#Fire Rated Fans manufacturer

Explore tagged Tumblr posts

Text

Are you looking for Fire Rated Fans Manufacturer in India

Fire Rated Fans Manufacturer From Faridabad, India:

Ventilair India Pvt. Ltd. offers Fire Rated fans that are used in exhaust air applications where fresh air intake and cooling are required. Stale & polluted air suction is required. These fans feature cast aluminum alloy impellers, static and static characteristics. dynamically balanced and coupled directly to the electric motor. Fans that fall into this category include wall fans, duct fans, and amplifiers; Mounted on the feet. In case of fire, this fan is suitable for 2 hours at 250 °C. These fans are suitable for underground car park ventilation, tunnel, elevator and booster ventilation; Pressure Scale & Industrial ventilation.

About Us:

Our team of skilled professionals keeps a strict vigil on the manufacturing process to make sure that only faultless products reach our esteemed customers.Established in the year 1988 in Faridabad (Haryana, India), “Ventilair India Private Limited” is amongst the leading Manufacturers and Exporters of a wide variety of air pollution control systems and equipments. Our product range includes Air Cooling System,

Visit Us: Fire Rated Fans Manufacturer

Contact Information:

No. 11/7, Mile Stone, Mathura Road, Faridabad - 121003, Haryana, India

+91 9971026641

0 notes

Text

So I did go see the Borderlands movie this morning, and holy cannoli, it was a flaming dumpster fire of a movie. Spoilers about below just FYI

However!

Kevin Hart ended up being one of the saving graces when I thought he would be the worst of the lot! Sure, he doesn't physically embody Roland from the games, but performance and combat-wise, he was very solid! Jamie Lee Curtis as Tannis was alright as well. She nailed a lot of Tannis' mannerisms to a T, and overall, unlike Lilith and Moxxi, I didn't mind her being aged up. Kreig was great despite being pretty much silent most of the game, and looked like he'd been quite literally pulled right out of the game and dropped into the movie.

Tina was very meh, it's like they wanted her to me more unhinged but restrained themselves at the last moment, and it doesn't work in the Borderlands world. They also had this thing where she's really a clone of a supposed "Daughter of Eridium", whatever the hell that means??? I think if it had been rated R or unrated like it should have been, Tina would have made more of an impact, but she just ended up being very meh.

Lilith was...well, I'm not sure. Most of the movie kinda centers around her backstory/her mom, which tbh is not what I wanted to see from a Borderlands movie? Like seeing some twists about Pandora/her being older was fine, but to have almost everyone fawning over her/her mother got old super quick, and they waited until the end for her to be the badass siren we all know and love??? I'm not the biggest Lilith fan, but Cate did her best with a script that couldn't decide if they wanted Lilith to be an asshole or sympathetic, which for an actor who's played/loves the games, has to suck :/

Jack Black was not great, and to find out he VA'd the Claptrap lines before they started filming makes his odd detachment make so much freaking sense. It always felt like Claptrap was just slightly removed from everything, and I couldn't nail down why until I googled that midway through the movie (which btw my sister, a friend, and I were the only ones in it lol). They should have just gotten the VA for him, Jack was not it :/

The CGI was either really good or really bad, and Lilith's wig did not blend in with any of it at all lmao. The sets/Pandora/costumes, aside from Tina's, were pretty damn good, but where it really shined was the guns. I could literally point out specific guns and their manufacturers despite all the motion of combat, and to be able to do that for even a casual gamer? Loved it.

Sadly though, despite them having been credited for months leading up tot he film, Hammerlock, Wainwright, Ellie and Scooter all got cut from the movie and it's a fucking travesty. I was kind of hoping Hammerlock would kick ass, but to get to the end and find out the asshat who ruined this movie said "oh they were gone for pacing" made me SO mad.

THEY FILMED A WEDDING SCENE YOU ASSHAT, I WANT THAT FOOTAGE AND I WANT IT NOW

Overall, my score is a 1.5/10

#personal#borderlands#borderlands movie#borderlands movie spoilers#idk if it's even worth tagging this lol

32 notes

·

View notes

Text

when i found out that mr puzzles was originally a human in the canon smg4 series, i was like "oh wow i was right, i was fucking right about this" since i headcanoned him to be originally a human in the past so for this post ill be the first to fill up the shit for mr puzzles past self

under the cut ↓↓↓

peak grammar: on

Long long ago, a boy named Terry Vincent Winston grew up watching a lot of TV shows, which inspired him to work on a TV station. Because of this, he became asocial to everyone else—including his friends and families—and dropped out from school 5 times. He is a big fan of old-school cartoons and is also happens to be an artist, as he used to draw characters from one of his favorite cartoon show.

In his 20s, Winston is looking for available jobs for any TV stations but he can't find a single thing since he wasn't too much interested in becoming an actor; so instead he found The Puzzlevision Company, a multinational manufacturing multi-industry. The Puzzlevision Company is seperated by two companies: the main company where they produce Puzzlevision televisions, and Puzzlevision Entertainment for multimedia works produced by Winston. He used to be fine with ratings that are not under 3 stars, and 50,000,000 Puzzlevision TVs are sold worldwide.

However, with new shows produced with higher ratings than his own shows, Winston started to become a hypocrite and also a perfectionist as he started to worry about the future ratings on his shows. After new informations about him abusing his power as the CEO by manipulating his workers in order to have his shows flawlessly perfect came out, his reputation and public image were tainted. Due to this, he was fired and replaced with a new CEO that's kinder than Winston himself.

To hide his true identity, he programmed a mechanical body, decaptivated his own head, and become the being seen today. He also decided to make his own shows while not connected to Puzzlevision Entertainment.

----

aaaaaand thats it for todays episode hope you guys like it

(his backstory might change in the future but idk if i would)

#smg4#supermarioglitchy4#supermemeguardian4#mr puzzles#smg4 mr puzzles#tv adware#smg4 puzzlevision#smg4 tv adware#puzzlevision#i love writing even though i write like shit

