#Ford Modular Engine History

Explore tagged Tumblr posts

Text

Ford Modular Engine: A Revolução dos Motores V8 e V6 da Ford

O Ford Modular Engine representa uma das maiores inovações tecnológicas da indústria automobilística, redefinindo a potência e a eficiência dos motores V8 e V6. Projetado pela Ford na década de 1990, o Modular Engine rapidamente se tornou um pilar nos veículos de alta performance da montadora, equipando carros como o Ford Mustang, F-150 e Crown Victoria. Neste artigo, exploraremos a evolução,…

#4.6 Ford Modular#4.6 vs 5.4 Ford#5.4 Ford Modular#5.4 Ford Supercharger#Best Ford Modular Engine#Ford 4.6 Mods#Ford 4.6 Reliability#Ford 4.6 Tuning#Ford 5.4 Engine Build#Ford 5.4 Performance#Ford DOHC Engine#Ford Modular Crate Engine#Ford Modular Engine#Ford Modular Engine History#Ford Modular Engine Review#Ford Modular Engine Sound#Ford Modular Exhaust#Ford Modular HP#Ford Modular Parts#Ford Modular Problems#Ford Modular Rebuild#Ford Modular Stroker#Ford Modular Torque#Ford Modular Turbo#Ford Modular Upgrades#Ford Modular V8#Ford SOHC Engine#Ford V8 Engine#Modular Engine Drag Race#Modular Engine Swap

0 notes

Text

Complete History of Ford Modular Engines - Dave Stribling @diyford

In 1991 Ford introduced its overhead camshaft V-8 in the Lincoln Town Car and labeled it the modular engine. The label came from the method of producing the engine, not the fact that parts are easily interchanged between engine configurations. Eventually it was installed in the full-size Ford Crown Victoria, Mercury Grand Marquis, and the 1994 Ford Thunderbird as the old Windsor small-block V-8…

View On WordPress

0 notes

Text

Why Texas Is a Top Destination for Quality Vehicle Engines?

The engine of your vehicle is the heart that keeps it beating, and when it comes to quality engine production, you’ll find that Texas holds the keys to revealing peak performance. As you search for a reliable engine that meets your specific needs, you’re likely to find yourself drawn to the Lone Star State. But what sets Texas apart from other destinations? Is it the state’s rich history of engine building, the cutting-edge manufacturing facilities, or something else entirely? Let’s take a closer look at what makes Texas a top choice for vehicle engines.

Unparalleled Expertise in Engine Building

How do top-tier engine builders consistently produce high-performance, reliable vehicle engines? It starts with unparalleled expertise in engine building. In Texas, you’ll find skilled professionals with extensive knowledge of various engine models, including the Ford used engine and the popular used Coyote engine for sale. These experts have spent years honing their craft, studying engine dynamics, and mastering the art of precision engineering.

When you choose an engine builder in Texas, you’re getting more than just a replacement engine. You’re getting a custom-built powerhouse that’s tailored to your specific needs. These builders take pride in their work, carefully selecting and refurbishing components to guarantee maximum performance and reliability. Whether you’re looking for a high-performance engine or a reliable workhorse, Texas engine builders have the expertise to deliver.

Their attention to detail and commitment to quality are what set them apart from the competition. By combining technical knowledge with hands-on experience, these engine builders create engines that are not only powerful but also durable and long-lasting.

State-of-the-Art Manufacturing Facilities

Within Texas’ thriving engine-building industry, state-of-the-art manufacturing facilities play a pivotal role in the production of high-performance, reliable vehicle engines. As you explore the manufacturing landscape in Texas, you’ll notice that many facilities are equipped with cutting-edge technologies, including advanced machining tools, robotics, and automation systems. These technologies enable manufacturers to optimize production processes, reduce waste, and improve overall efficiency.

You’ll also find that many Texas-based facilities have implemented Industry 4.0 solutions, such as IoT sensors and AI-powered quality control systems. These solutions enable real-time monitoring and data analysis, allowing manufacturers to identify potential issues before they become major problems. Additionally, many facilities have achieved certifications such as ISO 9001 and IATF 16949, demonstrating their commitment to quality and continuous improvement.

The state-of-the-art manufacturing facilities in Texas are also designed with flexibility and scalability in mind. Many facilities have modular layouts, allowing manufacturers to quickly adapt to changing demand or new technologies. This flexibility enables manufacturers to respond rapidly to market trends and stay ahead of the competition.

Competitive Pricing and Incentives

Texas’ competitive pricing and incentives are a significant draw for companies looking to establish or expand their engine-building operations in the state. As you explore the Lone Star State’s offerings, you’ll discover that the cost of establishing and maintaining a manufacturing facility is lower compared to other states. This is largely due to the state’s favorable business climate, which features lower taxes, minimal regulations, and a highly competitive labor market.

When it comes to incentives, Texas offers a range of programs designed to support businesses in the automotive sector. These include the Texas Enterprise Fund, which provides financial incentives to companies that create jobs and invest in the state. Additionally, the state’s Skills Development Fund offers training and development programs for employees, helping to guarantee that your workforce has the skills needed to succeed in the industry.

Diverse Range of Engine Services

As you establish or expand your engine-building operations in Texas, you’ll find an extensive range of engine services at your disposal. From cylinder head machining and crankshaft grinding to engine block boring and honing, you can access the specific services you need to maintain, repair, or rebuild your engines. Many Texas-based engine shops also offer advanced services, including 3D engine scanning, CNC machining, and engine performance testing. Additionally, you can leverage the state’s strong network of suppliers and manufacturers to source high-quality engine components, such as pistons, rings, and bearings. This thorough range of services allows you to streamline your operations, reduce lead times, and increase overall efficiency. Moreover, many Texas-based engine shops have invested in the latest technology and equipment, ensuring that your engines receive the highest level of care and precision. By taking advantage of these diverse engine services, you can improve your engine-building capabilities and stay competitive in the market.

Conclusion

As you rev up your engine, imagine the precision and expertise that went into crafting it. Texas, the hub of high-performance engine production, is where your vehicle’s heartbeat comes to life. With world-class facilities, skilled technicians, and state-of-the-art technology, the Lone Star State delivers durable, custom-built engines that purr like a well-oiled machine. The result: a driving experience that’s as smooth as the Texas plains and as powerful as a Texan’s pride.

Blue Prism Automotive

3419 Westminster Ave #1037 Dallas, TX 75205, United States

Tel: (469) 546-3400

Map Location: https://maps.app.goo.gl/jbiCKBuRBLYKKjhP7

0 notes

Text

Why the 2023 Range Rover Sport chose a BMW V8 over other options

The 2023 Range Rover Sport is one of the most anticipated luxury SUVs of the year. It promises to deliver a refined and powerful driving experience, with a sleek design and a spacious interior. But what makes this model stand out from the rest is its engine choice: a BMW V8. Why did Land Rover decide to use a BMW V8 instead of developing its own engine or using another option? In this article, we will explore the reasons behind this decision and what it means for the performance, efficiency and reliability of the 2023 Range Rover Sport.

The history of Land Rover and BMW

Land Rover and BMW have a long history of collaboration. In 1994, BMW acquired Land Rover from British Aerospace, and became its parent company until 2000, when it sold it to Ford. During this period, BMW invested heavily in Land Rover's development, and introduced several innovations, such as the Range Rover P38A, the Freelander and the Discovery Series II. BMW also supplied Land Rover with some of its engines, such as the 4.4-liter V8 that powered the Range Rover L322 from 2002 to 2005, and the 3.0-liter inline-six diesel that was used in the Range Rover Sport from 2005 to 2009. These engines were praised for their smoothness, power and refinement, and helped Land Rover establish its reputation as a premium SUV brand.

The benefits of using a BMW V8

In 2019, Land Rover announced that it had signed a new deal with BMW to source its V8 engines for its future models. This was seen as a strategic move, as Land Rover was facing several challenges with its own engine production. For one thing, Land Rover's V8 plant in Wolverhampton was nearing its capacity limit, and expanding it would require a significant investment. For another thing, Land Rover's V8 engines were not very competitive in terms of emissions and fuel economy, especially in light of the stricter regulations in Europe and China. By using a BMW V8, Land Rover could benefit from several advantages. First of all, BMW's V8 engines are widely regarded as some of the best in the industry, offering a balance of performance, efficiency and reliability. They are also modular, meaning that they can be adapted to different models and specifications. For example, the 2023 Range Rover Sport will use a 4.4-liter twin-turbocharged V8 that produces 523 horsepower and 553 pound-feet of torque, while the upcoming Range Rover SVR will use a more powerful version that delivers 600 horsepower and 590 pound-feet of torque. Secondly, using a BMW V8 could help Land Rover reduce its development costs and time, as well as its emissions and fuel consumption. By outsourcing its engine production to BMW, Land Rover could focus more on other aspects of its vehicles, such as design, technology and quality. Moreover, BMW's V8 engines are more efficient than Land Rover's own engines, thanks to features such as variable valve timing, direct injection and cylinder deactivation. This could help Land Rover meet the environmental standards in different markets and improve its customers' satisfaction.

