#Electronic Ignition Module

Explore tagged Tumblr posts

Text

Mech Pregnancy and Protoform Development of Gestating Sparklings

Here is what I have compiled on Cybertronian "reproduction" from More Than Meets the Eye, specifically the Holiday Special and Volume 5:

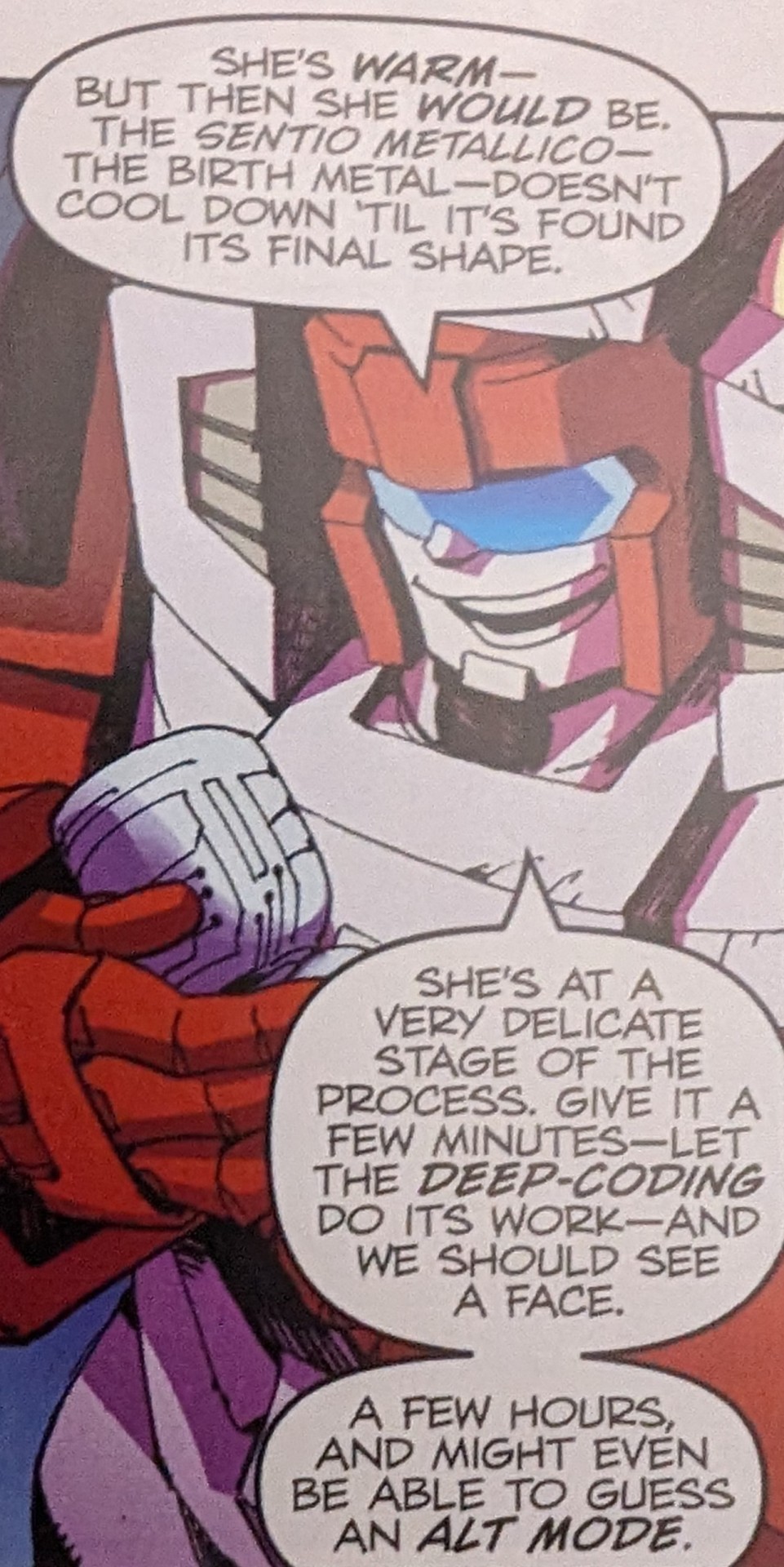

Holiday Special:

So this would be the protoform development for a forged sparkling and it lends support to that, if Cybertronians gave birth to their own Sparklings, then they would likely be an egg-like form (yes, I know it's not actually a sparkling, but can we all agree that Swerve is strangely well-informed on protoform development for forged Cybertronians?)

So what would slide out from the gestation tank has no discernable features yet and still needs hours if not days before the protoform resembles an adult Cybertronian, but I still don't have an answer for the size of this thing - at what point does it reach its full size? Cybertronians before the war went to academies, so what point does the protoform receive an education instead of having relevant information jammed into its brain module right before deployment like a MTO cold construct?

(More under cut)

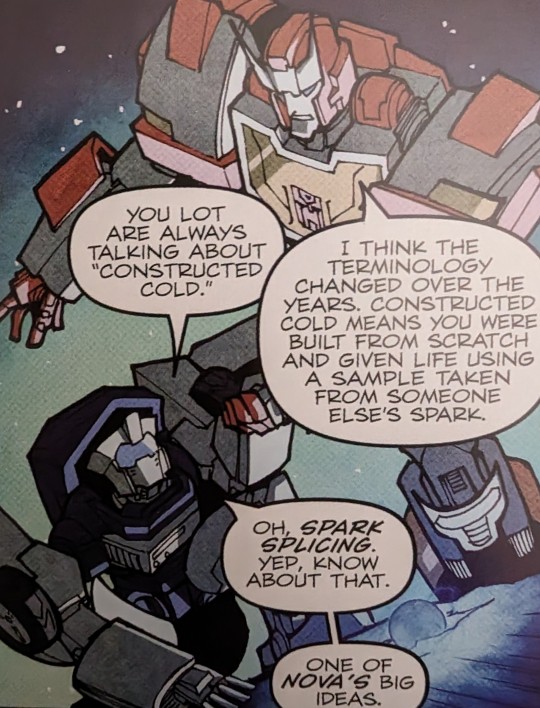

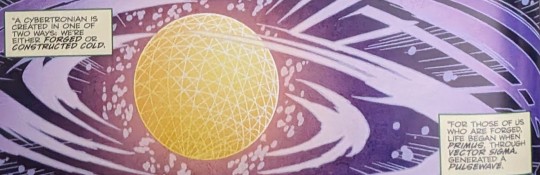

But, let's be honest, I am going out of order here. Let's go to Volume 5 where we encounter a hot spot of re-ignited sparks on the moon:

So this is being constructed cold.

And this is forged - as well as the official story for how cold constructed bots were made, which apparently differs from the truth. Here is the truth for how cold constructed sparks were actually formed:

So all cold constructs were made from the matrix - but what if they did come from igniting healthy sparks to make new ones?

What if you used the energy of two sparks to create an entirely new one and that sparkling attached itself to a parent spark for some time before it dropped to a gestation tank (this is common in fanfiction and I love it so much, it makes the most sense)? As these two orbs of immense power and life resonate with one another, creating waves of energy that can be interpreted as pleasurable for the interfacing bots, excess energy could gather itself into a separate orb that borrows the life code from both parents, becomes randomized, and this creates a new life code for a separate entity. It stays in the spark chamber for a period of time - I don't know, decoding or storing energy or something, I am very bad with electronics - before dropping down to an artificial gestation tank.

