#FUSION WELDED COPPER

Explore tagged Tumblr posts

Note

Oooh, The Furnaced!Macaque AU be looking good. So many angst options!

(At least Buddha was nice enough to make the urn with the FFM top)

Spideys Brain: <Ey, let’s make this angstier.>

“What, Mac actually being dead?”

<Nope! Even better!SWK and Mac were reduced to ashes, yeah? What if they were really close in there, so the ash piles were actually one pile?>

“Go on…”

<SWK regenerating from the ashes…he also grabbed onto Mac’s ashes – I mean, it was probs reactionary, like, starting as soon as he dissolved into ash…right on top of Mac’s. Or Mac dissolved into ashes while on top of him, whichever floats the boat…>

“Wait, you mean, like Mac being like an ashy symbiote inside SWKs body that comes out. Would be, him breathing out smoke and, whoa, here’s Macky!”

<Cool idea, not quite. Think Steven Universe Gems.>

“So, they like fused. Can they unfuse?”

<Nope! Loss of self and identity crisis up the wazoo!>

So yeah…Lao Tzu cracking that bad boy open to see what’s up and this unholy combination of both SWK and LEM comes out screaming and hitting – confused, gotta be in a lot of pain, freaking the fuck out in general. Heaven shrieks in terror as this abomination continues the rampage that leaves nearly all of Heaven in shambles – can’t believe they are wishing for SWK to be the one to do it instead.

Dunno what else to say, but I guess there would be a lot of derealizations, disassociations and identity crises down the line. Maybe identity death? Definitely grieving over the loss of self. That Journey is gonna be FUN.

Hmm….Welded Monkey AU? It’s a synonym of fused and, get this, *married*. Guess when they work it out, they might go Garnet on all this, then? Just a Garnet that couldn’t defuse even if they wanted to…okay, bad example…

(Also, imagine the general Wukongverse reaction to this…this fused monkey that still struggles with feeling real and has no actual identity…like, they love their LEMs but that is just the purest of nightmare fuel even for them – who would’ve thought the furnace could bring forth even more fears?)

Ohohoho

"Welded Monkey!au" is delightfully devious.

Sun Wukong and the Six Eared Macaque may have technically "died" to the Furnace...

But the four-armed, firey-eyed, six-eared, and two-tailed Welded Monkey King of the Crucible was born.

And of course this is considering that the being born from the furnace is a grown fusion, and was not compressed into a fresh Diamond Stone Egg from the ashes...

Both two previous minds clashing and marrying and a whole new mind forming all at once. Not even the Buddha is sure what to make of it.

The battle in heaven is legendary, and even the strongest warrior Erlang Shen is left permanently injured - the Welded Monkey being his equal match + 1. But like with the original story, the Monkey proves far too proud to turn down a bet from the Buddha (though the Macaque part of them yells that it's a trick).

Tripitaka finds his bodyguard 500 years later chained under the Mountain, and nearly faints from the sight.

A tall, bronze-furred monkey that looks at the monk with equal fascination and disgust. Molten copper and iron still dripping from their maw. Lets just say Guanyin needs to apply the crown immediately or else the combined anger of SWK and the spite of LEM means one less Journey member.

Many demons run at the sight of them.

The Welded Monkey (aka "Alloy/Héjīn) refers to themselves only in plural pronouns, as to respect their original forms.

They wield a staff and can jump into the shadows of their foes. To the unknowing, it's like seeing an Asura fight on earth.

Their personality is one of opposites; cheeky and demure, boisterous and calculating, honest and scheming, theatric and shy. So many aspects of Sun Wukong and Macaque combined.

It gets a little awkward for them to explain what's exactly going on. Enemies think it's an interesting power-up. Former friends are the most confused.

PIF: "So are you Sun Wukong or are you Macaque?" Hejin: "Yes and no." DBK: "So their child? Being a combination of both?" Hejin: "We have their memories though." DBK: "Hmm... what's it like?" Hejin, thinking for a while: "Noisy. On the inside." PIF: "I always did think Wukong and Macaque would marry. Just not in this way."

I imagine their Journey is more one of finding their own personality and identity after their creation, and them/the world as a whole accepting the loss of who they once were.

The Wukongverse def pities/is terrified of what Hejin respresents. Hejin is not a SWK/LEM child, nor are they just them combined - they are something Else.

The different Lao Tzu/Laozi's make sure to note; "Do Not put more than one monkey in the Furnace at once."

#furnaced!macaque au#furnaced!macaque#welded monkey!au#others aus#lego monkie kid#lmk#shadowpeach#sun wukong#liu er mihou#six eared macaque#character fusion

40 notes

·

View notes

Text

Best Practices in Exothermic Welding: Tips from Top Manufacturers ..

When it comes to creating strong, long-lasting electrical connections, Exothermic Welding Manufacturers set the gold standard. This process, also known as thermite welding, ensures reliable bonding for grounding, railway tracks, and various industrial applications. But achieving flawless welds isn't just about having the right materials—it’s about following the best practices that industry leaders swear by.

In this guide, we’ll dive into expert-backed tips to help you get the best results from Exothermic Welding Manufacturers and ensure your connections are durable, efficient, and safe.

1. Choose High-Quality Welding Materials

The foundation of a perfect weld starts with top-tier materials. Exothermic Welding Manufacturers emphasize the importance of using high-purity copper, high-quality welding molds, and properly stored welding powder. Cheap or subpar materials can lead to weak bonds, increased resistance, and, ultimately, failure in critical applications.

✔ Pro Tip: Always source materials from reputable Exothermic Welding Manufacturers to ensure consistency and reliability.

2. Properly Clean the Surfaces Before Welding

One of the most overlooked aspects of exothermic welding is surface preparation. Even the best Exothermic Welding Manufacturers stress that contaminants like dirt, rust, and grease can weaken the final bond. Before starting, use a wire brush or cleaning solvent to remove any impurities.

✔ Pro Tip: A clean surface allows for better metal fusion, ensuring the strongest possible connection.

3. Use the Right Mold and Maintain It Well

The welding mold is a crucial component of the process. Exothermic Welding Manufacturers design molds to withstand extreme temperatures and repeated use. However, poor maintenance can cause misalignment, leaks, or uneven welds.

✔ Pro Tip: Regularly inspect molds for cracks or residue buildup. Always preheat the mold before welding to remove moisture and prevent defects.

4. Follow the Correct Welding Procedure

Even with the best materials, an improper technique can ruin the weld. Leading Exothermic Welding Manufacturers recommend the following steps for a flawless weld:

Ensure proper alignment of conductors.

Secure the mold tightly to avoid leakage.

Use the correct amount of welding powder for the connection size.

Ignite the reaction safely and allow the mold to cool before removing the weld.

✔ Pro Tip: Stick to the manufacturer’s guidelines for the best results. Cutting corners can lead to weak joints and costly rework.

5. Prioritize Safety at All Times

Safety is non-negotiable in exothermic welding. Exothermic Welding Manufacturers strongly advise wearing protective gloves, goggles, and fire-resistant clothing. The reaction generates intense heat, and improper handling can lead to severe burns or injuries.

✔ Pro Tip: Always conduct welding in a well-ventilated area and keep a fire extinguisher nearby as a precaution.

6. Store Welding Materials Properly

Exothermic welding materials are highly reactive and must be stored correctly. Leading Exothermic Welding Manufacturers recommend keeping welding powder in dry, cool places away from moisture and open flames. Exposure to humidity can cause the powder to clump, making it ineffective.

✔ Pro Tip: Use airtight containers to extend the shelf life of your welding materials.

7. Work with Trusted Exothermic Welding Manufacturers

At the end of the day, the quality of your welds depends heavily on the Exothermic Welding Manufacturers you choose. Reputable manufacturers provide tested and certified products, ensuring consistent performance across all your applications.