The drawbacks of using a BMW V8

Of course, using a BMW V8 also has some drawbacks for Land Rover. One of them is the loss of exclusivity and identity. Some critics argue that by using a BMW engine, Land Rover is compromising its brand image and heritage, and becoming more dependent on another company. They claim that Land Rover should develop its own engines that reflect its values and character, rather than relying on someone else's technology. Another drawback is the potential risk of compatibility issues and quality problems. While BMW's V8 engines are generally reliable, they are not immune to faults and failures. For instance, some owners of BMW vehicles have reported issues such as oil leaks, coolant leaks, timing chain failures and carbon buildup. These issues could affect Land Rover's vehicles as well, if they use the same engines. Moreover, integrating a BMW engine into a Land Rover vehicle could pose some challenges in terms of calibration, tuning and cooling.

The future of Land Rover and BMW

Despite these drawbacks, using a BMW V8 seems to be a smart decision for Land Rover in the short term. It allows Land Rover to offer its customers a high-performance and high-quality SUV that can compete with other luxury brands in the market. It also gives Land Rover some time to develop its own engine solutions for the long term. Land Rover has already announced that it is working on developing its own hybrid and electric powertrains for its future models. By 2030, Land Rover aims to have all its vehicles electrified in some form or another. This means that the BMW V8 could be one of the last internal combustion engines that Land Rover uses in its vehicles.

FAQs

Why did Range Rover choose the BMW V8 over other engines? The decision was based on a collaborative process that considered factors such as performance, reliability, and shared technological vision. What advantages does the BMW V8 offer in terms of performance? The BMW V8 is renowned for its power, efficiency, and an exhilarating driving experience, setting new standards in automotive performance. How will this decision affect potential buyers? Buyers can expect an enhanced driving experience, aligning with the luxury and performance standards set by Range Rover. Are there any criticisms or concerns regarding the engine choice? The article addresses potential criticisms transparently, providing insight into the decision-making process. What does the future hold for Range Rover and its engine choices? Speculation on future models and potential industry trends is discussed, offering a glimpse into what lies ahead. Read the full article

0 notes

Text

Legendary Performance: Ford Mustang 4.6 Engine for Enthusiasts

Introduction

The Ford Mustang has etched its place in automotive history as an American icon, capturing the hearts of enthusiasts and drivers alike with its timeless design and unrivaled performance. At the heart of this legendary pony car lies the Ford Mustang 4.6 engine, a true masterpiece of engineering that has left an indelible mark on the world of high-performance vehicles. In this article, we explore the legendary performance of the Ford Mustang 4.6 engine, a powerhouse that continues to ignite the passion of automotive enthusiasts.

Unleashing the Stallion

The Ford Mustang 4.6 engine for sale is a testament to raw power and precision engineering. As the V8 powerhouse roars to life, it unleashes a symphony of horsepower and torque, ready to surge forward with unbridled energy. From a standstill to high speeds, the acceleration is awe-inspiring, making every drive an unforgettable experience for both driver and passenger.

The legendary performance of the 4.6 engine ensures that the Mustang remains a force to be reckoned with on the road and the racetrack. Whether cruising along city streets or conquering twisting mountain roads, the Mustang effortlessly displays its prowess and leaves an everlasting impression of its legendary performance.

Heritage of Innovation

Introduced in the mid-1990s, the Ford Mustang 4.6 engine marked a significant milestone in Mustang's history. With its innovative overhead camshaft design, the 4.6 engine ushered in a new era of performance and refinement. This engineering marvel not only improved horsepower and fuel efficiency but also offered enthusiasts the opportunity to modify and customize the engine to their heart's content.

The modular design of the 4.6 engine made it a favorite among tuners and modifiers, providing a versatile platform for performance upgrades. This adaptability has allowed generations of enthusiasts to embrace the spirit of customization, enhancing the Mustang's already formidable performance to new heights.

Unmatched Thrill on the Track

For performance enthusiasts, the Ford Mustang 4.6 engine has proven its mettle on the racetrack, solidifying its status as a true powerhouse. Over the years, the engine has been a staple in various motorsport events, including drag racing, road course competitions, and quarter-mile sprints.

With the Mustang's unmistakable rumble reverberating around the track, the 4.6 engine has showcased its prowess, crossing the finish line with breathtaking speed and determination. Its performance on the track is a testament to its engineering excellence and the unyielding passion it ignites in drivers who seek the thrill of legendary performance.

Enthusiasts' Pursuit

For automotive enthusiasts, the Ford Mustang 4.6 engine is more than just an assembly of metal and pistons; it's a representation of their love for all things automotive. The pursuit of this legendary engine becomes a quest for the ultimate driving experience—a journey that brings them closer to the essence of American muscle.

Whether searching for a pristine classic Mustang with the 4.6 engine or undertaking a project to restore and upgrade this iconic powerhouse, enthusiasts embrace the challenge with unwavering determination. The joy of finally owning and driving a Mustang equipped with the 4.6 engine is a realization of their passion and a tribute to the legacy of the pony car.

Conclusion

The Ford Mustang 4.6 engine for sale is a paragon of legendary performance that continues to captivate the hearts of enthusiasts. With its raw power, innovative design, and unmatched performance on the track, it stands as a symbol of American muscle car heritage.

For those who seek the thrill of legendary performance, the Ford Mustang 4.6 engine offers a driving experience like no other. Embracing the spirit of customization and personalization, enthusiasts unleash the full potential of this powerhouse, etching their own legacy in the annals of Mustang history.

So, to all the automotive enthusiasts and Mustang lovers out there, embrace the legend, harness the horsepower, and let the Ford Mustang 4.6 engine take you on a journey of legendary performance that will leave a lasting impression for generations to come.

0 notes

Text

The best U.S. fighters that were ALMOST placed on aircraft carriers

Fernando Valduga By Fernando Valduga 03/07/2023 - 00:49in History, Military

Over the years, the Pentagon has repeatedly tried to cut dollars from its main budgets, picking up fighters designed for the long and well-groomed runways of the U.S. Air Force and converting them to the turbulent world of naval aviation. See some projects of fighters that did not reach the flight deck of an aircraft carrier.

America's Nimitz and Ford class aircraft carriers represent the country's most powerful form of force projection, with fleets of F/A-18 Super Hornets and stealthy F-35Cs waiting on each huge flight deck to provide more combat power than can be gathered by entire nations. But although these fighters were chosen specifically for their ability to act in the air and withstand the rigors of rigid aircraft carrier launches and landings, not all the fighters that Uncle Sam tried to put in his fleet of flat tops were suitable for the job.

The approach of using a fighter designed for the USAF for use in the aircraft carrier, of course, culminated in the Joint Strike Fighter program - an effort that sought to launch a single multifunctional fighter for the Air Force, Navy, U.S. Marines and a list of foreign partners. And although the resulting F-35 has proven to be a technological marvel, the numerous budget overflows and technical setbacks of the program seem to have been more than enough to scare the Pentagon and prevent it from making the same mistake again.

Today, the U.S. Navy and the U.S. Air Force have next-generation fighters in development, both being designed under the auspices of the Next Generation Air Dominance (NGAD) program and with the aim of sharing a series of modular internal systems... but each branch is careful to explain that these programs are maturing independently and will eventually produce different platforms - apparently as a

But the F-35 was far from being the first fighter that legislators or Pentagon officials tried to make work for both branches. Here are the jets that paved the way for the Joint Strike Fighter concept and why they failed where the F-35 managed to succeed (burning budgets as aviation fuel).

Vought 1600: Putting the F-16 on aircraft carriers

The F-16 Fighting Falcon has been the U.S. Air Force's 'cargo donkey' fighter for more than 40 years and, at one point in 1975, it seemed that an aircraft-port-capable version would do the same for the U.S. Navy.

To meet the Navy's needs, the Vought 1600 was larger than the F-16A. It stretched about one meter more, with a wingspan of just over 11 meters it was half a meter wider than the USAF fighter's version. The larger wings would give the aircraft better stability at lower speeds. The fuselage was slightly flattened and enlarged, and its canopy was designed to rotate forward. Although it was different from the F-16, this project can now be found on the F-35.