And this is where the valve/plug comes into play if you so desire because now we have the issue of, where is the spark going to go? It needs a protoform. It needs the materials to make a protoform. It also needs liquids.

Cybertronians seem to live off energon and anything you can make from energon, but there have been references and images in the comics of Cybertronians have oil as a waste product, so they need a separate compartment for oil away from their energon tank and they also are said to have (in fanfiction, at least): oral solvents, lubricant, transfluid, optic fluid, etc... All those will require their own compartments and they will all have either been diluted from the energon or will have an origin in a separate liquid that isn't mentioned. Let's keep in mind that they will also need some sort of oil for their hinges and their nanites for upkeep.

So I believe these gestation tanks are where the Sparklings develop their egg-like protoform with all these liquids that they themselves can't make yet, and I think they get what they need from nanite colonies as there is no umbilical cord (not unless you want the bots to have belly buttons). I like to think of them as nannyites - nanites that, once a protoform hits the gestation tank, have latent codes that becomes active and now have protoform-related tasks versus whatever tasks they did beforehand. The nannyites will likely take these resources from the carrying parent, everything from fluids to energon stores to living metal that the nannyites will adapt or make compatible for the sparkling.

So this carrying parent suddenly has fewer nanites colonies themselves, a thinner layer of living metal, and depleted storages of fluids.

Hear me out, hear me out: Valveplug interfacing helps the carrying parent because transfluid will contain necessary materials for the protoform.

I am going to take it a step further and say that it is that first shot of transfluid into the gestation tank during spark and valveplug interfacing creates input that electronically signals to the receiving parent to gather the excess energy from the spark play via centripetal force like a satellite and that force signals the excess energy to turn on life codes it recycled from both parents and create its own life code. That transfluid inside of the gestation tank also turns on those latent codes for the nannyites to get the compartment prepared. It's that first dose of necessary materials and every dose of transfluid after that is stored in the gestation tank for the protoform.

Which brings me to the idea that I have seen on AO3 where bots go into heat:

What if a mech goes into heat as a way to store transfluid from their partner?

I am largely talking out of my ass here because I don't know anything about how machines work, but I know there are a lot of hormones and signals and work that goes into human pregnancy.

The downside of this is that, if all bots were once forged and now they are, let's say, "birthed", then these constructs would be artificial: the gestation tank and the fertile centripetal force with its satellite sparkling and the interface array with its gestational passage and the nannyites and the transfluid. These would have to be constructed cold and surgically added, and you would have to create codes that turn on these cascading or stacking protocols (I don't know the correct computer term for when one event triggers another event triggers another event and so on) and you would have to manufacture filters and tanks and lines for the creation of gestational lubricant and transfluid.

This is just me rambling because I can't stop thinking about all this, but I am not ready to write a mechpreg story.

Please talk to me about Cybertronian reproduction, I am not normal about this.

#macaddam#transformers#mtmte#tf comics#more than meets the eye#mechpreg#valveplug#interface#Protoform#Protoform Development#cybertronian biology#HOW DO WE MAKE ROBOT BABIES

753 notes

·

View notes

Text

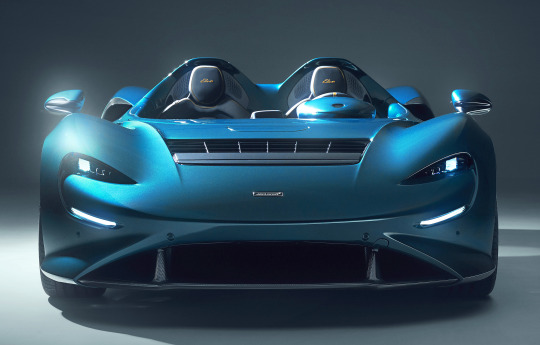

Novitec McLaren Elva, 2023. The German tuner has revealed their version of McLaren's roofless hypercar that has been boosted to produce 907hp thanks to its N-Tronic module with revised mapping for the fuel injection, ignition, and electronic boost pressure control. There are also new wheels and somehow they have managed to lower the car by 20mm

#Novitec#Novitec McLaren Elva#McLaren Elva#hypercar#tuned car#2023#open roof#custom car#900hp#mid-engine#V8#lowered

221 notes

·

View notes

Text

From Engine to Electronics: Proper Diagnostic Techniques for Resolving Maserati Problems

Maserati, the epitome of Italian luxury and performance, is renowned for its stylish design and high-performance capabilities. However, like any high-end vehicle, Maserati can encounter a range of issues, from engine troubles to electronic malfunctions. Proper diagnostics is crucial in maintaining the health and performance of these sophisticated machines. This article will guide you through the common problems Maserati face and the proper diagnostic techniques to resolve them.

Common Maserati Problems

1. Engine Issues

Maserati engines are marvels of engineering, but they can develop problems over time. Common engine issues include:

Misfires and Rough Idling: This can be caused by faulty spark plugs, ignition coils, or fuel injectors.

Overheating: Often due to a malfunctioning cooling system, such as a failed water pump or a clogged radiator.

Oil Leaks: These can originate from various seals and gaskets, leading to low oil levels and potential engine damage.

2. Transmission Problems

Maserati transmissions are designed for performance but can experience:

Slipping Gears: This could indicate worn-out clutch plates or issues with the transmission fluid.

Delayed Shifts: Often due to problems with the transmission control module or low fluid levels.

3. Electrical and Electronic Failures

Modern Maseratis are equipped with advanced electronics that can sometimes fail, including:

Dashboard Warning Lights: These can indicate issues ranging from simple sensor failures to serious engine problems.

Infotainment System Glitches: Problems with the touch screen, navigation, or audio system are not uncommon.

Diagnostic Techniques

1. OBD-II Scanner

The On-Board Diagnostics II (OBD-II) scanner is an essential tool for diagnosing Maserati problems. It can read error codes from the car's computer, providing insight into various issues.

How to Use: Connect the OBD-II scanner to the port located under the dashboard. Turn on the ignition and follow the scanner’s instructions to retrieve the error codes.

Interpreting Codes: Each code corresponds to a specific problem. For example, P0300 indicates a random/multiple cylinder misfire, while P0128 points to a coolant thermostat issue.

2. Visual Inspection

A thorough visual inspection can reveal obvious issues such as leaks, damaged components, or worn-out parts.

Engine Bay: Check for oil leaks, loose connections, and the condition of belts and hoses.

Undercarriage: Inspect for fluid leaks and damage to the exhaust system.

Electrical Connections: Look for corroded or loose battery terminals and wiring issues.

3. Multimeter Testing

A multimeter is useful for diagnosing electrical issues in a Maserati.

Battery Voltage: Measure the voltage across the battery terminals. A healthy battery should read around 12.6 volts when the car is off and around 14 volts when running.

Sensor Checks: Test various sensors, such as the oxygen sensor or mass airflow sensor, to ensure they are functioning correctly.

4. Compression Test

A compression test helps diagnose internal engine problems such as worn piston rings or valves.

Procedure: Remove the spark plugs and insert a compression gauge into each cylinder. Crank the engine and note the pressure readings. Low or uneven readings indicate internal engine issues.

