#Electric steam boiler

Explore tagged Tumblr posts

Text

The Benefits of Choosing an Electric Steam Boiler for Your Industry

An electric steam boiler is a reliable and efficient solution for modern industries seeking sustainable heating options. Unlike traditional boilers, electric steam boilers eliminate the need for fossil fuels, significantly reducing carbon emissions and enhancing environmental sustainability. These boilers are highly energy-efficient, converting nearly all electrical energy into usable steam, which lowers operational costs. With compact designs and easy installation, they save valuable floor space and adapt seamlessly to various industrial applications. Electric steam boilers also ensure precise temperature control, providing consistent performance for industries like food processing, pharmaceuticals, and manufacturing. Their low-maintenance design minimizes downtime, while their safe, emission-free operation aligns with stringent environmental standards.

Why Electric Steam Boilers Are Gaining Popularity in Modern Industries?

Electric steam boiler are rapidly becoming the preferred choice for industries worldwide. Their ability to deliver efficient, reliable steam without the need for fossil fuels is a major advantage. Unlike traditional boilers, electric models are compact, easier to install, and eliminate emissions, making them an environmentally friendly solution for heating and processing needs.

Energy Efficiency: A Key Advantage of Electric Steam Boilers

One of the biggest selling points of electric steam boilers is their unmatched energy efficiency. They operate with nearly 100% energy conversion, meaning minimal waste during the process. Industries looking to cut energy costs benefit significantly from this feature, especially in applications that demand consistent steam production over extended periods.

Electric Steam Boilers vs. Traditional Boilers: Which is Better?

Electric steam boilers outperform traditional boilers in several areas. They don’t require fuel storage or combustion, which reduces maintenance efforts and costs. Additionally, their clean operation aligns with global sustainability goals. While traditional boilers may be suitable for specific large-scale applications, electric steam boilers are ideal for businesses prioritizing safety, efficiency, and eco-friendliness.

Top Industrial Applications of Electric Steam Boilers

Electric steam boilers are versatile and cater to a wide range of industries. Food processing plants, pharmaceutical production facilities, and chemical manufacturing units rely on these boilers for precise steam generation. Additionally, laundry services, breweries, and small-scale manufacturers find them indispensable for their energy efficiency and consistent performance.

Environmental Benefits of Using Electric Steam Boilers

With growing concerns about climate change, electric steam boilers offer a greener alternative to traditional boilers. Their operation produces zero emissions, helping industries reduce their carbon footprint. For companies striving to meet environmental regulations, electric boilers are a step toward sustainability without compromising on performance.

Factors to Consider When Choosing an Electric Steam Boiler

Selecting the right electric steam boiler depends on several factors, including your industry’s specific steam requirements, the desired temperature range, and space availability. Efficiency ratings, ease of maintenance, and the reputation of the manufacturer are also important. Investing in a reliable boiler tailored to your needs ensures long-term operational success.

How Electric Steam Boilers Contribute to Operational Cost Savings?

Electric steam boilers provide significant cost savings over time. By eliminating the need for fuel storage and complex combustion systems, they reduce maintenance costs. Their energy-efficient operation lowers electricity bills, making them a cost-effective choice for industries aiming to optimize their heating and steam generation processes.

Conclusion

Electric steam boilers are transforming industrial heating with their efficiency, safety, and eco-friendly design. They offer unparalleled benefits, including reduced operational costs, energy efficiency, and compliance with environmental standards. Whether you operate in food processing, manufacturing, or other steam-reliant industries, electric steam boilers provide a reliable and sustainable solution. By investing in the right boiler, industries can enhance productivity while contributing to a greener future.

0 notes

Text

What is the Purpose of Electric Steam Boiler?

An Electric Steam Boiler is a device that converts electrical energy into heat to produce steam. Unlike traditional steam boilers that use fossil fuels such as coal, oil, or natural gas, electric steam boilers rely on electricity to heat water and generate steam. This steam can then be used for a variety of purposes, from heating and power generation to industrial processes.

Main Purposes and Applications of Electric Steam Boiler

Industrial and Commercial Heating

One of the primary purposes of electric steam boilers is to provide reliable and efficient heating for industrial and commercial applications. For instance, industries such as food processing, pharmaceuticals, and textiles often require precise temperature control and consistent steam output. Electric steam boilers can meet these demands with minimal maintenance and operational costs.