✔ Pro Tip: Look for manufacturers with a strong track record, industry certifications, and positive customer feedback.

Final Thoughts

Exothermic welding is a game-changer for creating strong, corrosion-resistant electrical connections. By following these expert-backed best practices—from material selection to proper technique—you can achieve flawless welds every time.

For the best results, always rely on Exothermic Welding Manufacturers known for quality and innovation. Investing in top-tier materials and adhering to proper welding techniques will ensure the durability and efficiency of your electrical connections.

0 notes

Text

Additive Manufacturing Market, Industry Forecast, 2024–2030.

Additive Manufacturing Market Overview:

Sample Report :

Additionally, Increasing focus on metal additive manufacturing technologies. Researchers and companies have been actively working on expanding the range of metals and alloys available for AM. This includes not only traditional metals like titanium, aluminum, and stainless steel but also high-performance alloys for specialized applications. The development of new metal powders suitable for various AM processes has been a focus area. The integration of Additive Manufacturing with traditional manufacturing processes in companies were exploring hybrid manufacturing approaches that combine the strengths of additive and subtractive methods. This integration aimed to leverage the design flexibility of Additive Manufacturing and the efficiency of traditional methods to optimize production workflows. These factors impact the growth in Additive Manufacturing Market.

Market Snapshot:

Additive Manufacturing Market — Report Coverage:

The “Additive Manufacturing Market Report — Forecast (2024–2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Additive Manufacturing Market.

AttributeSegment

By Type

● Materials

● Systems

● Services & Parts

By Material

● Plastics

○ Acrylonitrile Butadiene Styrene (ABS)

○ Polylactic Acid (PLA)

○ Polyethylene (PE)

▪ High-Density Polyethylene (HDPE)

▪ Low-Density Polyethylene (LDPE)

▪ Linear Low-Density Polyethylene (LLDPE)

▪ Others

○ Polycarbonate (PC)

○ Polypropylene (PP)

○ Polyethylene Terephthalate (PETE)

○ Nylon

○ Others

● Metals

○ Iron

○ Steel

○ Silver

○ Aluminum

○ Copper

○ Titanium

○ Gold

○ Zinc

○ Others

● Ceramics

○ Glass

○ Silica

○ Quartz

○ Others

● Others

By Technology

● Powder Bed Fusion

○ Direct Metal Laser Sintering (DMLS)

○ Selective Laser Sintering (SLS)

○ Selective Laser Melting (SLM)

○ Electron Beam Melting (EBM)

○ Others

● Binder Jetting

● Directed Energy Deposition

○ Laser Deposition Technology (LDT) excluding LCT

○ Laser Additive Manufacturing (LAM)

○ Laser Metal Deposition (LMD)

○ Laser Engineering Net Shape (LENS)

○ Laser Cladding Technology (LCT)

○ Electron Beam Additive Manufacturing (EBAM)

○ Wire Arc Additive Manufacturing (WAAM)

○ Laser Deposition Welding (LDW)

○ Others

● Material Extrusion

● Material Jetting

○ Drop On Demand (DOD)

○ Polyjet by Object

○ Others

● Vat Polymerization

○ Stereolithography (SLA)

○ Digital Light Processing (DLP)

○ Continuous Liquid Interface Production (CLIP)

○ Others

● Others

By End-Use Industry

● Industrial

● Aerospace

○ Commercial

○ Military

○ Others

● Consumer Goods

○ Furniture

○ Watches and Jewelry

○ Shoes and Soles

○ Others

● Oil & Gas

● Automotive

○ Passenger Cars

○ Light Commercial Vehicles (LCV)

○ Heavy Commercial Vehicles (HCV)

○ Others

● Medical & Healthcare

● Electrical & Electronics

○ Conductors

○ Resistors

○ Sensors

○ Semiconductors

○ Others

● Building and Construction

○ Residential

○ Commercial

○ Industrial

○ Infrastructure

The COVID-19 pandemic had a mixed impact on the Additive Manufacturing (AM) market. While disruptions in global supply chains initially posed challenges for material sourcing, the flexibility of AM processes proved beneficial in addressing urgent needs for medical equipment and components. The demand for 3D printing surged during the pandemic, with AM technologies being utilized for the rapid production of ventilator parts, face shields, and other critical supplies. The crisis highlighted the agility of AM in responding to unforeseen challenges and increased awareness of its potential across various industries.

Inquiry Before Buying :

The situation in Ukraine had indirect effects on the Additive Manufacturing (AM) market, primarily through broader geopolitical and economic repercussions. Disruptions in supply chains, especially for metals and other raw materials used in AM processes, were potential concerns. Additionally, uncertainties in global markets may have influenced investment decisions and R&D activities in the AM sector. However, the impact varied depending on the resilience of individual companies and their exposure to the geopolitical developments.

Key Takeaways:

North America Dominated the Market

Geographically, in the Additive Manufacturing market share, the North America region has held a dominant market share of 41% in 2023, Rising government investments and projects in the United States for additive manufacturing have also raised the growth of the market. For instance, to address the challenges in single laser melting (SLM), America Makes awarded GE Global $2.6 million to build an open-source, multi-laser production machine and AM platform. Additionally, in Canada, the rising partnership between research universities in the field of additive manufacturing is also influencing the growth of the market. U.S. is anticipated to lead the global additive manufacturing market with the largest installed base for 3d printer in the world. With such a dominant presence of the 3d printers in the country U.S. is likely to contribute more than one third in the revenue generated by additive manufacturing worldwide.

Metal is the Fastest Growing Segment

In the Additive Manufacturing Market forecast, the Metal segment is estimated to grow with a CAGR of 23.5% during the forecast period. Metals are a better option for 3D printing compared to plastics, as they have more industrial usage. Often the 3D metal printing shows itself to be unique as the new technologies can readily surpass what was offered by traditional processes. In AM of metals a powder feedstock or more rarely a wire is fully melted by the energy input of a laser or electron beam and transformed layer by layer into a solid part of nearly any geometry. The most popular processes for AM of metals are Laser Beam Melting (LBM), Electron Beam Melting (EBM) and Laser Metal. In a survey conducted across the globe, about 23% of the 3D printing materials used are metals. The 3D printing metals segment is also poised to grow as it has a competitive edge over other plastic materials used in 3D Printing. Metal 3D printing is too expensive, furthermore other companies, like Desktop Metal and Markforged, are developing approaches to manufacture affordable metal 3D printers.

Schedule A Call :

Aerospace to Hold Largest Market Share

According to the Additive Manufacturing Market analysis, the Aerospace segment is estimated to hold the largest market share of 34% in 2023, the aerospace and defense industry is a perfect example of how to use additive manufacturing (AM) (commonly referred to as 3D Printing) to produce components that are heavier and lighter than parts manufactured using conventional manufacturing methods. Additive manufacturing or 3D printing has applications in the aerospace industry such as engine compartments, cabin accessories, air ducts among others. NASA researchers are looking into how electroplated SLA parts perform in space. Engineers at NASA’s Goddard Space Flight Center designed brackets that were 3D printed on printers, electroplated, and sent to space aboard a summer 2022 SpaceX commercial resupply services (CRS-25) mission to the International Space Station (ISS). The results could inform how NASA and possibly other aerospace manufacturers may incorporate electroplating and additive manufacturing into potential future product plans.