23 notes

·

View notes

Text

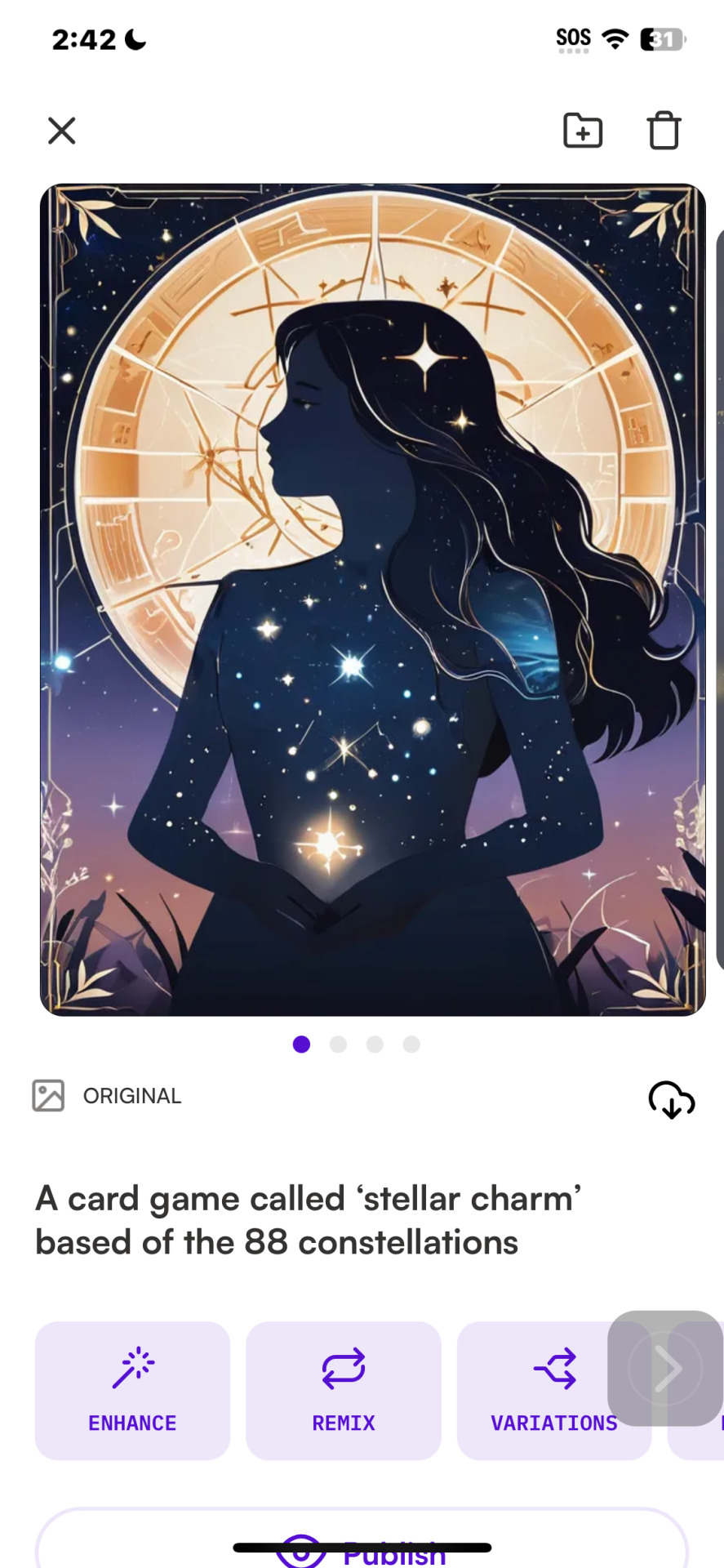

Business Model for Stellar Charm:

Target Market: The target market for Stellar Charm will be primarily young adults and teenagers who are interested in strategy-based card games. The game will also appeal to astronomy enthusiasts and fans of fantasy and mythology.

Revenue Streams: The primary source of revenue for Stellar Charm will be the sales of the game itself. In addition, the game can generate revenue through expansion packs, limited edition cards, and merchandise such as t-shirts, posters, and figurines.

Distribution Channels: Stellar Charm will be sold through various distribution channels such as online marketplaces like Amazon and Etsy, as well as through brick and mortar stores specializing in board games and card games. The game will also be available for purchase directly from the company's website.

Marketing and Advertising: To reach the target market, Stellar Charm will utilize a mix of digital and traditional marketing strategies. This will include social media marketing, influencer partnerships, targeted online ads, and participation in gaming conventions and events. The game will also have a strong presence on popular gaming forums and communities.

Production and Manufacturing: The game will be produced and manufactured in-house to maintain quality control and minimize production costs. This will also allow for faster turnaround time for new expansions and updates.

Pricing Strategy: The price of the base game will be set at a competitive rate to attract customers. Expansion packs and limited edition cards will be priced slightly higher to appeal to collectors and enthusiasts. Discounts and promotions will also be offered periodically to encourage sales.

Customer Support: Stellar Charm will have a dedicated customer support team to handle any queries or concerns from customers. This will ensure a positive customer experience and help build brand loyalty.

Partnerships and Collaborations: In order to increase brand awareness and reach a wider audience, Stellar Charm will collaborate with other popular games and brands. This can include cross-promotion, co-branded products, and special events.

Cost Structure: The main costs involved in running the business will include production and manufacturing costs, marketing and advertising expenses, and operational expenses such as rent, utilities, and salaries. The company will also invest in research and development to continuously improve the game and create new expansions.

Future Plans: As the game gains popularity, the company can consider developing a digital version of Stellar Charm for mobile or computer platforms. This can open up new revenue streams and reach a larger audience. The company may also consider licensing the game to other countries to expand its market reach. Play style

Card Name and Type: This feature displays the name of the battle card and its type, such as "Stellar Charm - Magical" or "Stellar Charm - Elemental". This helps the player identify the card and its category, which can be useful in planning their strategy.

Element: The element of the card is represented by a symbol or color and is crucial in determining its strengths and weaknesses. For example, a water element card may be strong against fire but weak against lightning. The player must keep this in mind when using the card in battles.

Attack Points: This feature displays the attack points of the card, which represents its offensive power. The higher the attack points, the stronger the card's attack will be. The player can use this information to strategically choose when to use the card in battle.

Defense Points: The defense points of the card represent its defensive capabilities. The higher the defense points, the better the card can withstand attacks from the opponent. The player can use this feature to strategically defend against the opponent's attacks.

Special Ability: Some battle cards may have a special ability that can be activated during battle. This feature will describe the special ability, such as "Healing Aura" or "Double Attack", and how it can be used in battle. The player must carefully consider when to use the special ability to gain an advantage over their opponent.

Fusion Requirements: The fusion requirements feature displays the elements or types of cards needed to fuse with the Stellar Charm card to create a more powerful card. This adds a layer of strategy to the game as the player must strategically choose which cards to fuse with the Stellar Charm card to create the most advantageous outcome.

Lore: The lore of the card provides a background story or description of the card, which can help the player understand the card's role in the game. This feature can also add an element of immersion and depth to the game, making it more engaging for the player. The game would be called "Constellation Clash" and it would be a two-player strategy battle card game. The objective of the game would be to collect and control the most constellations by the end of the game. Card Types:

Constellation Cards

These cards represent the 88 constellations and each one has its own unique abilities and strengths.

Zodiac Cards - These cards represent the 12 zodiac signs and can be used to enhance the abilities of constellation cards.

Star Cards - These cards represent individual stars and can be used to boost the power of constellation cards.

Element Cards - These cards represent the four elements (fire, water, air, and earth) and can be used to counter certain constellation cards.

Action Cards - These cards have various effects and can be used to interrupt or change the course of the game. Card Styles:

Basic Cards - These cards have a simple design and represent the less powerful constellations.

Advanced Cards - These cards have a more intricate design and represent the more powerful constellations.

Mythical Cards - These cards have a unique design and represent the rare and powerful constellations. Gameplay:

Set-Up - Each player starts with a deck of 20 constellation cards, 10 zodiac cards, 10 star cards, and 5 element cards. Each player also starts with 5 action cards in their hand. The remaining action cards are placed in a separate deck.

