#Geared Pinion Shafts

Explore tagged Tumblr posts

Text

Geared Pinion Shafts

TDMC India is a top provider of Geared Pinion Shafts, engineered for superior performance and precision. Our shafts are designed to optimize gear interactions and enhance operational efficiency in various machinery. With a commitment to quality and durability, TDMC India ensures that each pinion shaft meets the highest standards for reliable and smooth operation.

0 notes

Text

04/07/2024: Flap Differential

Annoyingly one day Amy came home… and I’d noticed the rear near side mud flap was missing, wtf!? This was a long time ago and it was in fact it a new mud flap that appeared to be stolen! Now I’m not one to throw accusations around but it seemed odd to me and they (bolts) were loctited in.

So cut a long boring story short, I had a spare used flap in the box of spares, ordered stainless steel brackets and fasteners. The brackets went for powder coating and eventually (today) I fitted it all.

Top tip: Scour pad and some washing up liquid with warm water is the recipe for getting the weathered mud flap back into something presentable, plus with the addition of a plastic enhancer - not bad aye!?, just a shame it makes the rear cross member look like turd.

Now onto the D110, a leak on a truck is like it shedding a tear of disrepair… I mean if I was leaking fluid I’d likely be pretty upset as well. So, we focus our or my attention to the rear differential input seal, which has had a moist casing for a while.

How to….

1. Mark the propshaft position on the drive flange for correct refitting.

2. Remove the propshaft bolts using a spanner/socket, then secure the propshaft out of the way.

3. Use a socket and breaker bar to remove the pinion nut.

4. Slide off the drive flange �� a light tap with a rubber mallet may help.

5. Remove the Old Differential Seal, by carefully prying out the old seal using a seal puller or flathead screwdriver.

6. Clean the seal mating surface to remove any debris or old sealant, inspect and grease bearing if necessary.

7. Install the New OEM Differential Seal, by lightly coating the outer edge of the new seal with gear oil for ease of installation.

8. Carefully press or tap it into place using a rubber mallet or a seal driver, ensuring it sits flush and even.

9. Reinstall the drive flange onto the pinion shaft.

10. Apply thread-locking compound to the pinion nut threads and tighten it securely (refer to manufacturer torque specs).

11. Reattach the propshaft, aligning it with the marks made earlier.

12. Check the seal area for any gaps or damage.

13. Refill the differential with fresh oil if it was drained.

14. Test drive and inspect for leaks.

Final Notes:

- Using a genuine OEM seal ensures longevity and a proper fit.

- If you don’t have the correct torque values, tighten the pinion nut securely but avoid overtightening.

- Regularly inspect for leaks after installation.

Parts for Rear Mudgaurds

RH Mudflap Bracket 90: MUC3986

LH Mudflap Bracket 90: MUC3987

Mudflap Support Plate 90 (both sides): MUC1512

Parts for rear differential input seal

Flange Kit: NSTSTC3124G

Rear Propshaft Bolt Kit: DA1424

#landrover#defender#landroverdefender#overlander#4x4#defendertd5#defender90#jlr#d90#britpart#defender110#overland#landroverphotoalbum#paddockspares#d110

6 notes

·

View notes

Text

1971 AMC Javelin capable track car & turns heads as stunning show car

In The Unfair Advantage, Mark Donohue wrote, “I thought the 1971 Javelins were about the most attractive Trans Am sedans on the street.” He also said the Penske Javelins were half race car and half show car. This car was built with that same approach in mind. It is a seriously capable track car on the track and turns heads as a most stunning show car. This car is as close a replica as reasonably possible of the car that won the Trans Am Series Championship in 1971. There are many ���tribute” TA Javelins, but none built to this level of replication. The original car was built by Penske Racing and Mark Donohue. I am selling the car due to failing eyesight and wishing it to pass hands to a new owner that can appreciate and use the car for what it is, a faithful replica of a Trans Am Champion.

The car was built to replicate not only the look but also the mechanicals and structure of the original car using period technology and parts. It is not street legal in current form. The car is stunning to look at and the sound of the exhaust is true Trans Am music. Below are some of the specifications and details about the car. Driven as a “Track Day” car, never raced competitively.

Engine

Barry Allen Racing built 360 cid (destroked to 304 cid) AMC "service block" engine

AMC 291-C iron heads ported by Barry Allen Racing

T&D shaft rocker system Custom Diamond forgedpistons 12.5:1 compression ratio

K1 Connecting rods

Proprietary cam grind specified by Barry Allen Racing

Solid roller Edelbrock Torker intake "air-gapped" by Barry Allen Racing

850 CFM Holley double pumper

Aviaid 4 stage dry sump system, Peterson dry dump tank

Dyno 587 HP @ 7600 RPM

NOS tach drive Mallory distributor converted to electronic MDS electronic ignitionbox

Engine oil cooler

Custom exhaust system closely replicating Penske design, tunneled into modified floor structure

Drivetrain

McLeod metallic race clutch McLeod aluminumflywheel Lakewood SFI bell housing

Richmond Super T10 Plus transmission, upgraded by Roltek Race Transmissions Hurst Competition Plus shifter

Custom driveshaft

AMC 20 full floater rear axle conversion Moser floater axles

4.10: 1 ring and pinion gear set.

Body The donor car was a rust free Nevada 71 Javelin. It has the livery of the original TA Javelin, including the Penske designed A pillar air collectors that direct outside air to the driver. Rear wheel wells are re-shaped unique to the 71 TA Javelin and to accommodate the larger Goodyear Blue Streak tires. The pans are "tunneled" to accommodate the recessed exhaust system into the floor. Full cage to meet period SCCA rules.

