#End Suction Centrifugal Pump

Explore tagged Tumblr posts

Text

An end suction pump has axial suction and a 90-degree angle separating the suction and discharge. The End Suction Pump is one term for this kind of centrifugal pump. A centerline discharge is used in numerous designs to comply with local, national, or worldwide regulations. The two primary types of end-suction centrifugal pumps are long coupled and tightly coupled. The second kind is referred to be a Mon bloc style by some. The primary casing characteristic of larger end-suction pumps is frequently a twin volute, which lessens the stresses operating on the impeller, motor, shaft, and bearings.

It is the kind of pump that is most frequently utilized globally. Its construction and operation are really simple. Flows can be very low or very high, and pressures can range from moderate to high. Most of the time, the pump is one stage, although some manufacturers provide multi-stage models as well. Here, cast iron, bronze, and stainless steel are the most often utilized materials.

The centrifugal pump is a versatile pumping technology that is widely used in a wide range of daily tasks and businesses. End suction pumps are available from Flowmore in a range of materials to suit a range of applications.

Alternatives

Pumps that are mounted on frames or close-coupled are available. A close-coupled pump does not require field alignment because the impeller is attached directly onto the motor shaft.

Lined end-suction pumps are a robust choice for applications involving very abrasive liquids due to their structure. Such pumps are equipped with a long-lasting, replaceable liner that can withstand a lot of abuse.

0 notes

Text

#shakti pump#Submersible Pumps#Vertical Multistage#Centrifugal Pumps#Monoblock End Suction Pumps#Solar Pumps

0 notes

Text

0 notes

Text

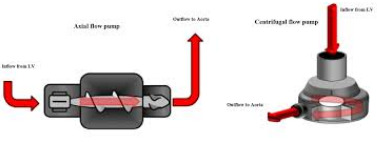

Centrifugal Blood Pumps Market Trends and Analysis: Comprehensive Overview of Market Size, Share, Growth

The global centrifugal blood pumps market size is expected to reach USD 136.1 million by 2030, registering a CAGR of 5.0% during the forecast period, according to a new report by Grand View Research, Inc. Demand for centrifugal blood pumps is increasing owing to its several advantages such as low maintenance costs, small in size, and less capital investment. Thus, such advantages offered by centrifugal blood pumps are estimated to fuel the market growth during the forecast period.

Centrifugal Blood Pumps Market Report Highlights

The electronic segment held the largest revenue share in 2023. High product efficacy is a major factor augmenting segment growth.

The hospitals segment is leading market growth due to the increasing number of patient visits and advanced infrastructure in hospitals as compared to other healthcare facilities.

North America held the largest revenue share in the market in 2023 and is predicted to maintain its dominance over the forecast period. This is attributable to strong per capita healthcare spending and favorable healthcare policies that have led to the introduction of cardiotomy suction devices.

For More Details or Sample Copy please visit link @: Centrifugal Blood Pumps Market Report

Growing clinical experience and cardiotomy suction devices have led to a significant increase in usage of mechanical centrifugal blood pumps and to the improvement of outcomes after short and long-term support. As the interventional methods in the cardiovascular field continue to develop and a majority of critically ill patients undergo treatment, the demand for mechanical centrifugal blood pumps is increasing drastically in this field.

Changing lifestyles and an increase in the prevalence of lifestyle-associated diseases are also expected to contribute to market growth. The increasing prevalence of diseases such as diabetes, obesity, and cardiovascular diseases coupled with the rising number of geriatric population are fueling the demand for cardiovascular procedures. Treatment of such diseases involves the use of cardiotomy suction devices, which, in turn, is expected to drive the market over the forecast period.

List of Key Players in the Centrifugal Blood Pumps Market

Medtronic

LivaNovaplc

Qura srl

Abbott Laboratories

Terumo Corporation

Braille Biomedica Ltd.

Getinge AB

3M

Baxter International

For Customized reports or Special Pricing please visit @: Centrifugal Blood Pumps Market Report

We have segmented the global centrifugal blood pumps market report based on type, end use, and region.

#CardiovascularDevices#MedicalTechnology#BloodPumps#HealthcareInnovation#CardiacCare#MedicalDevices#HeartHealth#CriticalCare#SurgicalSupport#CardioDevices#MedicalAdvancements#HealthcareTrends#PatientCare#CardiacSurgery#MedicalResearch

0 notes

Text

Lowara End Suction Pumps: Key Features and Benefits

Lowara, a leading brand in the pump industry, is renowned for its high-quality and reliable pumping solutions. Among its extensive range of products, the Lowara end suction pumps stand out for their efficiency, versatility, and robust design. Whether you're in the industrial, commercial, or agricultural sector, understanding the key features and benefits of these pumps can help you make an informed decision for your specific applications. In this blog, we will introduce you to the world of Lowara end suction pumps, exploring their standout features and the advantages they bring to various operations.