Turn Sequence - The game is played in turns. Each turn, a player can perform the following actions in any order:

Play one constellation card from their hand onto the field.

Play one zodiac or star card from their hand onto the field, and attach it to a constellation card already on the field.

Play one action card from their hand and resolve its effect.

Battle Phase - Once both players have finished their turns, a battle phase begins. The player who has the most stars attached to their constellation cards has the first attack. Each player takes turns attacking and defending until all battles have been resolved.

Battle Rules - During a battle, the attacking player chooses one of their constellation cards to attack with. The defending player can choose to block the attack with one of their constellation cards or take the full damage. If the attack is blocked, the defender's constellation card is discarded. If the attack is not blocked, the defender takes damage equal to the difference between the attacking constellation card's power and the defending constellation card's power.

Element Advantage - Certain constellation cards have an advantage over others based on their element. If a constellation card with a higher element attacks a constellation card with a lower element, the attacking card's power is increased by 50%.

Mythical Card Rule

If a player has a mythical card on the field, they can choose to activate its special ability once per turn during the battle phase.

End of Turn - After the battle phase, the player can choose to discard any cards from their hand and draw new ones, up to their hand limit of 5 cards.

End of Game - The game ends when one player has control of at least 10 constellations or when one player runs out of cards in their deck. The player with the most constellations under their control wins the game. The phases of the game would develop as players strategically play their cards, trying to gain control of the most powerful constellations and using their zodiac and star cards strategically to enhance their abilities. The game would also require players to carefully manage their resources and choose when to use their action cards for maximum impact. With the mythical cards adding an extra element of surprise, every game would be unique and challenging.

Zodiac Cards: These are the most powerful and rare cards in the game, representing the 12 zodiac signs. Each Zodiac Card has a unique ability and high attack and defense points.

Star Cards: These cards represent the stars within each constellation and are the backbone of any deck. They have a balanced mix of attack and defense points and can be used strategically to support other cards.

Mythology Cards: These cards are based on the ancient stories and myths associated with each constellation. They have powerful abilities that can turn the tide of battle, but are limited in number and should be used sparingly.

Elemental Cards: There are 4 elemental card types in the game - Fire, Water, Earth, and Air, each representing a different element from the universe. These cards have a rock-paper-scissors relationship with each other, with one element being strong against another and weak against the third. They can be used to counter opponent's cards and add an element of strategy to the game.

Celestial Cards: These cards represent celestial objects such as planets, comets, and galaxies. They have powerful abilities that can affect multiple cards at once, but are also limited in number and should be used strategically.

Constellation Cards: These cards represent the constellations themselves and have a unique ability that can only be activated when a player has a certain number of cards from the same constellation in their hand.

Support Cards: These cards do not have any attack or defense points, but instead, provide support to other cards in a player's hand. They can boost attack or defense points, provide additional abilities, or even revive defeated cards. Card Styles:

Standard Cards: These cards have a simple design with the constellation name and image on the front and the card type and stats on the back.

Foil Cards: These are rare and valuable versions of the standard cards, with a metallic sheen and enhanced artwork.

Holographic Cards: These cards have a holographic design that changes depending on the angle they are viewed from. They are highly sought after by collectors.

Legendary Cards: These are the most powerful and rare cards in the game, with unique artwork and abilities. They are highly coveted and can only be obtained through special events or by trading with other players.

Promo Cards: These limited edition cards are only available through special promotions, such as tournaments or special edition sets.

Prism Cards: These cards have a prism design that creates a rainbow effect when viewed under light. They are highly prized by players for their unique design.

Cosmic Cards: These cards have a cosmic design, with images of galaxies, stars, and other celestial objects. They are considered the most visually stunning cards in the game.

#Business model#play styles#card types#rules#objectives#card elements#stellar charm#battle strategy card game#TCG#Stellar Charm Cards

9 notes

·

View notes

Text

VIZSLASABER’S MASTERLIST ──── archive of our own.

MY AO3

flee the fire that devours | WIP, rated T, 34.7k, 4/15 chapters | rex & anakin skywalker, cody/obi-wan kenobi, anakin skywalker & obi-wan kenobi

Rex stands, horrified and still, as Krell starts raving about a new order, a plan, about how blind they’ve been—and the feeling builds.

He won’t soon forget this: the hatred boiling in his feeble, manufactured, armor-protected chest, whispering that he’s no Jedi, that sometimes even unarmed men need to die. Rex’s fingers twitch. Is this what it feels like to make rash decisions, he wonders? Is this what it feels like, right before the pressure finally builds enough to break?

(Rex fires, and Krell lives. The galaxy unspools from there.)

in the absence of the sun | complete, rated G, 28.5k, 10/10 chapters | anakin skywalker & obi-wan kenobi & ahsoka tano

“Master,” Anakin says suddenly as they approach the large hangar bay doors. “Do you... remember your mother at all?”

Obi-Wan turns his head sharply. “What?” he replies, just as a thought comes floating to the surface of his mind, made of hot desert sands and kind smiles and goodbye hugs, years ago when he still had someone to turn to (but he never really could turn to Qui-Gon, could he, not when the man was too preoccupied with the mistakes he never had the chance to fix).

(On a relief mission to Stewjon, Obi-Wan finds his roots.)

tell it to my heart | oneshot, rated G, 1.8k | tech/phee genoa

“You miss him,” Phee says. It isn’t a question.

“He is helping the enemy,” Tech replies. His throat feels tight.

Phee gives him a meaningful look. “Doesn’t mean you can’t miss him, Brown Eyes.”

18+ a river runs through it | oneshot, rated E, 12k | cody/fem!obi-wan kenobi

There is a kind of fear that is unique to a Jedi.

(Cody and Obi-Wan. A lesson in attachment.)

stories of home | oneshot, rated G, 1.7k | obi-wan kenobi/satine kryze

Her words are so quiet that Obi-Wan has to lean closer, even when Satine's cheek is pressed into his chest and his hand is gripping hers. He feels her breath fan on his chest, sees her lips move, but her words are lost to the midnight breeze.

Now with his ear just above her mouth, Obi-Wan breathes, “What?”

She clears her throat softly, then straightens, adjusting both of their positions but keeping their fingers intertwined. This time, when she says them, Satine's words are more clear: “Tell me a story.”

(In a clearing in the forests of Draboon, Satine voices an idea.)

LAST UPDATED | May 13, 2024

#masterlist#tcw fanfic#ao3#ao3 fanfic#star wars the clone wars#star wars#the bad batch#obitine#codywan#commander cody#satine kryze#techphee#fluff#fic recs#sw fic rec#sw fic#codywan smut#star wars: the clone wars#archive of our own#vzs masterlist

15 notes

·

View notes

Text

Discover Japan’s Finest Whisky: A Guide to Premium Bottles

For whisky fans, Japanese whisky is synonymous with excellence, craftsmanship, and deep-rooted subculture. From the sensitive balance of Hibiki blends to the peaty richness of Yoichi malts, Japan gives a number of the maximum subtle and sought-after whiskies in the international. Whether you're a pro collector or just beginning your whisky journey, experiencing bottles like Yoichi, Hakushu Kogei Peated Malt, Hibiki 100th Anniversary, Yamazaki Kogei, Yamazaki 18 Year, Hibiki 21 Year, and Yoichi 10 Year Single Malt is a need to. Let’s explore what makes these premium whiskies unique and wherein to find them.

