#Epoxy Floor Coating Manufacturers

Explore tagged Tumblr posts

Text

How Epoxy Flooring Manufacturers Ensure Durability and Quality

Epoxy flooring is known for its strength, durability, and aesthetic appeal, making it a popular choice for both residential and commercial spaces. Ensuring that epoxy floors last for years while maintaining their visual appeal requires a great deal of expertise in manufacturing. Epoxy flooring manufacturers follow stringent quality control measures and employ advanced technologies to guarantee that their products meet the highest standards. Here’s how they ensure durability and quality in every project.

1. High-Quality Raw Materials

The foundation of any durable epoxy flooring system lies in the quality of the raw materials used. Epoxy flooring manufacturers source premium resins, hardeners, and other additives to ensure a solid and long-lasting floor coating. The choice of materials is crucial, as poor-quality components can lead to cracks, discoloration, and premature wear. Manufacturers often conduct tests on these materials to confirm their strength, resistance to chemicals, and ability to withstand high traffic and heavy machinery.

2. Advanced Manufacturing Techniques

Epoxy floor coatings are manufactured using precise, controlled processes that guarantee consistency and uniformity. The mixing of the resin and hardener, for example, must be exact to ensure proper curing and adhesion. Epoxy floor coating manufacturers use sophisticated mixing equipment and automated systems to minimize human error and ensure the consistency of every batch. By using these advanced techniques, they can avoid common issues such as uneven curing or bubbling, which could impact the floor’s durability.

3. Rigorous Testing Procedures

Before being released to the market, epoxy flooring undergoes rigorous testing to check for various performance attributes. These tests assess factors such as scratch resistance, moisture resistance, UV stability, and thermal endurance. By conducting such tests, manufacturers ensure that their products can withstand the wear and tear of daily use without compromising on aesthetics or functionality. This process is essential for verifying the long-term viability of the product in both commercial and residential environments.

4. Customization for Specific Needs

Not all spaces are the same, and different environments require specialized flooring. Epoxy flooring manufacturers often offer customized solutions tailored to meet specific needs, whether it's for heavy-duty industrial floors or decorative finishes for showrooms. These customizations can include variations in thickness, texture, and color, ensuring that the product not only fits the functional requirements but also matches the aesthetic goals of the space. By understanding the unique demands of each space, manufacturers can deliver flooring solutions that excel in both performance and appearance.

5. Continuous Innovation and Improvement

Epoxy flooring manufacturers are continually innovating to improve the quality of their products. From introducing new types of resins to developing advanced curing processes, the industry is constantly evolving. This drive for innovation helps manufacturers stay ahead of the curve and offer products that meet or exceed industry standards. By investing in research and development, manufacturers can produce floors that are even more durable, environmentally friendly, and easier to install than ever before.

If you are considering epoxy flooring for your space, MB Enterprises is one of the trusted manufacturer that delivers high-quality, durable solutions tailored to your needs.

0 notes

Text

#Anti Static PU Flooring Service in Maharashtra#Car Parking Coating Service in Maharashtra#Chemical Resistant Floor Coatings In Maharashtra#Epoxy Pu Floor Coating Service In Pune#Epoxy Self-Level Flooring Service In Goa#Floor Waterproofing Service in Pune#FRP Coating Service In Maharashtra#Industrial Coatings Manufacturers In Goa#Industrial Flooring Contractor in Mumbai

0 notes

Text

Epoxy Self-Leveling is Ideal for Commercial & Industrial Flooring

Epoxy self-leveling, also known as epoxy self-flowing floor and epoxy ground, is made of epoxy resin as the main material, curing agent, diluents, solvents, dispersants, defoamers and some fillers and other mixed processing of epoxy floor coating, combined with a specific floor construction process, on-site ground decorative construction of a class of flooring. This process can be based on the unevenness of the ground downstream flow, the ground for automatic leveling, and rapid drying, after curing the ground will form a smooth, flat, seamless mirror effect surface layer. In addition, self-leveling also has moisture-proof, antibacterial, anti-corrosion and other characteristics.

Main characteristics of epoxy self-leveling

Epoxy self-leveling has chemical properties such as water resistance, oil resistance, acid and alkali resistance, salt spray corrosion resistance, and physical properties such as abrasion resistance, stamping resistance and scrub resistance. And the surface is bright, flat, beautiful, no joints, easy to clean, easy maintenance, durable, can meet the needs of modern industry on the floor, in the flooring materials occupy an important position, is the ideal long-lasting flooring materials for modern industry, and has been widely used in medicine, automobile, electronics, food, electricity, chemical industry and other industrial floor decoration.

