#Five Axis CNC Machine

Explore tagged Tumblr posts

Text

🚀Unlock new heights in manufacturing! 👀 Come and see how CNC Machining China can meticulously craft and customize your dream parts! 🛠️ From Custom CNC Machining to 5 Axis CNC Machining Services, we can do it all! 🏭 Walk into our CNC Machining Shops and witness the miracle of high-precision and high-efficiency machining! ✨ Whether it is complex surfaces or precision components, we can handle them one by one! 💪 Come and feel the powerful strength of Made in China! #CNCMachining #CustomMachining #FiveAxisMachining

#CNC laser Cutting Machine#CNC lathe Machine#CNC Machine Near me#Desktop CNC Milling Machine#Five Axis CNC Machine#Operator CNC Machine#CNC Machine definition#CNC Machine meaning#CNC Machine Price#CNC Machining Services#Explain CNC Machine#Small CNC Machine

0 notes

Text

GD prototyping Precision impeller CNC machining,5 axis CNC machines can improve our production efficiency and apability, especially for high precsion plastic and metal parts.

#cncmachining#cnc machining services#cnc milling services#5 axis machining#five axis cnc machining#impeller machining#parts machining

1 note

·

View note

Text

How to Choose The Right CNC Machining Service Provider

I believe that every company that is starting a business or that needs to find CNC machining will have such questions. We all know that finding a reputable CNC machining company can be challenging as mistakes can lead to loss, unforeseen complications, mistakes, and unfinished tasks. On the other hand, the right choice will increase your productivity and reduce production costs and project turnaround times. When looking for CNC machining services, you want to make sure they have a solid reputation and experience with the type of product machining you want. The reason for such doubts, I think, is related to the following reasons. This blog will explore the tips you need to consider when choosing a CNC machining service provider.

1. Processing ability We all know that when you need to do a mold project fabrication, it is crucial to first make sure that the company you want to place your mold order with has the capabilities your project requires. Most will tell you that to understand what they do you need to consider the technology and systems they offer. It is true, but when your company needs five-axis CNC machining, if there is a three-axis company that uses three-axis production technology to achieve the same accuracy as five-axis machining, will you choose or not? Know that a large company with hundreds of machines running will double your money when the five-axis machine starts spinning. In the current state of the economy, reducing your cost of capital is key. At present, the general CNC processing enterprises have at least a dozen production machines, which can fully meet your production needs and reduce your costs. All you have to do is wait a few more days.

2. Focus on price and long-term value Most people often use price as the deciding factor when choosing a CNC machining company. There's nothing wrong with that in itself, but sometimes you'll find that low-priced companies don't guarantee high-quality service. When you send out a processing order, you invest in the time and overall product needed to complete the project. You will have to waste time and money finding another CNC machining company to fix the poor-quality product on your first job. Here, my suggestion is to cooperate with a processing company with relatively long production experience. Generally speaking, the old-fashioned machining technology companies do a good job of communication services in this area. You can communicate the manufacturing status of your parts in real-time, whether they are CNC-turned service or CNC-milled service.

It is important to note that CNC machining equipment is a very expensive investment for any company. The production cost of parts products is mainly related to the raw materials used, tolerance, complexity, finishing, and other factors, so some people say that "the cost of using high-quality CNC machine tools is usually reflected in the customer's pricing, but the product quality is guaranteed, which is high Qualitative." This sentence is true in itself, but it is still a bit inappropriate.

3. Check the number of equipment and the latest equipment When your project requires high precision, you can send an inquiry to the company you intend to manufacture the parts, whether there is enough new equipment to meet your product design and style manufacturing needs, of course, you need to add new equipment and experienced excellent Operators will greatly shorten your production cycle.

Final thoughts! Above are some important tips when choosing a CNC machining service provider. Other things to check are certifications and whether they offer excellent quality control. Finally, don't forget to ask about all the services they offer, after all some sites have multiple types of services and they don't list them all. If you like this article, follow me. The next article will take you to some CNC machining service companies that I think are better.

#CNC machining company#CNC machining#CNC machining service provider#five-axis CNC machining#CNC-turned service#CNC-milled service#CNC machining service

1 note

·

View note

Text

EXPLORING THE 5 COOL PARTNER SELLER ELECTRONICS PRODUCTS-Part1

Exploring the 5 Cool Partner Seller Electronics Products

Prologue

Are you an electronics enthusiast looking to expand your electronics project repertoire? Want to take your skills to the next level by exploring new and exciting products? Look no further than our list of five cool electronics products from partner sellers!

Whether you’re interested in building your own smart home devices, experimenting with sensors, or creating your own robot, these products are sure to inspire you. They cover a lot of application areas, from loop detectors used to monitor vehicle count in parking garages to Arduino CNC shields used in CNC machines, from simple pulse sensors used to detect cardiovascular pulse signals from fingertip to RGB LED panel light used in smart home, these products are unique, compact, and functional. Not only are these products fun to build and use but they’re also designed to help you learn new skills and techniques along the way.

What’s more, these products all come from trusted partner sellers who are committed to developing high-quality products. They’re happy to provide technical support for customers who have questions, so you can be sure you’re getting the best in electronics.

So get ready to dive into the world of electronics and explore these five cool partner seller products. You’re sure to find something that piques your interest and takes your own electronics projects to the next level.

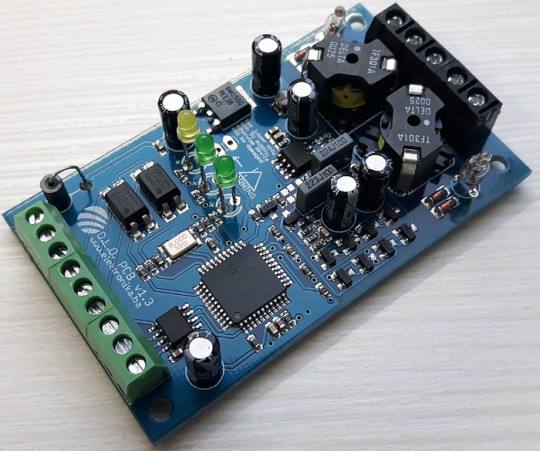

Inductive Loop Vehicle Detector by Elektronika-ba

Whether you need to monitor occupancy and count vehicles in parking garages, control vehicle access at door and barrier controls, or facilitate traffic light installations and traffic controllers, the inductive loop detector is the perfect solution. It can even detect the direction and speed of vehicle traffic, making it an invaluable tool for a variety of traffic-related applications. In addition, this device can function as a stand-alone speed trap and can be easily interfaced with Arduino.

We can also provide a pre-programmed PIC chip to meet your project requirements.

