#Expanded Polystyrene (EPS) Market analysis

Explore tagged Tumblr posts

Text

#Expanded Polystyrene (EPS) Market#Expanded Polystyrene (EPS) Market size#Expanded Polystyrene (EPS) Market share#Expanded Polystyrene (EPS) Market trends#Expanded Polystyrene (EPS) Market analysis#Expanded Polystyrene (EPS) Market forecast

0 notes

Text

Thermal Insulation Packaging Market: An In-Depth Analysis

The thermal insulation packaging market is experiencing significant growth, driven by increasing demand for temperature-sensitive goods and advancements in packaging technologies. According to a report by Report Prime, the market is projected to expand from USD 26.50 billion in 2023 to USD 45.12 billion by 2030, at a compound annual growth rate (CAGR) of 7.90% during the forecast period.

Market Overview

Thermal insulation packaging involves materials and solutions designed to maintain the temperature of products during storage and transportation. This is particularly crucial for industries such as pharmaceuticals, food and beverages, and chemicals, where temperature control is essential to preserve product integrity.

Get Sample PDF

Key Drivers

Growing Demand for Temperature-Sensitive Products: The pharmaceutical and biotechnology sectors require stringent temperature control for products like vaccines and biologics. Similarly, the food industry demands thermal packaging to maintain the freshness of perishable items.

Expansion of E-commerce: The rise in online retailing of perishable goods has necessitated efficient thermal insulation solutions to ensure products reach consumers in optimal condition.

Regulatory Compliance: Stringent regulations regarding the transportation of temperature-sensitive goods compel industries to adopt reliable thermal insulation packaging to meet compliance standards.

Market Segmentation

The thermal insulation packaging market can be segmented based on product type, material, application, and region.

By Product Type:

Boxes: Widely used for shipping temperature-sensitive products.

Bags: Employed for smaller quantities requiring thermal protection.

Carton Liners: Used to line cartons, providing an additional layer of insulation.

Bubble Cushioning: Offers both insulation and protection against physical damage.

By Material:

Polystyrene: Includes expanded (EPS) and extruded (XPS) forms, known for excellent insulation properties.

Polyurethane (PUR): Offers superior thermal resistance, suitable for extreme temperature conditions.

Polyethylene: Commonly used due to its flexibility and durability.

Vacuum Insulated Panels (VIPs): Provide high thermal resistance in a thin profile, ideal for space-constrained applications.

Corrugated Fiber Board: An eco-friendly option with moderate insulation properties.

By Application:

Pharmaceuticals: Ensuring the efficacy of temperature-sensitive drugs and vaccines.

Food & Beverages: Maintaining the freshness and safety of perishable goods.

Chemicals: Preventing temperature-induced reactions during transport.

Horticulture Products: Protecting plants and flowers from temperature extremes.

Electronics: Safeguarding temperature-sensitive electronic components.

Regional Analysis

North America: Dominates the market due to advanced pharmaceutical and food industries, along with stringent regulatory standards.

Europe: Significant growth attributed to increasing demand for sustainable packaging solutions and a robust pharmaceutical sector.

Asia-Pacific: Expected to witness substantial growth owing to rapid industrialization, urbanization, and expanding e-commerce activities.

Middle East & Africa: Growth driven by the development of cold chain logistics and increasing pharmaceutical imports.

Latin America: Steady growth anticipated due to improving economic conditions and rising demand for temperature-sensitive goods.

Challenges

High Costs: Advanced thermal insulation materials like VIPs and PUR can be expensive, impacting adoption among cost-sensitive end-users.

Environmental Concerns: Disposal of non-biodegradable materials such as polystyrene poses environmental challenges, prompting a shift towards sustainable alternatives.

Supply Chain Complexity: Maintaining the integrity of thermal insulation packaging throughout complex supply chains requires meticulous planning and execution.

Opportunities

Sustainable Materials: Development of eco-friendly insulation materials presents opportunities for market growth, aligning with global sustainability trends.

Technological Advancements: Integration of smart technologies, such as temperature monitoring sensors, can enhance the functionality of thermal insulation packaging.

Emerging Markets: Expansion into developing regions with growing pharmaceutical and food industries offers potential for market penetration.

Recent Developments

Innovations in Sustainable Packaging: Companies are investing in research to develop biodegradable and recyclable thermal insulation materials to address environmental concerns.

Strategic Partnerships: Collaborations between packaging manufacturers and pharmaceutical companies are on the rise to develop customized solutions for specific temperature-sensitive products.

Regulatory Compliance Initiatives: Businesses are enhancing their packaging solutions to comply with evolving regulations, ensuring product safety and quality during transportation.

Conclusion

The thermal insulation packaging market is poised for robust growth, driven by increasing demand for temperature-sensitive products, advancements in packaging technologies, and a global emphasis on sustainability. However, challenges such as high costs and environmental concerns need to be addressed. Companies that invest in sustainable materials, technological innovations, and strategic partnerships are well-positioned to capitalize on emerging opportunities in this dynamic market.

0 notes

Text

Expanded Polystyrene (EPS) Market Inclinations & Development Highlighted Status and Forecast 2025-2037

Analysis of Global Expanded Polystyrene (EPS) Market Size by Research Nester Reveals Market to Achieve a CAGR of 5.4% During 2025-2037, Reaching USD 36.3 billion by 2037

Research Nester’s latest report, "Global Expanded Polystyrene (EPS) Market: Supply & Demand Analysis, Growth Forecasts & Statistics Report 2025-2037," offers an in-depth competitor analysis and insights into market segmentation by density and end use industry. It includes a detailed assessment of market drivers, technological innovations, and sustainability trends shaping the expanded polystyrene (EPS) sector.

Sustainable Packaging and Construction Demand to Drive Market Expansion

The expanded polystyrene market is anticipated to witness significant growth due to increased demand in various sectors, mainly driven by the construction and packaging industries. Growing infrastructure investment, especially in emerging economies, increases demand for EPS steadily due to its insulation properties and efficiency in energy use. Besides, ecological concerns have changed the focus towards sustainable packaging solutions, which, in turn, facilitates the use of EPS within the packaging industry since it provides better protection and cushioning. Furthermore, technological advancement allows the recycling and reuse of EPS and guarantees a positive outlook for the market by 2037.