2. Power Generation

In some cases, electric steam boilers are used in power generation systems. They can produce steam to drive turbines, which in turn generate electricity. Although less common compared to traditional steam boilers fueled by fossil fuels, electric steam boilers can be a part of a sustainable power generation strategy, particularly in areas where renewable energy sources are plentiful.

3. Process Heating

Many industrial processes require steam for heating, sterilization, or other critical functions. Electric steam boilers provide a clean and efficient means to generate the required steam. For example, in the pharmaceutical industry, electric steam boilers ensure that the steam used in sterilization processes is free from contaminants.

4. Comfort Heating

Beyond industrial uses, electric steam boilers can also be employed in large residential or commercial buildings for comfort heating. They offer an effective way to heat large spaces and can be particularly advantageous in areas where traditional fuel sources are not feasible.

Advantages of Electric Steam Boilers

Environmental Benefits

Electric steam boilers are often considered more environmentally friendly compared to their fossil-fuel counterparts. They produce no direct emissions, which helps reduce air pollution and greenhouse gas emissions. This makes them an attractive option in areas with strict environmental regulations or in facilities aiming to reduce their carbon footprint.

2. Efficiency and Control

Electric steam boilers boast high efficiency, often exceeding 99%, as there is minimal heat loss in the conversion process. Additionally, they offer precise temperature and pressure control, ensuring that steam is produced at exactly the desired specifications. This precision can lead to improved process control and reduced energy waste.

3. Reduced Maintenance

Compared to traditional steam boilers that require regular maintenance of combustion systems and fuel handling, electric steam boilers have fewer moving parts and require less upkeep. This translates to lower maintenance costs and less downtime.

4. Compact Design

Electric steam boilers are typically more compact than their fossil-fuel counterparts, making them ideal for facilities with limited space. Their smaller size also means they can be installed in locations where traditional boilers might not fit.

5. Safety

Safety is a critical concern in any heating system, and electric steam boilers offer enhanced safety features. They eliminate the risks associated with fuel storage and combustion, reducing the likelihood of explosions or fires.

Limitations and Considerations

While electric steam boilers offer numerous advantages, they also come with some limitations. The primary drawback is the cost of electricity, which can be higher than that of fossil fuels in certain regions. Additionally, the capacity of electric steam boilers may be limited compared to large-scale fossil-fuel boilers, which could be a consideration for facilities with very high steam demands.

Conclusion

Electric steam boilers serve a vital role in various applications by providing an efficient, reliable, and environmentally friendly means of generating steam. Whether for industrial processes, commercial heating, or power generation, their benefits make them an appealing choice in many scenarios. As the world continues to focus on sustainability and energy efficiency, electric steam boilers are likely to play an increasingly important role in the heating landscape.

For more details, please contact us!

Website :- www.steamaxenergyindia.com

Contact No. :- +91-7053901803

Email :- [email protected]

#Electric Steam Boiler#Electric Steam Boiler Manufacturer#Electric Steam Boiler Supplier#Electric Steam Boiler manufacturer in India#steam boiler#steamax energy india

1 note

·

View note

Text

Automatic Electric Boiler in Dindigul

#Automatic Electric Boiler#Energy-Solution#Electric Cooking Steam Boiler#Electric steam Boiler#AutomaticElectricBoiler#Special Steam Vessel For Variety Rice & Thum Ricet#Electric Cooking Stove

1 note

·

View note

Text

Electric Steam Boiler Pricing in the Indian Market

Electric steam boiler prices are influenced by a multitude of factors, each playing a pivotal role in determining the overall cost. From capacity specifications to technological advancements, Thermodyne Engineering System, as a leading boiler manufacturer, has mastered the art of providing transparency in pricing while catering to the diverse needs of the industry. Thermodyne's electric steam boilers are not just about generating power; they are a testament to efficiency. The pricing structure reflects a commitment to delivering technologically advanced solutions that optimize energy usage. The result? A cost-effective approach to steam generation that aligns with both economic and environmental sustainability. For more information contact us at https://www.thermodyneboilers.com/electra-electrode-type-boilers/

#Electric Steam Boiler#Industrial Boilers#Boiler Manufacturer#Energy Efficiency#Sustainable Operations#Reliable Boiler

0 notes

Text

Why Should You Buy Electric Steam Boilers from a Reputable Manufacturer? Let’s Discover!

