global Overhead Conveyor Market, By Product Type (I-Beam Trolley Conveyors, Enclosed Track Conveyors and Others), Application (Construction, Industrial, Oil and Gas, Transportation and Others), Function (Process Link, Process Decoupling, Buffering/ Storage, Sorting and Sequencing), Technology (Pouch Sorter and Power and Free System), Capacity (Up to 1000 items/H, 1000-10000 items/H and >10000 items/H), Weight (0-3 kg, 3-5 kg, 5-10 kg, 10-20 kg and 20-50 kg), Sales Channel (Direct and Via Main Contractors), Automation Grade (Manual, Semi-Automatic and Automatic), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

**Segments**

- **By Product Type**: The overhead conveyor market can be segmented based on the type of product. This includes categories such as enclosed track overhead conveyor, overhead power & free conveyor, and overhead trolley conveyor, among others. Each type offers unique features and advantages depending on the specific industry and application requirements. Enclosed track overhead conveyors, for example, are known for their durability and flexibility, making them suitable for various environments. On the other hand, overhead power & free conveyors are preferred for their ability to handle complex material flow processes efficiently. - **By Load Capacity**: Another crucial segment of the overhead conveyor market is based on load capacity. Different industries have varying load requirements, which necessitate conveyors with different capacities. The market offers options ranging from light-duty overhead conveyors for smaller loads to heavy-duty conveyors capable of handling large and heavy materials. Customers can choose the appropriate load capacity based on their operational needs and the nature of goods being transported. - **By End-User Industry**: The overhead conveyor market can also be segmented by end-user industry. Various sectors such as automotive, food & beverage, aerospace, warehousing & distribution, and manufacturing utilize overhead conveyors for their material handling needs. Each industry may have specific requirements in terms of conveyor design, material compatibility, safety features, and automation capabilities. Understanding the unique demands of different industries allows market players to offer tailored solutions that cater to diverse customer preferences and operational challenges.

**Market Players**

- Dematic - TGW Logistics Group - Daifuku Co., Ltd. - Siemens - Pacline Conveyors, Inc. - Allied Conveyor Systems - FATA Automation - Rapid Industries - Ssi Schaefer - Eisenmann SE

https://www.databridgemarketresearch.com/reports/global-overhead-conveyor-marketThe global overhead conveyor market is witnessing steady growth attributed to the increasing demand for efficient material handling solutions across various industries. As businesses strive to enhance productivity, streamline operations, and optimize logistics processes, the adoption of overhead conveyors is on the rise. One of the key trends driving market growth is the focus on customization and flexibility in conveyor systems. Companies are looking for tailored solutions that can accommodate their unique requirements, whether it be in terms of load capacity, product type, or industry-specific needs.

In addition to customization, technological advancements are playing a significant role in shaping the future of the overhead conveyor market. Automation, IoT integration, and smart conveyor systems are revolutionizing material handling operations, leading to improved efficiency, reduced labor costs, and enhanced overall performance. Market players are investing in research and development to introduce innovative conveyor solutions that leverage the latest technologies to meet the evolving demands of modern industries.

Moreover, sustainability has emerged as a key driver in the overhead conveyor market, with companies increasingly focusing on eco-friendly and energy-efficient solutions. Green initiatives and regulatory pressures are prompting businesses to adopt conveyors that minimize environmental impact while maximizing operational benefits. This shift towards sustainability is not only driven by corporate responsibility but also by the potential cost savings and long-term advantages associated with energy-efficient conveyor systems.

Furthermore, the competitive landscape of the overhead conveyor market is characterized by the presence of established players as well as emerging companies looking to gain a foothold in the industry. Market leaders such as Dematic, TGW Logistics Group, and Daifuku Co., Ltd. continue to dominate the market with their extensive product offerings, global presence, and strategic partnerships. These key players are focusing on expanding their product portfolios, enhancing their distribution networks, and investing in technological innovations to maintain their competitive edge.

As the global economy continues to recover from the impacts of the COVID-19 pandemic, the demand for overhead conveyors is expected to witness a resurgence across various end-user industries. The need for efficient and reliable material handling solutions will drive market growth**Segments** - **By Product Type**: The overhead conveyor market segmentation by product type includes enclosed track overhead conveyor, overhead power & free conveyor, and overhead trolley conveyor. These conveyor types offer distinct features and advantages suitable for various industries and specific application requirements. Enclosed track conveyors are recognized for their durability and flexibility, making them versatile for different environments. On the other hand, power & free conveyors are ideal for managing complex material flow processes efficiently. - **By Load Capacity**: Load capacity is a critical segment in the overhead conveyor market, catering to varying load requirements across different industries. Customers can choose from light-duty overhead conveyors for smaller loads to heavy-duty conveyors capable of handling large and heavy materials based on their operational needs and transported goods. - **By End-User Industry**: Another significant segment is categorizing the overhead conveyor market by end-user industry, including automotive, food & beverage, aerospace, warehousing & distribution, and manufacturing. Each industry has unique requirements in terms of conveyor design, material compatibility, safety features, and automation capabilities, prompting tailored solutions to meet diverse customer preferences and operational challenges.