Key Drivers and Challenges Impacting the Expanded Polystyrene (EPS) Market

Growth Drivers:

Increasing demand for sustainable packaging solutions

Expansion of the construction sector

Technological advancements in recycling capabilities

Challenges:

Environmental regulations on plastic use

Price volatility of raw materials

Access our detailed report at: https://www.researchnester.com/reports/expanded-polystyrene-eps-market/5163

By density, high density EPS is expected to dominate the market with a 68.5% share during the forecast period, driven by strong properties that make the material apt for heavy-duty applications involving construction and automotive components. High density EPS offers superior insulation, thus supporting the growing attention being paid to energy-efficient building materials and global sustainability initiatives. Therefore, the segment is well-placed for considerable opportunity with increasing demands for durable, energy-saving materials.

By region, Asia Pacific is expected to dominate the market with a share of 47.6% during the forecast period. In China, EPS finds huge demand due to continuous infrastructural projects and a strong manufacturing sector. Government policies have been formulating and promoting energy-efficient construction methods. The growth of the EPS market in India is driven by the booming construction sector that is bustling with urban development projects and, at the same time, government initiatives to build public facilities such as apartments, schools, and hospitals. India has now shifted its focus to low-income housing and green building standards, raising the need for energy-efficient and cost-effective insulation material.

Customized report@ https://www.researchnester.com/customized-reports-5163

The expanded polystyrene market is highly competitive and includes leading players such as BASF SE, Synthos S.A., TotalEnergies SE, and Dow Chemical Company at the forefront. Large companies with substantial R&D and worldwide distribution networks continue to hold this competitive edge with the latest advances in sustainable EPS solutions. Companies such as StyroChem International, SABIC, and NOVA Chemicals Corporation consolidate their positions further through additional investment in environment-friendly production technologies and expansion of their respective EPS portfolios.

Request Report Sample@ https://www.researchnester.com/sample-request-5163 Research Nester Analytics is a leading service provider for strategic market research and consulting. We provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates, and executives make informed decisions regarding future marketing strategy, expansion, and investments. We believe every business can expand its horizon with the right guidance at the right time. Our out-of-the-box thinking helps clients navigate future uncertainties and market dynamics.

Contact for more Info:

AJ Daniel

Email: [email protected]

U.S. Phone: +1 646 586 9123

U.K. Phone: +44 203 608 5919

0 notes

Text

Geofoam Market: Current Analysis and Forecast (2024-2032)

According to a new report by UnivDatos Market Insights, the Geofoam Market is expected to reach USD billion by 2032 by growing at a CAGR of ~5.2%.

Geofoam coatings market volume has been growing constantly within the past decade due to the development of new construction materials and heightened concerns for environmentally friendly solutions. Geofoam, a lightweight fill material manufactured from expanded polystyrene (EPS), has become an important component in construction as well as civil engineering applications because of its insulation value, simplicity of construction, and reasonable cost. With industries requiring other solutions to construction-related issues, the geofoam coatings market is rapidly becoming progressive and creating many opportunities.

Market Overview

Geofoam coatings are mainly used in construction applications, infrastructure, and landscaping industries. Installation of Geofoam coatings is for various purposes of the construction of roads for embankment fill or even a retaining wall for green roofs. Due to the nature of this material, a lesser load will be imposed on the existing structures hence reducing the chances of structures settling down. In addition, geofoam has good thermal properties, for this reason, geofoam is well-suitable in areas that experience very high or very low temperatures.

The structure of the market composite comprises the players as small regional manufacturers and large multinational corporations. An emphasis on competition has been observed throughout innovation in the material formulations, as the companies work on research and development of geofoam coatings to improve their performance. This includes enhanced fire rating, waterproofing, and mechanical properties as well as to suit the specific use of the building.

Key Drivers of Market Growth

Several factors contribute to the growth of the geofoam coatings market:

Infrastructure Development: Recent modernization and increase in population density in urban areas have led to increased infrastructure development globally. The government is spending more money on constructing roads, bridges, and other infrastructures, which implies a huge market for efficient construction materials such as geofoam.

Sustainability and Eco-Friendliness: With increased concerns about the impact of pollution on the environment, there is increased concern about adopting ecological construction. Geofoam is a recyclable product, and it emits fewer pollutants into the atmosphere during the production process as producers worldwide seek environmentally friendly materials.

Cost-Effectiveness: Geofoam coatings are also a win in that they simplify the transportation and installation costs of the products. They have tended to reduce the overall weight of the structures hence reducing the cost of designing and materials for foundations, this makes them suitable for developers and contractors.

Versatile Applications: This is because geofoam can be used in many different fields, including civil engineering and landscaping, and even in thermal insulation. This adaptability drives demand from many industries – broadens the market appeal.

Regional Insights

Like other coatings industries, it has different regional characteristics in terms of construction policies, construction style, and economies.

North America: The geofoam coatings market in North America is large especially in the United States though the market is universally widespread. There is evidence of the region's construction industry brains and an ongoing pipeline of projects that support the demand. Furthermore, awareness of the best practices to go for in terms of materials has also caused individuals to give geofoam a nod in different projects.

Europe: There has been a high demand for geofoam coatings in Europe because of the many environmental laws governing construction as well as sensitivity to sustainable construction. These are some of the countries that are at the vanguard of applying advanced construction materials in their developmental projects such as Germany and the Netherlands.

Asia-Pacific: The Asia-Pacific region is estimated to have the greatest CAGR in the geofoam coatings market. Increased demand is caused by, among others, population and urbanization, and significant capital expenditure by the government in infrastructure projects. Some of the major companies that are currently involved in the use of geofoam solutions especially in their large construction projects include China and India.

