#Epoxy Flooring Manufacturers

Explore tagged Tumblr posts

Text

High-Quality Sealants and Construction Chemicals in UAE – SPEC

SPEC is a leading name among Sealants Manufacturers in UAE, providing high-performance solutions for various industries. As one of the top Construction Chemicals Manufacturers in UAE, SPEC offers premium products, including PU Sealant Manufacturers solutions, ensuring durability and flexibility for diverse applications.

With expertise in Epoxy Flooring Manufacturers, SPEC delivers seamless and durable flooring systems, ideal for industrial and commercial spaces. Their specialized range also covers Concrete Repair in Dubai UAE, addressing structural issues with long-lasting repair solutions. Additionally, SPEC is a trusted provider of Cementitious Waterproofing in Dubai UAE, offering advanced waterproofing systems for concrete structures, ensuring protection against moisture and water damage.

Committed to quality and innovation, SPEC continues to be a preferred choice in the UAE market. Whether you need reliable sealants, waterproofing, or concrete repair solutions, SPEC delivers top-tier products tailored to meet construction and industrial needs. Explore SPEC��s extensive range of construction chemicals designed for superior performance and long-lasting results.

#Sealants Manufacturers in UAE#Construction Chemicals Manufacturers in UAE#Construction Chemicals in Dubai UAE#Best concrete Repair Product#Concrete Repair in Dubai UAE#PU Sealant Manufacturers#Polysulphide Sealants in Dubai UAE#Acrylic Sealants in Dubai UAE#PU Waterproofing in Dubai UAE#Cemetitious Waterproofing in Dubai UAE#Acrylic Waterproofing in Dubai UAE#Polyurethane flooring in Dubai UAE#Epoxy Flooring Manufacturers#Industrial coatings in Dubai UAE

0 notes

Text

On-Site Epoxy Pours Done Right

Not only do I pay close attention to detail, I do right by you, the client. It never fails, I advise clients not to do their own epoxy work because there is so much that goes into it. Even if I provide a step-by-step, attention to detail is key. Too many people rush things or forget one step or try to take shortcuts and end up spending more time, money, and frustration than they would have to…

#cabinets#concrete#countertop#countertop store#countertops#custom#diy#epoxy#epoxy river#floor#garage floor#granite#home#home-improvement#houston county#jacksonville#kathleen#kitchen#lawton#live edge#macon#manufacturing#marble#mga#middle ga#middle georgia#near me#new#okc#oklahoma

0 notes

Text

Discover the Best Epoxy Flooring Manufacturers for Superior Flooring Solutions- MB Enterprises

0 notes

Text

How ESD Flooring Protects Electronics Manufacturing from Costly Failures

In electronics manufacturing, even a tiny electrostatic discharge (ESD) can cause catastrophic damage to sensitive components. Without the right ESD control measures, companies risk production failures, equipment damage, and regulatory non-compliance. One of the most critical, yet often overlooked, elements of an effective static control system is the flooring. Epoxy.com specializes in…

#Circuit Board Protection#Conductive Epoxy#Electronics Manufacturing#Electrostatic Dissipative Flooring#Static Control

0 notes

Text

1 note

·

View note

Text

#epoxy flooring#epoxy floor paint#epoxy floor paint price in india#epoxy floor paint price#latest marble flooring design#epoxy flooring Manufacturer & Supplier India.

1 note

·

View note

Text

Epoxy floors can provide a safe and clean work environment for various industries. Epoxy resin flooring is a cost-effective and low-maintenance solution that combines functionality with aesthetics, making it a preferred choice for commercial facilities looking to improve safety, durability, and cleanliness. Epoxy Flooring can be made anti-slip, enhancing safety by reducing the risk of falls and accidents, which is particularly crucial in manufacturing environments.