Specifications

Number of operating modes: 4

Tuning: Automatic

Detection type: Presence/Pulse

Presence time: Adjustable in 3 steps

Pulse duration: 250 ms / 500 ms

Signal filtering: Adjustable in 2 steps (NORMAL, HIGH)

Loop inductance: 20 uH — 1000 uH

Frequency range: 20 kHz — 145 kHz

Frequency selection: 2 combinations (LOW, HIGH)

Sensitivity: Maximum 0.0025% Δf/f, adjustable in 8 steps

Detection speed: 10 ms by default, adjustable

Start-up time: ~ 1 second per channel (or longer if the frequency is not stable)

Temperature range: -35°C — 120°C

Sensor protection: Galvanic isolation + gas discharge tube for lightning protection

Don’t settle for less — click here to learn more about the Inductive Loop Vehicle Detector and experience the compact, yet cool detector!

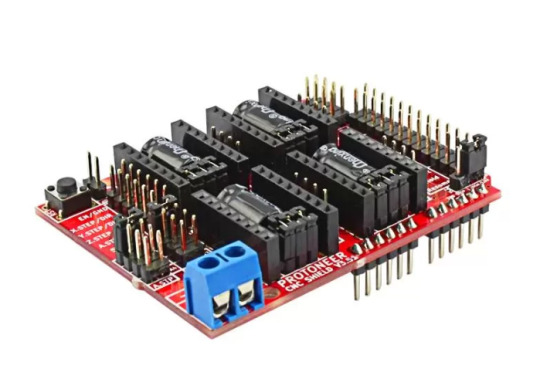

Arduino CNC Shield V3.51 by Protoneer

Designed by Protoneer, this kit is packed with features to ensure high precision control of your stepper motors, you can use it to easily build small CNC routers, DIY laser cutters, 3D printers, or any project that requires precise stepper motor control.

Our latest version 3.51 includes several enhancements to make assembly and installation even easier. We’ve added end-stop and probe signal filtering circuitry to eliminate false triggers and allow the use of unshielded cables for end-stops and probes. We’ve also increased the size of the solder pads for easier assembly and updated the probe pin labels to make installation a breeze.

With the Arduino CNC Shield Kit, you’ll have everything you need to build your own CNC router or mill with ease.

Features

Includes Noise Filers on all end stops and the probing pin. (New in V3.51)

GRBL 0.9 compatible. (Open source firmware that runs on an Arduino UNO that turns G-code commands into stepper signals https://github.com/grbl/grbl)

4-Axis support (X, Y, Z, A-Can duplicate X, Y, Z or do a full 4th axis with custom firmware using pins A4 and A3)

2 x End stops for each axis (6 in total)

Coolant enable

Uses removable Pololu A4988 compatible stepper drivers. (A4988, DRV8825 and others)(Not Included)

Jumpers to set the Micro-Stepping for the stepper drivers. (Some drivers like the DRV8825 can do up to 1/32 micro-stepping )

Compact design.

Stepper Motors can be connected with 4-pin molex connectors or soldered in place.

Runs on 12–36V DC. (At the moment only the Pololu DRV8825 drivers can handle up to 36V so please consider the operation voltage when powering the board.)

Don’t wait — click here to see more about the Arduino CNC Shield V3.51 and start your next project today!

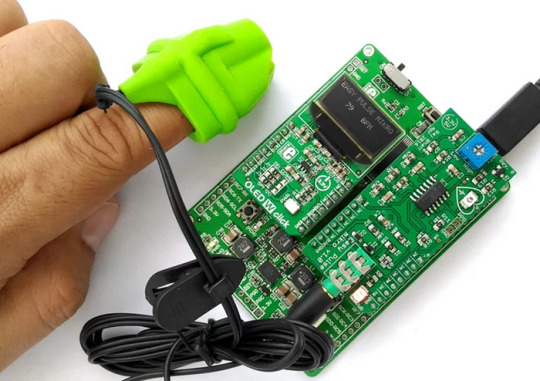

Easy Pulse Mikro by Embedded Lab

What’s more, the Easy Pulse Mikro is designed in the convenient Mikro bus form factor, making it easy to integrate with a wide range of mikroElektronika’s development boards. With all necessary instrumentation and amplification built right in, this powerful sensor provides a clean and precise analog PPG waveform output that’s routed to the AN pin of the mikroBus connector.

Whether you’re a hobbyist, student, or professional developer, the Easy Pulse mikro is the perfect tool for monitoring heart rate and other vital signs.

Click here to see more about the Easy Pulse mikro.

Features

Compatible with mikroBus socket.

Filtered and amplified analog PPG signal output

On-board potentiometer for adjusting amplifier gain, if needed (rotate clock-wise for increasing gain)

Onboard LED for indicating heartbeat. It flashes synchronously with the heartbeat on detecting the pulse from the fingertip.

2 notes

·

View notes

Text

What new uses are there for the five-axis?#cncmachine #cncmachining #cnc #machine #cncmachinist #cncmillingmachine #cncrouter #cncporn #cncmill #cncmilling #cncplasma #cnclathe #cnccutting #cnclaser #cnctools #machinist #tools #cncprogramming #mold #components #machinetools #jinsucnc #5axis #cncoperator #factory #machining #aluminum #instagram #fyp

#cnc milling#cncmachine#cncmachine tools#cncmachining#cncmill#cncrouter#cnctool#machine#cnc lathe#tool

6 notes

·

View notes

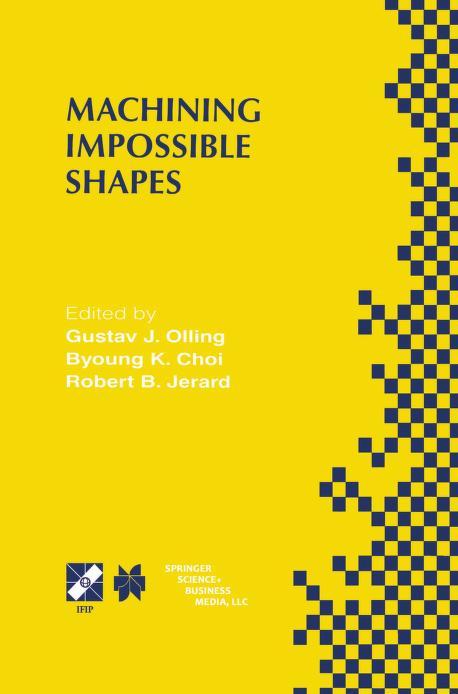

Photo

This book is essential reading for researchers and practitioners in computer science, technical managers and software specialists This book provides a comprehensive treatment of the subject of sculptured surface machining in terms of user needs, CAM software solutions and theoretical research results and issues. State-of-the-art capabilities of the best commercial CAM systems are compared to user needs, and advanced academic research is presented. Among the topics covered are the following: Generative NC for dies and molds; 5-axis machining of impellers; Cutting simulation and NC verification; Virtual machining; CAPP for die and mold machining; NURBS-based CNC interpolators

Cutting Molds/Dies from Scan data

Experiences from a Quantum Leap Improvement in Turbine Manufacturing

A Generative Approach for Die Pattern Machining

Geometric Contributions to 3-Axis Milling of Sculptured Surfaces

Efficiency of Multi-Axis NC Machining of Sculptured Part Surfaces

Best-Fit of Sculptured Surfaces

Point-based Geometric Modelling

Virtual Machining and the Manufacturing Model

Virtual CNC with Performance Error Modeling

Fast Simulation of Sculptured Surface Milling with 3-Axis NC Machine

Simulation of Ball-nose End Milling Operations �� Selection of Geometric Resolution Parameters

