#Fertilizer Machine

Explore tagged Tumblr posts

Text

Transform your fertilizer production with Beidou Automatic Control! With 20 years of expertise in top-quality manufacturing, we offer comprehensive solutions tailored to your needs. From automated production lines to specialized mixing and packaging equipment, our products boost efficiency for all scales. Whether you seek customized solutions or standard setups, Beidou Controls delivers reliable support and professional service to propel your business forward. Elevate your production today!

【website】https://www.beidouace.com

【email】[email protected]

#fertilizerequipment#watersolublefertilizer#granulatorfertilizer#energyefficient#automatic#solutions#BeiDou#farmingindustry#manufacturer#NPK#mixing#africabusiness#fertilizermarket

#fertilizer machine#manufacturer#beidou#agriculture#efficient#farming#mixing#solutions#npk fertilizer production line

0 notes

Text

☘☘☘Nice to meet you. ☘☘☘

We are fertilizer machine manufacturer from China. We mainly supply granular NPK fertilizer mixing machines and water soluble fertilizer (powdery/crystal NPK fertilizer mixing) machines, loading belt conveyor, dust removal machines, belt scales as well as pakcaging machines.

Email: [email protected] WhatsApp: +86 187 335 88029 Website: www.beidouace.com

#beidou company#fertilizer machine#fertilizers#fertilizersusidy#compoundfertilizer#fertilizer production line#mineralfertilizer#fertilizervideos#farmingwaste#fertilizerplant#npkfertilizer

0 notes

Text

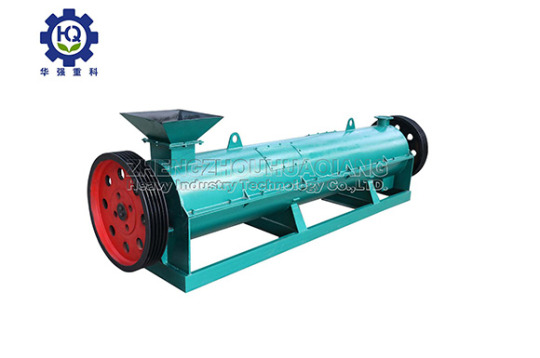

NPK fertilizer production machine: a booster for modern agriculture

In the development process of modern agriculture, NPK fertilizer (nitrogen, phosphorus, potassium fertilizer) plays a crucial role, and NPK fertilizer production machines are the core force to achieve its efficient production.

https://www.organicfertilizerproduction.com/d/pic/industry-info/npk-(1).jpg

The NPK fertilizer production machine is like a precise nutritionist, carefully adjusting the ratio of nitrogen, phosphorus and potassium. It starts with the selection of raw materials and strictly checks to ensure the quality and purity of each raw material. In the production process, through advanced technology and precision control system, according to scientific formula, nitrogen, phosphorus, potassium raw materials are accurately measured and mixed.

The design and functionality of these machines are constantly evolving. Some use efficient mixing devices to ensure the uniform integration of fertilizer components; Some are equipped with advanced granulation equipment, so that the produced NPK fertilizer particles are uniform in size and easy to store and apply. Moreover, in order to ensure the quality and stability of the fertilizer, the production machine also has a strict detection and monitoring system to adjust the production parameters in real time.Many agricultural enterprises use Huaqiang Heavy Industry Technology's advanced NPK

fertilizer production machine, according to the needs of different crops and soil, customized chemical production of a variety of special NPK fertilizer. After these fertilizers are applied to farmland, the yield and quality of crops are significantly improved, and the enterprise has brought rich economic benefits.

In short, NPK fertilizer production machine with its efficient, accurate and reliable performance, provides a steady stream of high-quality fertilizers for modern agriculture, and becomes an important support for promoting agricultural development and ensuring food security.

0 notes

Text

In the last checkpoint of organic fertilizer production, packaging is not only related to the appearance and image of the product, but also the key link to ensure the quality of the finished product and storage safety. Choosing the right packaging machinery is of great significance for enhancing the competitiveness of the organic fertilizer market and extending the shelf life of products. The following three packaging machinery, It is based on the Organic Fertilizer Ring die Granulator , the Disc Granulaor (Pan Granulator) and the New Type Organic Fertilizer Granulator produces organic fertilizer characteristics that are carefully selected to ensure that each grain is perfectly encapsulated and safely reaches the farmer.

