#five axis cnc machining

Explore tagged Tumblr posts

Text

GD prototyping Precision impeller CNC machining,5 axis CNC machines can improve our production efficiency and apability, especially for high precsion plastic and metal parts.

#cncmachining#cnc machining services#cnc milling services#5 axis machining#five axis cnc machining#impeller machining#parts machining

1 note

·

View note

Text

How to Choose The Right CNC Machining Service Provider

I believe that every company that is starting a business or that needs to find CNC machining will have such questions. We all know that finding a reputable CNC machining company can be challenging as mistakes can lead to loss, unforeseen complications, mistakes, and unfinished tasks. On the other hand, the right choice will increase your productivity and reduce production costs and project turnaround times. When looking for CNC machining services, you want to make sure they have a solid reputation and experience with the type of product machining you want. The reason for such doubts, I think, is related to the following reasons. This blog will explore the tips you need to consider when choosing a CNC machining service provider.

1. Processing ability We all know that when you need to do a mold project fabrication, it is crucial to first make sure that the company you want to place your mold order with has the capabilities your project requires. Most will tell you that to understand what they do you need to consider the technology and systems they offer. It is true, but when your company needs five-axis CNC machining, if there is a three-axis company that uses three-axis production technology to achieve the same accuracy as five-axis machining, will you choose or not? Know that a large company with hundreds of machines running will double your money when the five-axis machine starts spinning. In the current state of the economy, reducing your cost of capital is key. At present, the general CNC processing enterprises have at least a dozen production machines, which can fully meet your production needs and reduce your costs. All you have to do is wait a few more days.

2. Focus on price and long-term value Most people often use price as the deciding factor when choosing a CNC machining company. There's nothing wrong with that in itself, but sometimes you'll find that low-priced companies don't guarantee high-quality service. When you send out a processing order, you invest in the time and overall product needed to complete the project. You will have to waste time and money finding another CNC machining company to fix the poor-quality product on your first job. Here, my suggestion is to cooperate with a processing company with relatively long production experience. Generally speaking, the old-fashioned machining technology companies do a good job of communication services in this area. You can communicate the manufacturing status of your parts in real-time, whether they are CNC-turned service or CNC-milled service.

It is important to note that CNC machining equipment is a very expensive investment for any company. The production cost of parts products is mainly related to the raw materials used, tolerance, complexity, finishing, and other factors, so some people say that "the cost of using high-quality CNC machine tools is usually reflected in the customer's pricing, but the product quality is guaranteed, which is high Qualitative." This sentence is true in itself, but it is still a bit inappropriate.

3. Check the number of equipment and the latest equipment When your project requires high precision, you can send an inquiry to the company you intend to manufacture the parts, whether there is enough new equipment to meet your product design and style manufacturing needs, of course, you need to add new equipment and experienced excellent Operators will greatly shorten your production cycle.

Final thoughts! Above are some important tips when choosing a CNC machining service provider. Other things to check are certifications and whether they offer excellent quality control. Finally, don't forget to ask about all the services they offer, after all some sites have multiple types of services and they don't list them all. If you like this article, follow me. The next article will take you to some CNC machining service companies that I think are better.

#CNC machining company#CNC machining#CNC machining service provider#five-axis CNC machining#CNC-turned service#CNC-milled service#CNC machining service

1 note

·

View note

Text

CNC development history and processing principles

CNC machine tools are also called Computerized Numerical Control (CNC for short). They are mechatronics products that use digital information to control machine tools. They record the relative position between the tool and the workpiece, the start and stop of the machine tool, the spindle speed change, the workpiece loosening and clamping, the tool selection, the start and stop of the cooling pump and other operations and sequence actions on the control medium with digital codes, and then send the digital information to the CNC device or computer, which will decode and calculate, issue instructions to control the machine tool servo system or other actuators, so that the machine tool can process the required workpiece.

1. The evolution of CNC technology: from mechanical gears to digital codes

The Beginning of Mechanical Control (late 19th century - 1940s)

The prototype of CNC technology can be traced back to the invention of mechanical automatic machine tools in the 19th century. In 1887, the cam-controlled lathe invented by American engineer Herman realized "programmed" processing for the first time by rotating cams to drive tool movement. Although this mechanical programming method is inefficient, it provides a key idea for subsequent CNC technology. During World War II, the surge in demand for military equipment accelerated the innovation of processing technology, but the processing capacity of traditional machine tools for complex parts had reached a bottleneck.

The electronic revolution (1950s-1970s)

After World War II, manufacturing industries mostly relied on manual operations. After workers understood the drawings, they manually operated machine tools to process parts. This way of producing products was costly, inefficient, and the quality was not guaranteed. In 1952, John Parsons' team at the Massachusetts Institute of Technology (MIT) developed the world's first CNC milling machine, which input instructions through punched paper tape, marking the official birth of CNC technology. The core breakthrough of this stage was "digital signals replacing mechanical transmission" - servo motors replaced gears and connecting rods, and code instructions replaced manual adjustments. In the 1960s, the popularity of integrated circuits reduced the size and cost of CNC systems. Japanese companies such as Fanuc launched commercial CNC equipment, and the automotive and aviation industries took the lead in introducing CNC production lines.

Integration of computer technology (1980s-2000s)

With the maturity of microprocessor and graphical interface technology, CNC entered the PC control era. In 1982, Siemens of Germany launched the first microprocessor-based CNC system Sinumerik 800, whose programming efficiency was 100 times higher than that of paper tape. The integration of CAD (computer-aided design) and CAM (computer-aided manufacturing) software allows engineers to directly convert 3D models into machining codes, and the machining accuracy of complex surfaces reaches the micron level. During this period, equipment such as five-axis linkage machining centers came into being, promoting the rapid development of mold manufacturing and medical device industries.

Intelligence and networking (21st century to present)

The Internet of Things and artificial intelligence technologies have given CNC machine tools new vitality. Modern CNC systems use sensors to monitor parameters such as cutting force and temperature in real time, and use machine learning to optimize processing paths. For example, the iSMART Factory solution of Japan's Mazak Company achieves intelligent scheduling of hundreds of machine tools through cloud collaboration. In 2023, the global CNC machine tool market size has exceeded US$80 billion, and China has become the largest manufacturing country with a production share of 31%.

2. CNC machining principles: How code drives steel

The essence of CNC technology is to convert the physical machining process into a control closed loop of digital signals. Its operation logic can be divided into three stages:

Geometric Modeling and Programming

After building a 3D model using CAD software such as UG and SolidWorks, CAM software “deconstructs” the model: automatically calculating parameters such as tool path, feed rate, spindle speed, and generating G code (such as G01 X100 Y200 F500 for linear interpolation to coordinates (100,200) and feed rate 500mm/min). Modern software can even simulate the material removal process and predict machining errors.

