#MaterialProcessing

Explore tagged Tumblr posts

Text

Discover the key factors that make impact crushers perfect for reusing construction materials. Learn how their high efficiency, adjustable settings, and ability to handle various materials contribute to sustainable and cost-effective construction projects. To know the key factors https://austinrockcrushing.com/2024/10/23/which-factors-make-impact-crushers-ideal-for-reusing-construction-materials/

#RockCrushing#CrushingServices#RockProcessing#AggregateCrushing#CrushingExperts#RockCrusher#RockExcavation#CrushingAndScreening#HeavyEquipment#CrushingSolutions#SitePreparation#MaterialProcessing#RockRecycling#ConstructionCrushing#CrushingContractors#MiningCrushing#RockReduction#CrushingOperations#RockCrushingExperts#CrushingTechnology#EfficientCrushing#StoneCrushing#RockBreaking#CrushingEquipment#RockCrushingServices

0 notes

Text

Plowshare Mixers ensure efficient and uniform mixing for a wide range of materials, enhancing productivity in industrial processes. Unlock the potential of precision mixing today!

For more information, visit: https://www.bhagwatipharma.com/plowshare-mixers-unlocking-the-potential/

0 notes

Text

Labtron vertical planetary ball mill has a low center of gravity, touch-screen microcomputer, and safety switch. It offers forward/reverse control, timing, power-off memory, low noise, minimal loss, adjustable speed range of 70-670 r/min, and motor protection.

0 notes

Text

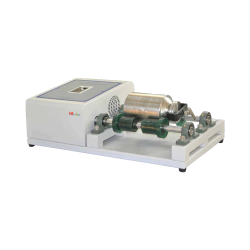

Ball Mill 32 Kg

Labmate Ball Mill offers ultra-fine crushing with an adjustable roller speed of 60-570 ±10 rpm. It supports various grinding balls like zirconia, alumina, PU, and tungsten. The roller control allows precise speed adjustment for optimal milling intensity. Ideal for versatile material grinding.

0 notes

Text

Benchtop Ball Mill 580 rpm

Labtron Benchtop Ball Mill handles batches up to 3.96 L and features a speed range of 70–580 rpm. It offers both dry and wet milling under vacuum with a 12 L capacity, 4 pots (1-3 L each), and supports continuous operation for up to 72 hours, assuring prolonged and uninterrupted processing.

0 notes

Text

Discover the power of carbide rotary files as they expertly cut through a range of materials. Perfect for industry professionals looking to enhance their craft with precision and durability. See these tools in action and elevate your work process.

#CarbideFiles#PrecisionEngineering#IndustryTools#ManufacturingTech#ToolPerformance#MaterialProcessing

0 notes

Text

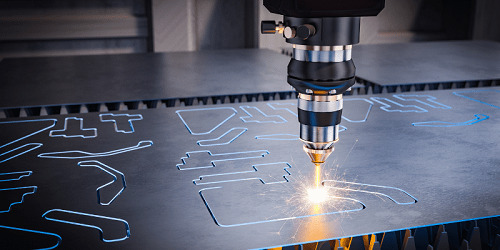

Laser Cutting Machine Market Evolution: Historical Analysis and Future Projections

The global laser cutting machines market size is expected to reach USD 10,351.0 billion by 2030, registering a CAGR of 5.5% over the forecast period, according to a study conducted by Grand View Research, Inc. Over the forecast period, it is anticipated that the growing trend of automation in the manufacturing sector and the rising demand for the end-use industry will increase demand for these machines. The growing application of CO2, fiber, and Yttrium Aluminum Garnet (YAG) lasers in various applications, such as industrial sectors and consumer electronics, is predicted to boost the demand for laser cutting machines. Industries such as consumer electronics are contributing to the market growth owing to the increasing use of lasers in material processing operations such as pruning, welding, and engraving. Furthermore, the requirement for high-power input and performance-based cutting tools drives demand and market growth for laser cutting machines over the forecast period.

Laser Cutting Machines Market Report Highlights

During the forecast period, the gas laser technology segment is expected to witness the highest CAGR of 6.1 %. The growth is attributed to the increasing demand for these lasers for better machine tools and equipment for laser printing, dye laser pumping, reading barcodes, and producing holograms

The fusion cutting is expected to register the highest CAGR of 6.1 % from 2023 to 2030. The advantage of fusion cutting is that it creates a cutting edge that is practically oxide-free and ideal for cutting thin sheets, which is expected to contribute to the growth of the segment

Over the course of the forecast period, the industrial sector is expected to dominate the laser cutting machine industry. It held a market share of 39.8 % in 2022. The need for laser cutting equipment is rising as industrial processes increasingly become automated. These tools consistently and quickly cut parts and patterns with precision

The rising GDP and quickening growth of the region's manufacturing sector, the Asia Pacific region is anticipated to continue growing. Additionally, businesses that use laser cutting to create semiconductors, consumer electronics, and automotive components are experiencing rapid regional growth. The need for laser cutting equipment in this area is rising along with the expansion of these industries

For More Details or Sample Copy please visit link @: Laser Cutting Machines Market Report

The development of innovative process lasers to maximize the manufacture of tailored three-dimensional glass elements, as well as a shift out of traditional semiconductor lasers and towards quantum cascade lasers, will likely drive up the demand for laser cutting machines. Continuous developments in laser technology enable manufacturers to engage in R&D to obtain a competitive advantage. Furthermore, due to the demand for high-speed and precision cutting and drilling the integration of the Internet of Things, Artificial Intelligence, and automation software with drilling machines is also supporting the laser cutting machine industry’s growth.