The Excellence of Yoichi Whisky

Hailing from Japan’s northernmost distillery, Yoichi whisky is thought for its bold and smoky man or woman. The maritime weather of Hokkaido, mixed with traditional coal-fired pot nonetheless distillation, imparts a deep complexity to its flavors. Whisky lovers who experience peaty notes and a protracted, warm finish will locate Yoichi a super match.

For an excellent extra delicate enjoy, Yoichi 10 Year Single Malt stands proud with its properly-balanced smoky aroma, suggestions of dried fruit, and oak. Aged to perfection, this whisky promises a smooth yet effective ingesting enjoy that showcases the first-rate of Japanese single malts.

Hakushu Kogei Peated Malt – A Unique Peaty Delight

For individuals who admire peated whisky with a hint of Japanese elegance, Hakushu Kogei Peated Malt is a incredible desire. Produced inside the lush forests of Hakushu Distillery, this whisky contains a clean, earthy person with layers of smoke, inexperienced apple, and herbs. It’s an excellent bottle for folks who love the complexity of peated whiskies however prefer a cultured and sensitive finish.

Celebrating Hibiki’s one centesimal Anniversary

One of the maximum celebrated whisky manufacturers in Japan, Hibiki, marks its legacy with Hibiki one centesimal Anniversary. This restrained version launch embodies the harmony of mixed whisky, combining special malt and grain whiskies to create an top notch balance of sweetness, spice, and oak. The elegant bottle design and rich, multi-layered flavors make it a prized addition to any whisky series.

The Craftsmanship of Yamazaki Kogei

Yamazaki Kogei is a extraordinary expression from Japan’s first and most well-known whisky distillery, Yamazaki. Crafted the use of first-class craftsmanship and innovative getting old strategies, this whisky gives a deep, delicate taste with notes of dark fruit, honey, and subtle spice. For folks who recognize a whisky with historical past and complexity, this bottle is a should-attempt.

Yamazaki 18 Year – A Masterpiece of Aging

Among Japan’s maximum prestigious elderly whiskies, Yamazaki 18 Year is a collector’s dream. This single malt whisky is aged in a aggregate of American, Spanish, and Japanese Mizunara okaycasks, giving it a one-of-a-kind profile with layers of dried fruit, chocolate, and sandalwood. It is an excellent preference for unique occasions or as a steeply-priced gift for whisky fanatics.

Hibiki 21 Year – A True Whisky Legend

Regarded as one of the greatest combined whiskies within the international, Hibiki 21 Year is a rare and splendid spirit. Aged for over many years, this whisky gives a velvety clean texture with wealthy notes of darkish chocolate, dried fruit, and Mizunara very wellspice. Its perfect balance and lingering end make it a ought to-have for severe creditors and connoisseurs.

0 notes

Text

Jet Fan Basement Ventilation Supplier in Maharashtra

Axialair Corporation is a leading Manufacturer and Supplier of Jet Fan Basement Ventilation Supplier in Maharashtra, India. We are based in Ahmedabad, Gujarat, India. Axialair Corporation is a leading provider of innovative and high-quality Jet Fan Basement Ventilation solutions designed to improve air circulation, enhance safety, and ensure optimal indoor air quality. Jet fans are an essential component in underground and basement ventilation systems, particularly in commercial, industrial, and residential settings, where traditional ventilation methods might not suffice. Our Jet Fan Basement Ventilation Systems are engineered to provide efficient and reliable ventilation, ensuring a healthy and safe environment while optimizing energy usage and reducing operating costs. Specifications: Usage/Application: Basement Ventilation Power: 100 W Current: 20 A Speed: 2800 RPM Size: 406 mm (Diameter) Material: Mild Steel Airflow Capacity: 6500 CFM Mounting Type: Roof Mounted Surface Finish: Polished Sound Level: 63 dBA Applications: Parking Garages Underground Facilities Data Centers Emergency Ventilation Systems Warehouses and Industrial Spaces What is a jet fan, and how does it work? Jet fans are compact ventilation systems that generate thrust to move air efficiently without requiring extensive ductwork. Are jet fans suitable for fire safety? Yes, fire-rated jet fans are specifically designed to extract smoke and provide clear escape routes during emergencies. Axialair Corporation is Jet Fan Basement Ventilation Supplier in Maharashtra, India Including Mumbai, Pune, Nagpur, Thane, Pimpri-Chinchwad, Nashik, Kalyan-Dombivli, Vasai-Virar, Aurangabad, Navi Mumbai, Solapur, Mira-Bhayandar, Bhiwandi-Nizampur, Jalgaon, Amravati, Nanded-Waghala, Kolhapur, Ulhasnagar, Sangli, Malegaon, Akola, Latur, Dhule, Ahmednagar, Chandrapur, Parbhani, Ichalkaranji, Jalna, Ambarnath, Bhusawal, Panvel, Badlapur, Beed, Gondia, Satara, Barshi, Yavatmal, Achalpur, Osmanabad, Nandurbar, Wardha, Udgir, Hinganghat. Contact us today for inquiries or to place an order! View Product: Click Here Read the full article

#Achalpur#Ahmedabad#Ahmednagar#Akola#Ambarnath#Amravati#Aurangabad#AxialairCorporation#Badlapur#Barshi#Beed#Bhiwandi-Nizampur#Bhusawal#Chandrapur#Dhule#ExporterofJetFanBasementVentilation#Gondia#Gujarat#Hinganghat#Ichalkaranji#India#Jalgaon#Jalna#JetFanBasementVentilation#JetFanBasementVentilationSupplier#JetFanBasementVentilationSupplierinGujarat#JetFanBasementVentilationSupplierinindia#JetFanBasementVentilationSupplierinMaharashtra#Kalyan-Dombivli#Kolhapur

0 notes

Text

Fast-Installed Biogas Storage Tanks With Low Project Cost

In the world of biogas production, whether for energy generation, waste management, or agricultural applications, biogas storage tanks play a crucial role. They must provide a reliable and efficient means of storing biogas produced through anaerobic digestion. Shijiazhuang Zhengzhong Technology Co., Ltd. (Center Enamel) offers Biogas Storage Tanks that combine fast installation, cost-effectiveness, and high-performance standards, making them the ideal choice for both large and small-scale biogas projects.

Why Choose Fast Installed Biogas Storage Tanks?