Numerical control system analysis and implementation

The "brain" of CNC machine tools - the numerical control system (such as Fanuc 30i, Siemens 840D) converts G codes into electrical pulse signals. Taking a three-axis milling machine as an example, the servo motors of the X/Y/Z axes receive pulse commands and convert rotary motion into linear displacement through ball screws, with a positioning accuracy of up to ±0.002mm. The closed-loop control system uses a grating ruler to feedback position errors in real time, forming a dynamic correction mechanism.

Multi-physics collaborative control

During the machining process, the machine tool needs to coordinate multiple parameters synchronously: the spindle motor drives the tool to rotate at a high speed of 20,000 rpm, the cooling system sprays atomized cutting fluid to reduce the temperature, and the tool changing robot completes the tool change within 0.5 seconds. For example, when machining titanium alloy blades, the system needs to dynamically adjust the cutting depth according to the hardness of the material to avoid tool chipping.

3. The future of CNC technology: cross-dimensional breakthroughs and industrial transformation

Currently, CNC technology is facing three major trends:

Combined: Turning and milling machine tools can complete turning, milling, grinding and other processes on one device, reducing clamping time by 90%;

Additive-subtractive integration: Germany's DMG MORI's LASERTEC series machine tools combine 3D printing and CNC finishing to directly manufacture aerospace engine combustion chambers;

Digital Twin: By using a virtual machine tool to simulate the actual machining process, China's Shenyang Machine Tool's i5 system has increased debugging efficiency by 70%.

From the meshing of mechanical gears to the flow of digital signals, CNC technology has rewritten the underlying logic of the manufacturing industry in 70 years. It is not only an upgrade of machine tools, but also a leap in the ability of humans to transform abstract thinking into physical entities. In the new track of intelligent manufacturing, CNC technology will continue to break through the limits of materials, precision and efficiency, and write a new chapter for industrial civilization.

#prototype machining#cnc machining#precision machining#prototyping#rapid prototyping#machining parts

2 notes

·

View notes

Text

EXPLORING THE 5 COOL PARTNER SELLER ELECTRONICS PRODUCTS-Part1

Exploring the 5 Cool Partner Seller Electronics Products

Prologue

Are you an electronics enthusiast looking to expand your electronics project repertoire? Want to take your skills to the next level by exploring new and exciting products? Look no further than our list of five cool electronics products from partner sellers!

Whether you’re interested in building your own smart home devices, experimenting with sensors, or creating your own robot, these products are sure to inspire you. They cover a lot of application areas, from loop detectors used to monitor vehicle count in parking garages to Arduino CNC shields used in CNC machines, from simple pulse sensors used to detect cardiovascular pulse signals from fingertip to RGB LED panel light used in smart home, these products are unique, compact, and functional. Not only are these products fun to build and use but they’re also designed to help you learn new skills and techniques along the way.

What’s more, these products all come from trusted partner sellers who are committed to developing high-quality products. They’re happy to provide technical support for customers who have questions, so you can be sure you’re getting the best in electronics.

So get ready to dive into the world of electronics and explore these five cool partner seller products. You’re sure to find something that piques your interest and takes your own electronics projects to the next level.

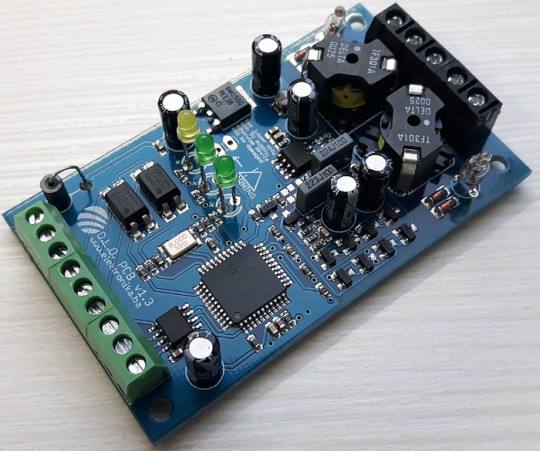

Inductive Loop Vehicle Detector by Elektronika-ba

Whether you need to monitor occupancy and count vehicles in parking garages, control vehicle access at door and barrier controls, or facilitate traffic light installations and traffic controllers, the inductive loop detector is the perfect solution. It can even detect the direction and speed of vehicle traffic, making it an invaluable tool for a variety of traffic-related applications. In addition, this device can function as a stand-alone speed trap and can be easily interfaced with Arduino.

We can also provide a pre-programmed PIC chip to meet your project requirements.

Specifications

Number of operating modes: 4

Tuning: Automatic

Detection type: Presence/Pulse

Presence time: Adjustable in 3 steps

Pulse duration: 250 ms / 500 ms

Signal filtering: Adjustable in 2 steps (NORMAL, HIGH)

Loop inductance: 20 uH — 1000 uH

Frequency range: 20 kHz — 145 kHz

Frequency selection: 2 combinations (LOW, HIGH)

Sensitivity: Maximum 0.0025% Δf/f, adjustable in 8 steps

Detection speed: 10 ms by default, adjustable

Start-up time: ~ 1 second per channel (or longer if the frequency is not stable)

Temperature range: -35°C — 120°C

Sensor protection: Galvanic isolation + gas discharge tube for lightning protection

Don’t settle for less — click here to learn more about the Inductive Loop Vehicle Detector and experience the compact, yet cool detector!

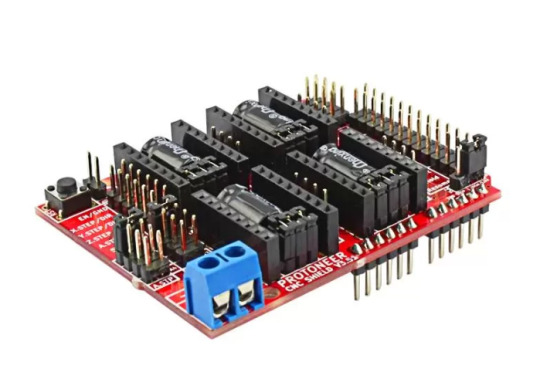

Arduino CNC Shield V3.51 by Protoneer

Designed by Protoneer, this kit is packed with features to ensure high precision control of your stepper motors, you can use it to easily build small CNC routers, DIY laser cutters, 3D printers, or any project that requires precise stepper motor control.

Our latest version 3.51 includes several enhancements to make assembly and installation even easier. We’ve added end-stop and probe signal filtering circuitry to eliminate false triggers and allow the use of unshielded cables for end-stops and probes. We’ve also increased the size of the solder pads for easier assembly and updated the probe pin labels to make installation a breeze.