Machining Process Modeling for Intelligent Rough Machining of Sculptured Parts

Bridging the Gap Between Tool Path Generation for Sculptured Surface Machining and Computer Aided Process Modelling Techniques

Automatic Five-Axis CNC Feedrate Selection via Discrete Mechanistic, Geometric, and Machine Model Integration

Milling Simulation with an adaptive Strategy

Deformed Swept Volume Analysis to NC Machining Simulation with Cutter Deflection

Segmentation and Surface Fitting in Reverse Engineering

Surface Reconstruction from Point Clouds

Reverse Engineering Employing a Wrap-Around SurfaceTriangle Set

Manufacturability of Reverse Engineered CAD-models : a case study

https://archive.org/details/springer_10.1007-978-0-387-35392-0

3 notes

·

View notes

Text

Precision Engineering with 5 Axis Machining in India Trusted Manufacturers & Suppliers

In the era of advanced manufacturing, 5 Axis Machining India is transforming industries with its precision, efficiency, and ability to create complex components. As leading 5 Axis Machining Manufacturers, Sinnar Ureplas specializes in high-quality machining solutions, catering to aerospace, automotive, medical, and industrial sectors. Our state-of-the-art CNC technology ensures superior accuracy, reduced production time, and cost-effective solutions.

As trusted 5 Axis Machining Suppliers, we provide intricate 5 Axis Machining India, ensuring durability and performance. Read on to learn about the benefits, applications, and why Sinnar Ureplas is the preferred partner for precision machining.

Precision Engineering with 5 Axis Machining in India – Trusted Manufacturers & Suppliers

Manufacturing industries are evolving rapidly, demanding higher precision, faster production, and cost-effective solutions. 5 Axis Machining in India has emerged as a game-changer, allowing manufacturers to produce highly intricate parts with exceptional accuracy. Sinnar Ureplas, a trusted name among 5 Axis Machining Manufacturers, offers advanced machining solutions that cater to industries requiring high-quality precision components.

What is 5 Axis Machining?

5 Axis Machining refers to CNC (Computer Numerical Control) machining that operates along five different axes simultaneously. Unlike traditional 3-axis machines, which move only along the X, Y, and Z axes, 5 Axis Machines offer two additional rotational movements, allowing for intricate shaping and detailing. This multi-directional capability enhances flexibility, precision, and efficiency in the production of complex components.

Key Benefits of 5 Axis Machining

✅ Higher Precision & AccuracyWith advanced movement control, 5 Axis Machining ensures extreme precision, reducing errors and eliminating the need for multiple setups.

✅ Enhanced Production SpeedUnlike traditional machining, 5 Axis Machining Manufacturers reduce processing time by cutting materials from multiple angles in a single operation.

✅ Complex Component ManufacturingIndustries such as aerospace, medical, and automotive rely on 5 Axis Machining Suppliers for creating intricate parts that require detailed contouring.

✅ Cost-Effective SolutionsBy minimizing material waste and reducing manual intervention, 5 Axis Machining lowers production costs while improving efficiency.

✅ Superior Surface FinishWith fewer tool changes and seamless movement, the final product has a smoother surface finish, eliminating the need for additional polishing.

Process of 5 Axis Machining at Sinnar Ureplas

1️⃣ Client Consultation & Design Analysis – Understanding project requirements and optimizing designs. 2️⃣ Material Selection & Preparation – Choosing the right materials for durability and performance. 3️⃣ CNC Programming & Machine Setup – Ensuring precision cutting and minimal waste. 4️⃣ Machining & Quality Inspection – High-precision manufacturing with rigorous quality checks. 5️⃣ Final Product Delivery – On-time delivery of customized 5 Axis Parts in India.

If you are looking for precision-driven 5 Axis Machining in India, Sinnar Ureplas is your ideal partner. With advanced CNC technology, skilled engineers, and a commitment to quality, we provide machining solutions that exceed industry expectations.

Contact us today to learn more about our 5 Axis Machining Services and get a custom quote!Visit: https://sinnar-ureplas.com/5-axis-machining-manufacturers-suppliers-india.php

Contact: +91 89753 22242

0 notes

Text

5 Axis Water Jet Cutting Machine

In the realm of precision cutting technologies, the 5 axis water jet cutting machine stands out as a versatile and powerful tool. This comprehensive guide will explore the features, benefits, applications, and considerations for purchasing a 5 axis water jet cutting machine.

5 Axis Water Jet Cutting Machine

A 5 axis water jet cutting machine utilizes a high-pressure stream of water, often mixed with an abrasive substance, to cut through various materials. The “5 axis” designation refers to the machine’s ability to move the cutting head along five different axes: X, Y, Z, A, and B. This multi-axis capability allows for intricate and precise cuts on complex geometries.

Unlike other cutting methods, such as laser or plasma cutting, water jet cutting does not generate heat. This means there is no heat-affected zone (HAZ), which can alter the material properties and cause warping or distortion.

Water jet cutting is an environmentally friendly process. It does not produce harmful fumes or gases, and the water used in the process can be recycled. Additionally, the absence of heat means there is no risk of fire or explosion.

Water Jet Cutting Machine Key Features:

High-Pressure Water Jet: Uses a high-pressure stream of water mixed with an abrasive material to cut through materials. The pressure can reach up to 60,000 psi or more.

Versatility: Capable of cutting a variety of materials, including metals, glass, stone, ceramics, composites, and even food products.

Precision Cutting: Provides high accuracy and smooth edges without the need for secondary finishing processes.

Cold Cutting Process: As there is no heat-affected zone, it prevents material warping or changes in material properties due to heat.

Eco-Friendly: Uses water and natural abrasives, making it a cleaner alternative compared to other cutting methods.

User-Friendly Interface: Often equipped with advanced software for easy programming and operation, allowing for the import of CAD/CAM files.

Applications of a 5 Axis Water Jet Cutting Machine

Water Jet Cutting Machine Applications:

Metal Fabrication: Cutting intricate metal parts for automotive, aerospace, and manufacturing industries.

Stone and Tile Cutting: Creating detailed designs and shapes for countertops, flooring, and decorative stone pieces.

Glass Cutting: Producing precise cuts for architectural glass, mirrors, and other glass products.

Composite Materials: Cutting carbon fiber, fiberglass, and other composite materials used in various industries.

Prototyping: Creating accurate prototypes and models for various engineering and design applications.

Art and Sculpture: Producing detailed and intricate art pieces from various materials.

Aerospace Industry

In the aerospace industry, the 5 axis water jet cutting machine is used to cut complex shapes and components from high-strength materials. Its precision and ability to cut without generating heat make it ideal for aerospace applications.