5. Professional Diagnostic Tools

Maserati dealerships and specialized repair shops use advanced diagnostic tools that can access proprietary systems and provide more detailed information.

SD2/SD3 Diagnostic Systems: These are specialized tools used by Maserati technicians to diagnose and program vehicle systems accurately.

Diagnostic Software: Tools like Xentry or PIWIS can interface with Maserati's electronic systems for comprehensive diagnostics.

Addressing Common Issues

1. Engine Repairs

Misfires and Rough Idling: Replace faulty spark plugs, ignition coils, or fuel injectors. Regular maintenance and using high-quality fuel can prevent these issues.

Overheating: Ensure the cooling system is functioning correctly by checking the water pump, radiator, and thermostat. Flushing the coolant system periodically is also recommended.

Oil Leaks: Identify the source of the leak and replace the necessary seals or gaskets. Regularly check oil levels and change the oil according to the manufacturer's recommendations.

2. Transmission Solutions

Slipping Gears: Inspect and replace worn clutch plates and ensure the transmission fluid is at the correct level. Consider a fluid change if necessary.

Delayed Shifts: Diagnose and repair issues with the transmission control module or solenoids. Regular transmission servicing can prevent many of these problems.

3. Electrical Fixes

Dashboard Warning Lights: Use an OBD-II scanner to identify and address the underlying issue. Reset the warning lights after repairs are completed.

Infotainment System Glitches: Perform software updates and check for any loose connections or faulty components. In some cases, a complete system reset may be required.

Conclusion

Proper diagnostics are essential for maintaining the performance and reliability of your Maserati. By using the right tools and techniques, you can identify and resolve issues promptly, ensuring your luxury car continues to deliver the driving experience it was designed for. Regular maintenance and timely repairs are key to keeping your Maserati in top condition, from the engine to the sophisticated electronics.

#maserati car#maserati car diagnosis#maserati service center#maserati car maintenance#maserati car mechanic

2 notes

·

View notes

Text

Top Reasons Why the Check Engine Light Turns on in a Mini Cooper

The check engine light (CEL) in your Mini Cooper is a vital component of your vehicle's onboard diagnostics system. While its illumination might be alarming, it serves as a critical alert to potential issues that could affect your car's performance and longevity. Understanding the top reasons behind this warning can help you address the problem promptly and avoid costly repairs.

1. Oxygen Sensor Failure

The oxygen (O2) sensor measures the level of oxygen in the exhaust gases to ensure optimal fuel-air mixture for combustion. A failing O2 sensor can cause:

Poor fuel economy

Increased emissions

Engine misfires

Solution: Replace the faulty oxygen sensor promptly. Driving with a malfunctioning sensor can lead to further damage to the catalytic converter.

2. Loose or Damaged Gas Cap

One of the simplest yet common triggers for the check engine light is a loose, cracked, or damaged gas cap. This can lead to fuel vapor leakage, impacting your vehicle’s evaporative emissions system.

Solution: Check if the gas cap is securely tightened. If damaged, replace it with a compatible one to resolve the issue.

3. Catalytic Converter Problems

The catalytic converter reduces harmful emissions by converting exhaust gases into less toxic substances. Common issues include clogging or damage, often caused by neglected maintenance or prolonged driving with engine misfires.

Symptoms:

Decreased fuel efficiency

Sulfur-like odor (rotten egg smell)

Poor acceleration

Solution: Have the catalytic converter inspected and repaired or replaced by a professional mechanic.

4. Faulty Ignition Coils or Spark Plugs

Faulty ignition coils or worn-out spark plugs can lead to incomplete combustion, causing engine misfires and triggering the CEL.

Symptoms:

Rough idling

Engine hesitation or loss of power

Poor fuel economy

Solution: Replace spark plugs and ignition coils as per the manufacturer's recommendations or when they show signs of wear.

5. Mass Airflow Sensor (MAF) Issues

The mass airflow sensor monitors the amount of air entering the engine to adjust the fuel injection system accordingly. A faulty MAF sensor can result in:

Reduced fuel efficiency

Difficulty starting the car

Stalling during idle

Solution: Clean or replace the MAF sensor and check for associated air intake system issues.

6. Vacuum Leaks

Your Mini Cooper’s engine relies on a network of vacuum lines for various functions, such as operating the brake booster and controlling emissions. Cracks or loose connections in these lines can trigger the CEL.

Symptoms:

Rough idling

Hissing noise under the hood

Decreased engine performance

Solution: Inspect vacuum hoses and connections for damage and have them repaired or replaced as needed.

7. Malfunctioning Exhaust Gas Recirculation (EGR) System

The EGR system reduces nitrogen oxide emissions by recirculating a portion of the exhaust gases into the engine. A clogged EGR valve can affect engine performance and trigger the CEL.

Symptoms:

Increased emissions

Rough engine performance

Reduced fuel efficiency

Solution: Clean or replace the EGR valve and inspect the related components.

8. Faulty Sensors or Wiring Issues

Modern Mini Coopers rely on a network of sensors and electronic components to ensure proper functioning. Faulty sensors (such as the crankshaft position sensor) or damaged wiring can disrupt communication with the engine control module (ECM).

Solution: Use diagnostic tools to identify the problematic sensor or wiring issue and replace or repair it.

Diagnosing the Problem

When the check engine light comes on, it's essential to address the issue promptly. Here’s how to proceed:

Check for Obvious Issues: Inspect the gas cap, visible wires, and connections.

Scan for Trouble Codes: Use an OBD-II scanner to retrieve diagnostic trouble codes (DTCs) from the ECM.

Consult a Professional: If the issue isn’t clear, visit a certified mechanic experienced in Mini Cooper repairs for a thorough diagnosis.

Preventive Maintenance Tips

Schedule regular engine tune-ups and inspections.

Replace components like spark plugs, filters, and sensors at recommended intervals.

Use high-quality fuel and follow the manufacturer’s guidelines for oil changes and other services.

By understanding the common reasons for the check engine light in your Mini Cooper, you can take proactive steps to maintain its performance and reliability. Prompt attention to these issues not only extends your car’s lifespan but also ensures a smoother and more enjoyable driving experience.

#mini cooper#mini cooper check engine light#mini cooper service center#mini cooper maintenance#mini cooper mechanic#mini cooper services

0 notes

Text

White-Rodgers 50A66-743 Direct Replacement Integrate | HnKParts

The White-Rodgers 50A66-743 Direct Replacement Integrated Control is an electronic control module designed for use in HVAC and gas appliances. It integrates multiple functions into a single unit, including ignition, gas valve control, and flame sensing, ensuring reliable operation and safety in systems such as furnaces, boilers, and other gas-fired equipment. This direct replacement part simplifies repairs, offering compatibility with a wide range of systems. The 50A66-743 is built to provide dependable performance and easy installation, restoring efficient operation to your equipment.

0 notes

Text

Restoring the Porsche 911SC: Simplifying Ignition System Upgrades

Restoring the ignition system of a classic Porsche 911SC has been streamlined with the availability of the Perma-Tune 911SC623 kit. Designed for the 3.0-liter engine models, this kit addresses many of the challenges associated with finding compatible ignition components for older vehicles. The Perma-Tune solution provides a full set of components necessary for an effective restoration, including a module, coil, distributor wiring harness, distributor, cap, and rotor.