#epoxyflooring#sherwinwilliams#warehousefloorpainting#epoxy floor#epoxy flooring#manufacturing flooring#epoxy floor contractor nj#commercial floor#commercial flooring

1 note

·

View note

Text

#Anti Static PU Flooring Service in Maharashtra#Car Parking Coating Service in Maharashtra#Chemical Resistant Floor Coatings In Maharashtra#Epoxy Pu Floor Coating Service In Pune#Epoxy Self-Level Flooring Service In Goa#Floor Waterproofing Service in Pune#FRP Coating Service In Maharashtra#Industrial Coatings Manufacturers In Goa#Industrial Flooring Contractor in Mumbai

0 notes

Text

Epoxy Self-Leveling is Ideal for Commercial & Industrial Flooring

Epoxy self-leveling, also known as epoxy self-flowing floor and epoxy ground, is made of epoxy resin as the main material, curing agent, diluents, solvents, dispersants, defoamers and some fillers and other mixed processing of epoxy floor coating, combined with a specific floor construction process, on-site ground decorative construction of a class of flooring. This process can be based on the unevenness of the ground downstream flow, the ground for automatic leveling, and rapid drying, after curing the ground will form a smooth, flat, seamless mirror effect surface layer. In addition, self-leveling also has moisture-proof, antibacterial, anti-corrosion and other characteristics.

Main characteristics of epoxy self-leveling

Epoxy self-leveling has chemical properties such as water resistance, oil resistance, acid and alkali resistance, salt spray corrosion resistance, and physical properties such as abrasion resistance, stamping resistance and scrub resistance. And the surface is bright, flat, beautiful, no joints, easy to clean, easy maintenance, durable, can meet the needs of modern industry on the floor, in the flooring materials occupy an important position, is the ideal long-lasting flooring materials for modern industry, and has been widely used in medicine, automobile, electronics, food, electricity, chemical industry and other industrial floor decoration.

Epoxy self-leveling composition

Epoxy self-leveling includes two parts: concrete base and epoxy self-leveling floor coating.

Concrete grass-roots level: The concrete with strength level not less than C25 is poured and moulded at one time, when the floor has the requirement of pressure resistance and impact resistance, the concrete grass-roots level can be processed by two-way reinforcing steel mesh.

Epoxy self-leveling floor coating: bottom coating, middle coating, putty layer, top coating.

The bottom coating is epoxy primer, using penetration and adhesion of epoxy primer, continuous and uniform coating film, no leakage, to enhance the adhesion of the grass-roots surface.

The middle coating is epoxy mortar layer, epoxy two-component add appropriate amount of 100 mesh quartz sand, enhance the smoothness of the coating surface and the strength of the coating.

Putty layer for epoxy putty layer, epoxy two-component add appropriate amount of putty powder, further leveling of the coating surface, to achieve a flat surface, smooth.

The top coating is coated with colour paint, and the self-leveling epoxy top coating is evenly troweled.

Epoxy self-leveling construction precautions

Epoxy self-leveling floor coating is a kind of epoxy resin, it is widely used in building construction, is a kind of environmentally friendly and harmless paint. It can ensure that the ground after the construction of non-skinning, as well as the flatness of the grass-roots level and surface strength, but also to fill the ground base of the original cuts or cracks, to ensure that the surface effect of self-leveling and anti-cracking. At the same time, the product can also be high-pressure washing of the grass-roots level to ensure that the ground clean.

However, epoxy self-leveling floor coating in the use of the process there are some precautions that must be observed, otherwise it will cause some irreparable damage to the building construction.

Construction temperature needs to be ≥5℃, if you want to construct in <5℃ need to choose special formula. Humidity is recommended for construction below 75%.

Construction to ensure air circulation, modulation of the amount of use, not more than 30 minutes.

Construction process to do a good job of maintenance, to avoid the intrusion of dust and debris, affecting the effect of paint.

After the construction is completed, it needs to be maintained for at least 7 days before being put into use. During the maintenance period, especially can not have water or all kinds of solution infiltration.

It is strictly prohibited to mix with other paints.

Must be strictly in accordance with the prescribed proportion of the addition of curing agent.

Keep the surface of the coated material clean, and the water content of the coated material must be less than 7%.

Keep the painting environment clean, it is strictly prohibited to construct in the environment with a lot of dust.

Epoxy self-leveling coating characteristics

Epoxy self-leveling coating is made of epoxy resin and special curing agent as main material, and is processed by adding various auxiliaries, pigments and fillers through strict proportioning. It not only has excellent chemical properties such as water resistance, oil resistance and chemical corrosion resistance, but also has the advantages of good adhesion, high mechanical strength, low shrinkage of paint film after curing, and can be coated into a thick film at a time, so it is widely used in modern industrial flooring.