Latin America and the Middle East: Nevertheless, the markets in Latin America and the Middle East are only starting to appreciate the advantages of geofoam coatings. The development of infrastructure in these regions offers great business prospects for market players.

Challenges and Restraints

Despite its promising growth prospects, the geofoam coatings market faces several challenges:

Regulatory Compliance: The change in regulatory measures for markets in different geophysical regions of the globe poses a challenge to manufacturers that seek to venture into these markets. Meeting local structural codes and safety requirements should be met but always proves to be very cumbersome and costly.

Market Competition: The market for geofoam coatings is being established; thus, many players occupy different segments of the market. For businesses to make profitable returns the products must be unique and constantly beneficial for consumers.

Awareness and Education: While more people are beginning to recognize the utility of geofoam there is still a large population of builders and contractors that can benefit from being informed of these advantages. Other significant recommendations include augmenting and enhancing marketing and marketing education for the proper use of geofoam coatings.

Access sample report (including graphs, charts, and figures): https://univdatos.com/get-a-free-sample-form-php/?product_id=25266

Outlook

The Geofoam coatings market is expected to create healthy growth over the decade across geographic regions. Since infrastructure development remains one of the global strategic development goals, it is expected that the market for lightweight and sustainable materials will continue to grow. New applications of material science like bio-based geofoam, and better formulation are the further boosters to this market.

It is therefore important that manufacturers, construction firms, and other regulatory agencies work together to ensure that these challenges are overcome, and the benefits of geofoam coatings are well enhanced. Geofoam is a part of the construction industry, and as sustainability has now become the single most important philosophy for the construction processes at present and in the future, geofoam will become even more significant.

Conclusion

The overall outlook of the geofoam coatings market over the Globe is a prime growth opportunity supported by infrastructural advancements, sustainability factors, and product cost. Growing demands for high-quality construction products and materials are likely to drive the market in the future as far as construction works are concerned. As it was established this is a fledging market where stakeholders must constantly respond to the challenges train the market and explore the various available opportunities that come with the use of geofoam coatings brought about by technological advancement. Geofoam is set to be a premier material in the construction industry as the sector drifts towards sustainability

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

Related Chemical Market Research Industy Report:-

Biobased Leather Market: Current Analysis and Forecast (2024-2032)

Chitosan Market: Current Analysis and Forecast (2024-2032)

0 notes

Text

0 notes

Text

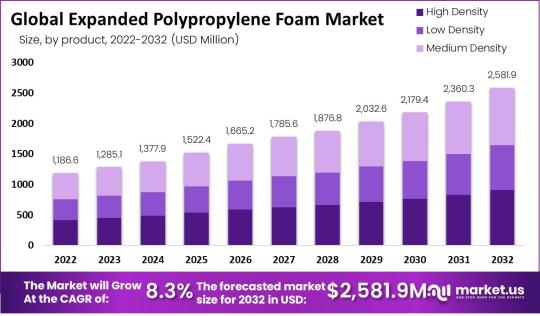

Expanded Polypropylene Foam: High-Density Segment Sees Surge in Automotive and Packaging Uses

Overview :

Expanded Polypropylene Foam Market was valued at USD 1,186.6 million and is expected to reach USD 2581.9 million in 2032. This market is estimated to register a CAGR of 8.3% between 2023 and 2032.

Get a Sample Copy with Graphs & List of Figures @ https://market.us/report/expanded-polypropylene-foam-market/request-sample/

Expanded polypropylene (EPP) foam is a versatile material known for its excellent impact resistance and lightweight properties. It is widely used in various industries due to its durability and cushioning ability. In consumer goods, EPP foam provides protection for sensitive electronics like computer equipment and circuit boards, where its shock-absorbing qualities help prevent damage during transport and use. Additionally, EPP foam's insulating properties make it valuable in packaging, building, and construction, where it contributes to energy efficiency and structural integrity.

Looking ahead, the demand for EPP foam is expected to grow, particularly in the toy and sports equipment sectors. As consumers become more health-conscious and seek products that offer better protection and safety, EPP foam's role in these areas is likely to expand. Its use in toys can provide safer play experiences for children, while in sporting goods, it can enhance comfort and injury prevention. This increasing awareness and preference for quality and safety are driving factors that will likely boost the global market for expanded polypropylene foam.

Key Market Segments

Based on Product

High Density

Low Density

Medium Density

Based on Application

Bumpers

Roof Pillars

Seat Bracing

Armrests

Other Applications

Based on End-User

Automotive

Packaging

Consumer goods

Appliances

Oil & Gas

Other End-Users

By Product Analysis:

The expanded polypropylene (EPP) foam market is segmented into high density, low density, and medium density, with high-density foams leading the market. In 2022, high-density EPP foams commanded over 42.0% of the market share, largely due to their use in automotive safety components and packaging.

By Application Analysis:

In terms of application, bumpers emerged as the leading segment, capturing over 42.0% of the market share in 2022. The increasing need for high-impact-resistant packaging for vehicle components drives this dominance, as EPP foam bumpers provide crucial safety features and impact absorption in automotive interiors and exteriors.

By End-Users Analysis:

The automotive sector is the primary end-user of expanded polypropylene foam, driven by its cost-effectiveness, mechanical strength, and moldability. EPP foam contributes to weight reduction in vehicles, enhancing fuel efficiency by up to 7% and lowering VOC emissions from interior components.

Key Players

JSP

BASF SE

Kaneka Corporation

DS Smith

Furukawa Electric Co., Ltd.

Hanwha Group

Sonoco Products

Knauf Industries

Izoblok

Dongshin Industry Incorporated

Clark Foam Products Corporation

Paracoat Products Ltd.

Molan-Pino South Africa

Signode Industrial Group LLC

Armacel

Furukawa Electric Co., Ltd.

Other Market Players

Drivers:

The expanding automotive industry is a major driver for the expanded polypropylene (EPP) foam market, as its lightweight and impact-resistant properties are ideal for components like bumpers and panels. Additionally, the growth of e-commerce and the increasing demand for sustainable packaging solutions are boosting the use of EPP foam in the packaging sector.

