#Energy Storage System

Explore tagged Tumblr posts

Text

With negative electricity prices occurring frequently for 468 hours, how can energy storage solve the dilemma of Europe's energy transition?

Recently, the phenomenon of "negative electricity prices" has reappeared in the European electricity market. On January 2nd, due to the wind power generation reaching as high as 40 gigawatts, far exceeding the market demand, the German overnight market experienced negative electricity prices for four consecutive hours. Power generators had to pay users to consume the excess electricity. This is not an isolated case. In 2024, the cumulative duration of negative electricity prices in Germany reached 468 hours, a year-on-year increase of 60%. Not only Germany, but also France and Spain have successively been hit by negative electricity prices. According to data from the European Power Exchange (Epex Spot), the duration of negative electricity prices in France doubled to 356 hours in 2024, while Spain had a cumulative negative electricity price duration of 247 hours throughout the year, entering the "negative electricity price club" for the first time.

The Energy Transition Behind Negative Electricity Prices The frequent occurrence of negative electricity prices is the result of the entire Europe's active promotion of the transition to renewable energy. In 2023, Germany added 17 gigawatts of new renewable energy installed capacity, with the total installed capacity approaching 170 gigawatts, a year-on-year increase of 12%. Among them, the photovoltaic power generation almost doubled, and the proportion of wind and solar power generation in the energy structure continued to increase. However, the rapidly growing clean energy has also exposed the structural problems of the European power system:

Insufficient energy storage facilities: The existing energy storage capacity in Europe is far from sufficient to deal with the situation of power surplus. Especially in strong wind or high sunlight weather, the power generation surges while the electricity cannot be effectively stored, leading to frequent situations of oversupply.

Insufficient flexibility of the power grid: The existing power grid is difficult to quickly respond to power generation fluctuations and cannot balance the mismatch between supply and demand brought about by clean energy.

Reduction of traditional energy sources: As the cornerstone of stable power supply, the gradual phase-out of traditional energy sources has further weakened the resilience of the power grid.

Energy Storage: The Key to Solving Negative Electricity Prices

In order to deal with the frequent negative electricity prices and the power fluctuations brought about by the development of clean energy, European countries are accelerating the layout of energy storage facilities. According to the "European Energy Storage Market Outlook 2024-2028" report released by the European Photovoltaic Industry Association, the new installed capacity of the European energy storage market in 2023 reached 17.2 gigawatts, with a cumulative installed capacity of 35.9 gigawatts. However, the report predicts that by 2030, Europe will need more than 100 gigawatts of energy storage installed capacity to balance the power supply and demand, and there is still a huge gap at present.

Currently, the energy storage construction in Europe mainly focuses on the following two major areas: Residential energy storage systems: The small-scale energy storage systems for individual photovoltaic users are growing rapidly. For example, the residential energy storage market in Germany is expected to grow from 8 gigawatt-hours in 2023 to 38 gigawatt-hours in 2030. Although these systems are convenient, their capacity is limited, making it difficult for them to play a significant role in power grid peak regulation.

Large-scale grid-side energy storage facilities: To solve the problem of insufficient capacity of residential energy storage, Europe is accelerating the construction of large-scale grid-side energy storage facilities. These facilities can not only effectively reduce the energy storage cost but also provide strong peak regulation support during peak power consumption periods.

AEAUTO: Boosting the Upgrade of the European Energy Storage Market Against the backdrop of the continuously expanding energy storage demand in Europe, Chinese energy storage enterprises have ushered in unprecedented opportunities. As a world-leading provider of energy storage system solutions, AEAUTO, with its technological advantages and product innovations, is actively participating in the development of the European energy storage market.

The energy storage batteries of AEAUTO use lithium iron phosphate (LiFePO4) cells and have the following core advantages:

High energy density: It can meet the needs of large-scale power storage while saving floor space.

Intelligent management system (BMS): It supports real-time monitoring of the battery status and provides protection against overcharging, over-discharging, over-current, and high temperatures.

Flexible configuration: It supports multi-module parallel connection and is suitable for residential, commercial, and industrial energy storage needs.

Long lifespan and low cost: With a cycle life of up to 6,000 times, it reduces the cost of use throughout the life cycle, which is 1.5 times the average level of similar products in the market.

Compatibility: It can seamlessly connect with more than 90% of the mainstream inverter brands in Europe.

In addition, AEAUTO's products have passed international certifications such as UKCA, TÜV, CE, and ISO, and are widely compatible with the mainstream photovoltaic and energy storage systems in the European market, providing customers with plug-and-play customized solutions.

The feedback from the European market in 2024 shows that AEAUTO's energy storage products, with their excellent performance and reliability, have achieved a customer satisfaction rate of 96.8%. Moreover, more than 500MWh of energy storage projects have been successfully deployed in European, Middle Eastern, Southeast Asian and other countries and regions, widely covering the residential, commercial, and industrial energy storage fields.

The energy storage demand in Europe will continue to surge. The construction of large-scale facilities is expected to ease the contradiction of negative electricity prices and promote the stability of the power system. AEAUTO will take technological innovation as its core to assist the energy transition in Europe and inject impetus into global sustainable development.

0 notes

Text

The Growing Demand for BESS in EV Charging Stations

The worldwide electric vehicle (EV) transformation continues to expand as customers choose electric vehicles over traditional gasoline cars because of their environmentally-friendly character. Building sound and effective EV charging infrastructure represents the greatest obstacle during this transition. The expanding electric vehicle marketplace creates greater need for enhanced and affordable charging stations, which also operate at higher speeds.