Automotive Industry

The automotive industry benefits from the versatility and precision of the 5 axis water jet cutting machine. It is used to cut various components, including body panels, interior parts, and engine components.

Architecture and Construction

In architecture and construction, the 5 axis water jet cutting machine is used to create intricate designs and patterns in materials such as stone, glass, and metal. It is also used for cutting custom tiles, countertops, and decorative elements.

Manufacturing

Manufacturing industries use the 5 axis water jet cutting machine for cutting parts and components from a wide range of materials. Its precision and ability to handle complex geometries make it a valuable tool for producing high-quality products.

CNC Water Jet Cutting Machine Advantages:

Versatility: Can cut almost any material with high precision.

No Heat Distortion: Ideal for materials sensitive to heat.

Precision: High degree of accuracy and detail.

Clean Cutting Process: Minimal dust and fumes, making it safer and more environmentally friendly.

0 notes

Text

What Are The Features & Benefits of 5-Axis CNC Machining?

With the rapid development of modern manufacturing industry, high precision and high efficiency processing technology has become the key to enhance the competitiveness of enterprises. As a kind of high-end CNC machining technology, 5-axis machining process has attracted much attention because of its excellent performance and wide range of applications.

Features of 5-Axis Machining 1.Complex surfaces can be machined 5-Axis Machining enables the machining of complex surfaces and facilitates reverse engineering and other process requirements.

2.Reduction of machining procedures By using 5-axis simultaneous machining, the number of machining programmes has been greatly reduced and the machining efficiency has been improved.

3.Improved machining accuracy 5-axis machining enables the simultaneous machining of multiple faces, improving the geometric accuracy and surface quality of the part.

4.Increased machining freedom The use of 5-axis machining increases the degree of freedom in machining parts and facilitates the machining of special shaped parts.

Benefits of 5-Axis Machining 1.Machining accuracy ①Reduced clamping errors Conventional multi-face machining often requires multiple clamping of the workpiece, with each clamping introducing a certain amount of positioning error. A 5-axis machining centre is capable of machining multiple faces in a single clamping. For example, for a part with a complex shape, such as the impeller of an aero-engine, the five-axis simultaneous machining can avoid the datum conversion error caused by multiple clamping, thus improving the overall machining accuracy of the part. This feature of multi-face machining in one clamping also ensures the relative positional accuracy between machined surfaces. For instance, when machining a mould, the positional relationship between the faces of the cavity and the core can be more accurately matched to the design requirements, improving the mould's closing accuracy.

②Optimization of tool cutting angles The two rotary axes of the 5-axis machining centre allow flexible adjustment of the tool attitude.This enables the tool to always maintain the optimum cutting angle when machining complex surfaces. For example, when machining aircraft engine blades with twisted surfaces, the tool can adjust its angle with the machining surface in real time according to the changes in the blade surface, avoiding deflection or overcutting of the tool in the cutting process, thus improving the dimensional accuracy and surface quality of machining. This precise control of the cutting angle of the tool also effectively reduces uneven tool wear and further improves the stability of machining accuracy.

2.Processing efficiency ①Multi-face machining in one clamping As mentioned earlier, 5-axis machining centres do not need to change clamping positions as often as 3-axis machining centres to machine different faces. In the case of a hexahedral part, for example, 3-axis machining may require three clamping positions to complete the machining of six faces, whereas a 5-axis machining centre can do so in a single clamping position. This not only saves clamping time, but also reduces production stoppages due to clamping operations, greatly improving overall machining efficiency. This advantage of 5-axis machining is even more evident when machining complex parts, such as those with multiple bevels and curved surfaces.It can continuously machine different surfaces, avoiding cumbersome operations such as setting and tool setting during multiple clamping.

②Optimized cutting paths The CNC of a 5-axis machining centre can generate more optimal cutting paths according to the geometry and machining requirements of the part. Compared to 3-axis machining, it reduces idle travelling time and allows for more continuous and efficient tool movement during the cutting process. For instance, when machining a part with a complex internal structure, a 5-axis machining centre can improve machining efficiency by reasonably planning the tool path, avoiding unnecessary tool lifting and movement, and increasing the ratio of cutting time to total machining time. In addition, for parts with special shapes, such as propellers, the 5-axis machining centre is able to cut along the natural shape of the part, rather than in layers, as is the case with 3-axis machining, further increasing machining speed.

3.Ability to machine complex parts ①Complex surface machining The 5-axis machining centre can easily cope with the task of machining a variety of complex surfaces. For example, in the automotive industry, the conceptual design of car exteriors is increasingly pursuing unique shapes. The body shells of some concept cars have complex free-form surfaces, which can be accurately machined by 5-axis machining centres. In the aerospace field, the complex curved surfaces of components such as aircraft wings and fuselages also require five-axis machining centres to achieve high-precision machining. For parts with internally complex surfaces, such as moulds or impellers with special runners, the multi-axis capability of the 5-axis machining centre allows it to cut deep into the part without the limitations of tool accessibility that are associated with traditional machining methods.

②Machining of parts with inverted structure When parts have inverted structures (e.g. internal pits, protruding reverse structures, etc.), 3-axis machining centres often find it difficult to machine them directly, and it may be necessary to use a special process or to disassemble the part before machining it.On the other hand, 5-axis machining centres can adjust the attitude of the tool so that the tool can reach the inverted part for machining. For example, in the manufacture of moulds, some injection moulds with internal inverted buckle, 5-axis machining centre can directly carry out a one-time processing, which not only improves the processing efficiency, but also ensures the overall structural integrity of the parts.

4.Improvement of cutting conditions ①Optimization of cutting force distribution 5-axis machining centres can optimize the distribution of cutting forces on the workpiece by adjusting the tool attitude. This is particularly advantageous when machining thin-walled parts. For example, when machining thin-walled structural parts in the aerospace field, reasonable adjustment of the tool attitude can make the cutting force act uniformly on the thin wall, avoiding deformation or rupture of the thin wall due to the concentration of the cutting force, and improving the machining quality of the parts. For some less rigid parts, such as large aluminium alloy structural parts, by optimizing the cutting force distribution, it is also possible to ensure the machining accuracy at the same time, the use of greater cutting parameters to improve the machining efficiency.

②Improvement of cutting heat emission The generation of cutting heat is unavoidable during the machining process. 5-axis machining centres can improve the path of cutting heat by adjusting the contact angle between the tool and the workpiece. For example, when cutting at high speeds, having the tool cut into the workpiece at an angle allows more of the heat of cutting to be carried away by the chips and reduces the build-up of heat on the workpiece and tool.This helps to extend the life of the tool and also prevents problems such as deformation and hardness changes in the workpiece due to overheating and improves machining quality.

5.Wide applicability 5-axis machining centres are widely used in several industries. In the aerospace field, it is capable of machining high-precision and high-complexity parts. In the automotive manufacturing field, it is used for machining engine blocks, large moulds and other key components. In mould manufacturing, 5-axis machining centres are able to complete the machining of moulds quickly and accurately through the precise 5-axis simultaneous technology. In addition, 5-axis machining is also suitable for medical equipment, electronic products and other manufacturing fields that require high precision and surface quality.