Ease of Manufacturing Complex Design

he basic physical difference in how objects are made with the additive manufacturing process produces some major functional differences when compared with other traditional manufacturing processes. The most significant of these functional differences is the ability of additive manufacturing to produce complex geometries that would be difficult or impossible to achieve using conventional manufacturing methods. These intricate geometries are also stronger and lighter than their conventional counterparts. Additive manufacturing eliminates the additional costs normally associated with creating more complex objects. A highly complex component usually costs much more using conventional methods. This is primarily because conventional fabrication methods rely on the conversion of three-dimensional illustrations into two-dimensional drawings for fabrication, as well as the labor cost of assembling such components. However, regardless of the complexity of a component, the method in additive manufacturing is the same. Thus, no additional cost is incurred for manufacturing complex designs using additive manufacturing.

Buy Now :

Relatively Lower Production Cost for Rapid Manufacturing

The manufacturing companies experience various benefits while using additive manufacturing methods to produce objects. Since the complexity of the component has little or no impact on the manufacturing time and costs, additive manufacturing is ideal for low-cost production as well as small and (very) large series. Design changes can be implemented quickly at a low cost. Metal structures are made up of atom by atoms in additive manufacturing, as opposed to subtractive approaches like chemical etching. As a consequence, almost every piece of metal is utilized during the production process, with almost no waste of material and reducing material wastage. When using additive manufacturing, all of the extra features that are needed for the assembly, such as fasteners, brazing, or welding, can be omitted. Thus, additive manufacturing also reduces assembly costs.

Difficulty in Producing Large Single Parts

Even if additive manufacturing were to dramatically increase production speed and volume performance, it would still be unable to manufacture large single parts. This is yet another major challenge confronting additive manufacturing researchers as they pursue new applications for 3D printing technology. Arc-based wire feed metal AM was chosen as the best process to produce large metal parts. While metal powder bed printers are available commercially, they are not currently capable of producing large-scale metal parts. Therefore, arc-based wire feed technology provided the most cost-effective solution. The building envelope for current additive manufacturing technologies is limited, meaning even larger components that can be printed must still be assembled by mechanical joining or welding.

For More Details on This Report — Request for SampleKey Market Players:

duct/Service launches, approvals, patents and events, acquisitions, partnerships and collaborations are key strategies adopted by players in the Additive Manufacturing Market. The top 10 companies in this industry are listed below:

Proto Labs, Ltd.

3D Systems, Inc

Stratasys Ltd.

Desktop Metal

Autodesk, Inc.

Materialise NV

Markforged

Optomec, Inc.

Dassault Systemes

Titomic Limited

Geographies Covered

North America (U.S., Canada and Mexico), Europe (Germany, France, UK, Italy, Spain, Netherlands and Rest of Europe), Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand and Rest of Asia-Pacific), South America (Brazil, Argentina, Colombia and Rest of South America), Rest of the World (Middle East and Africa).

Key Market Players

For more Automation and Instrumentation Market reports, please click here

0 notes

Text

What Is Welding? Learn the Definition, Types, and Process

Welding is the process of fusing two or more parts using heat, pressure, or both. It’s often done on metal, thermoplastics, and even wood. The resulting joint is known as a weldment, and the conjoined parts are known as the parent material. The material used to create the weldment is called a filler or consumable. Some people would say that welding is an art form since some materials call for specific processes or techniques.

Thinking about starting a career in welding? It helps to know some key industry terms, applications, and more. Start with understanding the types of welds you’ll be asked to create and build your knowledge from there.

Table of Contents

Types of Welds

Slot Weld

Plug Weld

Full Penetration Weld

Partial Penetration Weld

Start Your Career in Skilled-Trade Industry

Welding Process

1. Gas Metal Arc Welding (GMAW/MIG)

2. Gas Tungsten Arc Welding (GTAW/TIG)

3. Shielded Metal Arc Welding (SMAW)

4. Flux Cored Arc Welding (FCAW)

Other welding processes you may come across include:

There’s a Big Shortage of Skilled Welders Right Now

Become a Qualified Welder

Types of Welds

Slot Weld

A slot weld is a joint between two overlapping parts. It’s created by depositing a filet weld around the edge of a hole in one part that’s joined to the second part through the exposed surface of the hole.

Plug Weld

To create a plug weld, you’ll use a filler metal to join one part to the surface of another overlapping part through the hole.

Full Penetration Weld

Also known as complete joint penetration (CJP), full penetration welds occur when the weld metal fully penetrates the joint with complete root fusion.

Partial Penetration Weld

A partial penetration weld occurs when the weld metal is intentionally not fully penetrating. You may also hear this type of weld referred to as partial joint penetration (PJP).

Start Your Career in Skilled-Trade Industry

Open the door to a rewarding career!

Request Info

Welding Process

1. Gas Metal Arc Welding (GMAW/MIG)

Gas metal arc welding, sometimes called MIG welding, uses a thin wire as an electrode and is typically used in construction and automotive applications. You’ll typically use this process on metals like copper, stainless steel, nickel, and more.

During MIG welding, the wire heats up as it’s fed through the welding instrument. To keep air containment out of the weld, you must use a shielding gas like carbon dioxide, oxygen, argon, or helium.

2. Gas Tungsten Arc Welding (GTAW/TIG)

Also known as TIG welding, this process is typically used for welding thin and non-ferrous metals like aluminum, copper, lead, or nickel. TIG welding is different from other processes because it uses a non-consumable tungsten electrode to form a weld.

Common applications for this welding process include bicycle or aircraft manufacturing.

3. Shielded Metal Arc Welding (SMAW)

Often called stick welding, shielded metal arc welding is a common process used among home-shop welders. This process involves manual techniques using a flux-coated electrode consumable.

Stick welding is not known for its high quality or durability, however, it’s one of the most low-cost processes.

4. Flux Cored Arc Welding (FCAW)

Flux-cored arc welding involves continuously feeding a wire as your weld, much like MIG welding. However, flux-cored arc welding is broken into two distinct processes.

One uses a shielding gas. The other uses self-shielding agents produced when fluxing agents decompose within the wire. This process makes it possible to weld in outdoor conditions.

FCAW is commonly applied in construction projects because the semi-automatic arc provides high welding speeds and portability.

Other welding processes you may come across include:

Submerged Arc Welding (SAW)

Gas Welding/Oxyacetylene Welding

Thermit Welding

Forge Welding

Electron Beam Welding

Atomic Hydrogen Welding

Plasma Arc Welding

Resistance Welding

There’s a Big Shortage of Skilled Welders Right Now

According to the American Welding Society (AWS), there will be a massive welder shortage by 2024. Estimates show the industry will face a staggering 400,000 worker shortage. This is likely due to a large portion of the industry retiring.

This creates more opportunities for people looking to start a new career or switch careers to welding. All you need to do is get the right training and education to gain the experience you need to become a skilled welder.

Become a Qualified Welder

Starting a new career or switching careers can seem like an uphill battle. But when you attend a skilled trade training program dedicated to your success, you’ll realize how attainable your goals really are.

At EIT, our welding program provides you with the practical experience and hands-on training employers seek. Check out what our one-year welding program can offer you.

0 notes

Text

Quality and Consistency The Role of Monel 400 Filler Wire Suppliers

In industries where corrosion resistance, high strength, and durability are crucial, Monel 400 has established itself as a go-to material, particularly in applications requiring welding. Monel 400 is a nickel-copper alloy renowned for its exceptional resistance to seawater, acids, and various corrosive environments. As the demand for this alloy increases, the role of Monel 400 filler wire suppliers becomes vital. This article explores how these suppliers contribute to quality and consistency in welding applications, ensuring that businesses achieve optimal results in their projects.

Understanding Monel 400

Monel 400 is composed primarily of nickel (approximately 67%) and copper (about 28%), along with small amounts of iron, manganese, and other elements. This unique composition grants the alloy several key properties that make it suitable for various applications:

Corrosion Resistance: Monel 400 is particularly resistant to pitting and crevice corrosion, making it ideal for marine applications and environments where aggressive chemicals are present.