Biogas storage is essential in managing the volatile nature of biogas production. The production rate of biogas can fluctuate depending on the type of organic waste being processed, the season, and operational conditions. Having a storage system that can respond quickly to these fluctuations is vital to maintaining a consistent supply of biogas.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Center Enamel's Biogas Storage Tanks are specifically designed to address the need for quick installation, low operational costs, and long-term durability, providing the best value for biogas producers. Here are the key benefits and features of our biogas storage solutions:

1. Fast Installation Process

One of the biggest advantages of our Biogas Storage Tanks is their modular design, which allows for fast and efficient installation. The tanks are made of bolted steel panels coated with Glass-Fused-to-Steel or fusion-bonded epoxy coatings, which can be assembled quickly on-site without the need for expensive cranes or complex equipment. The bolted construction eliminates the need for welding, minimizing installation time and reducing labor costs.

Key benefits of the fast installation include:

Minimal construction time: Our biogas storage tanks can be installed in a fraction of the time compared to traditional concrete tanks.

Reduced site preparation: The modular tank design requires less foundation preparation and less space for assembly.

Lower labor costs: The bolted panels are easy to handle and assemble, requiring fewer specialized labor skills.

2. Low Project Cost

Cost-effectiveness is a major concern for biogas plant operators, especially when dealing with large-scale projects or tight budgets. Our Biogas Storage Tanks offer a low initial investment, and the modular bolted design ensures that construction and maintenance costs are minimized.

By opting for Center Enamel's biogas storage tanks, customers can benefit from:

Affordable solution: The bolted construction method reduces both material and labor costs.

Low operational costs: The Glass-Fused-to-Steel (GFS) and fusion-bonded epoxy coatings provide long-term corrosion resistance, reducing the need for repairs and extending the tank's service life.

Energy savings: The robust design minimizes heat loss, helping to maintain the temperature of stored biogas, which improves operational efficiency and reduces energy consumption.

3. Durability and Long Service Life

Biogas storage tanks are exposed to demanding conditions such as fluctuating temperatures, high pressure, and aggressive gases. Glass-Fused-to-Steel (GFS) and fusion-bonded epoxy coatings provide superior protection against corrosion, abrasion, and chemical exposure, ensuring that the tank remains operational for many years with minimal maintenance.

Our biogas storage tanks offer:

Corrosion and abrasion resistance: The durable enamel coating protects the steel from both internal and external corrosion, ensuring longevity even in the most aggressive environments.

High-pressure tolerance: These tanks can withstand the pressure generated by the biogas stored within, preventing rupture and ensuring safe operation.

Leak-proof design: The seamless and smooth interior ensures there are no leak points, which is critical in maintaining the integrity of the biogas system.

4. Environmental Benefits

Biogas is an environmentally friendly source of energy, and our biogas storage tanks further support sustainability efforts by being made of eco-friendly materials. The Glass-Fused-to-Steel coating is a natural product that does not contain harmful substances, making it a safe option for storing biogas and other gases.

The tanks are designed to withstand extreme weather conditions and UV exposure, which is particularly important when tanks are installed outdoors. Additionally, the efficient sealing and insulation properties help to minimize methane emissions, ensuring that the storage system meets stringent environmental regulations.

5. Customizable to Your Needs

Our Biogas Storage Tanks are customizable to meet the specific requirements of each project. Whether you're handling small-scale agricultural waste or managing larger biogas plants, we can tailor the tank size, capacity, and configuration to suit your needs. Additionally, the tank roof design can be adapted based on the biogas storage conditions, such as a double-membrane roof for gas-tightness

Key Features of Our Biogas Storage Tanks

Modular, bolted construction for quick installation and easy relocation if necessary.

High gas-tightness to preserve the integrity of the biogas and prevent loss.

Corrosion-resistant enamel coating (Glass-Fused-to-Steel or Fusion Bonded Epoxy) that provides superior protection against the harsh biogas environment.

Double membrane roof for gas collection and pressure stability or customizable roofs for specific requirements.

Adjustable sizes and capacities to fit different biogas production volumes, ranging from small-scale farms to large municipal facilities.

Designed for high-pressure storage with safe pressure release valves to prevent system overload.

Applications of Biogas Storage Tanks

Biogas storage tanks are used in a wide range of applications, including:

Agricultural biogas plants: Storing biogas produced from organic waste, crop residues, and animal manure.

Municipal biogas plants: Capturing and storing biogas from wastewater treatment facilities and landfills.

Industrial biogas plants: Storing biogas generated by food processing, paper production, and other industries with organic waste.

Energy production: Providing a reliable source of biogas for conversion into electricity, heat, or biomethane.

Installation Process

The installation of Biogas Storage Tanks is simple and fast. The bolted steel panels are assembled on-site, reducing transportation and labor costs. Once the foundation is prepared, the modular panels are bolted together and sealed to form a leak-proof, durable storage unit. Additional accessories, such as pressure relief valves and gas collection systems, are installed as needed.

The installation process includes:

Site preparation and foundation work to ensure stability.

Tank assembly by bolting pre-coated steel panels.

Roof installation based on the selected design (single or double membrane).

Final inspection and testing for gas-tightness and safety.

Shijiazhuang Zhengzhong Technology Co., Ltd. (Center Enamel) offers fast-installed biogas storage tanks that provide exceptional durability, low project costs, and long-term performance. Designed to meet the needs of small and large biogas producers alike, our tanks offer a cost-effective and environmentally friendly solution for biogas storage. With quick installation, minimal maintenance, and customizable sizes, our tanks ensure that your biogas project operates efficiently while minimizing upfront costs and operational expenses.

Contact us today to learn more about our biogas storage tanks and how we can help you build a reliable and sustainable biogas storage system for your wastewater treatment or energy production needs.

0 notes

Text

The Importance of fire-rated wrap in preventing fire spread

While fires can start accidentally, the damage from their uncontrolled spread is fully preventable with the proper safety precautions. One crucial precaution is using fire-rated wrap insulation around structural elements like beams, columns, and ceilings. Understanding how fire-rated wrap contains fires allows us to appreciate its importance for protecting people.

How fires spread

When a fire begins inside a building, it first consumes any nearby flammable materials such as wood or paper. As the fire grows hotter, it releases gases and particles capable of igniting other combustible surfaces they contact. This enables the fire to rapidly fan out across the entire structure. One of the primary means of propagation is through concealed spaces like walls, ceilings, and attic cavities. The intense heat causes flames and burning embers to travel extraordinarily quickly through these spaces, jumping to new locations.

The role of fire-rated wrap

Fire-rated wrap plays a vital role in limiting this path of spread. It is a specifically designed insulation or barrier material that is approved to maintain its integrity when exposed to high heat and flames for a minimum period of time. When wrapped around structural elements, it prevents them from igniting even when the space around them is engulfed in fire.

This stops the fire from penetrating into concealed voids and spreading unseen. The fire-rated wrap also insulates the structure, keeping it from reaching ignition temperatures for longer. Both actions buy critical time for occupants to evacuate and firefighters to respond before the entire building is engulfed.

Testing and ratings

Fire-rated wrap products undergo stringent testing in accredited laboratories to determine their fire resistance rating. The materials are subjected to intense, controlled fires and evaluated on their ability to contain the flames. Ratings of 30 minutes, 60 minutes, or even higher are then assigned based on test results. Proper installation as per the manufacturer's guidelines is also critical for the wrap to perform as rated. Specifying fire-rated wrap insulation rated for the required fire separation period helps assure safety and code compliance.