Are you in search of a top-quality electric steam boiler? If you want a reliable and efficient steam producer for your laundries and ironing machines, you need to connect with a reputed electric steam boiler manufacturer from a renowned company near your location. These boilers offer outstanding features that make them the ideal choice for various applications, ensuring they can meet small to medium steam requests while preventing thermal plant overloads. In addition, their quick and easy installation process and adherence to safety norms make them a convenient option for any facility.

Unmatched Performance and Versatility:

These electric steam boilers are high-performing. They offer 15–180 KW power options to meet your needs. These boilers work with mains or stainless steel reservoirs. They're ideal for a variety of tasks, such as cotton polishing and steam gun fur ironing.

Convenient Control and Utilisation:

Effectively using these boilers requires simplicity. The boilers have an easy-to-use front control panel. Level control and automatic water feed allow you to focus on your work without interruptions. Industrial and commercial boilers are designed for the end user.

Reliable and Safe Construction:

These electric steam boilers prioritise safety, as they should. Safety-compliant electrical connections ensure safe and reliable operation. The boilers' central electrical panel simplifies maintenance and troubleshooting. These boilers are durable and can withstand industrial and commercial environments.

Trustworthy Partner for All Your Boiler Needs:

You need a partner who is trustworthy and knowledgeable about boilers. Australia's largest boiler company offers a wide selection and excellent service. They're known for providing high-quality products and reliable maintenance to Australia's industrial and commercial sectors. They can handle all your boiler needs, from installation to maintenance.

All in all,

A well-known boiler manufacturer can provide high-quality electric steam boilers that meet your needs. These boilers are ideal for laundries, ironing machines, and other applications due to their performance, convenience, safety and industry-leading support.

So, don't compromise on the quality of your steam production; choose a reliable electric steam boiler manufacturer today and experience the difference in your boiler operations.

1 note

·

View note

Text

CHP Plant 1 🏭 (EC 1), Łódź, Poland

#aesthetic#cyberpunk#tech#tech aesthetic#electricity#engineering#elektrostantsiyapost#power plant#chp plant#turbine#generator#boiler#coal power plant#technology#industrial#tech museum#power generation#steam turbine#electrical engineering#power engineering#cooling towers#circuits#steam drum#pump#deaerator#synchronizer#old tech#vintage#electrical engineer#electrical

44 notes

·

View notes

Note

whats the weirdest train you know?

Oh there are so e really fucking weird ones a lot of weird ones were very niche and were designed for something very specific but some were actually rather popular like the better garratt which were very popular in South Africa but weren't that common anywhere else although some were used in Australia and because South Africa only ceased Steam Traction in 1991 many of the Locomotives were sold off and sent overseas mainly to the UK, New Zealand, and Australia

But that's just the better garratt which weren't that weird and about 1200 were built from about 1908 to 1968 to about 100 different designs

The next few Locomotives were much less common starting with an Ancestor of the Garratt; The Double Fairlie

These were an type of strange Double ended Locomotive in the 1860s but really only the Ffestiniog & Welsh Highland Railway used them and they still have a few like the one above (they also purchased a few Garratts from South Africa seen above)

Next on to the Steam turbines which were largely experimental and never really panned out but several different designs were built mostly one-offs

Most of them didn't work very well

Next is a retrofit of an regular steam Locomotive to be able to use a different fuel source during a coal shortage that being the Bizarre Swiss Steam-Electric Locomotive

Switzerland has almost no Coal and thus during world war 2 had no coal but they did have cheap Hydroelectricity and their railways were mostly Electrified so they just made the abombonations

#steam locomotive#trainposting#electric traction#steam boiler#south African Railways#beyer garratt#Swiss railways#sbb#welsh highland railway#pennsylvania railroad#union pacific

33 notes

·

View notes

Text

No longer transgender, I am now trainsgender. Taking the HRT that makes me grow wheels and a steam boiler

#if i was to be a train i would prefer to be an electric train#so maybe instead of growing a steam boiler im growing a pantograph?#but i feel like the joke may not work quite as well if i say that#also the specific train i get gender envy from are the old french tgv's#the angular orange ones#posts made by a sleep deprived smidge

14 notes

·

View notes

Text

SOFLIN Egg Boiler Electric Automatic Off 7 Egg Poacher For Steaming, Cooking, Boiling And Frying, (350 Watts,Multicolor)