High Strength: The alloy maintains its mechanical properties even at elevated temperatures, ensuring reliability in high-pressure and high-temperature applications.

Excellent Fabricability: Monel 400 can be easily welded and formed, allowing for versatility in manufacturing processes.

The Importance of Monel 400 Filler Wire Suppliers

Welding with Monel 400 requires specific filler wires that maintain the alloy's properties and enhance the quality of the weld. This is where Monel 400 filler wire suppliers play a critical role. Here are several ways these suppliers contribute to the quality and consistency of welding operations:

1. Quality Assurance

Quality is paramount in welding applications, especially when dealing with high-performance materials like Monel 400. Reputable Monel 400 filler wire suppliers prioritize quality assurance throughout their supply chain. They source their filler wires from manufacturers that adhere to stringent industry standards and certifications.

By providing products that meet or exceed specifications, these suppliers help ensure that the welds made with Monel 400 filler wire are robust and reliable. High-quality filler wire is essential for preventing defects such as porosity, undercutting, and lack of fusion, which can compromise the integrity of the welded joint.

2. Consistency in Supply

Consistency is crucial when working with Monel 400 filler wire. Fluctuations in quality or availability can lead to significant disruptions in welding operations, resulting in project delays and increased costs. Trusted Monel 400 filler wire suppliers maintain a reliable inventory and ensure that their products consistently meet the required specifications.

By partnering with suppliers known for their dependable supply chain, businesses can minimize the risk of running into material shortages or variations in product quality. This consistency allows manufacturers to maintain their production schedules and meet project deadlines effectively.

3. Technical Expertise

Experienced Monel 400 filler wire suppliers offer valuable technical expertise that can greatly benefit businesses engaged in welding operations. These suppliers understand the intricacies of welding with Monel 400 and can provide insights into best practices, including the selection of appropriate filler wires, welding techniques, and equipment settings.

By leveraging this expertise, businesses can make informed decisions regarding their welding processes, ensuring optimal results. Whether it's advice on joint design, pre-weld preparation, or post-weld treatments, reliable suppliers can serve as a resource for improving welding performance.

4. Custom Solutions

Every welding project is unique, and standard filler wires may not always meet specific requirements. Trusted Monel 400 filler wire suppliers often offer customized solutions tailored to the needs of their clients. This may include producing filler wires in various diameters, lengths, or formulations to suit particular welding applications.

Customization ensures that manufacturers have access to the right materials for their projects, enhancing the overall quality and performance of the welded joints. This flexibility can also lead to cost savings by reducing waste and optimizing the welding process.

5. Comprehensive Product Range

Leading Monel 400 filler wire suppliers typically offer a wide range of products beyond just filler wires. This can include other forms of Monel 400, such as rods, sheets, and plates, allowing manufacturers to source all necessary materials from a single supplier. Having a comprehensive product range simplifies the procurement process and enhances operational efficiency.

Access to multiple product forms enables businesses to streamline their inventory management and reduce the time spent searching for various suppliers. This one-stop-shop approach can significantly improve procurement efficiency.

6. Competitive Pricing

While quality is critical, cost considerations also play a significant role in sourcing materials. Established Monel 400 filler wire suppliers often have strong relationships with manufacturers, allowing them to negotiate better pricing on their products. This can result in competitive prices for businesses without compromising quality.

By obtaining high-quality Monel 400 filler wire at reasonable rates, companies can enhance their project cost-effectiveness. Many suppliers also offer discounts for bulk purchases, further contributing to cost savings.

7. Strong Customer Support

Reliable Monel 400 filler wire suppliers prioritize customer service and strive to provide comprehensive support throughout the procurement process. From initial inquiries to post-sale assistance, knowledgeable staff are available to help businesses navigate any challenges.

Whether it’s addressing questions about product specifications or providing guidance on optimal welding techniques, strong customer support enhances the overall experience. This commitment to service fosters long-term relationships between suppliers and manufacturers, ultimately benefiting both parties.

Applications of Monel 400 Filler Wire

Monel 400 filler wire is used in various applications across different industries, thanks to its unique properties. Here are some common uses:

Marine Applications: Due to its exceptional resistance to seawater corrosion, Monel 400 filler wire is widely used for welding components in marine environments, such as propeller shafts, valves, and piping systems.

Chemical Processing: In chemical plants, Monel 400 filler wire is used to weld tanks, pipes, and other components that handle corrosive substances, ensuring the longevity and safety of the equipment.

Oil and Gas: Monel 400 filler wire is commonly employed in the oil and gas industry for welding equipment that operates in harsh environments, including offshore drilling rigs and production facilities.

Aerospace: Monel 400 filler wire finds applications in aerospace for welding components that require high strength and resistance to corrosion, such as fuel systems and structural elements.

Conclusion

The role of Monel 400 filler wire suppliers in ensuring quality and consistency cannot be overstated. By providing high-quality materials, maintaining a reliable supply chain, and offering technical expertise, these suppliers significantly contribute to the success of welding operations across various industries.

As businesses seek to enhance their welding processes, partnering with trusted Monel 400 filler wire suppliers becomes essential. The advantages of quality assurance, customization options, comprehensive product ranges, and competitive pricing enable manufacturers to optimize their operations and achieve superior results.

In an industry where precision and reliability are critical, investing in high-quality Monel 400 filler wire and building strong relationships with reputable suppliers can lead to significant long-term benefits. Embrace the potential of Monel 400 filler wire and the invaluable support provided by its suppliers to elevate your welding projects and achieve unparalleled success.

0 notes

Text

What Are the Benefits of Using Stainless Steel 309H Welded Pipes? | Platinex Piping Solution

One of the most important materials, presently, in the manufacturing industry is stainless steel. Owing to its strength and resistance to corrosion, it is an attractive alloy which is appealing to the eyes .Amongst all other types of stainless steel; the 309H is a uniquely designed alloy suitable for applications under hostile conditions and high temperature. Maybe, the most common form of 309H

What is 309H Welded Pipe, and What Sets It Apart from Others?

309H welded pipes are duplex stainless steel and stainless steel has a high corrosion resistance and strength properties. These types of pipes are made with higher chromium than usual alloy steel pipelines of categories 304/304L.The reason for this is their resistance to corrosive agents such as in oil refineries, marine environments, chemical processing plants, and other industrial settings with presence of corrosive agents. Copper-enriched such welded pipe therefore provides higher resistance to creep-rupture at elevated temperatures. Alongside all this, Stainless Steel 309H Welded Pipes will show themselves to have a high ductility and formability level, which allows them to be ideally welded.

The Multiple Advantages of Using Stainless Steel 309H Welded Pipes in the Work.

Highly Resistant to Corrosion

High temperature resistance is also a feature of 309H stainless steel pipes welded by means of brazing. This feature places them in a preferred position in chemical, petrochemical and power generation industries where exposure to corrosive agents is impossible to avoid. The pipe made from a strong material can withstand even the highest pressure and chemicals.

Offers Excellent Weld ability

The stainless steel 309H welded pipes are also easily joinable together and weld able- the reasons exactly they are known in applications greatly. This material features a great fusion capacity as it may be easily molded into many desired shapes and sizes. This way, they can help not one, but many different industries.

Cost-Effective and Low Maintenance

Installing the stainless steel 309H welded tubes into myriad industrial processes, of course, brings the possible cut-off from maintenance and operating expenses in the future. The spiral weld pipes do not need the Maintenance as they are very durable and their resistance to corrosion is the highest, of up to 90%. Moreover, they do not call for a regular changeover requires industries do not spend too much on buying expensive replacement counterpart and downtime.

