#FPC cables

Explore tagged Tumblr posts

Text

youtube

Panasonic New Product Brief: CF1 Series Board-to-FCP Automotive Connectors

https://www.futureelectronics.com/m/panasonic. The new Panasonic CF1 Series Board-to-FPC connection has a 125°C heat resistance and necessary vibration characteristics suitable for the automotive and transportation market. Panasonic's CF1 Series Automotive Connectors preserve contact reliability using a double-sided clip contact structure. Panasonic's CF1 Series Connectors also have an Inertia lock construction to prevent half-mating for the 4-pin type. https://youtu.be/RRzfdltuUlg

#Panasonic CF1#Board-to-FCP Automotive Connectors#CF1 Series Board-to-FPC connection#heat resistance#automotive#transportatio#Automotive Connectors#relay wiring harnesses#FPC cables#Youtube

0 notes

Text

It is called "FPC Cable with EMI Shielding Film",if you just engage in or somehow need this product or custom another new one,welcome contact me to know more details

#FPC Cable with EMI Shielding Film#FPC Cable#EMI Shielding Film#FPC with EMI Shielding Film#with EMI Shielding Film

0 notes

Text

FFC & FPC Jumper Cables Market Competitive Landscape and Qualitative Analysis by 2032

The FFC (Flexible Flat Cable) and FPC (Flexible Printed Circuit) jumper cables market refers to the industry that deals with the production and sale of these types of cables. FFC and FPC cables are flexible, thin, and lightweight cables that are commonly used for making electrical connections in various electronic devices and systems.

The global FFC / FPC jumper cables market is expected to grow from USD 1.02 Billion in 2022 to USD 2.06 Billion by 2030, at a CAGR of 7.5%

FFC jumper cables consist of flat conductive ribbon cables with insulation layers, and they are typically used for short-distance, high-density interconnects. FPC jumper cables, on the other hand, are made of flexible substrates with printed circuits, allowing them to be bent or folded to fit into tight spaces. They are commonly used for applications that require both flexibility and reliability.

The FFC and FPC jumper cables market has experienced significant growth in recent years due to the increasing demand for electronic devices such as smartphones, tablets, laptops, gaming consoles, and automotive electronics. These cables are used in a wide range of applications, including display panels, touchscreens, cameras, sensors, connectors, and more.

Key factors driving the market growth include the miniaturization of electronic devices, the need for lightweight and flexible wiring solutions, the growing demand for high-speed data transmission, and the advancements in technology that enable the production of more efficient and reliable FFC and FPC cables.

I recommend referring to our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into the humidity sensors market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in the market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/ffc-&-fpc-jumper-cables-market/1282/

Market Segmentations:

Global FFC & FPC Jumper Cables Market: By Company • Molex • Sumitomo Electric • Johnson Electric • Samtec • TE Connectivity • Cvilux • Luxshare-ICT • Axon Cable • Hezhi Electronic • Xinfuer Electronics • Hitachi Metals, Ltd • Würth Elektronik • VST Electronics • JSB TECH • Cicoil Flat Cables • Sumida-flexcon • Nicomatic • JST • Omron Global FFC & FPC Jumper Cables Market: By Type • FFC Connectors • FPC Connectors Global FFC & FPC Jumper Cables Market: By Application • PC/PC Display • CD-ROM Drive • TV • Printer • DVD/BD Player • Car Stereo • Game Machine • GPS • Others Global FFC & FPC Jumper Cables Market: Regional Analysis All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global FFC & FPC Jumper Cables market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/ffc-&-fpc-jumper-cables-market/1282/

Reasons to Purchase FFC & FPC Jumper Cables Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

• To make well-informed business decisions: These research reports give companies data-driven insights that they may use to plan their strategy, develop new products, and devise marketing and advertising plans.

In general, market research studies offer companies and organization’s useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy development, and business planning.