Price: (as of – Details) PERFECT EGGS EVERY TIME: Cooking eggs to your desired firmness is easier than ever! An easy to use measuring cup with firmness markings is included, allowing you to cook your eggs to desired hardness of soft, medium or hard and make it consistent every timeONE-TOUCH COOKING: No complex operations, FAST AND SAFE TO USE. with only One-Touch Power Button, SOFLIN couldn’t be…

View On WordPress

#Automatic#Boiler#boiling#Cooking#Egg#Electric#Frying#home appliances kitchen under 700#Poacher#SOFLIN#Steaming#WattsMulticolor

0 notes

Text

The global Pressure Vessels Market is projected to reach USD 62.7 billion in 2028 from USD 50.3 billion in 2023 at a CAGR of 4.5% according to a new report by MarketsandMarkets™.

#pressure vessels market#pressure vessel tank#pressure vessel#pressure vessels#pressure vessel market#energy#power#electricity#power generation#utilities#oil and gas#oil and gas industry#vessels#vessel#nuclear power plant#power plant#power plants#steam boilers#oil refinery#chemical refinery#refining#petroleum refining#refineries

0 notes

Text

Hello, Manish here from Balkrishna Boilers Pvt. Ltd.

Greetings of the day

We are manufacturers and suppliers of all types of Boilers, Heating and Drying System Since Last 20 Years. Over the period of 2 decades we have focused on developing innovative technologies in process heating.

With Quest-For-innovation, Balkrishna Boilers Pvt Ltd has established a State-of-Art Design & Development Centre, focusing constantly on Innovation, Development & Enhancement of its capabilities and products. And thus Balkrishna Boilers Pvt Ltd today has over 1000+ successful installations in India & overseas for various products like Steam Boilers, Electric Boilers etc with an experience of handling of over 100 types of different fuels.

As a policy & procedure we follow the most stringent quality assurance standards right from the procurement of best quality raw materials to final dispatches, all the while carrying out several levels of testing and minute inspections for boilers and other heating proccesses. The quality assurance procedures are dedicated to ensure that all products and services conform to the exacting standards and are in-line with the contractual specifications agreed with and by the customer.

Website: www.balkrishn.com

Please let us know about your opinion on the same

Cheers, Team Balkrishna Boilers Pvt. Ltd.

Manish Patel (M): +91 98250 24450

1 note

·

View note

Text

What is the use of Electric Steam Boilers ?

Steamax Energy India is a renowned manufacturer of Electric Steam Boilers, providing efficient and reliable solutions for various industrial applications. Their electric steam boilers are designed with cutting-edge technology, ensuring high performance, energy efficiency, and easy operation.

Features:

1. High Efficiency:

Steamax Energy's Electric Steam Boilers are designed to provide maximum efficiency, reducing energy consumption and operating costs.

2. Compact Design:

These boilers feature a compact design, making them suitable for installations with limited space.

3. Automatic Control:

Equipped with advanced automation, the boilers offer precise temperature and pressure control, ensuring consistent steam output.

4. Environmentally Friendly:

Being electric, these boilers produce zero emissions, making them an eco-friendly choice.

5. Safety Features:

Steamax Energy ensures the highest safety standards with features like pressure relief valves, low water cut-off, and over-temperature protection.

6. Durable Construction:

Made from high-quality materials, these boilers are built to last, providing long-term reliability.

How It Works:

Steamax Energy's Electric Steam Boilers operate by converting electrical energy into heat, which is then used to produce steam. The electric heating elements inside the boiler heat the water, creating steam under pressure. This steam is then distributed for various industrial applications. The automatic control system ensures that the desired steam pressure and temperature are maintained without manual intervention.

Uses:

Electric Steam Boilers by Steamax Energy India are used across various industries, including:

1. Textile Industry:

For processes like dyeing, finishing, and ironing.

2. Food Processing:

For cooking, sterilization, and cleaning.

3. Pharmaceutical Industry:

For sterilizing equipment and processing ingredients.

4. Chemical Industry:

For heating, drying, and processing chemicals.

5. Hospitality:

For laundry, kitchen, and spa facilities.

6. Breweries and Distilleries:

For brewing, distillation, and sterilization processes.

With a strong commitment to quality and customer satisfaction, Steamax Energy India continues to be a leader in the manufacturing of Electric Steam Boilers, catering to the diverse needs of industries across India.