To withstand aircraft carrier landings, the heavier landing gear was affixed to the Vought 1600 landing gear next to the standard aircraft carrier's equipment, such as a landing hook. The fuselage itself was reinforced and, in order to offer the range of engagement that the Navy needed, a pulse-doppler radar for direction beyond the visual range was also added.

In all, the structural changes needed to transform the F-16 into the Vought 1600 added more than 3,000 pounds to the aircraft. Other changes were made to the fuselage and wings as the subsequent iterations of the Vought 1600 materialized. The V-1602, for example, had even more wing area and received a heavier GE F101 engine.

The Navy in the end ended up going to the YF-17 which then became the F/A-18 Hornet.

You can read the full story about the efforts to put the F-16 on the aircraft carriers here.

The F-15N Sea Eagle

The F-14 Tomcat may be a legendary fighter that received Hollywood treatment in the 1986 Top Gun, but for a short time in the 1970s, the Navy considered canceling the Tomcat in favor of flying the F-15 from its aircraft carriers.

In order to make the F-15 suitable for aircraft carrier service, McDonnel Douglas has made a number of significant changes to the Eagle's design. The F-15A, like many modern fighters, already had a hook for use on short landing strips or in case of emergency, but an aircraft fighter needs to rely on its hook for each landing, so a larger reinforced hook was added. To facilitate storage below deck on aircraft carriers, the wings of the Sea Eagle would be folded at a 90-degree angle just over 5 meters from each end.

The landing gear would also have to be replaced by a more robust set that could withstand the abuse of aircraft carrier landings on a swinging ship. McDonnell Douglas said it would start designing the new equipment if the Navy wanted to move forward with the aircraft.

With these changes incorporated, the F-15 earned only 3,000 pounds which, combined with better maneuverability, higher maximum speed and a much lower price, made this new Sea Eagle look like a good deal. But there was a glaring deficiency: as capable as the F-15N could be, it could not carry the latest and largest U.S. air-to-air missile, the AIM-54 Phoenix, limiting its ability to engage Soviet long-range bombers, which was the role this platform intended to fulfill.

You can read the full story about the efforts to put the F-15 on the aircraft carriers here.

NATF-22 Sea Raptor

The U.S. Air Force F-22 Raptor is often described as the most powerful air superiority fighter in the world, but for a short period of time, it was almost accompanied by a sister platform modified specifically for the Navy, the NATF-22.

Lockheed's YF-22 project was already so promising years before it entered service that Congress pressured the Navy to consider adopting a sweep wing version of the new fighter under the NATF (Naval Advanced Tactical Fighter) program that began in 1988. If the U.S. Navy had chosen to seek an F-22 variant with aircraft carrier capacity, there would be a number of significant technical obstacles to be overcome. Aircraft designed for aircraft carrier operations need to deal with a very different set of takeoff and landing challenges than their ground counterparts, and the Raptor's stealth has made external design changes complex and expensive.

The fuselage needed to be more physically robust to withstand the incredible forces applied to the aircraft during catapult launches and short-range landings, which would also need to be supported by a rear hook at the rear of the aircraft. In addition, the NATF-22 would have to leverage the same type of variable sweep wing approach found in the F-14 to grant the aircraft the ability to fly slowly enough to land safely aboard an aircraft carrier.

It is logical that the variable fringence wing project would compromise some degree of stealth of the aircraft. If the connecting surfaces of the moving wings produced a high enough return on the radar to ensure a blocking of weapons in the aircraft, the value of such a fighter would be fundamentally compromised.

And while the F-22 can be fast and maneuverable, the Navy's existing F-14 Tomcats were faster. Perhaps the most forceful of all, despite their high maintenance costs, the F-14 Tomcats were still significantly cheaper than building a new stealth fighter for the Navy flattops, even if it was heavily borrowed from the U.S. Air Force program.

F-117N Seahawk

In 1993, four years after the U.S. Air Force revealed the Nighthawk to the world, Lockheed approached the U.S. Navy with a proposal for an aircraft-based version of the famous "stealth hunt". This new F-117N would be an attack aircraft for any low-observation (furtiva) climate. At the time, it seemed a logical progression to the air power of the United States.

Apparently aware that the operational F-117 was not the most capable combat aircraft, Lockheed's new proposal offered a drastically improved version of the platform, complete with twice the internal load capacity of the first.

The wings would have a sweep of 42 degrees, instead of the 50 degrees of the Nighthawk, and would extend 50% more, to 12 meters. On the tail of the aircraft, additional horizontal ailerons have been added to make it more manageable at the low speeds required for landings on aircraft carriers.

Not satisfied with the Nighthawk's maximum speed of about 680 miles per hour, Lockheed looked at the most powerful F114 engines that would later find a home in the Super Hornet. These post-combustion turbofans built by GE produced 13,000 pounds of thrust in normal operation and up to 22,000 pounds with the post-combustor driven. The use of a pair of these engines in the Seahawk would make him significantly faster than his U.S. Air Force brother Nighthawk and could potentially take him to supersonic flight.

Source: Sandboxx

Tags: Military AviationHISTORYUSN - United States Navy/U.S. Navy

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, has participated in several events and air operations, such as Cruzex, AirVenture, Daytona Airshow and FIDAE. He has works published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work around the world of aviation.

Related news

MILITARY

Indonesia fails to report payment schedule in its participation in the South Korean project KF-21

03/07/2023 - 18:58

A Norwegian air force F-35A fighter under maintenance. Norway has decided to build a national F-35 maintenance facility at its main F-35 operating base, but will continue to ship its aircraft to Italy's FACO plant in Cameri for heavy maintenance. (Photo: Forsvaret)

MILITARY

Norway will have a new maintenance center for its F-35

03/07/2023 - 16:00

ARMAMENTOS

France selects MBDA for Larinae vagrant ammunition project

03/07/2023 - 14:00

SMOKE SQUAD

Smoke Squadron starts the Santos Dumont Circuit 150 Years

03/07/2023 - 10:06

MILITARY

IMAGES: RAF officially retires its fleet of C-130J Super Hercules transport aircraft

03/07/2023 - 09:24

MILITARY

Chinese J-20B fighter made the first flight with a new series of engines

02/07/2023 - 18:14

homeMain PageEditorialsINFORMATIONeventsCooperateSpecialitiesadvertiseabout

Cavok Brazil - Digital Tchê Web Creation

Commercial

Executive

Helicopters

HISTORY

Military

Brazilian Air Force

Space

Specialities

Cavok Brazil - Digital Tchê Web Creation

1 note

·

View note

Text

The 10 Ugliest Cars of All Time

It’s true that there’s more to life than looks, but some car designers sometimes let their imagination run wild until they cross the limits of good taste. Let’s take a look back at these automotive gems, a little too different from the others.

1953 : Reliant Regal

Acclaimed for its lightness and urban design, the Reliant Regal is the first car perched on three wheels.

Whether a manufacturing defect or a simple expression of British eccentricity, the Regal has since become a symbol of British popular culture. Impossible to have missed the appearance of this weirdness in Mr Bean’s adventures!

1957 : Edsel

As the 1960s approached, XXL models appeared on the other side of the Atlantic. Ford tried to give a new lease of life to its business by launching a brand of cars that were more powerful, more comfortable, but also more fanciful. But Edsel failed to seduce… An episode often described as the greatest commercial failure in the history of the United States…

1961 : Citroën Ami 6

A compromise between the DS and the 2CV, the Citroën Ami 6 is the ideal car for small purses looking for a car with a well thought-out design. Designer Flaminio Bertoni created the curvaceous lines reminiscent of a friendly face, although the car has sometimes been called a “toad” by its detractors. Nevertheless, the Ami 6 was the best-selling car of 1966, ahead of the Renault 4.

1976 : Renault 14

Nicknamed “the pear”, the Renault 14 sold one million units despite its futuristic design for the time. Compact and lightweight, the R14 also boasts highly contrasting volumes: tight at the front and massive at the rear to meet the new needs of families seeking comfort. An exceptional interior space that marks a real turning point in automotive design.

1980 : Renault Fuego

In spite of an appearance in the James Bond Dangerously yours, the Renault Fuego does not make the unanimity by its style very anchored in the Eighties. Among the innovations, the fully glazed “bubble” tailgate and the black fluted side strip are supposed to give the whole an aerodynamic line. While the look is sporty, the engine hasn’t really lived up to its promises.

