#Extruded Plastics Market

Explore tagged Tumblr posts

Text

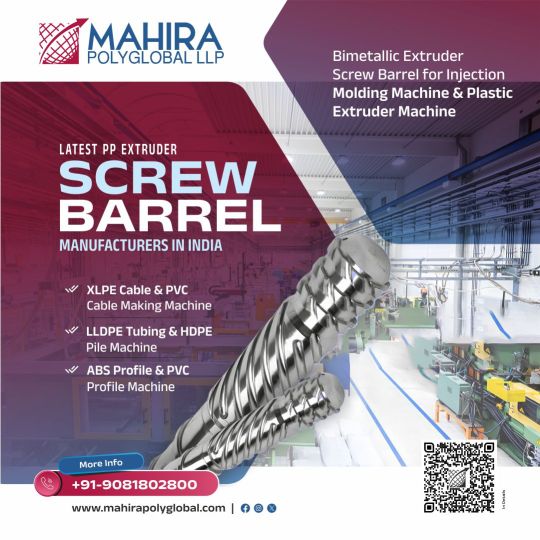

Extruder Screw Barrel

we are leading manufacturer and supplier of Extruder Screw Barrel in india & worldwide, we assure the finest quality, robustness, and accuracy in our extruder screw barrels, facilitating smooth plastic processing for various kinds of industries. Our extruder screw barrel, which effectively melts and shapes raw materials, is an essential part of the plastics manufacturing process.

For more information, please contact us : +91- 9081802800, email : [email protected] https://www.mahirapolyglobal.com/product/screw-barrel-extruder-screw-barrel

#extruder screw barrel#plastic extruder screw barrel#hs code for extruder screw barrel#extruder screw and barrel#extruder screw barrel manufacturer#screw barrel#extruder screw barrel for plastic extrusion machine#mahira#mahirapolyglobal#commercial#marketing#sales#ecommerce#manufacturingexcellence

0 notes

Text

#Extruded Plastics Market Share#Extruded Plastics Market Scope#Extruded Plastics Market Size#Extruded Plastics Market Price#Extruded Plastics Market Research#Extruded Plastics Market Revenue#Extruded Plastics Market Report#Extruded Plastics Market Demand#Extruded Plastics Market Value#Extruded Plastics Market Estimation#Extruded Plastics Market Segmentation#Extruded Plastics Market Growth#Extruded Plastics Market Analysis#Extruded Plastics Market Insight#Extruded Plastics Market Forecast#Extruded Plastics Market Index#Extruded Plastics Market Trends#Extruded Plastics Market Opportunities#Extruded Plastics Market Scenario#Extruded Plastics Market Valuation#Extruded Plastics Market Outlook#Extruded Plastics Market Overview#Extruded Plastics Market Statistics#Extruded Plastics Market Investment Analysis#Extruded Plastics Market Intelligence Report#Extruded Plastics Market Market Research Future#Extruded Plastics Market Types#Extruded Plastics Market Growth Rate#Extruded Plastics Market Satistics#Extruded Plastics Market Development

0 notes

Text

Blow Molding: Transforming Plastic into Innovative Products

Blow molding is a manufacturing technique for producing hollow plastic items. It is a flexible process capable of producing a wide range of plastic containers, bottles, automobile components, toys, and other items. The method is extremely cost-effective and efficient, making it a popular choice in a variety of sectors.

What Is the Process of Blow Molding?

Blow molding usually entails the following steps:

Extrusion is the process of melting plastic pellets and extruding them into a hollow tube, commonly known as a parison.

Mold Cavity: The parison is put in a mold cavity, which is frequently custom-designed to match the shape of the object.

Inflation: When air is introduced into the parison, it expands and takes on the shape of the mold.

Cooling: The plastic within the mold is allowed to cool and solidify.

The molded item is ejected from the mold.

Variations in Blow Molding

Blow molding from blow molding manufacturer comes in a variety of forms, including:

Extrusion Blow Molding (EBM) is the most prevalent form, and it is used to make bottles and containers.

Injection Blow Molding (IBM): This process is best suited for tiny, precise items like medical vials and some automotive components.

Stretch Blow Molding (SBM): A popular method for producing PET bottles, it provides better control over the finished product's properties.

Continuous Extrusion Blow Molding (CEBM): This technique is mostly utilized for the high-volume manufacture of smaller goods such as milk jugs.

Blow Molding Manufacturers' Role The heart of this business is made up of blow molding producers. They take raw materials and turn them into a diverse range of products that fulfill the demands of many sectors. Here's a deeper look at their key responsibilities:

Design on Demand: Blow molding manufacturers collaborate closely with clients to create unique molds that meet the product specifications.

Material Expertise: They have an extensive understanding of various plastic materials, ensuring that the appropriate material is selected for the intended use.

Precision Manufacturing: Blow molding companies use cutting-edge technology to accurately regulate factors like temperature, pressure, and cooling, resulting in consistent product quality.

Quality Control: Strict quality control methods guarantee that each product fulfills industry standards as well as customer specifications.

To keep ahead of market expectations, Blow molding manufacturer China continually innovates in terms of materials, processes, and designs.