With the Arduino CNC Shield Kit, you’ll have everything you need to build your own CNC router or mill with ease.

Features

Includes Noise Filers on all end stops and the probing pin. (New in V3.51)

GRBL 0.9 compatible. (Open source firmware that runs on an Arduino UNO that turns G-code commands into stepper signals https://github.com/grbl/grbl)

4-Axis support (X, Y, Z, A-Can duplicate X, Y, Z or do a full 4th axis with custom firmware using pins A4 and A3)

2 x End stops for each axis (6 in total)

Coolant enable

Uses removable Pololu A4988 compatible stepper drivers. (A4988, DRV8825 and others)(Not Included)

Jumpers to set the Micro-Stepping for the stepper drivers. (Some drivers like the DRV8825 can do up to 1/32 micro-stepping )

Compact design.

Stepper Motors can be connected with 4-pin molex connectors or soldered in place.

Runs on 12–36V DC. (At the moment only the Pololu DRV8825 drivers can handle up to 36V so please consider the operation voltage when powering the board.)

Don’t wait — click here to see more about the Arduino CNC Shield V3.51 and start your next project today!

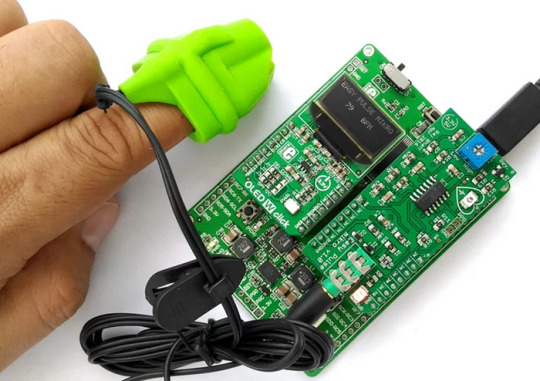

Easy Pulse Mikro by Embedded Lab

What’s more, the Easy Pulse Mikro is designed in the convenient Mikro bus form factor, making it easy to integrate with a wide range of mikroElektronika’s development boards. With all necessary instrumentation and amplification built right in, this powerful sensor provides a clean and precise analog PPG waveform output that’s routed to the AN pin of the mikroBus connector.

Whether you’re a hobbyist, student, or professional developer, the Easy Pulse mikro is the perfect tool for monitoring heart rate and other vital signs.

Click here to see more about the Easy Pulse mikro.

Features

Compatible with mikroBus socket.

Filtered and amplified analog PPG signal output

On-board potentiometer for adjusting amplifier gain, if needed (rotate clock-wise for increasing gain)

Onboard LED for indicating heartbeat. It flashes synchronously with the heartbeat on detecting the pulse from the fingertip.

2 notes

·

View notes

Text

Boosting Machining Accuracy and Performance with WIDMA’s Precision Tools

In today's competitive manufacturing landscape, precision and efficiency are paramount. Industries such as automotive, aerospace, and general engineering demand high-quality machining solutions to meet stringent requirements. WIDMA, a division of Kennametal India, offers a range of advanced machines designed to enhance machining accuracy and performance. This article explores how WIDMA's Tool Grinding Machines, Fine Boring Machines, and Deep Hole Drilling Machines contribute to superior manufacturing outcomes.

Enhancing Tool Life with WIDMA's Tool Grinding Machines

WIDMA's Tool Grinding Machines are engineered to deliver precision and consistency in tool manufacturing and regrinding processes. Models like the Ezeegrind Pro+ and Ezeegrind Neo are five-axis CNC machines suitable for producing and resharpening carbide round tools. They accommodate tool diameters ranging from 3 to 16 mm and offer a maximum flute length of 170 mm. The Ezeegrind Pro+ features a two-wheel pack Automatic Wheel Changer (AWC), enhancing productivity, especially when grinding complex geometries.

Key features include:

Direct Drive Grinding Spindle: Provides 7 kW continuous power (11 kW peak) for stable and efficient operations.

Advanced Software Options: ProfSIM and SV Toolbox software facilitate the production and regrinding of standard and complex tools.

Safety and Connectivity: Equipped with safety interlocks, remote diagnostics, and optional IoT capabilities for real-time monitoring.

These machines ensure extended tool life, reduced downtime, and consistent quality, making them indispensable in modern machining setups.

Achieving Precision with WIDMA's Fine Boring Machines

Precision in bore finishing is critical in applications like engine block manufacturing and hydraulic component production. WIDMA's Fine Boring Machines are designed to meet these exacting standards. Available in vertical and horizontal configurations, these machines can be equipped with single or multiple spindles to suit various production needs.

Notable features include:

Tool Correction Feature: Ensures high-precision bore dimensions, enhancing the quality of the final product.

Flexible Configurations: Adaptable to different component sizes and production volumes.

By delivering accurate and smooth bore finishes, WIDMA's Fine Boring Machines play a vital role in improving the overall performance and reliability of critical components.

Deep Hole Drilling Excellence with WIDMA's Solutions

Deep hole drilling presents unique challenges, including maintaining straightness and achieving precise depths. WIDMA addresses these challenges with its range of Deep Hole Drilling Machines, including the Gun Drilling Machines and BTA Drilling Machines.

These machines offer:

Multiple Spindle Options: Configurations ranging from one to four spindles to match production capacity requirements.

Advanced Coolant Systems: Enhance tool life and maintain drilling accuracy.

Modular Design: Facilitates quick deliveries and greater flexibility in operations.

WIDMA's deep hole drilling solutions are ideal for industries requiring precise and efficient drilling capabilities, such as oil and gas, medical implants, and defense sectors.

Why Choose WIDMA for Precision Machining Solutions?

WIDMA stands out in the machining industry for several reasons:

Technological Innovation: Continuous development of advanced CNC machines tailored to industry needs.

Customization: Ability to provide solutions that meet specific customer requirements.

Global Recognition: Trusted by leading manufacturers worldwide for quality and performance.

By integrating WIDMA's precision tools into your manufacturing processes, you can achieve higher accuracy, improved efficiency, and superior product quality.

Incorporating WIDMA's advanced machining solutions into your operations can significantly enhance machining accuracy and performance. With a commitment to innovation and quality, WIDMA continues to be a reliable partner for industries aiming for excellence in manufacturing.

0 notes

Text

How to Select Top-Quality 5-Axis CNC Machining Providers

Selecting a top-quality 5-axis CNC machining provider is a critical decision for manufacturers, engineers, and procurement specialists who require precision parts and components. Whether you're in aerospace, automotive, medical devices, or any industry that demands complex geometries and tight tolerances, the right CNC machining partner can significantly impact product quality, lead times, and cost-efficiency.