Complete Kit for Easy Installation

The Perma-Tune 911SC623 kit simplifies the installation process by offering a plug-and-play wiring harness and hardware that fits directly into the existing setup. This ease of installation eliminates the need for modifications or custom fitting, often a concern when dealing with vintage cars. The components are designed to align seamlessly with the original equipment, helping to maintain the integrity and aesthetic of the Porsche 911SC while ensuring operational efficiency.

Modern Functionality with Classic Appeal

A key feature of the Perma-Tune 911SC623 kit is its ability to combine modern electronics with a period-correct appearance. The parts are designed to mirror the original components, crucial for those aiming to meet concourse-level standards. At the same time, the modern electronics integrated into the components offer enhanced reliability and performance, which can be especially valuable for owners who plan to drive their vehicles regularly.

Enhancing the Restoration Experience

The Perma-Tune 911SC623 ignition restoration kit offers a comprehensive solution for enthusiasts and restorers of the Porsche 911SC. By providing all the necessary components in one package and ensuring compatibility with the original design, the kit removes much of the guesswork and effort traditionally associated with restoring classic car ignition systems, enabling a smoother and more reliable restoration process.

0 notes

Text

The Multifaceted World of JST Connector Production

The Multifaceted World of JST Connector Production

JST connectors are a cornerstone in the realm of electrical and electronic connectivity, playing a pivotal role in various industries. From automotive to consumer electronics, the production of JST connectors is a complex and multifaceted process that ensures high quality and reliability. This article delves into the different aspects of JST connector production, highlighting its significance and the meticulous processes involved.Get more news about jst connector production,you can vist our website!

1. Historical Perspective JST Mfg Co., established in 1957, was Japan’s first manufacturer and distributor of solderless terminals. Over the decades, JST has evolved into one of the top ten connector manufacturers globally, known for its innovation and excellence. The company’s commitment to continuous improvement and customer satisfaction has been the driving force behind its success.

2. Technological Innovation JST connectors are renowned for their cutting-edge technology and innovation. The company offers a product line of over 100,000 unique items, providing customers with the tools needed for endless innovation. From simple to complex, sealed, shielded, or even insert-molded connectors, JST’s products are designed to meet the diverse needs of various industries. The company’s focus on miniaturization and waterproofing has led to the development of advanced connectors like the WMCB and JWPS series.

3. Production Process The production of JST connectors involves several meticulous steps to ensure the highest quality and reliability. The process begins with the design and development phase, where engineers create prototypes and conduct mechanical, electrical, and environmental tests3. Once the design is finalized, the manufacturing process involves precision stamping, molding, and assembly. JST’s global network of production sites ensures timely delivery and cost efficiency.

4. Applications in Various Industries JST connectors are ubiquitous in the automotive industry, found in almost every part of a vehicle, from airbags and headlights to ignition coils and data control modules. In consumer electronics, JST connectors are used in devices like smartphones, laptops, and gaming consoles. The aerospace and telecommunications industries also rely on JST connectors for their high-performance and reliability.

5. Quality Assurance Quality is paramount in JST connector production. The company adheres to stringent quality control measures to ensure that each connector meets the highest standards. JST’s commitment to quality is evident in its RoHS2 compliance, which ensures that its products are environmentally friendly and safe for use. The company also invests in continuous improvement initiatives to enhance product performance and customer satisfaction.

6. Future Prospects As technology continues to advance, the demand for high-quality connectors will only increase. JST is well-positioned to meet this demand with its innovative products and commitment to excellence. The company’s focus on research and development will drive future growth and ensure that JST remains at the forefront of the connector industry.

Conclusion JST connector production is a testament to the company’s dedication to innovation, quality, and customer satisfaction. From its humble beginnings in 1957 to its current status as a global leader, JST has consistently pushed the boundaries of what is possible in the world of electrical and electronic connectivity. As industries continue to evolve, JST connectors will undoubtedly play a crucial role in shaping the future of technology.

0 notes

Text

Download Future Sound Of Ambient

In the world of music production, sound design is an art form that transcends mere creativity; it requires the right tools to bring your sonic visions to life. Introducing Future Sound Of Ambient, an essential plugin that opens the door to limitless possibilities in ambient sound creation. With this innovative tool, you can explore new dimensions of soundscapes that transport your listeners to ethereal realms.

Why Choose Future Sound Of Ambient?

Future Sound Of Ambient is meticulously crafted for producers, composers, and sound designers seeking to incorporate rich, immersive ambient sounds into their projects. Whether you are working on film scores, video games, or simply looking to enhance your music with atmospheric textures, this plugin is your go-to resource.

1. Versatile Sound Library: With a diverse range of presets and sound textures, Future Sound Of Ambient caters to various genres and styles. From lush pads and ethereal drones to intricate soundscapes, you’ll find everything you need to craft the perfect ambient atmosphere. The expansive library is designed to spark inspiration and ignite your creativity.

2. User-Friendly Interface: Designed with both beginners and professionals in mind, the intuitive interface of Future Sound Of Ambient allows for seamless navigation and quick access to all essential features. With its visually appealing layout, you can easily manipulate sounds, layer effects, and fine-tune your creations without the steep learning curve.

3. Advanced Modulation Options: Unlock the potential of your sound design with advanced modulation capabilities. Future Sound Of Ambient allows you to apply various modulation sources, giving you the freedom to create dynamic, evolving soundscapes that breathe life into your music. This level of control ensures that every sound you create is unique and tailored to your artistic vision.

4. High-Quality Audio Engine: Quality is paramount in audio production, and Future Sound Of Ambient delivers. Its high-resolution audio engine ensures that every sound you generate maintains clarity and richness, allowing your compositions to shine in any context. Whether you’re mixing for a club or a cinematic release, your sounds will resonate with unparalleled depth.

5. Seamless Integration: Compatible with major DAWs such as Ableton Live, Logic Pro, FL Studio, and more, Future Sound Of Ambient integrates effortlessly into your existing workflow. This compatibility ensures that you can start creating without any disruptions, allowing you to focus on what truly matters—your music.

Applications of Future Sound Of Ambient

Future Sound Of Ambient is not just a tool; it’s an essential partner in your creative process. Here are a few ways you can utilize this powerful plugin:

Film Scoring: Create haunting soundscapes that enhance the emotional depth of your scenes. The plugin’s ambient textures and atmospheric sounds are perfect for setting the mood in films and documentaries.

Game Development: Enhance the immersive experience of your video games with dynamic audio that responds to player actions. The rich sound library can help you design soundscapes that pull players into the game world.

Music Production: Incorporate ambient sounds into your tracks to add layers of depth and richness. Whether you’re producing electronic music, pop, or experimental genres, this plugin provides the perfect sonic palette.

Getting Started with Future Sound Of Ambient

Downloading and installing Future Sound Of Ambient is a straightforward process. Simply visit the product link below, complete your purchase, and follow the installation instructions. Once installed, you can immediately start exploring the extensive library and begin creating stunning ambient tracks.

Download Future Sound Of Ambient Now!

Join a Community of Creators

When you invest in Future Sound Of Ambient, you’re not just acquiring a plugin; you’re joining a community of like-minded artists who are passionate about pushing the boundaries of sound design. Engage with other users, share your creations, and gain inspiration from a collective of creators eager to explore new horizons.