Brakes

Brake system closely replicates the Penske design Period Hurst-Airheart 4piston calipers,

Wilwood 11" X 1.25" rotors, front and rear. Front Wilwood hubs

Tilton pedals/ bias bar

Girling dual master cylinders,

Girling in-line booster actuating front brakes, rear manual, Front brakes arecooled via 3" duct from headlight buckets

Suspension

Hyperco 900# front springs

"Pro" rear shocks

Dual adjustable Vari-Shock front shocks OpenTracker “Double Roller”Mustang front spring perches spherical bearings Boxed control arms, spherical bearings, upper and lower Modified lower control arms to allow track camber w/ screw-in ball joints Relocated torsion bar type front anti -sway bar Rear torsion anti-sway bar configuration replicating Penske design Lee 9:1 ratio full bearing race steering box ididit steering column SuperLite 15 X 8 “Minilite” wheels Goodyear Blue Streak Specials 6:00-15 front tires Goodyear Blue Streak Specials 7:00-15 rear tires Fuel system/Safety Pyrotec 18 gallon fuel cell Dual Carter fuel pumps, all fuel lines AN braided Fire suppression system Current G-Force 5 point harness Spares include Hurst-Airheart caliper cores In-line brake booster Front fenders Cowl induction hood Upper/lower control arms Front coil springs Taillight lenses

For Sale on Hemmings

2 notes

·

View notes

Text

Exciting News for Noida & Greater Noida Industries! 🔥 VIRAT SPECIAL STEELS PVT. LIMITED , INDIA is thrilled to announce that we are now supplying SPECIAL STEELS directly to Noida and Greater Noida! 🌟

🏭 Whether you're a large car manufacturer, an engineering unit, or even a micro-industry, our high-quality special steels are crucial for your production needs. From heavy vehicle components to precision engineering, our steels are designed to meet your toughest requirements.

🔧As one of India's top suppliers of Tool Steel, Die Steel, and Mould Steel, we also offer a comprehensive range of special steel grades to cater to your specific needs.

Product List:

DIE STEEL ( HH 370 - 410 BHN ) (DIN-1.2714 / AISI L6 )

HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

ALLOY STEELS, EN-SERIES ETC.

🚗🔩 Our product range is perfect for:

Heavy vehicle, tractors, and automobile transmission parts

General engineering applications

Ball and roller bearings, gears of all types

Camshafts, universal joints, driving pinions

Link components, axles, arbours

Gear shafts and spinning tools

📍 Located near Noida in Gurgaon, our headquarters are at the heart of India's industrial hub, ensuring quick and reliable service.

🤝 Let Virat Special Steels be your trusted partner in driving industrial growth in the Noida and Greater Noida region.

For more information visit: https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-noida/

Contact us today to discuss your special steel needs and how we can help propel your projects forward!

📞+91-98140 21775 🌐www.viratsteels.com 📩 [email protected]

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#noida#GreaterNoida#SpecialSteels#ColdWorkSteels#HighSpeedSteels#SteelTrades

2 notes

·

View notes

Text

Super Lubricating Abilities for The Steel Industry

Lubrication is a crucial element required for any moving machine and its parts. Without lubricants, the life-expectancy and efficient functioning of any rotating equipment is greatly reduced. Productivity is delayed due to premature bearing failures, increased use of energy, and machine downtime. This leads to further losses of production which calls for new and improved lubrication solutions.

When lubricants are used in machines, their main functions are to:

Transport contaminated particles to filters and maintain cleanliness

Create a film between metal surfaces to reduce friction

Protect metal parts from corrosion

Cool surfaces by dissipating heat

The steel manufacturing industry involves processes that are exposed to high temperatures, extreme loads, and corrosive and humid environments. These factors influence the way lubricants work on machines, creating more demand for super lubricating abilities.

Molygraph’s speciality lubricants have, therefore, been developed to offer several benefits to clients. Our diverse and complete range of lubricant solutions helps in managing critical steel manufacturing processes. The cost of maintenance is reduced as productivity is improved through quality lubrication. Our products are environment-friendly, making them a safe and protective fit for operators.

Molygraph’s Customised Range of Speciality Lubricants

We have developed three versatile lubrication applications for the steel industry, namely:

Integrated Steel Plant

Steel Pelletizing Plant

Sponge Iron Plant

1. Integrated Steel Plant

Our lubrication products cover a wide range of areas at integrated steel plants. We aim to help reduce costs by enhancing productivity regardless of any extreme environmental conditions. From ironmaking to finished products, lubrication solutions are, thus, developed to meet all requirements at Integrated Steel Plants.

The application components shown below are based on the areas our products can be used.

Raw Material Preparations: Storage

Raw Material Processing: Coke Oven Plant, Lime Plant, Sinter Plant

Pig Iron Production: Blast Furnace

Caster: Continuous Caster

Hot Rolling Mill: Work/Back-Up Roll Bearings, Chokes Window Liner, Rolling Mill Drive Shaft Gear Couplings, and Re-Heating Furnace Table Roll Bearing

Cold Rolling Mill: Work/Back-Up Roll Bearings, Roll Chokes Liner, Rolling Mill Drive Shaft, Gear Couplings, Pickling Line, Squeezer Roll Bearing, Water Rinse Tank Bearing, Wringer Roll Bearing, Arb Blower Fan Bearing

Bar and Rod Mill: Reheating Furnace Withdrawal/Roll Table Bearing, Work/Back-Up Roll Bearing, Roll Chokes Liner, and Rolling Mill Drive Shaft Gear Couplings

2. Steel Pelletizing Plant

The process of pelletizing iron involves converting iron ore fines into uniformly sized iron pellets. These pellets are then charged directly into the blast furnace. Our lubricating range of products is designed to meet the challenging and demanding processes involved in the Steel Pelletizing Plant.

The application components involved in the following processes are:

Grinding Mill: Ball Mill Girth Gear, Ball Mill Girth Gear Pinion Bearing

Mixture Machine: Mixture Machine Bearing, Mixture Machine Gear

Balling Disc: Balling Disc Girth Gear, Balling Disc Bearing

Travelling Guide: TG Plumber Block Bearing

Kiln: Kiln Girth Gear – Spray System, Support Roller Bearing/Kiln, Thrust Bearing/Bucket, Elevator Bearing, Sliding Surface of Track

3. Sponge Iron Plant

Sponge iron is produced from the direct reduction of iron ore, and it can be further processed into wrought iron. It is useful as feedstock for speciality steel manufacturers. The lubricants in this process are required to be thermally and mechanically stable. It should also be able to resist water washouts.