**Global Overhead Conveyor Market, By Product Type, Application, Function, Technology, Capacity, Weight, Sales Channel, Automation Grade, Country, Industry Trends, and Forecast to 2028** - I-Beam Trolley Conveyors, Enclosed Track Conveyors, and Others - Construction, Industrial, Oil and Gas, Transportation, and Others - Process

Key Coverage in the Overhead Conveyor Market Report:

Detailed analysis of Global Overhead Conveyor Market by a thorough assessment of the technology, product type, application, and other key segments of the report

Qualitative and quantitative analysis of the market along with CAGR calculation for the forecast period

Investigative study of the market dynamics including drivers, opportunities, restraints, and limitations that can influence the market growth

Comprehensive analysis of the regions of the Overhead Conveyor industry and their futuristic growth outlook

Competitive landscape benchmarking with key coverage of company profiles, product portfolio, and business expansion strategies

Table of Content:

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Global Overhead Conveyor Market Landscape

Part 04: Global Overhead Conveyor Market Sizing

Part 05: Global Overhead Conveyor Market Segmentation by Product

Part 06: Five Forces Analysis

Part 07: Customer Landscape

Part 08: Geographic Landscape

Part 09: Decision Framework

Part 10: Drivers and Challenges

Part 11: Market Trends

Part 12: Vendor Landscape

Part 13: Vendor Analysis

Browse Trending Reports:

Threat Detection Systems Market Pipe Coating Market Fragrance Fixatives Market Mobile Campaign Management Platform Market Menstrual Cramps Treatment Market Roof Insulation Market Mobile Robotics Market Varnish Makers Market Urinary Incontinence Market Treatment Resistant Depression Market Robotic Prosthetics Market Neutropenia Market Polycystic Kidney Disease Adpkd Market Grain Analysis Market Solid State Solar Cell Market Panel Mount Industrial Display Market Automotive Mini Led Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

Key Drivers Fueling Growth in the Aramid Fiber Market

The global aramid fiber market was estimated at USD 4.09 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 8.1% from 2024 to 2030. This growth is largely attributed to rising demand from various industries, including oil and gas, healthcare, and manufacturing. The increasing focus on workplace safety, driven by stringent government regulations, is anticipated to further fuel market expansion throughout the forecast period.

However, the market experienced sluggish growth during the COVID-19 pandemic, primarily due to a decline in demand from the industrial sector. Government-imposed restrictions led to temporary shutdowns across a wide range of industries, significantly limiting market activity during that period.

Gather more insights about the market drivers, restrains and growth of the Aramid Fiber Market

Market Dynamics

Aramid fibers are renowned for their strength, synthetic nature, and heat resistance. These advantageous properties make them highly desirable in military and aerospace applications, particularly for ballistic-grade body armor fabric. One of the key features of aramid fibers is that they neither ignite nor melt under typical levels of oxygen, which provides excellent flame and heat resistance. Additionally, aramid fibers serve as substitutes for metal wires and organic fibers in structural composite applications, particularly in ropes used on oil rigs, marine and aerospace industries, automobiles, and bulletproof vests. Their superior mechanical properties—5% to 10% higher than those of other synthetic fibers—enhance their applicability in these demanding environments.

The aramid fiber industry is continuously evolving, with ongoing efforts to develop and manufacture synthetic fibers that meet the demands of new technologies. This includes replacing asbestos, which is known to be carcinogenic and toxic. Aramid fibers contribute strength and wear resistance to friction materials that do not contain asbestos. They allow for the selection of inert fillers based on thermal and wear characteristics, minimizing concerns related to the physical properties of those fillers. While asbestos is strong and can withstand chemical and high-temperature exposure, making it relatively inexpensive compared to other materials, its hazardous nature makes it a less desirable option in many applications.

Aramid fibers are used in two main types of applications: reinforcement in composites and fabrics in clothing. In the composite sector, they are utilized in military vehicles, sports goods, and aircraft. In the fabric sector, aramid fibers are crucial in creating protective clothing, such as bulletproof vests and fire-resistant garments. They are extensively employed across various applications, including protective gloves, sailcloth, flame- and cut-resistant clothing, snowboards, helmets, filament-wound pressure vessels, body armor, optical fiber cable systems, ropes and cables, tire reinforcement, rubber goods, tennis strings, hockey sticks, jet engine enclosures, asbestos replacement, and circuit board reinforcement.