Click Here, To Buy Premium Report: https://stringentdatalytics.com/purchase/ffc-&-fpc-jumper-cables-market/1282/?license=single

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - 91-9763384149

Email Id - [email protected]

Web - https://stringentdatalytics.com/

0 notes

Text

DVI output adapter for RP2350 Feather HSTX port 🔌🖥️💡

The RP2350 Feather has an FPC output connector for accessing the HSTX - high-speed transmission - peripheral. This lets us drive DVI displays really easily! Today, we got the prototype PCBs for our HSTX to DVI adapter board; after connecting up a 22-pin FPC cable, we can test out DVI driving via CircuitPython. With HSTX, we don't need to overclock or use PIO, and there's a lot more RAM on the RP2350, so we can easily do 320x240 with 16-bit color and have plenty of SRAM left over. It would be neat if we could do DVI from the PSRAM as a framebuffer at some point for really big displays!

#adafruit#circuitpython#rp2350#feather#fpc#hstx#dvi#hdmi#sram#prototyping#electronics#dviadapter#dviproject#fpgadisplay#displaytech#highspeeddata#techinnovation#diyhardware#featherboard#microcontroller#raspberrypi#displayoutput#circuitdesign#openhardware

7 notes

·

View notes

Text

Polyimide Films and Tapes Market Industry Leaders Size & Share Outlook & New Revenue Pockets

The polyimide films & tapes market is estimated to be USD 1.3 billion in 2023 and is projected to reach USD 1.8 billion by 2028, at a CAGR of 8.7% from 2023 to 2028. Growing end-use industries such as electronics, automotive, and aerospace are expected to drive the market. Polyimide films are highly resistant and widely used as insulation material in electrical applications such as flexible printed circuit boards.

Download PDF Brochure at https://www.marketsandmarkets.com/Market-Reports/polyimide-film-market-205319946.html

Based on the end-use industry, electronics will be the fastest-growing segment during the forecast period.

Due to its superior thermal stability, endurance, and electrical insulating capabilities, polyimide films are frequently used in the electrical sector. They are essential in many electrical applications, ensuring the effectiveness and safety of electrical systems and parts. Electrical wires and cables frequently use polyimide sheets as insulation. They have a high dielectric strength that prevents electrical breakdown and short circuits even at high temperatures.

Based on the application, the flexible printed circuits segment is expected to be the fastest-growing segment during the forecast period—flexible printed circuits. Flexible printed circuits (FPCs) are produced significantly using polyimide films, which have specific characteristics that are very beneficial in this application. Thin, light circuit boards called FPCs are made to be flexible and portable. In FPCs, polyimide sheets are frequently utilized as the substrate (base material). Polyimide films work well due to their flexibility, high-temperature resistance, and excellent electrical insulating properties.

Request For FREE Sample of Report at https://www.marketsandmarkets.com/requestsampleNew.asp?id=205319946

Based on region, the Asia Pacific region is expected to be the fastest-growing regional segment of the polyimide films & tapes market. In the Asia Pacific region, demand for polyimide films and tapes has been rising rapidly for several reasons. Polyimide films and tapes are used in various industries in the Asia Pacific region, including electronics, automotive, aerospace, and more. China, Japan, South Korea, and Taiwan all play significant roles in the electronics and semiconductor sector in the Asia Pacific region.

#Polyimide Films and Tapes Market#Polyimide Films and Tapes#Polyimide Films and Tape#Polyimide Films#Polyimide Film#Polyimide Tapes#Polyimide Tape

0 notes

Text

FPCs are suitable for mass assembly,while flat cables and wire connections are suitable for sample and experimental purposes.The main factor affecting the cost of FPCs is the circuit area,while the main factor affecting the cost of flat cables is the number and length of wires.🧑🏫

#pcb#flex pcb#rigid-flex pcb#flex circuit pcb#flexible pcb board#flexible circuit board#fpcway#fpcway.com#www.fpcway.com#today on tumblr

0 notes

Text

0 notes

Text

Cable Assembly Market - Global Opportunity Analysis and Industry Forecast (2024-2031)

Meticulous Research®, a renowned global market intelligence firm, has published an insightful report titled, "Cable Assembly Market by Product Type (Rectangular, Coaxial, Fiber Optic, Power, Modular, FFC/FPC, Telephone), End-use Equipment (Computers & Peripheral, Medical, Industrial, Automotive, Transportation, Telecom, Datacom), Geography - Global Forecast to 2031."