Our range of lubricants covers the entire spectrum of applications including Kiln & Cooler Slip Seal, Kiln & Cooler Girth Gear, Support Roller Bearing, Vibrator Screen Bearing, Id/Fd Fan Bearing, and so much more. You can know more about the Sponge Iron Plant on our website.

Are you prepared to take your steel manufacturing processes to the next level? We have a Field Engineering Services Team ready to support, guide you and provide end-to-end lubrication education. Get the best deals in lubrication for steel with Molygraph.

#polyurea grease manufacturers#grease oil manufacturers#steel lubricants#steel industry lubricants#grease for stainless steel

0 notes

Text

EN19 Alloy Steel Supplier in Karnataka

EN19 Steel is a high-quality alloy steel containing chromium and molybdenum, known for its high fatigue strength, toughness, abrasion resistance, and impact resistance. It falls under low alloy steel and can be heat-treated to achieve a range of properties. EN19 steel is often used in demanding mechanical engineering applications, particularly in the automotive, oil, and gas industries. EN19 corresponds to the 709M40 grade in the updated BS 970-1996 standard and is valued for its versatility and strength.

EN19 Grade Application:

EN19 is widely used in mechanical and engineering applications requiring high tensile strength and durability. Its typical uses include:

Gears, pinions, shafts, and spindles

High-stress fasteners like bolts and studs

Components in the oil, gas, and automotive industries

EN19 Equivalent Grades:

BS: 709M40

DIN: 42CrMo2

IS: 40Cr4Mo3

EN: EN19

SAE/AISI: 4140

Other Supplied Grades:

MS, EN1A, EN3B, EN8, EN8D, EN9, EN24, EN31, EN32B, EN36C, EN41B, IS2062, 42CrMo4, HCHCR, D2, D3, H11, H13, CW1, OHNS, M2, M35, M42, DIN-1.2714, P20, SAE1018, SAE4140, 16MnCr5, C45, S40C, S355J2G3, etc.

#e19alloysteel#alloysteel#EN19 Alloy Steel Supplier in Karnataka#e19alloysteels#e19alloysteelinkarnatka

0 notes

Text

Alloy Steel Sheets & Plates Exporters

Alloy Steel Plates Supplier is defined as having 1.5% to 5% total alloy content. Its common alloying elements are manganese, silicon, chromium, nickel, molybdenum, and vanadium, which contain as many as four or five of these alloys in varying amounts. which is been used by the manufacturers who works with petrochemical industries, oil and gas industries, chemical industries, shipbuilding etc. Alloy steel wear plates is a smooth, chromium carbide rich overlay plate manufacturers and Supplier by a patented production process maximizing abrasion resistance and reducing hang up.

Alloy Steel Sheet is been designed from alloys such as chromium, molybdenum, nickel, manganese, silicon so on, they are industrial product that is generally used in various industries applications. 4130 alloy steel sheet is low-alloy steels containing chromium and molybdenum as strengthening agents. It provides good strength and toughness, weldability and machinability. Alloy steel 4340 sheet is a heat treatable low alloy steels which contains nickel, chromium, molybdenum, they are commonly used for heavy duty industrial, aerospace and automotive applications.

It has high strength and toughness in heat treated condition. 6150 alloy steel sheet is useful in heavily stressed machinery parts including gears, shafts, hand tool components and pinions. It is a fine grained, highly abrasion resistant carbon-chromium alloy steel. Alloy Steel Plates Grades are ASTM A387 Gr 5, ASTM A387 Gr 9, ASTM A387 Gr 11, ASTM A387 Gr 12, ASTM A387 Gr 22 and ASTM A387 Gr 91.

Specification Schedule of Alloy Steel Sheets & Plates

SpecificationsASTM A387 / ASME SA387Thickness1mm-300mmWidth 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, 4050mm etcLength2000mm, 2440mm, 3000mm, 5800mm, 6000mm, 12000mm, 15000mm etcSurface2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching Manufacturer and SupplierFinishHot rolled plate (HR), Cold rolled sheet (CR)FormCoils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip Manufacturer and Supplier

Chemical Properties of Alloy Steel Sheets & Plates

GradesCMnPSSICrMoASTM A387 Grade 50.15 max0.3 – 0.60.0350.030.5 max4.00 – 6.000.45 – 0.65ASTM A387 Grade 90.15 max0.30 – 0.60.030.031.0 max8.0 – 10.00.9 – 1.1ASTM A387 Grade 110.05 – 0.170.4 – 0.650.0350.0350.5 – 0.801.0 – 1.50.45 – 0.65ASTM A387 Grade 120.05 – 0.170.4 – 0.650.0350.0350.15 – 0.40.8 – 1.150.45 – 0.6ASTM A387 Grade 220.05 – 0.150.3 – 0.60.0350.0350.5 max2.0 – 2.50.9 – 1.1

Mechanical Properties of Alloy Steel Sheets & Plates

Tensile StrengthYield StrengthElongationin 200mm (%)Elongation in 50mm (%)70-90 ksi, 485-620 MPa45 Ksi, 310 MPa1822

Equivalent Standard of Alloy Steel Sheets & Plates

Material GroupCommon NameTypeUNSForging Spec.Casting Spec. EquivalentDINDIN W. NoApplicationLow ASMoly SteelC-1/2MoK12822A182-F1 cl2A217-WC115M031.5415Up to 470ºC* (875ºF)AS Chrome Moly1.1/4Cr-1/2MoK11572A182-F11 cl2A217-WC613CRM0441.7335Up to 593ºC (1100ºF)2.1/4Cr-1MoK21590A182-F22 cl3A217-WC910CRM09101.7380Up to 593ºC (1100ºF), HP steam5Cr-1/2MoK41545A182-F5/F5aA217-C512CRMO1951.7362High temp refinery service9Cr-1MoK90941A182-F9A217-C12X 12 CrMo 9 11.7386High temp erosive refinery service9Cr-1Mo-VA182-F91A217-C12AX 10 CrMoVNb 9 11.4903High pressure steam