2 notes

·

View notes

Text

0 notes

Text

0 notes

Text

Global Plastic Injection Molding Machine Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2030

An Injection molding machine, also known as an injection press, is a machine for manufacturing plastic products by the injection molding process. It consists of two main parts, an injection unit and a clamping unit. Machines are classified primarily by the type of driving systems: hydraulic, electric, or hybrid. Instead of being driven by a hydraulic system, all-electric machines use digitally controlled, high speed and highly efficient servo motors to drive the whole process. Each axis is controlled by an independent motor for injection, extruder, clamping and ejection. According to our (Global Info Research) latest study, the global Plastic Injection Molding Machine market size was valued at USD 10370 million in 2022 and is forecast to a readjusted size of USD 12560 million by 2030 with a CAGR of 2.8% during review period. The influence of COVID-19 and the Russia-Ukraine War were considered while estimating market sizes. From the analysis of product segment, small and medium-sized models (clamping force ≤ 650 tons) occupy more than 90% of the market. Injection molding machines are mainly used in general plastics industry, automotive industry and home appliance industry. Haitian International, ENGEL Holding GmbH, ARBURG GmbH, Sumitomo Heavy Industries, Milacron, Wittmann Battenfeld, Fanuc, Toshiba, Nissei Plastic, Husky, JSW Plastics Machinery, Toyo, Chenhsong, Yizumi, LK Technology, Cosmos Machinery, Tederic, UBE Machinery and Windsor are the key manufacturters of Plastic Injection Molding Machine. This report is a detailed and comprehensive analysis for global Plastic Injection Molding Machine market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Clamping Force and by Application. As the market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2023, are provided.

Sample Request: https://www.reportsintellect.com/sample-request/2911740 Key Features Global Plastic Injection Molding Machine market size and forecasts, in consumption value ($ Million), sales quantity (Units), and average selling prices (USD/Unit), 2019-2030 Global Plastic Injection Molding Machine market size and forecasts by region and country, in consumption value ($ Million), sales quantity (Units), and average selling prices (USD/Unit), 2018-2029 Global Plastic Injection Molding Machine market size and forecasts, by Clamping Force and by Application, in consumption value ($ Million), sales quantity (Units), and average selling prices (USD/Unit), 2019-2030 Global Plastic Injection Molding Machine market shares of main players, shipments in revenue ($ Million), sales quantity (Units), and ASP (USD/Unit), 2019-2030

Inquire Request: https://www.reportsintellect.com/discount-request/2911740 The Primary Objectives in This Report Are: To determine the size of the total market opportunity of global and key countries To assess the growth potential for Plastic Injection Molding Machine To forecast future growth in each product and end-use market To assess competitive factors affecting the marketplace This report profiles key players in the global Plastic Injection Molding Machine market based on the following parameters - company overview, production, value, price, gross margin, product portfolio, geographical presence, and key developments. Key companies covered as a part of this study include Haitian International, ENGEL Holding GmbH, ARBURG GmbH, Sumitomo Heavy Industries and Milacron, etc. This report also provides key insights about market drivers, restraints, opportunities, new product launches or approvals, COVID-19 and Russia-Ukraine War Influence. Market Segmentation Plastic Injection Molding Machine market is split by Clamping Force and by Application. For the period 2018-2029, the growth among segments provides accurate calculations and forecasts for consumption value by Clamping Force, and by Application in terms of volume and value. This analysis can help you expand your business by targeting qualified niche markets. Market segment by Clamping Force Below 250T 250-650T Above 650T Market segment by Application Automotive Home Appliance General Plastic Others Major players covered Haitian International ENGEL Holding GmbH ARBURG GmbH Sumitomo Heavy Industries Milacron Wittmann Battenfeld Fanuc Toshiba Nissei Plastic Husky JSW Plastics Machinery Toyo Chenhsong Yizumi LK Technology Cosmos Machinery Tederic UBE Machinery Windsor Market segment by region, regional analysis covers North America (United States, Canada and Mexico) Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe) Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia) South America (Brazil, Argentina, Colombia, and Rest of South America) Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa)

0 notes

Text

Future of U.S. Geosynthetics Market: Insights from Industry Experts

The U.S. geosynthetics market size was estimated at USD 3.08 billion in 2023 and is expected to grow at a CAGR of 5.8% from 2024 to 2030. The U.S. is expected to account for a significant market share of the total shale gas consumption in the future on account of increasing drilling activities for shale gas and tight oil supply conditions. This is projected to positively drive the geosynthetics market in the country over the forecast period.

Geosynthetics are used for base reinforcement, separation, and stabilization of roads and pavements. Furthermore, these products also find their application in subsurface drainage systems for dewatering, road base, and structure drainage. Geotextiles are used in the strengthening of industrial units, car parks, and new roadways. The incorporation of geosynthetics entails sustainable development, a small volume of earthwork, low carbon footprint, and an increased rate of construction. The growth of the construction industry around the world, including the U.S., is expected to remain one of the key market drivers for the global geosynthetics market, further boosting the market in the U.S.

Gather more insights about the market drivers, restrains and growth of the U.S. Geosynthetics Market

Key U.S. Geosynthetics Company Insights

The market is majorly run by petrochemical manufacturers across the U.S. The competition in the market is also high due to the presence of a large number of manufacturers. Market players have established strategic partnerships with the distributors to supply their product offerings. Stringent government regulations and depleting petroleum feedstock have contributed to shifting the focus of manufacturers on renewable energy sources and prompted extensive research and development of bio-based raw materials.

Some of the prominent players in the U.S. geosynthetics market are TenCate Geosynthetics Americas; Maccaferri; Concrete Canvas Ltd.; NAUE GmbH & Co. KG; and Propex Operating Company, LLC

• NAUE GmbH & Co. KG, formerly known as Naue Fasertechnik GmbH & Co. KG, was established in 1967. It changed its name to NAUE GmbH & Co. KG in 2005. The company has its headquarters in Germany, with a global presence across North America, Asia, Europe, Australia, South America, and the Middle East & Africa.

• Maccaferri provides advanced solutions for problems related to erosion control, soil reinforcement, stabilization of the soil, and infrastructure development in application areas such as roads, railways, canals, rivers, coastal defenses, and landfills. It owns over 70 subsidiaries in over 100 countries. As of 2018, the company employed over 3,000 individuals globally.