1992 : Aixam Mega Club

The Aixam Mega Club marks the return of a segment that has disappeared since the Citroën Méhari: that of the useful and modular beach car. Georges Blain, owner of the license-free car brand Ariola, sought to diversify by offering for sale a car that was different from the others in every way. Far from going unnoticed, this unique look will be available in no less than 10 versions: convertible, covered, sheet metal, 4×4…

1998 : Fiat Multipla

Duck or dolphin, it’s hard to identify what inspired Fiat designers to create the Multipla. In France, sales of this car never took off, unlike in Italy, where the Multipla was the best-selling compact MPV in 2002. This limited success can be explained by the “practical” advantages (large cabin, six seats, etc.) appreciated by parents with large families.

2000 : Pontiac Aztek

A cross between SUV, MPV and pickup, the Pontiac Aztek aims to appeal to all driver profiles by meeting the needs of each.

This risky approach has resulted in a misshapen and rather expensive creation that is now being sold off in the U.S. auto market.

2005 : SsangYong Rodius

By producing a minivan with an imposing design, the Korean brand SsangYong is setting out to conquer the Western automotive market.

Cubic rear, stylized front, 180° swivel seats, length exceeding 5 meters… the appearance of the Rodius is very different from those of other minivans.

2015 : Toyota Scion XB

Even if they come from a foreign factory, the cars produced for the American market stand out, or rather impose themselves, by their opulent appearance.

The geometric shapes of the Toyota Scion XB are no exception to the rule, and are more like the aesthetics of a large refrigerator than a car designed to appeal to young drivers.

1 note

·

View note

Photo

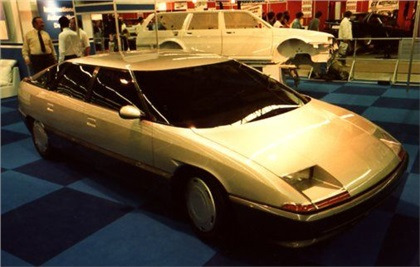

That Time Forgot: IAD Alien (and related concepts)

I gotta admit. For the longest time, I thought that this car, with its supremely space-age design, was not real. But after a bit of a search and some other things... I found it was. I believe some people might share this sentiment. Today, I’m going to talk about the history behind the IAD Alien, along with, as a bonus, all of the other things IAD made over the years.

IAD, or International Automotive Design, was a British design company founded in 1976 by husband and wife Yvonne and John Shute. The company originally designed bodies for trains (my other interest), but eventually branched out to designing bodies for automobiles. Increasing demand eventually caused IAD to branch out to encompassing various different facets of the industry, from design and sculpting models to small-scale production. In the 1980s, IAD was one of the biggest automotive design firms in the world, competing against such giants like Bertone, Italdesign and of course, Pininfarina, and also had multiple facilities around the world.

Touted as “Britain’s Largest Styling Company”, IAD meant business. To prove that they were a force in the industry, they designed a number of concept cars throughout the 1980s to early 1990s, and we’ll be talking about them here. I will not be counting cars that were designed by IAD, but manufactured by another company.

The first of the concept cars they designed was known as the TRX.

The TRX was a radical restyling of the Triumph TR7, designed by Martin Longmore. The TRX attempted to make the car have a completely different appearance, but keeping the fundamental structure of the car as close as possible to the TR7. General Electric Plastics helped to fund the project. It was displayed at the 1980 Birmingham Motor Show.

Their next project was the Arrival, displayed at the 1985 Frankfurt Motor Show. The car attempted to demonstrate IAD’s expertise with computer-aided design, showing a proposal for a five-door sedan designed entirely with a computer.

The next car IAD would design would turn out to be arguably their most famous design yet, helped by the fact that a Hot Wheels model was produced replicating the car: the Alien.

The IAD Alien was designed by Longmore and Marcus Hotblack, and was their proposal for a futuristic mid-engined supercar. Featuring a canopy door which tilted forward for unhindered entrance and egress, the Alien showcased a number of interesting solutions for the general public. The car was first introduced at the 1986 Turin Motor Show.

The car itself featured a highly sophisticated interior with a starship-like steering wheel and heads-up display for the dashboard. The interior was also well-protected, with an integrated roll cage in the car. Quite possibly the most interesting part of the car was its modularity; owners of the car could switch out engines on the fly for easy upgrading, maintenance or to change to something else the driver suited. A bit over the top, yes, but that’s what the ‘80s were like.

Unfortunately, the car was non-functional, and Longmore and Hotblack would move on to their next project.

The Impact was their next project, also designed by Longmore and Hotblack. Built on a Ford Sierra chassis and powered by a 2.8L Cologne V6, the Impact aimed to be one of the most barrier-free SUVs possible, with folding steps when any of the doors opened. A split tailgate and underfloor storage allowed the Impact to store more than a usual SUV could. It was branded as a Sports/Utility Car by a brochure, and featured an in-car navigation system. The car was showcased at the 1987 Frankfurt Motor Show.

To add to their SUV portfolio, IAD did up the Interstate. Designed by Tony Pettman, the usual Ford Cologne V6 was fitted underneath a soundproof cover, allowing for some of the quietest rides. It too, like the Impact, was introduced at the 1987 Frankfurt Motor Show.

Following up the Impact was the Hunter, a rugged off-road vehicle equipped with navigational systems and a telephone. Appearing very similarly to the Impact, the Hunter was also fitted with the same Ford Cologne V6 and featured weatherproof seats made out of foam. It was showcased at the 1988 Turin Motor Show, and was designed by Longmore, Hotblack and Dave Ancona.

After the Hunter came the Royale, designed by Bill Barranco and Jose Diaz de la Vega. The Royale was built around a highly modified Subaru XT-6, with the wheelbase stretched. Meant for business executives, the Royale had a rotary keypad and controls for the CD player and satnav systems available to both rear passengers. The headlights and taillights were engineered by Phillips (yes, that Phillips), and featured a massive LED screen in the rear of the car integrated with the taillamps engineered to give various pieces of road safety information. It, like the Hunter, was also shown off at the 1988 Turin Auto Show.

Their next car was the rather interesting-looking (and potentially rather unsightly) Venus. Introduced at the 1989 Tokyo Motor Show, the Venus was designed by Michael Ani and touted as a futuristic supercar with both performance and a distinctive appearance. The design aimed to form a blend between the technical and aesthetic aspects of the car. A functioning model of the car was eventually built on a Lotus Elise chassis.

Their next project was simply titled the Mini MPV. Powered by a Ford Escort’s CVH 1.9L engine, the Mini MPV could seat six people in three rows. It debuted at the 1990 Turin Motor Show and may have been trialed at Los Angeles International Airport at the time.

Okay, I’m breaking the “outsourced production” rule, but technically this thing was designed by IAD but never produced, so it sort of qualifies. This is the IAD Magia (or Lancia Magia), designed by Ani and Brian Osborn. Featuring the 2.0L FIAT Twin-Cam inline-4 from a Lancia Delta Integrale, the Magia featured a “svelte body” on top of a Lancia Dedra platform, and was touted as “a car to capture the imagination of all the devotees of sporting coupes”. The car was shown off at the 1992 Turin Auto Show, where it was extremely well received, although serial production never materialized.

Reeling from the effects of the European Union’s automobile industry’s worst recession, IAD went into receivership and was acquired by Mayflower Group in 1993. John Shute would die two years later on 13 January 1995, aged 54. Despite his death, IAD would go on to design one more concept on their own.

That design was the EuroTaxi. This was a taxi designed to be the cheapest and most efficient taxi to operate by miles. The EuroTaxi attempted to extend service intervals through the use of both an internal combustion engine and an onboard battery pack, and as a result, decrease downtime. The car was showcased at the 1995 Frankfurt Motor Show, but of course, no orders were placed. The EuroTaxi would turn out to be IAD’s last design.

With the money running dry due to said recession, Britain’s Leading Styling Company were forced to release their chokehold on the car design industry and vanished. The company’s design facilities were bought over by Daewoo Motors, and IAD faded into obscurity, never to be heard from again, while Pinifarina, Bertone and Italdesign are still around today, designing cars.

Okay, now that we’ve gotten the history of IAD out of the way, let’s talk about what you came for: the Hot Wheels version of the IAD Alien.

The Alien was designed by Larry Wood and first introduced in the 1989 Speed Fleet series in the above color, somewhat replicating that of the real Alien; however, this color is quite rare and was quickly replaced by the far more common red version. The casting never received any mention of IAD on it; for all its releases it was simply titled “Alien”.