Epoxy self-leveling composition

Epoxy self-leveling includes two parts: concrete base and epoxy self-leveling floor coating.

Concrete grass-roots level: The concrete with strength level not less than C25 is poured and moulded at one time, when the floor has the requirement of pressure resistance and impact resistance, the concrete grass-roots level can be processed by two-way reinforcing steel mesh.

Epoxy self-leveling floor coating: bottom coating, middle coating, putty layer, top coating.

The bottom coating is epoxy primer, using penetration and adhesion of epoxy primer, continuous and uniform coating film, no leakage, to enhance the adhesion of the grass-roots surface.

The middle coating is epoxy mortar layer, epoxy two-component add appropriate amount of 100 mesh quartz sand, enhance the smoothness of the coating surface and the strength of the coating.

Putty layer for epoxy putty layer, epoxy two-component add appropriate amount of putty powder, further leveling of the coating surface, to achieve a flat surface, smooth.

The top coating is coated with colour paint, and the self-leveling epoxy top coating is evenly troweled.

Epoxy self-leveling construction precautions

Epoxy self-leveling floor coating is a kind of epoxy resin, it is widely used in building construction, is a kind of environmentally friendly and harmless paint. It can ensure that the ground after the construction of non-skinning, as well as the flatness of the grass-roots level and surface strength, but also to fill the ground base of the original cuts or cracks, to ensure that the surface effect of self-leveling and anti-cracking. At the same time, the product can also be high-pressure washing of the grass-roots level to ensure that the ground clean.

However, epoxy self-leveling floor coating in the use of the process there are some precautions that must be observed, otherwise it will cause some irreparable damage to the building construction.

Construction temperature needs to be ≥5℃, if you want to construct in <5℃ need to choose special formula. Humidity is recommended for construction below 75%.

Construction to ensure air circulation, modulation of the amount of use, not more than 30 minutes.

Construction process to do a good job of maintenance, to avoid the intrusion of dust and debris, affecting the effect of paint.

After the construction is completed, it needs to be maintained for at least 7 days before being put into use. During the maintenance period, especially can not have water or all kinds of solution infiltration.

It is strictly prohibited to mix with other paints.

Must be strictly in accordance with the prescribed proportion of the addition of curing agent.

Keep the surface of the coated material clean, and the water content of the coated material must be less than 7%.

Keep the painting environment clean, it is strictly prohibited to construct in the environment with a lot of dust.

Epoxy self-leveling coating characteristics

Epoxy self-leveling coating is made of epoxy resin and special curing agent as main material, and is processed by adding various auxiliaries, pigments and fillers through strict proportioning. It not only has excellent chemical properties such as water resistance, oil resistance and chemical corrosion resistance, but also has the advantages of good adhesion, high mechanical strength, low shrinkage of paint film after curing, and can be coated into a thick film at a time, so it is widely used in modern industrial flooring.

The coating film is tough, wear-resistant, good chemical resistance, non-toxic and non-flammable.

The surface is smooth and clean, with good decorative properties, and can meet the requirements of class 100 cleanliness level.

It has high adhesion, strong mechanical strength, chemical resistance and good electrical properties.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#epoxy self-leveling#epoxy self-leveling flooring#epoxy self-leveling floor coating#self-leveling epoxy#epoxy coating

0 notes

Text

Honoring Strength, Courage, and Hope

On World Cancer Day, CAPA stands with warriors, survivors, and caregivers around the globe. Let's unite in the fight against cancer, spreading awareness, supporting research, and offering love and compassion to those affected.