• TENAX Group was established in 1960 and headquartered in Viganò, Italy. The company majorly specializes in extruding thermoplastic polymers. Its product range includes fences, screens, plastic nets, geogrids, and geosynthetics, which find applications in areas such as pipeline, packaging, industrial, geotechnical, gardening, fencing, construction, and agriculture.

U.S. Geosynthetics Market Report Segmentation

This report forecasts market share and revenue growth at country levels and provides an analysis of industry trends in each of the sub-segments from 2018 to 2030. For the purpose of this study, Grand View Research has segmented the U.S. geosynthetics market report based on product:

Product Outlook (Volume, Million Square Meters; Revenue, USD Billion, 2018 - 2030)

• Geotextiles

o By Raw Material

o By Product

o By Application

• Geomembranes

o By Raw Material

o By Application

o By Technology

• Geogrids

o By Raw Material

o By Application

o By Product

• Geonets

o By Raw Material

o By Application

• Geocells

o By Raw Material

o By Application

Order a free sample PDF of the U.S. Geosynthetics Market Intelligence Study, published by Grand View Research.

#U.S. Geosynthetics Market#U.S. Geosynthetics Market Size#U.S. Geosynthetics Market Share#U.S. Geosynthetics Market Analysis#U.S. Geosynthetics Market Growth

0 notes

Text

https://www.verifiedmarketreports.com/pt/product/plastic-screw-extruder-market/

0 notes

Text

Extruded Plastics Market Analysis, Size, Share, Growth, Trends, and Forecasts by 2031

The Global Extruded Plastics market stands as a testament to the resilience and adaptability inherent in the plastics industry. This market, deeply intertwined with the broader polymer sector, plays a vital role in shaping the modern world.

𝐆𝐞𝐭 𝐚 𝐅𝐫𝐞𝐞 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭:https://www.metastatinsight.com/request-sample/2597

Top Companies

Chevron Phillips Chemical Company LLC • DuPont de Nemours Inc

Exxon Mobil Corporation

Formosa Plastics Corporation

Saudi Basic Industries Corporation (SABIC) • Sigma Plastics Group

D W Plastics Ltd.

BASF SE

Celanese Corporation

China Plastic Extrusion Ltd.

Covestro AG

Eastman Chemical Company

GSH Industries

Berry Global Inc

JM EAGLE INC

As industries evolve and consumer demands shift, the Extruded Plastics market emerges as a linchpin in the production and fabrication of a myriad of everyday items.

𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭:@https://www.metastatinsight.com/report/extruded-plastics-market

The Extruded Plastics market revolves around the extrusion process, a manufacturing technique that transforms raw plastic materials into a diverse array of products. This process involves heating raw plastic resins and forcing them through a die to create continuous profiles of varying shapes and sizes. The resulting products find applications across numerous sectors, ranging from construction and packaging to automotive and electronics.

One of the key drivers of the Global Extruded Plastics market lies in its versatility. The ability to mold plastics into complex shapes and structures, coupled with their lightweight nature, positions extruded plastics as the material of choice in an increasingly diverse range of applications. From the ubiquitous PVC pipes used in construction to the intricate profiles used in automotive components, extruded plastics have become indispensable in modern manufacturing.

The packaging industry stands out as a major consumer of extruded plastics. The demand for flexible and lightweight packaging solutions has propelled the market forward. Extruded plastic films and sheets cater to the evolving needs of the packaging sector, providing durability, cost-effectiveness, and customization options. Additionally, the rise of sustainable packaging practices has spurred innovation within the Extruded Plastics market, leading to the development of eco-friendly alternatives.

Beyond packaging, the construction industry relies heavily on extruded plastics for a spectrum of applications. Window profiles, pipes, and insulation materials exemplify the adaptability of extruded plastics in construction. The inherent durability, corrosion resistance, and thermal insulation properties make extruded plastics a preferred choice in architectural projects across the globe.

The Global Extruded Plastics market is a dynamic and integral player in the larger landscape of polymer-based industries. Its adaptability, versatility, and continual innovation underscore its significance in shaping various sectors. As the world progresses, the Extruded Plastics market will undoubtedly remain at the forefront of material technology, contributing to the creation of a wide array of products that define our modern way of life.

Global Extruded Plastics market is estimated to reach $310.2 Million by 2031; growing at a CAGR of 4.4% from 2024 to 2031.

Contact Us:

+1 214 613 5758

#ExtrudedPlastics#ExtrudedPlasticsmarket#ExtrudedPlasticsindustry#marketsize#marketgrowth#marketforecast#marketanalysis#marketdemand#marketreport#marketresearch

0 notes

Text

Powering Circular Economies: The Rise of Recycling Equipment

The global recycling equipment market size is expected to reach USD 40.69 billion by 2030, according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.4% from 2024 to 2030. Growing concerns pertaining to the depletion of non-renewable resources, along with the high production cost of primary materials such as metals and plastic is anticipated to augment the demand for recycling equipment.

The advent of modern technologies has been demonstrated to be effective, in terms of detecting different types of materials. The increasing necessity for scrap has forced scrap yards to set up technologically advanced recycling equipment. For instance, large recycling facilities have installed sensors to identify metals through infrared scanning and x-rays.

The increasing demand for recycled metals from the automotive, construction, electronics, and food and beverage industries on account of the product’s environment-friendly nature and ability to reduce the cost of production, energy consumption, and emissions, thereby boosting the demand for recycling equipment over the forecast period.

Increasing use of plastics coupled with poor end-of-life waste management has resulted in widespread plastic pollution. Plastic pollution has a severe impact on the environment as well as human health. Thus, the recycling of plastics is expected to play a crucial role over the coming years, resulting high demand for recycling equipment to produce recycled plastics.