This guide explores key factors to consider when choosing a high-quality 5-axis CNC machining services to ensure your manufacturing needs are met with excellence.

1. Understand the Capabilities of 5-Axis CNC Machining

Before you even start your search, it's essential to understand what 5-axis CNC machining offers and why it's necessary for your application. Unlike traditional 3-axis machining, 5-axis machines move the tool or the part in five different directions simultaneously. This capability allows for:

Greater precision

Complex geometries in a single setup

Reduced tooling costs

Faster production times

Industries such as aerospace, defense, energy, and medical often rely on 5-axis machining for parts like turbine blades, impellers, orthopedic implants, and aerospace structural components.

2. Evaluate Technical Capabilities

Not all CNC providers offering 5-axis machining are equal. When evaluating potential partners, assess their technical capabilities by considering:

a. Machine Specifications

Types and brands of 5-axis machines used (e.g., DMG Mori, Haas, Mazak, Hermle)

Tolerances they can achieve (typically within ±0.005mm for high-end applications)

Size and weight capacity of their machines

b. Software and Programming Expertise

CAD/CAM software proficiency (e.g., Mastercam, Siemens NX, SolidWorks)

Ability to handle complex G-code and simultaneous 5-axis programming

Integration with customer CAD files and version control

3. Certifications and Quality Standards

Top-quality providers often have certifications that demonstrate their commitment to precision and process control. Key certifications to look for include:

ISO 9001: General quality management system certification

AS9100: Required for aerospace and defense machining

ISO 13485: Critical for medical device manufacturing

ITAR Compliance: For defense-related projects in the U.S.

These certifications ensure that the provider follows strict manufacturing and inspection procedures, and that they have a documented process for continual improvement.

4. Track Record and Industry Experience

Experience matters, especially when working with highly precise components. Look for a provider with a solid track record in your industry or with similar part requirements. Ask the following:

How many years have they been offering 5-axis CNC services?

Can they provide case studies or references?

What types of projects have they successfully completed?

A provider familiar with the nuances of your industry will be better equipped to handle specific material requirements, compliance issues, and design tolerances.

5. Materials and Machining Capabilities

Top 5-axis CNC shops should have experience working with a variety of materials, including:

Metals: Aluminum, titanium, stainless steel, Inconel, brass, copper

Plastics: PEEK, Delrin, PTFE, ABS, nylon

Composites and exotic alloys

The ability to machine hard-to-work materials without sacrificing quality or tool life is a hallmark of a skilled provider. Ask what materials they specialize in and if they can recommend alternatives that might improve manufacturability or cost.

6. Inspection and Quality Control Processes

Even the best machines can produce poor parts if not properly managed. Inspection capabilities are crucial in selecting a CNC provider. Look for:

CMM (Coordinate Measuring Machine) reports and in-process inspection capabilities

Use of non-contact inspection methods such as laser scanning or optical comparators

First Article Inspection (FAI) protocols and Statistical Process Control (SPC) capabilities

A shop that emphasizes inspection and provides detailed documentation with each part shipment shows a commitment to quality assurance.

7. Lead Times and Production Capacity

Timely delivery can be just as critical as precision. Ask the provider about:

Their average lead times for prototyping, low-volume, and high-volume orders

Capacity to scale with your production demands

Availability of backup machines and scheduling flexibility

Delays in manufacturing can cause major setbacks, especially for time-sensitive markets like medical devices or defense. A reliable provider should have the bandwidth to meet tight deadlines without compromising on quality.

8. Customer Service and Communication

Clear, responsive communication is often overlooked but vital in CNC partnerships. Look for a provider who:

Assigns a dedicated account or project manager

Responds promptly to RFQs and design change requests

Offers DFM (Design for Manufacturability) feedback to optimize part design

Provides real-time updates during the production process

Transparent communication reduces the risk of errors and ensures that both parties are aligned throughout the manufacturing process.

9. Location and Logistics

While global sourcing is common, geographic proximity can affect lead times and shipping costs. Consider:

Local providers for rapid prototyping or short turnaround jobs

International providers for cost efficiency in high-volume runs (but factor in shipping and customs delays)

Providers with in-house logistics or reliable shipping partners

Some top-tier shops also offer just-in-time (JIT) delivery and kanban inventory management, which can streamline your supply chain.

10. Pricing Transparency and Value

Cost is always a factor, but the lowest price doesn't guarantee the best value. When comparing quotes:

Make sure all pricing is detailed and transparent (materials, setup, tooling, QA)

Watch out for hidden fees for design revisions, expedited service, or post-processing

Consider total cost of ownership, including quality rework, delivery delays, and customer service

A slightly higher upfront cost from a quality provider often translates to long-term savings through reduced waste, faster time-to-market, and fewer part failures.

Conclusion

Choosing a top-quality 5-axis CNC machining provider requires more than a quick Google search or a price comparison. It demands a strategic evaluation of technical expertise, quality systems, industry experience, and customer service.

By focusing on precision, reliability, scalability, and trustworthiness, you can build a strong partnership with a machining provider that enhances your product quality and supports your business goals. Ask detailed questions, visit their facilities if possible, and treat the selection process as an investment in your product’s success.

A high-quality CNC partner isn’t just a vendor—they’re a critical extension of your engineering and manufacturing team.

0 notes

Text

Boost Machining Efficiency with the Right Clamping System: From ER Collets to Zero Point Solutions

In the fast-evolving world of CNC machining and precision engineering, the importance of choosing the right toolholding and workholding systems cannot be overstated. Whether you are focused on high-speed milling, intricate turning, or complex multi-axis machining, selecting the appropriate system can greatly influence productivity, precision, and surface finish. In this blog, we explore five of the most widely used and advanced technologies in this domain: Hydro Grip, ER Collet Chucks, Shrinkfit, Zero Point Clamping Systems, and Electromagnetic Chucks.

1. Hydro Grip: Precision Under Pressure

Hydro grip toolholders utilize hydraulic pressure to achieve a high clamping force on the cutting tool. Known for their exceptional vibration damping and concentricity, hydro grip holders are ideal for applications that require high surface finish and tool longevity. These holders are particularly suited for high-speed machining and fine milling operations, where minimal runout and superior stability are crucial.

2. ER Collet Chucks: Versatile and Economical

The ER collet chuck remains a popular and versatile toolholding solution across a wide range of applications. It can hold drills, taps, reamers, and end mills with various shank sizes using different collet sizes in the same chuck. Their relatively low cost, wide availability, and easy setup make them a favorite in both production and prototyping environments. While not as rigid as some high-end systems, ER chucks offer excellent value and flexibility.