Together, we can make a difference. Together, we can bring light to the darkness. Join us in honoring the resilience and determination of cancer fighters everywhere. #WorldCancerDay #CAPACares #StrengthInUnity

To know more tile adhesives and waterproofing floors, epoxy grouts visit: https://capaindia.in/product/capa-flex/, https://capaindia.in/product/capaproof-hybrid-w/

#best tile adhesive in india#top tile adhesive brands in india#top building materials companies in india#tile adhesive manufacturers#tile adhesives for fixing natural stones#high strength flooring mortars#tile adhesive companies in india#floor repairs mortars in india#tile adhesives for vitrified tiles#block jointing mortar manufacturers in india#Flooring mortar#Tile and stone adhesive#Industrial Grouts#floor repairs mortars#epoxy grouts#Powder grouts#Ready mix plaster manufacturers#Machine sprayable plaster#Thin joint mortars#Thin joint mortars for AAC blocks#Waterproofing mortar#Waterproofing system#floor repairs mortars in India#best flooring solutions in india#best waterproofing mineral mortars in india#aliphatic polyurethane waterproofing coating#elastomeric waterproofing coating#flexible waterproofing mortar for crack bridging#waterproofing solutions for crack bridging#affordable waterproofing solutions

0 notes

Text

0 notes

Text

Industrial environments must be carefully planned to ensure safety and efficiency. To prevent slip and trip injuries at your facility an anti-slip epoxy floor coating might be the right solution. The coating minimizes the risk of slips and falls and creates a secure and efficient workspace for heightened productivity in manufacturing facilities.

#epoxy floor contractor nj#warehousefloorpainting#commercial flooring#epoxy flooring#epoxy contractor nj#epoxycoating#epoxy floor#epoxyflooring#sherwinwilliams#commercialflooring#facilitymanagement#flooringexperts#floorsystem#seamlessflooring#facilitymaintenance#epoxyfloor#warehouseflooring#flooringsolution#industrialfloor

2 notes

·

View notes

Text

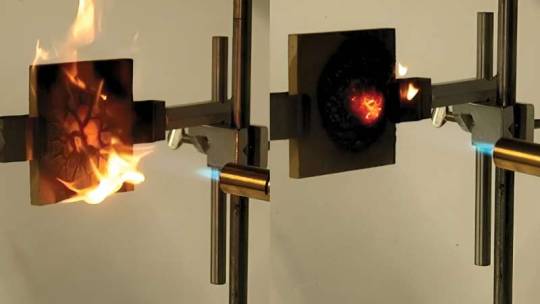

Recycling the non-recyclable: New epoxy resin resists flames and reduces waste

Empa researchers have developed an epoxy resin that can be repaired and recycled, in addition to being flame-retardant and mechanically strong. Potential applications range from coating for wooden flooring to composites in aerospace and railways. Epoxy resins are tough and versatile polymers. In combination with glass or carbon fibers, they are used, for example, to manufacture components for aircraft, cars, trains, ships and wind turbines. Such epoxy-based fiber-reinforced polymers have excellent mechanical and thermal properties and are much lighter than metal. Their weakness: They are not recyclable—at least not yet. Now Empa researchers led by Sabyasachi Gaan at Empa's Advanced Fibers laboratory have developed an epoxy resin-based plastic that is fully recyclable, repairable and also flame retardant—all while retaining the favorable thermomechanical properties of epoxy resins. They have published their findings in the Chemical Engineering Journal.

Read more.

#Materials Science#Science#Recycling#Epoxy#Resins#Flames#Waste#Flame retardants#Polymers#Thermosets#Vitrimers

11 notes

·

View notes

Text

EPOXY FLOOR GRINDING WORKS

Manycon Saudi is one of the best Epoxy Floor Grinding Contractors in Saudi Arabia & all GCC & India

In Saudi Arabia, Manycon Contracting Company offers professional epoxy floor coating application services in addition to a variety of other concrete flooring services for clients throughout Qatar, Saudi Arabia and India. Our flooring services epoxy floor paint application, concrete polishing, shot blasting and concrete grinding, concrete stain application, flooring and adhesive removal.. Our epoxy floor coating and concrete flooring services are ideal for commercial buildings and industrial plants.

The following are some of the main types of buildings, which would benefit from our epoxy coating and floor finishing services.

Aircraft Hangars

Chemical Plants

Manufacturing Plants

Warehouses & Distribution Facilities

Laboratories

Hospitals

Commercial and Residential Garages

Showrooms

Commercial Kitchens

Office Buildings

Retail Spaces & Mall

Athletic Facilities

2 notes

·

View notes

Text

Epoxy Floors in Oklahoma City: The Ultimate Flooring Solution

When it comes to durable, attractive, and long-lasting flooring options, epoxy floors in Oklahoma City are gaining popularity. Whether you're a homeowner looking to upgrade your garage or a business owner seeking a practical and aesthetically pleasing solution for your commercial space, epoxy flooring is a versatile choice that offers numerous benefits.