Restraints:

The high cost and price volatility of polypropylene, a key raw material, can impact profitability and increase finished product costs. EPP foam also faces competition from cheaper alternatives like expanded polystyrene (EPS) and may encounter challenges from emerging materials and technologies.

Opportunities:

There is significant growth potential in the automotive and packaging sectors, with emerging applications in building insulation and cushioning. The development of new uses, such as in toys and sports equipment, and advancements in manufacturing technology could reduce costs and broaden the material’s market reach.

Challenges:

Despite its advantages, EPP foam's market growth may be hampered by the development of new materials that could replace it in certain applications. Limited availability and higher costs associated with its recycling could also affect its overall market adoption and sustainability.

0 notes

Text

2032, Expanded Polystyrene (EPS) Recycling Market Growth and Research 2024-2032

The Reports and Insights, a leading market research company, has recently releases report titled “Expanded Polystyrene (EPS) Recycling Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Expanded Polystyrene (EPS) Recycling Market Size share, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Expanded Polystyrene (EPS) Recycling Market?

The expanded polystyrene (EPS) recycling market size reached US$ 19.7 Billion in 2023. Looking forward, Reports and Insights expects the market to reach US$ 36.5 Billion by 2032, exhibiting a growth rate (CAGR) of 6.7% during 2024-2032.

What are Expanded Polystyrene (EPS) Recycling?

EPS recycling is the practice of collecting, sorting, and processing EPS foam products to reclaim the material for reuse. EPS, also known as Styrofoam, is a lightweight and rigid plastic material utilized in packaging and insulation. The recycling process involves compressing the foam to reduce its size and then melting it down to create dense blocks or pellets suitable for manufacturing new products. EPS recycling contributes to environmental sustainability by diverting EPS waste from landfills and reducing the demand for new plastic production.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1775

What are the growth prospects and trends in the Expanded Polystyrene (EPS) Recycling industry?

The expanded polystyrene (EPS) recycling market growth is driven by various factors. The market for recycling expanded polystyrene (EPS) is expanding, fueled by growing environmental consciousness and regulatory measures promoting recycling practices. EPS, widely utilized in packaging and construction, significantly contributes to plastic waste. Recycling EPS involves collecting, cleaning, and processing it into reusable material for diverse applications. Market growth is propelled by increasing demand for recycled EPS in the construction and packaging sectors, driven by sustainability objectives and economic advantages. Moreover, technological advancements in EPS recycling and government support for recycling initiatives are further driving market growth. Hence, all these factors contribute to expanded polystyrene (EPS) recycling market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By EPS Waste Type:

Post-consumer EPS waste

Pre-consumer EPS waste

By EPS Recycling Process:

Mechanical recycling

Chemical recycling

Other recycling processes

By End-Use Industry:

Packaging

Construction

Electrical and Electronics

Automotive

Others

By Recycled EPS Product:

Packaging materials

Insulation boards

Molded products

Composite materials

Others

By Source of Collection:

Municipal recycling programs

Industrial and commercial collection

Retail collection

Other

By Recycling Equipment:

Shredders

Granulators

Densifiers

Extruders

Others

By Application:

Packaging

Building and construction

Insulation

Consumer goods

Others

By Distribution Channel:

Direct sales

Distributor sales

E-commerce

By Market Type:

Business to Business (B2B)

Business to Consumer (B2C)

Segmentation By Region:

North America:

United States

Canad

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Dart Container Corporation

NOVA Chemicals Corporation

ACH Foam Technologies, LLC

Ravago Recycling Group

Styro Recycle LLC

Total, Petrochemicals & Refining USA, Inc.

Alpek Polyester

Repsol S.A.

Vanden Recycling

Plasti-Fab Ltd.

NexKemia Petrochemicals Inc.

EPS Industry Alliance

Vita Group

FPC Foam Plastics Corporation

Winco Foam Industries Limited

View Full Report: https://www.reportsandinsights.com/report/Expanded Polystyrene (EPS) Recycling-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Expanded Polystyrene (EPS) Recycling Market share#Expanded Polystyrene (EPS) Recycling Market size#Expanded Polystyrene (EPS) Recycling Market trends

0 notes

Text

Styrene Market Report: Trends, Analysis, and Projections

Styrene, a key monomer in the production of various polymers and plastics, holds a significant position in the global petrochemical industry. This blog explores the dynamics of the global styrene market, analyzing key drivers, applications across industries, emerging trends, and future growth prospects.

Understanding the Styrene Market:

Styrene (C8H8) is an aromatic hydrocarbon obtained from the dehydrogenation of ethylbenzene, primarily used in the production of polystyrene, acrylonitrile-butadiene-styrene (ABS), styrene-butadiene rubber (SBR), and various thermoplastic elastomers.

Market Dynamics:

Polystyrene Production: Styrene is a crucial raw material for manufacturing polystyrene (PS), a versatile thermoplastic used in packaging, disposable containers, insulation, and consumer goods due to its lightweight and insulating properties.

ABS and SBR Production: Styrene contributes to the production of ABS, a high-impact engineering thermoplastic used in automotive parts, appliances, and electronics, as well as SBR, a synthetic rubber widely used in tires, footwear, and industrial applications.

Expanded Polystyrene (EPS): Styrene is essential for producing EPS foam, used in insulation boards, packaging materials, and construction applications due to its lightweight, thermal insulation, and cushioning properties.

Resins and Coatings: Styrene-based resins and coatings find applications in fiberglass-reinforced composites, boat hulls, automotive parts, and protective coatings for metal and concrete surfaces.

Applications Across Industries:

Packaging: Polystyrene foam, containers, packaging materials.

Automotive and Transportation: ABS plastics, SBR rubber for tires.

Construction: EPS insulation, foam boards, building materials.

Consumer Goods: Appliances, electronics, household products.

Market Trends:

Circular Economy Initiatives: Growing emphasis on recycling, sustainability, and circular economy models drive innovations in styrene recycling technologies and the development of bio-based styrene from renewable feedstocks.