According to the report, the global cable assembly market is expected to reach a valuation of $299.2 billion by 2031, growing at a compound annual growth rate (CAGR) of 6.3% from 2024 to 2031. This robust growth is primarily driven by increasing demand from the aerospace sector and a surge in global internet penetration. The expansion of telecommunications infrastructure, rising demand for custom cable assemblies, the proliferation of electric vehicles, and the increasing adoption of data centers are also anticipated to fuel market growth. However, competition from wireless technologies and the prevalence of counterfeit products pose significant challenges to market participants.

Download Sample Report Here: https://www.meticulousresearch.com/download-sample-report/cp_id=4975

Key trends shaping the cable assembly industry include the miniaturization of cable assemblies and the rapid adoption of Industry 4.0 technologies across various sectors.

Market Segmentation

The global cable assembly market is analyzed by product type, end-use equipment, and geographic region, offering a comprehensive view of market trends and dynamics at both regional and global levels.

Product Type

The market encompasses a wide range of cable assembly products, including rectangular cable assemblies, RF/coaxial cable assemblies, fiber optic assemblies, power cable assemblies, and custom cable solutions, among others. In 2024, the rectangular cable assembly segment is expected to dominate the market due to its widespread use in vehicles, industrial automation, and machinery, where power, signal, and data transmission are crucial.

However, the fiber optic cable assembly segment is forecasted to experience the highest CAGR during the projection period. This surge is driven by the increasing demand for high-speed internet, the need to connect servers and storage systems within data centers, and the growing application of fiber optics in telecommunications and enterprise networks.

Check complete table of contents with list of table and figures: https://www.meticulousresearch.com/product/cable-assembly-market-4975

End-Use Equipment

The report segments the market based on various end-use applications, including computers and peripherals, medical devices, industrial machinery, automotive systems, telecom equipment, and data centers. In 2024, the automotive sector is expected to hold the largest share, spurred by the rising demand for electric vehicles, vehicle electrification, and the integration of advanced driver assistance systems (ADAS) and in-vehicle infotainment (IVI) technologies.

The datacom equipment segment is predicted to register the fastest growth, driven by the increasing use of fiber optic cables in data centers to support high-speed data transmission and the expansion of data center facilities worldwide.

Geographic Insights

Regionally, North America is poised to hold the largest share of the global cable assembly market in 2024, driven by the growing demand for advanced cable solutions in the automotive, telecom, and energy sectors. The region’s rapid deployment of 5G technology and renewable energy infrastructure further bolsters this growth.

Quick Buy: https://www.meticulousresearch.com/Checkout/21248218

Meanwhile, the Asia-Pacific region is forecasted to experience the highest CAGR over the next seven years. The region's booming electronics manufacturing sector, rapid industrialization, urbanization, and increased investment in telecommunications and IT infrastructure are key factors contributing to this accelerated growth.

Key Market Players

Leading companies in the cable assembly market include:

TE Connectivity Ltd. (Switzerland)

Amphenol Corporation (U.S.)

Molex, LLC (U.S.)

3M (U.S.)

Lapp Group (Germany)

Eland Cables Limited (U.K.)

Flux Connectivity Inc. (Canada)

Fischer Connectors SA (Switzerland)

CommScope, Inc. (U.S.)

Rosenberger Hochfrequenztechnik GmbH & Co. KG. (Germany)

Samtec (U.S.)

HARTING Technology Group (Germany)

Smiths Interconnect Group Limited (U.S.)

Carlisle Interconnect Technologies (U.S.)

W. L. Gore & Associates, Inc. (U.S.)

These industry leaders are at the forefront of innovation, adopting strategies such as product development, mergers and acquisitions, and partnerships to strengthen their market positions.

Request Sample PDF Copy Here: https://www.meticulousresearch.com/request-sample-report/cp_id=4975

Market Outlook and Opportunities

The report answers critical questions for stakeholders, including:

What are the key market segments by product type, end-use equipment, and geography?

How is the competitive landscape evolving?

What are the major drivers, restraints, opportunities, and challenges shaping the market?

Which regions and industries will experience the most significant growth?