In the U.S. market, growth is expected to be driven by the increased adoption of advanced material handling equipment, such as wagon tipplers, belt conveyor systems, and bucket elevators. These innovations facilitate the efficient movement and handling of materials, particularly within the cement industry. Additionally, the trend towards zero-labor warehousing has led to the adoption of advanced robotic systems, which is expected to further benefit market growth. Protective gear designed to safeguard workers from risks associated with hazardous jobs and challenging environmental conditions is another critical aspect of the aramid fiber market.

A significant portion of this protective gear is specifically engineered to shield employees from infections and pollution. Various end-use industries, including manufacturing, oil and gas, mining, healthcare, construction, and military, extensively utilize protective apparel. The ongoing increase in both onshore and offshore drilling activities, along with the expansion of the shale oil and gas industry, is expected to drive demand for aramid fibers in the U.S. market.

Among the different types of aramid fibers, the para-aramid fiber segment is projected to witness significant growth. This increase is attributed to the rising demand for para-aramid fibers across various applications, driven by their rigid molecular structure, which enhances their performance in demanding environments. As industries continue to recognize the value of aramid fibers in enhancing safety and performance, the market is well-positioned for robust growth in the coming years.

Order a free sample PDF of the Aramid Fiber Market Intelligence Study, published by Grand View Research.

#Aramid Fiber Market#Aramid Fiber Market Analysis#Aramid Fiber Market Report#Aramid Fiber Industry#Aramid Fiber Market Dynamics

0 notes

Text

The Evolution and Growth of TPU Film in India: A Comprehensive Analysis

Introduction: Understanding the TPU Film Revolution

The Indian manufacturing sector has witnessed remarkable growth in recent years, with specialized materials like Thermoplastic Polyurethane (TPU) film emerging as a crucial component across various industries. As TPU film manufacturers in India continue to expand their operations, the country is positioning itself as a significant player in the global TPU market. This comprehensive analysis explores the current landscape, challenges, and opportunities within India's TPU film manufacturing sector.

The Rise of TPU Film Manufacturing in India

India's journey in TPU film production began modestly but has grown exponentially over the past decade. With increasing domestic demand and export opportunities, numerous manufacturers have established state-of-the-art facilities across industrial hubs in Gujarat, Maharashtra, and Tamil Nadu. These manufacturers have invested heavily in research and development, leading to innovative products that meet international standards while maintaining cost-effectiveness.

Understanding Thermoplastic in India

The best Thermoplastic polyurethane in India has evolved from being primarily import-dependent to having a robust domestic manufacturing base. The versatility of TPU as a material has driven its adoption across multiple sectors, from automotive to electronics. Indian manufacturers have mastered the art of producing different grades of TPU, catering to varied industrial requirements while maintaining high-quality standards.

Applications and Market Segments

Industrial Applications

The industrial sector remains the largest consumer of TPU films, utilizing them for:

Machine part protection

Conveyor belt systems

Industrial packaging

Anti-corrosion coatings

Consumer Electronics

The booming electronics industry has created substantial demand for TPU protective film, particularly in:

Smartphone screen protectors

Laptop covers

Tablet accessories

Wearable device protection

Automotive Sector

Modern vehicles incorporate TPU films in various applications:

Paint protection films

Interior surface protection

Undercarriage protection

Dashboard and console protection

Manufacturing Excellence and Technology

Advanced Production Techniques

Indian manufacturers have adopted cutting-edge technologies, including:

Precision extrusion systems

Advanced quality control mechanisms

Automated production lines

Clean room facilities for specialized products

Quality Control and Standards

The industry maintains strict quality parameters through:

ISO certifications

International testing standards

Regular quality audits

Advanced testing laboratories

Market Dynamics and Growth Factors

Economic Drivers

Several factors contribute to the sector's growth:

Increasing industrial automation

Growing electronics manufacturing

Rising automotive production

Export opportunities

Regulatory Environment

The government has supported the industry through:

Make in India initiatives

Industrial corridors development

Export promotion schemes

Quality standard implementation

Innovation and Research Development

Product Development

Indian TPU film manufacturers focus on:

Custom formulations

Enhanced durability

Improved clarity

Environmental sustainability

Sustainable Manufacturing

Sustainability initiatives include:

Reduced energy consumption

Waste reduction programs

Recycling initiatives

Eco-friendly formulations

Supply Chain and Distribution

Raw Material Sourcing

Manufacturers have developed robust supply chains through:

Local supplier development

International partnerships

Quality raw material sourcing

Strategic inventory management

Distribution Networks

Efficient distribution is achieved via:

Pan-India presence

Strategic warehousing

Just-in-time delivery

Digital tracking systems

Future Prospects and Challenges

Growth Opportunities

The sector shows promising growth potential in:

Electric vehicle components

Smart device protection

Medical device protection

Sustainable packaging

Industry Challenges

Manufacturers must address:

Raw material price fluctuations

Technology upgradation costs

International competition

Quality consistency

Environmental Considerations

Sustainable Practices

The industry is adopting:

Energy-efficient production

Water conservation

Waste reduction

Green technology integration

Regulatory Compliance

Manufacturers ensure:

Environmental clearances

Pollution control measures

Waste management systems

Safety protocols

Investment and Financial Aspects

Capital Requirements

The industry requires investments in:

Modern machinery

Research facilities

Quality control systems

Skilled workforce development

Return on Investment

Investors can expect:

Growing market share

Export opportunities

Technology valorization

Sustainable growth

Human Resource Development

Skill Development

Companies focus on:

Technical training programs

Quality control expertise

Research capabilities

Management skills

Employment Generation

The sector contributes through:

Direct employment

Indirect job creation

Skill enhancement

Career development

Market Competition and Positioning

Competitive Advantage

Indian manufacturers leverage:

Cost-effective production

Quality standards

Technical expertise

Customer service

Market Differentiation

Companies focus on:

Product specialization

Custom solutions

Value-added services

Technical support

Customer Service and Support

Technical Assistance

Manufacturers provide:

Application guidance

Problem-solving support

Product selection assistance

Installation support

After-Sales Service

Services include:

Product warranties

Technical support

Replacement policies

Customer feedback systems

Industry Collaborations and Partnerships

Research Institutions

Partnerships exist with:

Technical institutes

Research laboratories

Testing facilities

Innovation centers

International Collaborations

Companies maintain:

Technology transfers

Joint ventures

Export partnerships

Knowledge exchange

Quality Assurance and Testing

Testing Protocols

Manufacturers implement:

Material testing

Performance testing

Durability testing

Environmental testing

Certification Standards

The industry maintains:

ISO certifications

Industry standards

Environmental compliance

Safety certifications

Market Expansion Strategies

Domestic Growth

Companies focus on:

Regional expansion

Market penetration

Product diversification

Customer base expansion

Export Markets

Opportunities exist in:

Southeast Asia

Middle East

Africa

South America

Conclusion

The TPU film manufacturing sector in India represents a dynamic and growing industry with significant potential for further expansion. As manufacturers continue to invest in technology, quality, and sustainability, the sector is well-positioned to meet both domestic and international demand. The industry's commitment to innovation, quality, and customer service ensures its continued growth and success in the global market.

Frequently Asked Questions (FAQs)

What makes TPU film different from other protective films?

TPU film offers superior elasticity, durability, and scratch resistance compared to other materials. It has excellent optical clarity, self-healing properties for minor scratches, and maintains its protective properties even under extreme conditions. Unlike other films, TPU can be easily applied without bubbles and doesn't yellow over time.

How long does TPU protective film typically last?

The lifespan of TPU film varies depending on usage conditions and quality, but high-quality TPU protective films can last between 3-5 years under normal conditions. Industrial-grade TPU films used in heavy-duty applications may have even longer lifespans when properly maintained and installed.

Is TPU film environmentally friendly?

Modern TPU films are increasingly being manufactured with environmental considerations in mind. Many TPU film manufacturers in India now produce recyclable variants and use eco-friendly production processes. While traditional TPU is not biodegradable, newer formulations are being developed with enhanced environmental properties.

What thickness of TPU film is ideal for electronic device protection?

For electronic devices, TPU film thickness typically ranges from 0.1mm to 0.3mm. The ideal thickness depends on the specific application: screen protectors usually use 0.1-0.15mm film for better touch sensitivity, while back covers might use 0.2-0.3mm for enhanced protection. Custom thicknesses are available for specific requirements.

0 notes

Text

Screw Conveyors Manufacturers

Screw Conveyors Manufacturers in India

In the modern industrial landscape, efficient material handling systems are essential for optimizing productivity and ensuring smooth operations. Among the various solutions available, Screw Conveyors Manufacturers in India have emerged as a preferred choice for transporting bulk materials across a range of industries. In India, the manufacturing sector has seen a significant rise in the demand for screw conveyors, driven by rapid industrial growth, technological advancements, and increasing awareness of efficient handling processes. This blog explores the importance of screw conveyors, their working mechanisms, the landscape of manufacturers in India, challenges faced by the industry, and the future of this essential equipment.