Conclusion

In conclusion, Future Sound Of Ambient is more than just a plugin; it’s a gateway to an expansive world of sound. Its versatility, user-friendly design, and high-quality audio make it an indispensable tool for anyone serious about sound design. Don’t miss out on the opportunity to elevate your audio experience—download Future Sound Of Ambient today and transform your music into an unforgettable auditory journey.

#AmbientMusic#SoundDesign#MusicProduction#FilmScoring#GameDevelopment#AudioProduction#FutureSound#VSTPlugin#MusicProducer#SoundLibrary#AmbientSoundscapes#ElectronicMusic#CreativeProcess#DAW#HighQualityAudio#ProducerLife#Soundscape#AmbientTextures#InnovativeMusic#SonicExploration

0 notes

Text

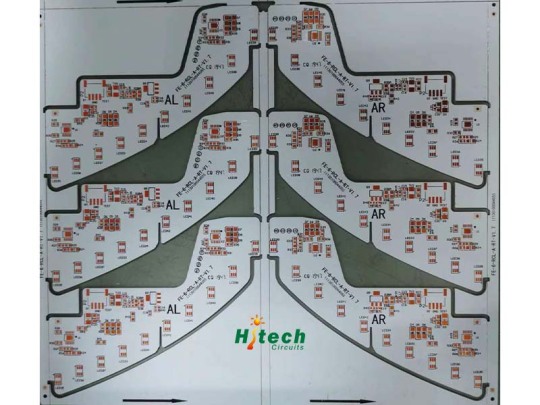

Main usages and applications of aluminium PCB board:

Audio devices: input, output amplifiers, balanced amplifiers, audio amplifier, preamplifier, power amplifier etc.

Power Supply: switching regulator, DC / AC converter, SW regulator .

Telecommunications electronic equipment: high-frequency electric amplifiers, filtering appliance, transmitter circuit etc .

Office automation equipment: electric motor, drivers etc .

Automotive: electronic regulator, ignition, power controllers etc .

Computer: CPU board, floppy drive, power device etc .

Power Modules: converter, solid-state relay, power rectifier bridges etc .

Lamps Lighting: with the promotion of energy-saving lamps, Aluminum base PCB , are widely used on LED lights.

0 notes

Text

One-Stop Printed Circuit Board Fab & Assembly Solutions for Automotive Industry

Automotive PCB Assembly Manufacturing Services

Automotive PCB Assembly Manufacturing Services

What is Automotive PCB?

Automotive circuit boards include central control circuit boards, ignition control circuit boards, power amplifier circuit boards, audio-visual media player boards, etc. according to their function and region. Due to brand manufacturers, electronic buses, etc., many circuit modules and backplanes do not have a unified standard name.

With the increasing demand of consumers for the functionality, safety, comfort, and entertainment of automobiles, especially for autonomous driving, the proportion of hybrid electric vehicles and pure electric vehicles in new energy vehicles has also increased by a considerable amount. The demand for PCB circuit board products for new energy vehicles has also increased.

What Types of PCBs are Found in Automotive Electronics?

Electric vehicles have consistent, essential, and innovative requirements. Today, Tesla is leading the wave of innovation. However, innovations in electric vehicle manufacturing and design require durable, reliable, and rugged PCB applications. Therefore, this is difficult to do without professiopnal automotive PCB manufacturers. High-performance automotive PCB requirements can significantly withstand harsh driving conditions and could be a catalyst for innovation in the growing new energy drive systems.

Electric vehicle PCB demand mainly comes from powertrain-related equipment (vehicles, battery management systems (BMS), voltage conversion systems (DC-DC, inverters, etc.), and other high and low voltage devices). In addition, mmWave radar is an important sensing device for realizing intelligent and autonomous driving and has obvious advantages compared with other sensors.

High power copper plated PCB is one of the most widely good to use PCB applications in emerging industries. Flexible PCBs, HDI PCBs, and LED PCBs are good to use in AC/DC power converters, audio and video, digital displays, braking systems, automatic dimming, electronic mirror controls, automotive lighting, engine timing systems, and remote diagnostic systems.

Common Uses of PCBs in Automobiles

Circuit boards commonly found in automobiles are ones utilized for safety features. These are the boards that also require the utmost in reliability.

In particular, the circuit used for airbag deployment rate / crash sensors are invaluable in dissipating static electricity and triggering the airbag's deployment at the exact moment when it’s needed.

Other critical safety features often requiring high-reliability PCBs include anti-lock brake systems and sensors that would trigger such features.

More vehicle functions powered by boards include power converters, fluid monitors, engine timing, LED lighting, power distribution systems, on-board and remote diagnostics, security systems, and other sensors for non-critical situations (gas, tire pressure, and so on).

Audio/video equipment, touchscreens, and GPS systems are found in most modern automobiles and make use of boards to connect all the electrical components.

Automotive PCB Technologies

Our automotive customers select us for our expertise in advanced technologies. Technologies we have the capability to provide include the list below, as single-sided, double-sided, and multi-layer boards.

Metal Core PCBs

Metal core PCBs are good to use in circuits where a lot of heat appears. Similarly, heat needs to dissipate quickly so as not to damage components. During the operation of the circuit board, heat comes due to some electronic components.

The purpose of metal is to transfer heat from critical circuit board components to less important areas, such as the backing of a metal heat sink or the metal core. Therefore, these PCBs are easy to thermally manage.

Heavy Copper PCBs

When printed circuit boards were first put into practical use, the electrolytic copper foil was almost always good to use as a conductor material. The technique of forming metal by electroplating is electroforming, or electroforming for short.

Since thin copper foil is easy to produce inexpensively by the electroforming process, electrolytic copper foil eventually became the standard conductor material for printed circuit boards. Furthermore, it was good to use in large quantities.

HDI Automotive PCB Manufacturers

HDI PCB technology is also known as 'microvia', and sometimes as 'sequential build-up' or simply 'build-up' technology. We refer to it as HDI, following the approach of the IPC standard that defined it.

It come on on the use of via holes less than 150µm (0.006in) in diameter that can go to adjacent layers of a PCB without having to go through all layers, smaller then are easy to drill mechanically. It is commonly called a "microvia" and can be buried (buried microvia) or sealed (blind microvia).

Microvias come on by laser-drilling and through-plating vias between each pair of adjacent copper layers before they are glued together to make the finished PCB. When the end result is a via hole that only connects between internal copper layers, it is a buried microvia.

Rigid PCBs

FR4 rigid PCBs offer no flexibility and are often used for video screens and rear-view cameras. They are not ideal for high vibration placements or tight form fitting spaces.

Flex PCBs

Because of their flexible & durable nature, these PCBs can be used in automobile corners and bends. They’re made of polyester films, polyimide, or plastic.

Rigid-Flex board

The combination of the rigid board and the flexible board can not only provide the support of the rigid board but also have the bending characteristics of the flexible board. Therefore, it can meet the requirements of three-dimensional assembly.

Flexible-rigid boards are the most complex connecting structures in EA. A simple GZHP has one rigid and one flexible layer. Complex GBPs can have 20 or more connecting sets of oneway and two-way GBPs between rigid external PBs.

The creation of GPP and GZHP is due to the need to miniaturize EA; the disproportion between the volume and mass of ERP (unpackaged and surface-mounted components) placed on rigid PCBs and the volume and mass of rigid PCBs.