Customized packaging machines to suit various needs

For the particles produced by the Organic Fertilizer Ring die Granulator , we recommend the use of packaging machinery with adjustable function. These machines can automatically adjust the packaging parameters according to different particle sizes and densities, ensuring that each bag of fertilizer is neither too tight to cause damage, nor too loose to cause waste. Customized packaging, so that each package of organic fertilizer can accurately match the market demand, improve customer satisfaction.

Moisture-proof sealing treatment of finished products of Disc Granulaor (Pan Granulator)

The organic fertilizer particles produced by the Disc Granulaor are round and full, but attention should be paid to moisture-proof. Therefore, in the packaging process, packaging machinery with efficient moisture-proof and sealing performance should be selected. These machines use high-quality waterproof materials, combined with advanced sealing technology, effectively isolate air and moisture, ensure stable quality of fertilizer during storage and transportation, and reduce nutrient loss.

Intelligent packaging solutions for New Type Organic Fertilizer Granulator products

For the high-quality fertilizer produced by the New Type Organic Fertilizer Granulator, we recommend the use of intelligent packaging production lines. This kind of production line integrates weighing, filling, sealing, palletizing and other links, and the whole process is automated, which greatly improves the packaging efficiency and accuracy. At the same time, the intelligent system can also monitor the packaging quality in real time, find and correct problems in a timely manner, and ensure that each package of organic fertilizer meets quality standards. Intelligent packaging solutions can also flexibly adjust packaging specifications and styles according to market needs to meet diversified and personalized market needs.

0 notes

Text

In the pursuit of sustainable agricultural development today, organic fertilizer production is not only the key to improve soil health, but also an important way to achieve green agriculture. In order to achieve this goal, we need to integrate the concept of energy conservation and green production in the production process of organic fertilizer, and modern organic fertilizer equipment is the practitioner of this concept.

First, let's focus on the New Type Organic Fertilizer Granulator and Hydraulic Type Roller Granulator. These two granulators lead the energy saving trend of organic fertilizer production with their efficient energy utilization and excellent granulation effect. By optimizing the granulation process, they reduce energy consumption while ensuring uniform particles and nutrient stability, providing great convenience for subsequent packaging, transportation and use.

In raw material treatment, the application of Chain Crusher and Straw Crusher has effectively reduced the crushing energy consumption of raw materials, reduced dust pollution, and realized the resource utilization of waste. With its strong crushing capacity and stable performance, these shredders provide a high-quality raw material base for organic fertilizer production.

In terms of mixing uniformity, the Double Shafts Mixer, with its efficient mixing capacity, ensures full mixing of raw materials and additives, improving the overall quality of the fertilizer. At the same time, these mixers are designed to pay attention to energy saving and consumption reduction, contributing to green production.

As an important link in the production of organic fertilizer, Drum screener machine accurately separates different particle sizes of fertilizer particles with its continuous and efficient working mode, which not only ensures the uniformity of products, but also avoids the waste of energy. The flexible application of Vibrating Screen further improves the screening efficiency and reduces the energy consumption.

In the Fertilizer drying and cooling stage, Drum Fertilizer Dryer and Drum Fertilizer Cooler achieve low temperature drying and rapid cooling by optimizing thermal efficiency, effectively reducing energy consumption and emissions. These devices not only improve the quality of the finished fertilizer, but also meet the requirements of green production.

Finally, the application of Coating Machine puts on a protective film for organic fertilizer, extends the shelf life of fertilizer and improves the utilization rate of nutrients. Although this link seems simple, it is yet another interpretation of the concept of green production, because it reduces the waste of fertilizer and improves the economic and environmental benefits of agricultural production.

#organic fertilizer machine#organic fertilizer#organic fertilizer production line#fertilizer machine#fertilizer production line#fertilizer granulator machine#fertilizer granulator#fertilizer

0 notes

Text

Boost Your Crop Yields With Fieldking Fertilizer Spreaders Machine

Check out Fieldking's fertilizer spreaders, which evenly spread fertilizer across your fields. These machines help your crops get the nutrients they need to grow better. Fieldking's spreader machine are strong, efficient, and easy to use, saving you time and effort.

They are perfect for any farm, making fertilizing quick and simple. Visit our website to find the right fertilizer spreader to improve your farm's productivity today: https://www.fieldking.com/product-portfolio/fertilizer-spreader

#spreader machine#spreader#machine#fertilizer spreader for sale#fertilizer machine#fertilizer spreader

0 notes

Text

youtube

Working Principle of NPK Compound fertilizer Granulator. NPK compound fertilizer production line.