0 notes

Text

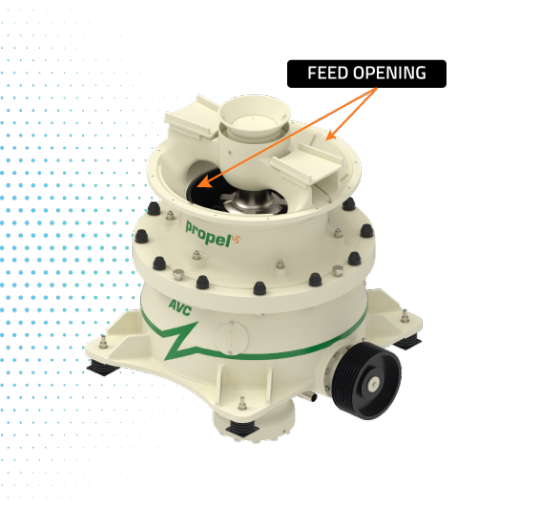

In depth – Avc Cone Crusher

Inside-Out | April 29, 2022

In the last issue, the In-Depth column focused on Jaw Crusher. This time, the spotlight turns on to our Cone Crusher. Some of the factors that R&D department considered before getting to make the Cone Crusher

The product must meet the customer’s unique requirement.

Cutting – edge technology must be put to work.

The product must cater to the 100 TPH to 350 TPH segment and serve the crushing industry.

The product must be in a position to evolve.

CONE CRUSHER MODEL

AVC 125 / AVC 160 / AVC 220 / AVC 250 / AVC 350

SM 100 / SM 150 / SM 200 / SM 250

Cone crushers are used in the mineral, mining, and aggregate industry for fragmentation and production of rock materials. Cone crushers are the most commonly used crusher type for the secondary and tertiary crushing stages. AVC Cone Crushers can be easily adjusted to different types of production requirements with change of chambers, eccentric strokes, and counter shaft speeds.

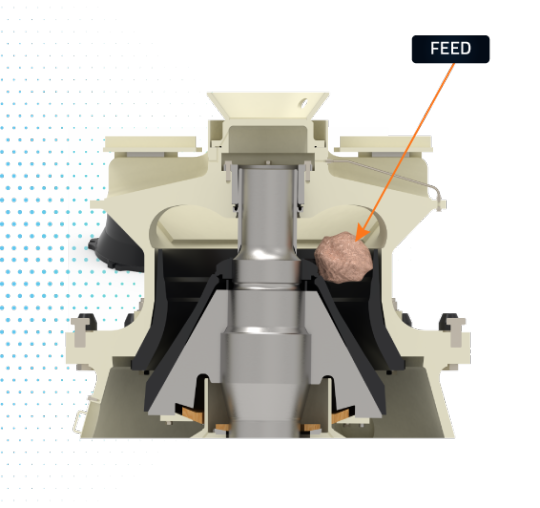

CONE CRUSHER WORKING PRINCIPLE

Both cone and gyratory crushers have an oscillating shaft.

The material is crushed in a crushing cavity, between an external static element (Concave) and an inner moving element (Mantle) mounted on the oscillating shaft assembly.

An eccentric shaft rotated by a gear and pinion produces the oscillating movement of the main shaft.

The eccentricity causes the cone head to oscillate between o.s.s. (open side setting) and c.s.s. (closed side setting) discharge opening.

In addition to c.s.s., eccentricity is one of the major factors that determine the capacity of cone crushers.

The Cone crushers are equipped with a hydraulic setting adjustment system, which adjusts c.s.s. and thus affects product gradation.

CRUSHER TERMINOLOGY

Feed: The raw material that is to be crushed.

Capacity: The output of the crusher computed in tons per hour (mtph/stph).

Product Size: The size of the screened material.

Feed Opening: The largest distance between the top of the crushing members as measured when the two crushing members are at their farthest relationship during one revolution of the eccentric. As a general rule the maximum size of feed should be 60 to 80% of the open side feed opening depending of the crusher type and the raw material to be crushed.

Discharge setting (S): The distance between the bottoms of the crushing members as measured at the point where the two crushing members are at their closest relationship during their gyrating circle (CSS-Closed Side Setting). The discharge setting regulates product sizes.

Minimum discharge setting: The smallest permissible distance between the bottom of concave and mantle as measured at the point where the two crushing members are at their closest relationship during their gyrating circle.

Stroke: The difference between open side setting (OSS) and closed side setting (CSS).

Open circuit operation: The type of operation where precise uniformity of product size is not considered to be of prime importance and the feed is run through the crusher only once.

Closed circuit operation: The type of operation where precise uniformly of the product size is important and the product is screened as it is being discharged and the material which does not pass through screen is returned to the crusher.

SAFETY

Safety of our operators, service engineers and customers has always been our top priority and to ensure that, Propel Cone Crusher comes with

Limited numbers of service points.

Special lifting tools are given to ease maintenance.

Cone crushers designed by Propel Industries have the following features for better maintenance

Closed Side Setting (CSS)

V Belt change

Lubrication

Liners change

We have given set of recommended maintenance procedures in Operation & Maintenance Manual which is absolutely safe to practice.

SALIENT FEATURES

Sturdy construction – strong in all directions and ensures excellent durability against shock-loads.

Setting adjustment made with wedge & traditional shim plates.

Quick and easy installation of Concave & Mantle to the crusher.

Designed with sacrificial parts to protect the main components of the crusher such as top shell, bottom shell and head. This reduces total lifecycle costs and increases uptime, as it is less expensive to change the sacrificial parts than the main components.

Ensured top shell, bottom shell, head and main shaft strength by Finite Element Analysis

IE2 Electric drive motor enabling energy saving

WHY CUSTOMERS OPT FOR OUR CONE CRUSHERS?