Beyond the basics

While fire-rated wraps come in different forms like boards, mats, or wraps, not all are equally effective. Opting for ones that incorporate intumescent technologies proves to have better expansion capabilities to fill gaps when exposed to heat or flames. This helps ensure an enhanced seal compared to traditional fiber or cement-based wraps.

Similarly, multipurpose wraps that can act as both thermal insulation and a rated fire barrier save costs by serving dual functions. Overall, the use of fire-rated wrap is crucial wherever there is a risk of hidden fire spread through structural elements, keeping occupants and property safe. Fire-rated wrap insulation plays an important role in controlling the spread of structural fires and buying valuable time for evacuation and emergency response. By containing the fire within the room or area of origin, it prevents an otherwise containable small fire from turning into a disastrous conflagration. While not always visible, the life-saving benefits of using approved fire-rated materials cannot be overstated.

0 notes

Text

Common Issues with Hot Air Generators and How to Fix Them

Hot air generators are essential in various industries, but they can encounter common issues such as uneven heating, poor airflow, and overheating. Uneven heating may be caused by clogged filters or faulty heating elements, which can be fixed by cleaning or replacing these parts. Poor airflow is often due to obstructions in the ductwork or fan malfunctions, requiring regular maintenance and inspection. Overheating could result from a malfunctioning thermostat or inadequate ventilation, which can be resolved by adjusting the settings or ensuring proper airflow. Regular maintenance, timely cleaning, and addressing these issues promptly can prevent more significant problems and extend the lifespan of your hot air generator, ensuring efficient and consistent performance in the long run.

What is a Hot Air Generator and How Does It Work?

A hot air generator is an essential device that converts energy into heat, typically used in industries like food processing, textiles, and chemical manufacturing. These generators work by burning fuel such as diesel, natural gas, or using electricity to heat air, which is then circulated through ducts or directly into workspaces. The process ensures consistent temperature control, making it ideal for applications requiring precise heat management. Understanding how hot air generator operate helps users choose the right type for their specific industrial needs.

Types of Hot Air Generators: Which One Suits Your Needs?

There are different types of hot air generators based on fuel type and design. The three main types are electrical, gas-fired, and diesel-fired generators. Electric hot air generators are ideal for small and medium-scale applications, providing clean energy with minimal emissions. Gas-fired generators are more common in large industrial settings due to their energy efficiency. Diesel-fired generators are preferred in areas where gas supply might be limited. Each type has its pros and cons, and choosing the right one depends on the application, energy source, and operating costs.

Key Features to Consider When Buying a Hot Air Generator

When investing in a hot air generator, it's important to consider several key features. Look for generators with temperature control options, energy-efficient burners, and durable construction. Additionally, some generators come with advanced control panels that allow remote monitoring and automation, which can improve efficiency. The size and capacity of the generator should also match the scale of your operation, ensuring you get the optimal heat output without excessive energy consumption.

Applications of Hot Air Generators in Various Industries

Hot air generators are widely used across various industries, each requiring specific temperature and heating conditions. In the food industry, they are used for drying and baking processes, while in textiles, they aid in processes like dyeing and drying fabrics. Chemical industries rely on hot air generators for precise temperature control in the production of various compounds. These generators are also crucial in the pharmaceutical industry, where they help in the sterilization and drying of materials. The flexibility and adaptability of hot air generators make them essential across different sectors.

Energy Efficiency and Environmental Impact of Hot Air Generators

Modern hot air generators are designed with energy efficiency in mind, which is crucial for reducing operational costs and environmental impact. Energy-efficient models use less fuel, reducing carbon emissions and lowering the overall cost of running the generator. Many newer models come equipped with low-emission burners and better insulation to retain heat, making them more environmentally friendly. Understanding the efficiency ratings and fuel consumption of your hot air generator can significantly impact your overall energy use, especially for large-scale industrial operations.

Maintenance Tips for Prolonging the Life of Your Hot Air Generator

Proper maintenance is key to ensuring your hot air generator performs optimally and lasts longer. Regular inspection of fuel lines, burners, and heat exchangers is essential to avoid potential breakdowns. Clean any residue from the generator’s interior, especially for diesel-fired units, to prevent blockages. Keeping filters clean and ensuring proper lubrication of moving parts will minimize wear and tear. Routine maintenance will not only extend the lifespan of the generator but also improve its efficiency and safety.

Hot Air Generator Price Guide: What to Expect in 2024?

The cost of a hot air generator varies depending on factors like fuel type, capacity, and additional features. In 2024, prices are influenced by advancements in technology, increasing demand for energy-efficient solutions, and stricter environmental regulations. Electric hot air generators tend to be more expensive upfront but offer lower long-term operating costs due to their efficiency. Gas-fired and diesel-fired models may be cheaper initially but can have higher fuel costs. A proper price guide can help you balance initial investment with operational expenses to find the best fit for your business.

Conclusion

Investing in the right hot air generator is crucial for industries that require reliable and consistent heat. With various types available, including electric, gas-fired, and diesel-fired options, businesses can choose based on their specific needs, budget, and energy availability. Key features such as energy efficiency, capacity, and maintenance requirements should be carefully considered to ensure long-term savings and optimal performance. By choosing a high-quality, well-maintained hot air generator, industries can improve productivity, reduce energy costs, and minimize their environmental footprint, making it an essential piece of equipment for efficient operations in 2024 and beyond.

0 notes

Text

0 notes

Text

Best Fan Rod and Junction Box Supplier in India

A junction box plays a crucial role in electrical systems, serving as a protective enclosure where wires are joined together. It ensures that connections are safe, secure, and protected from external elements. Junction boxes help prevent short circuits and electrical fires, making them an essential component in both residential and commercial setups.

Best Junction Box WholesalerWhen looking for the best junction box wholesaler, it's important to find a supplier who provides high-quality products at competitive prices. A good wholesaler ensures timely delivery, reliable products, and excellent customer support, making the purchasing process smooth for contractors and electricians.

Junction Box Manufacturer in IndiaIndia is home to numerous junction box manufacturers, offering a wide range of options to meet diverse electrical needs. These manufacturers use advanced technologies and strict quality controls to ensure their products meet industry standards and provide long-lasting performance in various applications.

Junction Box WholesalerA reliable junction box wholesaler ensures that businesses and contractors have access to quality products at affordable rates. They maintain a large stock of different types of junction boxes, ensuring that buyers can find the right fit for their specific requirements.

Best Junction Box Manufacturers in IndiaThe best junction box manufacturers in India stand out for their commitment to quality, innovation, and customer satisfaction. They focus on producing durable and reliable junction boxes, ensuring that their products can withstand harsh conditions and meet electrical safety standards.

Top Junction Box Manufacturers in IndiaThe top junction box manufacturers in India are known for their expertise in producing a wide variety of junction boxes that cater to various sectors, including residential, commercial, and industrial projects. These manufacturers continually improve their designs to meet evolving electrical safety standards.