Environmentally Friendly

Sustainable material stainless steel is stackable to that it can be recyclable and stay so again and again as characteristic as before. Use of welded stainless steel 309H pipes in industries will in no way increase carbon footprint, which all other materials used for the same do. Not only does it help in protecting natural resources by decreasing the depletion of minerals and the environmental impact of mining but it also uses existing resources more intelligently.

The stainless-steel 309H welded pipes range demonstrate an abundance of qualities, and this is therefore, why they are the best pick compared to other types. Such ductile and resistant metallural substance with superior weld ability, wear and corrosion resistance is the economical, low-main tangential, and environment friendly alternative. Industries of manufacturing where there are products with a higher level performance and that are meant to serve functions of high efficiency can stand to gain from the use of stainless steel pipes which have been welded. A variety of harsh conditions and operations are conquerable by pipes. Besides that, smooth functioning of activities with no more extra effort of maintaining and repairing pipelines are also added as an advantage. Their outstanding exclusive property that is due to their unique strength and durability makes them eco-friendly as well as viable economically.

0 notes

Link

0 notes

Text

Exploring ASTM B619 Welded Pipe: Applications and Advantages

ASTM B619 is a standard specification for welded nickel-chromium-molybdenum-copper alloy (UNS N06022) and nickel-chromium-molybdenum-tungsten alloy (UNS N10665) pipe. These alloys are designed for use in corrosive environments, particularly those containing reducing and oxidizing chemicals. ASTM B619 welded pipes are critical in industries such as chemical processing, petrochemicals, pharmaceuticals, and power generation. This blog explores the properties, applications, and benefits of ASTM B619 welded pipes, emphasizing their importance in modern industrial applications.

What is ASTM B619 Welded Pipe?

ASTM B619 specifies seamless and welded pipes made from nickel-chromium-molybdenum-copper (Alloy C276, UNS N06022) and nickel-chromium-molybdenum-tungsten (Alloy B-2, UNS N10665) alloys. These materials are highly resistant to corrosion in a wide range of aggressive environments, including acids, chlorides, and seawater. Welded pipes under ASTM B619 are manufactured using fusion welding processes, ensuring uniformity, strength, and integrity throughout the pipe length.

Key Properties of ASTM B619 Welded Pipe

ASTM B619 welded pipes exhibit several critical properties that make them suitable for corrosive environments:

Corrosion Resistance: Nickel-based alloys like C276 and B-2 offer exceptional resistance to a wide range of corrosive chemicals, including acids (sulfuric, hydrochloric), chlorides, and seawater.

High Temperature Performance: These alloys maintain their mechanical strength and corrosion resistance at elevated temperatures, making them suitable for high-temperature applications.

Mechanical Strength: ASTM B619 welded pipes provide excellent mechanical properties, including high tensile strength and toughness, ensuring reliability in demanding conditions.

Weldability: The alloys are easily weldable using conventional welding techniques, allowing for easy fabrication and repair of piping systems.

Low Maintenance: Due to their corrosion resistance, ASTM B619 welded pipes require minimal maintenance, reducing downtime and operational costs.

Longevity: These pipes have a long service life in aggressive environments, offering reliable performance over extended periods.

Applications of ASTM B619 Welded Pipe

ASTM B619 welded pipes find extensive use in industries requiring resistance to corrosive environments:

Chemical Processing: They are used in chemical plants for transporting acids, alkalis, and other corrosive chemicals.

Petrochemical Industry: ASTM B619 pipes are employed in oil refineries, gas processing plants, and offshore platforms where exposure to corrosive fluids is common.

Pharmaceutical Industry: These pipes are used in pharmaceutical manufacturing processes that involve corrosive solvents and chemicals.

Power Generation: ASTM B619 pipes are utilized in power plants for handling corrosive cooling water, steam, and chemicals in boiler systems.

Waste Treatment: They are used in wastewater treatment facilities for conveying corrosive liquids and gases.

Pulp and Paper Industry: ASTM B619 pipes find application in pulp and paper mills for handling corrosive chemicals used in bleaching and processing.

Benefits of Using ASTM B619 Welded Pipe

ASTM B619 welded pipes offer numerous advantages, making them a preferred choice in corrosive environments:

Corrosion Resistance: Superior resistance to a wide range of corrosive chemicals ensures longevity and reliability.

High Performance: These pipes maintain their mechanical properties at high temperatures, ensuring consistent performance in demanding conditions.

Safety: Reliable corrosion resistance reduces the risk of leaks and failures, enhancing operational safety.

Cost-Effectiveness: Despite their initial cost, ASTM B619 welded pipes offer long-term savings due to reduced maintenance and extended service life.

Versatility: Available in various sizes and configurations, they can be tailored to meet specific application requirements.

Environmental Sustainability: Nickel-based alloys are fully recyclable, promoting environmental sustainability and compliance with green initiatives.

Conclusion

ASTM B619 welded pipes made from alloys such as C276 and B-2 play a crucial role in industries where corrosion resistance and reliability are paramount. Their exceptional properties make them ideal for handling corrosive chemicals in chemical processing, petrochemicals, pharmaceuticals, and power generation. Understanding the benefits and applications of ASTM B619 welded pipes underscores their critical importance in ensuring efficient, safe, and sustainable operations in modern industrial environments.

#ASTM B619 Welded Pipe#Nickel-Chromium-Molybdenum Alloys#Corrosion Resistance#Chemical Processing#Petrochemical Industry#Power Generation#Mechanical Strength#High Temperature Performance

0 notes

Text

The Science Behind Exothermic Welding: A Deep Dive with Leading Manufacturers..

When it comes to creating strong, reliable, and corrosion-resistant electrical connections, one method stands out—exothermic welding. This process, trusted across industries like railways, power grids, and telecommunications, ensures permanent metal bonding. But how exactly does it work? And what makes a top-tier Exothermic Welding Manufacturers essential for quality and safety? Let’s dive deep into the science behind it.

What Is Exothermic Welding?

At its core, exothermic welding (also known as thermite welding) is a chemical reaction that generates intense heat, fusing metals together. Unlike traditional welding, this method doesn’t require an external power source. Instead, it relies on a powdered mixture of copper oxide and aluminum, which, when ignited, produces molten copper that permanently bonds conductors.

The result? A highly conductive, durable, and maintenance-free connection that withstands extreme environmental conditions. No wonder industries with high safety standards trust this method!

Why Do Experts Prefer Exothermic Welding?

Industry professionals, from electrical engineers to railway operators, choose exothermic welding over traditional methods because of:

Superior Conductivity: The molecular bond ensures zero resistance, preventing voltage drops. Corrosion Resistance: Unlike mechanical joints, exothermic welds don’t degrade over time. Long-Lasting Performance: A well-executed weld lasts as long as the infrastructure itself. Cost-Effectiveness: No need for maintenance or frequent replacements.

But achieving these benefits depends entirely on the quality of materials and precision of the process—which brings us to the role of a trusted Exothermic Welding Manufacturers.

The Role of a Leading Exothermic Welding Manufacturer

A topExothermic Welding Manufacturers does more than just produce welding kits. They invest in research, safety, and innovation to enhance product performance. Here’s what sets the best manufacturers apart:

1. High-Purity Welding Materials

The purity of copper oxide and aluminum powders directly impacts the weld quality. Leading manufacturers ensure precise chemical composition for a flawless reaction every time.

2. Strict Quality Control

Every batch of welding materials undergoes rigorous testing to meet international standards like IEEE, UL, and ASTM. This guarantees consistent and safe results in critical applications.

3. User-Friendly Kits

Manufacturers design pre-measured welding kits with safety enhancements, making the process foolproof even in the most challenging environments.