Through the above introduction of the features and benefits of 5-axis machining, we can see the importance and superiority of 5-axis machining, which is not only able to achieve complex surface machining, but also has the advantages of high precision, high machining efficiency, smooth surface, low production cost and so on, which is an important development direction of the manufacturing industry.

https://gdprototyping.en.alibaba.com/

#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#cnc machining service#5 axis cnc machining#5 axis milling#5 axis cnc milling#cnc milling#5 axis cnc#5 axis precision machining

1 note

·

View note

Text

A Continuous Fiber Laser Welding Machine's Functions

Metal materials like copper and aluminum can be welded with a continuous fiber laser welding machine. For welding stability, the fuselage uses a high-strength gantry bed structure design. With its higher photoelectric conversion efficiency, lower power consumption, and higher beam quality, the current advanced continuous laser is chosen as the light source.

Benefits of the fiber laser apparatus include its small size, convenient use, and compact structure. Welding equipment can be efficiently integrated with other equipment in the system thanks to its versatile laser output mode. High speed and precision are ensured by the highly responsive servo motor output, which works with the high-precision and high-strength screw linear module as the operating transmission mechanism.

In the field of new energy lithium battery PACK modules, this makes the laser welding machine an essential piece of equipment. With its outstanding beam quality, quick welding speed, and gorgeous, sturdy welding pool, the continuous fiber laser welding machine offers the ideal, stable, and effective welding solution for the lithium battery welding process.

Unlocking the Advantages: Your Guide to the Equipment's Benefits

Perfect welding: Easy adjustment, fine focusing, imported optical lenses, high-precision laser welding head.

High-quality fiber laser: Internationally recognized, with years of industrial application, a long lifespan, and no maintenance required.

Energy efficiency: Low power consumption, high electro-optic conversion efficiency, and excellent beam quality.

Adjustable power: A continuous 2000-watt (adjustable) pure fiber laser that can penetrate materials with depths ranging from 0.1-3 mm.

Precision control: A precise servo system ensures welding accuracy.

User-friendly interface: Easy-to-learn PC industrial computer with a welding CNC programming system.

Wide range capabilities: large surface stroke welding, a gantry frame motion structure, high machine tool precision, and a stable, long-lasting service life.

Enhanced functionality: Data-saving call functions, strong drawing and editing graphics capabilities, and compatibility with a range of input formats.

Exploring Equipment Indicators and Parameters: Key Features

This welding equipment offers a range of features that make it versatile and reliable for various applications:

Material Compatibility: Welds materials with thicknesses ranging from 0.5 mm to 2.0 mm, suitable for diverse projects.

Workspace Flexibility: Effective travel range spans 870 mm in the X-axis and 600 mm in object workpiece height.

Adjustable Welding Speed: Operates at speeds of up to 10 mm/s, ensuring welds meet specific requirements.

Power Options: Offers adjustable laser power levels, including 2 KW, 3 KW, and 6 KW.

Durability: Features an optical fiber working medium with a service life exceeding five years.

Material Versatility: Suitable for welding nickel strips, copper sheets, and aluminum rows.

Welding Modes: Offers both continuous and pulse modes for versatile welding processes.

Spot Welding Capabilities: Achieves contact surface melting depths ranging from 0.5 mm to 1 mm, ensuring strong welds with tensile strength exceeding material destructive strength.

Characteristics of the Equipment

This welding equipment offers advantageous features for a seamless and efficient welding experience:

Maintenance-Free Operation: Reduces downtime and maintenance costs.

Adjustable Parameters: Allows for easy modification of welding parameters, including motion speed.

Fault Alerts: Real-time fault alarm prompts for immediate issue resolution.

Flexible Operation: Offers automatic and manual operation modes, supporting arc and straight-line interpolation.

Laser Processing: Enables the creation of various plane graphics such as points, straight lines, circles, and squares.

Durable Components: Equipped with imported lenses in the welding field mirror to withstand high laser-generated temperatures.

User-Friendly System: Easy-to-learn operating system simplifies manual operation.

Smoke and Slag Control: Built-in air-blown wind knife ensures welding quality.

Cooling System: A water-cooled cycle in the welding head ensures stable welding effects.

Precision Mechanism: High-precision screw transmission and high-speed servo motors ensure accuracy and responsiveness.

Environmental Conditions

To ensure optimal performance and safety, adhere to these specifications for the operating environment:

Ambient Temperature: Operates effectively between 5°C and 35°C.

Humidity: Maintain relative humidity levels between 20% and 90% to prevent condensation and corrosion.

Air Source Pressure: Requires a compressed air source with a pressure range of 0.5 to 0.6 Mpa.

Power Supply Voltage: A stable voltage of 380V at 50Hz or 60Hz is required.

Total Power: Consumes ≤10KW of power to prevent electrical overloading.

Load-Bearing Capacity: The installation area must support up to 500 kg/m².

Grounding Type: Direct grounding ensures safety and minimizes electrical hazards.

Installation Environment: Requires a flat, vibration-free, and shock-free area for precise and stable operations.

Adhering to these specifications ensures reliable operation, extending the equipment’s service life while preventing potential issues related to environmental conditions.

Final Thoughts

The continuous fiber laser welding machine represents a revolutionary step forward in welding technology. Its ability to deliver precise, efficient, and versatile welding solutions makes it an essential tool across industries, including automotive, aerospace, and renewable energy. By understanding its functions, benefits, and operational requirements, manufacturers can fully leverage this equipment to enhance productivity, reduce costs, and achieve superior product quality.

Investing in a continuous fiber laser welding machine is not just about adopting advanced technology—it's about future-proofing your manufacturing processes for the demands of tomorrow.

#Fiber Laser Welding Machine#Fiber Laser Welding Technology#High-Precision Welding Machines#Laser Welding for Copper and Aluminum#Industrial Laser Welding Equipment#Applications of Fiber Laser Welding#High-Strength Welding Equipment#Lithium Battery PACK Welding Solutions#Laser Welding for Automotive Manufacturing#Spot Welding vs. Continuous Laser Welding

0 notes

Text

Why does 5-axis CNC machining require drilling on the top and rotation on the bottom?

During 5-axis CNC machining, the top is drilled while the bottom is rotating because this setting can avoid collision between the tool and the parts of the fixed equipment, quickly approach the part geometry, and maintain the best cutting position and consistent chip load, thereby improving equipment life and production efficiency.