How are leading companies positioned in the market, and what strategies are they adopting?

Download your free sample of the report here for an in-depth analysis of the cable assembly market.

For further inquiries, please contact:

Meticulous Research® Email: [email protected] Phone: +1-646-781-8004 Follow us on LinkedIn: Meticulous Research®

0 notes

Text

Fix iOS 18 iPhone Battery Health By JCID Battery Repair Cable

Good News! JCID has just done a test, iOS 18 doesn’t affect JCID Battery Repair Cable for iPhone battery health repair, and Apple iOS18 system no longer requires a 0-cycle adapter. iPhone battery health data repair solution:JCID battery programmer (V1SE, V1S Pro, JCID-Q1) with JCID battery tag-on repair FPC cable and clear voltage drop and lock capacity function. JCID battery repair cable…

View On WordPress

0 notes

Text

FPCway: Specialized manufacturer of flexible printed circuit boards

and rigid-flexible printed circuits

In today's fast-paced technology landscape, the demand for smaller, lighter, and more complex electronic devices continues to rise. Whether it's a sleek smartphone in your pocket or a sophisticated medical device in a hospital, these devices rely on cutting-edge printed circuit boards (PCBS) to run efficiently. Among the many types of printed circuit boards available, flexible printed circuits (flex PCBs) and rigid-flex printed circuits (Rigid-Flex PCBS) are increasingly favored due to their versatility and rich and diverse design possibilities.

Advantages of Flexible Printed Circuit (Flex PCB) :

Space efficiency: Very thin and lightweight, ideal for small electronic devices.

High reliability: Fewer interconnections and solder joints increase reliability and reduce points of failure.

Strong durability: Flexible printed circuits can withstand vibration, shock and extreme temperatures, making them ideal for harsh environments.

Freedom of design: The flexibility of the substrate allows for creative and innovative designs that may not be possible with rigid printed circuits.

Advantages of rigid-flex PCBs:

Space optimization: Flexible printed circuit (Flex PCB) components allow the integration of multiple PCBS and connectors, saving valuable space.

High reliability: Fewer connectors and solder joints reduce the risk of connection failure and signal loss.

Complex geometry: Rigid-flexible printed circuits can be designed to fit non-standard and irregular shaped enclosures.

Reduce weight: Reduce connectors and cables to reduce the overall weight of the device.

FPCway is a PCB manufacturing company located in Shenzhen, China, specializing in the manufacture of flexible printed circuit boards and rigid-flexible printed circuits. The circuit boards produced have been widely used in mobile communication, Internet of Things, optoelectronics, industrial control, medical equipment, consumer electronics and other high-tech industries. The products produced by FPCway are exported to all over the world. At present, FPCway has more than 5000 square meters of FPC workshop, which has 12 SMT production lines and 2 THT production lines. FPCway has more than 200 employees, with more than 20 senior executives with decades of industry experience. With this experience and advanced equipment, we have maintained excellent technical capabilities and strong competitiveness in the Flex PCB industry.

FPCway: From prototype to assembly to product

FPCway provides Flex PCB and rigid-flex PCBs from prototype design to assembly to product, while more than 200 professionals ensure zero defects and the fastest delivery time. The company sources materials from well-known brands and maintains ISO 9001, IATF16949 quality systems and UL certification, facilitating customers' access to commercial products.

Flexible PCB prototype: The production process of FPCB products usually starts from making prototypes, FPCWay almost does not limit the appearance size of FPCB, and can adjust the substrate, thickness and layer number of products according to customer needs.

Flexible PCB assembly: Bring goodness to life

Designing and manufacturing flexible printed circuits (flex PCBs) and rigid-flex PCBS is a highly specialized process that requires specialized knowledge and advanced equipment. Flexible printed circuit (Flex PCB) components are a key step in translating these innovative designs into functional electronic devices. FPCway's engineers consider the flexibility and form factor required by the customer to create a suitable flexible printed circuit (Flex PCB) layout choice; Secondly, the appropriate substrate material is selected based on factors such as flexibility, temperature resistance and intended application. The manufacturer then uses a combination of addition and subtraction processes to create the flexible circuit, which involves etching, drilling, and laminating together. FPCway uses advanced automatic pickers to precisely place components on manufacturing flexible printed circuits (flex PCBs) or rigid-flex PCBS, then apply solder paste to the component pads, heat the components to melt the solder and establish electrical connections. Finally, engineers ensure that flexible printed circuit (Flex PCB) or rigid-flex PCBs components meet quality and functional standards through rigorous testing to ensure that the product has zero defects.