For more details, please contact us!

Website :- www.steamaxenergyindia.com

Contact No. :- +91-7053901803

Email :- [email protected]

#Electric Steam Boilers#Electric Steam Boilers in India#Electric Steam Boilers Manufacturer#Electric Steam Boilers Supplier

0 notes

Text

What is the Pressure of a Steam Boiler?

Steam boilers are widely used in various industries for heating, power generation, and mechanical processes. A critical aspect of a steam boiler’s operation is its pressure, which determines the efficiency and effectiveness of the boiler in producing and distributing steam. But what is the pressure of a steam boiler and how does it affect its performance?

Understanding Steam Boiler Pressure

The pressure of a steam boiler refers to the force exerted by the steam within the system, measured in units like pounds per square inch (PSI) or bar. It’s a crucial parameter in boiler operation because the pressure dictates the temperature at which the water boils and turns into steam. The higher the pressure, the higher the temperature of the steam, and the more energy-dense it becomes.

Steam boilers operate across a range of pressures, from low to high, depending on their specific application. Generally, they are categorized as:

Low-pressure boilers: Operate at a pressure below 15 PSI.

Medium-pressure boilers: Operate at pressures between 15 and 300 PSI.

High-pressure boilers: Operate at pressures above 300 PSI, with some industrial boilers reaching up to 1,500 PSI or more.

How Pressure Affects Steam Boilers

The pressure of a steam boiler directly influences its efficiency, safety, and overall functionality. The higher the pressure, the greater the amount of steam that can be produced and distributed efficiently. Here's how pressure impacts key aspects of a steam boiler:

Temperature and Steam Production: As boiler pressure increases, so does the boiling point of water. For example, water boils at 212°F (100°C) at atmospheric pressure (0 PSI), but at 250 PSI, it boils at around 400°F (204°C). This higher temperature steam carries more thermal energy, which can be harnessed for industrial processes, power generation, and heating systems. Thus, a higher pressure allows the boiler to produce more steam in a shorter time, improving efficiency.

Energy Efficiency: Higher-pressure steam contains more energy per unit, allowing it to transfer more heat with less steam volume. This means that high-pressure steam boilers are generally more energy-efficient, as they can transport more heat with less fuel consumption. However, efficiency gains must be balanced with the costs of maintaining high-pressure systems.

Boiler Size and Application: Boilers that operate at higher pressures tend to be more compact, as the increased pressure enables more efficient steam production. High-pressure boilers are often used in power plants, manufacturing facilities, and large-scale heating systems. Low-pressure boilers, on the other hand, are more commonly found in smaller applications, such as residential heating and low-demand industrial settings.

System Design and Materials: The pressure in a steam boiler influences the design and materials used. Higher-pressure boilers require more robust materials, thicker walls, and advanced safety systems to handle the increased stress. This also means that high-pressure boilers are generally more expensive to manufacture and maintain.

Safety Considerations: The higher the pressure in a boiler the more critical safety becomes. High-pressure steam contains a lot of energy, and any failure in the system can lead to catastrophic outcomes. To manage this risk, boilers are equipped with pressure relief valves, gauges, and automatic shutdown systems to ensure that the pressure remains within safe operating limits.

Types of Steam Boilers and Their Pressure

Steam boilers come in different types, each with varying pressure ranges depending on their application:

Low-Pressure Steam Boilers: These operate at pressures below 15 PSI and are used in residential heating, small-scale commercial applications, and industries that require low-temperature steam. Low-pressure boilers are relatively safe and easy to operate but are limited in their steam capacity.

High-Pressure Steam Boilers: Typically used in industries like chemical production, power generation, and large-scale heating systems, these boilers operate at pressures above 300 PSI. The high pressure enables the generation of steam at much higher temperatures, making these systems highly efficient for energy-intensive operations.

Superheated Steam Boilers: These boilers produce steam at pressures above 300 PSI but also raise the steam temperature beyond its saturation point. Superheated steam is used in power plants and turbines, where extremely high-temperature steam is necessary to drive mechanical processes and generate electricity.

Factors Influencing Boiler Pressure

Several factors determine the operating pressure of a steam boiler, including:

Application Needs: The specific requirements of the process or heating system will dictate the pressure. For instance, a food processing plant may need lower pressure for sterilization, while a power plant will require high-pressure steam for electricity generation.