Five-axis CNC, dancing metal art! Look at the precise drilling on the top and the flexible rotation on the bottom. Every process is a persistent pursuit of perfection. High-tech equipment and high-efficiency production make cold metal glow with infinite possibilities! #Five-axis CNC machining #The beauty of machinery #High-tech production

https://cnc-5-axis.com/cnc-screw-machining-for-aviation/

#CNC laser Cutting Machine#CNC lathe Machine#CNC Machine Near me#Desktop CNC Milling Machine#Five Axis CNC Machine#Operator CNC Machine#CNC Machine definition#CNC Machine meaning#CNC Machine Price#CNC Machining Services#Explain CNC Machine

0 notes

Text

CNC Milling Machines Market Report

CNC Milling Machines Market Report: A Comprehensive Analysis of the Global Market

Industry Dimensions

The global CNC Milling Machines Market size was valued at USD 82.48 billion in 2023 and is projected to reach from USD 89.52 billion in 2024 to USD 172.31 billion by 2032, growing at a CAGR of 3.92% during the forecast period (2024–2032). CNC milling machines are computer-controlled machines that use rotating cutters to remove material from a workpiece. These machines are widely used in various industries, such as automotive, aerospace, and electronics, for precision machining and manufacturing.

Get Your Exclusive Sample of the CNC Milling Machines Market Report Today starting at just USD 1850! : https://straitsresearch.com/report/cnc-milling-machines-market/request-sample

Industry Key Trends

Some of the key trends in the CNC Milling Machines Market include:

Increasing demand for precision machining: The demand for precision machining is increasing, driven by the growing need for complex and intricate parts in various industries.

Advancements in technology: Advancements in technology, such as the development of more advanced CNC controls and the use of artificial intelligence and machine learning, are driving growth in the market.

Growing adoption of Industry 4.0: The growing adoption of Industry 4.0, which involves the use of automation, robotics, and data analytics to improve manufacturing efficiency, is driving growth in the market.

Increasing focus on energy efficiency: The increasing focus on energy efficiency is driving growth in the market, as companies seek to reduce their energy consumption and costs.

CNC Milling Machines Market Size and Share

The global CNC Milling Machines Market size is projected to reach USD 172.31 billion by 2032, growing at a CAGR of 3.92% during the forecast period.

CNC Milling Machines Market Statistics

Some of the key statistics in the CNC Milling Machines Market include:

Market size: The global CNC Milling Machines Market size was valued at USD 82.48 billion in 2023.

Growth rate: The market is projected to grow at a CAGR of 3.92% during the forecast period.

Segmentation: The market can be segmented by product type, axis type, and end-user.

Regional Trends

The global CNC Milling Machines Market can be segmented into several regions, including:

North America: The North American market is driven by the presence of major industries, such as automotive and aerospace, which require precision machining and manufacturing.

APAC: The APAC market is driven by the growing demand for precision machining and manufacturing in countries, such as China, Japan, and South Korea.

Europe: The European market is driven by the presence of major industries, such as automotive and aerospace, which require precision machining and manufacturing.

LAMEA: The LAMEA market is driven by the growing demand for precision machining and manufacturing in countries, such as Brazil and South Africa.

To purchase the report: https://straitsresearch.com/buy-now/cnc-milling-machines-market

CNC Milling Machines Market Segmentations

The global CNC Milling Machines Market can be segmented into several categories, including:

By Product Type:

Vertical CNC Milling Machines

Horizontal CNC Milling Machines

Universal CNC Milling Machines

By Axis Type:

3-Axis

4-Axis

Others

By End-User:

Automotive

Electrical and Electronics

Aerospace and Defense

Others

For more details: https://straitsresearch.com/report/cnc-milling-machines-market/segmentation

Top Players in CNC Milling Machines Market

Some of the top players in the CNC Milling Machines Market include:

Doosan

Five

F-Zimmermann

JTEKT

Makino

Ace Micromatic Group

DMG MORI SEIKI

The CHIRON Group

GF Machining Solutions Management

HYUNDAI WIA

Gleason Corporation

GROB-WERKE

Haas Automation

Detailed Table of Content report: @https://straitsresearch.com/report/cnc-milling-machines-market/toc

0 notes

Text

TK-5120 5AXES CNC SPRING COILING MACHINE

1. Controlled with five axes: wire feed axis, cam axis,upper cutter axis, lower cutter axis and pitch axis.

2. The five axes can work single-step or synchronously.

3. Computer interface displayed in Chinese and English which makes the operation easy

4. Equipped with right and left rotation cutter frame.

5. Cutter can perform straight cut, opposite cut and twist cut.

6. Computer has automatic programming function.

0 notes

Text

Learn more about Jeek Precision

Dongguan Jeek Precision Technology Co., Ltd. is a company specializing in precision machining and customization services, committed to providing customers with high-quality, high-precision component solutions. The company is located in Dongguan City, Guangdong Province. With advanced technical equipment and rich industry experience, it has become an important partner in many fields.Jeek Precision provides a variety of customized services such as CNC machining, injection molding, plastic molding, etc., which are widely used in electronics, automobiles, medical, aerospace and other industries.

Core Technology and Services:

CNC Machining (CNC Machining) CNC machining technology is one of the core advantages of Dongguan Jeek Precision. The company has a number of high-precision CNC machine tools from three to five axes, which can process parts with complex shapes and high precision requirements according to customer needs. Whether it is mass production or small batch customization, Jeek Precision can provide high-efficiency and high-precision machining services to meet customers' strict requirements in shape, size and precision. Five-axis machining is particularly suitable for complex parts that require simultaneous processing at multiple angles and directions.

Injection Molding Jeek Precision's injection molding service is suitable for large-scale production of plastic parts. The company has advanced injection molding machines and a professional mold design team, which can provide customers with high-precision and high-stability plastic parts. By continuously optimizing the injection molding process, the company can ensure that the products meet high standards in dimensional accuracy and surface quality to meet the different needs of customers.

Plastic molding (stamping, extrusion, etc.) In addition to CNC machining and injection molding, Jeek Precision also provides plastic molding services for metal and plastic materials. Whether it is stamping, hot stamping, or metal extrusion molding, the company can provide high-precision and efficient production processes, which are suitable for the production of various parts in the electronics, automotive, medical and other industries.

Customized services and engineering support Jeek Precision can not only provide conventional processing services, but also provide customized solutions according to customer needs. From product design, sample production to mass production, the company's team of engineers will participate in the whole process to ensure the smooth progress of each link, and provide necessary technical support and process optimization to help customers gain competitive advantages in the market.

Quality control and certification Quality control is a core competitiveness of Jeek Precision. The company strictly follows international quality standards for production and has advanced testing equipment, such as three-coordinate measuring machines, hardness testers, surface roughness testers, etc., to ensure the accuracy and quality of each batch of products. The company has passed the ISO9001 quality management system certification and provides other industry certifications according to customer needs, such as IATF16949 (automotive industry) and ISO13485 (medical industry).

Post-processing and assembly In order to further improve the quality and function of the products, Jeek Precision also provides a variety of post-processing services, such as surface spraying, electroplating, oxidation treatment, etc., to ensure the corrosion resistance, wear resistance and aesthetics of the products. In addition, the company's assembly team can provide customers with precise component assembly services to ensure the high reliability of the final product.