Demand from Emerging Economies: Increasing urbanization, infrastructure development, and rising consumer demand in emerging economies fuel the demand for styrene-based products across multiple industries.

Technological Advancements: Innovations in polymerization processes, catalyst technologies, and material science lead to the development of high-performance styrene-based polymers with enhanced properties and applications.

Future Prospects:

The global styrene market is poised for continued growth, driven by the expanding plastics, packaging, automotive, and construction sectors. Sustainable practices, technological innovations, and strategic collaborations will shape the market's evolution towards greener and more efficient production processes.

Conclusion:

Styrene remains a vital component in the production of polymers, plastics, and rubber materials essential for diverse industries. Understanding market trends, regulatory shifts towards sustainability, and technological advancements is crucial for stakeholders in the styrene market. With a focus on innovation, recycling, and market diversification, the styrene market presents promising opportunities for growth and advancements in global industrial applications and sustainable solutions.

0 notes

Text

Comprehensive Analysis of the Expandable Polystyrene Market

The expandable polystyrene (EPS) market is witnessing significant growth globally, driven by increasing demand from various end-use industries such as packaging, construction, and automotive. This article provides a comprehensive analysis of the expandable polystyrene market, focusing on key trends, drivers, challenges, and future outlook.

Market Overview

Expandable polystyrene, commonly known as EPS, is a lightweight, versatile, and cost-effective plastic material used in a wide range of applications. Its unique properties such as insulation, cushioning, and moisture resistance make it suitable for packaging, insulation, and construction purposes. The global EPS market is experiencing steady growth, propelled by its widespread adoption across diverse industries.

Key Market Trends

Growing Demand for Sustainable Packaging Solutions

With increasing environmental concerns and regulations aimed at reducing plastic waste, there is a growing demand for sustainable packaging alternatives. Expandable polystyrene offers recyclable and reusable packaging solutions, making it an attractive choice for environmentally conscious consumers and businesses.

Buy the Full Report for the EPS Industry Installed Capacity and CapEx Forecast, Download a Free Report Sample

Expansion in Construction and Building Materials

The construction industry is a significant consumer of expandable polystyrene, where it is used for insulation, lightweight concrete, and decorative molding applications. As the construction sector continues to expand globally, particularly in emerging economies, the demand for EPS in building materials is expected to rise steadily.

Market Challenges

Environmental Concerns and Recycling Challenges

Despite its benefits, expandable polystyrene faces criticism due to its non-biodegradable nature and potential environmental impact. The recycling of EPS can be challenging due to its low density and volume, leading to concerns about landfill pollution and marine debris. Addressing these environmental concerns and improving recycling infrastructure are key challenges for the EPS industry.

Volatility in Raw Material Prices

The EPS market is sensitive to fluctuations in raw material prices, particularly the prices of styrene monomer, which is a key feedstock for EPS production. Volatility in raw material prices can impact production costs, profit margins, and pricing strategies for EPS manufacturers, posing challenges for market stability and profitability.

Future Outlook

Despite challenges, the expandable polystyrene market is expected to continue growing, driven by increasing demand from end-use industries such as packaging, construction, and automotive. Innovations in recycling technologies, development of bio-based alternatives, and growing awareness of sustainable practices are expected to shape the future of the EPS industry.

0 notes

Text

Polymers Market - Forecast, 2024-2030

Global Polymers Market

Global Polymers Market size is forecast to reach around $ 997.77 billion by 2030, after growing at a CAGR of 5.4% during 2024-2030. Polymer is one of the widely used chemical products in almost all the sectors such a medical, aerospace, packaging, automotive, construction, electrical appliances, and medical sector, and consequently, the global polymers market is thriving. Polymers are used widely as a substitute of metal and mineral based products due to its high performance, cost-effectiveness, and low weight. Increase in the retail sector and prospering e-commerce industry is demanding for more packaging material that is influencing the significance of the polymers market. The major factors driving the growth of this market are the increasing demand for polymers in various end-use industries, the rising adoption of lightweight and sustainable materials, the technological innovations, and the supportive government policies and initiatives. However, some of the challenges faced by this market are the fluctuations in the raw material prices, the environmental concerns, the competition from alternative materials, and the trade barriers. Furthermore, growing demand for polymer in the electronic industry for the manufacturing of different electrical parts such as switches and sockets are driving the Polymers Market.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐑𝐞𝐩𝐨𝐫𝐭 𝐒𝐚𝐦𝐩��𝐞

Report Coverage

The report: “Polymers Market – Forecast (2024-2030)”, by Industry ARC, covers an in-depth analysis of the following segments of the Global Polymers Market.

By Type: Polypropylene, Polyethylene (HDPE, LDPE, LLDPE, and Others), Polyvinyl Chloride, Polystyrene (Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS)), Polyurethane (Flexible Polyurethane Foam, Rigid Polyurethane Foam, Thermoplastic polyurethane (TPU), and Others), and Others.

By Process: Injection Moulding, Extrusion, and Others.

By End-Use Industry: Packaging (Rigid and Flexible), Building and Construction (Roofing, Windows, Flooring, and Others), Automotive (Engine, Tires, Body Panel, and Others), Electrical and Electronics, Agriculture, Medical/Healthcare, and Others.

By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, Italy, France, Spain, Netherlands, Russia, Belgium, and Rest of Europe), Asia Pacific (China, Japan, India, South Korea, Australia and New Zealand, Taiwan, Indonesia, Malaysia, and Rest of Asia Pacific), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), and RoW (Middle East and Africa)

Key Takeaways

In the Latin America region, Brazil is the major market for the Polymer owing to a rise in the purchasing power of consumers, growing consumer packaged goods market, and rise in corn, wheat, and sugarcane production and consumption across the country owing to the Bio-based plastic and polymers are gaining prominent growth.

The polymers are observed to be the better substitutes than glass, and metals that is leveraging the polymers market. The increasing demand for specialty polymers are fuelling the growth of the polymers market.