Ceramic Substrate Board

Ceramic substrate board is best for manufacturing single- and double-sided printed circuit boards with vias such as aluminum oxide and nitride. Generally, the technology has advantages over traditional thin-film and thick-film technologies for manufacturing ceramic printed circuit boards.

Single and double-sided printed circuit boards made using this technology come by high resolution, high electrical conductivity, solderability, and weldability along the switching tracks.

The manufactured ceramic printed circuit boards can be good to use for the manufacture of hybrid electronic circuits, in the field of the auto industry, optoelectronics, and microwave technology.

Why Choose Hitechpcba as PCB Assembly Solutions for the Automotive Industry

Automotive PCB assembly is a specialized process that requires experience and knowledge in order to produce high-quality results. There are many steps involved in the assembly process, and each one must be performed with precision and care. If even one step is done incorrectly, it can affect the performance and reliability of the finished product. Here are some reasons why choosing our automotive PCB assembly services is the best decision for your business:

1. Our PCBs meet the minimum tolerance requirements for RoHS, REACH and Conflict Minerals. We also have a variety of green certification programs, including ENIG, HAL and HASL.

2. We understand the importance of quality and reliability in PCBs, and we work hard to ensure that our products meet or exceed industry standards.

3. We have extensive experience in this field, and our team is composed of skilled and experienced engineers. We understand the unique challenges and requirements that this market demands. We use the latest technologies and equipment to ensure that our automotive PCB assembly services are of the highest quality.

4. We use only the highest quality components and materials in our PCB assembly process. This ensures the durability and reliability of your products. Our PCBAs can withstand heavy current loads. They are able to do this because of their excellent thermal conductivity, which helps dissipate heat and protect the components around them.

5. We have a comprehensive quality assurance system in place that guarantees the accuracy and consistency of your products.

At our company, we take great pride in the fact that we source all of our materials from trusted and reliable suppliers. We believe that this is what sets us apart from our competitors, and it’s something that we’re really proud of. We understand that our customers rely on us to provide them with high-quality products, and by working with only the best suppliers, we can ensure that we always deliver on our promise.

0 notes

Text

Baso Gas Products Bgn891-1C-Pulse Furnace Replacement Mod | PartsHnC

The BASO Gas BGN891-1C Pulse Furnace Replacement module controls flame modulation and gas ignition, functioning as the electronic brain of your furnace to provide accurate temperature management.

0 notes

Text

Understanding and Fixing BMW Car Computer Issues: Must-Know Updates and Maintenance Tips

Modern BMW vehicles are marvels of engineering, integrating advanced computer systems that manage everything from engine performance to navigation and safety features. These onboard computers, also known as Electronic Control Units (ECUs), are essential for the smooth operation of your car. However, like any complex system, they can encounter issues that may affect your vehicle's performance, safety, and overall driving experience. This article explores common BMW car computer problems, how to fix them, and essential maintenance tips to keep your vehicle's software up to date.

The Role of Computers in BMW Vehicles

BMW vehicles rely on a network of ECUs, each responsible for controlling specific systems within the car. These include:

Engine Control Module (ECM): Manages engine functions, including fuel injection, ignition timing, and emissions control.

Transmission Control Module (TCM): Controls gear shifts, ensuring smooth and efficient transmission performance.

Body Control Module (BCM): Manages electrical systems like lighting, windows, and locks.

Infotainment System: Handles multimedia functions, navigation, and connectivity features.

Safety Systems: Includes airbags, ABS, and stability control systems, ensuring driver and passenger safety.

Given their integral role, any malfunction in these computer systems can lead to significant issues, ranging from minor inconveniences to serious safety concerns.

Common BMW Car Computer Problems

BMW car computers can develop issues for various reasons, including software bugs, hardware failures, or external factors like voltage fluctuations. Here are some of the most common problems:

Software Glitches and Bugs

Software glitches are a frequent cause of computer problems in BMW vehicles. These can manifest as erratic behavior in the infotainment system, unexpected warning lights, or unresponsive control modules. Often, these issues arise from outdated software or bugs in the current version.

Faulty Sensors

BMW vehicles rely on numerous sensors to monitor everything from engine temperature to wheel speed. If a sensor fails or sends incorrect data, it can cause the associated ECU to malfunction. For example, a faulty oxygen sensor can lead to poor fuel efficiency and increased emissions, while a malfunctioning ABS sensor may compromise braking performance.

Communication Errors

The various ECUs in a BMW communicate with each other through a network called the CAN bus (Controller Area Network). If there’s a communication error, it can cause multiple systems to fail or behave unpredictably. This might manifest as warning lights on the dashboard, malfunctioning electronics, or even engine stalling.

Battery and Power Issues

The ECUs in your BMW require a stable power supply to function correctly. If the battery is weak or there are issues with the alternator, it can cause the computers to behave erratically. Symptoms may include flickering lights, intermittent system failures, or even a complete shutdown of electronic systems.

Hardware Failures

Over time, the hardware components of ECUs can wear out or fail. This could be due to age, exposure to extreme temperatures, or moisture ingress. Hardware failures can lead to permanent loss of functionality in affected systems, requiring repair or replacement of the ECU.

Diagnosing BMW Car Computer Issues

Diagnosing computer problems in a BMW requires specialized equipment and knowledge. Here’s how you can approach the diagnosis:

Use an OBD-II Scanner

An OBD-II (On-Board Diagnostics) scanner is a vital tool for diagnosing computer-related issues. When a problem occurs, the ECU stores a fault code that can be read using a scanner. These codes provide valuable insight into the nature of the issue, allowing for targeted troubleshooting.

Check for Software Updates

BMW regularly releases software updates to fix bugs, improve system stability, and enhance performance. If you’re experiencing issues, checking for and installing any available updates should be one of the first steps. This can often resolve software-related glitches.

Inspect Sensors and Wiring

Faulty sensors or damaged wiring can cause a range of issues. A visual inspection of the sensors and wiring harnesses can help identify any obvious damage or disconnections. In some cases, further testing with a multimeter may be necessary to confirm the sensor’s functionality.

Battery and Alternator Testing

Ensure that your BMW’s battery and alternator are functioning correctly. A weak battery or faulty alternator can cause voltage drops, leading to erratic behavior in the vehicle’s computer systems. A simple battery test or alternator check can help rule out these issues.

Consult a Professional

If you’re unable to diagnose the issue yourself, or if the problem seems complex, it’s advisable to consult a BMW specialist. They have the expertise, tools, and access to BMW-specific diagnostic software to accurately diagnose and repair any computer-related problems.

Fixing BMW Car Computer Issues

Once the issue has been diagnosed, the next step is to address it. Here’s how to fix common BMW car computer problems:

Software Updates

Installing the latest software updates is often the easiest way to resolve glitches and bugs. BMW offers updates through their dealerships, and in some cases, they can be installed via a USB drive or over-the-air (OTA) if your vehicle supports it. Regular updates help ensure that your car’s software remains stable and secure.

Sensor Replacement

If a faulty sensor is identified, replacing it with a new one is essential. Genuine BMW parts are recommended to ensure compatibility and reliability. After replacement, the system may need to be recalibrated to ensure the new sensor functions correctly.

Repairing or Replacing Wiring

Damaged wiring should be repaired or replaced to restore proper communication between ECUs. This might involve soldering broken connections, replacing corroded wires, or installing new wiring harnesses.