BESS stands as an essential component to fulfill this particular need. The integration of BESS at EV charging stations helps operators break away from grid dependence and control demand spikes while it improves charging performance. Research shows why BESS plays an essential role in EV charging stations and indicates a fast-growing market trend and its impact on sustainable transportation design.

Why EV Charging Stations Need Battery Energy Storage Systems (BESS)?

Traditional EV charging stations obtain energy from the electric power grid directly. The system works for regions which have reliable grid infrastructure but fails when power grids face stability problems or become overloaded. The incorporation of BESS into EV charging stations has become necessary because of these reasons:

1. BESS installations help oversee peak charging periods and minimize stress on the electricity network

The demands for charging power increase during both morning and evening peak times because that is when most drivers perform charging operations. The simultaneous charging of multiple EVs might lead to power outages along with voltage fluctuations as well as elevated electricity expenditures resulting from strong demand.

BESS performs an essential role by capturing energy during periods of low demand and distributing it at the moment of high demand which reduces system pressure and maintains continuous power supply.

2. Supporting Fast Charging Infrastructure

The increasing number of EV users requires installation of quick charging facilities to provide brief electrical charging instead of traditional extensive charging methods. High-power fast chargers need substantial energy supplies that exceed the current capacity of numerous present power grids when they operate at peak efficiency.

Using BESS technology enables charging stations to keep energy reserves in advance to supply high-power electricity to fast chargers without causing grid overload. The wider availability of ultra-fast charging becomes more practical because of this development.

3. The use of BESS allows charging operators to lower their electricity expenses.

Power prices differ throughout daily hours according to customer consumption. Power stations funded by grid electricity face increased tariff rates when usage peaks.

Operators achieve substantial cost benefits through BESS technology by storing electricity at low prices during night hours or at times of renewable power surplus for utilization at peak hours.

How BESS Enhances the Efficiency of EV Charging Stations?

1. Integration with Renewable Energy Sources

Solar power and wind energy systems are increasingly used to power EV charging stations thus making them more environmentally sustainable. Renewable energy supply functions intermittently because it does not consistently generate power at precise times.

BESS functions as an energy reserve to capture additional power from solar or wind operations which it distributes to chargers at moments when renewable generation declines thus maintaining a continuous charging station operation.

2. Enabling Off-Grid and Remote Charging Stations

A dependable electrical power grid does not exist in all regions such as rural areas and highways that show restricted charging infrastructure. BESS provides independent operation to off-grid charging stations that store renewable energy from solar panels wind turbines and other green energy sources.

The EV charging network achieves expansion into remote locations due to BESS which encourages EV adoption in areas with limited charging infrastructure.

3. Grid Stabilization and Demand Response

The power grids exhibit changes between supply and demand levels. The power system stability during times of high demand suffers from grid instability which results in either power outages or voltage reductions.

Smart BESS systems incorporated into EV charging facilities function as grid-supporting assets because they deliver saved energy to the power grid during critical moments. The usefulness of BESS enables improved grids while safeguarding against blackouts.

The market trends creating an increased need for BESS in EV charging stations include

1. Government Incentives and Policies

Government agencies support the EV transition and charging equipment development through subsidies and tax breaks together with grants for energy storage system installation. The implementation of BESS receives enhanced appeal for charging station operators through these incentives.

2. Increasing EV Adoption Worldwide

Manufacturers across the world are moving toward electric mobility while the total number of EVs in operation will experience substantial growth throughout the coming decade. The increasing demand for charging infrastructure requires more efficient facilities that need to expand their availability and BESS devices can assist with this development.

3. Advances in Battery Storage Technology

Large-scale production together with advancements in battery technology have led to a decreasing cost for lithium-ion batteries which are the most prevalent type of BESS. The reduction of battery costs makes the integration of BESS with EV charging stations more profitable.

4. Corporate Investments in Sustainable Charging Infrastructure

Leading companies that include automobile manufacturers and energy suppliers with charging facilities are using storage-driven smart charging systems to deliver quicker and cheaper and emissions-reduced EV charging services.

Challenges in BESS Adoption for EV Charging Stations

The use of BESS at EV charging stations presents several implementation difficulties:

BESS implies substantial initial expenditures yet the resulting electricity savings lead to long-term savings that help recuperate these costs.

Over time batteries run down in performance thus leading to necessary battery replacements.

The implementation of large BESS systems demands sufficient installation space which becomes limited in fast charging areas.

State or local regulations concerning grid connection of battery storage solutions remain in development in certain geographic areas.

The issues related to power backup systems continue to resolve due to technological progress along with nationwide governmental backing for such initiatives.

#Battery Energy Storage System#Energy Storage System#Energy Storage Technology#Energy Storage Solution#BESS

0 notes

Text

Sustainable Strategies to Overcome Environmental Challenges in Lithium Mining

As the global demand for electric vehicles and renewable energy storage surges, lithium mining has become pivotal in powering the green energy revolution. However, this surge brings forth significant environmental challenges that necessitate immediate attention.

Environmental Impacts of Lithium Mining

Water Usage and Contamination

Lithium extraction is notably water-intensive, especially in arid regions. Traditional evaporation methods consume approximately 1.9 million liters of water per metric ton of lithium, primarily sourced from undrinkable brine. In contrast, chemical extraction methods require significant freshwater, potentially impacting local water supplies. This extensive water usage can lead to groundwater depletion and contamination, adversely affecting local communities and ecosystems.