3. Shrinkfit: Heat for High Performance

Shrinkfit holders offer a secure and precise grip on cutting tools by using thermal expansion. The holder is heated to expand the bore, allowing the tool to be inserted, and then it contracts as it cools, gripping the tool tightly. This method provides high concentricity, superior holding power, and is particularly effective in high-speed applications. Although it requires specialized heating equipment, the results are worth it for operations demanding maximum rigidity.

4. Zero Point Clamping Systems: Reduce Setup Time

When it comes to workholding, zero point clamping systems revolutionize how quickly and accurately parts can be positioned on the machine table. By using pneumatic or hydraulic pressure to lock pallets or fixtures into repeatable locations, these systems drastically reduce setup times and improve productivity. Ideal for batch production and modular setups, zero point systems enable rapid changeovers without sacrificing precision.

5. Electromagnetic Chucks: Ideal for Ferrous Materials

For applications involving ferrous workpieces, electromagnetic chucks provide a flexible and non-invasive workholding solution. By using a magnetic field to hold the workpiece, they eliminate the need for mechanical clamps, reducing deformation and allowing machining on multiple sides. Electromagnetic chucks are particularly valuable in grinding, milling, and light-duty machining applications, and their ability to be switched on and off simplifies loading and unloading.

0 notes

Text

5 Common CNC Router Controller Issues and How to Fix Them

In the world of modern manufacturing, CNC routers are indispensable for achieving precision and efficiency. However, even the most advanced machines are vulnerable to technical glitches—particularly with their controllers. A CNC router controller is essentially the command center that translates software instructions into physical movement. When something goes wrong here, it can bring your entire operation to a halt.

This article dives deep into the five most common CNC router controller issues, how to troubleshoot them effectively, and what you can do to prevent them in the future. Whether you're running a small shop or managing a high-volume production line, these insights will help keep your machine in top shape.

1. Controller Won’t Power On

You hit the switch—and nothing. No lights, no motion, no signs of life.

Why It Happens:

Blown fuses or breakers.

Loose or disconnected power cables.

Malfunctioning power supply unit (PSU).

Incorrect input voltage or surge damage.

How to Fix It:

Check and replace any blown fuses.

Make sure power cords are firmly connected and not frayed.

Test the PSU with a multimeter to verify correct output voltage.

Use a voltage regulator or surge protector to prevent future damage.

Pro Tip: Label your power supply connections clearly during setup. It makes troubleshooting faster and easier.

2. Freezing or Crashing During Jobs

Midway through a cut, your router suddenly locks up. Job ruined, material wasted.

Why It Happens:

Controller overheating due to poor airflow.

Bugs or incompatibility in the firmware/software.

Memory overload from excessive G-code complexity.

EMI (electromagnetic interference) or loose data connections.

How to Fix It:

Keep the controller clean and properly ventilated.

Ensure all software and firmware are updated to stable versions.

Break up large files into smaller toolpaths.

Use shielded cables and ensure proper grounding to eliminate EMI.

Maintenance Hack: Consider using CNC Control Retrofits that come with improved cooling and processing power to reduce these occurrences significantly.

3. Axis Movement Not Working

If your CNC router won’t move along the X, Y, or Z axis, you’re essentially grounded.

Why It Happens:

Stepper driver failure.

Motor or cable disconnects.

Faulty G-code or coordinate settings.

Loose or stripped motor couplings.

How to Fix It:

Double-check driver and motor connections.

Test drivers individually by swapping them between axes.

Inspect and fix any loose mechanical parts.

Review your CAM setup to ensure proper motion commands are being sent.

Upgrade Tip: If your machine frequently suffers from axis issues, consider CNC Control Retrofits that upgrade your stepper systems to more reliable and powerful servo motors.

4. Controller Doesn’t Connect to Computer

You plug in the USB cable and nothing happens—no connection, no control.

Why It Happens:

Outdated or missing drivers.

Cheap or damaged USB cables.

Wrong COM port selected in software.

Firmware and software version mismatch.

How to Fix It:

Install the correct drivers (often CH340 or FTDI).

Replace USB cable with a short, shielded one.

In your control software, manually select the correct COM port.

Verify the firmware on your controller is compatible with your software version.

Pro Note: Avoid USB hubs. Connect directly to your PC's port whenever possible.

5. Spindle Won’t Start or Has Speed Issues

Spindle problems can cause major setbacks—especially when cuts rely on consistent speeds.

Why It Happens:

No PWM or analog control signal.

Misconfigured spindle driver or VFD.

Incorrect G-code spindle commands (e.g., M3, S1000).

Motor overload or faulty wiring.

How to Fix It:

Ensure all spindle control wiring is secure and accurate.

Verify VFD settings align with your spindle motor specs.

Use test commands (M3 S1000, M5) to isolate the problem.

Test spindle motor directly to confirm it’s functional.

Expert Insight: CNC Control Retrofits often include improved spindle control systems, allowing for smoother and more reliable speed regulation across various materials.

Bonus: Preventing CNC Controller Problems

Fixing problems is good. Preventing them is better. Here’s how:

Regular Cleaning: Dust buildup is the silent killer of electronics.

Firmware Updates: Always run the most stable versions—not betas.

Cable Management: Keep power and signal wires separated.

Surge Protection: Always use voltage regulators or UPS systems.

Monthly Checklist: Schedule a 15-minute inspection every month to check connections, clean filters, and back up your machine settings.

Conclusion

CNC routers are amazing tools—but only when the controller is functioning flawlessly. Whether you're dealing with power issues, motion problems, or connectivity failures, the key is understanding what’s going wrong and how to fix it efficiently.

As we've seen, many common problems can be traced back to simple issues like loose wires or outdated software. But if you're constantly struggling with performance or compatibility, it's worth considering CNC Control Retrofits to upgrade aging systems with modern, more reliable hardware.

By applying the strategies in this guide, you'll not only be ready to fix issues quickly, but you'll also be in a strong position to prevent future downtime, maximize efficiency, and get the most out of your CNC investment.

1 note

·

View note

Video

youtube

Five-axis machining of automobile engines,Simultaneous 5-axis CNC milling is an advanced processing technique that can manufacture high-precision and complex part.