Application areas: Dongguan Jeek Precision's products are widely used in many industries. The following are some typical application areas:

Electronic industry: Provide precision components such as housings, connectors, circuit board brackets, etc. for electronic products to ensure the stability and functionality of electronic equipment. Automotive industry: Automobile manufacturing provides various precision parts, such as engine parts, body parts, chassis parts, etc., to meet the automotive industry's requirements for high precision and high strength. Medical equipment: The company provides high-precision parts for the medical device industry, including medical instrument housings, precision surgical tools, etc., to ensure that the products meet strict medical standards. Aerospace: Provide high-strength, high-precision parts for the aerospace field to ensure reliability and stability in extreme environments. Consumer goods: The company provides exquisite appearance design and high-functionality parts in the consumer goods industry, such as home appliances, smart hardware, etc., to meet the increasingly diverse market needs. Company advantages: Technological innovation: The company always pays attention to the update and innovation of technology, and continuously introduces advanced equipment and technology to ensure that it can meet the growing needs of customers. Lean production: By optimizing the production process, Jeek Precision has greatly improved production efficiency, reduced costs, and ensured the high quality of each product. Professional team: The company has an experienced and technically competent team of engineers who can provide customers with all-round technical support to ensure the smooth progress of the project. Dongguan Jeek Precision Technology Co., Ltd. has won wide recognition and trust from domestic and foreign customers with its excellent technology, rich industry experience and customer-oriented service concept. The company will continue to use innovation as a driving force to continue to provide customers with high-quality, high-precision products and solutions to help customers succeed in the competition in the global market.

Learn about Geek Precision Click.

0 notes

Text

Innovative Precision Engineering Solutions with WIDMA

WIDMA, a renowned name in the field of precision engineering, is a leading provider of advanced metal-cutting solutions. With decades of expertise, WIDMA caters to industries requiring high-quality machines designed for accuracy, durability and efficiency. Among its flagship offerings are the CNC grinding machine, gundrilling machine and steering machine, each engineered to meet the evolving needs of modern manufacturing.

CNC Grinding Machine: Advanced Tool for Precision

A CNC grinding machine is a versatile tool designed to create and regrind tools with extreme accuracy. It is essential in industries such as automotive, aerospace and general engineering, where high precision and productivity are critical. WIDMA’s CNC grinding machines are equipped with:

Five-Axis Control: Ensures smooth and accurate tool grinding, including complex geometries.

Automated Processes: Reduces manual intervention, ensuring consistent quality.

Customizable Features: Adaptable to manufacture round tools, shaper cutters, hobs and special cutters.

WIDMA’s grinding machines are powered by user-friendly software that simplifies programming while delivering precision. This makes them a preferred choice for manufacturers seeking high-quality tooling solutions.

Gundrilling Machine: Precision for Deep Drilling

A gundrilling machine is indispensable in manufacturing components requiring deep and precise holes, especially in sectors like oil and gas, medical equipment and defence. WIDMA’s gundrilling machines are engineered for:

High Accuracy: Capable of achieving a high length-to-diameter ratio with minimal deviation.

Efficient Cooling Systems: Ensures smooth operation and longevity by maintaining optimal temperatures during drilling.

Versatile Applications: Suitable for operations such as counterboring, BTA drilling and more.

WIDMA’s expertise in deep-hole drilling machines guarantees unmatched reliability and precision, making it an industry leader in this domain.

Steering Machine: Driving Excellence in Manufacturing

The steering machine is a critical component in automotive manufacturing, particularly in the production of steering systems. WIDMA’s steering machines are designed to deliver:

Enhanced Productivity: Capable of performing multiple operations simultaneously to streamline production cycles.

Precision Engineering: Ensures accurate machining of critical components for optimal performance.

Custom Solutions: Adaptable to meet specific manufacturing needs, ensuring flexibility and efficiency.

WIDMA’s steering machines are widely recognized for their robust performance, ensuring consistent quality in high-demand environments.

Why Choose WIDMA?

Established in 1984, WIDMA has emerged as a trusted name in manufacturing solutions. Its state-of-the-art facility in Bengaluru houses cutting-edge technology and a team of expert engineers committed to delivering excellence. Whether it’s a CNC grinding machine, gundrilling machine, or steering machine, WIDMA’s offerings are tailored to enhance productivity and precision.

Conclusion

WIDMA’s advanced machines and customer-centric approach have made it a go-to choice for industries across the globe. By integrating innovative technology and engineering expertise, WIDMA continues to set benchmarks in the manufacturing sector. Choose WIDMA for your precision engineering needs and experience unparalleled performance.

0 notes

Text

CNC Foam Router for Professional Foam Shaping and Design

In the world of professional foam shaping and design, precision is key. From creating intricate sculptures to producing custom packaging solutions, foam is used in a wide variety of industries, and the demand for precision-cut foam continues to rise. The solution to this demand lies in the CNC foam router—a state-of-the-art tool that revolutionizes foam cutting, carving, and shaping.

Use a rotary cutting tool (router bit) to carve and shape foam. Suitable for detailed 3D carving, engraving, and milling. Can handle a wider range of foam types, including polyurethane and polyethylene.A CNC foam cutter is a specialized type of CNC machine designed to cut and shape foam materials with high precision and efficiency. These machines are commonly used in various industries, including packaging, prototyping, model making, insulation, and more.

What is a CNC Foam Router?

CNC foam router is a specialized machine that uses computer numerical control (CNC) technology to cut, carve, and shape foam materials with remarkable accuracy. These routers are designed to work with various types of foam, including expanded polystyrene (EPS), polyethylene (PE), polyurethane (PU), and more. CNC foam router machine is a specialized type of CNC machine designed for cutting, shaping, and carving foam materials. These machines are widely used in industries such as packaging, prototyping, model making, and even in the production of theater and movie props.

The CNC foam router operates based on pre-programmed instructions from CAD (computer-aided design) software. This allows operators to create highly detailed designs and shapes in foam quickly and consistently. The process is automated, reducing the chances of human error and ensuring uniformity across multiple pieces.

Types of CNC Foam Cutter

4 Axis Foam CNC Router

The 4-axis CNC Router machine refers to the computer numerical control equipment including X, Y, Z, and additional rotation axis. It has 3 straight coordinates and 1 rotating coordinate. 4-axis CNC Router engraving machines are usually equipped with rotating axes or rocking spindles, so they can contact the workpiece from different angles and effectively work, so as to realize the 3D processing of cylindrical, curved and circular surfaces.

4 axis CNC router is quite good at processing 3D workpieces. It generally falls into two types. The first type described hereunder is equipped with a rotating spindle that can swing by 180°. It can engrave 3D patterns and drill holes on side surfaces of wood, MDF, acrylic, foam, rubber, and other materials. For example, 3D letters, signs, reliefs, and sculptures.

5 Axis CNC Foam Router

The 5 axis CNC Router machine, also known as the 5 axis CNC machining center, is equipped with a 3D CNC system.Designed as a 5 axis CNC processing solution with high cost-effectiveness, it refers to the machine's capacity to move tools or parts on five different axes for complex surface processing. As a piece of advanced CNC equipment, the 5 axis CNC machining center or CNC router is crafted especially for complex curved surfaces. It finds extensive application in industries like aviation, aerospace, automotive, military, scientific research, precision instruments, high-precision medical equipment, etc. Also, it can handle a wide variety of materials such as wood, metals, stones, plastic, styrofoam, composites, and so on.