1. What Are End Suction Pumps?

Overview: End suction pumps are a type of centrifugal pump where the suction inlet is positioned at the front of the pump and the discharge outlet is located at the top. They are widely used for their simplicity, efficiency, and ability to handle a variety of fluids.

Applications: These pumps are commonly used in water supply, irrigation, heating and cooling systems, and industrial processes. Their versatility makes them an excellent choice for many applications.

2. Key Features of Lowara End Suction Pumps

High-Efficiency Design: Lowara end suction pumps are engineered for maximum efficiency, reducing energy consumption and operational costs. The advanced hydraulic design ensures smooth fluid flow, minimizing turbulence and maximizing performance.

Durable Construction: Built to withstand harsh operating conditions, Lowara end suction pumps are constructed from high-quality materials such as stainless steel and cast iron. This ensures long-term durability and resistance to corrosion and wear.

Versatility: Available in a range of sizes and configurations, Lowara end suction pumps can handle different flow rates and pressures, making them suitable for a wide range of applications, from small-scale commercial installations to large industrial operations.

Easy Maintenance: These pumps are designed with ease of maintenance in mind. The back pull-out design allows for easy access to internal components without disturbing the pipework, reducing downtime during maintenance and repairs.

Lowara Smart Pump Technology: Some models are equipped with Lowara’s Smart Pump technology, which includes integrated control systems for monitoring and optimizing pump performance. This feature helps in reducing energy consumption and improving operational efficiency.

3. Benefits of Using Lowara End Suction Pumps

Cost-Effective Operation: The high efficiency and low energy consumption of Lowara end suction pumps translate to significant cost savings over time. These pumps offer an excellent return on investment, particularly in energy-intensive applications.

Reliable Performance: With their robust construction and reliable design, Lowara end suction pumps deliver consistent performance, even in demanding environments. This reliability reduces the risk of downtime, ensuring smooth and continuous operation.

Flexibility in Application: The wide range of models and options available makes it easy to find a Lowara end suction pump that fits your specific needs. Whether you need a pump for clean water, aggressive chemicals, or high-temperature fluids, there is a suitable Lowara model available.

Environmentally Friendly: By reducing energy consumption and minimizing environmental impact, Lowara end suction pumps support sustainable operations. The efficient design and smart control systems help in reducing the carbon footprint of your pumping system.

Ease of Integration: Lowara end suction pumps are designed to integrate seamlessly into existing systems. Whether you are upgrading an old pump or installing a new one, these pumps can be easily adapted to your setup.

4. Popular Models in the Lowara End Suction Pump Range

Lowara e-SH Series: A stainless steel end suction pump ideal for applications requiring corrosion resistance, such as water treatment and food processing.

Lowara e-NSC Series: Designed for industrial and commercial applications, this series offers high efficiency and low lifecycle costs, making it a popular choice for large-scale operations.

Lowara FCE Series: Known for its compact design and easy maintenance, the FCE series is perfect for HVAC systems and other building services.

5. Case Study: Lowara End Suction Pumps in Action

Scenario: A commercial building needed an efficient and reliable pumping solution for its HVAC system. The existing pumps were outdated, consuming too much energy and requiring frequent maintenance.

Solution: The building management chose Lowara end suction pumps from the e-NSC Series for their high efficiency and low maintenance needs. The pumps were easily integrated into the existing system, reducing energy consumption and improving overall system performance.

Outcome: The new Lowara pumps resulted in a 20% reduction in energy costs and significantly fewer maintenance issues, leading to lower operating expenses and increased system reliability.

Lowara end suction pumps offer a blend of efficiency, durability, and versatility that makes them a top choice for various applications. Whether you need a pump for industrial processes, commercial buildings, or water supply systems, Lowara’s end suction pumps provide a reliable and cost-effective solution. With advanced features like Smart Pump technology and robust construction, these pumps ensure long-term performance and energy savings, making them an excellent investment for any operation.For more info contact Lowara Pump Supplier in UAE or call us at +971 4 2522966.

#lowara pumps uae#lowara pump dealer in dubai#lowara pump distributors#lowara pumps#lowara pump suppliers#lowara pump supplier in uae

0 notes

Text

Global Top 15 Companies Accounted for 58% of total Boiler Feedwater Pump market (QYResearch, 2021)

A boiler feedwater pump is a specific type of pump used to pump feedwater into a steam boiler. The water may be freshly supplied or returning condensate produced as a result of the condensation of the steam produced by the boiler. These pumps are normally high pressure units that take suction from a condensate return system and can be of the centrifugal pump type or positive displacement type.