The recycling equipment market is fragmented with key manufacturers striving for market leadership. Key players are expected to concentrate on forward integration to increase their profits and expand their regional presence. Manufacturers are anticipated to collaborate with engineering solution providers to offer high-quality product solutions at reasonable prices.

Recycling Equipment Market Report Highlights

The baler press equipment segment is likely to dominate the market in 2023, as it is used for compressing various recycling materials such as cardboard, paper, plastic, aluminum, and non-ferrous metals into dense bundles known as bales

The plastic segment is estimated to witness a CAGR of 6.1% over the forecast period owing to the rising use of plastics coupled with poor end-of-life waste management has resulted in plastic pollution due to which demand for recycled plastic is increasing

Asia Pacific accounted for 39.9% of the global revenue share in 2023, owing to the increased industrial construction and infrastructure activities in emerging nations such as India, China, Vietnam, and Thailand

The recycling equipment demand in India is expected to witness a CAGR of 6.3% from 2024 to 2030, owing to the new regulations and initiatives by the government of India regarding recycling waste

Strategies adopted by companies in the recycling equipment market usually include expansion of product portfolio and distribution network, new product development, and technological advancements

Recycling Equipment Market Segmentation

Grand View Research has segmented the global recycling equipment market on the basis of equipment, processed material, and region:

Recycling Equipment Outlook (Revenue, USD Million, 2018 - 2030)

Baler Press

Shredders

Granulators

Agglomerators

Shears

Separators

Extruders

Others

Recycling Equipment Processed Material Outlook (Revenue, USD Million, 2018 - 2030)

Metal

Plastic

Construction Waste

Paper

Rubber

Others

Recycling Equipment Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

France

UK

Spain

Italy

Asia Pacific

China

India

Japan

Central & South America

Brazil

Argentina

Middle East & Africa

Saudi Arabia

UAE

Order a free sample PDF of the Recycling Equipment Market Intelligence Study, published by Grand View Research.

0 notes

Text

Extruded Plastics Market Focusing On The Basis Of Material, Application, End-Use, Region And Forecast 2030: Grand View Research Inc.

San Francisco, 23 December 2024: The Report Extruded Plastics Market Size, Share & Trends Analysis Report By Material (PE, PVC, PS, PC), By End-use (Construction, Automotive), By Application, By Region, And Segment Forecasts, 2024 – 2030 The global extruded plastics market size to reach USD 221.18 billion by 2030 and is expected to grow at a CAGR of 3.9% from 2024 to 2030. The demand for…

View On WordPress

0 notes

Text

The Film Blowing Extruder: Revolutionizing Plastic Film Production

A Film Blowing Extruder is a machine that extrudes plastic material, typically polyethylene (PE) or other polymers, into a thin film. The process involves melting plastic pellets, extruding them into a tube of film, and then expanding the tube by blowing air into it, which forms a bubble. The bubble is then cooled and flattened into a thin film, ready for use in various industries like packaging, agricultural films, and more.

The Film Blowing Extruder Process

Feeding the Raw Material:

The first step in the process is the introduction of plastic pellets into the extruder barrel. These pellets are usually made from polyethylene (PE), polypropylene (PP), or other polymer materials that are suitable for film production.

Melting the Plastic:

The plastic pellets are subjected to heat within the barrel, where the screw gradually moves them forward, melting the plastic into a molten state. This is achieved through a combination of mechanical and thermal energy.

Extruding the Film:

Once the plastic is melted, it is forced through the die head, forming a tube of molten plastic. The die is designed to ensure a uniform thickness and smooth surface of the film.

Blowing the Bubble:

The molten plastic tube is inflated using compressed air, forming a bubble. The size and thickness of the bubble depend on the desired properties of the final film. The air pressure and speed of inflation play a crucial role in achieving consistent film thickness.

Cooling and Solidifying:

After the film blowing extruder is inflated, it is cooled quickly to solidify its structure. This cooling can be achieved either by water rings or air-cooling systems. Proper cooling ensures the film retains its integrity and flexibility.

Flattening the Film:

Once the film is cooled, it is flattened into a two-dimensional film using rollers or other flattening mechanisms. This process ensures that the film is smooth and uniform, with no wrinkles or defects.

Winding:

The flattened film is then wound onto a roll. This roll can be used for further processing, such as printing, cutting, or converting into bags or other packaging materials.

Advantages of Using Film Blowing Extruder

Cost-Effective Production: Film blowing is a continuous process, meaning that once the machine is set up, it can produce large quantities of film with minimal downtime, making it cost-effective.

High-Quality Films: The film blowing process ensures high-quality films with uniform thickness, smooth surfaces, and excellent mechanical properties. The ability to control film thickness during the inflation stage helps in producing films with consistent quality.

Flexibility: With the ability to produce different types of films—such as multilayer, stretchable, or biodegradable films—film blowing extruders offer flexibility to meet various market demands.

Environmental Sustainability: Advances in biodegradable plastics and multi-layer film technology have made it possible to produce more sustainable films. Film blowing extruders are now being used to produce eco-friendly alternatives that reduce the environmental impact of plastic packaging.

Conclusion

The film blowing extruder is an indispensable tool in modern manufacturing. It allows for the production of high-quality, versatile plastic films used in countless industries, from packaging to agriculture. With continued advancements in technology, these machines are becoming more energy-efficient, capable of producing multilayer films, and adaptable to new, eco-friendly materials. The role of the film blowing extruder in the modern world of plastic manufacturing cannot be overstated, as it continues to meet the growing demand for functional, cost-effective, and environmentally conscious plastic films.

0 notes

Text

PVC Additives Market-Industry Forecast, 2024–2030

PVC Additives Market overview

Request Sample Report :

Report Coverage

The report: “PVC Additives Market- Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the PVC Additives Industry.