Features of a CNC Foam Cutting Machine

Key Advantages of CNC Foam Cutting Machine

One of the primary benefits of a CNC foam router is its precision and accuracy. Unlike traditional manual cutting methods, which can lead to inconsistencies and material waste, CNC foam routers provide highly precise cuts. This ensures that foam materials are cut to exact specifications, minimizing waste and producing uniform, high-quality results.

In addition to precision, CNC foam routers are highly customizable. They can easily accommodate a wide range of intricate designs, from basic geometric shapes to more elaborate, complex patterns. With CAD software, designers can create any shape or pattern, which is then executed with exact precision by the router. This flexibility makes the CNC foam router ideal for a variety of custom applications, including sculptures, packaging, and prototypes.

Efficiency and Automation

Another major advantage of CNC foam routers is their versatility. These machines can handle different types of foam, from rigid materials like polyurethane and PVC to softer options like polystyrene. This makes CNC foam routers suitable for diverse industries, from packaging and architectural modeling to artistic sculpture and prototypes.

Speed and efficiency are also key benefits of CNC foam routers. Unlike traditional manual cutting methods, which can be slow and labor-intensive, CNC machines work quickly and continuously, cutting large volumes of foam in a fraction of the time. This makes them ideal for businesses with high-volume production needs, helping to meet tight deadlines.

Additionally, automation is a major selling point. Once the design is input into the system, the CNC foam router takes over the cutting process, reducing the need for skilled labor and minimizing human error. This automation increases productivity, reduces mistakes, and frees up resources for other tasks, significantly enhancing operational efficiency.

Applications of CNC Foam Milling

Common Applications of CNC Foam Milling

CNC foam routers offer remarkable versatility, making them ideal for various industries. In foam sculptures and artwork, artists and designers use these machines to craft intricate, detailed designs for art installations and commercial displays. From simple shapes to complex textures, CNC foam routers excel in transforming creative concepts into tangible pieces with precision.

In the packaging industry, CNC foam routers are used to create custom foam inserts for the safe transport of fragile items, such as electronics, medical devices, and automotive parts. By carving foam to exact specifications, these routers ensure products are securely packaged, minimizing the risk of damage during transit. Similarly, CNC foam routers play a significant role in prototypes and models, where engineers and designers rely on foam to create accurate initial product models before progressing to more expensive materials.

Expanding Industries for CNC Foam Routers

CNC foam routers are also widely used in architectural models, where architects rely on them to create detailed foam models of buildings and landscapes. Foam is a cost-effective material, and CNC routers can efficiently turn 3D digital designs into physical models, which are essential for presentations and design development.

In advertising and signage, CNC foam routers carve custom shapes, letters, and logos from foam, which are then painted for use in eye-catching displays, signs, and banners. The ability to create bold and intricate designs makes these routers ideal for large-scale advertising projects. Additionally, in the entertainment industry, CNC foam routers are employed for set design, crafting foam props, stage sets, and scenery. These routers allow designers to construct realistic environments for theater, film, and television productions.

Why Choose a CNC Foam Cutting for Your Business?

There are numerous reasons why investing in a CNC foam router is a wise decision for your business. Here are some of the most compelling reasons:

Increased Productivity:CNC foam routers dramatically improve productivity. With automation, the router can work continuously without requiring breaks, unlike manual labor. This not only speeds up the production process but also allows your business to handle more orders in less time, increasing overall throughput.

High-Quality Results:Because CNC foam routers offer extreme precision, the quality of the final product is significantly higher. Whether you're cutting a foam model, creating packaging inserts, or producing intricate sculptures, the results will be uniform and exact. Consistent quality across every product is essential for customer satisfaction and long-term business success.

Cost-Effectiveness:Although the initial cost of a CNC foam router may seem high, the long-term savings are considerable. These machines reduce labor costs, material waste, and production time, which translates into significant cost savings. Additionally, CNC foam routers can help companies meet tight deadlines, avoiding costly delays.

Flexibility and Customization:The customization potential offered by CNC foam routers is unparalleled. From prototypes to large-scale production, CNC foam routers can be programmed to cut any design imaginable. The flexibility to produce both large quantities of identical parts and unique one-off items makes the CNC foam router an indispensable tool in many industries.

Reduced Labor Requirements:Manual foam cutting can be labor-intensive and physically demanding. CNC foam routers reduce the need for skilled manual labor, allowing operators to focus on machine operation, design programming, and oversight. The automation process also reduces human error, ensuring that each cut is accurate.

Choosing the Right Machine

Selecting the right CNC foam router for your business involves considering several factors, including:

Machine Size and Cutting Area:The size of the foam you plan to work with will determine the size of the CNC foam router you need. Larger machines are capable of cutting larger sheets of foam, while smaller machines are suitable for more intricate designs and smaller foam pieces.

Cutting Capabilities:Different CNC foam routers have different cutting capabilities. Some may be better suited for simple, straight cuts, while others are equipped to handle more complex designs, including curves and 3D shapes. Consider your business's specific needs when selecting a machine.

Software Compatibility:Most CNC foam routers are compatible with popular CAD/CAM software. Make sure the machine you choose integrates well with the software you use for design and programming.

Cost and Budget:CNC foam routers vary in price depending on their size, features, and brand. Make sure to assess your business's budget and weigh the potential return on investment when selecting a machine. While the initial investment may be high, the long-term benefits in terms of productivity and quality will justify the cost.

Technological Advancements in CNC Foam Cutter Machines

Integration with CAD/CAM Software

Modern 3D CNC foam router machines are often integrated with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. This integration allows for seamless design and manufacturing processes, reducing errors and improving overall efficiency.

Automation and Robotics

The incorporation of automation and robotics into CNC machining has further enhanced productivity. Automated 3D CNC foam router machines can perform multiple tasks without human intervention, increasing throughput and reducing the risk of human error.

IoT and Industry 4.0

The advent of the Internet of Things (IoT) and Industry 4.0 has brought about significant changes in CNC machining. Machines are now connected to networks, allowing for real-time monitoring, predictive maintenance, and improved decision-making processes.

Conclusion

CNC foam router is an indispensable tool for businesses in industries that require precision foam cutting and shaping. From custom packaging to artistic sculptures and prototypes, CNC foam routers offer unmatched precision, speed, and versatility. By automating the foam cutting process, these machines not only enhance productivity but also reduce material waste and labor costs, allowing businesses to scale efficiently.

Investing in a CNC foam router is a smart decision for any company looking to stay competitive in the rapidly evolving foam industry. Whether you're cutting foam for practical applications or creating detailed artistic designs, a CNC foam router will give you the flexibility and control to meet the demands of your customers and grow your business.

0 notes