Progression in 3D printing is improving the growth aspects of polymers and plastic manufacturing. The changing preference of consumers from metal 3D printing to plastic material 3D printing is leading to substantial growth in the polymers market.

Fluctuation in international oil prices tend to force companies to search for an alternative stable source of the raw material for packaging, which further provides lucrative opportunities for the growth of Polymer industry.

Evolution of the natural and environment-friendly polymers in the packaging sector for food packaging, cosmetics packaging and pharmaceutical packaging is driving the growth.

Comparatively lower awareness about the biodegradable polymer in emerging nations like India, Thailand, South Africa and Qatar are hampering the market growth.

0 notes

Text

Shaping Tomorrow's Chill: Foam Cooler Box Market's Influence on Packaging Trends

Foam cooler boxes are insulated cooler boxes made using expanded polystyrene (EPS) foam which provides effective insulation and keeps food and beverages cool for long hours. Foam cooler boxes are durable, reusable and lightweight. They are available in different sizes and capacities to meet the cooling needs of individuals, families, and commercial users. The ease of use and portability offered by foam cooler boxes makes them a preferred option for picnics, outdoor activities, parties, and fieldwork. The global Foam Cooler Box Market is estimated to be valued at US$ 2.93 Bn in 2023 and is expected to exhibit a CAGR of 8.6% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights. Market Opportunity: The rising environmental concerns have compelled regulators and consumers to reduce the use of single-use plastic products. Foam cooler boxes can replace single-use plastic coolers and are emerging as a sustainable solution for on-the-go cooling needs. They are reusable, produce no waste, and have a significantly lower carbon footprint than plastic coolers. The stringent regulations on single-use plastics worldwide are expected to drive the demand for eco-friendly foam cooler boxes during the forecast period. Foam cooler box manufacturers are capitalizing on this opportunity by marketing their products as sustainable alternatives, which is expected to significantly boost the foam cooler box market growth. Porter's Analysis Threat of new entrants: High capital requirements in production setup and established brand recognition create barriers for new players. Bargaining power of buyers: Buyers have high bargaining power due to the availability of substitutes. Buyers can negotiate on price. Bargaining power of suppliers: The market has many raw material suppliers. Suppliers' bargaining power is moderate. Threat of new substitutes: Substitutes like polyurethane coolers and hard-sided coolers are available at lower costs. Competitive rivalry: The market is dominated by global players and competitive pricing pressures exist. SWOT Analysis Strength: foam coolers are affordable, durable, lightweight, and insulated. Increased demand for outdoor recreation drives the market. Weakness: foam coolers easily get damaged when squeezed tightly. Regular cleaning is required to maintain cooling efficiency. Opportunity: expanding organized retailing and e-commerce channels provide growth opportunities. Increasing tourism and camping activities boost sales. Threats: strict environmental regulations on foam use pose challenges. Substitutes like hybrid coolers threaten market share. Key Takeaways The global foam cooler box market is expected to witness high growth due to increasing outdoor recreational activities worldwide.

The regional analysis of Asia Pacific comprising countries like China, India, and Japan is also expected to grow at a steady pace during the forecast period. Rising middle-class incomes and increasing young population indulging in tourism and travel positively influence the regional market. Key players operating in the foam cooler box market are YETI, Igloo, Coleman, Rubbermaid, Grizzly, Engel, Bison Coolers, ORCA, Pelican, Polar Bear Coolers, AO Coolers, Kula Coolers, IceMule, RTIC, Canyon Coolers, OtterBox, Kysek, Magellan Outdoors, Everest, and Stanley.

#Foam Cooler Box Market Share#Foam Cooler Box Market Growth#Foam Cooler Box Market Demand#Foam Cooler Box Market Trend#Foam Cooler Box Market Analysis

0 notes

Text

Expanded Polystyrene Price, Trend, Prices, Demand & Market Analysis | ChemAnalyst

The Expanded Polystyrene (EPS) market is currently witnessing dynamic fluctuations in prices, driven by a myriad of factors that span both global and regional landscapes. This versatile material, known for its lightweight and insulating properties, finds extensive applications in various industries such as construction, packaging, and automotive. Understanding the intricacies of the EPS market prices requires a nuanced analysis of the factors influencing its supply and demand dynamics.

One of the primary drivers affecting EPS prices is the raw material costs. The production of Expanded Polystyrene involves the polymerization of styrene, derived mainly from petrochemical sources. Consequently, fluctuations in crude oil prices exert a significant impact on the overall EPS production costs. As the crude oil market experiences volatility due to geopolitical tensions, supply-demand imbalances, or other global events, EPS manufacturers are compelled to adjust their prices to reflect the changing cost structures.

Moreover, environmental considerations play an increasingly pivotal role in shaping the EPS market landscape. As the world shifts towards sustainable practices, the demand for eco-friendly alternatives to traditional materials has risen. This has led to a surge in research and development efforts within the EPS industry to create biodegradable or recyclable options. The adoption of such environmentally friendly alternatives can influence market prices, as companies invest in new technologies and adapt their production processes, thereby impacting the overall supply chain dynamics.

In addition to raw material costs and environmental factors, global economic conditions significantly contribute to the volatility in EPS market prices. Economic downturns, such as the global recession in 2008, demonstrated how a contraction in various industries can lead to reduced demand for EPS products, causing a downward pressure on prices. Conversely, periods of economic growth and increased construction activities tend to boost the demand for EPS, resulting in higher market prices.

Get Real Time Prices of Caustic Soda: https://www.chemanalyst.com/Pricing-data/expanded-polystyrene-65

Trade dynamics and geopolitical factors also contribute to the price fluctuations in the EPS market. Trade tensions, tariffs, and changes in international policies can disrupt the supply chains of EPS manufacturers, leading to uncertainties in pricing. For example, restrictions on the import or export of EPS-related products can impact the availability of raw materials or finished goods, influencing market prices on a global scale.