Carbon Emissions

The energy-intensive nature of lithium extraction contributes to substantial greenhouse gas emissions. For instance, hard rock mining methods, such as those employed in Australia and China, involve open-pit mining and roasting using fossil fuels, leading to significant carbon emissions.

Land Degradation and Habitat Destruction

Open-pit mining practices result in significant land degradation, leading to the destruction of natural habitats and ecosystems. Removing vegetation can cause soil erosion and biodiversity loss, disrupting local wildlife and plant species.

Strategies for Sustainable Lithium Mining

To mitigate these environmental challenges, the following sustainable strategies can be implemented:

Adoption of Sustainable Mining Practices

Implementing sustainable mining practices can significantly reduce the environmental footprint of lithium extraction. This includes utilizing renewable energy sources for mining operations, adopting closed-loop water systems to minimize water usage, and employing advanced technologies to reduce emissions.

Development of Low-Carbon Extraction Methods

Innovations such as direct lithium extraction in deep geothermal plants offer a low-carbon alternative to traditional methods. This approach not only reduces greenhouse gas emissions but also provides a sustainable source of lithium, making geothermal plants cost-competitive in energy systems.

Recycling and Reuse of Lithium-Ion Batteries

Promoting the recycling and reuse of lithium-ion batteries can alleviate the demand for new lithium mining. Effective recycling processes can recover valuable materials, reducing the need for virgin resource extraction and minimizing environmental impacts.

Conclusion

While lithium mining is essential for advancing clean energy technologies, it is imperative to address its environmental challenges through sustainable practices. By adopting innovative extraction methods, implementing responsible mining practices, and promoting recycling, we can minimize the environmental impact and pave the way for a more sustainable future.

#DLE#Electric Vehicles#Energy Storage#Energy Storage System#Lithium Ion Batteries#Lithium Mining#Renewable Energy

0 notes

Text

Revolutionize Home Energy Management with ESS for Residential Applications

In an era where energy efficiency and sustainability are priorities, an Energy Storage System (ESS) for residential applications is a game-changer. Designed to optimize energy use, these systems empower homeowners with greater control over their power needs, ensuring reliability, cost savings, and eco-friendliness. Whether you live in a solar-powered home or simply want to enhance energy independence, an ESS is an ideal solution for managing energy consumption effectively.

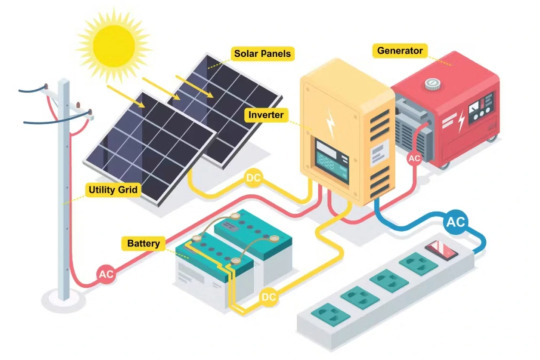

What is an Energy Storage System (ESS)?

An Energy Storage System (ESS) is a cutting-edge solution that stores electricity for later use. It collects excess energy during periods of low demand—often generated by renewable sources like solar panels—and supplies it when energy demand peaks or during power outages. By bridging the gap between energy production and consumption, an ESS ensures a consistent and efficient power supply for residential needs.

Key Features of ESS for Residential Applications

1. Efficiency and Sustainability

Homeowners seeking to minimize their environmental footprint will find ESS an invaluable tool. It allows the efficient use of renewable energy sources like solar power, reducing dependency on the grid and lowering carbon emissions. By storing surplus energy, it ensures that no energy goes to waste.

2. Reliability During Power Outages

An ESS provides peace of mind during grid failures or blackouts by acting as a backup power source. This ensures uninterrupted access to essential devices and appliances, making it especially beneficial in regions prone to power outages.

3. Cost Savings

With an ESS, homeowners can reduce energy costs by using stored energy during peak hours when electricity rates are higher. Additionally, it allows users to take full advantage of time-of-use energy pricing models.

4. Modular and Scalable Design

Modern ESS solutions feature a modular design that can be easily scaled to meet the energy needs of households of varying sizes. Whether you’re powering a small apartment or a large family home, an ESS can be customized to suit your requirements.

5. Low Maintenance

Designed with longevity and efficiency in mind, an ESS requires minimal maintenance. This ensures that homeowners can enjoy reliable performance without the hassle of frequent upkeep.

Applications of ESS in Residential Settings

1. Solar-Powered Homes

For homes equipped with solar panels, an ESS is indispensable. It stores excess energy generated during the day for use at night or during cloudy conditions, maximizing the benefits of renewable energy.

2. Off-Grid Living

An ESS enables complete energy independence for those who prefer an off-grid lifestyle. By efficiently storing and managing energy, it eliminates the need for a connection to the traditional power grid.

3. Grid-Tied Systems

For homes still connected to the grid, an ESS offers a hybrid solution. It reduces reliance on the grid while ensuring energy is available during outages or high-demand periods.

Advantages of Investing in an ESS for Residential Use

High Energy Density: Modern ESS systems offer compact solutions with high energy storage capacity.

Long Lifespan: Advanced battery technologies ensure durability and reliable performance over the years.