According to the new market research report “Global Boiler Feedwater Pump Market Report 2023-2029”, published by QYResearch, the global Boiler Feedwater Pump market size is projected to reach USD 0.88 billion by 2029, at a CAGR of 4.6% during the forecast period.

Figure. Global Boiler Feedwater Pump Market Size (US$ Million), 2018-2029

Figure. Global Boiler Feedwater Pump Top 15 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Boiler Feedwater Pump include KSB, Grundfos, Flowserve Corporation, Ebara Corporation, TORISHIMA, Sulzer, DESMI, MTH Pumps, SanChang Pump, Speck, etc. In 2021, the global top 10 players had a share approximately 58.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

China Supplier POPPET TYPE SOLENOID VALVE GS020600V for steam turbine

"China Supplier POPPET TYPE SOLENOID VALVE GS020600V for steam turbine Deyang YOYIK have power plant professional accessories, non-standard pieces, to spare parts for processing. Only need to figure the number of other companies need drawings and drawings number. If you have any questions or concerns, please contact us. YOYIK has a good talent pool, the company is developing, you need to support, in order to witness its growth.

Yoyik can offer many spare parts for power plants as below:

DF-POPPET TYPE SOLENOID VALVE GS020600V-DF

Isolation valve F3DG5S2-062A-220DC60-DFZK rotary vacuum pump P-545 centrifugal pump types DFB80-50-20 OPC solenoid valve Z2804076 piston vacuum pump PVH74QIC-RSM-1S-1X-C25-31 oil pump cost 16G2AT-HMP(25)-DK025-1400 wet solenoid directional valve 4WE10D3X/CG220NZ4 multi stage centrifugal pump DFBII100-80-230 Globe valve J961H-25 end suction centrifugal pump DFB125-80-250-03 O-RING φ140/φ133.4 Xφ3.5 oil transfer gear pump DLZB820-R65-3 axial piston pumps PVH74(QI)C-RM-10-C14 BLADDER NXQ-AB-100/10 mechanical seal pump 109-20SIC/SIC mechanical seal pump BGM37G/50R-G9 vacuum cleaner P-1753 Low pressure oil pump SDV10-1P7P twin screw pump DLZB820-R64A-12 O-ring C8689067 industrial centrifugal pump DFB100-65-260 piston pumps PVH74RO1A-RSM-1S-10-C25-3 Elastomer W096317-VTN piston hydraulic pump A10VS071DRS/32R-VPB22U99 vane pump parts F3.SV.20.4.1.A stator cooling water pump coupling cushion 65-250B coil 300AA00309A 110VDC mechanical seal BKM79.4143B piston pumps PVH74QIC-RSM-IS-10-C25-31 stainless steel Throttle valve (flange) 50BJ-1.6P with reverse flange screw pump stainless KF80KZ/15F4 hydraulic vane pump F3-V10-1S4S-1B20 stainless steel globe valve (flange) 100FJ-1.6PA2 solenoid valve 4WE6Y6X/EG220NZ4/B08V Dome valve insert seal DN200, P/N. P5524C-01 Braking Magnet DF22025 POPPET TYPE SOLENOID VALVE GS020600V

300MW turbine DC Emergency pump impeller 70YB-45 solenoid valve 4WE10Y33/CG24N9K4 pressure hose S100-AC-AC-0020 pressure hose SMS-12/15-1219-C roots vacuum pump P-540 electric pump for lubrication 2CY-29/3.3 pressure hose S110-AC-AL-0050 hydraulic oil 300S90B vickers vane pump F3-SV10 copper sleeve P-1825 electric motor centrifugal water pump YCZ50-250A solenoid valve D1VW20BV-750*B510 centrifugal pump types DFB80-80-220-03 flexible coupling HSNS210-40A vacuum pump 220v MO1225OBGCC15A pump mechanical seal 8b1d pressure hose SMS-12/20-305mm-B servo valve 072K4160 servo valve HY-SFF8.05 centrifugal pump suction IS80-50-200 pump mechanical seal G50 AC explosion-proof motor YB2-100L1-4/2.2KW/380V/1420r/min HYDROGEN DRYER COMPRESSOR 300FS1/2-F reciprocating piston pump PV2R3-94-RBAF1 hydraulic electric pump 200AY150 vane vacuum pump F3-V10-1S6S-1C-20 O-ring C8689543 pressure hose SMS-20-1524mm-B chemical pump centrifugal 65-250B mechanical seal for water pump BKM(FX)103055 vacuum hand pump P-1916 DDV valve D634-327C the diaphragm KS0125ZMAW16BQ13UNOER pressure hose SMS-15-305mm-C vacuum pump 2S-185A hydraulic pump piston PVH74ROIA-RSM-IS-10-C25-3 POPPET TYPE SOLENOID VALVE GS020600V