Major players are resorting to strategies such as product launches, mergers & acquisitions, and expansions to gain greater market shares. For instance, in May 2022, Yamazaki Mazak Pvt. Ltd. announced the launch of 3D based fiber laser cutting machine for cutting steel products- FG -400 NEO. The 3D laser is equipped with an efficient laser fiber oscillator which offers efficient energy conversion and enhanced productivity.

The laser is also compatible with cutting copper, brass, and aluminum. The laser is outfitted with a feature that enables users to easily modify the laser beam's diameter and form, enabling the cutting of sheets of different thicknesses. The oscillator's maximum output is limited to 4 kW, along with a rapid input rate on the X, Y, and Z axes is 60, 36, and 30 m/min, respectively. The continuous launch of advanced products is contributing to the laser cutting machine industry’s growth.

#LaserCuttingMachine#CuttingEquipment#CNCMachines#PrecisionCutting#MaterialProcessing#Metalworking#Fabrication#IndustryInsights#TechnologyTrends#MarketForecast#BusinessStrategy#InvestmentOpportunities#SupplyChain

0 notes

Link

Roller Cutting Press (RCP) Machines by RIDAT | Precision in Thermoforming

Explore RIDAT's Roller Cutting Press (RCP) machines, expertly designed for precision cutting of plastic thermoformed sheets, rubber, leather, board, foil, and more. Enhance your thermoforming processes with our top-notch equipment featuring solid steel rollers and dual control switching.

#RollerCuttingPress#ThermoformingEquipment#ManufacturingMachinery#MaterialProcessing#RIDATTechnology#GasketCutting

0 notes

Text

Granulator Knives Market Forecast 2024 to 2032

Granulator knives are cutting tools used in granulation processes, which involve breaking down larger materials into smaller particles or granules. These knives play a crucial role in various industries, such as plastics recycling, pharmaceuticals, food processing, and more.

The Granulator Knives Market was valued at USD 40.98 Million in 2022 and is expected to register a CAGR of 5.21 % by 2032.

As environmental concerns and regulations related to waste disposal and pollution increase, industries are placing greater emphasis on recycling and waste management. Granulators play a critical role in recycling processes, helping to break down materials like plastics, rubber, and metals into smaller granules for reuse. This drives the demand for efficient and durable granulator knives.

Get a Free Sample Copy

#GranulatorKnives#CuttingBlades#SizeReduction#IndustrialCutting#KnifeTechnology#MaterialProcessing#GranulationEquipment#BladeSolutions#KnifeManufacturing

0 notes

Text

Quantum Cascade Laser Chips Market: $1.2B to $3.8B by 2034 💡

Quantum Cascade Laser (QCL) Chips Market is expected to expand from $1.2 billion in 2024 to $3.8 billion by 2034, with a CAGR of 11.5%. This rapid growth reflects the increasing demand for mid- to far-infrared laser technology, which is revolutionizing various sectors including spectroscopy, environmental monitoring, and medical diagnostics.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS10694 &utm_source=SnehaPatil&utm_medium=Article

Market Drivers and Key Segments

QCL chips, which operate in the mid- to far-infrared spectrum, offer unique advantages in high-resolution sensing and compact design. These benefits make them ideal for industries requiring precise and reliable measurement tools. The telecommunications sector leads the market, benefiting from the demand for high-speed data transmission and the continuous evolution of network infrastructures. Industrial applications, particularly material processing and sensing, are the second-largest segment, driven by the need for efficiency and precision in manufacturing processes.

Regional Growth Dynamics

The North American market leads in terms of market share, driven by robust technological innovation and R&D investments. The United States, in particular, is at the forefront of QCL adoption, particularly in telecommunications and aerospace applications. Europe also remains a strong player, with countries like Germany and the United Kingdom making significant contributions to industrial and automotive sectors. Meanwhile, in the Asia-Pacific region, China and Japan are emerging as key players, thanks to their rapid industrialization and growing focus on advanced manufacturing technologies.

As technological advancements continue, these regions are set to fuel further growth, providing a fertile landscape for strategic collaborations and continued innovation in quantum cascade lasers.