FPCway through the construction of a strong talent team and increase capital investment in the purchase of new equipment, and from prototype design to assembly to the entire process of product accurate control, to ensure product quality, FPCway at a very competitive price to provide first-class service. The company stands out in the flexible printed circuit board industry for its superior technical capabilities, excellent product quality and timely delivery of products.

0 notes

Text

xiwai 2.0M Up Down Angled USB 2.0 Type-A Male to USB-C Type-C Male Data Flat Slim FPC Cable for FPV & Disk & Phone

http://i.securitythinkingcap.com/T9897N

0 notes

Text

https://applefix.co.nz/blog/samsung-repair-hamilton-new-zealand-samsung-a52-broken-lcd-fpc-connectors

Samsung Repair Hamilton New Zealand Samsung A52 Broken LCD FPC connectors

Repairing broken FPC (Flexible Printed Circuit) connectors on Samsung devices requires precision and care to ensure proper functionality. Here’s a general guide on how to solder a broken FPC connector on a Samsung device:

Tools and Materials Needed:

Soldering Iron: A fine-tipped soldering iron (preferably temperature-controlled).

Desoldering Tools: Such as solder wick or a desoldering pump.

Replacement FPC Connector: Ensure you have a compatible replacement part.

Flux: Helps in soldering and desoldering by promoting better solder flow.

Solder: Use lead-free solder with a small diameter for precision work.

Magnifying Lamp or Loupe: Optional but highly recommended for better visibility.

Anti-static wrist strap: To prevent static discharge that could damage sensitive components.

Samsung Repair experts in Hamilton New Zealand 937 victoria street Hamilton New Zealand 078393188

Steps to Solder a Broken FPC Connector:

Prepare the Work Area:

Work on a clean, well-lit surface with good ventilation.

Use an anti-static mat if available to prevent static electricity buildup.

Inspect the Damage:

Identify the extent of the damage to the FPC connector and surrounding components.

Prepare the Replacement Connector:

If necessary, remove any adhesive or remnants of the old connector from the PCB using a soldering iron and desoldering braid/pump.

Align and Secure the Replacement Connector:

Place the new FPC connector in the correct orientation on the PCB.

Use a small piece of double-sided tape or a small amount of adhesive (if appropriate and if it won’t interfere with soldering) to temporarily secure it in place.

Soldering Process:

Apply a small amount of flux to the pads where the FPC connector will be soldered.

Tin the soldering iron tip with a small amount of solder.

Heat the pad on the PCB and the corresponding pad on the FPC connector simultaneously.

Touch the solder to the joint, allowing it to flow smoothly and create a good electrical connection. Be careful not to bridge adjacent pads.

Repeat this process for each pad of the FPC connector, ensuring all connections are solid and clean.

Inspect and Test:

Once soldered, visually inspect the joints under magnification if possible to ensure there are no solder bridges or cold joints.

Test the functionality of the FPC connector by gently inserting the flex cable and checking for proper alignment and functionality.

Reassemble and Final Checks:

If everything works correctly, reassemble the device carefully.

Perform a final functionality test to ensure all features dependent on the FPC connector (such as display, touch, etc.) are working properly.

Tips:

Practice on Scrap: If you're new to soldering FPC connectors, practice on an old circuit board or scrap PCB to gain confidence and skill.

Patience and Precision: Take your time and avoid rushing through the soldering process to minimize the risk of damage.

Important Considerations:

Safety: Always work in a well-ventilated area and be cautious with hot soldering irons and electronic components.

Compatibility: Ensure the replacement FPC connector is compatible in terms of size and pin configuration with your Samsung device.

By following these steps carefully and methodically, you should be able to successfully solder a broken FPC connector on a Samsung device, restoring its functionality.