DFYLSYC-2024-7-15-A

"

0 notes

Text

JUAL POMPA KSB ETANORM ETN (COOLING WATER/HOT WATER)

POMPA KSB ETANORM ETN (COOLING WATER/HOT WATER) Pompa Etanorm ETN adalah jenis pompa centrifugal pumps merk KSB yang di khususkan untuk media Air dengan suhu normal dengan maksimal suhu 90 derajat. Pompa Etanorm ETN ialah pompa yang mempunyai elemen utama yakni berupa motor penggerak dengan sudu impeller yang berbutar dengan kecepatan tinggi. Prinsip kerjanya yakni mengubah energi mekanis alat penggerak menjadi energi kinetis fluida (kecepatan) kemudian fluida Oli Panas/Air Panas dengan suhu Tinggi di arahkan ke saluran buang dengan memakai tekanan (energi kinetis sebagian fluida Oli Panas/Air Panas diubah menjadi energi tekanan) dengan menggunakan impeller yang berputar di dalam casing. Casing tersebut dihubungkan dengan saluran hisap (suction) dan saluran tekan (discharge), untuk menjaga agar di dalam casing selalu terisi dengan cairan sehingga saluran hisap harus dilengkapi dengan katup kaki.

Pompa KSB Etanorm ETN Horizontal end suction sentrifugal pump, cocok untuk pasokan air umum, irigasi, pertamanan, sirkulasi air hangat, panas dan dingin, pengiriman air kondensat dan air umpan boiler dan aplikasi pemadaman kebakaran. Pump Size :25 to 150 mm Capacity :up to 660 m /hr. Head :up to 160 m Discharge press. :up to 16 bar Temperature :-30 to 140 C Speed :up to 2900 rpm

Aplikasi utama Pompa KSB ETANORM ETN

Pompa untuk menangani cairan bersih atau agresif yang bukan keduanya secara kimiawi maupun mekanis agresif terhadap bahan pompa. Sistem pasokan air Sirkuit pendingin Kolam renang Sistem pemadam kebakaran Sistem irigasi umum Sistem drainase Sistem pemanas Sistem pendingin udara Sistem irigasi semprot Cairan ditangani air laut Air payau Air minum Air panas Air layanan Air pemadam kebakaran air garam Agen pembersih Kondensat Minyak

Detail desain

Desain Pompa selubung Volute Instalasi horisontal Desain tarik belakang Tahap tunggal Dimensi dan peringkat ke EN 733 Persyaratan untuk Arahan 2009/125/EC casing pompa Casing volute yang terbelah secara radial Casing volute dengan kaki pompa yang dicor secara integral2) Cincin keausan selubung yang dapat diganti (opsional untuk selubung bahan C) Jenis impeler Impeller radial tertutup dengan baling-baling melengkung berlipat ganda Segel poros Segel poros Type Pompa Etanorm ETN - Pompa KSB ETANORM ETN 040-025-160 - Pompa KSB ETANORM ETN 040-025-200 - Pompa KSB ETANORM ETN 050-032-125 - Pompa KSB ETANORM ETN 050-032-160 - Pompa KSB ETANORM ETN 050-032-200 - Pompa KSB ETANORM ETN 050-032-250 - Pompa KSB ETANORM ETN 050-032-125 - Pompa KSB ETANORM ETN 050-032-160 - Pompa KSB ETANORM ETN 050-032-200 - Pompa KSB ETANORM ETN 050-032-250 - Pompa KSB ETANORM ETN 065-040-125 - Pompa KSB ETANORM ETN 065-040-160 - Pompa KSB ETANORM ETN 065-040-200 - Pompa KSB ETANORM ETN 065-040-250 - Pompa KSB ETANORM ETN 065-040-315 - Pompa KSB ETANORM ETN 065-050-125 - Pompa KSB ETANORM ETN 065-050-160 - Pompa KSB ETANORM ETN 065-050-200 - Pompa KSB ETANORM ETN 065-050-250 - Pompa KSB ETANORM ETN 065-050-315 - Pompa KSB ETANORM ETN 080-065-125 - Pompa KSB ETANORM ETN 080-065-160 - Pompa KSB ETANORM ETN 080-065-200 - Pompa KSB ETANORM ETN 080-065-250 - Pompa KSB ETANORM ETN 080-065-315 - Pompa KSB ETANORM ETN 100-080-160 - Pompa KSB ETANORM ETN 100-080-200 - Pompa KSB ETANORM ETN 100-080-250 - Pompa KSB ETANORM ETN 100-080-315 - Pompa KSB ETANORM ETN 100-080-400 - Pompa KSB ETANORM ETN 125-100-160 - Pompa KSB ETANORM ETN 125-100-200 - Pompa KSB ETANORM ETN 125-100-250 - Pompa KSB ETANORM ETN 125-100-315 - Pompa KSB ETANORM ETN 125-100-400 - Pompa KSB ETANORM ETN 150-125-200 - Pompa KSB ETANORM ETN 150-125-250 - Pompa KSB ETANORM ETN 150-125-315 - Pompa KSB ETANORM ETN 150-125-400 - Pompa KSB ETANORM ETN 200-150-200 - Pompa KSB ETANORM ETN 200-150-250 - Pompa KSB ETANORM ETN 200-150-315 - Pompa KSB ETANORM ETN 200-150-400