Battery and Alternator Replacement

If the battery or alternator is found to be faulty, replacing it with a new unit will restore stable power to the vehicle’s computer systems. It’s essential to choose a battery with the correct specifications for your BMW model to avoid further issues.

ECU Repair or Replacement

In cases where the ECU itself has failed, repair or replacement may be necessary. Some specialized shops can repair ECUs, while in other cases, replacing the unit with a new or refurbished one may be required. After installation, the ECU will need to be programmed to match your vehicle’s specific configuration.

Maintenance Tips to Prevent BMW Car Computer Issues

Preventing computer-related issues in your BMW involves regular maintenance and care. Here are some tips to keep your vehicle’s systems running smoothly:

Regular Software Updates

Keep your BMW’s software up to date by regularly checking for updates. This not only prevents issues but also ensures your vehicle benefits from the latest features and improvements.

Routine Inspections

Regularly inspect the sensors, wiring, and battery to catch potential problems early. Addressing minor issues before they escalate can prevent major system failures.

Proper Battery Maintenance

Maintain your battery’s health by keeping it clean and ensuring the terminals are free from corrosion. If your vehicle is not driven frequently, consider using a battery maintainer to keep it charged.

Use Genuine BMW Parts

When replacing sensors, wiring, or ECUs, always use genuine BMW parts. These parts are designed to work seamlessly with your vehicle’s systems, ensuring reliability and longevity.

Professional Service

Regularly service your BMW at a reputable workshop or dealership. Professional technicians can identify and address issues before they become serious, keeping your car’s computer systems in optimal condition.

Conclusion

BMW vehicles are equipped with sophisticated computer systems that require proper care and attention to function correctly. By understanding common computer-related issues, knowing how to diagnose and fix them, and following essential maintenance tips, you can ensure your BMW continues to deliver the performance and driving experience you expect. Regular updates, timely repairs, and the use of genuine parts are key to keeping your vehicle’s systems running smoothly, allowing you to enjoy the luxury and innovation that BMW is known for.

0 notes

Text

Fenwal 35-665725-121-24V 15Secp.P.30Seci.P.4Sectfi | PartsHnC

The Fenwal 35-665725-121 is a multi-function ignition control module intended for gas-fired appliances such as furnaces and boilers. Operating on a 24V power supply, this component efficiently manages ignition timing. It runs on a 24-volt system and controls multiple steps of the ignition process to ensure safe and efficient functioning. The Fenwal 35-665725-121 improves heating system efficiency by adjusting ignition time and sequence, resulting in increased energy savings and lower operational expenses. Its design and steady performance improve HVAC equipment while decreasing downtime as well as servicing requirements. This electronic ignition control unit is critical in optimizing heating system performance, assuring comfort and reliability in both residential and commercial settings.

#partshnc#airconditionerparts#hvacparts#partshncbuzz#furnaceparts#Fenwal#FenwalParts#35-665725-121#IgnitionControlModule

0 notes

Text

Common Issues with Bosch Range Ignition Device and How to Fix Them

The ignition device in a Bosch range is essential for maintaining efficient and reliable operation by generating the spark required to light the gas and start the burner flames. Ignition devices may have a variety of problems that affect their functioning, just like any other mechanical or electrical component. Managing the functionality of Bosch range depends on understanding some typical issues and how to fix them. The ignition device plays an essential role in the operation of a gas range because it initiates the combustion process required for cooking. It's a stovetop burner or an oven burner, dependable ignition maintains that you may cook accurately and safely. Electronic ignition systems are common in contemporary Bosch ranges.

Common Issues with Bosch Range Ignition Devices

Ignition Clicking but Not Lighting

When the ignition mechanism clicks repeatedly but does not ignite the burner, it indicates a failure in the system.

Signs

The igniter is making audible clicking noises.

When rotating the burner knob, there is no flame or ignition.

Potential Reasons

A misaligned or filthy igniter.

Faulty spark module.

Resolutions

To make sure the igniter sparks properly, clean and realign it.

If the problem persists after cleaning, replace the spark module which is available at HnkParts.

Weak or No Spark

Improper lighting of the burner may occur due to a weak or nonexistent spark during ignition.

Signs

When the igniter is on, there may be a faint or nonexistent spark.

a challenge to get the burner started.

Potential Reasons

worn-out electrode or igniter.

problems with electricity, like a broken ignition switch.

Resolutions

Examine the electrode or igniter and replace it if it is worn out or broken.

To get the spark working properly again, inspect, fix, or replace the ignition switch.

Igniter Continuously Clicking

The igniter continues to click after the burner is ignited or turned off, indicating a chronic issue with the ignition system.

Signs

The igniter is making a constant clicking noise.

Regardless of the burner's state, clicking happens.

Potential Reasons

Debris or moisture causes electrical shorts.

Issues with the wiring or the ignition module.

Resolutions

To get rid of debris, clean and dry the igniter and the surrounding region.

Examine and swap out the ignition module, and fix any damaged wiring connections.

Delayed Ignition

When there is a lag between turning the burner knob and the burner lighting up, there may be an issue preventing the flame from starting right away.

Signs

There is a discernible lag in ignition following burner knob rotation.

Burner finally catches fire, but it takes a while.

Potential Reasons

unclean burners or clogged gas ports.

an igniter that has failed.

Resolutions

To guarantee clear gas flow, properly clean the burners and gas ports.

If the range igniter isn't producing sparks right away, replace it.

Uneven Flame or Flame Outages

Description

Uneven or frequent flame outages during burner operation can disturb cooking and signal problems with gas supply or ignition stability.

Signs

The flame wavers or varies in size.

The burner flame abruptly goes out while in use.

Potential Reasons

Boiled gas or problems with the gas supply.

Flame stability is impacted by a malfunctioning ignition device.

Resolutions

Clear any buildup or debris from the burner components to prevent obstructions in the passage of gas.

If the ignition device isn't producing a consistent spark, check it and replace it.

Diagnosing Bosch Range Ignition Issues

Visual Testing

In order to diagnose ignition problems, a comprehensive visual inspection is necessary

Procedure for Examining the Igniter

Visible Damage or Debris: Inspect the igniter or electrode for evidence of wear, corrosion, or buildup of debris.

Sync and Linkage: Make that the igniter is firmly attached to the burner's electrical harness and that it is positioned in relation to the burner.

Tests of Function

Spark Tests Being Performed:

Spark Intensity: To make sure the spark is robust and steady, light the igniter and watch the intensity of the spark.

Multiple Burners: To find any variations in spark behavior, test each burner separately.

Electrical component testing:

Check the continuity and appropriate voltage supply of electrical connections, such as switches and modules, using a multimeter.

Step-by-Step Repair Solutions

Cleaning the Ignition Device

Materials Required:

a gentle cloth or brush

a mild cleaning agent or detergent

Procedure for Cleaning:

Cut Off Power: To guarantee safety, disconnect the Bosch range from the power source.

Igniter cleaning: Use a soft brush to remove any debris from the igniter and its surroundings.

Check for Reliability: For persistent residue, use a mild detergent solution to get rid of it.

Dry Completely: Before reassembling and testing, let the igniter and its constituent parts dry entirely.

Replacing the Ignition Device

Replacement Process

Cut Gas Supply: To avoid unintentional gas leaks, cut off the range's gas supply.