0 notes

Text

Website : https://glcncmachining.com/

Address :

China Factory : #10, Xinrong Street, Chang'an, Dongguan, Guangdong 523845, China

Singapore Factory : No.3 Joo Koon Circle, Singapore 629032

Phone : +86 180 2756 7310

About Great Light GreatLight Metal Technology Co., Ltd CNC MACHINING PTE. LTD Great Light was founded in 2011, Adjacent to Shenzhen, And is located in Chang’an, Dongguan City, The capital of precision processing of hardware molds. Factory is about 7,600 square meters, With 150 employees, Equipped with large high-precision 5-Axis, 4-Axis, 3-Axis CNC Machining centers, Lathes, Milling machines, Grinders, Spark machines, Vacuum mold machines, SLM 3D Printers, SLA 3D Printers, SLS 3D Printers and other peripheral equipment precision equipment 127 sets, With 3 wholly-owned manufacturing factories, Is a production enterprise specializing in precision processing of rapid prototyping handboard models. Great Light focuses on the design, processing, customized production and application of precision handboard models, Providing new and old users with precision CNC Processing services (three-axis, four-axis, five-axis processing), CNC Milling services, Die-casting molds/metal die-casting processing services, Vacuum casting customization, Sheet metal processing customization, Stainless steel 3D printing, Aluminum alloy 3D printing, Titanium alloy 3D printing, Mold steel 3D printing and nearly 100 kinds of rapid prototyping processing services and comprehensive solutions. And it is equipped with a one-stop post-surface processing service. Great Light has many years of experience in precision prototype model processing, With high precision (±0.001mm / 0.001 In and above precision requirements can be processed), After-sales guarantee, Free rework for quality issues.

Business Mail : [email protected]

#CNC Machining#CNC Machining Services#5-Axis CNC Machining#4 Axis CNC Machining#3 Axis CNC Machining#CNC Milling & Turning#Sheet Metal Fabrication

1 note

·

View note

Text

5 Axis CNC Milling Router Machine for Custom Mold

5 axis CNC wood machine is a highly advanced and versatile machine that can greatly improve the speed, accuracy, and quality of woodworking projects. By providing greater flexibility and precision in the cutting process, a 5-axis CNC wood machine can help woodworkers to create complex and intricate designs with ease and efficiency.By providing greater flexibility and precision in the cutting process, a 5-axis CNC milling router can help manufacturers and designers to create complex and intricate designs with ease and efficiency.

So this 3d CNC router milling machine can realize embossing, lettering, hollowing, cutting, vertical carving, round carving, etc,it also can be seamlessly spliced, suitable for various shapes.And this machine has widely used in foam molds, wooden sculptures, aerospace models, disappearing casting foam molds, large sculptures, wedding decorations, external wall dry hanging, garden engineering, large sculptures, handicrafts and other industries.

5 axis cnc router machine for sale

The 5 axis CNC mill is equipped with a 5-axis head, and plus a 9kw automatic tool change air cooling spindle, which makes the machine more powerful. Syntec CNC controller Taiwan of 5 axis foam CNC has high-speed precision, which greatly improves the production efficiency of 5 axis router. The 5 axis router is suitable for processing foam, 3D molds, other materials.If you plan to buy a Chinese 5 axis CNC mill, iGOLDENCNC’s multi-function 5 axis woodworking CNC machine will be your best choice.

5-axis machining also provides the ability to machine extremely complex parts from a solid, and this type of machining can also save a lot of drilling time. Drilling a series of holes with different compound angles is very time consuming. With a five-axis machine, the drill can be automatically oriented along the correct axis for each hole, so that the drilling can be completed faster. 5-axis CNC machine can reach even the most complex angles.

If your parts require complex 4D and 5D parts, then you need a machine shop equipped with 5-axis machines and the best operators. Combined with the highest finishing and tolerances, we are able to achieve complexity that cannot be achieved with 2-axis or 3-axis machine. It only needs to be set once, which can be transformed into higher productivity and higher workpiece quality. This process allows you to machine complex parts that would otherwise require casting. If you have low-volume production or prototype manufacturing, you can machine parts in a few weeks instead of waiting months to complete the casting.

Automatic tool changers: These systems can automatically changecutting tools during the cutting process, allowing the machine to perform multiple operations without the need for manual intervention.

T-Slot Working 5 Axis CNC Table

The 5 axis router aluminum CNC router table with “T” groove, the wood CNC table for mechanically fixing the Syntec CNC router is made of a special reinforced aluminum plate and is separated by grooves to accommodate the fixture.

This 5 axis CNC machine has a large workbench, the standard area of the workbench is: 2000*3000*1000mm. This workbench can almost accommodate most materials. And the size of this machine can be customized. The length could be as long as 12 meters, and the width of the machine could be as wide as 3 meters, and the Z working height of the machine could be 2 meters. If you think The size is too large or too small, then you can tell us the size you want, and we can make the machine you want according to your requirements.

Advanced Accessories Of CNC Foam Router Machine

This large 5 axis CNC woodworking machine adopts the Japanese Shimpo reducer, which has high precision, high stability, and good wear resistance. And it adopts the Hiwin square rail. The guide rail is high precision, low noise, wear-resistant, and long service life. The 5-axis CNC router machine uses a vacuum and aluminum T-slot working table, which is multi-functional and the material can be fixed easier.

The 5 axis woodworking cnc router with ATC function, it’s easy to accomplish full set processing of complex parts from milling, slotting, drilling, sawing, mortise, mortise, etc, the advanced model designed by iGOLDENCNC, combined with a competitive set of configurations.

Hot applications include:

Composite materials industry: Trimming and punching of various composite materials such as plastic parts, glass fiber reinforced plastic parts, rubber and plastic products;

Mold industry: 5 axis processing of FRP wood mold, casting wood mold, resin products, sludge model and various non-metal molds;

Ceramic sanitary industry: 5 axis processing of gypsum molds, 5 axis processing of various gypsum products;

Furniture industry: 5 axis processing of solid wood furniture, 5 axis processing of various furniture tenon and mortise pieces, 5 axis processing of stair elbows, and 5 axis processing of various furniture.

0 notes

Text

Optimizing Large Component Machining with Vertical Turning Lathes

In today’s fast-paced manufacturing world, handling large and heavy components efficiently is a common challenge. When precision meets weight, traditional horizontal machining solutions often fall short. That’s where Vertical Turning Lathes (VTLs) come into play, offering a high-performance solution for industries that deal with bulkier parts. Let’s dive into how these machines—alongside Vertical Turret Lathes and 5-axis turnmill centers—optimize production, and why WIDMA is a name you should know.

Why Vertical Turning Lathes Are a Game-Changer

Imagine trying to machine a massive pump housing or a large motor body on a traditional lathe. Balancing the component, ensuring accuracy, and maintaining safety becomes cumbersome. A Vertical Turning Lathe solves this by positioning the workpiece vertically—letting gravity do part of the job.

Key Benefits of Vertical Turning Lathes

Gravity-Assisted Work Holding: The vertical orientation naturally stabilizes heavy parts.

Improved Chip Disposal: Gravity aids in removing chips, preventing re-cutting and tool damage.

High Metal Removal Rates: Perfect for roughing operations on large workpieces.

Compact Footprint: Despite their capacity, VTLs take up less floor space than their horizontal counterparts.