untuk menentukan Flow dan Head untuk Pompa media Air dapat menghubungi kami kembali. PT Indira Mitra Boiler Jln. LoveBird blok D19/21 RT12 RW005 Permata Sepatan,Pisangan jaya ,Sepatan, Kab. Tangerang, Banten-15520 ZAENAL ARIFIN Sales Engineer Phone : (021) 59375021 Mobile : 081385776935 Whatshap : 081385776935 Email : [email protected] Email : [email protected] Read the full article

0 notes

Text

Centrifugal Pumps: A Cornerstone in Fluid Handling

Centrifugal pumps are a staple in fluid handling applications, renowned for their efficiency, reliability, and versatility. These pumps are essential across various industries, providing the necessary force to move fluids through systems with ease. This blog delves into the features, benefits, and applications of centrifugal pumps, highlighting the high-quality solutions offered by Raah International.

What is a Centrifugal Pump?

A centrifugal pump is a type of rotodynamic pump that uses a rotating impeller to increase the velocity of a fluid. The fluid enters the pump near the rotating axis, is accelerated by the impeller, and exits through the discharge outlet. This process converts kinetic energy into hydrodynamic energy, resulting in a steady flow of liquid.

Key Features of Centrifugal Pumps

High Efficiency:

Centrifugal pumps are designed to handle large volumes of fluids efficiently, making them ideal for applications requiring high flow rates.

Simple Design:

The straightforward design with fewer moving parts reduces maintenance requirements and enhances reliability.

Versatility:

Suitable for a wide range of fluids, including water, chemicals, and slurries, allowing for broad application across various industries.

Durable Construction:

Constructed from robust materials that can withstand harsh operating conditions and corrosive environments.

Quiet Operation:

Typically operate with minimal noise, making them suitable for environments where noise reduction is crucial.

Types of Centrifugal Pumps

Single-Stage Centrifugal Pumps:

Features: Consist of a single impeller, ideal for applications requiring low to moderate pressure.

Applications: Commonly used in water supply systems, irrigation, and HVAC systems.

Multi-Stage Centrifugal Pumps:

Features: Multiple impellers arranged in series to increase pressure.

Applications: Suitable for high-pressure applications such as boiler feed, reverse osmosis, and high-rise building water supply.

Submersible Centrifugal Pumps:

Features: Designed to operate while fully submerged in the fluid being pumped.

Applications: Used in sewage treatment, flood control, and water wells.

End-Suction Centrifugal Pumps:

Features: Fluid enters the pump horizontally through the suction nozzle.

Applications: Widely used in industrial, commercial, and residential water systems.

Benefits of Using Centrifugal Pumps

Cost-Effective:

Typically have lower initial costs and are more economical to operate and maintain compared to other types of pumps.

Easy Installation:

Simple design and construction make them easy to install and integrate into existing systems.

Wide Range of Applications:

Capable of handling various types of fluids, including clean water, chemicals, and slurries, making them versatile for multiple industries.

Reliable Performance:

Known for their reliability and ability to provide continuous, consistent flow, crucial for critical applications.

Energy Efficiency:

Designed to operate efficiently, reducing energy consumption and operational costs.

Applications of Centrifugal Pumps

Water Supply and Distribution:

Essential for municipal water supply systems, irrigation, and residential water distribution.

Chemical Processing:

Used for transferring and circulating chemicals in processing plants, ensuring safe and efficient operation.

Oil and Gas Industry:

Employed in refining processes, transporting petroleum products, and managing wastewater.

HVAC Systems:

Integral to heating, ventilation, and air conditioning systems, providing efficient circulation of fluids.

Wastewater Treatment:

Used in sewage treatment plants for transporting and processing wastewater and sludge.

Raah International’s Centrifugal Pump Solutions

Raah International offers a comprehensive range of centrifugal pumps designed to meet the diverse needs of various industries. Their products are characterized by:

Advanced Technology: Incorporating the latest innovations to ensure superior performance, precision, and durability.

Robust Construction: Engineered for long-lasting reliability in demanding environments.

Custom Solutions: Providing tailored centrifugal pump solutions to meet specific operational requirements and industry standards.