Eco-Friendly Solution: Reduces reliance on fossil fuels and minimizes carbon footprint.

Energy Independence: Empowers homeowners with control over their energy usage and costs.

Conclusion

Investing in an Energy Storage System (ESS) for residential applications is a step toward a more sustainable, cost-effective, and reliable energy future. Whether you’re harnessing solar energy, living off-grid, or seeking to lower electricity bills, an ESS offers a comprehensive solution tailored to your needs. With features like modular design, long lifespan, and seamless performance during power outages, it’s an essential tool for modern homeowners.

Take control of your energy consumption and enjoy the benefits of uninterrupted power. Explore our advanced ESS solutions today and make the switch to smarter, greener energy management.

Original Source: https://lithiumionbatterysupplier.blogspot.com/2024/11/revolutionize-home-energy-management.html

#battery manufacturer#Energy Storage System#Energy Storage System (ESS) for residential applications#ESS for residential applications

0 notes

Video

youtube

Zero-carbon photovoltaic storage and charging demonstration station

Dagong New Energy Technology Luoyang Co., Ltd

Official Site:www.energystorageltd.com/

Mail:[email protected]

WhatsApp :8619337982677

#energy storage#new energy#battery#solar photovoltaic#energy storage system#Energy Storage Battery Pack#lithium battery

0 notes

Text

How to Install a Hybrid Inverter

Installing a hybrid inverter involves several important steps and requires careful planning to ensure safety and efficiency. Here’s a detailed guide to help you through the process:

1. Pre-Installation Preparation

Assess Your Needs:

Determine the required size and capacity of the inverter based on your energy consumption and the specifications of your solar panels and battery storage.

Obtain Necessary Permits:

Check local regulations and obtain any required permits for installing a hybrid inverter and connecting it to the grid.

Select a Suitable Location:

Choose a well-ventilated, shaded area for mounting the inverter, away from direct sunlight and extreme temperatures.

Ensure the location is easily accessible for maintenance and monitoring.

2. Gather Tools and Equipment

Required Tools:

Screwdrivers

Drill and drill bits

Wire strippers

Multimeter

Safety gear (gloves, safety glasses)

Required Equipment:

Hybrid inverter

Mounting bracket or panel

Conduits and cables

Disconnect switches

Battery bank (if not already installed)

Solar panels (if not already installed)

3. Installation Steps

Step 1: Mount the Inverter

Secure the mounting bracket or panel to the chosen location using screws and a drill.

Attach the inverter to the bracket or panel, ensuring it is firmly in place.

Step 2: Connect the Solar Panels

Run the cables from the solar panels to the inverter’s input terminals.

Use conduits to protect the cables and ensure a neat installation.

Connect the positive and negative wires to the corresponding terminals on the inverter.

Step 3: Connect the Battery Bank

Connect the battery bank to the inverter’s battery input terminals.

Ensure correct polarity (positive to positive, negative to negative) to avoid damage to the system.

Use appropriate fuses and disconnect switches for safety.

Step 4: Connect to the Grid

Connect the inverter to your home’s main electrical panel via the grid input terminals.

Install a disconnect switch between the inverter and the main panel to isolate the system when needed.

Step 5: Configure the Inverter

Follow the manufacturer’s instructions to configure the inverter settings, including battery type, charging parameters, and grid connection settings.

Use the inverter’s interface or a connected monitoring system to complete the configuration.

4. Testing and Commissioning

Safety Checks:

Double-check all connections for tightness and correct polarity.

Ensure all fuses and disconnect switches are properly installed and in the off position.

Power Up:

Turn on the battery disconnect switch, followed by the solar panel disconnect switch.

Turn on the inverter and monitor the startup sequence for any error messages.

System Testing:

Use a multimeter to verify voltage and current levels at various points in the system.

Ensure the inverter is correctly managing power flow from the solar panels, battery, and grid.

Test backup power functionality by simulating a grid outage.

5. Final Steps

Monitoring and Maintenance:

Set up any remote monitoring features provided by the inverter for real-time performance tracking.

Schedule regular maintenance checks to ensure the system continues to operate efficiently and safely.

Documentation:

Keep a record of the installation, including wiring diagrams, configuration settings, and maintenance logs.

Provide documentation to local authorities if required for compliance with regulations.

Conclusion

Installing a hybrid inverter can be complex, but following these steps will help ensure a safe and efficient installation. Always refer to the manufacturer’s instructions for specific details related to your inverter model, and consider hiring a professional installer if you are not confident in performing the installation yourself.

#Hybrid Inverter#Solar Hybrid Inverter#Multi-Mode Inverter#Solar and Battery Inverter#DC to AC Conversion#Solar Energy System#Grid-Tied Inverter#Inverter Efficiency#Energy Storage System#Integrated Solar Inverter#Residential Solar Inverter#Commercial Inverter Solutions#Inverter Installations#Clean Energy Inverter

0 notes

Text

BLIIoT ARM Industrial Edge Computer ARMxy Series for Photovoltaic Power Generation and Energy Storage System

Faced with the vast and complex geographical environment and the inherent volatility of photovoltaic energy storage systems, power station operators face a dual challenge: how to monitor power generation, energy storage status and equipment health in real time and accurately? How to ensure the stable operation of the monitoring system in bad weather and remote areas? Traditional monitoring solutions can no longer meet the needs of efficient operation and maintenance, and a highly integrated, flexible and intelligent solution is about to emerge.