Epoxy Flooring Basics

Epoxy flooring is a type of surface coating that combines resin and hardener to create a strong, seamless, and highly resilient floor. It's a popular choice in various settings, from industrial facilities and warehouses to retail stores and homes. In Oklahoma City, epoxy floors are appreciated for their ability to withstand the city's variable weather conditions and heavy foot traffic.

Advantages of Epoxy Floors

Durability: Epoxy flooring is incredibly durable and can handle heavy loads without cracking or chipping. It can withstand the weight of vehicles, making it an ideal choice for garages and auto shops.

Easy Maintenance: Epoxy floors are effortless to clean and maintain. They are resistant to stains, chemicals, and moisture, making them perfect for areas prone to spills and accidents.

Aesthetically Pleasing: Epoxy floors are available in a wide range of colors and patterns, allowing you to customize your flooring to match your style and space. They can also be enhanced with decorative elements like flakes, metallic pigments, or quartz.

Longevity: When properly installed and maintained, epoxy floors can last for many years, making them a cost-effective investment.

Safety: Epoxy floors can be customized to include anti-slip additives, making them safer for areas where slip and fall accidents are a concern.

Applications of Epoxy Flooring in Oklahoma City

Residential Garages: Many homeowners in Oklahoma City are choosing epoxy flooring for their garages. It not only enhances the appearance of the space but also protects the concrete underneath from oil, grease, and other stains.

Commercial and Industrial Spaces: Epoxy flooring is a popular choice for commercial and industrial spaces in Oklahoma City. It can withstand heavy machinery, high foot traffic, and chemical exposure, making it suitable for manufacturing facilities, warehouses, and factories.

Retail Stores: Retailers appreciate the clean and polished look of epoxy floors, which can elevate the ambiance of their stores. The customizable design options allow for branding elements to be incorporated into the flooring.

Restaurants and Bars: Epoxy flooring's resistance to spills and easy cleaning make it a practical choice for the food and beverage industry. It also offers an opportunity for creative designs to enhance the dining experience.

Installation Process

Professional installation is crucial to achieving the full benefits of epoxy flooring. The process typically involves the following steps:

Surface Preparation: The existing concrete floor is thoroughly cleaned and prepared, which may include repairing cracks and imperfections.

Primer Application: A primer is applied to ensure proper adhesion between the epoxy coating and the concrete surface.

Epoxy Coating Application: The epoxy mixture is applied to the prepared surface, and it can be customized with various colors and patterns.

Additional Design Elements: If desired, decorative elements like flakes, metallic pigments, or quartz can be added during the epoxy application.

Topcoat Application: A clear topcoat is applied to provide additional protection and enhance the floor's shine.

Conclusion

Epoxy flooring installation offer a durable, attractive, and low-maintenance flooring solution for residential, commercial, and industrial spaces. With their customizable design options, resistance to stains and chemicals, and long lifespan, epoxy floors have become a top choice for those seeking a practical and aesthetically pleasing flooring solution in the vibrant city of Oklahoma. Whether you want to upgrade your garage or enhance your commercial space, epoxy flooring is a versatile option that can meet your needs and exceed your expectations.

https://mtcustomconcrete.com/epoxy/

2 notes

·

View notes

Text

Mastering Epoxy Floor Waterproofing: Essential Tips and Tricks

Epoxy flooring is a popular flooring option for both residential and industrial areas. It is durable, easy to clean, and offers a sleek, modern look. However, one of the biggest concerns is its susceptibility to water damage. This is where floor waterproofing singapore comes into play. In this article, we'll discuss essential tips and tricks for mastering floor waterproofing.

Understand the Importance

Before we dive into tips and tricks, it's important to understand why floor waterproofing is so essential. floors are not naturally waterproof and can suffer from damage due to water exposure. Water damage can lead to bubbling, peeling, and even cracking of the flooring. This can result in costly repairs and replacements. You can protect them from water damage, extend their lifespan, and save money in the long run.

Choose the Right Waterproofing Product

Choosing the right waterproofing product is crucial for effective floor waterproofing. There are many options available in the market, but not all products are created equal. It's important to choose a high-quality product that is specifically designed for floors. Look for a product that is easy to apply, dries quickly, and offers long-lasting protection against water damage.