4. Continuous Innovation

With industries evolving, so do welding techniques. Leading manufacturers research and develop advanced ignition methods and eco-friendly welding compounds for safer and more efficient applications.

The Science Behind the Reaction: How Exothermic Welding Works

1️⃣ Preparation: The metal surfaces are cleaned, and a graphite mold is set up. 2️⃣ Powder Placement: A pre-measured amount of exothermic welding compound is added to the mold. 3️⃣ Ignition: A spark ignites the mixture, triggering a high-temperature reaction (up to 2500°C). 4️⃣ Fusion: The molten copper flows, bonding the conductors at a molecular level. 5️⃣ Cooling & Removal: After a few seconds, the mold is removed, revealing a solid, permanent joint.

This entire process takes just a few minutes, yet the result is a bond that lasts for decades!

Industries That Rely on Exothermic Welding

A high-quality Exothermic Welding Manufacturers supplies solutions for industries where reliability is non-negotiable:

Construction: Grounding and earthing in high-rise buildings. Railways: Welded rail tracks for smooth, uninterrupted travel. Power Grids: Secure electrical grounding for substations. Telecommunications: Lightning protection for telecom towers. Oil & Gas: Safe electrical bonding in explosive environments.

Wherever durability and safety matter, exothermic welding is the go-to solution.

💡 Final Thoughts: Choosing the Right Exothermic Welding Manufacturer

Not all welding products are created equal. A reliable Exothermic Welding Manufacturer ensures high-quality materials, safety compliance, and innovation, making a huge difference in long-term performance.

If you want permanent, corrosion-resistant, and high-conductivity connections, always choose a manufacturer with a proven track record and industry certifications. After all, in mission-critical applications, there’s no room for error.

0 notes

Text

High-Frequency Welding: An Introduction

High-Frequency Welding: An Introduction High-Frequency Welding, also known as Radio Frequency (RF) Welding or Dielectric Welding, is a specialized technique used to join thermoplastic materials. In this process, electromagnetic waves at frequencies typically ranging from 27 to 40 MHz are applied to the area to be joined. The result is a strong bond between the materials without the need for external heat.Get more news about High Frequency Welding Machine,you can vist our website!

Steps for High-Frequency Welding Process Preparation: The materials to be welded are carefully cleaned and aligned along the joint line. Proper preparation ensures a strong bond. Clamping: Clamps or a pneumatic system hold the prepared materials together during the welding process, maintaining alignment. Application of High-Frequency Energy: An electrode (usually made of copper) is placed on one side of the joint, while a grounding plate is placed on the other side. High-frequency electric current passes through the electrode, creating an oscillating electromagnetic field. Heating and Melting: The high-frequency electromagnetic field generates heat within the thermoplastic materials, causing them to soften and melt along the joint line. Pressure and Fusion: Once the material reaches the desired melting point, pressure is applied using the clamping mechanism. This ensures intimate contact between the melted surfaces, promoting fusion. Cooling and Finishing: After welding, the joint cools down, stabilizing the newly fused area. Additional steps, such as trimming or finishing, may be performed to achieve the desired final product. Advantages of High-Frequency Welding Precision: HF welding allows for precise bonding of components. Quick and Effective: It creates strong bonds efficiently. No External Heat Required: Unlike traditional welding methods, HF welding doesn’t rely on external heat sources. High-Frequency Welding finds applications in industries such as packaging, automotive, textiles, and medical equipment manufacturing. Its ability to create reliable bonds makes it a valuable technique in modern production processes.

0 notes

Text

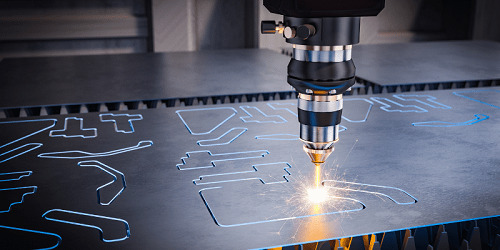

Laser Cutting Machine Market Evolution: Historical Analysis and Future Projections

The global laser cutting machines market size is expected to reach USD 10,351.0 billion by 2030, registering a CAGR of 5.5% over the forecast period, according to a study conducted by Grand View Research, Inc. Over the forecast period, it is anticipated that the growing trend of automation in the manufacturing sector and the rising demand for the end-use industry will increase demand for these machines. The growing application of CO2, fiber, and Yttrium Aluminum Garnet (YAG) lasers in various applications, such as industrial sectors and consumer electronics, is predicted to boost the demand for laser cutting machines. Industries such as consumer electronics are contributing to the market growth owing to the increasing use of lasers in material processing operations such as pruning, welding, and engraving. Furthermore, the requirement for high-power input and performance-based cutting tools drives demand and market growth for laser cutting machines over the forecast period.

Laser Cutting Machines Market Report Highlights

During the forecast period, the gas laser technology segment is expected to witness the highest CAGR of 6.1 %. The growth is attributed to the increasing demand for these lasers for better machine tools and equipment for laser printing, dye laser pumping, reading barcodes, and producing holograms

The fusion cutting is expected to register the highest CAGR of 6.1 % from 2023 to 2030. The advantage of fusion cutting is that it creates a cutting edge that is practically oxide-free and ideal for cutting thin sheets, which is expected to contribute to the growth of the segment

Over the course of the forecast period, the industrial sector is expected to dominate the laser cutting machine industry. It held a market share of 39.8 % in 2022. The need for laser cutting equipment is rising as industrial processes increasingly become automated. These tools consistently and quickly cut parts and patterns with precision

The rising GDP and quickening growth of the region's manufacturing sector, the Asia Pacific region is anticipated to continue growing. Additionally, businesses that use laser cutting to create semiconductors, consumer electronics, and automotive components are experiencing rapid regional growth. The need for laser cutting equipment in this area is rising along with the expansion of these industries

For More Details or Sample Copy please visit link @: Laser Cutting Machines Market Report

The development of innovative process lasers to maximize the manufacture of tailored three-dimensional glass elements, as well as a shift out of traditional semiconductor lasers and towards quantum cascade lasers, will likely drive up the demand for laser cutting machines. Continuous developments in laser technology enable manufacturers to engage in R&D to obtain a competitive advantage. Furthermore, due to the demand for high-speed and precision cutting and drilling the integration of the Internet of Things, Artificial Intelligence, and automation software with drilling machines is also supporting the laser cutting machine industry’s growth.

Major players are resorting to strategies such as product launches, mergers & acquisitions, and expansions to gain greater market shares. For instance, in May 2022, Yamazaki Mazak Pvt. Ltd. announced the launch of 3D based fiber laser cutting machine for cutting steel products- FG -400 NEO. The 3D laser is equipped with an efficient laser fiber oscillator which offers efficient energy conversion and enhanced productivity.

The laser is also compatible with cutting copper, brass, and aluminum. The laser is outfitted with a feature that enables users to easily modify the laser beam's diameter and form, enabling the cutting of sheets of different thicknesses. The oscillator's maximum output is limited to 4 kW, along with a rapid input rate on the X, Y, and Z axes is 60, 36, and 30 m/min, respectively. The continuous launch of advanced products is contributing to the laser cutting machine industry’s growth.

#LaserCuttingMachine#CuttingEquipment#CNCMachines#PrecisionCutting#MaterialProcessing#Metalworking#Fabrication#IndustryInsights#TechnologyTrends#MarketForecast#BusinessStrategy#InvestmentOpportunities#SupplyChain

0 notes

Text

Exploring the Intricacies of TIG Welding: Techniques, Applications, and Advantages

Introduction:

Tungsten Inert Gas (TIG) welding, also known as Gas Tungsten Arc Welding (GTAW), is a highly versatile welding process widely utilized across various industries. Renowned for its precision, control, and quality, TIG welding offers unique advantages and capabilities that make it indispensable for numerous applications. In this article, we'll delve into the intricacies of TIG welding, including techniques, applications, and the advantages it offers to welders and industries alike.