Top Junction Box WholesalerA top junction box wholesaler is recognized for their ability to provide consistent supply and excellent service. They work closely with manufacturers to offer the best quality junction boxes to customers at competitive prices, ensuring timely deliveries and product availability.

Cheap Junction Box Manufacturers in IndiaFor budget-conscious projects, cheap junction box manufacturers in India provide cost-effective solutions without compromising on safety or quality. These manufacturers produce reliable junction boxes that meet the basic requirements of electrical installations while keeping costs low.

Fan Rod ManufacturerA fan rod manufacturer specializes in producing rods used for installing ceiling fans at varying heights. These rods are essential for maintaining proper air circulation, especially in rooms with high ceilings, ensuring that fans function efficiently.

Best Extension Fan Rods ManufacturerThe best extension fan rods manufacturer provides sturdy and reliable fan rods that can extend the height of ceiling fans, improving air circulation in large or tall rooms. Their products are made from high-quality materials that ensure durability and stability over time.

Best Fan Rods Manufacturer in IndiaWhen it comes to ceiling fan installations, the best fan rods manufacturer in India offers a variety of sizes and finishes to suit different room designs. Their rods are known for their strength and ability to support ceiling fans securely, ensuring safe and efficient operation.

Cheap Fan Rods ManufacturersFor projects on a budget, cheap fan rods manufacturers provide cost-effective solutions without compromising on quality. These manufacturers focus on producing affordable fan rods that are durable enough to meet the needs of both residential and commercial customers.

Top Fan Rods Manufacturer in IndiaThe top fan rods manufacturer in India is known for providing high-quality, durable fan rods that cater to a variety of ceiling fan installations. Their products are designed to withstand daily wear and tear, ensuring a long-lasting and secure fit for fans.

Top Fan Rods ManufacturerA top fan rods manufacturer consistently delivers high-quality fan rods that meet industry standards. Their products are trusted by electricians and contractors for their durability and reliable performance in a range of settings.

Best Fan Rods WholesalerThe best fan rods wholesaler is a go-to source for contractors and retailers looking to purchase fan rods in bulk. They offer competitive pricing and a wide selection, making it easy for businesses to find the right products for their clients.

Top Fan Rods WholesalerA top fan rods wholesaler stands out for their exceptional customer service, reliable supply chain, and variety of fan rod options. They are a trusted partner for businesses looking to stock up on quality fan rods that meet the needs of their customers.

Best Fan Rod SupplierThe best fan rod supplier ensures that customers receive top-quality fan rods that are durable and well-suited for ceiling fan installations. Their focus on quality and customer satisfaction makes them a preferred choice for electricians and contractors.Best Fan Rod Supplier in IndiaAs the best fan rod supplier in India, this supplier offers a wide range of fan rods that are manufactured to meet the highest safety and quality standards. Their products are designed to be both functional and aesthetically pleasing, making them popular in both residential and commercial markets.

0 notes

Text

Customization in Three-Phase Transformer Manufacturing: Meeting Industry-Specific Requirements

The world of modern industry is diverse, with each sector demanding specialized tools and equipment to suit its unique operational needs. One such critical piece of equipment is the three-phase transformer, an essential component in energy distribution and management systems. While standard off-the-shelf transformers might serve general purposes, many industries require custom-designed transformers tailored to specific operational challenges and requirements. Customization in three-phase transformer manufacturing is thus vital for ensuring optimal performance, safety, and efficiency.

Why Customization Matters

Industries such as renewable energy, mining, oil and gas, heavy manufacturing, data centers, and utilities often operate under specific environmental conditions, regulatory standards, and load requirements. A generic transformer may not always meet the technical, operational, or safety demands of such industries. Customization allows for the modification of core design features, such as voltage ratings, insulation, cooling mechanisms, and size, to ensure that the transformer fits seamlessly within the intended operational environment.

The main reasons industries seek custom three-phase transformers include:

Environmental conditions: Harsh environments, such as those found in mining or offshore oil platforms, demand robust transformer designs capable of withstanding extreme temperatures, humidity, dust, or corrosive substances.

Load variations: Some industries, like data centers or heavy manufacturing, experience significant fluctuations in load. Custom transformers can be designed to handle varying load conditions efficiently.

Energy efficiency: As companies strive to reduce operational costs and environmental footprints, custom transformers are often built to minimize energy losses, improve power quality, and increase overall efficiency.

Compliance and standards: Certain industries, especially those in highly regulated sectors like healthcare or energy, have specific regulatory standards that must be met. Custom transformers ensure compliance with local, national, or international standards such as IEC, IEEE, and NEMA.

Key Aspects of Customization

Customization in three-phase transformer manufacturing involves tailoring different elements to meet specific industry requirements. Here are some of the critical components that can be modified:

1. Voltage and Power Rating

The primary requirement in transformer customization often revolves around voltage and power ratings. Some industries may require high-voltage transformers for long-distance power transmission, while others may need lower voltage transformers to step down electricity for machinery or equipment. Custom three-phase transformers can be designed to operate at the exact voltage and power levels necessary for the industry, ensuring efficiency and minimizing energy losses.

2. Cooling Systems

Different industries require different cooling methods based on operational environments and load demands. For example, oil-immersed transformers are often used in outdoor settings, where natural air cooling may not be sufficient. On the other hand, dry-type transformers are more suited for indoor applications such as hospitals or office buildings, where safety from fire and moisture is critical. Custom transformers can incorporate specialized cooling techniques like forced-air, water-cooled, or fan-assisted systems to meet the environmental conditions and operational needs of various sectors.

3. Core Design and Winding

The transformer core design plays a crucial role in its efficiency and performance. Custom transformers often feature specialized core materials and lamination techniques that reduce hysteresis and eddy current losses. Similarly, winding configurations can be customized for different load profiles or harmonic conditions, ensuring that the transformer operates at peak performance under specific industrial loads.

4. Insulation and Protection

The choice of insulation materials and protective features is often industry-specific. For example, transformers used in renewable energy sectors, such as wind farms or solar installations, must be insulated to handle fluctuating voltages and outdoor conditions. Custom transformers can also be built with added protection features like surge protection, lightning arresters, or overcurrent relays to enhance durability and ensure reliable performance.

5. Size and Installation Constraints

In some industries, space is a premium. Custom transformers can be designed to fit within restricted spaces while still maintaining operational efficiency. This is particularly important in sectors like data centers, where space management is critical, or in offshore platforms where transformers must be compact yet robust.

Industry-Specific Examples of Customization

1. Renewable Energy

The renewable energy industry, including wind, solar, and hydropower, often faces unique challenges in power distribution. Fluctuating energy generation due to environmental factors, coupled with the need to connect to existing grid systems, requires transformers that can handle variable loads. Custom three-phase transformers designed for renewable energy applications often feature advanced voltage regulation, insulation for outdoor conditions, and high efficiency to minimize energy losses.