The Alien features a plastic wraparound body rivited to the base, with metal fender flares and a plastic canopy. This canopy can theoretically be removed, but I’m not going to attempt to do so; instead, I’ll show a picture of one with the canopy removed.

The casting has a metal base, which makes this casting quite heavy. It actually has some decent details on the undercarriage.

The base features few markings apart from the logo and copyright information. I can honestly see people not being able to identify this car, but this was at a time where little other information other than copyright and the Hot Wheels logo was placed on the base; this lasted from about the mid-’80s to the mid-to-late-’90s, at which point it was presumably mandated to put the name of the casting on the base unless it couldn’t fit.

The Alien enjoyed the privilege of being released quite often when it was in the lineup, but ultimately this casting was doomed in 1999 for one reason, and one reason only: the Final Run Series.

The Final Run Series started in 1999 and acted as what I would consider a very glorified funeral for a casting; Hot Wheels would give these cars special tires and paint, in exchange for vowing to never produce them again by cutting their toolings in half. The Alien was unfortunately one of the castings to fall victim to the Final Run Series, and although it might not have been one of the more popular castings to retire that year, it was still retired regardless. As the first batch of cars to be Final Run, having been introduced in the 1999 series, the Alien will never be seen again in the Hot Wheels lineup unless a new tool and die is created for it, which I believe is highly unlikely. The Final Run Series itself has been on hiatus since 2006. In total, the Alien had fifteen releases.

Always on the receiving end of very loud decals due to its plastic sides and large fenders, the Alien will be dearly missed (by me, at least) in the Hot Wheels lineup, and I wouldn’t mind seeing a modern recreation of the Alien return to the Hot Wheels lineup as a premium piece.

I hope this post has given you a better idea on the history of this futuristic British supercar concept, and the history of its small Hot Wheels counterpart. As usual, I’d write something like this any day.

- Grunty

3 notes

·

View notes

Text

Electric vehicles have come a long way since the 1890s

Wood wheels and 24 batteries helped this whip go down in infamy. (Courtesy american-automobiles.com/)

Battery-powered whips might seem like novel additions to your local thoroughfares, but they’ve actually been around for more than a century. This is how the cars have progressed, from buggy to pickup.

1890s: William Morrison’s ride (above)

Scotland-native William Morrison was one of the first inventors to create an electric vehicle for America’s streets. Twenty-four batteries under the seats provided the carriage with just 4 horsepower and a top speed of 20 mph as it rolled on steel-clad wooden wheels.

Huzzah, no more hand cranks (or cramps). (Courtesy thehenryford.org/)

1914: Detroit Electric 47

The model 47, made by the Anderson Electric Car Company, could start instantly without the hand-cranking its combustion-driven cousins required. Thomas Edison piloted one of these, as did Henry Ford’s wife. The car promised a respectable 80 miles of range per charge.

Ford did it first. (Courtesy Ford UK/)

1967: Ford Comuta

The first gas-free Mustang may have debuted in 2019, but Ford’s earlier EV was cuter: a 7-foot-long conveyance that could reach a maximum speed of 40 mph, travel for 40 miles per charge, and seat a family of four (snugly). Power came from four 12-volt lead-acid packs.

This retro-looking model won big on the market. (Courtesy historicvehicle.org/)

1970s: The Sebring-Vanguard

The cheese-block-shaped two-seater held the title of most produced electric vehicle in American history for four decades. It housed eight 6-volt golf-cart batteries, but with its lightweight frame, it could run for some 35 miles after one serving of electrons from the grid.

The EV1 was only available for leasing. (Stephen Kim/Getty Images/)

1996: GM EV1

General Motors envisioned its EV1 as a regular commuter car, and not just a niche option. To offset the heft of its lead-acid power units, the automaker constructed it with plastic body panels and an aluminum frame. GM made only about 1,100, which customers had to lease.

Before the Model S came the Roadster. (Courtesy Tesla/)

2008: Tesla Roadster

This sleek two-seater kicked off the era of lithium-ion power. The 6,831 cells weighed some 700 pounds but helped push the ride from zero to 60 in four seconds and gifted it with a range of 245 miles. To keep those elements cool, an antifreeze-like solution flowed around them.

The Leaf is the best-selling EV around the globe. (Bloomberg/Getty Images/)

2010: Nissan Leaf

For a quarter the price of the Roadster, the Leaf promised 100 miles from its 192 lithium-ion cells. Nissan styled it to look more like a regular car and less like other green options on the market. Its bulging headlamps managed airflow, limiting wind noise in the absence of engine sounds.

Now we're getting to the good stuff: planet-friendly pickups. (Courtesy Rivian/)

2018: Rivian R1T and R1S

This pickup and SUV (not shown) both use the same modular, skateboard-like chassis; it holds the vehicles’ four motors, shielded batteries, and power-management system. The configuration allows the freedom to include features such as a mobile kitchen, for camping.

This story appears in the Spring 2020, Origins issue of Popular Science.

0 notes

Text

CANSOFCOM: Next Generation Fighting Vehicle – DEW Engineering Teams with Supacat

by Greg Burton, DEW Engineering

In July 2019, the Department of National Defence (DND) announced the intention to procure approximately 55 to 75 Next Generation Fighting Vehicles (NGFV) to replace the existing High Mobility Multipurpose Wheeled Vehicles (HMMWV). The HMMWV are used by the Canadian Special Operations Forces Command (CANSOFCOM) for expeditionary operations.

Formal industry engagement commenced with a Letter of Interest (LOI) and Request for Information (RFI) about the High Level Mandatory Requirements (HLMR) that had been developed for the new NGFV. The HLMR categories included survivability, lethality, mobility, electrical architecture, durability and sustainability, transportability, interoperability and reliability.

To augment the information requested in the RFI, a voluntary Industry Vehicle Demonstration was offered for industry to present their vehicles in an interactive environment with DND. Vehicles participating in the demonstration were expected to best meet the HLMR, being mature and of high technology readiness.

The demonstration took place at Canadian Forces Base Petawawa, Ontario between October and November. Information gleaned during this industry engagement should enable DND to refine and finalize requirements and support concepts, and complete definition activities sooner than planned, accelerating the schedule for delivery to the troops.

DEW Engineering and Development (DEW) of Ottawa, Ontario and Miramichi, New Brunswick has been following the NGFV program since its inception in the early 2010s. DEW has a long history of successfully bidding on Canadian armoured and logistics vehicle programs, either as prime or as team member.

Previous DEW work on armoured vehicles includes the Armoured Vehicle General Purpose (AVGP) Depot Level Inspection and Repair (DLIR), the Leopard 1 Thermal Weapon Sight and turret rebuild, the M113 Life Extension and the Wheeled Light Armoured Vehicle (LAV) Life Extension.

Logistics truck completions include the Medium Logistics Vehicle Wheeled (MLVW), the Light Support Vehicle Wheeled (LSVW), and most recently, the Medium Support Vehicle System (MSVS) Militarized Commercial-Off-The-Shelf (MilCOTS).

DEW also has a long history of developing, testing and manufacturing ballistic and blast armour for armoured and logistics vehicles. Virtually every legacy vehicle type in the Canadian Army has been equipped with DEW armour since 1994.

Today, DEW is the largest manufacturer of composite armour in North America, supplying armour to General Dynamics Land Systems and General Dynamics Land Systems – Canada for all US Army Stryker vehicles, RG31 Mine Resistant Ambush Protected (MRAP) vehicles, and other international customers. DEW also supplies all door armour to the Ford Motor Company for its pursuit rated police cars in North America.

DEW armour has saved the lives of countless Canadian, US and allied soldiers and police officers. With this responsibility in mind, DEW President, Ian Marsh said, “We looked for a partner for the NGFV program that had a history of designing, building and delivering superior Special Forces vehicles. In Supacat, from Devon, England we found the right firm.” Supacat’s High Mobility Transporter (HMT) is a world class expeditionary vehicle with exceptional off road performance. In particular, its air bag suspension provides a very stable firing platform, and significantly lowers user fatigue, enabling operators to arrive ‘fit to fight’ at their objective.

Since the early 1980s, Supacat has designed a family of modular, high mobility vehicles that can be tailored to meet customer requirements. Over 1000 Supacat vehicles have been procured by the world’s premier Special Forces including the UK, USA, Australia, Denmark, New Zealand and Norway. Director and Head of Supacat, Phil Applegarth says, “The HMT is often quoted as the Special Forces vehicle of choice and is in service with four of the Five Eyes nations.” Indeed, Supacat has been following the Canadian NGFV program, and is keen to close the Five Eyes interoperability loop.