By Type: Stabilizers, Impact Modifiers, Processing Aids, Lubricants, Plasticizers, Fillers, Others.

By Form: Granules, Powder, and Liquid.

By Fabrication Process: Extrusion, Injection Molding, Blow Molding and Others.

By Application: Pipes, Packaging, Furniture’s, Door and Windows, Cables, Medical Devices, Flooring, and Others.

By End Use: Building and Construction, Automotive industry, Textile Industry, Electrical and Electronics, Medical Industry, Food and Beverages, and Others.

By Geography: North America, South America, Europe, APAC, and RoW.

Key Takeaways

Asia Pacific dominates the PVC Additives market owing to rapid increase in building and construction sector.

Certain applications require higher impact strength than PVC would demonstrate normally.

The market drivers and restraints have been assessed to understand their impact over the forecast period.

The report further identifies the key opportunities for growth while also detailing the key challenges and possible threats.

The other key areas of focus include the various applications and end use industry in PVC Additives market and their specific segmented revenue.

Inquiry Before Buying:

PVC Additives Market Segment Analysis — By Type

Stabilizers held the largest share in the PVC Additives market in 2019. This growth is mainly attributed to the increasing demand for stabilizers in varied applications such as pipes & fittings, rigid & semi-rigid films, and others. Due to their superior properties, such as UV resistance, weathering and heat-aging, stabilizers are increasingly favored over other types of additives. To avoid premature degradation, many polymers are vulnerable to environmental degradation and require the addition of a stabilizer such as an antioxidant or UV absorbent. Hampered phenols and obstructed amine light stabilizers (HALS) deactivate emerging radicals, like air-oxidated peroxy compounds. UV absorbers dissipate UV radiation through the material by a method that is non-destructive. Monomers are added to free radical inhibitors as stabilizers to prevent premature polymerization.

PVC Additives Market Segment Analysis — By Forms

Granules held the largest share in the PVC Additives market in 2019. Granules help to increase the density of the freshly synthesized polymer since it lacks the flowing properties required to be processed by an extruder. Due to their plasticity property, they can be molded or shaped by application of heat. Other characteristics of plastic are its low electrical conductivity, low density, transparency and toughness which allowed it to be used for the creation of different products. In addition, plastic’s versatility has led to its use in a wide array of industries. In order to produce normal and high-strength concretes, 10%, 20%, and 30% replacement ratios by volume of PVC granules and powder are used.

PVC Additives Market Segment Analysis — By Fabrication Process

Extrusion held the largest share in the PVC Additives market in 2019. Extrusion is used mainly for handling large plastic volumes. The pellets, granules, chips, or powders are fed into the extruder and melted under high temperatures. PVC compounding is a process where additives are mixed with the base resin in order to obtain a homogenous mix. The additives are used either to enhance process capabilities or to improve product efficiency. The use of sizing parts will generate any length of profiles to the desired length. Co-extrusion allows the manufacture of semi-finished multi-layer products with special barrier properties.

PVC Additives Market Segment Analysis — By Application

Pipes is projected to witness highest share in PVC Additives market in 2019. This rise is mainly due to the growing demand for pipes & fittings in piping and plumbing, gas pipeline laying, and telecommunication and electrical cable sheathing. Due to the replacement of traditional concrete, iron, and steel-based pipes & fittings with PVC pipes in the building & construction industry, the market for PVC additives in the pipes & fittings segment is expected to witness significant development. The market for building materials is on high demand, with the continually growing population. The prerequisite for housing is pipes and fittings, which are a critical necessity. Urbanization with a large network of connections has contributed to an increase in drainage requirements. There is a growing demand for pipes and fittings to cope with advanced piping links, which in turn drives market growth. Globally, there has been a rising demand for rainwater harvesting system that has helped to heat up the pipe and fit market. In 2019, recently the commercial sector has slowed as the risk for a downturn in global construction increases due to COVID-19 pandemic which led to temporary lockdown of all economic activities across globe.

PVC Additives Market Segment Analysis — By End Use

Building and construction dominates the PVC Additives market growing at a CAGR of 6.00%. With the growing construction industry and its demand for PVC Additives particularly in the regions of Asia-Pacific, North America and Europe, the demand of PVC Additives for all kinds of buildings is expected to see an upsurge. Residential application segment is witnessing growth due to the rising penetration from untapped markets. First-mover advantage in untapped regions and relatively low acquisition costs remain key driving forces in this application market. Furthermore, R&D in PVC Additives will support the growth of the PVC Additives market.

Schedule A Call :

PVC Additives Market Segment Analysis — Geography

Asia-Pacific (APAC) dominated the PVC Additives market growing at CAGR of 41% followed by North America and Europe. APAC as a whole is set to continue to be one of the largest and fastest growing construction markets globally. Large and more developed markets such China, India, Japan, and South Korea are expected to grow more in the coming years. China is driving much of the PVC Additives market demand in Asia-Pacific region followed by India and Japan. Of the five fastest growing regions in construction sector, other than U.S. all are Asian countries including China and India who majorly drive the demand for construction investment in this regions. The strong and healthy growth in construction sector is associated with growing population and middle class economy, which tend to drive APAC residential construction market further and hence the PVC Additives market. The number of buildings that have illuminated PVC Additives is growing sharply in APAC region. The increasing number of new building constructions, along with the rise in the number of renovation projects has further propelled the market. Currently the construction industry has been affected due to COVID-19 pandemic where most of the industrial activity has been temporarily shut down. In in turn has affected the demand and supply chain as well which has been restricting the growth in year 2020.