For more detailed information on Raah International’s centrifugal pump offerings and to explore a range of products tailored to your specific needs, visit there Centrifugal Pump page.

0 notes

Text

Achema 24: ITT presents comprehensive range of pumps, valves and services

ITT will highlight pumping systems and valves from its industrial process brands, Goulds Pumps, Engineered Valves, Rheinhütte Pumpen and Bornemann. Featured products from Goulds Pumps include: - The 3410 Small Capacity Double Suction Pump, designed for a wide range of industrial, municipal and marine services. Benefits of the 3410’s design include long life, low maintenance, easy inspection, sealing flexibility and optimized parts interchangeability. - The 3700i Single-Stage, Overhung Process Pump for petroleum, petrochemical, boiler circulation and general industrial applications requiring high temperatures or pressures. Goulds Pumps, a leader in American Petroleum Institute (API) engineered pump package solutions, will also feature the Goulds 3700i API 610, a center-lined mounted process pump designed for optimum reliability that employs state-of-the-art mechanical design features for sustained reliability and performance. - The Model ICM, a metallic magnetic drive chemical process pump made of Ductile Iron, 316 Stainless Steel, Duplex SS, Alloy 20, Hastelloy and Titanium, designed for normal and demanding chemical process applications. ICM pumps reduce customer lifecycle cost by minimizing maintenance, operating and installation costs, offer a comprehensive range of materials and accessories to support a wide range of applications, integrate options to connect safety and monitoring devices, and feature standardized and simplified design for easy maintenance and minimal spare parts inventory requirements. Engineered Valves will spotlight: - The EnviZion Valve, which uses innovative, embedded technologies to improve process reliability, streamline installation and maintenance processes, and enhance production capacity for manufacturers. The design ensures constant sealing force to eliminate external leakage and features a breakthrough mount and turn configuration that enables installation and maintenance without tools or fastener re-torquing. This effectively reduces valve maintenance time by up to 90% and saves operators upwards of $78,000 per year in repair costs when compared to competitors. The design has gained a considerable reputation for resolving application challenges associated with common 4-bold valve designs. - The Integrated Sensing Platform (ISP) combines expert knowledge of valve design with cutting edge valve position feedback and network communications to monitor solution performance and alert to risks of disruption in EnviZion products and other hygienic diaphragm valves. The app-powered device was created to be compact and discrete, with network output options and can be automatically calibrated for operator convenience. Featured products from Rheinhütte Pumpen include: - The RKuV, a vertical centrifugal pump that was specially developed to handle aggressive media that are contaminated with solids or that crystallize out. The RKuV pump is insensitive to dry running and operation against closed slide valves because there is no sleeve bearing used in the machine. - The GVRN pump series, designed specifically for use in almost all sulphuric acid applications. Pumps are available in nine sizes to cover the widest range of difficult and sophisticated applications. - The RCNKu+ series of horizontal, single-stage, end-suction, top-discharge centrifugal pumps, standardized to EN 22858 and ISO 5199. The cost-effective, easy to service, reliable pumps are used for handling chemically aggressive and flammable liquids in chemical processing and environmental technology applications. Bornemann will display: - The new SLW Series pumps are designed for the chemical and petrochemical industries to meet the growing demand for hermetically sealed pumps. The Twin Screw Pumps conveying elements of the SLW Series not only convey the product, but also transmit the torque, due to their two-screw design forming a hermetically sealed chamber with the pump casing. -

The SLH5G pump The SLH-5G Twin Screw Pumps, rotary positive pumps that use screws to convey the product along the screw axis. The contact-free intermeshing screws and the housing form closed chambers, constantly moving product from suction to discharge. - The HC pump series, a rotating positive displacement pump, covers a wide range of performance in pressure, flow, temperature and viscosity of the conveyed products. Their advantages are operational safety, reliability and consistent performance, long life and low operating costs. Achema 2024 Hall 8, Booth J38 www.itt.com Read the full article

0 notes

Link

They are widely used in various industries for applications such as transferring liquids between tanks, boosting water pressure in buildings, and circulating cooling water in industrial processes.

The basic design of a centrifugal pump includes a housing, a rotating impeller, and an inlet and outlet for fluid. When the impeller rotates, it creates a centrifugal force that moves the fluid from the inlet to the outlet. As the fluid flows through the impeller, it gains kinetic energy and is forced out at a higher pressure than when it entered.

Centrifugal pumps are popular because they are efficient, reliable, and easy to install and maintain. They can handle a wide range of fluid viscosities and flow rates and can be configured in a variety of sizes and shapes to fit specific applications. However, they are not suitable for high-pressure applications and can experience cavitation if the inlet pressure is too low.