BLIIoT Industrial Edge Computer ARMxy

1. Hardware customization to adapt to diverse needs The ARMxy industrial computer is equipped with a high-performance Rockchip microprocessor and adopts a 4*A53 SOC architecture. It is designed for industrial applications and can not only withstand extreme temperature changes, but also has excellent vibration resistance. Considering the special environment of photovoltaic power stations, engineers carefully configured I/O boards with DI and AI modules, which can capture light intensity, temperature changes and electrical parameters in real time, laying a solid foundation for accurate monitoring.

2. Both hardware and software are used to build an intelligent ecosystem. The system is equipped with Ubuntu Linux. Taking advantage of its open source advantages, it integrates a series of efficient tools, such as Docker container technology, allowing for rapid deployment and updating of monitoring applications, ensuring the flexibility and advancement of the software environment. The addition of the QT framework makes the operation interface intuitive and friendly, and even non-technical personnel can easily grasp the system status. What is more worth mentioning is that the integration of Node-Red simplifies the data flow processing logic, making the construction of the automatic control logic intuitive and fast.

3. Edge computing improves decision-making speed Considering the delay problem of remote monitoring and data processing, ARMxy has built-in edge computing capabilities to pre-process key data on site, greatly reducing the time for data to and from the cloud. Even when the communication conditions are poor, it can quickly respond to abnormal situations to ensure the safe and stable operation of the power station.

4. Cloud interconnection, operation and maintenance are under control Through the integrated 4G/WiFi/Bluetooth module, ARMxy transmits real-time data to the cloud server. The operation and maintenance team can view the power station status anytime and anywhere through the remote monitoring platform. Whether it is power generation efficiency analysis or fault warning, they can know what they are doing and make decisions quickly.

Since the deployment of the ARMxy industrial computer, the operation and maintenance efficiency of the photovoltaic power station has been significantly improved, the fault response time has been shortened by 70%, the power generation efficiency has increased by about 3% compared with before, and the maintenance cost of the energy storage system has decreased by nearly 5%. More importantly, through intelligent analysis of a large amount of data, the power station has achieved the optimal scheduling of power generation and energy storage, greatly improving energy utilization.

In the exploration of photovoltaic energy storage monitoring, ARMxy industrial computers have proved their value as a smart engine with their strength. It not only optimizes the existing operation and maintenance model, but also leads a technological innovation in green energy management. In the future, with the continuous iteration of technology and the expansion of application scenarios, ARMxy will continue to work with more industry partners to jointly open a new era of intelligent and efficient energy.

#ARM#arm computer#Edge Gateway#PV#Smart Power#Photovoltaic Power Generation#Energy Storage System#BLIIoT

0 notes

Text

Battery manufacturer, factory

#battery#batteries#import#energystorage#new energy#energy#energy storage system#energy storage solutions#energy storage market#solar energy#solar system#factory#made in china#for you

1 note

·

View note

Text

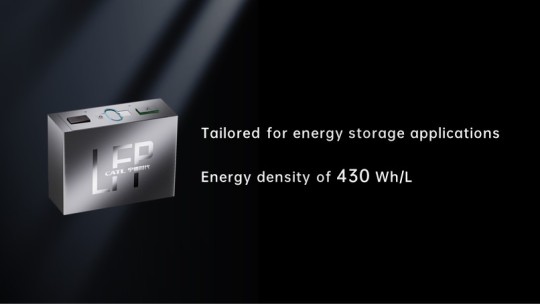

CATL Unveils TENER: Zero-Degradation Energy Storage Breakthrough

CATL Introduces TENER: World's First Five-Year Zero-Degradation Energy Storage System with 6.25MWh Capacity

On April 9th, CATL revealed TENER, the world's inaugural mass-producible energy storage system boasting zero degradation within its initial five years of operation, in Beijing, China. With comprehensive safety features, a five-year lifespan free of degradation, and a robust 6.25MWh capacity, TENER is poised to accelerate the widespread adoption of new energy storage technologies and propel the sector toward higher quality standards.

Pioneering Mass-Production of Zero-Degradation Systems

While maintaining capacity over the first five years of use marks a significant leap forward in battery lifespan extension, ensuring zero degradation of power is equally crucial for energy storage power plants seeking to align with the demands of emerging electric power systems. By harnessing biomimetic SEI (solid electrolyte interphase) and self-assembled electrolyte technologies, TENER has overcome barriers to lithium ion movement, achieving zero degradation in both power and capacity. This guarantees consistent auxiliary power consumption levels throughout its entire lifecycle, effectively creating an "ageless" energy storage solution.

Empowered by state-of-the-art technologies and advanced manufacturing capabilities, CATL has addressed challenges posed by highly reactive lithium metals in zero-degradation batteries, thereby mitigating thermal runaway risks stemming from oxidation reactions.

Unmatched Energy Density in a Compact Form: 20-foot Container housing 6.25MWh Capacity

TENER boasts an impressive 6.25MWh capacity within a TEU container, marking a 30% increase in energy density per unit area and a 20% reduction in overall station footprint. This innovative design enhances energy density and efficiency within limited spatial constraints.

CATL's cutting-edge cell technology underpins the system's outstanding performance. TENER is equipped with long-lasting, zero-degradation cells tailored for energy storage applications, achieving an impressive energy density of 430 Wh/L, a significant milestone for LFP batteries used in energy storage.