The name High Mobility Transporter may sound innocuous, but its key missions are Direct Action in support of Counter Terrorism, High Value Task operations and conventional warfare. The HMT is designed to transport personnel and equipment into operational zones, including directly onto objectives and to support the exit of other assets. The HMT is robust and well-protected, enabling long range and enhanced mission duration, highlighting the payload and self-sustainability of the patrol. It provides the crew with various options for engaging adversaries without dismounting from the protection of the vehicle.

For the NGFV program, the DEW Supacat team will offer the new HMT Extenda Mk2, which was unveiled during the DSEI 2019 trade show in London, England. This vehicle has the unique feature of being convertible between 4x4 and 6x6 within hours, by adding or removing a 3rd axle module. This capability offers users with incredible flexibility to reconfigure the vehicle to meet different operational requirements and environments.

The HMT can be fitted with NATO Generic Vehicle Architecture to enable the integration of a wide variety of mission systems, including Remote Weapon System, Intelligence Reconnaissance and Surveillance systems, and C4 systems. It is also a superb joint fires effects vehicle.

Of course, the HMT is air portable and has been certified by a number of user nations with different aircraft. Unlike many other military vehicles, the HMT can meet the homologation standards, allowing it to be driven on all roads without restriction which reduces logistics burden and cost. Because of its modularity, the users can select between open or closed cabs, different levels of protection, seating layouts and payload configurations, not to mention weapon systems.

According to Applegarth, “The HMT is ITAR free, and can be supported by the Supacat global supply network which includes our Canadian teammate DEW Engineering.” Supacat undertook a rigorous program of trials to verify the performance of the HMT Extenda. It successfully completed two 12,500km tours of Australia in 2 weeks in order to verify reliability and performance over long distances.

“The innovations found in the HMT Extenda deliver increased capability, payload and performance. In feedback from our users, the vehicle’s performance and capability exceeded their expectations and enabled a wider range of tactical options. Mission success was achieved through enhanced terrain access and protection. They were able to do things they had previously thought were not possible,” said Applegarth. Although the Industry Vehicle Demonstration in Petawawa was not the same as the Australia trials, the HMT Extenda did amply demonstrate its mobility to Canadian troops over a broad sampling of terrains and weather conditions.

DEW’s Marsh said, “I have no doubt there will be stiff competition to win NGFV, but I am confident that the DEW Supacat team have a winning next generation fighting vehicle.”

0 notes

Text

GM Unveils New Lithium-Ion Battery Tech, Vows 400-Mile Cars

General Motors reveals its all-new modular platform and battery system, Ultium, Wednesday, March 4, 2020 at the Design Dome on the GM Tech Center campus in Warren, Michigan. (Photo by Steve Fecht for General Motors)r

General Motors is going electric in a big way. This week the company announced plans for a new battery technology called Ultium that will have more range than Tesla and be used in a broad array of future EVs including an upcoming Cadillac luxury SUV and flagship sedan. GM says the technology uses less hard-to-get, hard-on-miners cobalt, and cell costs should fall below the $100-per-kilowatt-hour level that starts to make EVs more competitive than gasoline-engine cars.

The batteries will be built as rectangular pouches rather than cylindrical cells – more space-efficient – that can be stacked horizontally and vertically. GM promises 19 battery and drive unit configurations initially for affordable cars, luxury cars, SUVs and pickups. GM and partner LG Chem are scheduled to break ground in the next three months on a $2 billion plant in Lordstown, Ohio, that could create more than 1,100 jobs. Sorry, make that “good-paying jobs,” since this is an election year.

General Motors chairman / CEO Mary Barra at the Ultium rollout Wednesday in Michigan at GM’s Design Dome.

GM is spending this week briefing analysts, media, employees, and partners at its Warren, Michigan, Design Dome on its Empire Strikes Back strategy. Since fall, relative-newcomer Tesla tripled in value and is worth more than GM and Ford combined as analysts see Tesla being the best pure-play for people who want to get in on EVs as an investment. “GM is building toward an all-electric future because we believe climate change is real,” said chairman and CEO Marry Barra Wednesday. She pegged GM’s EV investment at $3 billion annually.

One attention-grabber is GM’s claim that its new battery technology will provide a range of 400 miles or more per charge, slightly topping the 390 miles Tesla claims for the Tesla Model S Long Range sedan. (Tesla, for its part, plans to lay out its future EV and battery plans within the next month or so.) GM didn’t go into detail on what size battery pack would accomplish the feat, although you’d obviously need larger packs for larger cars.

Working with LG Chem, GM’s new battery technology uses rectangular pouch cells rather than cylindrical cells. Battery modules will be built in Lordstown, Ohio.

The new battery technology will have configurations from 50 kWh to 200 kWh for cars and SUVs. Performance vehicles will achieve 0-60 mph acceleration of as little as 3 seconds. GM says most will have 400-volt battery packs, and support for Level 2 charging (possible at home with 220 volts) and DC fast charging at up to 200 kW. The truck platform would have 800-volt battery packs and 350 kW fast-charge capability. This would include commercial vehicles.

For both cars and trucks, the pouch cells will allow for even higher energy density and lower centers of gravity. The ability to stacks cells horizontally or vertically is unique in the industry. GM also says battery management is built-in and – compared with the current Chevrolet Bolt – reduces battery pack wiring 80 percent.

GM says the new cells will have “the highest nickel and lowest cobalt content in a large format pouch cell.” It also says its researchers are working to eliminate cobalt as one of the battery components. Currently, cobalt is tough to mine, comes from countries that are not always friendly to the US, and working conditions are said to be unsafe, although there’s considerable discussion about whether that’s because of inherent dangers or because the mining companies don’t treat workers well.

GM’s new battery technology will be called Ultium.

GM plans an extensive rollout of new electric vehicles starting this year. According to GM:

Chevrolet, Cadillac, GMC and Buick will all be launching new EVs starting this year. The next new Chevrolet EV will be a new version of the Bolt EV, launching in late 2020, followed by the 2022 Bolt EUV, launching Summer 2021. The Bolt EUV will be the first vehicle outside of the Cadillac brand to feature Super Cruise, the industry’s first true hands-free driving technology for the highway, which GM will expand to 22 vehicles by 2023, including 10 by next year.

The self-driving, shared EV called the Cruise Origin was shown in concept form in January in San Francisco. Next up to be announced is the Cadillac Lyriq in April. The GMC Hummer EV will be introduced May 20 with production due to begin in fall 2020 at GM’s Detroit-Hamtramck plant, the company’s first plant just for EVs.

GM is staking its massive investment on a big uptick in demand for EVs – whether voluntary, helped by tax incentives, or mandated because of concerns about climate change. GM says:

Third-party forecasters expect U.S. EV volumes to more than double from 2025 to 2030 to about 3 million units on average. GM believes volumes could be materially higher as more EVs are launched in popular segments, charging networks grow and the total cost of ownership to consumers continues to fall.

GM revealed an all-new modular architecture and Ultium batteries at the GM Design Dome in Michigan.

GM is right to be optimistic since there’s pretty much nowhere to go but up for the EV industry. The market last year for electric vehicles was 330,000 in the US out of 17.0 million light vehicles sold, 1.9 percent, and those 48 vehicles include both pure EVs and plug-in hybrids that go 15 to 50 miles on battery before the combustion engine kicks in (but not hybrids like the Toyota Prius).

Pure EVs, 18 models total, accounted for 245,000 sales, or 1.4 percent of the US market. But when Tesla Model 3, Model X, and Model S got done feasting on the market – with no tax credits to offer anymore – what’s left amounted to barely 50,000 sales. Just six pure-EV models managed more than 5,000 sales last year:

Tesla Model 3, 158,925

Tesla Model X, 19,225

Chevrolet Bolt EV, 16,148

Tesla Model S, 14,100

Nissan Leaf, 12,365

Audi e-tron, 5,369

GM had two other electrified vehicles on sale in 2019, the end-of-life Chevrolet Volt PHEV with 4,910 sales and the Cadillac CT6 PHEV with 24 sales. The year before Chevy killed the Volt PHEV, it actually had slightly more sales than the Bolt EV, but demand for plug-ins continues to be soft. Last year the Toyota Prius Prime was the second-best-selling electrified vehicle with 23,630 sales, but the only PHEV with more than 10,000 sales was the Honda Clarity, at 10,728. BMW has the most electrified vehicles, six, with five of them PHEVs.

History has shown that first-to-market status doesn’t always guarantee long-term dominance. Facebook was not the first social media platform. Remember Myspace? In other words, Tesla absolutely dominates the market for EVs today, but this is a long race, not a sprint.