Process Overview:

TIG welding employs a non-consumable tungsten electrode to generate an arc between the electrode and the workpiece. A shielding gas, typically argon or helium, is used to protect the weld pool from atmospheric contamination. Unlike other welding processes, TIG welding does not require filler metal, although it can be used optionally depending on the application. The precise control afforded by TIG welding makes it suitable for welding thin materials and intricate joints with minimal distortion.

Techniques and Equipment:

TIG welding requires a steady hand and precise control of welding parameters to achieve optimal results. Welders must maintain a constant arc length, control the heat input, and manipulate the torch angle and travel speed to ensure proper fusion and penetration. TIG welding undercut equipment typically consists of a power source, a TIG torch with a non-consumable tungsten electrode, a shielding gas supply, and a foot pedal or hand control for adjusting welding current. Advanced TIG welding machines may feature pulse settings, AC/DC capabilities, and programmable functions for enhanced versatility.

Applications:

TIG welding finds widespread use in industries such as aerospace, automotive, electronics, nuclear, and precision fabrication, where high-quality welds are essential. Common applications of TIG welding include:

Aerospace Components:

TIG welding is favored for its ability to produce clean, precise welds on thin-gauge materials used in aircraft components, such as fuselage panels, engine parts, and exhaust systems.

Automotive Fabrication:

TIG welding is employed for welding aluminum and stainless steel components in automotive manufacturing, including exhaust systems, chassis components, and fuel tanks.

Pipe Welding:

TIG welding is used for welding stainless steel, carbon steel, and exotic alloys in pipe fabrication for industries such as petrochemical, pharmaceutical, and food processing.

Thin Sheet Metal Fabrication: TIG welding excels at joining thin sheet metal materials used in electronics enclosures, medical devices, and architectural components, where precision and aesthetics are paramount.

Advantages:

TIG welding offers several advantages over other welding processes, including:

High-Quality Welds: TIG welding produces clean, precise welds with minimal spatter, distortion, and defects, making it suitable for applications requiring superior weld quality.

Versatility:

TIG welding can be used to weld a wide range of materials, including aluminum, stainless steel, carbon steel, titanium, and copper alloys, providing versatility in fabrication and repair tasks.

Control and Precision: TIG welding offers precise control over welding parameters, allowing welders to achieve precise bead placement, penetration, and fusion, even on thin materials and complex geometries.

No Flux Required:

Unlike some welding processes like flux-cored arc welding (FCAW) or submerged arc welding (SAW), TIG welding does not require flux, reducing the risk of weld contamination and simplifying post-weld cleaning.

Conclusion:

TIG welding is a versatile and precise welding process that offers numerous advantages for a wide range of applications. From aerospace components and automotive fabrication to pipe welding and thin sheet metal fabrication, TIG welding finds use in industries where high-quality welds and precise control are essential. By mastering TIG welding techniques and leveraging its capabilities, welders can achieve superior weld quality, reliability, and performance in their projects.

0 notes

Text

Forging a Legacy: Exploring the Timeless Craft of Metalworking

In the age of rapid technological advancements, where 3D printing and automation dominate headlines, a timeless craft still holds its ground – metalworking. This ancient art form, which has been a part of human civilization for millennia, continues to thrive, combining tradition and innovation to shape the world around us. In this article, we delve into the world of metalworking, from its historical roots to its contemporary applications, exploring the enduring allure of this craft.

A Journey Through Time

The roots of metalworking stretch deep into the annals of human history. The discovery of metals and the development of metallurgical techniques have been pivotal moments in our progress as a species. From the Bronze Age to the Iron Age, metals like copper, bronze, and iron revolutionized our tool-making, weaponry, and artistic endeavors.

Throughout history, metalworkers were revered artisans who crafted intricate armor, weaponry, and jewelry. The blacksmith's hammer and anvil became symbols of their craft as they shaped raw metal into functional and artistic forms. The legacy of these skilled craftsmen can be seen in the masterpieces of ancient Greece, the ornate armor of medieval knights, and the intricate jewelry of various cultures across the globe.

The Heart of the Forge

The blacksmith's forge is at the core of traditional metalworking, where raw metal transforms into something more profound. The process begins by heating metal until it reaches a malleable state. Skilled blacksmiths then employ their expertise, manipulating the metal with precision and artistry—the marriage of heat, force, and finesse results in everything from ornate gates to sturdy horseshoes.

One fascinating facet of blacksmithing is the creation of Damascus steel, renowned for its extraordinary strength and mesmerizing patterns. This ancient technique involves layering different types of iron and folding them repeatedly during the forging process. The result is not just a weapon but a work of art, with intricate patterns adorning the blade.

Despite the advent of modern manufacturing techniques, traditional blacksmithing continues to endure as an artisanal craft. Today, blacksmiths create bespoke pieces, both functional and decorative, forging a link between our past and our present.

The Fusion of Fire and Metal: Welding

Welding is the modern-day incarnation of ancient blacksmithing. It involves joining metals by heating them until they melt and then cooling them to form a strong bond. Welding has become indispensable in various industries, from construction to automotive manufacturing.

Different welding techniques, such as arc, MIG, and TIG welding, offer versatile solutions for other applications. MIG welding, for instance, is known for its speed and ease of use, making it ideal for mass production. In contrast, TIG welding offers the precision necessary for delicate tasks, like crafting medical equipment from stainless steel.

Welding plays a pivotal role in constructing modern infrastructure and machinery. It enables the assembly of steel beams, the creation of pipelines, and the fabrication of aerospace components. In the hands of artists and sculptors, welding has also become a medium for crafting intricate metal sculptures that adorn public spaces and galleries.

Crafting Beauty in Metal: The Art of Jewelry Making

Metal jewelry making is a branch of metalworking that marries craftsmanship and creativity. Artists and artisans shape metals like gold, silver, and copper into wearable works of art. Techniques like soldering, casting, and forging bring jewelry designs to life, allowing for intricate settings, delicate filigree work, and unique gemstone arrangements.

Soldering is a common technique that bonds metal components together using a soldering iron or torch. This method enables jewelers to create intricate designs and settings for gemstones. Casting involves pouring molten metal into a mold to produce detailed shapes and patterns. Forging allows jewelers to shape metal by hammering it while heated, resulting in customized pieces that reflect their artistic vision.

Metal jewelry makers often incorporate gemstones and other materials, creating pieces that tell stories and evoke emotions. Whether a delicate silver necklace or a bold statement ring, metal jewelry-making epitomizes the fusion of craftsmanship and creativity.

Technology Meets Tradition: Modern Metalworking

In a world where technology constantly pushes boundaries, metalworking has been included. Computer-aided design (CAD) and manufacturing (CAM) have revolutionized the industry, allowing intricate designs to be translated into physical objects with unparalleled precision. CNC (Computer Numerical Control) machines, guided by these digital designs, cut, mill, and shape metal to incredible levels of accuracy, reducing errors and increasing efficiency.

These technological advancements have expanded the possibilities of metalworking across industries. In aerospace and automotive manufacturing, CNC machines produce precision components critical for safety and performance. In architecture, metalworking techniques enable the construction of innovative and awe-inspiring structures. Additionally, artists and sculptors can now access advanced tools and equipment to realize their creative visions.

Metalworking is not just a craft; it's a timeless art that continues to shape our world. From its ancient roots in blacksmithing to its modern applications in industries and creative endeavors, this craft bridges the past, present, and future. As technology evolves, metalworking evolves, pushing the boundaries of what can be achieved. Yet, it remains rooted in tradition, preserving the essence of a craft that has captivated humanity for millennia. Past and future coexist in the world of metalworking, forging a legacy that is as enduring as the metals themselves.