Boiler Design: The design of the boiler, including its heating surface area and fuel type, influences the pressure range it can handle. Modern boilers are designed to optimize efficiency at specific pressure levels, ensuring they meet the demands of the system while operating safely.

Maintenance and Safety Protocols: Proper maintenance is critical for keeping a steam boiler operating at its intended pressure. Regular inspections, cleaning, and calibration of pressure-relief valves are necessary to prevent pressure from exceeding safe limits.

Conclusion

In conclusion, the pressure of a steam boiler is a fundamental factor in determining its efficiency, safety, and application range. Whether operating at low, medium, or high pressure, steam boilers must be carefully designed and maintained to ensure they meet the specific needs of the system while adhering to safety protocols. High-pressure boilers offer greater efficiency and steam capacity, making them ideal for industrial and power generation applications, while low-pressure boilers are well-suited for smaller, less demanding systems. Ultimately, understanding and managing boiler pressure is key to optimizing performance and ensuring safe operation in any steam-generating system.

#electric cooking steam boiler#automatic electric boiler#electric cooking stove#special steam vessel for variety rice & thum ricet#Cooking Stove in Namakkal#Electric Cooking Stove in Namakkal#Dosa Stove in Namakkal#Electric Dosa Stove in Namakkal#Automatic Electric Boiler in Namakkal#Cooking Steam Boiler in Namakkal

1 note

·

View note

Text

Electric Steam Boilers Redefining Industrial Heating

Thermodyne, a pioneer in boiler manufacturing, stands out as a leader in India and Asia, renowned for its unwavering commitment to quality and innovation. Electric Steam Boilers, crafted by Thermodyne, epitomize energy efficiency, delivering exceptional performance in every operation. These boilers empower businesses with precise control over their industrial processes, ensuring a steadfast and dependable heat source. Embracing sustainability, Thermodyne seamlessly integrates eco-friendly technologies into its Electric Steam Boilers, minimizing environmental impact without sacrificing performance. For more information contact us at https://www.thermodyneboilers.com/electra-electrode-type-boilers/

#Electric Steam Boiler#Industrial Heating Solutions#Boiler Manufacturer#Reliable Heat Source#Eco-Friendly Boilers

0 notes

Text

What You Need To Know When Buying Industrial Steam Boilers

Boilers are considered to be the most essential part of every processing industry. Especially in the manufacturing industry they play a significant role and the performance of the organization depends on it to a great extent. If you want to improve the productivity or the operational efficiency, be careful while choosing a boiler. You can prefer using steam boilers, widely used by many industries nowadays. Initially you have to invest a good amount for buying a steam boiler but it will provide you flawless service for years.

Why are steam boilers that run on electricity widely used?

Among all, electrical steam boilers can be perfect for your industrial use. It uses electricity rather than combustion of fuel to produce hot steam. Compared to others they are more popular because of its easy maintenance and economical installation. Cleaning or maintenance is very easy and less time consuming. Besides, such boilers do not emit harmful gasses that will pollute the environment. If you want to keep a check on the pollution that is caused due to industrial production, use electric boilers. They are safer than fossil blaze boilers as there is no scope of gas or oil leaking that can create an explosion. Anyhow if you want to purchase the best product at a reasonable price, look for reputed electric steam boiler manufacturers. It is safe to buy directly from a leading and trusted manufacturer.

What should you consider before buying steam boilers?

Buying a boiler for industrial use will be one of your biggest investments. Cost is the most vital thing that will come to your mind first. Do not ready pay any amount the supplier asks for. Buy from a well established and certified manufacturer that will deliver premium quality products at a competitive price.

Is the boiler right for your production? Often people make the mistake of buying without verifying its performance. Make sure you are purchasing a high performing boiler; else it will be a waste of money.

In order to keep your business operations running smoothly you will want the boiler to deliver uninterrupted service. So it is best to purchase a package boiler that has a burner, feed pump, level controls and other requisite things. You should also consider the reliability and durability of the machine while purchasing it from package boiler suppliers.

Therefore, this was all about why you should use steam boilers, where to purchase it from and things to consider before buying.