Furthermore, technological advancements within the EPS industry play a crucial role in shaping market prices. Innovations in manufacturing processes, equipment efficiency, and product quality can impact the overall cost structure, potentially leading to changes in market prices. Companies investing in cutting-edge technologies to enhance their production capabilities or reduce energy consumption may experience cost advantages, allowing them to adjust their pricing strategies accordingly.

Regional market conditions also contribute to the variability in EPS prices. Different regions have distinct demand patterns, regulatory frameworks, and economic structures that influence the pricing dynamics. For instance, regions experiencing rapid urbanization and infrastructure development may witness a surge in demand for EPS in construction applications, impacting prices in that specific market segment.

In conclusion, the Expanded Polystyrene market prices are subject to a complex interplay of factors that range from raw material costs and environmental considerations to economic conditions, trade dynamics, technological advancements, and regional market trends. As the industry continues to evolve, companies operating within the EPS sector must remain agile and responsive to these multifaceted influences. Continuous monitoring of market drivers and a strategic approach to adapting to changing conditions will be crucial for businesses seeking to navigate the dynamic landscape of the Expanded Polystyrene market.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Middle East and Africa Sandwich Panel Market Analysis, Demand, Report 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the Middle East and Africa sandwich panel market size at USD 248.73 million in 2022. During the forecast period between 2023 and 2029, BlueWeave expects the Middle East and Africa sandwich panel market size to grow at a CAGR of 6.50% reaching a value of USD 386.52 million by 2029. The increasing number of commercial and industrial building projects, such as cold storage facilities and medical facilities, as well as increased attention to the buildings' appealing designs and aesthetics, are significant growth factors for the Middle East and Africa sandwich panel market.

Middle East and Africa Sandwich Panel Market – Overview

A modular construction material used to cover buildings and other structures is called sandwich paneling. These panels are made of two layers that together comprise the outside structure and provide stiffness, shape, and weather resistance. They have a core that has insulating qualities for both sound and heat. Expanded polystyrene (EPS), mineral wool, rigid polyurethane (PUR), and polyisocyanurate (PIR) are some examples of the various insulating materials that can be used to make the cores. There are several varieties of sandwich panel-facing profiles, including micro profile, linear, corrugated, smooth, stamping, and sinusoidal.

Sample Request @ https://www.blueweaveconsulting.com/report/middle-east-and-africa-sandwich-panel-market/report-sample

Middle East and Africa Sandwich Panel Market

Segmental Information

Middle East and Africa Sandwich Panel Market – By Application

Based on application, the Middle East and Africa sandwich panel market is segmented into wall panels, roof panels, insulated panels, and others. The wall panels segment holds the largest share in the Middle East and Africa sandwich panel market. Sandwich panels are used in the building industry for a variety of purposes, including the construction of walls and ceilings. The main portion of the building's exterior is its walls. As a result, outside walls are crucial for energy conservation. The thickness and technical requirements of the wall panel sandwich will change depending on the insulation needs.

Impact of COVID-19 on Middle East and Africa Sandwich Panel Market

The unprecedented COVID-19 pandemic negatively impacted the growth of the Middle East and Africa sandwich panel market. The imposition of lockdown to mitigate the virus spread caused supply chain disruptions in the countries. Furthermore, the lockdown impeded the operations of the construction industry, which caused a huge shortage of labor as well as raw materials in the market. To concentrate on the healthcare industry, the construction of industrial and commercial buildings was suspended, which severely impacted the region's demand for sandwich panels.

Competitive Landscape

Major players operating in the Middle East and Africa sandwich panel market include Kingspan Group, TSSC Group, Zamil Steel, Qatar Steel Industries Factory, DANA Group, Al Ghurair Construction Industries, Emirates Building Systems, Saudi Rock Wool Factory, Qatar Insulation Company, and Frigoglass Industries Nigeria Limited

These companies employ various strategies to further enhance their market share, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

0 notes

Text

Global Expandable Polystyrene Market Analysis and Forecast

Expandable Polystyrene (EPS) is a versatile material widely used in various industries, from packaging to construction. This article provides a comprehensive analysis and forecast of the global Expandable Polystyrene market, examining key trends, market dynamics, and future prospects for this essential polymer.

Understanding Expandable Polystyrene (EPS)

Expandable Polystyrene (EPS) is a lightweight, rigid, plastic foam composed of small beads. It is known for its excellent insulation properties, shock absorption, and versatility, making it a valuable material in multiple applications.

For more insights on the EPS market forecast, download a free report sample

Expandable Polystyrene Market Size and Growth

1. Market Size

The global Expandable Polystyrene market is substantial, driven by its wide range of applications, including packaging, construction, and automotive industries.

2. Market Growth

The market has experienced steady growth due to factors like urbanization, increased consumer demand for packaged goods, and the need for energy-efficient construction materials.

Expandable Polystyrene Market Key Trends and Drivers

1. Sustainable and Recyclable Solutions

The demand for sustainable EPS solutions, including recyclable materials and reduced environmental impact, is a significant trend driven by environmental regulations and consumer preferences.

2. Construction Industry Growth

The construction industry's expansion, particularly in emerging markets, has increased the demand for EPS insulation materials, contributing to market growth.

3. Packaging Innovations

Innovations in packaging, such as protective packaging solutions and lightweight containers, have boosted EPS usage in the packaging sector.

4. Automotive Lightweighting

The automotive industry's focus on reducing vehicle weight for improved fuel efficiency has led to the increased use of EPS in automotive components.

5. Consumer Electronics Packaging

The growth of the consumer electronics market has driven demand for EPS packaging materials that offer protection during transportation and storage.

Expandable Polystyrene Market Key Players and Competitive Landscape

The global Expandable Polystyrene market features several key players and a competitive landscape:

1. EPS Manufacturers

Leading EPS manufacturers like BASF SE, TotalEnergies SE (formerly Total S.A.), and Styron LLC (a Trinseo company) dominate the market, providing a wide range of EPS products.

2. Packaging Companies

Packaging companies such as Sonoco Products Company and DS Smith Plc utilize EPS in their packaging solutions, contributing to market competitiveness.