Remove Old Igniter: Gently unplug the old electrode or igniter from the mounting bracket.

Install New Igniter: Reconnect the wiring and firmly fasten the replacement igniter in its designated location.

Test Ignition: After the range's power and gas supply have been restored, check that the burner ignition is operating properly by testing it.

Handling Electrical Problems

Finding Malfunctioning Parts: To identify malfunctioning switches, modules, or wire connections, use diagnostic equipment such as a multimeter.

Steps for Repair and Replacement: To improve ignition system performance, replace or repair faulty electrical parts in accordance with diagnostic results.

Preventive Maintenance Tips:

Normative Cleaning Procedures and Frequency:

Make sure the burner assemblies and igniter parts of the Bosch range are cleaned on a regular basis.

To prevent breaking delicate components, use non-abrasive cleaning solutions.

Typical Inspections

Checklist for Inspection:

Check the burner ports, electrodes, and igniter on a regular basis for wear or obstructions.

Inspect electrical connections for corrosion and tightness.

Expert Maintenance

Maintaining the safety and continuous cooking performance of Bosch range ignition systems requires effective troubleshooting and maintenance. Through comprehension of prevalent ignition problems and application of suitable remedies, consumers can enhance the performance of their ranges and avert expensive repairs. The longevity and efficiency of Bosch appliances are enhanced by routine cleaning, careful inspections, and prompt repairs, all of which lead to a seamless cooking experience.

#hnkparts#hnkbuzz#appliacepartsonline#generalelectric#whirlpool#homeappliances#samsung#refrigerator#dishwasher

0 notes

Text

Bakers Pride M2138X Ram Ignition Control (Module Only) | PartsFe

By incorporating electronic ignition control, allowing for precise and reliable ignition of the oven's burners. This feature enhances safety and eliminates the need for manual ignition. Includes a flame monitoring system that continuously assesses the presence and stability of the flame. In the absence of a stable flame, the module can shut off the gas supply, enhancing safety.

0 notes

Text

How Does The Range Rover 2.0 Engine Integrate With The Vehicle's Electronics?

The Range Rover 2.0 engine is renowned for its robust performance and advanced engineering. However, its excellence goes beyond the mechanical realm. The integration of this engine with the vehicle's electronic systems is a testament to modern automotive innovation. We explores the sophisticated interplay between the Range Rover 2.0 engines and the vehicle's electronics, shedding light on how this synergy enhances performance, safety, and user experience.

Advanced Engine Control Unit (ECU)

The Engine Control Unit (ECU) is the brain behind the Range Rover 2.0 engine's operations. This sophisticated computer manages various engine functions, including fuel injection, ignition timing, and air-fuel ratio. By continuously monitoring and adjusting these parameters, the ECU ensures optimal engine performance and efficiency. Moreover, the ECU communicates with other electronic systems in the vehicle, such as the transmission control unit, to synchronize operations and enhance drivability. The seamless integration of the ECU with the vehicle’s electronics is crucial for achieving the desired balance between power and efficiency.

Real-Time Diagnostics and Monitoring

The integration of the Range Rover 2.0 engine with the vehicle's electronics allows for real-time diagnostics and monitoring. Advanced sensors placed throughout the engine and other critical components constantly relay data to the ECU and other control modules. This data is used to monitor the health and performance of the engine, identifying any issues before they become serious problems. For instance, sensors can detect anomalies in temperature, pressure, or emissions, prompting the ECU to take corrective action or alert the driver via the dashboard. This proactive approach helps in maintaining the engine's longevity and reliability.

Enhanced Fuel Efficiency

The integration of the Range Rover 2.0 engine with electronic systems significantly enhances fuel efficiency. The ECU plays a vital role in this aspect by precisely controlling the fuel injection process. It adjusts the amount of fuel injected into the engine based on various factors such as engine load, speed, and temperature. Additionally, the ECU works in tandem with the vehicle’s stop-start system, automatically shutting down the engine when the vehicle is stationary and restarting it when the accelerator is pressed. This intelligent fuel management system reduces fuel consumption and emissions, contributing to a more eco-friendly driving experience.

Optimized Performance

Performance optimization is another key benefit of the integration between the Range Rover 2.0 engine and vehicle electronics. The ECU continuously adjusts various engine parameters to ensure peak performance under different driving conditions. For instance, during acceleration, the ECU increases the fuel supply and adjusts the ignition timing to deliver maximum power. Conversely, during cruising or deceleration, it reduces fuel consumption to enhance efficiency. This dynamic adjustment capability ensures that the engine performs optimally at all times, providing a smooth and responsive driving experience.

Advanced Safety Features

The integration of the Range Rover engine with vehicle electronics enhances safety features. The ECU interacts with various safety systems such as the Anti-lock Braking System (ABS), Electronic Stability Control (ESC), and traction control. For example, if the ECU detects a loss of traction, it can reduce engine power to prevent wheel spin and maintain vehicle stability. Additionally, the ECU can work with the adaptive cruise control system to automatically adjust the vehicle's speed based on traffic conditions. These advanced safety features help in preventing accidents and ensuring a safer driving experience.

Seamless Infotainment Integration

The Range Rover 2.0 engine’s integration with the vehicle’s electronics extends to the infotainment system as well. Modern Range Rovers are equipped with advanced infotainment systems that offer a wide range of features such as navigation, entertainment, and connectivity. The ECU communicates with the infotainment system to provide real-time data such as fuel efficiency, engine performance, and maintenance alerts. Additionally, the infotainment system can display this information in an easy-to-understand format, allowing drivers to stay informed and make better decisions while driving.

Intelligent Drive Modes

The integration of the Range Rover 2.0 engine with vehicle electronics enables intelligent drive modes. These drive modes, such as Eco, Comfort, and Sport, allow drivers to customize the vehicle’s performance based on their preferences and driving conditions. The ECU adjusts various engine and transmission parameters to optimize performance for each drive mode. For example, in Eco mode, the ECU focuses on maximizing fuel efficiency, while in Sport mode, it prioritizes performance and responsiveness. This flexibility enhances the driving experience by allowing drivers to tailor the vehicle's performance to their needs.

Predictive Maintenance

Predictive maintenance is a significant advantage of the Range Rover 2.0 engine’s integration with vehicle electronics. The ECU and other electronic control modules continuously monitor the engine's health and performance, identifying potential issues before they become serious problems. For instance, sensors can detect wear and tear on critical components such as the timing belt or spark plugs, prompting the ECU to alert the driver about the need for maintenance. This proactive approach helps in preventing unexpected breakdowns and costly repairs, ensuring that the engine remains in top condition.

Conclusion

The integration of the Range Rover 2.0 engine with the vehicle's electronics represents a significant advancement in automotive technology. This seamless interplay enhances various aspects of the driving experience, from performance and efficiency to safety and convenience. By leveraging advanced electronic systems, the Range Rover 2.0 engine delivers a driving experience that is not only powerful and efficient but also safe and enjoyable. As automotive technology continues to evolve, the integration between engines and electronics will play an increasingly important role in shaping the future of driving. Read the full article

#RangeRover2.0Engine#RangeRover2.0EnginePerformance#RangeRover2.0Engines#RangeRover2.0EnginesReliability#supplyandfitRangeRover2.0engine

0 notes