Hello Everyone, welcome to our Zhejiang Tongli Heavy Machinery Co., Ltd Official Channel, should of done this video before, but anyways. In this video we will walk you through the working principle of the granulator.

website: https://www.cementl.com

Email: [email protected]

whatsapp: +86 15988878668

#fertilizerproductionmachine#fertilizermanufacturingequiptment#fertilizerplantmachinery#fertilizerplantequiptment#fertilizerproductionequiptment#fertilizer#fertilizer machine#npk fertilizer production line#compound fertilizer production line#fertilizer machinery#fertilizer equipment supplier#fertilizer industry#compound fertilizer equipment#Youtube

0 notes

Text

Hi, there. As a fertilizer machine manufacturer, we have been in this industry for 18 years. Recently, we created a new website as well as this new Tumblr account. We hope to build further relationships with our overseas and B2B clients. We will keep pace with industry news and are devoted to providing first-class fertilizer machines for you.

0 notes

Text

New England Metal and Hardcore Festival

#gig flyer#New England metal and hardcore festival#festival#killswitch engage#slaughter to prevail#suicidal tendencies#machine head#converge#after the burial#as I lay dying#nails#better lovers#suicide silence#emmure#full of hell#xibalba#year of the knife#brand of sacrifice#200 stab wounds#brat#corpse pile#mammoth grinder#jarhead fertilizer#Fleshgod apocalypse#foreign hands#tribal gaze#peeling flesh#snuffed on sight#the zenith passage#alluvial

3 notes

·

View notes

Text

ट्राईकोडर्मा विरिडी एक उच्च गुणवत्ता वाला जैविक एजेंट है। Tricoderma viride की तेजी से विकास होती है, और यह मिट्टी में पोषक तत्वों और ऑक्सीजन को जल्दी से उपयोग कर सकता है, जिससे पौधों की बीमारी के रहने का वातावरण बिगड़ जाता है और फफूंद को नष्ट कर्ता हेl

#biopesticide#fertilizer granules compaction machine#fertilization#organic fertilizer production line#organic fertilizer equipment

2 notes

·

View notes

Text

youtube

Fertilizer blending and bagging plant

#fertilizer machine#fertilizer production line#fertilizers#mineralfertilizer#fertilizer batching#fertilizer blending#fertilizer bagging#dust collecter#agriculture#Youtube

0 notes

Text

The important position of coating machine in organic fertilizer production line

1. Improve the quality of organic fertilizer: Organic fertilizer coating machine through the coating treatment of organic fertilizer, can improve the physical and chemical properties of organic fertilizer, make it more suitable for plant growth needs. The coated organic fertilizer is beneficial to plant absorption of nutrients, improve fertilizer utilization, and thus improve crop yield and quality.

2. Extend the fertilizer effect period: After the organic fertilizer coating machine is coated, the organic fertilizer releases nutrients in the soil more slowly and evenly, which is conducive to extending the fertilizer effect period. As a result, crops have a steady supply of nutrients throughout the growing season, which helps to improve yield and quality.

3. Reduce environmental pollution: The utilization rate of organic fertilizer after the organic fertilizer coating machine is high, which reduces the loss of fertilizer and the pollution of soil and groundwater. At the same time, the harmful gases such as ammonia nitrogen generated during the application of coated organic fertilizer are less, which is conducive to reducing greenhouse gas emissions and reducing environmental pressure.

4. Promote the improvement of soil ecology: the organic fertilizer treated by the organic fertilizer coating machine contains rich organic matter and microorganisms, which helps to improve the soil structure, increase the soil porosity, and improve the soil water and fertilizer retention ability.

5. Save resources: organic fertilizer coating machine helps to improve the utilization rate of organic fertilizer, reduce the dependence on chemical fertilizers, and save limited resources. This is of great significance for organic fertilizer production line to achieve agricultural sustainable development.

6. Improve economic benefits: The organic fertilizer treated by the organic fertilizer coating machine has good quality, large market demand, and can bring higher economic benefits.

2 notes

·

View notes

Text

In the fine process of organic fertilizer production, cooling technology plays a pivotal role, which is not only a key part of ensuring product quality, but also an important means to improve production efficiency and save energy.

Cooling technology is necessary

In the production process of organic fertilizer, whether through the high pressure molding of the Double Roller Press Granulator, or the innovative process of the New Type Organic Fertilizer Granulator, the particles often have a higher temperature and a certain humidity in the early stage of formation. If not cooled in time, these high temperature and high humidity particles are not only easy to caking, affecting the appearance and fluidity of the product, but also may lead to nutrient loss due to accelerated internal chemical reactions. Therefore, cooling technology has become an indispensable bridge between granulation and packaging.