Prepare the Surface

Proper surface preparation is key to successful floor waterproofing. Before applying any waterproofing product, make sure the surface is clean and free of any dirt, oil, or debris. Use a degreaser to remove any oil or grease stains, and then thoroughly clean the surface with a pressure washer or a scrub brush. Once the surface is clean, allow it to dry completely before applying any waterproofing product.

Apply the Waterproofing Product

When applying the waterproofing specialist product, make sure to follow the manufacturer's instructions carefully. Use a roller or a brush to apply the product evenly over the entire surface. Be sure to apply a sufficient amount of the product to ensure complete coverage. Once the product has been applied, allow it to dry completely before walking on the surface or applying any additional coats.

Maintain Your Epoxy Floors

Proper maintenance is key to preserving the waterproofing of your floors. Regularly clean your floors using a mild detergent and a soft-bristled brush or mop. Avoid using abrasive cleaners or tools that could damage the waterproofing layer. If you notice any damage or wear on your floors, address it immediately to prevent further water damage.

Consider Adding a Sealant

In addition to using a waterproofing product, you may also want to consider adding a sealant to your floors. A sealant can provide an extra layer of protection against water damage and can help to enhance the durability and lifespan of your floors.

Use a Moisture Meter

Before applying any waterproofing product, it's important to check the moisture levels of your concrete or substrate. Use a moisture meter to ensure that the surface is dry and free of any moisture. Applying a waterproofing product to a surface that is not completely dry can result in ineffective waterproofing and may even cause more damage.

Conclusion

epoxy floor waterproofing services is a crucial step in protecting your floors from water damage and extending their lifespan. By choosing the right waterproofing product, properly preparing the surface, and maintaining your floors, you can master floor waterproofing and enjoy the benefits of a long-lasting, waterproof flooring option.

#concrete crack repair epoxy injection#injection grouting chemical#water leakage repair#water pipe leakage repair#ceiling water damage repair

2 notes

·

View notes

Text

Epoxy Flooring Trends in Raleigh: What to Expect in 2025

As we look ahead to 2025, several exciting trends in epoxy flooring are emerging, especially for Raleigh homeowners. These innovations enhance the aesthetic appeal of spaces and offer practical benefits.

1. Smart Epoxy Floors

Imagine floors that can interact with your smart home system. In 2025, epoxy coatings are expected to incorporate embedded technology, such as sensors for temperature regulation, wear tracking, and lighting integration. This means your floor could alert you to potential issues before they become significant problems, adding an extra layer of convenience and safety to your home.

2. Sustainable Materials

Eco-conscious homeowners will appreciate the shift towards sustainable epoxy options. Manufacturers are developing 100% recyclable epoxy materials and bio-based coatings made from renewable resources. These environmentally friendly choices reduce your home's carbon footprint without compromising durability or style.

3. Artistic and Custom Designs

Customization is taking a bold step forward with epoxy flooring. New techniques allow for photo-realistic designs, intricate patterns, and 3D effects. Whether you desire a floor that mimics natural stone or a unique artistic creation, epoxy flooring offers endless possibilities to reflect your style.

4. Metallic Finishes

Metallic epoxy floors continue to gain popularity due to their luxurious appearance. These finishes create a shimmering, multi-dimensional effect that can resemble marble, molten metal, or other high-end materials, providing a sophisticated look to any room.

5. Mixed Material Applications

Combining epoxy with other materials, such as decorative flakes or quartz, is becoming popular. This approach not only enhances the floor's visual appeal but also improves its texture and slip resistance, making it both beautiful and functional.

By staying informed about these trends, you can make educated decisions when upgrading your home's flooring. Consulting with professional epoxy flooring contractors in Raleigh will help you explore these options and find the perfect fit for your space.

0 notes

Text

Shop from the Best Epoxy Flooring Manufacturers- MB Enterprises

0 notes

Text

#Anti Static PU Flooring Service in Maharashtra#Car Parking Coating Service in Maharashtra#Chemical Resistant Floor Coatings In Maharashtra#Epoxy Pu Floor Coating Service In Pune#Epoxy Self-Level Flooring Service In Goa#Floor Waterproofing Service in Pune#FRP Coating Service In Maharashtra#Industrial Coatings Manufacturers In Goa#Industrial Flooring Contractor in Mumbai

0 notes

Text

Concrete Floor Coating Market Analysis: Key Challenges and Opportunities

Growing Construction Activities and Demand for Durable Flooring Solutions Drive Growth in the Concrete Floor Coating Market.