Understanding Screw Conveyors

Screw conveyors are mechanical devices used to transport bulk materials in a horizontal, inclined, or vertical orientation. They consist of a rotating helical screw, often enclosed in a tube, that moves materials along the conveyor's length. This design allows for efficient handling of various materials, including grains, powders, pellets, and even viscous substances.

Key Features of Screw Conveyors

Versatility: This versatility makes them suitable for various industries, including agriculture, food processing, construction, and mining.

Space Efficiency: Their compact design allows screw conveyors to fit into tight spaces, making them ideal for facilities with limited floor area. This space-saving feature enables industries to maximize their operational efficiency.

Durability: Built from robust materials, screw conveyors are designed to withstand harsh working conditions, including high temperatures and abrasive materials. This durability ensures long operational life and reliability.

Low Maintenance: With fewer moving parts compared to other conveyor systems, screw conveyors typically require less maintenance. This reduces operational costs and minimizes downtime, making them a cost-effective solution.

Customizable Designs: Manufacturers often offer customizable solutions tailored to specific needs, allowing industries to select the right size, material, and configuration for their applications.

The Manufacturing Landscape in India

India's screw conveyor manufacturing sector is expanding rapidly, driven by several key factors:

1. Industrial Growth

The country’s rapid industrialization has led to an increased demand for efficient material handling systems. As industries expand and diversify, the need for reliable transportation solutions like screw conveyors has surged.

2. Technological Advancements

Indian manufacturers are increasingly adopting modern technologies in their production processes. Innovations in materials, design, and automation are enhancing the efficiency and effectiveness of screw conveyors, making them more appealing to a broader range of industries.

3. Growing Export Potential

As global demand for material handling equipment rises, Indian manufacturers are exploring export opportunities. Establishing a presence in international markets can provide significant growth potential and bolster the domestic manufacturing sector.

4. Skilled Workforce

This talent pool is essential for producing high-quality screw conveyors that meet international standards.

Challenges Faced by Manufacturers

Despite the positive outlook for screw conveyor manufacturers in India, several challenges can hinder their growth:

1. Intense Competition

The market for screw conveyors is becoming increasingly competitive, with numerous manufacturers vying for market share. Companies must differentiate themselves through innovation, quality, and exceptional customer service.

2. Quality Assurance

Maintaining consistent quality in manufacturing is critical for the performance and reliability of screw conveyors. Variability in production processes or raw materials can lead to performance issues, necessitating stringent quality control measures.

3. Economic Fluctuations

Fluctuations in the economy can impact investment in new equipment. Manufacturers must remain adaptable to changing market conditions and be prepared to adjust their strategies accordingly.

4. Regulatory Compliance

Manufacturers must stay updated on changing regulations and ensure their products comply, which can require significant resources and expertise.

The Future of Screw Conveyor Manufacturing in India

The future for screw conveyor manufacturers in India looks promising, characterized by several emerging trends:

1. Sustainability Initiatives

As industries increasingly prioritize sustainability, there is a growing demand for eco-friendly designs and materials. Manufacturers focusing on developing environmentally responsible solutions will likely gain a competitive advantage.

2. Smart Technology Integration

The integration of smart technologies, such as IoT and AI, is set to revolutionize the material handling industry. Smart screw conveyors equipped with sensors can monitor performance in real-time, optimize operations, and reduce maintenance needs.

3. Customization and Flexibility

With diverse industrial needs, there is a rising demand for customizable screw conveyor solutions. Manufacturers who can offer tailored designs that cater to specific operational requirements will be better positioned to meet customer demands.

4. Global Expansion

As global demand for efficient material handling solutions grows, manufacturers in India may find opportunities to expand into international markets. Establishing partnerships and collaborations can help penetrate new regions and enhance market reach.

Conclusion

Screw conveyors are essential components of efficient material handling systems, playing a vital role in various industries. The manufacturing landscape for screw conveyors in India is evolving rapidly, driven by industrial growth, technological advancements, and a skilled workforce. While challenges exist, the future for manufacturers in this sector is bright, characterized by trends toward sustainability, smart technology integration, and customization. By focusing on innovation, quality, and customer service, manufacturers in India can make significant contributions to improving operational efficiency across diverse industries. As the demand for reliable material handling solutions continues to rise, screw conveyors will undoubtedly play a pivotal role in shaping a more efficient and sustainable industrial landscape in India.