Practice case sharing

Taking a large organic fertilizer production plant as an example, the plant introduced an advanced Rotary Drum Granulator, combined with an efficient cooling system, to achieve an integrated production from granulation to cooling. Inside the drum, the raw material is thoroughly mixed and granulated and goes directly into the cooling section below. The cooling section uses an advanced air circulation system to adjust the wind speed and temperature to ensure that the particles are evenly cooled to the appropriate level in a short period of time, preserving the integrity and nutritional content of the particles, while improving the overall efficiency of the production line.

Innovative application of cooling technology

With the advancement of technology, cooling technology is also constantly innovating. For example, some manufacturers have begun to try to combine the cooling system with an intelligent control system to automatically adjust the cooling parameters through real-time monitoring of the temperature and humidity of the particles to achieve accurate control. This intelligent cooling method not only improves the cooling efficiency, but also greatly reduces energy consumption and labor costs.

#fertilizer machine#Organic fertilizer production line#fertilizer granulator#fertilizer granulator price person

0 notes

Text

In the green transformation of modern agriculture, the automatic control and intelligent monitoring technology of organic fertilizer production line is gradually becoming the key to improve production efficiency and ensure product quality. The wide application of this technology not only realizes the precise regulation of the production process, but also significantly reduces labor costs and energy consumption, and injected a strong impetus for the intelligent upgrading of the organic fertilizer industry.

Automation control technology:

In the organic fertilizer production line, the core equipment such as the New Type Organic Fertilizer Granulator and Hydraulic Type Roller Press Granulator realizes the fully automated operation from raw material delivery to finished product output through the integrated PLC control system. According to the preset parameters, the system automatically adjusts the speed, pressure and other key indicators of the granulator to ensure uniform particle size and regular shape. At the same time, mixing equipment such as Horizontal Mixer and Vertical Mixer have also joined the ranks of automatic control, which improves the mixing efficiency of raw materials and the quality of finished products through accurate matching and uniform mixing.

Intelligent monitoring technology:

In order to monitor the running status and product quality of the production line in real time, key equipment such as Drum Fertilizer Dryer and Drum Fertilizer Cooler are equipped with intelligent sensors and monitoring systems. These systems can monitor equipment temperature, humidity, speed and other key parameters in real time, once found abnormal immediately alarm and automatically adjust to the safety state, effectively avoid the occurrence of production accidents. Through intelligent identification technology, screening equipment such as Drum screener machine and Vibrating Screen can accurately screen finished products to ensure the consistency of product particle size and improve screening efficiency and accuracy.

More advanced is that the intelligent monitoring technology is also applied to post-processing equipment such as the Coating Machine , which ensures that the fertilizer has good slow release and anti-caking by monitoring the thickness and uniformity of the coating layer in real time. Combined with big data analysis technology, the operation data of the whole production line is collected and analyzed, which provides a scientific basis for production optimization and decision-making.

The automatic control and intelligent monitoring technology of organic fertilizer production line is leading the industry to develop in a more efficient and intelligent direction. With the continuous progress of technology and the in-depth promotion of application, it is believed that the organic fertilizer industry will usher in a broader development prospect.

#organic fertilizer machine#fertilizer machine#organic fertilizer#fertilizer production line#fertilizer granulator machine#fertilizer granulator

0 notes

Text

Check Out Fieldking's Fertilizer Spreader Machine

Find Fieldking's fertilizer spreaders, made to make spreading fertilizer on crops easier. These machines are designed to spread fertilizer evenly across fields, helping crops grow better. Our spreader machine is strong and accurate, so farmers can rely on it every farming season.

With easy-to-use features and modern technology, spreaders help farmers fertilize their fields faster and better. Visit our product page: https://www.fieldking.com/product-portfolio/fertilizer-spreader

#spreader machine#fertilizer machine#agriculture#agricultural machinery#farm equipment#farming tools#agriculture equipment

0 notes

Text

hallo i am MENSTRUATING :D

#every time i get it im like 'OH MY GOODNESS THANK THE HEAVENS I AM STILL A YOUNG AND FERTILE FUCKING MACHINE!! 🥺🙊🕊️💓'#hurrah!!#'im not BARREN'#'MY ORGANS WORK!!'

4 notes

·

View notes