Now read:

EVs Finally Get Some Love from the Most Important JD Power Study

No need to wait for Tesla: the Chevrolet Bolt is excellent (and already shipping)

Tesla Teardown Scares Competitors: ‘We Cannot Do This’

from ExtremeTechExtremeTech https://www.extremetech.com/extreme/307027-gm-unveils-new-lithium-ion-battery-tech-vows-400-mile-cars from Blogger http://componentplanet.blogspot.com/2020/03/gm-unveils-new-lithium-ion-battery-tech.html

0 notes

Text

Back to the 50’s. Action From America’s Largest Street Rod Show.

There is no angel hair at Back To The 50’s. No velvet ropes and stanchions. No carpeted display areas or mirrors. Nobody goes home with a 3-foot-long cardboard check for $10,000 in prize money. In fact, there are no awards, trophies, plaques, or prizes at Back To The 50’s. There are street rods and street rodders—more of them than at any other enclosed event in America. In 2018, approximately 12,000 cars and trucks rolled into the Minnesota State Fairgrounds for the Minnesota Street Rod Association’s 45th annual party in St. Paul.

All those participants, combined with the commercial vendors, the Sunday swap meet crowd, and all those spectators, guarantee that for three days every summer, Back To The 50’s is basically the third largest city in Minnesota.

Back To The 50’s is not strictly limited to street rods. The show also welcomes customs, classic trucks, sports cars, Gassers, street cruisers, exotic cars, and a few that defy categories—as long as they are of 1964 and earlier vintage.

The 1964 cars and trucks that make up the newest participating vehicles were only 10 years old when the MSRA held the very first Back To The 50’s show back in 1974 in a shopping center parking lot. That premiere event, with approximately 150 vehicles, is a familiar part of Minnesota street rodding history now. It didn’t take long for the show to outgrow its original venue.

STREET RODDER was there in 2018, as we are every year, to take in all the fun and enjoy the cars, in addition to finding 10 outstanding rides for the Painless Performance Products/STREET RODDER Top 100 program and one Blue Oval vehicle for the Best Ford In A Ford program. Back To The 50’s is also a popular location for the STREET RODDER Road Tour every year.

Sunday Swap Meet The swap meet is a one-day-only part of Back To The 50’s. For sellers, it’s a chance to unload some unfinished—or unstarted—project cars. For buyers, it’s a chance to find parts for a homebuilt project, or to find something they didn’t know they were looking for until they saw it on a table or on a trailer. For us, it’s a chance to see potential rods of the future. We hope the raw material in these photos will be finished cars someday, displayed at shows and driven on the street.

See much more swap meet treasure at hotrod.com/articles/back-50s-2018-swap-meet.

STREET RODDER Best Ford In A Ford A Coyote-Powered, Homebuilt, Factory Five 1933 Roadster

When it comes to choosing Ford power for his street rod, Greg Root, our Best Ford in a Ford winner from Back To The 50’s, didn’t need persuading. Greg, from Lake Elmo, Minnesota, worked for Ford and Roush building prototype vehicles. His Factory Five 1933 Ford replica is the most recent of many Ford-powered FoMoCo vehicles he’s built and driven.

We encountered Greg’s Coyote-running roadster next to the Ford Performance Parts rig. With its pearl white ’glass body, contemporary wheel and tire combination, race-inspired cockpit, and modular engine, it’s a modern interpretation of a classic hot rod.

Greg likes Factory Five’s offerings and originally intended to build a 427 Cobra reproduction. Instead, he decided on the 1933 Hot Rod, which has a little more room inside. He said the styling and the fact that you don’t see many of them around, is part of the appeal.

Along with the body, Greg used Factory Five’s chassis setup, featuring a tubular frame, A-arm and coilover independent front suspension, and three-link rear suspension with coilovers. The Ford 8.8-inch rear with 3.86:1 gears and brakes came from a 1989 Mustang. Wide 255- and 305-series ZR-rated Nitto tires roll on 18- and 20-inch Super Nova 5 wheels from American Racing—complementing the contemporary classic theme of the roadster.

The interior features Factory Five’s race bucket seats and banjo-style steering wheel on an ididit column. Greg built the center console and dash and added the Racepak digital instrument display, push-button ignition switch, Vintage Air controls and louvers, USB ports, and Pioneer Mixtrax AV receiver.

Greg pulled the Ford 5.0L Coyote and six-speed from a 2014 Mustang. Troy Knutson fabricated custom mounts to perch the engine and transmission on the Factory Five ’rails, and DP Performance used SCT Performance tuning hardware to get the engine running perfectly. An active online community of Factory Five owners helped with suggestions when questions came up.

Greg enjoys showing and driving the roadster—but what he enjoys even more is turning wrenches in his basement shop. His mind is already onto the next project car. Maybe a GT40. Maybe with a Coyote engine. Definitely Ford in a Ford.

See more of Greg Root’s Factory Five 1933 Ford at hotrod.com/articles/2018-back-50s-best-ford-ford.

Painless Performance Products Presents STREET RODDER Top 100 Tech Tip: EFI Injectors If you have acquired an engine that has sat for 6 months or longer, be sure to remove the injectors and have them tested before attempting to start the engine, as the reformulated fuels of today will cause the injector solenoids to stick closed.

1932 Ford Roadster | Dennis Van Kleek & Kay Larson | Vadnais Heights, MN

Dennis Van Kleek and Kay Larson wanted a timeless, unique Deuce, and this Dearborn Deuce roadster, built by Jim Petrykowski at Metal Fab, is it. Tangerine Pearl paint, dark tan custom upholstery, and Budnik wheels enhance the appearance. A carbed 351W engine supplies power. The car has covered 24,000 miles across 19 states. Vintage Air and Classic Instruments add to the success of those road trips.

1950 Mercury coupe | Les & Sue Severin | Hutchinson, MN

Les Severin found his Merc in a junkyard 36 years ago. Inspired by the famous Bettencourt Merc from the ’50s, its custom cues include the healthy chop, radiused corners, 1951 Merc front bumper, 1953 Kaiser rear bumper guard, 1951 Kaiser grille, vinyl tuck ’n’ roll, and wide whites on Wheelsmith wheels. The paint is Oriental Blue paint over white. The engine is a 4V 455 Olds.

1941 Willys coupe | Mike Hughes | Faribault, MN

A Willys Gasser is the car everyone wants, Mike Hughes says. His is packed with a blown 410ci Hemi. Mickey Thompson rubber rolls on 15-inch five-spokes. The vintage drag race interior features fiberglass buckets, a Grant steering wheel, and Stewart-Warner gauges. Creative Metal and Vescio’s Restoration participated in the project. House Of Kolor provided the Candy Red paint.

1947 Chevy Fleetline | Wayne & Pat Hassemer | Bloomer, WI

Wayne Hassemer bought three rusting Chevys to create this metallic green beauty. Custom mods include Frenched headlights, V-butted windshield, shaved sheetmetal, and a relocated “foot scraper” plate. A Demon carb tops the Chevy 406 small-block. Interior features VDO gauges, a Premier stereo, and lot of Ultraleather. The 15-year build was interrupted by family life, but now it’s driving time.

1949 International pickup | Joseph Ackerley | Forest Lake, MN

This International sat in a Minnesota body shop for 20 years before being built in Joseph Ackerley’s home shop. He shaved the door handles and driprails, welded the hood into a single piece, and added a Chevy box. A 383 stroker Chevy is fed by a Demon carburetor. Tan leather and vinyl complements all that Viper Red paint. VDO gauges and a Pioneer audio system are cab upgrades.

1947 Cadillac convertible | Jack DeJoy | Prior Lake, MN

Jack DeJoy built the 1947 Cadillac he had always wanted with a pancaked hood, filled cowl, shaved handles, and bright paint. The owner-designed interior wears leather-covered seats facing a 1949 Cadillac dash. It’s a Cadillac underhood, too, with a 500ci injected engine. Colorado Custom wheels are wrapped in Hankook radials. Impressive work from this 80-year-old street rodder.

1959 Chevy Impala | Kyle Severin | Alexandria, MN

The Crown Sapphire 1959 Impala was stock and partially restored before Kyle Severin rebuilt it as a ’60s-inspired restomod cruiser. The original-looking interior is updated with Vintage Air A/C, Dakota Digital gauges, and modern audio components. The tri-power 409 is packed with plenty of hi-po internals. Chrome reverse Wheelsmith wheels are matched with Diamond Back whitewalls.