Whether you're machining cast iron, steel, or composite materials, VTLs handle the job with remarkable consistency.

Vertical Turret Lathes: A Step Further in Automation

Now take a VTL and add a rotating tool turret—that’s your Vertical Turret Lathe. These machines increase machining flexibility by allowing multiple operations like drilling, boring, and tapping without needing to switch stations.

Advantages of Vertical Turret Lathes

Multiple Tools in One Setup: Reduces cycle time and manual intervention.

Higher Throughput: Especially useful in production environments with repetitive parts.

Consistency and Precision: Automated tool changes mean fewer errors and better repeatability.

For manufacturers aiming to scale efficiently while maintaining accuracy, a Vertical Turret Lathe offers an ideal middle ground between manual machining and full automation.

Embracing the Future with 5-Axis Turnmill Centers

When part complexity reaches another level—say intricate valve components or aerospace parts—you’ll want the flexibility of a 5-axis turnmill center. These machines combine turning and milling in one setup, drastically reducing lead times and setup errors.

Why 5-Axis Turnmills Make Sense

Complex Geometries, Single Setup: Eliminate multiple clamping and repositioning.

Higher Precision: Fewer setups mean fewer chances for dimensional errors.

Time-Saving: Multiple operations executed simultaneously or sequentially in a single go.

Integrating a 5-axis turnmill machine is like hiring a master machinist with five hands. It’s precise, efficient, and incredibly adaptable.

Why WIDMA Stands Out in Advanced Machining

With decades of industry expertise, WIDMA understands the evolving needs of precision machining. Their range of Vertical Turning Lathes, Vertical Turret Lathes, and 5-axis turnmill centers is engineered for industries that can’t compromise on performance.

What Makes WIDMA the Preferred Choice?

CNC-Driven Precision: All machines are designed with state-of-the-art CNC technology.

Industry-Specific Customization: Machines tailored for automotive, aerospace, energy, and general engineering applications.

Plug-and-Play Simplicity: Easy integration into existing production lines with minimal learning curve.

Proven Track Record: Trusted by global OEMs and Tier-1 suppliers.

WIDMA’s VTLs, such as the VT850, are particularly known for their ability to handle large components with exceptional stability and reliability. Their 5-axis VU-1150 turnmill lathe has even redefined how valve bodies are machined, reducing multiple setups into just two.

Conclusion: Smarter Machining Starts with Smarter Machines

Large component machining doesn’t have to be a bottleneck. By leveraging advanced solutions like Vertical Turning Lathes, Vertical Turret Lathes, and 5-axis turnmill centers, manufacturers can achieve higher throughput, tighter tolerances, and more reliable production.

And if you're looking for a partner who understands the nuances of heavy-duty precision machining, WIDMA is ready to deliver. With innovative technologies and a commitment to quality, WIDMA is shaping the future of large component manufacturing—one precise cut at a time.

0 notes

Video

youtube

Automatic Tool Change Five Axis Cnc Router Machine For Woodworking Carv...

0 notes

Text

Hydro Grip and Shrinkfit Explained: Advanced Toolholding for Modern CNC Machines

In the fast-evolving world of CNC machining and precision engineering, the importance of choosing the right toolholding and workholding systems cannot be overstated. Whether you are focused on high-speed milling, intricate turning, or complex multi-axis machining, selecting the appropriate system can greatly influence productivity, precision, and surface finish. In this blog, we explore five of the most widely used and advanced technologies in this domain: Hydro Grip, ER Collet Chucks, Shrinkfit, Zero Point Clamping Systems, and Electromagnetic Chucks.

1. Hydro Grip: Precision Under Pressure

Hydro grip toolholders utilize hydraulic pressure to achieve a high clamping force on the cutting tool. Known for their exceptional vibration damping and concentricity, hydro grip holders are ideal for applications that require high surface finish and tool longevity. These holders are particularly suited for high-speed machining and fine milling operations, where minimal runout and superior stability are crucial.

2. ER Collet Chucks: Versatile and Economical

The ER collet chuck remains a popular and versatile toolholding solution across a wide range of applications. It can hold drills, taps, reamers, and end mills with various shank sizes using different collet sizes in the same chuck. Their relatively low cost, wide availability, and easy setup make them a favorite in both production and prototyping environments. While not as rigid as some high-end systems, ER chucks offer excellent value and flexibility.

3. Shrinkfit: Heat for High Performance

Shrinkfit holders offer a secure and precise grip on cutting tools by using thermal expansion. The holder is heated to expand the bore, allowing the tool to be inserted, and then it contracts as it cools, gripping the tool tightly. This method provides high concentricity, superior holding power, and is particularly effective in high-speed applications. Although it requires specialized heating equipment, the results are worth it for operations demanding maximum rigidity.

4. Zero Point Clamping Systems: Reduce Setup Time

When it comes to workholding, zero point clamping systems revolutionize how quickly and accurately parts can be positioned on the machine table. By using pneumatic or hydraulic pressure to lock pallets or fixtures into repeatable locations, these systems drastically reduce setup times and improve productivity. Ideal for batch production and modular setups, zero point systems enable rapid changeovers without sacrificing precision.

5. Electromagnetic Chucks: Ideal for Ferrous Materials

For applications involving ferrous workpieces, electromagnetic chucks provide a flexible and non-invasive workholding solution. By using a magnetic field to hold the workpiece, they eliminate the need for mechanical clamps, reducing deformation and allowing machining on multiple sides. Electromagnetic chucks are particularly valuable in grinding, milling, and light-duty machining applications, and their ability to be switched on and off simplifies loading and unloading.

0 notes

Text

Undercut machining

In the world of CNC machining, precision and complexity are crucial factors in producing high-quality parts. One such challenging aspect of CNC machining is undercut machining, a specialized process that requires advanced techniques and equipment. This article explores the importance of undercut in machining, the role of 5-axis CNC machining services, and how CNC machining services effectively handle undercut features.

What is Undercut Machining?

Undercut machining refers to the process of creating recesses, grooves, or cutouts in a workpiece that cannot be accessed using conventional machining methods. These undercuts are essential in various applications, including aerospace, automotive, and medical industries, where complex geometries are required for functionality.

An undercut in machining occurs when a part has features that prevent a straight-line toolpath from reaching the desired area. Traditional 3-axis CNC machines struggle to produce these intricate designs, making advanced solutions necessary.

Challenges of Undercut Machining

Undercut machining presents several challenges that require specialized solutions, including:

Tool Accessibility – Standard cutting tools often cannot reach undercut areas due to geometric restrictions.

Precision and Accuracy – Maintaining tight tolerances in undercuts is difficult, requiring precise toolpath programming.

Material Considerations – Different materials respond differently to cutting forces, affecting the machining approach.