2. Mining and Heavy Industry

In mining and heavy industry, transformers must be built to endure rugged conditions such as dust, extreme temperatures, and vibrations. Transformers used in mining operations are often custom-designed with reinforced enclosures, enhanced cooling systems, and durable materials to prevent failures in harsh environments. Additionally, they are built to withstand high inrush currents caused by heavy machinery, ensuring a reliable power supply.

3. Healthcare and Data Centers

Both healthcare facilities and data centers demand uninterrupted power supply and high reliability. Custom transformers for these sectors often come with redundant systems, robust surge protection, and specialized cooling mechanisms to ensure continuous operation even during peak loads. In healthcare, transformers must meet strict safety and hygiene standards, while data centers require custom designs that optimize energy efficiency and manage space constraints.

Conclusion

Customization in three phase transformer manufacturing is critical for industries with specialized operational needs. By tailoring core elements such as voltage ratings, cooling systems, insulation, and protection mechanisms, manufacturers can provide transformers that meet the precise demands of each sector. Whether for renewable energy, mining, healthcare, or heavy manufacturing, custom three-phase transformers ensure optimal performance, safety, and compliance with industry-specific requirements, contributing to the overall efficiency and reliability of power distribution systems.

0 notes

Text

Electrical Motor Heat

Electrical motor heat in water pumps is a significant aspect of their operation and efficiency. Here’s a detailed look at how heat is generated in electrical motors, its impacts, and how to manage it:

Sources of Heat Generation in Electrical Motors

Electrical Resistance (I²R Losses):

Stator and Rotor Windings: As electric current flows through the copper or aluminum windings of the stator and rotor, electrical resistance causes heat. This is often the largest contributor to heat in electric motors.

Eddy Currents: These are circulating currents induced within the motor’s iron core, causing additional heating.

Magnetic Losses:

Hysteresis Losses: As the motor’s magnetic field reverses, energy is lost in the form of heat due to the hysteresis in the magnetic materials.

Core Losses: These occur in the laminated steel core of the motor due to alternating magnetic fields.

Mechanical Losses:

Bearing Friction: The bearings supporting the motor’s rotor experience friction, generating heat.

Windage Losses: Air resistance (windage) within the motor as the rotor turns can also produce heat.

Stray Load Losses:

These losses are due to imperfections in the motor’s design and manufacturing, including misalignment and surface roughness of components, leading to additional heat.

Impact of Electrical Motor Heat

Thermal Stress:

Component Degradation: Prolonged exposure to high temperatures can degrade insulation materials, windings, and bearings, reducing the motor’s lifespan.

Efficiency Reduction: Higher temperatures increase resistance in electrical components, further reducing efficiency.

Performance Issues:

Reduced Torque: Excessive heat can reduce the motor’s ability to generate torque, affecting its performance.

Thermal Expansion: Uneven thermal expansion of motor parts can lead to misalignment and increased wear.

Safety Concerns:

Fire Hazard: Overheating can pose a fire risk, especially if the insulation materials catch fire.

Shutdowns: Thermal protection systems may shut down the motor to prevent damage, leading to operational downtime.

Managing Heat in Electrical Motors

Cooling Systems:

Air Cooling: Most electric motors use air cooling, with external fans or fins to increase surface area for heat dissipation.

Liquid Cooling: For high-power applications, liquid cooling systems can be used to effectively remove heat.

Proper Ventilation:

Ensuring adequate airflow around the motor can help dissipate heat. Installing motors in well-ventilated areas can prevent overheating.

High-Efficiency Motors:

Using motors with higher efficiency ratings can reduce the amount of heat generated, as they convert more electrical energy into mechanical energy and less into heat.

Regular Maintenance:

Lubrication: Regularly checking and maintaining proper lubrication reduces frictional heat.

Cleaning: Keeping the motor and its cooling system clean from dust and debris ensures efficient heat dissipation.

Temperature Monitoring and Control:

Sensors: Installing temperature sensors in critical areas of the motor can provide real-time data on operating temperatures.

Automatic Shutdowns: Implementing automatic shutdown features when temperatures exceed safe thresholds can protect the motor from damage.

Material Selection:

Using materials with good thermal properties in motor construction can help manage and dissipate heat more effectively.

Load Management:

Ensuring the motor operates within its rated load limits can prevent excessive heat generation. Overloading a motor can lead to significant increases in heat production.

By understanding and managing the sources of heat generation in electrical motors, the performance and longevity of water pumps can be significantly enhanced. Proper cooling, maintenance, and monitoring are crucial to keeping motors operating efficiently and safely. For more info contact Water Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

Why Modular Cold Rooms are the Future of Cold Storage?

Modular Cold Rooms serve as a vital link in meeting the evolving demands for improved storage and transportation facilities, particularly for small and medium-sized enterprises. These on-site cold storage spaces are customisable in size and capacity, catering to the diverse requirements of various industries like:

Hospitality

Supermarket and retail

Plant cultivation and floriculture

Medications

Seafood and dairy products

Facilities for preparing meat, ripening and processing food

Additional specialised applications

Modular Cold Room is the future of Cold Storage because of the following reasons:

Adaptability - Versatility is the hallmark of Modular Cold Rooms, allowing businesses to tailor the storage space according to their specific needs. Whether it's adjusting refrigeration types, storage capacity, size and thickness, or implementing strip curtains, these rooms offer flexibility for future scalability or expansion.

Simple and Fast Installation - In the building sector, speed is crucial and prefabricated structures can expedite the installation process. With parts prepared in the production facility, assembly is swift and labour is utilised efficiently. This enables you to promptly establish and start utilising modular cold storage facilities.

Mobility - In contrast to traditional construction methods, modular cold rooms offer the advantage of easy assembly, disassembly, and relocation. This makes them beneficial for businesses with fluctuating trade volumes, allowing flexibility to adapt to varying needs over time.

Security & Safety - Reputable suppliers always prioritise the security and safety of modular cold storage. They ensure this by providing control valves and safety switches, along with features that guarantee smooth operation and employee safety.

Trustworthiness - Modular Cold Rooms provide extensive solutions for cold storage needs. They outperform fixed cold rooms in terms of operations, refrigeration capacity, and energy efficiency, regardless of size or modular features.

Total command - Many companies are concerned that the ease of modular cold rooms come at the expense of maintaining proper temperature. However this is not the case every time, instead Cold rooms typically feature microprocessor based electrical control panels for maintaining the proper temperature.

The Efficiency of Energy - Various factors such as the compressor, evaporator, condenser fan motors, type of refrigerator, and insulation materials in walls, doors, and flooring contribute to the energy efficiency of a cold room. To ensure efficient temperature control and overall energy savings, modular rooms are constructed using food-safe, high-density insulated sandwich panels with optimal thermal insulation and fire ratings.

Minimal upkeep - In the long run, regular check-ups are far simpler and less expensive than fixing problems as they arise. Opting for a regular cold room installation from a trusted supplier can simplify routine maintenance tasks and extend the cold room’s lifespan.

Mechair Industries is one of the leading modular cold room manufacturers in India. To get more details about our products, visit our website https://www.mechair.in/

0 notes