Dedicated Quality Management for Ultimate Safety

In pursuit of ultimate safety in energy storage, CATL has established an end-to-end quality management system encompassing technology development, proof testing, operation monitoring, and safety failure analysis. Tailored safety goals are set for different scenarios, with corresponding safety technologies developed to meet these objectives. To validate these technologies, CATL has created a validation platform simulating safety tests for energy storage systems across various power grid scenarios. Post-deployment, CATL continuously monitors system operation via AI-powered risk monitoring and intelligent early warning systems, calculating product failure rates throughout their lifecycle to refine safety design goals.

CATL has reduced cell failure rates to parts per billion levels for TENER, translating to lower operating costs and significantly enhanced internal rates of return when extended over the system's full lifecycle.

Energy storage plays a pivotal role in the green energy transition, and CATL is committed to delivering world-class solutions to customers globally. The introduction of TENER marks another milestone in CATL's ongoing commitment to energy transition. Looking ahead, CATL will continue its dedication to open innovation, collaborating with industry partners worldwide to lead the charge in innovation and advanced technology.

0 notes

Text

Background of the Rise of Residential Energy Storage Systems

The world attaches great importance to renewable energy and smart grids. With the promotion of initiatives such as the “Million Solar Roofs Plan” in the United States and the “Energy Transition” in Germany, the government provides high subsidies for the private use of photovoltaic power. As a result, households can achieve self - sufficiency in electricity and store surplus electricity, which is particularly prominent in the residential energy storage market in Germany and Europe. In today's era of rapid development of intelligence and information, the global electricity demand is growing explosively, bringing energy supply, pollution and consumption problems. Photovoltaic power generation is favored around the world. Thanks to policy support and the reduction of power generation costs of photovoltaic energy storage technology, residential photovoltaic power generation and energy storage systems have entered thousands of households. It can not only help households achieve self - sufficiency in electricity and reduce dependence on traditional power grids, but also store electricity for emergencies during peak periods of low power consumption.

Basic Structure and Working Mode of Residential Energy Storage System

Grid - connected Residential Energy Storage System Components: Solar cell array (the core, which converts solar energy into direct current, considering conversion efficiency, etc.), grid - connected inverter (converts direct current into alternating current, is compatible with household electrical equipment, and monitors and manages the operating status of the system), BMS management system (monitors the status of the battery pack and balances charge and discharge), battery pack (stores electrical energy, and its capacity, etc. affect energy storage capacity and service life. Commonly used batteries include lead - acid batteries, lithium - ion batteries, etc.), AC load (household electrical appliances). Working Modes: Mode 1: Photovoltaic provides energy storage and surplus electricity to the grid; Mode 2: Photovoltaic provides energy storage and electricity for some users; Mode 3: Photovoltaic only provides partial energy storage and does not transmit power to the public grid.

Off - grid Residential Energy Storage System Main Components: Solar array, photovoltaic inverter (has more functions in an off - grid system), BMS management system, battery bank, AC load. Working Modes: Mode 1 (sunny days): Photovoltaic provides energy storage and user electricity; Mode 2 (cloudy days): Photovoltaic and energy storage batteries provide users with electricity; Mode 3 (evening and rainy days): The energy storage battery provides users with electricity. Off - grid systems are suitable for areas where the grid is unstable or unavailable, and have higher requirements for battery bank capacity and management systems.

The Role of Battery Management System (BMS) in Residential Energy Storage Systems

The BMS is the “brain” and is of crucial importance. Main Functions: Data collection and monitoring (collect key parameters and current through real - time communication between the BCU and BMU modules), state estimation (calculate the state of charge of the battery and the remaining battery power based on the collected data), user interaction (display the real - time battery status, etc. through user interfaces such as touch screens). System Intelligent Management: Intelligent interaction (the BCU intelligently interacts with other system components through an independent CAN bus), safety control (the BMS implements secondary protection of charge and discharge through relays. When abnormal, the power is cut off to ensure the isolation of strong and weak electricity).

The Core of the Power Solution of the BMS of the Energy Storage System: Isolation Voltage Conversion

The key to the power solution design of the BMS is safe and efficient isolation voltage conversion. When the main control unit is based on a 24VDC system and the power requirement is less than 5W, a suitable power supply product can be used. For example, a power supply product can output 5VDC voltage to power the isolation module and low - dropout linear regulator (LDO). The LDO converts the 5VDC voltage to 3.3V to power the microcontroller (MCU). Multiple isolation modules in the system provide power for the CAN communication module, voltage and insulation detection circuit, and current detection circuit, and isolate the power circuit from the signal circuit and communication module to reduce electromagnetic interference and improve stability. Automotive - grade power supplies are widely used in vehicle BMS systems for vehicle battery management due to their excellent performance and stability.

In short, the residential energy storage system is an important link between the home and new energy. Its structure, working mode, battery management and power solution play a key role in the efficient utilization, stable supply and sustainable development of home energy. With the continuous advancement of technology and the promotion of applications, the residential energy storage system is expected to play a greater value in the future energy field.

1 note

·

View note

Text

#sustainable energy companies#energy storage system#green energy#renewable energy#solar energy#latest battery technologies

0 notes

Text

Residential Energy Storage Is A New Global Investment Option

As the global population grows and economies develop, energy demand continues to increase. However, fossil energy reserves are gradually decreasing, causing energy prices to rise. The global energy supply is insufficient and energy security issues are becoming increasingly prominent. In order to solve the problem of electricity consumption, more and more families choose to install residential energy storage systems. This is an energy storage system capable of charging from the grid or solar photovoltaic panels during off-peak periods. It then provides power to household appliances during grid peaks or outages.