Robust construction design for durability

Dynamic setting adjustment

Stable capacity throughout liner life

Same machine can be used as secondary, tertiary machine with a liner change

Easy maintenance

0 notes

Text

AR18 LN 2.0kW Starter Motor Kit

The Ark Racing® AR18 LN 2.0 kW long-nose starter motor kit has been a popular addition to many Formula One cars and sports racers.

The kit includes the motor, mounting plate, front tube, and pinion. It is complete with a fixing kit and is available now in many different guises.

We can supply fitting kits for Hewland FG, DG, and TL.

Whether using the original mounting points or rear case mounting, we can provide a solution.

Suitable for: Hewland® FG, DG, and TL

Specification: Material: Steel Casing / Aluminium Adapter Plate STD AR Shaft: Carbon Steel Pinion Gear: 9T Kilowatts: 2.0 kW Voltage: 12 Volts (D.O.R.) Direction of Rotation: ACW

If you can’t find what you’re looking for, contact us.

Ark Racing can create a solution to meet your requirements.

Call us on +44 (0)345 557 7408 or complete our online contact form.

“Ask about our Rebuild/Servicing Package”

0 notes

Text

How Ring Gear Assemblies Work?

Ring gear assemblies are a critical component in various mechanical systems, particularly in automotive and industrial applications. They play a pivotal role in the functioning of differentials, ensuring the smooth transmission of power and the efficient operation of machinery. This blog delves into the intricacies of ring gear assemblies, exploring their design, function, and significance.

Understanding the Basics To grasp how ring gear assemblies work, it's essential to start with the basics. A ring gear assembly typically consists of a large ring-shaped gear that meshes with a pinion gear. This interaction is crucial for transferring power from the drive shaft to the wheels or other moving parts of a machine.

Components of a Ring Gear Assembly: Ring Gear: A large gear with teeth on its inner or outer edge, depending on the application. Pinion Gear: A smaller gear that engages with the ring gear, driving its motion. Housing: Encloses the gears, providing structural support and protection. Bearings: Support the rotation of the gears, reducing friction and wear. Lubrication System: Ensures smooth operation and longevity by minimizing friction between moving parts.

The Working Principle The primary function of a ring gear assembly is to transfer rotational motion and torque from the drive shaft to the wheels or other components. This process involves several steps:

Power Input: The drive shaft, connected to the engine or motor, transmits power to the pinion gear. Engagement: The pinion gear meshes with the ring gear, converting the rotational motion of the drive shaft into the rotational motion of the ring gear. Torque Transfer: As the pinion gear rotates, it drives the ring gear, transferring torque to the connected components (e.g., wheels in a vehicle differential). Output Motion: The ring gear's rotation is transmitted to the output shafts, which then drive the wheels or other machinery parts.

Applications of Ring Gear Assemblies Ring gear assemblies are utilized in various applications, each requiring precise engineering and robust construction to ensure optimal performance. Some common applications include:

Automotive Differentials: In vehicles, ring gear assemblies are a key component of differentials, allowing wheels to rotate at different speeds while maintaining traction. This is crucial for smooth turns and stability on the road. Industrial Machinery: Heavy machinery and industrial equipment rely on ring gear assemblies for efficient power transmission, ensuring reliable operation under demanding conditions. Aerospace: In aerospace applications, ring gear assemblies contribute to the precise control and movement of various components, enhancing the overall performance and safety of aircraft. Marine: Marine vessels utilize ring gear assemblies in propulsion systems, enabling efficient power transfer from engines to propellers.

Key Factors in Design and Manufacturing The design and manufacturing of ring gear assemblies require meticulous attention to detail to ensure durability, efficiency, and reliability. Several key factors influence the performance of these assemblies:

Material Selection: The choice of materials is critical for withstanding the stresses and strains encountered during operation. High-quality steel and advanced alloys are commonly used for their strength and wear resistance. Precision Machining: Accurate machining of gear teeth is essential for smooth engagement and efficient power transfer. Advanced manufacturing techniques, such as CNC machining, ensure high precision. Heat Treatment: Heat treatment processes, such as carburizing and quenching, enhance the hardness and durability of gear teeth, extending the lifespan of the assembly. Quality Control: Rigorous quality control measures, including inspections and testing, ensure that each ring gear assembly meets stringent performance and safety standards.

Common Issues and Maintenance Despite their robust construction, ring gear assemblies can encounter issues over time due to wear and tear or improper maintenance. Some common problems include:

Wear and Tear: Continuous operation under high loads can lead to wear on gear teeth, affecting performance and efficiency. Misalignment: Improper alignment of gears can cause uneven wear, noise, and reduced lifespan. Lubrication Issues: Inadequate lubrication can result in increased friction and heat, leading to premature wear and potential failure. Bearing Failures: Worn or damaged bearings can affect the smooth rotation of gears, causing noise and vibration. To prevent these issues, regular maintenance is crucial. Key maintenance practices include:

Regular Inspections: Periodic inspections help identify signs of wear, misalignment, or damage, allowing for timely repairs. Proper Lubrication: Ensuring adequate and consistent lubrication minimizes friction and wear, enhancing the longevity of the assembly. Alignment Checks: Regular alignment checks ensure that gears mesh correctly, reducing the risk of uneven wear and noise. Bearing Maintenance: Monitoring and maintaining bearings is essential for smooth gear operation and reducing the risk of failure.

Advancements in Ring Gear Technology Technological advancements have significantly improved the performance and reliability of ring gear assemblies. Innovations in materials, manufacturing techniques, and design have led to more efficient and durable assemblies. Some notable advancements include:

Advanced Materials: The development of high-strength alloys and composite materials has enhanced the durability and performance of ring gear assemblies, allowing them to withstand higher loads and harsher conditions. Precision Manufacturing: Advances in machining and manufacturing technologies, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), have enabled the production of highly precise and efficient gear assemblies. Improved Lubrication Systems: Modern lubrication systems are more effective at reducing friction and wear, extending the lifespan of ring gear assemblies and enhancing their performance. Smart Monitoring: The integration of sensors and monitoring systems allows for real-time tracking of gear performance, enabling predictive maintenance and reducing the risk of unexpected failures.