PVC Additives Market Drivers

Replacement of conventional material with PVC will drive the market

PVC is replacing traditional building materials such as wood, metal, concrete and clay in many applications. Versatility, cost-effectiveness and excellent use record make it the most important polymer in the construction sector, accounting for 60%. These products are often lighter, less expensive and offer many performance advantages. Making it prominent material than conventional.

Rapid industrialization and infrastructure activity will augment the growth of PVC Additives

Improvement in economic climate along with boom in industrialization and infrastructure activity across the globe is leading the growth of PVC Additives. Oxford Economics has estimated global infrastructure investment needs to be $94 trillion between 2016 and 2040. This is 19 percent higher than would be delivered under current trends. With the increasing rate of industrialization and infrastructure activity, as a result of which PVC Additives growth is augmenting.

PVC Additives Market Challenges

Low R&D expenditure in the emerging markets and high maintenance cost will hamper the market to growth

Innovation is the key to developing new products, but most manufacturers are not investing much into R&D. Rather than cutting-edge technology, they invest in creating relevant technology. These factors are hampering the growth of the market. Because most of the pipes and fittings are located underground in the event of any malfunction or failure, the cost of repairs can be even greater.

Buy Now :

Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the PVC Additives market. In 2019 the PVC Additives market has been consolidated by the top five players accounting for xx% of the share. Major players in the PVC Additives market are BASF SE, Arkema SA, Akzo Nobel N.V, Adeka Corporation, Clariant AG and Others.

Acquisitions/Technology Launches/ Product Launches

In April 2017, Lanxess Corporation has completed acquisition of Chemtura. With this acquisition, Lanxess significantly expands its market position for PVC additives. A notable sampling includes: the sale of its proprietary OBS (organic-based heat stabilizers) for rigid PVC applications to Baerlocher; the sale of the rest of its PVC additives business to Galata Chemicals.

Key Market Players

The Top 5 companies in the PVC Additives Market are:

BASF SE

Arkema SA

Akzo Nobel N.V

Adeka Corporation

Clariant AG

For more Chemicals and Materials Market reports — Please click here

0 notes

Text

Extruded Plastic Market Industry Statistics: Growth, Share, Value,Trends Industry Analsis and Forecast by 2029

"Extruded Plastic Market Size And Forecast by 2029

Data Bridge Market Research analyses the extruded plastic market will exhibit a CAGR of 5.78% for the forecast period of 2022-2029 and is expected to reach the USD 363.93 billion by 2029.

Demand for Extruded Plastic Market solutions continues to rise, driven by consumer preferences for enhanced efficiency, sustainability, and customization. This growth is underpinned by evolving technologies, innovative product offerings, and strategic collaborations among market leaders. The interplay of these factors creates a fertile ground for revenue generation and industry expansion.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-extruded-plastic-market

Which are the top companies operating in the Extruded Plastic Market?

The Top 10 Companies in Extruded Plastic Market are leaders in their field, known for their strong market presence and innovative solutions. Their success is driven by their ability to adapt to market trends, invest in research and development, and meet customer needs effectively, making them key competitors in the Extruded Plastic Market.

**Segments**

- **Type:** The extruded plastic market can be segmented based on types such as High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), Polypropylene, Polyvinyl Chloride (PVC), and others. HDPE is widely used for its excellent moisture resistance and chemical stability, while LDPE is preferred for a more flexible packaging material. Polypropylene is known for its high heat resistance and good impact strength. PVC offers durability and weather resistance in various applications.

- **Application:** In terms of applications, the extruded plastic market can be categorized into packaging, building & construction, automotive, electrical & electronics, healthcare, and others. Packaging dominates the market due to the growing demand for flexible packaging in the food and beverage industry. The building & construction sector relies on extruded plastic products for their durability and lightweight properties. The automotive industry uses extruded plastic components for interior and exterior applications.

- **End-Use Industry:** Extruded plastic finds usage across various end-use industries such as packaging, construction, consumer goods, automotive, healthcare, and others. With the rise in e-commerce and online shopping, the demand for extruded plastic packaging materials has increased significantly. The construction industry benefits from extruded plastic products due to their cost-effectiveness and easy installation. In the healthcare sector, extruded plastics are used in medical devices, packaging, and drug delivery systems.

- **Region:** Geographically, the global extruded plastic market is segmented into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. Asia Pacific holds a significant share in the market due to rapid industrialization and urbanization in countries like China and India. North America and Europe also contribute prominently to the market growth with the presence of key players and technological advancements in the region.

**Market Players**

- Exxon Mobil Corporation - The Dow Chemical Company - LyondellBasell Industries Holdings B.V. - SABIC - Chevron Phillips Chemical Company LLC - INEOS - Formosa Plastics Corporation - Reliance Industries Limited - Hitachi Chemical Co., Ltd. - PPG Industries, Inc.

For a detailed analysis of the Global Extruded Plastic Market, refer to https://www.databridgemarketresearch.com/reports/global-extruded-plastic-marketThe global extruded plastic market continues to witness growth and innovation, driven by a variety of factors across different segments. In terms of types, the market's diversification into High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), Polypropylene, Polyvinyl Chloride (PVC), and others offers a wide range of options to cater to various industry needs. The unique properties of each type, such as moisture resistance in HDPE, flexibility in LDPE, heat resistance in Polypropylene, and durability in PVC, allow for versatile applications across sectors. This variety in material types enables manufacturers to customize products according to specific requirements, leading to enhanced performance across industries.

Moreover, the segmentation based on applications highlights the significant role extruded plastic plays in packaging, building & construction, automotive, electrical & electronics, healthcare, and other sectors. The dominance of packaging can be attributed to the increasing demand for flexible packaging solutions, particularly in the food and beverage industry. The construction sector benefits from the durability and lightweight nature of extruded plastic products, contributing to their widespread adoption in various applications. Additionally, the automotive industry relies on extruded plastic components for both interior and exterior purposes, emphasizing the material's versatility and utility in diverse environments.