The coating film is tough, wear-resistant, good chemical resistance, non-toxic and non-flammable.

The surface is smooth and clean, with good decorative properties, and can meet the requirements of class 100 cleanliness level.

It has high adhesion, strong mechanical strength, chemical resistance and good electrical properties.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#epoxy self-leveling#epoxy self-leveling flooring#epoxy self-leveling floor coating#self-leveling epoxy#epoxy coating

0 notes

Text

Honoring Strength, Courage, and Hope

On World Cancer Day, CAPA stands with warriors, survivors, and caregivers around the globe. Let's unite in the fight against cancer, spreading awareness, supporting research, and offering love and compassion to those affected.

Together, we can make a difference. Together, we can bring light to the darkness. Join us in honoring the resilience and determination of cancer fighters everywhere. #WorldCancerDay #CAPACares #StrengthInUnity

To know more tile adhesives and waterproofing floors, epoxy grouts visit: https://capaindia.in/product/capa-flex/, https://capaindia.in/product/capaproof-hybrid-w/

#best tile adhesive in india#top tile adhesive brands in india#top building materials companies in india#tile adhesive manufacturers#tile adhesives for fixing natural stones#high strength flooring mortars#tile adhesive companies in india#floor repairs mortars in india#tile adhesives for vitrified tiles#block jointing mortar manufacturers in india#Flooring mortar#Tile and stone adhesive#Industrial Grouts#floor repairs mortars#epoxy grouts#Powder grouts#Ready mix plaster manufacturers#Machine sprayable plaster#Thin joint mortars#Thin joint mortars for AAC blocks#Waterproofing mortar#Waterproofing system#floor repairs mortars in India#best flooring solutions in india#best waterproofing mineral mortars in india#aliphatic polyurethane waterproofing coating#elastomeric waterproofing coating#flexible waterproofing mortar for crack bridging#waterproofing solutions for crack bridging#affordable waterproofing solutions

0 notes

Text

What Industries Use Epoxy Flooring?

Epoxy flooring has become a popular choice for various industries due to its durability, chemical resistance, and seamless finish. This flooring solution provides a robust and aesthetically pleasing surface that can withstand heavy traffic, chemical spills, and harsh environmental conditions. Industries such as manufacturing, healthcare, food processing, automotive, and retail rely on epoxy flooring for safety, hygiene, and long-term performance. This article explores the key industries that benefit from epoxy flooring and highlights its applications.

Understanding Epoxy Flooring

Epoxy flooring is a type of resinous flooring system that combines epoxy resin and a hardener. When mixed, they create a rigid, plastic-like material that bonds strongly to the concrete substrate. Epoxy Flooring Manufacturers provide various formulations tailored to industry-specific requirements, including anti-slip properties, chemical resistance, and impact strength.

Industries That Use Epoxy Flooring

1. Manufacturing and Industrial Facilities

Manufacturing plants and industrial facilities require flooring solutions that can endure heavy machinery, constant foot traffic, and chemical exposure. Epoxy flooring provides the necessary durability and resistance to oils, solvents, and abrasions. Some benefits for this sector include:

High load-bearing capacity

Resistance to mechanical stress

Easy maintenance and cleaning

Anti-slip properties for worker safety

2. Warehouses and Logistics Centers

Warehouses and distribution centers demand strong, impact-resistant flooring to support forklifts, pallet jacks, and other heavy equipment. Epoxy flooring offers:

Enhanced durability against wear and tear

Clear demarcation for pathways and safety zones

Resistance to dust accumulation

Seamless surface for smooth material handling

3. Healthcare and Pharmaceutical Industry

Hygiene and cleanliness are top priorities in healthcare and pharmaceutical industries. Epoxy flooring is a preferred choice due to its:

Seamless, non-porous surface preventing bacterial growth

Resistance to chemicals and disinfectants

Compliance with hygiene regulations

Anti-slip coatings for enhanced safety

4. Food and Beverage Industry

Food processing plants, commercial kitchens, and beverage industries require flooring that meets strict sanitary regulations. Epoxy flooring is ideal due to:

Resistance to spills, grease, and chemicals

Easy-to-clean surfaces that prevent contamination

Anti-microbial properties

Slip-resistant coatings to ensure worker safety

5. Automotive Industry and Car Workshops

Epoxy flooring is extensively used in car workshops, showrooms, and assembly lines. It offers:

Resistance to oil, gasoline, and chemical spills

High durability against impact and abrasions

Aesthetic appeal for showrooms and service centers

Easy maintenance and cleaning

6. Retail and Commercial Spaces

Retail stores, malls, and commercial spaces opt for epoxy flooring due to its aesthetic versatility and durability. Benefits include:

Customization options with colors and patterns

High resistance to foot traffic

Easy cleaning and maintenance

Reflective surfaces for better lighting

7. Educational Institutions and Public Buildings

Schools, universities, and government buildings benefit from epoxy flooring because of:

Long-lasting durability

Cost-effective maintenance

Slip-resistant and safe surface

Customization for aesthetic appeal

8. Aerospace and Defense Facilities

Aircraft hangars, defense establishments, and aerospace industries require specialized flooring that resists jet fuel, heavy loads, and chemicals. Epoxy flooring provides:

Chemical resistance to aviation fluids

High load tolerance for aircraft movement

Smooth surface for easy cleaning and maintenance

Anti-static options for sensitive areas

The Role of Epoxy Flooring Manufacturers

Top Epoxy Flooring Manufacturers offer specialized solutions tailored to different industries. They provide high-performance coatings designed to enhance durability, safety, and compliance with industry standards. Customizable epoxy systems, including anti-slip coatings and static-dissipative flooring, ensure suitability for various applications.

Additional Protective Solutions: Cementitious Waterproofing in Dubai UAE

In addition to epoxy flooring, Cementitious Waterproofing in Dubai UAE plays a crucial role in protecting concrete structures from moisture damage. This waterproofing method is widely used in basements, water tanks, and industrial facilities to prevent leaks and enhance structural longevity.

Benefits of Cementitious Waterproofing:

Excellent water resistance

Easy application on various surfaces

Ideal for underground and submerged structures

Enhances concrete durability and prevents corrosion

Importance of Best Concrete Repair Product for Industrial Flooring

Damaged concrete surfaces can compromise the performance of epoxy flooring. Using the Best Concrete Repair Product ensures a smooth, durable base before applying epoxy coatings.

Features of High-Quality Concrete Repair Products:

Fast curing for minimal downtime

High adhesion strength

Crack and spall repair capabilities

Suitable for industrial and commercial applications

Conclusion

Epoxy flooring is a versatile solution used across numerous industries due to its durability, safety, and ease of maintenance. From manufacturing and healthcare to retail and aerospace, businesses benefit from its strength, chemical resistance, and aesthetic appeal. Additionally, Cementitious Waterproofing in Dubai UAE and the Best Concrete Repair Product enhance the longevity and performance of industrial flooring systems. Investing in high-quality epoxy flooring ensures a long-lasting, cost-effective, and functional workspace for various applications.

#Construction Chemicals Manufacturers in UAE#Construction Chemicals in Dubai UAE#Best concrete Repair Product#Concrete Repair in Dubai UAE#PU Sealant Manufacturers#Polysulphide Sealants in Dubai UAE#Acrylic Sealants in Dubai UAE#PU Waterproofing in Dubai UAE#Cemetitious Waterproofing in Dubai UAE#Acrylic Waterproofing in Dubai UAE#Polyurethane flooring in Dubai UAE#Epoxy Flooring Manufacturers#Industrial coatings in Dubai UAE#Sealants Manufacturers in UAE