Conclusion Understanding how ring gear assemblies work is crucial for appreciating their role in various mechanical systems. From automotive differentials to industrial machinery, these assemblies ensure efficient power transmission and reliable operation. Advances in technology continue to enhance their performance, making them more durable and efficient.

For those seeking high-quality ring gear assemblies, it's essential to partner with a trusted supplier. At Bright Industries, we specialize in providing top-notch ring gear assemblies tailored to your specific needs. Our commitment to quality and innovation ensures that you receive the best products for your applications. Contact Bright Industries today to learn more about our offerings and how we can help meet your gear assembly requirements.

0 notes

Text

SMD Gearbox: High-Performance Planetary Shaft-Style Output Gearbox

The SMD Gearbox Shaft-Style Output Gearbox is durable, lightweight, and fully enclosed for protection. It’s compatible with any motor, easy to install, and ideal for high-torque, low-inertia applications, with a long shaft design perfect for rack-and-pinion systems.

0 notes

Photo

Are you looking for Bright Round Bar #EN353 Steels or #AlloySteel?

Virat Special Steels is the biggest & leading Supplier & Stockiest of EN353 Steels.

EN 353 steel has carbon content material of 0.17 % & probably the most usual form of steel, because the carbon content material raises, the material becomes tougher & harder. It's observed that the hardness & wear resistance of the EN 353 steels elevated after the warmness therapy & the micro structure is exchange from ferrite to marten website.

This grade is in general used for a lot of automobiles functions comparable to heavy duty tools, shaft, pinion, cam shafts and gudgeon pins.

Steel Properties: En 353 steel has a carbon content of 0.17% and the commonest form of steel as it provides material properties that are acceptable for several automobile applications such as significant duty gear, shaft, pinion, camshafts and gudgeon pins. It’s neither outwardly brittle nor ductile due to its lower carbon content and lower hardness. Because the carbon content will increase, the metal becomes more durable and stronger.

Applications: Acceptable for many automobile applications such as heavy duty gear, shaft, pinion, camshafts, gudgeon pins. / Machining components.

The Leading Company Virat Special Steels Pvt. Ltd., is one of the largest Importer, Exporter and Stockist of Die Blocks (DIN 1.2714, #DB6, #H13, #H11), Tool Steels, Die Steels, Special Steels and Alloy Steels in various grades.

Learn more: https://www.viratsteels.com/en353.html For more information Contact us : [email protected]. +91- 9814021775

#viratspecialsteels#viratsteels#viratsteelsindia#EN353#EN353steel#EN353BrightBars#BrightBarStockist#2714steel#h13steel#din2714#din2738#db6steel#din2344#diesteel#mouldsteel#mouldsteelstockist#toolsteelsupplier#ludhiana#gurgaon#pune#india#forging

2 notes

·

View notes

Text

Top Features of Master Gear Manufacturing and Suppliers

In, master gears numerous industries are dependent on manufacturing. Gears are an essential piece of any machine. The force move that pinion wheels empower is unrivaled, making them indispensable parts in any machine. While the interest for the most recent hardware is on the ascent across numerous ventures, so is the requirement for master gears manufacturing. Various enterprises depend on gear makers to supply them with modified stuff and backbone that is applicable for their modern applications.

Precision and Accuracy

Master gears are made to exact tolerances, often as small as a few microns, so they can accurately replicate the gear geometry they are supposed to measure. This high accuracy is basic for keeping up with the trustworthiness of the staff assessment process.

The manufacturing profile of expert master gear is made with careful meticulousness, matching the plan particulars precisely. When used for testing, the master gear provides as an accurate standard against which to compare production gears.

Material Quality

Master gears are typically constructed from high-quality tool steel or similar materials that are renowned for their durability and wear resistance. This is fundamental as the cog wheels go through rehashed use in testing conditions.

Many expert gears go through surface solidifying processes, for example, carburizing or nit riding, to improve their wear obstruction and longevity. This makes sure that the gear doesn't lose its precision over time even when it's used a lot.

Advanced Machining Methods

To achieve the required precision and repeatability, master gears are manufactured using advanced manufacturing methods. CNC machines take into account the formation of complicated gear calculations with insignificant deviation from plan details.

In order to modify the mechanical property of the expert master gear, the producers apply different intensities of therapy. Gears are strength of the pinion wheels results from these wheels very powerful for experiments that identify for thorough testing performances.

Options for Customization

The master gear suppliers frequently provide options for customization to meet the particular requirements of their customers. This could include planning gears with extraordinary tooth profiles, custom distances across, or explicit materials to suit specific applications.

A few makers work intimately with clients to foster models of expert pinion wheels before full-scale creation. This guarantees that the eventual outcome meets every one of the practical necessities and fits consistently into the client's staff investigation process.

Adjustment and Investigation

Master gears are periodically regulated against reference standards to ensure that they are further processed with a high degree of accuracy. In order to continue to serve as the standard for gear testing it must be done with a level of exactness that meets these factors.

Master gears from a lot of manufacturers come with calibration certificates that show that the gear has been tested and meets specific industry standards like AGMA or ISO standards. This certification is essential for industries that must adhere to stringent regulatory standards.

Bottom Line

Gear manufacturing includes a wide exhibit of fundamental parts and processes that are principal to endless mechanical frameworks across different businesses. From transmitting movement and power between pivoting shafts to empowering speed guidelines, force enhancement, directional changes, and movement synchronization, gears assume a basic part in guaranteeing the productive activity of hardware and gear. Gears have a significant impact on productivity, precision, and dependability, which cannot be overstated in mechanical systems or manufacturing processes.

1 note

·

View note

Text

SBJ Nirmal Products: The Leading Supplier of Premium Rotavator Spare Parts

Agriculture is the foundation of food security and economic growth, making farm machinery an essential part of modern farming. Among these machines, rotavators play a vital role in preparing the soil for cultivation. The efficiency of a rotavator largely depends on the quality of its spare parts, and this is where SBJ Nirmal Products excels. As a leading rotavator parts manufacturer in Ludhiana, Punjab, SBJ Nirmal Products provides high-quality, durable, and affordable spare parts to farmers and agricultural dealers worldwide.