Residential energy storage power supply

1. Able to smooth the grid load.

Reduce the pressure on the power grid and improve the stability and reliability of the power grid.

2. Ability to take advantage of time-of-use electricity prices.

Charging and storage when electricity prices are low, and providing power to residences when electricity prices are high.

3. Ability to respond to power grid emergencies.

Ensure uninterrupted household power consumption and avoid data loss, equipment damage, and life inconvenience.

4. It can improve the autonomy and flexibility of household electricity consumption.

You can adjust the power mode and power consumption at any time according to your own needs and preferences.

Household energy storage power supplies can not only store electricity from the grid, but also from solar photovoltaic panels. Among them, solar energy is the most common and convenient renewable energy source. As long as there is sunlight, the energy storage system can convert solar energy into electricity through photovoltaic panels. Finally, the inverter converts the DC power into AC power and supplies the residential energy storage power supply for charging.

Residential energy storage paired with solar photovoltaic panel charging

1. Be able to make full use of solar energy, a clean, pollution-free and unlimited energy source. Reduce dependence on fossil energy, reduce carbon emissions, and protect the environment.

2. Able to charge during the day and discharge at night to achieve day and night balance. Improve energy efficiency and reduce energy waste.

3. It can continue to provide power to households even if the power grid is outage when there is sunlight. Increase the safety and stability of household electricity.

4. Automatically adjust the charge and discharge mode of energy storage based on solar power generation and household electricity consumption. Realize intelligent management and save manpower and time.

To sum up, residential energy storage power supply is a system that can provide electricity security for households. It not only saves electricity costs, but also promotes the development of renewable energy and reduces environmental pollution.

Now, more and more families are choosing to use household energy storage power supplies with light charging functions. Especially those households with large electricity consumption and large residential areas. Paired with photovoltaic panels for greater energy self-sufficiency. Achieve lower electricity bills, more stable power supply quality, and a more environmentally friendly lifestyle.

1 note

·

View note

Text

Sustainable Strategies to Overcome Environmental Challenges in Lithium Mining

As the global demand for electric vehicles and renewable energy storage surges, lithium mining has become pivotal in powering the green energy revolution. However, this surge brings forth significant environmental challenges that necessitate immediate attention.

Environmental Impacts of Lithium Mining

Water Usage and Contamination

Lithium extraction is notably water-intensive, especially in arid regions. Traditional evaporation methods consume approximately 1.9 million liters of water per metric ton of lithium, primarily sourced from undrinkable brine. In contrast, chemical extraction methods require significant freshwater, potentially impacting local water supplies. This extensive water usage can lead to groundwater depletion and contamination, adversely affecting local communities and ecosystems.

Carbon Emissions

The energy-intensive nature of lithium extraction contributes to substantial greenhouse gas emissions. For instance, hard rock mining methods, such as those employed in Australia and China, involve open-pit mining and roasting using fossil fuels, leading to significant carbon emissions.

Land Degradation and Habitat Destruction

Open-pit mining practices result in significant land degradation, leading to the destruction of natural habitats and ecosystems. Removing vegetation can cause soil erosion and biodiversity loss, disrupting local wildlife and plant species.

Strategies for Sustainable Lithium Mining

To mitigate these environmental challenges, the following sustainable strategies can be implemented:

Adoption of Sustainable Mining Practices

Implementing sustainable mining practices can significantly reduce the environmental footprint of lithium extraction. This includes utilizing renewable energy sources for mining operations, adopting closed-loop water systems to minimize water usage, and employing advanced technologies to reduce emissions.

Development of Low-Carbon Extraction Methods

Innovations such as direct lithium extraction in deep geothermal plants offer a low-carbon alternative to traditional methods. This approach not only reduces greenhouse gas emissions but also provides a sustainable source of lithium, making geothermal plants cost-competitive in energy systems.

Recycling and Reuse of Lithium-Ion Batteries

Promoting the recycling and reuse of lithium-ion batteries can alleviate the demand for new lithium mining. Effective recycling processes can recover valuable materials, reducing the need for virgin resource extraction and minimizing environmental impacts.

Conclusion

While lithium mining is essential for advancing clean energy technologies, it is imperative to address its environmental challenges through sustainable practices. By adopting innovative extraction methods, implementing responsible mining practices, and promoting recycling, we can minimize the environmental impact and pave the way for a more sustainable future.

#DLE#Electric Vehicles#Energy Storage#Energy Storage System#Lithium Ion Batteries#Lithium Mining#Renewable Energy

0 notes

Text

How Solar Energy Storage Systems Improve Grid Stability

As the world moves toward cleaner and more sustainable energy solutions, the integration of renewable energy sources like solar power into the grid has become a key focus. Solar energy offers numerous benefits, including reducing carbon emissions and providing a renewable source of electricity. However, the intermittent nature of solar power—dependent on weather conditions and daylight hours—presents challenges to grid stability and reliability. This is where solar energy storage systems come into play. By storing excess solar energy generated during the day, these systems help stabilize the grid, ensuring a consistent and reliable power supply. In this article, we will explore how solar energy storage systems contribute to grid stability and enhance the overall efficiency of the energy system.