Not sure how to fix, bring it to applefix & tech engineers @ 937 victoria street Hamilton new zealand

0 notes

Text

#Global FFC & FPC Jumper Cables Market Size#Share#Trends#Growth#Industry Analysis#Key Players#Revenue#Future Development & Forecast 2023-2032#global Global FFC & FPC Jumper Cables Market Size#global research market report

0 notes

Text

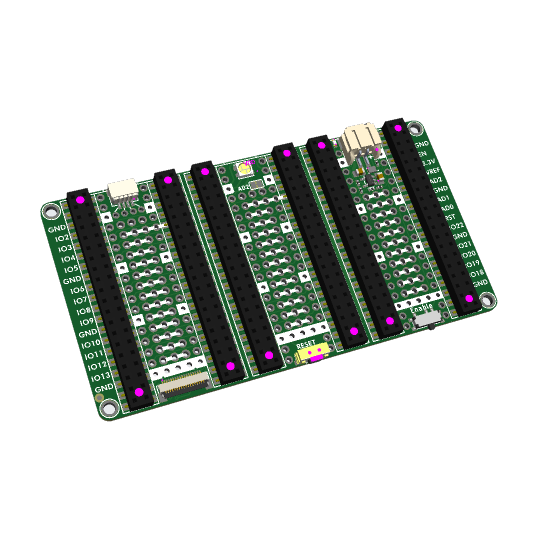

Coming soon - More PiCowbell underplates, this time a Tripler!

What? Adafruit Proto Doubler PiCowbell (https://www.adafruit.com/product/5906) is evolving! Congratulations…your Doubler has evolved into a Tripler! We've added yet another Pico footprint to our doubler, now its chonkier than ever and can handle big projects that need 2 'bells in addition to the Pico or Pico W (https://www.adafruit.com/search?q=pi+pico). We shuffled around some of the extras so that the middle row has the reset button and a NeoPixel controlled by pin AD2. Then on the left we put the I2C Stemma QT connector and squoozed in an EYESPI connector so you can quickly attach any of our EYESPI displays with an FPC cable (https://www.adafruit.com/search?q=EYESPI). we wanted to keep pins IO0 thru IO14 available so we didn't connect all the EYESPI pins, specifically Reset and Busy, but SPI and the TFT / touch control pins are set up. Time to book prototypes!

0 notes

Text

Notice: This page contains links that are sponsored by the affiliate programs of Amazon, Rakuten Advertising, eBa, Skimlinks, and Liliputing. All prices are subject to change, and the prices mentioned in this article are the most recent as of the time of publication. This article only represents the prices that were in effect at the time of publication; all prices are subject to change. One of the things that makes the Raspberry Pi 5 different from previous models is its fastest processor to date. However, that is not all. Its PCIe connector is another, allowing for fast connections to expansion boards. Many businesses have created HATs that enable you to connect a PCIe NVMe SSD to a Raspberry Pi 5 using that PCIe connector. However, the MCUzone MPW7 is a little different—it is a tiny board with an M.2 2230 module attachment port. You can purchase the MPW7 for as little as $10 (shipping included) on AliExpress. Why would someone want to upgrade their Raspberry Pi 5 with an M.2 2230 connector? The tiny computer's integrated hardware is limited to WiFi 5 and Bluetooth 5.0 because wireless connectivity is supported by design. With the help of this adapter, you can add a WiFi 6, WiFi 6E, or WiFi 7 module that supports more network bands, lower latency, and faster speeds, among other features. The board is said to support wireless modules by MCUZone, including Intel's: The board, an FPC cable (for connecting to the PCIe interface on a Raspberry Pi 5), and a set of four screws for mounting the board on top of the single-board computer are all included in the $10 starting price for the MPW7. Customers who intend to add a wireless module to the board may want to invest an additional $2 or so in a package that also comes with two wireless antennas. Alternatively, for a little bit extra, you can purchase a bundle that also comes with an aluminum case made to hold a Raspberry Pi 5 + MPW7. But the MPW7 isn’t only useful for connecting wireless cards. You can also use it for other M.2 2230 cards, including an AI accelerator featuring Google Edge TPU coprocessors. One other thing to keep in mind is that if you plan to use the MPW7 for Bluetooth, you’ll need to run a cable from a connector on the board to one of the Raspberry Pi’s USB ports. via CNX Software The two main revenue streams for Liliputing are affiliate links and advertising. For example, if you click the "Shop" button at the top of the page and make a purchase on Amazon, we will receive a small commission. Nevertheless, even if you detest online shopping and use an ad blocker, there are a few ways you can directly support the website.