Types of Centrifugal Pumps and Their Application

There are several types of centrifugal pumps, each with their own unique design and applications. Here are some of the most common types:

End-suction pumps: These pumps have a single inlet and are mounted horizontally. They are commonly used in applications where the flow rate is high and the head is relatively low, such as in water supply systems.

0 notes

Text

FV Direct Type Centrifugal Pump

The pump body is all PVDF and FRPP resin injection molding,so the inlet and outlet pipe lines should have support or suspension structure, should not be supported only by the joint flanges. The inlet pipeline should not have more than 2pcs 90° elbow. The FP, FV type centrifugal pump shall be installed at the front end of the suction tube to ensure that the pump is filled with liquid before starting the pump.The suction nozzle or the bottom valve shall be installed with a strainer, or a strainer shall be installed at the inlet to prevent the sundries from being sucked into the pump and ensure that the pump can function properly.

0 notes

Text

Are you looking for Suction Pumps Manufacturer, Supplier And Exporters In India?

If you are looking for Suction Pumps at best price, Indian Trade Bird is a B2B portal where you can find Best Suction Pumps. manufacturer, Supplier and Exporter from Ahmedabad, Coimbatore, Ghaziabad, Karnal, New Delhi.

Vacuum and flow are the main physical principles underlying suction devices. An end Suction Pumps is a type of centrifugal pump that is designed with a suction inlet located at the end of the pump casing. Removing respiratory secretions when the patient is unable to.

For more details Click here : https://www.indiantradebird.com/

0 notes

Text

0 notes

Text

Meeting the Needs of a Growing Population: The Evolving Global Cardiac Assist Devices Market

The global cardiac assist device market is expected to rise significantly, reaching US$2.48 billion by 2033. With a consistent growth rate of 6.1% throughout the course of the projection period, the market is expected to attain a considerable growth trajectory and reach US$1.37 billion by 2023.

In an attempt to innovate in the cardiac assist device market, major players in the industry have increased their R&D spending. Less invasive implantation procedures are made possible by small centrifugal pumps, further enhancing patient comfort and reducing surgical risks. The producers’ efforts are concentrated on this.

The market for cardiac assist devices is not without challenges, despite its bright future. High costs and associated risks may limit market growth, especially when it comes to ventricular assist devices. The cost of these devices may be prohibitive for patients in developing countries, which would limit their adoption and accessibility. Medical practitioners recommend ventricular assist devices, but they also alert patients to potential risks such infections, suction events, and pump thrombus.

Preview Next-Level Insights Sample : https://www.futuremarketinsights.com/reports/sample/rep-gb-467

It will take continual research and development to improve device safety and reduce complications in order to address these issues. The industry for cardiac assist devices is anticipated to keep growing. Technological developments together with rising knowledge and use of less intrusive remedies should propel market expansion. The creation of individualized and customized equipment suited to each patient’s requirements enhances results and patient satisfaction.

Key Takeaways:

The cardiac assist devices industry is anticipated to expand at a rate of 6.4% from 2023 to 2033 in the United Kingdom.

In 2022, the market for cardiac assist devices in Germany held an 11.2% share globally.

Ventricular assist devices are likely to dominate the market by drug class, accounting for around 62.49% share in 2022.

The hospital pharmacies sub-segment, in terms of end-user, is predicted to maintain a value share of 79.8% in 2022.

The cardiac assist devices industry in India is forecasted to advance at a CAGR of 5.1% during the forecast period.

How is the Competitive Landscape in the Cardiac Assist Devices Industry Structured?

As per FMI’s analysis, continuous innovation and gradation in cardiac assist devices have led to intense competition among top market players.

Key players are focusing on new product launches and gaining approvals from regulatory bodies to stay in the competition. Nearly 75% of the global market share is accounted for by the top 7 players operating in the cardiac assist devices market.

Organizations are also adopting winning strategies such as collaborations and mergers among key players. These strategies are also adopted by regional players to gain a leading position in the industry.

Key Players Operating in the Market

Terumo Corporation

Medtronic PLC

Abbott Laboratories

Abiomed Inc.

Teleflex Incorporated

Maquet GmbH

BerlinHeart GmbH

Others

Developments in the Market:

In June 2021, Abbott Laboratories announced that the company can support the expanded use of a mechanical circulatory support device, HEARTMATE 3™ Heart Pump, for the effective treatment of heart failure.

In February 2021, CARMAT, the leading designer and developer of the world’s most advanced artificial heart, received approval from the United States of America Food and Drugs Administration (FDA) to use the new version of its artificial heart in the US Early Feasibility Study (EFS).