0 notes

Text

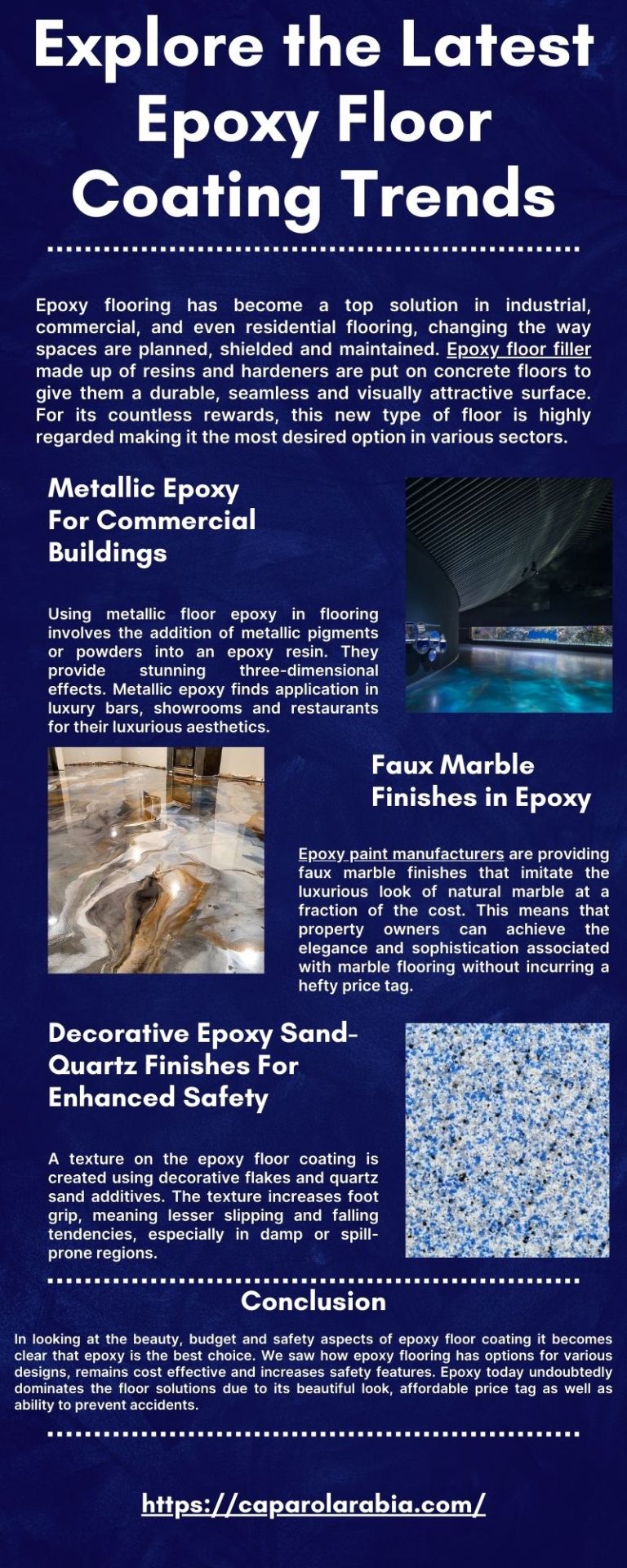

Explore the Latest Epoxy Floor Coating Trends

Epoxy flooring has become a top solution in industrial, commercial, and even residential flooring, changing the way spaces are planned, shielded and maintained. Epoxy floor filler made up of resins and hardeners are put on concrete floors to give them a durable, seamless and visually attractive surface. For its countless rewards, this new type of floor is highly regarded making it the most desired option in various sectors.

0 notes

Text

Top Epoxy Flooring Manufacturers for Durable and High-Quality Solutions

When it comes to durable and high-quality flooring solutions, epoxy flooring manufacturers play a crucial role in providing long-lasting options for both commercial and residential spaces. These manufacturers are known for their expertise in creating floor coatings that offer resistance to chemicals, abrasion, and wear.

By using advanced technology and high-quality materials, epoxy flooring manufacturers ensure that the floors are not only durable but also aesthetically appealing. Whether it's for industrial spaces or home garages, choosing the right manufacturer is essential for getting the best results. One of the top players in this industry is MB Enterprises, known for its exceptional epoxy flooring solutions and unmatched customer satisfaction.

0 notes

Text

0 notes

Text

Epoxy floors are ideal for commercial facilities that see a lot of foot or heavy machinery traffic since these floors are extremely durable.

#warehouses#facilitymanagment#facilitymaintenance#commercialflooring#epoxyfloor#epoxyfloorcoating#epoxycoating#FacilityManager#manufacturing#EpoxyFlooring#epoxy flooring contractors#epoxy flooring contractors nj#epoxy floor contractors#epoxyflooring#commercial flooring

0 notes

Text

Industrial Epoxy Flooring Services In Chennai.

#india#kolkata#delhi#baddi#ahmedabad#chennai#surat#banglore#epoxy#epoxyflooring#epoxyfloorcoating#epoxyflooringcost#industrial#commercial#flooring#services#manufacturer#supplier

0 notes