0 notes

Text

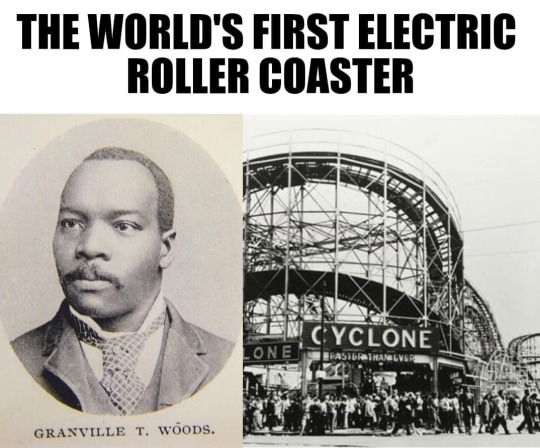

THE WORLD'S FIRST ELECTRIC ROLLER COASTER

Granville T. Woods (April 23, 1856 – January 30, 1910) introduced the “Figure Eight,” the world's first electric roller coaster, in 1892 at Coney Island Amusement Park in New York. Woods patented the invention in 1893, and in 1901, he sold it to General Electric.

Woods was an American inventor who held more than 50 patents in the United States. He was the first African American mechanical and electrical engineer after the Civil War. Self-taught, he concentrated most of his work on trains and streetcars.

In 1884, Woods received his first patent, for a steam boiler furnace, and in 1885, Woods patented an apparatus that was a combination of a telephone and a telegraph. The device, which he called "telegraphony", would allow a telegraph station to send voice and telegraph messages through Morse code over a single wire. He sold the rights to this device to the American Bell Telephone Company.

In 1887, he patented the Synchronous Multiplex Railway Telegraph, which allowed communications between train stations from moving trains by creating a magnetic field around a coiled wire under the train. Woods caught smallpox prior to patenting the technology, and Lucius Phelps patented it in 1884. In 1887, Woods used notes, sketches, and a working model of the invention to secure the patent. The invention was so successful that Woods began the Woods Electric Company in Cincinnati, Ohio, to market and sell his patents. However, the company quickly became devoted to invention creation until it was dissolved in 1893.

Woods often had difficulties in enjoying his success as other inventors made claims to his devices. Thomas Edison later filed a claim to the ownership of this patent, stating that he had first created a similar telegraph and that he was entitled to the patent for the device. Woods was twice successful in defending himself, proving that there were no other devices upon which he could have depended or relied upon to make his device. After Thomas Edison's second defeat, he decided to offer Granville Woods a position with the Edison Company, but Woods declined.

In 1888, Woods manufactured a system of overhead electric conducting lines for railroads modeled after the system pioneered by Charles van Depoele, a famed inventor who had by then installed his electric railway system in thirteen United States cities.

Following the Great Blizzard of 1888, New York City Mayor Hugh J. Grant declared that all wires, many of which powered the above-ground rail system, had to be removed and buried, emphasizing the need for an underground system. Woods's patent built upon previous third rail systems, which were used for light rails, and increased the power for use on underground trains. His system relied on wire brushes to make connections with metallic terminal heads without exposing wires by installing electrical contactor rails. Once the train car had passed over, the wires were no longer live, reducing the risk of injury. It was successfully tested in February 1892 in Coney Island on the Figure Eight Roller Coaster.

In 1896, Woods created a system for controlling electrical lights in theaters, known as the "safety dimmer", which was economical, safe, and efficient, saving 40% of electricity use.

Woods is also sometimes credited with the invention of the air brake for trains in 1904; however, George Westinghouse patented the air brake almost 40 years prior, making Woods's contribution an improvement to the invention.

Woods died of a cerebral hemorrhage at Harlem Hospital in New York City on January 30, 1910, having sold a number of his devices to such companies as Westinghouse, General Electric, and American Engineering. Until 1975, his resting place was an unmarked grave, but historian M.A. Harris helped raise funds, persuading several of the corporations that used Woods's inventions to donate money to purchase a headstone. It was erected at St. Michael's Cemetery in Elmhurst, Queens.

LEGACY

▪Baltimore City Community College established the Granville T. Woods scholarship in memory of the inventor.

▪In 2004, the New York City Transit Authority organized an exhibition on Woods that utilized bus and train depots and an issue of four million MetroCards commemorating the inventor's achievements in pioneering the third rail.

▪In 2006, Woods was inducted into the National Inventors Hall of Fame.

▪In April 2008, the corner of Stillwell and Mermaid Avenues in Coney Island was named Granville T. Woods Way.

510 notes

·

View notes