Furthermore, the end-use industry segmentation underscores the extensive reach of extruded plastic across different sectors such as packaging, construction, consumer goods, automotive, healthcare, and others. The surge in e-commerce activities and online shopping has propelled the demand for extruded plastic packaging materials, showcasing the material's importance in the modern retail landscape. Similarly, the construction industry continues to leverage extruded plastic products for their cost-effective nature and ease of installation, driving growth within the sector. In healthcare, extruded plastics find applications in medical devices, packaging, and drug delivery systems, highlighting their critical role in ensuring the safety and efficacy of healthcare products.

From a geographical perspective, regions like Asia Pacific, North America, Europe, Latin America, and the Middle East & Africa contribute significantly to the global extruded plastic market. Asia Pacific stands out as a key market player due to rapid industrialization and urbanization trends in countries like China and India, creating substantial opportunities for market growth. North America and Europe also hold prominent positions in the market, supported by the presence of major industry players and continuous technological advancements in the region. The regional distribution of the market emphasizes the global nature of the extruded plastic industry and the varying dynamics that shape its growth trajectory.

In conclusion, the global extruded plastic market presents a dynamic landscape characterized by diverse types, applications, end-use industries, and regional significance. With key players like Exxon Mobil Corporation, The Dow Chemical Company, LyondellBasell Industries Holdings B.V., and others driving innovation and competitiveness in the market, the industry is poised for continued expansion and evolution. As consumer demands evolve and new technologies emerge, the extruded plastic market is expected to witness further advancements, propelling its growth and relevance across a wide range of industries and applications.**Segments**

Global Extruded Plastic Market, By Type: - Low-Density Polyethylene (LDPE) - Polypropylene (PP) - Polyvinyl Chloride (PVC) - High-Density Polyethylene (HDPE) - Polystyrene (PS) - Acrylonitrile Butadiene Styrene (ABS) - Polycarbonate (PC) - Styrene - Others

End User: - Packaging - Building and Construction - Automotive - Consumer Goods - Electrical and Electronics - Energy - Medical - Power and Lighting - Others

Form: - Films - Sheets - Pipes and Tubes - Wires and Cables - Others

Country: - U.S. - Canada - Mexico - Brazil - Argentina - Rest of South America - Germany - France - Italy - U.K. - Belgium - Spain - Russia - Turkey - Netherlands - Switzerland - Rest of Europe - Japan - China - India - South Korea - Australia - Singapore - Malaysia - Thailand - Indonesia - Philippines - Rest of Asia-Pacific - U.A.E - Saudi Arabia - Egypt - South Africa - Israel - Rest of Middle East and Africa

Industry Trends and Forecast to 2029

**Market Players** - Formosa Plastics Corporation - SABIC - JM EAGLE, INC. - Sealed Air - Berry Global Inc. - DuPont - Atlantis Plastic Company - Chevron Phillips Chemical Company LLC - GSH Industries Plastics Manufacturing and Molding - Exxon Mobil Corporation - Engineered Profiles LLC - Arkema - Saint-Gobain Performance Plastics - Preferred Plastics, Inc. - SFR Industries - ACE - Absolute Custom Extrusions, Inc. - Britech Industries - Petro Extrusion Technologies, Inc. - Dow - Amcor plc

The global extruded plastic market is characterized by a diverse range of types, including Low-Density Polyethylene (LDPE), Polypropylene (PP), Polyvinyl Chloride (PVC), High-Density Polyethylene (HDPE), Polystyrene (PS), Acrylonitrile Butadiene Styrene (ABS), Polycarbonate (PC), Styrene, and others, catering to various industry needs. These different types offer unique properties that enable versatile applications across sectors, such as the moisture resistance of HDPE, flexibility of LDPE, heat resistance of Polypropylene, and durability of PVC. This variety allows manufacturers to customize products and enhance performance in packaging, construction, automotive, consumer goods, electrical and electronics, healthcare, and other industries.

In terms of end-users, the extruded plastic market serves sectors like packaging, building and construction, automotive, consumer goods, electrical and electronics, energy, medical, power and lighting, among others. The dominance of packaging is driven by the rising demand for flexible packaging solutions in the food and beverage industry, while the construction sector benefits from the lightweight and durable nature of extruded plastic products. The automotive industry utilizes extruded plastic components for interior and exterior applications, showcasing the material's versatility and utility across different environments.

Geographically, regions such as Asia Pacific, North America, Europe, Latin America, and the Middle East and Africa play significant roles in the global extruded plastic market. Asia Pacific leads the market due to rapid industrialization and urbanization in countries like China and India, offering substantial growth opportunities. North America and Europe also contribute prominently, supported by key industry players and technological advancements. This regional distribution underscores the global nature of the extruded plastic industry and the diverse dynamics influencing its growth trajectory.

In conclusion, the extruded plastic market's varied segments, applications, end-use industries, and regional significance highlight a dynamic landscape driven by innovation and competitiveness among market players. With major companies like Formosa Plastics Corporation, SABIC, JM EAGLE, INC., and others driving industry advancements, the market is poised for continued expansion and evolution. As new technologies emerge and consumer demands evolve, the extruded plastic market is expected to witness further growth, solidifying its importance across a wide range of industries and applications.

Explore Further Details about This Research Extruded Plastic Market Report https://www.databridgemarketresearch.com/reports/global-extruded-plastic-market

Key Insights from the Global Extruded Plastic Market :

Comprehensive Market Overview: The Extruded Plastic Market is experiencing significant growth, driven by technological advancements and increasing global demand.

Industry Trends and Projections: Trends like automation and sustainability are shaping the market, with projections indicating continued growth over the next few years.