Tool Deflection – The use of long-reach tools can lead to deflection, affecting accuracy and surface finish.

To overcome these challenges, manufacturers rely on 5-axis CNC machining services to execute complex machining operations with precision.

Role of 5-Axis CNC Machining Services in Undercut Machining

5-axis CNC machining services play a crucial role in effectively machining undercut features. Unlike conventional 3-axis machines, which have limited movement, 5-axis CNC machines offer greater flexibility by moving in five different directions simultaneously. This capability enables the machining of undercuts with higher accuracy and efficiency.

Benefits of Using 5-Axis CNC Machines for Undercut Machining

Improved Accessibility – The additional two axes allow the cutting tool to reach difficult areas without repositioning the workpiece.

Enhanced Precision – Advanced programming ensures precise tool movement, reducing errors in undercut machining.

Reduced Setup Time – Multi-axis movement eliminates the need for multiple setups, improving production efficiency.

Better Surface Finish – With optimized toolpaths, 5-axis machining provides superior surface quality, reducing post-processing requirements.

Versatility in Complex Parts – The ability to work on intricate designs makes 5-axis CNC machining services ideal for industries demanding precision components.

CNC Machining Services for Undercut Features

High-quality CNC machining services are essential for achieving perfect undercut features in machined parts. At XCMachining, we utilize cutting-edge technology and expertise to deliver precise undercut machining solutions.

How XCMachining Handles Undercut Machining

Advanced CAD/CAM Software – We use top-tier software to create detailed toolpaths, ensuring accuracy in undercut machining.

High-Precision 5-Axis CNC Machines – Our state-of-the-art equipment allows for seamless machining of complex undercut features.

Experienced Machinists – Our skilled team ensures that every project meets high standards of precision and quality.

Custom Tooling Solutions – We develop specialized cutting tools to access hard-to-reach areas effectively.

Material Expertise – From metals to plastics, we handle various materials with optimal machining strategies.

Conclusion

Undercut machining is a vital process in precision manufacturing, requiring specialized techniques and equipment to achieve the desired results. With the advancement of 5-axis CNC machining services, producing intricate undercut features has become more efficient and accurate. At XCMachining, we provide top-quality CNC machining services tailored to meet the demands of industries requiring complex geometries.

For reliable and high-precision undercut machining, trust XCMachining to deliver exceptional results.

0 notes

Text

5 Axis CNC Router for Wood Foam Eps Aluminum

5 Axis CNC Router Woodworking: In the woodworking industry, 5-axis CNC routers are indispensable for crafting intricate furniture, decorative panels, moldings, and architectural components with precision and detail. Whether it’s intricate carvings, complex joinery, or curved surfaces, 5-axis machining opens up a world of design possibilities for woodworkers.

5 Axis CNC Router Foam and EPS: Foam and EPS are widely used in industries such as packaging, insulation, and set design. 5-axis CNC routers enable the precise machining of foam and EPS blocks into custom shapes, packaging inserts, architectural models, and themed props for entertainment and advertising industries.

5 Axis CNC Router Aluminum Machining: Aluminum is a versatile material used in aerospace, automotive, and manufacturing industries due to its lightweight and high strength-to-weight ratio. 5-axis CNC routers excel at machining aluminum components such as aircraft parts, automotive panels, molds, and prototypes with intricate features and tight tolerances.

In the realm of advanced manufacturing, precision and versatility are paramount. Enter the 5-axis CNC router – a game-changer in the world of computer numerical control (CNC) machining. This comprehensive guide is your roadmap to mastering the capabilities and applications of 5-axis CNC routers. From understanding the fundamentals of 5-axis machining to exploring its diverse applications across industries, this guide equips you with the knowledge to unlock the full potential of this cutting-edge technology.

5 Axis CNC Router

A 5-axis CNC router is a machining tool capable of moving a cutting tool along five different axes simultaneously. Unlike traditional 3-axis machines that move along the X, Y, and Z axes, 5-axis routers add rotational movement around two additional axes, typically referred to as A and B axes. This multi-axis capability enables complex machining operations with unprecedented precision and efficiency.

This 5 axis CNC router machine is a 5 axis industrial CNC machining center. And the large 5 axis CNC router machine is designed for industrial use. As a CNC foam wood aluminum router cutter, it can process many materials. The work size of this CNC router machine is can be custom-made, and the length could be as long as 12 meters, and the width of the machine could be as wide as 3 meters, Z working height of the machine could be 2 meters. If you have a large factory, then I think this machine is very suitable for you. It can process almost all kinds of materials and apply to most of the engraving fields. iGOLDENCNC is a well-known 5 axis CNC router manufacturer, if you want to know For more information, please contact us.

By combining these five axes, a 5 axis CNC router machine can achieve complex machining operations and produce intricate parts and components. The simultaneous movement of the axes enables the machine to reach difficult-to-access areas, perform multi-sided machining, and create complex geometries with greater precision and efficiency.

The primary advantage of a 5-axis CNC machine is its ability to machine parts from multiple angles and orientations without the need for repositioning or resetting the workpiece. This capability reduces setup time, improves accuracy, and expands the range of possible machining operations. It allows for the creation of complex shapes, contours, and undercuts that would be challenging or impossible to achieve with fewer axes.

Applications of 5-Axis CNC Router

The versatility of 5-axis CNC routers lends itself to a myriad of applications across industries. In aerospace manufacturing, 5-axis machining is used to produce complex components such as turbine blades, airfoils, and structural components with intricate geometries and tight tolerances.

In the automotive industry, 5-axis routers are employed for prototyping, mold making, and machining of engine components, ensuring precision and efficiency in the production of vehicle parts.

Moreover, in the woodworking industry, 5-axis CNC routers enable the fabrication of intricate furniture designs, architectural components, and artistic sculptures with unparalleled accuracy and detail.

Medical device manufacturing also benefits from 5-axis machining, with applications ranging from orthopedic implants and surgical instruments to prosthetics and dental appliances.

It’s important to note that the specific features, capabilities, and sizes of 5-axis CNC machine can vary depending on the manufacturer and model. Different machines may have different work areas, spindle speeds, tool changers, and control systems. Therefore, it’s crucial to evaluate your specific machining requirements and consult with suppliers or manufacturers to select the most suitable 5-axis CNC machine for your needs.

5-axis CNC router represent the pinnacle of machining technology, offering unmatched precision, versatility, and efficiency. By mastering the capabilities of 5-axis machining, manufacturers can unleash their creativity and innovate across industries, from aerospace and automotive to woodworking and medical device manufacturing. Embrace the power of 5-axis CNC routers and elevate your manufacturing capabilities to new heights of excellence and competitiveness.

0 notes