The Concrete Floor Coating MarketSizewas valued at USD 4.75 Billion in 2023. It is estimated to hit USD 7.61 Billion by 2032 and grow at a CAGR of 5.4% over the forecast period of 2024-2032.

The global Concrete Floor Coating Market is witnessing substantial growth due to the increasing demand for durable, aesthetically appealing, and protective flooring solutions across various industries. These coatings enhance the longevity of concrete floors by offering resistance to abrasions, chemicals, and environmental factors, making them essential in industrial, commercial, and residential sectors.

Key Players in the Concrete Floor Coating Market:

Tennant Coatings (Tennant Ecoat)

Vanguard Concrete Coating (Vanguard Polyurea Coating)

BASF SE (MasterTop 1327)

Trucrete Surfacing Systems (Trucrete Epoxy Flooring)

PPG Pittsburgh Paints (Pittsburgh Paints & Stains Epoxy Floor Coating)

North American Coating Solution (NACS Epoxy Coating)

Sherwin-Williams Company, (Sherwin-Williams Epoxy Floor Coating)

Elite Crete Systems (Elite Crete Polyurethane Coating)

Pratt & Lambert (Pratt & Lambert Epoxy Coating)

Florock (Florock FloroCrete)

Future Scope:

The market for concrete floor coatings is expected to grow significantly in the coming years, driven by rapid urbanization, increasing infrastructure development, and the rising adoption of eco-friendly and high-performance coatings. The expansion of the industrial and commercial sectors, along with advancements in coating technology, is anticipated to further propel market growth.

Emerging Trends:

The Concrete Floor Coating Market is evolving with a shift toward sustainable and environmentally friendly solutions. Manufacturers are focusing on developing water-based and low-VOC (volatile organic compound) coatings to meet stringent environmental regulations. Additionally, the integration of nanotechnology is enhancing the durability and performance of these coatings. The increasing preference for decorative and polished concrete coatings in residential and commercial spaces is also a notable trend driving market expansion.

Key Market Points:

Rising demand for durable and protective floor coatings in industrial and commercial sectors.

Increasing adoption of eco-friendly, low-VOC, and water-based coatings.

Technological advancements in nanocoatings and high-performance solutions.

Growing preference for decorative and polished concrete coatings in residential applications.

Expanding infrastructure and construction projects globally fueling market growth.

Conclusion:

The Concrete Floor Coating Market is set for robust expansion in the foreseeable future, driven by technological advancements, sustainability initiatives, and increasing construction activities worldwide. Key industry players are focusing on product innovation and sustainability to meet evolving consumer demands and regulatory standards. As industries continue to emphasize durability and aesthetics, the market is expected to witness sustained growth and innovation in coating solutions.

Read Full Report: https://www.snsinsider.com/reports/concrete-floor-coating-market-3908

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Concrete Floor Coating Market#Concrete Floor Coating Market Size#Concrete Floor Coating Market Share#Concrete Floor Coating Market Report#Concrete Floor Coating Markett Forecast

0 notes

Text

Experience the Power of Aplicacer PU Flex

Designed for versatility, Aplicacer PU Flex offers unparalleled adhesive strength for a wide range of surfaces. Whether it's interior or exterior, dry or wet conditions, this multipurpose adhesive delivers superior performance every time. Say goodbye to challenges with its remarkable bonding ability on various substrates. Elevate your projects with Aplicacer PU Flex today! To know more about best waterproofing mineral mortars in india visit: https://capaindia.in/product/

#top tile adhesive brands in india#tile adhesive manufacturers#top building materials companies in india#best tile adhesive in india#tile adhesives for fixing natural stones#tile adhesives for vitrified tiles#high strength flooring mortars#block jointing mortar manufacturers in india#tile adhesive companies in india#floor repairs mortars in india#best waterproofing mineral mortars in india#elastomeric waterproofing coating#epoxy grouts in india#epoxy adhesive manufacturers#epoxy adhesives manufacturers#affordable waterproofing solutions#Flooring mortar#Tile and stone adhesive#Industrial Grouts#floor repairs mortars#epoxy grouts#Powder grouts#Ready mix plaster manufacturers#Machine sprayable plaster#Thin joint mortars#Thin joint mortars for AAC blocks#Waterproofing mortar#Waterproofing system

0 notes