Market by Category:

By Product Type:

Ventricular Assist Devices (VAD)

Left Ventricular Assist Device (LVAD)

Right Ventricular Assist Device (RVAD)

Biventricular Assist Device (BIVAD)

External Ventricular Assist Devices

Intra-Aortic Balloon Pump

By Modality Type:

Transcutaneous

Implantable

By End User:

Hospital

Ambulatory Surgical Centers

By Region:

North America

Latin America

Western Europe

Eastern Europe

Asia Pacific Excluding Japan (APEJ)

Japan

The Middle East & Africa (MEA)

0 notes

Text

China Yoyik Globe valve A156.33.01.01 for Electric Company Is a spare part for power plants

"China Yoyik Globe valve A156.33.01.01 for Electric Company Is a spare part for power plants. Deyang YOYIK specializes in producing all kinds of generating units supporting the processing of power plants, power plants, metallurgical systems, chemical systems, color systems, steel mills, chemical fertilizer plants, colored copper and aluminum processing plants, coking plants, oxygen plants and other industrial and mining enterprises , Including: rolling mill, compressor, circulating compressor, air compressor, steam turbine, high pressure pump ice machine, ball mill, coal mill, motor and other bearings, cross head, slide and other products. YOYIK strict promises, timely supply, in order to sincerity, refinement, durability, and trustworthy for the quality policy, only low-profit, user satisfaction, welcomed the new and old customers come to our factory.

Yoyik can offer many spare parts for power plants as below:

DF-Globe valve A156.33.01.01-DF

stator cooling water pump coupling cushion 65-250A dc vane pump F3-V10-1S6S-1C-20 Rod end bearing SIB12F/K stainless steel globe valve (welded) J20F1.6P transfer pump vane F3-SDV10-1B7B-1A vickers vane pump F3V101S6S1C20 impeller pump IHF80-50-200 centrifugal water pump DFB80-80-240 SEAL KIT NXQ-A-10/20 LEH centrifugal pump suction DFB80-80-220-03 EH circulating oil pump F3-V10-1S6S vacuum cleaner 30-WS-32 globe valve J965Y-32 DN20 JB/T308 AST solenoid valve DF2051-1MPa pressure hose SMS-20/N1/4-2438mm-B solenoid valve RV5-10-S-0-35 vacuum pump parts 30-WS-32 seal kit YGM-233 servo valve MOOG761-003 ball valve RKH20S-445-DN16PN400 screw pump stainless ACF090N41RBP screw pump diagram NM031BY01L06B vaccum pump ACG070K7 NVBP EH oil pump F3-V10-IS6S-IC-20 centrifugal pumps SLQ-63 sealing ring HB4-56J8-156 AST/OPC solenoid valve 0508.919T0301.AW027 radial piston pump PVH131Q1C.RSF.10.C25 transfer pump fuel 80AY50X6 vacuum pump ac P-1931A screw pump diagram HSNH440-46 CV valve (solenoid valve) 4WE6Y60-SG24M9K4-V manual vacuum pump ROTARYPUMP NO.30-WS SEARIAL pressure hose S110-AC-FC-0040 globe valve 40FWJ1.6P O-type seal ring φ25*1.8 Globe valve A156.33.01.01

rotary piston pump PVH074R01AB10A250000002001AE010A pump screw HSNH210-46A vacuum pump P1825B hydraulic oil pumps 150LY-32-B vacuum pump valve spring P-540 vacuum pump oil P-540 sealing ring HB4-56J8-152 Electro hydraulic servo valve DEC21NF58N S22KDFB5VAMN solenoid valveJ-110VDC-DN10-DOF/20D/2Nsealing ring HB4-56J8-142 electric oil transfer pump SDH65-50-160 dc motor coupling PVH074R01AB10A2500000001E010A EH oil pump sealing set PVH098R01AD30A manual vacuum pump HSNH440Q2-46NZ pressure hose SMS-20-3048mm-B HP starting oil pump 100LY-215-2 hydraulic jack pump 125LY-31-6 Mechanical seal of seal oil recirculation pump HSNH280-43NZ piston vacuum pump MOOG0514 7005 37 piston pump parts PVH074R01AA10A250000002001AB piston pump PV29-2L-5D-C00 pump screw ACF-090N5-ITBP bladder 32L EHV-32-330/90 Directional control valve DG4V-32AL-MU-P7-60 centrifugal pump impeller YCZ65-250C vacuum pump oil 30-WS-COML rotary vacuum pump P-1762 radial piston pump hydraulic PVH141R13AF30A230000002001AB01A screw pump working NM063BT01L06V non-return valve M-SR20KE15-1X vacum pump air vacuum PVH74(QI)C-RM-IS-10-C14 transfer pump oil YW-32-160 solenoid valve 34EH-H6B-T axial piston variable pump 25MCY14-1B accumulator bladder NXQAB-10/31.5-2-A Circulating pump 26SH-28 600S42 Globe valve A156.33.01.01

DFYLSYC-2024-7-15-A

"

0 notes