Emerging Opportunities: There are emerging opportunities in green technologies, digital solutions, and under-served regional markets.

Focus on R&D: Companies are investing heavily in R&D to innovate in areas such as AI, IoT, and sustainable product development.

Leading Player Profiles: Key players like Company A and Company B lead the market through their strong product offerings and global presence.

Market Composition: The market is fragmented, with a mix of established players and emerging startups targeting various niches.

Revenue Growth: The Extruded Plastic Market is seeing steady revenue growth, fueled by both consumer and commercial demand.

Commercial Opportunities: Key commercial opportunities include expanding into emerging regions, digital transformation, and forming strategic partnerships.

Find Country based languages on reports:

https://www.databridgemarketresearch.com/jp/reports/global-extruded-plastic-markethttps://www.databridgemarketresearch.com/zh/reports/global-extruded-plastic-markethttps://www.databridgemarketresearch.com/ar/reports/global-extruded-plastic-markethttps://www.databridgemarketresearch.com/pt/reports/global-extruded-plastic-markethttps://www.databridgemarketresearch.com/de/reports/global-extruded-plastic-markethttps://www.databridgemarketresearch.com/fr/reports/global-extruded-plastic-markethttps://www.databridgemarketresearch.com/es/reports/global-extruded-plastic-markethttps://www.databridgemarketresearch.com/ko/reports/global-extruded-plastic-markethttps://www.databridgemarketresearch.com/ru/reports/global-extruded-plastic-market

Data Bridge Market Research:

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]"

0 notes

Text

Extrusion Sheet Market Size, Share, Trends, Growth, Key Players, Report and Forecast 2025-2037

Research Nester assesses the growth and market size of the global extrusion sheet market which is anticipated to be on account of the growing adoption in the end use industries.

Research Nester’s recent market research analysis on “Extrusion Sheet Market: Global Demand Analysis & Opportunity Outlook 2037” delivers a detailed competitor’s analysis and a detailed overview of the global extrusion sheet market in terms of market segmentation by material type, application, end use, and by region.

Growing Demand for Lightweight and High-strength Materials to Promote Global Market Share of Extrusion Sheet

The global extrusion sheet market is estimated to grow majorly due to the increased integration of lightweight materials in the automotive industry. Automobile manufacturers have been under constant pressure to lower vehicle weight to boost fuel economy and comply with stringent pollution regulations. This has raised the need for durable yet lightweight materials like magnesium, aluminum, and high-performance polymers in the automotive industry. Extruded sheets made of these materials have grown in popularity as appealing substitutes for conventional steel components due to their energy absorption, flexibility in design, and resilience to corrosion.

Request Free Sample Copy of this Report @ https://www.researchnester.com/sample-request-6446

To reduce the weight of aircraft, the aerospace industry is increasingly using extruded sheets of magnesium and aluminum in airframe components. Extruded thin sheets are being used more often in the transportation and logistics sectors as a result of the emphasis on fuel efficiency and payload capabilities.

Some of the major growth factors and challenges that are associated with the growth of the global extrusion sheet market are:

Growth Drivers:

Technological advancements in extrusion sheets

Growing focus on the use of recyclable plastic materials

Challenges:

The market is characterized by fierce competition from long-standing competitors and recent newcomers. There are substantial financial obstacles for newcomers to overcome when starting production facilities. However, many new competitors can maintain competitive rates, which put a lot of pressure on prices. Prices are being hard negotiated by buyers, reducing manufacturers' profits. There is fierce competition among key players in the worldwide extrusion sheet market, with none holding a dominant position.

By materials type, the global extrusion sheet market is segmented into polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), and acrylonitrile butadiene styrene (ABS). The polypropylene (PP) segment is expected to garner the highest revenue by the end of 2037 by growing at a significant CAGR over the forecast period. The segment's expansion can be ascribed to its affordability and robustness. The sheets' resilience allows them to maintain their mechanical characteristics and original shape even after being bent and stretched repeatedly. This makes them ideal for continuous usage in industrial, packaging, and construction settings.

Request for customization @ https://www.researchnester.com/customized-reports-6446

Furthermore, PP sheets are less costly than sheets made of ABS, PVC, and polyethylene, among other polymers. They ask for less money upfront and for continuous production. It is also less expensive to recycle PP than it is to recycle other plastics. Owing to its durability and inexpensive production costs, PP provides customers with outstanding value for their money. These qualities make PP function better than other plastics and promote its widespread application across various industries.

By region, the Europe extrusion sheet market is poised to generate the highest revenue by the end of 2037. The market in Europe is characterized by a significant preference for eco-friendly and sustainable materials in response to the strict environmental regulations in the area. This has accelerated the creation and uptake of biodegradable and recycled extrusion sheets, especially in the packaging and automotive industries. Moreover, the region’s emphasis on updating its infrastructure is bolstered by the growing usage of plastic extrusion sheets for roofing and glazing in residential and commercial buildings.

This report also provides the existing competitive scenario of some of the key players which includes Owens Corning, Formosa Platsics Corporation, Karton S.p.A., Arla Plast AB, SML Maschinengesellschaft mbH, Corex Plastics Pty Ltd, Covestro AG, DS Smith plc, Evonik Industries AG, Ensinger GmbH, and others.

Access our detailed report @ https://www.researchnester.com/reports/extrusion-sheet-market/6446

About Research Nester-

Research Nester is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates and executives to take wise decisions for their future marketing strategy, expansion and investment etc. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds. Our out of box thinking helps our clients to take wise decision in order to avoid future uncertainties.

Contact for more Info:

AJ Daniel

Email: [email protected]

U.S. Phone: +1 646 586 9123

U.K. Phone: +44 203 608 5919

0 notes