3. Construction Material Suppliers

Suppliers of construction materials, including Kingspan Group and Owens Corning, play a significant role in providing EPS insulation materials.

4. Automotive Suppliers

Automotive suppliers like Faurecia SA and Magna International Inc. incorporate EPS in automotive components, including interior trim and structural parts.

5. Recycling Initiatives

Companies specializing in EPS recycling, such as Styrofoam Recycling, work towards sustainable solutions, creating a competitive niche in the market.

Expandable Polystyrene Market Future Outlook

The future of the global Expandable Polystyrene market is expected to be influenced by ongoing developments:

1. Circular Economy Initiatives

Greater emphasis on circular economy practices, including EPS recycling and waste reduction, will drive sustainable growth in the market.

2. Energy Efficiency Regulations

Stricter energy efficiency regulations and green building standards will boost the demand for EPS insulation materials in the construction sector.

3. Innovative Packaging Solutions

Continued innovation in packaging solutions, including protective packaging and sustainable materials, will shape the future of EPS in the packaging industry.

4. Alternative Materials

Research and development efforts to find alternative materials with similar properties to EPS will influence the market, driven by environmental concerns.

In conclusion, the global Expandable Polystyrene market is poised for growth, driven by sustainability trends, construction industry expansion, packaging innovations, and automotive lightweighting efforts. As the landscape evolves, staying informed about these trends and focusing on sustainable solutions will be crucial for manufacturers, suppliers, and consumers looking to meet the changing demands of various industries and reduce the environmental impact of EPS usage.

0 notes

Text

Cryogenic Insulation Market Size, Type, segmentation, growth and forecast 2023-2030

The Cryogenic Insulation Market is expected to grow from USD 1.20 Billion in 2022 to USD 4.54 Billion by 2030, at a CAGR of 18.00% during the forecast period.

Get the Sample Report: https://www.reportprime.com/enquiry/sample-report/11814

Cryogenic Insulation Market Size

Cryogenic insulation is a type of insulation that is specifically designed to maintain low temperatures, typically below -150°C, such as those found in cryogenic applications. It is used in various industries, including energy and power, chemicals, metallurgical, electronics, shipping, healthcare, and others. The cryogenic insulation market can be segmented based on type, including PU & PIR, cellular glass, polystyrene, fiberglass, perlite, and others. It can also be segmented by region, including North America, Asia Pacific, Middle East, Africa, Australia, and Europe. Key market players in the cryogenic insulation market include Saint Gobain, Owens Corning, Armacell International, Lydall, BASF, Cabot Corporation, Rochling Group, Johns Manville, Dunmore Corporation, Imerys Minerals, Aspen Aerogels, G+H Group, Hertel, and Amol Dicalite. Regulatory and legal factors specific to the market conditions may include safety regulations for handling cryogenic materials, environmental regulations regarding insulation materials, and licensing or certification requirements for manufacturers and installers. These factors play a significant role in the development, production, and distribution of cryogenic insulation products and services.

Cryogenic Insulation Market Key players

Saint Gobain

Owens Corning

Armacell International

Lydall

BASF

Buy Now & Get Exclusive Discount on this

Cryogenic Insulation Market Segment Analysis The Cryogenic Insulation market is witnessing significant growth owing to the increasing demand for LNG (liquefied natural gas) and other cryogenic gases across various industries. Cryogenic insulation helps in maintaining low temperatures and preventing heat transfer in applications involving storage and transportation of such gases. The market is characterized by the growing need for energy efficiency and the rising adoption of LNG as a cleaner fuel source.One of the major factors driving revenue growth in the Cryogenic Insulation market is the expanding LNG industry. The increasing global energy demand and the shift towards cleaner fuel sources have led to a surge in LNG production and consumption. This, in turn, is driving the demand for efficient cryogenic insulation solutions to ensure safe storage and transportation of LNG. The growth of the LNG industry is particularly evident in regions like Asia-Pacific, where countries like China and India are investing heavily in LNG infrastructure.Another key driver of the Cryogenic Insulation market is the growing demand for cryogenic insulation in the medical and healthcare sector. Cryogenic gases are extensively used in medical applications such as cryosurgery, cryopreservation, and cryotherapy. The need for reliable and efficient insulation materials for medical cryogenic equipment is increasing, thereby boosting the demand for cryogenic insulation products.In terms of trends, the Cryogenic Insulation market is witnessing a shift towards the adoption of advanced insulation materials. Traditional insulation materials like perlite and expanded polystyrene (EPS) are being replaced by more efficient options such as polyurethane foam and vacuum insulation panels. These advanced materials offer superior thermal performance and durability, making them increasingly preferred in cryogenic applications.However, the Cryogenic Insulation market also faces certain challenges. The high cost of advanced insulation materials and the complexity of installation are some of the key challenges faced by industry players. Moreover, the volatile prices of raw materials used in cryogenic insulation production can hinder market growth. Additionally, stringent regulations and safety standards pertaining to the handling and transportation of cryogenic gases pose challenges for market players.The main findings of the report indicate that the Cryogenic Insulation market is expected to witness significant growth in the coming years, driven by the expansion of the LNG industry and the increasing demand for cryogenic gases in various sectors. The adoption of advanced insulation materials is expected to witness a substantial rise, owing to their superior thermal performance. However, the market faces challenges due to the high cost of materials and the complexity of installation.To overcome these challenges, the report recommends industry players focus on research and development to develop cost-effective insulation materials and innovative installation techniques. Collaboration with stakeholders across the value chain, including raw material suppliers and end-users, can help in addressing market challenges and enhancing product offerings. Additionally, market players should stay updated with the evolving regulations and safety standards in the industry to ensure compliance and maintain customer satisfaction.This report covers impact on COVID-19 and Russia-Ukraine wars in detail.Purchase This Report: https://www.reportprime.com/checkout?id=11814&price=3590

Market Segmentation (by Application):

Saint Gobain

Owens Corning

Armacell International

Lydall

BASF

Information is sourced from www.reportprime.com

0 notes