1932 Ford pickup | Mac McCullough | Wayzata, MN

Mac McCullough’s truck was original, numbers-matching, rust-free, and had been apart for years when he began building it into a ’60s-style hot rod. A Corvette 327/365 engine with camel hump heads features Porter mufflers to maintain the vintage-style Mac wanted. The interior is distinguished by a pleated vinyl–covered bench, an original 1932 steering wheel, and Classic Instruments gauges.

1964 Chevy C10 | Stack Calhoun | Forest Lake, MN

Nuff Sedd Customs honored Stack Calhoun’s request to build something “timeless” and “classy;” ’70s-era C10 olive green paint and cherry bedwood add to the exterior appeal. Two-tone pleated vinyl covers the bench seat. A 450hp 355 Chevy moves the C10 down the road at 2,000 rpm at 75 mph with the A/C and stereo blasting. “It sounds like a muscle car but drives like a Cadillac,” Stack says.

1934 Ford Fordor Sedan | Gary & Lisa Beskau | Hastings, MN

Gary and Lisa Beskau commissioned their son-in-law Greg Spakow of Master Blastings, to undertake the frame-off rebuild of their Fordor. Body mods include one-piece front fenders and running boards, filled roof, and hood louvers—and Cinnamon Candy paint over copper. Suede and leather bench seats fill the interior. A 450hp Chevy 350 is dressed up with an Edelbrock air cleaner and valve covers.

The post Back to the 50’s. Action From America’s Largest Street Rod Show. appeared first on Hot Rod Network.

from Hot Rod Network https://www.hotrod.com/articles/back-50s-americas-largest-street-rod-show/ via IFTTT

0 notes

Photo

That Time Forgot: GM Ultralite

I kind of like this new life of mine, being able to pursue my own interests and stuff. However, I feel it is a disservice to keep this blog inactive, hence why I’ve decided to put this post up to show that this blog is not dead. Anyway, enough talk about this, and let’s talk about what you’re really here for: to talk about this car.

“100 mpg in the ‘90s? Impossible.” Is what many people will say... but they’ve definitely not seen this car before. Let’s talk about that.

This is the General Motors Ultralite, a car from 1992 that still looks futuristic... even today. Designed by Burt Rutan, Jim Lutz, Steve Small, Bill Rohlfing and Jim Bieck, the Ultralite was designed as a four-seat car that could comfortably carry all four passengers, have adequate performance and produce low emissions and astonishingly high miles per gallon.

First introduced at the 1992 Chicago Auto Show, the Ultralite was not just your normal concept car; it was actually fully functional. But then again, pretty much all of GM’s concept cars of that time were functional. This car featured a RR layout; or for those who don’t know, rear-engined, rear-wheel drive. A ten-minute promotional video was also produced.

The body of the Ultralite was made of carbon fiber and built by Scaled Composites; the entire body only weighed 420 pounds (191 kg)! With the body on, the car weighed about 1400 pounds (635 kg).

Performance of the Ultralite was expected to match or better that of GM’s quintessential compact sedan, the Chevrolet Lumina. As the body itself was so light, the Ultralite didn’t need too big a power plant to power it. The rear-engined car was powered by a 1.5L inline-3 two-stroke engine producing 111 horsepower, mated to a Saturn 4-speed automatic transmission; GM claimed top speeds of up to 135 mph (217 km/h). It also had a claimed 0-60 time of about 8 seconds, which, if you think about it, is pretty darned good for an engine of this size...

The Ultralite’s engine was placed in the rear in what was termed a “power pod” configuration, which was basically GM’s term for “removable engine”; this reminds me of the IAD Alien which had a very similar concept. This “power pod” had a number of advantages, including easier service and the added modularity of fitting different types of power plants.

The shape of the Ultralite was highly reminiscent of that of the older Ford Probe concepts designed by Ghia.

The interior looked somewhat futuristic and honestly quite nice, but the best part of the Ultralite’s appearance... were those doors.

Yep, that’s right; the Ultralite sported gullwing doors. It also... had no B-pillar.

Regardless, the Ultralite was probably one of the most futuristic cars ever conceived. Featuring fiber-optic headlamps and LED taillamps, the car also featured an airbag suspension on all four wheels, allowing it to ride high or low depending on what speed the car was going at. It also had an astonishingly low drag coefficient of 0.19, far lower than most cars of the time.

While the doors were (and still are) quite impressive, quite possibly one of the most impressive things about the Ultralite was its fuel economy. The car (being fully functional) was actually tested and rated by the EPA, clocking in a staggering 88 mpg; GM claimed the car could clock in 100 mpg if the car was driven at a sustained 50 mph (80 km/h) cruise.

GM did consider putting the Ultralite into production, although with a body made of carbon fiber it would have never been affordable. Additionally, with California’s zero-emission vehicle mandate looming, GM made a decision to scrap the Ultralite and produce the EV1 (above) instead. And we all know how that went...

However, not all was lost. Now, with the introduction of ever-tighter Corporate Average Fuel Economy standards, carbon fiber has become almost mainstream and smaller and smaller engines have become the norm to meet these strict standards, something the Ultralite was able to achieve... twenty years before the competition.

A total of two Ultralites were produced. Normally, I believe they sit amongst a sea of other innovative cars at the GM Heritage Center, but one Ultralite currently sits proudly amongst a sea of iconic movie cars in the Hollywood Dream Machines: Vehicles of Science Fiction and Fantasy exhibition at the Petersen Automotive Museum. Oh, speaking of movies... we’ll get to that bit now.

Due to its unique and futuristic shape, the Ultralite has been used in various science fiction movie productions, usually representing a car of the future. It had a number of big breaks in a number of science fiction films, all of which will be detailed below.

The most notable of the Ultralite’s appearances was in 1993, when it appeared in the film Demolition Man, alongside some seventeen other GM concept vehicles. Representing a 2042 Chevrolet police vehicle, this Ultralite was driven throughout the film and played a highly prominent role.

Twenty fiberglass replicas of the Ultralite were produced, which were used throughout the film as either police cars or civilian cars, recognizable by whether they have the “siren dome” or not; civilian Ultralites usually played minor background roles. There exists a rather grainy picture showing three of these replicas. Whether the two actual carbon fiber Ultralites took part in the filming is unclear, although it seems unlikely.

The Ultralite was seen again in the old television series seaQuest DSV, albeit only very briefly, in the episode The Fear That Follows which aired in 1994.

The Ultralite was seen again in the 1999 film Bicentennial Man starring Robin Williams, although again very briefly. Sure, it’s a cool car that’s in the movie, but there’s probably other reasons as to why people don’t remember this film...

Finally, a police Ultralite appeared in the movie A.I. Artificial Intelligence starring Haley Joel Osment. This was the last of its known appearances... well, according to IMCDb anyway.

It also appears that at least one of these fiberglass replicas was auctioned off by Warner Bros. around 2012, although with some generic police livery; as you can see, it looks pretty worse for wear...

Okay, now that I’ve gotten that out of the way, let’s talk about the reason why you’re here: the history of the casting.

This casting was introduced in 1993 in the Demolition Man series, alongside eight other cars that appeared in the movie: these were the Oldsmobile Aurora, Olds 442 W-30, GM Lean Machine, Corvette Stingray III, Pontiac Salsa, Pontiac Banshee, Buick Wildcat and the Chevrolet ACC Camaro (’93 Camaro), intended to represent the Chevrolet California IROC Camaro Concept. The designer of this casting is not known with any certainty, although I suspect it was done by Larry Wood. The Hot Wheels version of the Ultralite depicts the famous police Ultralite as seen in the movie, as evidenced by the siren dome up top.

Like all other Demolition Man castings, the Ultralite was packaged in a box containing a Cryo-Cube (essentially a Park’n Plates box with a picture of the real car instead of a license plate). The windshields and doors of this casting are molded into the body, and as such, are completely opaque; as a result, this car has no interior.

The rear replicates the rear of the real car somewhat well, although the wing up top seems a bit high and the rear “vent” seems a little bit too big as well compared to the real car.

A picture of the real Ultralite’s rear is shown above.

Early versions will say "‘93 WARNER” instead of “1993 MATTEL, INC”; I presume the license with Warner Bros. had expired, so they just scrubbed off the Warner licensing information and put their own on. Something else interesting to note is that this casting has a practically centered center of gravity; as it has a plastic base, this casting would be thought to be quite light, but it is in no way light. As the body is one huge hunk of metal (again, the windows are opaque), the Ultralite is supremely heavy, with all the weight concentrated around the center of the car. This theoretically makes the car better for downhill races, although I would seriously doubt the car’s ability to clear a loop.