#QuantumCascadeLaser #QCLChips #LaserTechnology #Photonics #MidInfraredLasers #Spectroscopy #EnvironmentalMonitoring #MedicalDiagnostics #Telecommunications #DataTransmission #HighSpeedNetworking #MaterialProcessing #IndustrialSensing #LaserInnovation #SemiconductorTech #PrecisionEngineering #AsiaPacificTech #EuropeInnovation #USTechLeadership #LaserDevelopment #TechGrowth

0 notes

Text

Explore crucial safety measures to implement during rock milling operations. Understand key best practices, equipment safety tips, and protective strategies to reduce hazards and promote a secure working environment. To learn about safety measures visit https://austinrockcrushing.com/2024/10/16/what-safety-precautions-should-be-taken-during-rock-milling/

#RockMilling#HorizontalMilling#Construction#Mining#CivilEngineering#Excavation#Landscaping#SitePreparation#RockCrushing#AggregateProduction#EarthMoving#HeavyEquipment#MillingServices#GeotechnicalEngineering#RockDrilling#SoilStabilization#RockGrinding#MaterialProcessing#EnvironmentalImpact#InfrastructureDevelopment#Quarrying#RockRemoval#MiningEquipment#EngineeringSolutions

0 notes

Photo

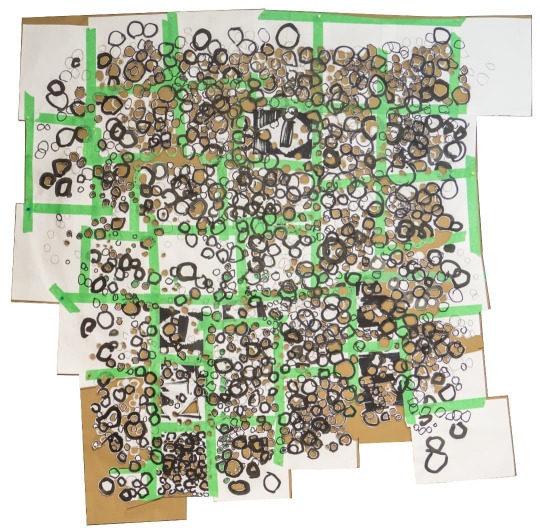

After visiting Carlyn Yandle's Studio I had to dig up 'the multitudination'. Like Yandle's work, too big, too complex to be understood by visuals alone. #edhunt #edhuntart #paper #wood #textile #material #materialprocess #marks #moves #makes #lines #theknife #theline #line #theknifedoesntlie (at Sun Wah Centre) https://www.instagram.com/p/CXHUFFePA7I/?utm_medium=tumblr

#edhunt#edhuntart#paper#wood#textile#material#materialprocess#marks#moves#makes#lines#theknife#theline#line#theknifedoesntlie

0 notes

Photo

RE_TOLD Branding

As mentioned in the previous post, this image illustrates how the branding for the HOME IncUBATOR and RE_TOLD is being CNC milled. 3/4″ thick Maple planks are being utilized as the base material. In the plank at the front of the image, the layers that will produce a smoothly contoured Letter D are apparent at the middle and left end of the plank. Once removed from the mill, the pieces are laminated with adhesive in a vacuum bag to ensure accurate alignment. Even though there is a vacuum table in the bed of the CNC Mill, we have to screw the planks down at the edges on a new spoil board to make sure that pieces are level and flat to maintain the level of mechanical perfection required.

#UDBS#UrbanDesignBuildStudio#weareUDBS#wearePROJECTRE_#PROJECT RE_#projectrepgh#CarnegieMellonUniversity#CMU#CMUSoA#SoA#SoAUDBS#RE_TOLD#HOMEIncUBATOR#ScalingChange#FordMakesLivesBetter#FordGIvesBack#FordC3#design#process#CNCmill#branding#MechanicalPerfection#DigitalFabrication#fabrication#material#MaterialProcess#lamination#craft#making#submission

0 notes

Text

wholesale mini film red manufacturer

This series of products are very flexible during usage, because the plastic handle can move actively when wrapping goods, Greatly reduced the hand motion, and the plastic handle can be repeated use.

mini film redRaw MaterialLLDPE + MLDPE 100% virgin materialProcessing TypeCastWidth7.6cm(3”) 10cm (4”) 12.7cm(5”)ThicknessRange from 10mic to 30micLength100m -500mColorClear, blue, white ,green, black, yellow, red,etcCore Size1.5” / 3”ElongationRange from 200% to 500%

0 notes

Text

Benchtop Ball Mill 260 mm

Labtron benchtop ball mill features an adjustable speed range of 60 to 570 ± 10 rpm and a Φ 25 × 260 mm roller. It supports small-batch production with both dry and wet milling modes, handling material and mill balls up to 2/3 volume. Versatile for processing a wide range of materials efficiently.

0 notes

Text

Style: Blue medium - Smiley face hit color handbag

Style: Blue medium – Smiley face hit color handbag

Style: shoulder bagBackpack method: single shoulder slung portableTexture: PU materialProcess: soft surfaceLifting part type: soft handleClosed way: zipperInternal structure: zipper pocket, cell phone pocket, document bag, luggageOuter bag type: inner patch pocketPopular elements: contrastpattern: plainWith or without interlayer: noneLuggage hardness: hardWhether it is foldable: NoApplicable…

View On WordPress

0 notes