0 notes

Text

Ethylene Vinyl Acetate Market Poised to Grow on Back of High Demand from Solar Panel Manufacturing Industry

Ethylene vinyl acetate (EVA) is a copolymer of ethylene and vinyl acetate which finds extensive usage as an encapsulant in photovoltaic (PV) module manufacturing. As an encapsulant, EVA protects PV cells from moisture and helps in improving their performance. It provides excellent adhesion to both front glass as well as back sheet. The global solar panel market has been growing rapidly over the past few years owing to supportive government policies and initiatives encouraging the adoption of renewable energy. With increasing deployment of solar panels worldwide, demand for EVA from this application segment is projected to surge substantially. The global ethylene vinyl acetate market is estimated to be valued at US$ 1710.66 Mn in 2024 and is expected to exhibit a CAGR of 3.4% over the forecast period 2024 to 2031, as highlighted in a new report published by Coherent Market Insights. Market Dynamics: The high demand from solar panel manufacturing is one of the major drivers propelling the growth of ethylene vinyl acetate market. Solar panel encapsulants account for over 40% of the overall EVA consumption. The government targets to increase usage of renewable sources of energy along with falling prices of solar panels have boosted the solar energy market size significantly. According to the International Renewable Energy Agency (IRENA), globally over 100 GW of solar PV was added in 2021 alone. This rising deployment of solar panels directly translates to increased consumption of EVA. Apart from this, EVA finds wide applications in hot melt adhesives, packaging, and cables. The growth in end-use industries is further augmenting demand. SWOT Analysis Strength: Ethylene Vinyl Acetate (EVA) is used as an effective polymer in several end use industries such as solar panels, medical devices, and footwear. EVA provides excellent flexibility, transparency, and reliability in production processes. EVA products show consistent performance even in extreme temperatures due to their durable nature. Weakness: Fluctuating raw material prices impact the cost of EVA production. Rising crude oil prices increase the commodity prices of ethylene and vinyl acetate, making EVA slightly expensive. EVA has poor mechanical properties and low melting point in comparison to other polymers. Opportunity: Surging demand for renewable energy sources is driving the solar PV industry. EVA encapsulants protect photovoltaic cells from moisture and UV damage, thereby enhancing module efficiency. Growing medical devices market especially for implants and prosthetics boosts EVA usage. Threats: Strict regulations regarding toxic emissions can adversely impact manufacturing units. Intense competition from substitute polymers may reduce EVA consumption gradually. Key Takeaways The global ethylene vinyl acetate market size is expected to witness high growth backed by increasing solar installations and growing medical device industry. The global ethylene vinyl acetate market is estimated to be valued at US$ 1710.66 million in 2024 and is expected to exhibit a CAGR of 3.4% over the forecast period 2024 to 2031.

Asia Pacific dominates the global market due to large solar PV sector and rapidly expanding construction industry in China and India. Key regional players are expanding their production capacities to meet local demand. Key players operating in the ethylene vinyl acetate market are DuPont, ExxonMobil, FPC, Hanwha Group, LyondellBasell, Sipchem, and Formosa Plastics. They are focusing on developing novel EVA grades with enhanced properties to strengthen their market position. Technological innovation and partnerships remain crucial for gaining competitive edge. New product launches with optimized performance characteristics could boost revenues. Collaboration with end users aids in developing customized polymer solutions.Get more insights on this topic:https://www.newswirestats.com/ethylene-vinyl-acetate-market-size-and-outlook/

#Ethylene Vinyl Acetate#Ethylene Vinyl Acetate Market#Ethylene Vinyl Acetate Market size#Ethylene Vinyl Acetate Market share#Coherent Market Insights

0 notes