Understanding Solar Energy Storage Systems

A solar energy storage system typically consists of solar panels, a battery storage unit, and an inverter. Solar panels capture sunlight and convert it into electricity, which is either used immediately or stored in the battery storage unit for later use. When sunlight is abundant, solar energy is generated in excess, and this surplus power can be stored in batteries. During periods of low sunlight, such as at night or on cloudy days, the stored energy is discharged to meet demand.

These storage systems are particularly beneficial in areas with high solar penetration, where they help mitigate the challenges associated with variable solar output and ensure that power is available when needed most.

1. Balancing Supply and Demand

One of the primary challenges in maintaining grid stability is balancing supply with demand. Traditional energy sources, such as coal or natural gas, can be ramped up or down quickly to meet fluctuations in demand. However, solar power generation is subject to daily and seasonal variations, making it harder to predict and manage.

Solar energy storage systems help by acting as a buffer between supply and demand. During times of high solar generation, when supply exceeds demand, excess energy is stored in batteries. Later, when solar generation is low or demand spikes, the stored energy is released to the grid, helping to balance supply and demand. This ability to store and dispatch energy as needed reduces the reliance on fossil fuels and enhances the grid's flexibility.

2. Smoothening Solar Power Fluctuations

Solar energy generation is inherently variable due to factors like cloud cover, time of day, and seasonal changes. These fluctuations can cause rapid changes in the power supply, which, if not managed, can lead to grid instability or power quality issues, such as voltage sags or frequency fluctuations.

Solar energy storage systems smooth out these fluctuations by storing excess energy during periods of high generation and releasing it when solar output drops. By providing a consistent flow of energy, storage systems help maintain a stable voltage and frequency on the grid, preventing sudden disruptions and ensuring that the power supply remains reliable for consumers.

3. Providing Backup Power During Peak Demand

Grid operators often face challenges during peak demand periods, such as hot summer afternoons when air conditioning usage is high, or during extreme weather events. At these times, electricity demand can exceed supply, leading to potential blackouts or the need for expensive peaking power plants that rely on fossil fuels.

Solar energy storage systems help alleviate this problem by discharging stored solar energy during peak demand times, reducing the strain on the grid and minimizing the need for peaking plants. This not only helps prevent power outages but also reduces the environmental impact associated with relying on fossil fuel-based power generation during periods of high demand.

4. Supporting Grid Resilience and Reliability

Solar energy storage systems contribute to the resilience of the grid by providing backup power during grid outages or disruptions. In areas prone to natural disasters, such as hurricanes, wildfires, or snowstorms, grid stability can be compromised. By integrating solar energy storage with the grid, communities can maintain a reliable power supply even during emergencies.

For example, when the grid goes down due to a storm, homes and businesses with solar energy storage systems can continue to operate on stored solar power, ensuring critical services remain available. This enhances grid resilience and reduces the reliance on centralized power plants, making the grid less vulnerable to large-scale outages.

5. Enabling the Transition to a Decentralized Energy Grid

The integration of solar energy storage systems is a key enabler of the transition toward a decentralized, distributed energy grid. Traditionally, electricity generation has been centralized in large power plants, with energy flowing in one direction from the plant to consumers. However, as more renewable energy sources, such as solar power, are integrated into the grid, energy generation becomes more distributed.

Solar energy storage systems support this shift by allowing homes and businesses to generate and store their own energy, reducing their reliance on centralized power plants. This distributed energy model not only improves grid stability by reducing congestion and transmission losses but also empowers consumers to take control of their energy production and consumption.

6. Enhancing Grid Stability Through Demand Response Programs

In addition to storing and discharging energy, solar energy storage systems can participate in demand response programs. These programs incentivize consumers to reduce or shift their energy usage during peak demand times in exchange for lower electricity rates or other rewards. By participating in these programs, solar energy storage systems can help reduce the overall demand on the grid, further enhancing its stability.

For example, during periods of high demand, a utility company may request that consumers with solar storage systems release their stored energy back to the grid. This reduces the need for fossil fuel-based power generation and helps maintain a stable and balanced grid.

7. Reducing Grid Congestion and Transmission Losses

Grid congestion occurs when there is too much energy being generated in one area and not enough infrastructure to transport it to areas with higher demand. This can lead to inefficiencies and increased transmission losses. Solar energy storage systems help mitigate this problem by storing excess energy locally, reducing the need for long-distance transmission and alleviating congestion on the grid.

By integrating solar energy storage systems with local energy generation, utilities can optimize energy distribution, reduce transmission losses, and improve overall grid efficiency.

Conclusion

Solar energy storage systems play a vital role in improving grid stability by balancing supply and demand, smoothing out fluctuations in solar power, providing backup power during peak demand, and supporting the transition to a decentralized energy grid. As the world increasingly relies on renewable energy sources, solar energy storage systems will continue to be a crucial component in ensuring a stable, reliable, and resilient power supply. By enhancing grid stability and reducing dependence on fossil fuels, these systems not only support a cleaner energy future but also help create a more sustainable and reliable energy grid for generations to come.

0 notes

Text

Energy storage systems | Getsun Power

GetSun Power offers cutting-edge Energy storage system designed for maximum efficiency and reliability. Our products utilize advanced technology to store and manage energy, providing a sustainable and cost-effective solution for your power needs. With GetSun Power, you can optimize energy usage and reduce your carbon footprint while ensuring uninterrupted power supply. Choose innovation, choose GetSun Power.

0 notes