1 note

·

View note

Text

The Comprehensive Guide to Why You Should Buy Copper Alloy Filler Wires

In the realm of welding, the choice of filler material can significantly impact the quality, strength, and longevity of the weld. Among the plethora of options available, copper alloy filler wires stand out as a reliable and versatile choice for various welding applications. From industrial manufacturing to intricate artistic endeavors, here is why you should consider investing in copper alloy filler wires offered by Castron Electrode online-

Superior Conductivity: Copper is renowned for its exceptional electrical and thermal conductivity. When used as a filler material, copper alloy wires ensure efficient heat transfer during the welding process. This characteristic facilitates smoother arc stability and better control over the welding parameters, resulting in precise and consistent welds. Hence, Buy Copper Alloy Filler Wires Online to design thermally and electrically conductive filler devices.

Enhanced Corrosion Resistance: Copper alloys possess inherent corrosion resistance, making them ideal for welding applications in corrosive environments. Whether it is joining components for marine structures or fabricating pipelines exposed to harsh chemicals, copper filler wires offer superior protection against rust and degradation, thereby extending the lifespan of welded structures.

High Strength and Ductility: Copper alloy filler wires exhibit excellent mechanical properties, including high tensile strength and ductility. This combination of strength and malleability allows for the creation of robust welds that can withstand mechanical stress, vibrations, and deformation without compromising structural integrity. Whether in automotive manufacturing or structural engineering, when you fix and Buy Copper Alloy Filler Wires Online, they contribute to the production of durable and reliable weldments.

Compatibility with Various Base Metals: Copper alloy filler wires by Castron Electrode online are compatible with a wide range of base metals, including steel, stainless steel, aluminum, and nickel alloys. This versatility makes them suitable for diverse welding applications across different industries. Whether you're working with ferrous or non-ferrous materials, copper filler wires ensure excellent fusion and metallurgical compatibility, resulting in strong and homogeneous weld joints.

Minimal Weld Spatter: Weld spatter, caused by the expulsion of molten metal droplets during the welding process, can mar the appearance of welds and require post-weld cleanup. Copper alloy filler wires exhibit low spatter characteristics, minimizing the need for rework and enhancing the overall efficiency of the welding operation. This not only saves time and resources but also ensures cleaner and more aesthetically pleasing welds.

Ease of Use and Versatility: Copper alloy filler wires are available in various diameters and compositions to suit different welding requirements. Whether you're performing gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), or oxy-acetylene welding, there's a copper filler wire formulation optimized for your specific application. Additionally, their ease of handling and feeding further enhances the welding experience, particularly for novice welders.

Cost-Effective Solution: Despite their numerous benefits, copper alloy filler wires offer excellent value for money compared to other specialty filler materials. Their widespread availability and relatively lower cost make them a cost-effective solution for welding operations without compromising on quality or performance. By investing in copper filler wires, businesses can achieve optimal weld results while minimizing expenditure on consumables.In conclusion, the decision to buy copper alloy filler wires is backed by a myriad of compelling reasons, including superior conductivity, corrosion resistance, mechanical properties, compatibility, minimal spatter, ease of use, and cost-effectiveness. Whether you're a professional welder, fabricator, or hobbyist, incorporating copper filler wires into your welding toolkit can elevate the quality and reliability of your weldments, ensuring lasting success in your endeavors. For more information, check the website https://shop.castonelectrode.in/product-category/copper-alloy-filler-wires/.

0 notes

Text

Welding Services and Metal Art: Crafting Sculptures and Decorative Pieces

When we think of welding services, our minds often gravitate toward industrial applications, construction sites, or the assembly of machines and vehicles. However, the scope of welding stretches far beyond these utilitarian boundaries, venturing into the vibrant world of art. In the hands of a skilled artisan, welding services transform simple metal parts into stunning sculptures and decorative pieces that defy convention and capture the imagination. Visit us on JGW Machine for better understanding.

The Fusion of Functionality and Creativity

At the intersection of artistry and engineering lies the craft of metal art. This discipline leverages the precision and strength provided by professional welding services to create works that are not only aesthetically pleasing but also structurally sound. The same techniques used to ensure the integrity of a bridge or the safety of a vehicle are applied with an artist’s touch to bring metal to life.

The Tools and Techniques of Metal Art

Crafting metal art begins with an idea, a vision shaped by the artist's creativity and experience. Welding services provide an array of tools and techniques to make this vision a reality. From TIG (Tungsten Inert Gas) welding, which offers control for detailed work, to MIG (Metal Inert Gas) welding, ideal for its adaptability and speed, each method offers something unique to the artist.

The intricate process of metal sculpture creation often starts with sketching and model-making, which allows the artist to explore various design options and structural considerations before the actual welding begins. The use of CAD (Computer-Aided Design) software is also increasingly common, bridging traditional welding services with modern technology.

The Artisan’s Palette: Materials in Metal Art

In metal art, the materials used are as diverse as the colors on a painter’s palette. Artists can choose from steel, bronze, copper, and aluminum, each with its own characteristics and charm. Recycled and upcycled metals are also popular in sustainable art circles, where the history of the material adds depth to the finished piece.

Welding Services: Enabling Complex Creations

Professional welding services allow artists to tackle complex projects that would otherwise be impossible. The expertise of seasoned welders is crucial when dealing with large-scale sculptures or intricate pieces that require precise joins. These experts can navigate the challenges of thermal expansion, distortion, and material behavior, ensuring that the final artwork stands the test of time.

Custom Decorative Pieces and the Welding Touch

Beyond sculptures, welding services play a significant role in creating custom decorative pieces. From bespoke furniture to intricate gates and railings, the welder’s touch can turn a functional item into a conversation starter. These pieces not only serve their primary purpose but also reflect the personal style and creativity of the owner.

Welding Services: Collaborating with Artists

Artists often collaborate with professional welding services to bring their projects to fruition. These partnerships can lead to groundbreaking work, pushing the boundaries of what can be achieved with metal. Welding companies that specialize in working with artists understand the need for a balance between technical proficiency and artistic sensitivity.

Challenges in Metal Art Creation

Creating metal art is not without its challenges. One of the most significant is dealing with the physical properties of metal, including its weight and the stresses placed on different parts of a sculpture. Welding services must account for these factors to prevent warping or collapse. Additionally, the finishing touches, such as polishing and coating, require a delicate approach to preserve the integrity of the welds and the overall design.

Education and Skills Development

For those interested in exploring the fusion of welding services and art, education and skills development are key. Many welders develop their artistic skills through formal education, apprenticeships, and continuous practice. It’s an area where technical expertise and creative flair are equally important, and where lifelong learning keeps the art form evolving.

The Role of Welding Services in Public Art

Public art installations are a testament to the collaboration between welding services and artists. These sculptures not only beautify spaces but also often become iconic landmarks. The durability and strength provided by professional welding ensure that these public artworks can withstand the elements and the test of time.

Conclusion

Welding services, often perceived as a purely industrial function, are integral to the creation of metal art. They offer the tools, techniques, and expertise necessary to turn raw metal into intricate sculptures and decorative pieces that enchant and inspire. Through the synergy of artist and welder, the medium of metal transcends its industrial roots and becomes a canvas for creativity. Whether it's a towering public sculpture or a finely crafted decorative gate, the art of welding is an unspoken narrative of our daily lives, adding beauty and character to our environments. As we continue to redefine the boundaries of art and craftsmanship, welding services will undoubtedly remain a pivotal force in the realm of artistic expression.

Read more:

JGW Machine: The Bright Revolution in LED

0 notes