About SBJ Nirmal Products

SBJ Nirmal Products is a trusted manufacturer and exporter of rotavator spare parts, catering to the needs of farmers in India, Bangladesh, Nepal, Sri Lanka, and beyond. With a focus on innovation, precision engineering, and cost-effectiveness, the company ensures that farmers get the best components to improve their agricultural productivity.

Why SBJ Nirmal Products is the Preferred Choice?

Superior Quality: Manufactured using high-grade steel and advanced technology.

Wide Range: Offers rotavator blades, gears, shafts, crown pinions, and more.

Affordable Pricing: Competitive prices to support farmers’ budgets.

Strong Market Presence: Trusted by dealers and distributors across multiple countries.

Customization: Provides tailor-made solutions for specific farming needs.

Comprehensive Range of Rotavator Spare Parts

1. Rotavator Blades

Rotavator blades are crucial for tilling the soil efficiently. SBJ Nirmal Products offers blades in different shapes and materials to suit various soil conditions.

Features:

Heat-treated for durability

Available in L-type, C-type, and J-type

Compatible with all major rotavator brands

2. Crown Pinions

Crown pinions are essential for power transmission in rotavators, ensuring smooth operation and optimal efficiency.

Features:

Made from hardened alloy steel

Provides high torque transmission

Minimizes wear and tear

3. Stub Axles

Stub axles support the movement and stability of the rotavator, making them essential for smooth operation.

Features:

High-strength corrosion-resistant material

Capable of withstanding heavy loads

Long-lasting performance

4. Gearbox Assemblies

A well-built gearbox ensures the smooth functioning of a rotavator. SBJ Nirmal Products provides precision-engineered gearbox components.

Features:

Manufactured using high-quality steel

Ensures low friction and high efficiency

Prolongs the lifespan of the rotavator

5. Bearings and Oil Seals

Bearings and oil seals are critical for reducing friction and ensuring smooth movement within the rotavator.

Features:

High load capacity for smooth operations

Rust-resistant material

Reduces maintenance needs

Customer-Centric Approach

1. Tailor-Made Solutions

SBJ Nirmal Products understands the unique needs of farmers and provides customized rotavator spare parts to suit different soil and weather conditions.

2. 24/7 Customer Support

The company has a dedicated support team to assist customers in choosing the right spare parts.

3. Timely Delivery

With a strong distribution network, SBJ Nirmal Products ensures that products reach farmers and dealers on time, every time.

Competitive Pricing for Maximum Affordability

Best price guarantee without compromising quality.

Bulk purchase offers for agricultural dealers.

Cost-effective solutions for farmers worldwide.

Why Choose SBJ Nirmal Products?

✅ Decades of Experience – Trusted in the industry for manufacturing top-quality rotavator spare parts. ✅ Global Presence – Exporting to India, Bangladesh, Nepal, Sri Lanka, and beyond. ✅ Advanced Manufacturing Techniques – CNC technology for precision and durability. ✅ High Performance – Corrosion-resistant, long-lasting, and efficient components. ✅ Farmer-Friendly Pricing – Affordable solutions for maximizing productivity. ✅ Eco-Friendly Practices – Sustainable and environmentally responsible manufacturing.

SBJ Nirmal Products: The Future of Rotavator Spare Parts

SBJ Nirmal Products continues to invest in innovation and research to develop even more efficient and durable rotavator parts. The company is working on:

Smart technology integration for advanced rotavator components.

Eco-friendly materials to ensure sustainability.

Increased production capacity to serve global markets better.

Final Thoughts

For farmers and dealers looking for high-quality rotavator spare parts, SBJ Nirmal Products is the ultimate choice. With a focus on affordability, durability, and efficiency, the company continues to lead the market with its top-notch rotavator components.

If you need rotavator blades, gears, shafts, crown pinions, or any other spare parts, SBJ Nirmal Products is the name you can trust.

#sbj#farming#sbj nirmal#rotavator parts manufacturer#agriculture#high-quality rotavator parts#agricultural machinery parts#sbj nirmal products#rotavator#agricultural equipment

0 notes

Text

What Is a Planetary Gearbox and How Does It Work?

A planetary gearbox, also known as an epicyclic gearing system, is a complex gear mechanism made up of outer gears called planet gears or pinions that surround a sun gear or sun wheel in the center. This complicated setup is routinely used to achieve great torque in an extremely small design. The planetary gearbox, which consists of the sun gear, planet gears, and ring gears, displays the sun gear at its center, surrounded by numerous planet gears evenly spaced around it, and enclosed by the ring gear.

How Does It Work?

A planetary gearbox operates through the interaction of several key components: the sun gear, planet gears or pinions, and the ring gear.

Sun Gear (Sun Wheel): The central gear in the gearbox is called the sun gear or sun wheel. It is typically connected to the input or power source that drives the gearbox.

Planet Gears (Pinions): Multiple planet gears or pinions surround the sun gear. These gears are typically mounted on a rotating carrier or arm.

Ring Gear (Annulus): The ring gear, also known as the annulus, surrounds and meshes with the planet gears. It has teeth on the inside and is fixed or stationary.

Gear Interaction: The planet gears mesh simultaneously with both the sun gear and the ring gear. The planet gears spin as a result of the rotation of the solar gear.

Rotation Direction: The planet gears rotate around their own axes while also orbiting or revolving around the sun gear. This combination of rotational and orbital motion generates torque transmission.

Output: The output of the planetary gearbox is typically taken from the planet carrier or the sun gear, depending on the configuration and application.

The gear ratios and torque distribution within a planetary gearbox can be controlled by the arrangement of gears and gear stages. By altering the number of teeth on each gear, different gear ratios can be achieved to suit specific requirements.

Overall, the planetary gearbox efficiently converts input power into output torque with high torque density, making it a popular choice for various applications requiring compact and robust transmission systems.

What Is Planetary Gears' Primary Function?

Epicyclic gears are typically utilized as speed reducers. This indicates that the motors (servo, brushless, or brushed) are slowed down in order to improve torque.

Planetary gear motors are better able to generate higher speed and torque when it comes to speed and output. The numerous contact points positioned in between the gears are mostly to blame for this. In fact, for the majority of typical designs, the planetary gear system may cut speeds by up to 10:1 and accept greater input speeds.

The planetary gearbox offers several advantages, including:

The operation of a planetary gearbox involves the interaction of these three components. The sun gear is driven by an input shaft, which causes it to rotate. As the sun gear rotates, it meshes with the planet gears, causing them to also rotate. The planet gears are connected to a carrier, which is held stationary by an output shaft.

The rotation of the planet gears around the sun gear and the stationary carrier creates a gear reduction effect. This means that the output shaft rotates at a slower speed than the input shaft, but with increased torque. The gear ratio of a planetary gearbox can be adjusted by changing the number of teeth on the gears or by changing the arrangement of the gears.

The design of a planetary gearbox offers several advantages. It provides a compact and lightweight solution for transmitting power, making it suitable for various applications, such as automotive transmissions and industrial machinery. Additionally, the multiple points of contact between the gears distribute the load evenly, resulting in smooth and efficient operation.

Planetary gearboxes are commonly used in different industries, including automotive, robotics, and industrial machinery. They can be used in conjunction with various power sources such as internal combustion engines, electric motors, or hydraulic motors

If you are interested in purchasing planetary gearboxes, you can find a variety of options at Kavitsu Transmission

What is the purpose of a planet gearbox?

Different uses exist for planetary gearboxes. We provide planetary gear sets for use in industrial and mobile applications, such as:

to increase torque in a robot.

lowering the rollers' speed in a printing press

To ensure exact location

In a device for reproducible product packing

Track drives Wheel drives

Conveyors

drives slew

driving hoists

Mixing

Winch motors

Pumps

injectors for coil tubing

drives for aggies and drills

Drives for cutter heads

Choosing a Planetary Gearbox: Some Advice

Since not all gearboxes are created equal, you must be careful to select the ideal one for the project at hand. The considerations stated below should be kept in mind while choosing a planetary gearbox for your application.

The sort of application you're building will determine the required backlash, torque density, and ratio features.

Environment: To avoid dirt, dust, and moisture from entering the gearbox and harming the inner components, choose a planetary gearbox with the proper sort of housing.

Space: The good news is that you can always choose a smaller planetary gearbox to fit your application. Always assess the space available in your application. To guarantee that your application functions as necessary, consult a specialist to obtain the appropriate-sized planetary gearbox.

Advantages & Disadvantages of Planetary Gearbox

Compound planetary gears have their own set of advantages and disadvantages to take into account, just like all other types of gearboxes. As you narrow down your selections, take into account the benefits and drawbacks of epicyclic gearing.

Advantages

No backlash: Gearing has nearly no backlash and is quite accurate.

Modular: The majority of planetary phases can be stacked since they are modular.

Shaft: Coaxial configuration means that there is no offset in the output shaft.

Gear: increased gear life at equivalent loads.

High power density: The burden is distributed among many planets.

Size: Planetary gears are lightweight and small, making them simple to employ in a variety of settings.

Torque: Transmissions with high torque levels are feasible.

High efficiency: Due to their low rolling power, planetary gear systems are approximately 95% more efficient.

Disadvantages

Noisy operation: Planetary gearheads frequently produce more noise when operating. However, other models, like those in the Kavitsu Transmission product line, promise to be quieter.

Load sharing: Since the gears must always be beveled with helical teeth, load sharing won't work if the gearing is inaccurate.

Lubrication: Grease lubrication is typically required for planetary gears in order to prevent wear. An oil bath option might be preferred by many consumers.

Cost: The price may be increased in order to guarantee low backlash and lifespan. This is typically due to the fact that they are made up of more parts than other kinds of gearboxes.

Loads: High-bearing loads can cause the dead stud to deteriorate quickly.

Conclusion

Our detailed post should have made it a lot simpler for you to learn how planetary gearboxes operate. Small planetary gearboxes made by Kavitsu Transmission are not only precise but also compact. Expect seamless functioning, minimal noise, and maximum transmission effectiveness.

Additionally, the major goal of our site is to instruct readers on how to use incremental encoders effectively for a variety of applications. Customers can also get the best goods and parts from Kavitsu Transmission to fit and enhance their present project!

0 notes

Text

Alloy Steel Sheets & Plates Exporters

Alloy Steel Plates Supplier is defined as having 1.5% to 5% total alloy content. Its common alloying elements are manganese, silicon, chromium, nickel, molybdenum, and vanadium, which contain as many as four or five of these alloys in varying amounts. which is been used by the manufacturers who works with petrochemical industries, oil and gas industries, chemical industries, shipbuilding etc. Alloy steel wear plates is a smooth, chromium carbide rich overlay plate manufacturers and Supplier by a patented production process maximizing abrasion resistance and reducing hang up.

Alloy Steel Sheet is been designed from alloys such as chromium, molybdenum, nickel, manganese, silicon so on, they are industrial product that is generally used in various industries applications. 4130 alloy steel sheet is low-alloy steels containing chromium and molybdenum as strengthening agents. It provides good strength and toughness, weldability and machinability. Alloy steel 4340 sheet is a heat treatable low alloy steels which contains nickel, chromium, molybdenum, they are commonly used for heavy duty industrial, aerospace and automotive applications.

It has high strength and toughness in heat treated condition. 6150 alloy steel sheet is useful in heavily stressed machinery parts including gears, shafts, hand tool components and pinions. It is a fine grained, highly abrasion resistant carbon-chromium alloy steel. Alloy Steel Plates Grades are ASTM A387 Gr 5, ASTM A387 Gr 9, ASTM A387 Gr 11, ASTM A387 Gr 12, ASTM A387 Gr 22 and ASTM A387 Gr 91.

For more information

Contact: 9821513630 , 9321113630

Email id: [email protected]

Address:

Office No 7, 42/46, Mughbat Lane, Shantaram Chawl, Girgaum, Mumbai - 400 004..

0 notes