#Dust Collector manufacturer in India

Explore tagged Tumblr posts

Text

Everything You Need to Know About Dust Collector Systems

In Industries ranging from woodworking to metalworking, Dust Collector Systems are essential for maintaining a clean, safe, and efficient workspace. These systems not only enhance the health and safety of workers but also improve the overall quality of products and extend the lifespan of equipment. In this blog, we’ll delve into what dust collector systems are, how they work, and why they are crucial for various industries.

What Is a Dust Collector System?

A Dust Collector System is a setup designed to capture and filter out dust and particulate matter generated during industrial processes. This system helps in removing airborne dust, which can be harmful to both the environment and the health of workers. The collected dust can then be safely disposed of or reused, depending on its nature and the industry.

Types of Dust Collector Systems

Baghouse Dust Collectors:

How They Work: These systems use fabric filters (bags) to capture dust particles. Air carrying the dust is drawn through the bags, which trap the particles while allowing clean air to pass through.

Advantages: Baghouse dust collectors are highly efficient and capable of handling large volumes of dust. They are also versatile, suitable for various applications.

2. Cyclone Dust Collectors:

How They Work: Cyclone collectors use centrifugal force to separate dust particles from the air. As the air spins inside the cyclone, the dust is thrown to the sides and collected at the bottom.

Advantages: Cyclones are effective for large particles and are often used as pre-filters for other types of dust collectors. They require less maintenance and are relatively simple.

3. Electrostatic Precipitators (ESPs):

How They Work: ESPs use electrical charges to capture dust particles. The air passes through an ionizing section where dust particles are charged and then collected on plates with an opposite charge.

Advantages: ESPs are highly effective for very fine dust particles and can handle high dust loads. They are also energy-efficient.

4. Cartridge Dust Collectors:

How They Work: These systems use cylindrical filters (cartridges) to trap dust particles. The cartridges have a large surface area, which allows them to handle high volumes of air.

Advantages: Cartridge collectors are compact and require less maintenance compared to baghouses. They are ideal for applications where space is a concern.

How Dust Collector Systems Work

Dust collector systems generally consist of the following components:

Dust Collection Hood: This is the part of the system where dust is initially captured. It is usually positioned close to the source of dust generation.

Ductwork: Ducts transport the dust-laden air from the collection hood to the main dust collector unit. Proper duct design is crucial for efficient dust collection and to minimize air resistance.

Dust Collector Unit: This is where the dust is filtered out of the air. The unit can be a baghouse, cyclone, ESP, or cartridge collector, depending on the system type.

Dust Disposal System: After the dust is collected, it is either disposed of or recycled. Some systems use conveyors or bins to manage the collected dust.

Benefits of Dust Collector Systems

Improved Air Quality: By capturing airborne dust, these systems help maintain a cleaner and healthier working environment. This is essential for protecting workers from respiratory issues and reducing the risk of dust-related health problems.

Enhanced Safety: Dust can be highly flammable or explosive in certain conditions. A dust collector system helps in mitigating these risks, ensuring a safer workplace.

Regulatory Compliance: Many industries are subject to regulations regarding dust emissions and air quality. Implementing an effective dust collector system helps in meeting these regulations and avoiding potential fines.

Increased Equipment Lifespan: Dust accumulation on machinery can lead to wear and tear, affecting performance and longevity. By keeping equipment clean, dust collector systems help in reducing maintenance costs and extending equipment life.

Product Quality: In industries like woodworking or pharmaceuticals, dust contamination can impact the quality of products. Dust collector systems help in maintaining product purity and consistency.

Choosing the Right Dust Collector System

Selecting the appropriate dust collector system depends on various factors, including:

Type and Volume of Dust: Different systems are suited for different types and amounts of dust. Assessing the dust characteristics is crucial for choosing the right system.

Space Availability: The size and layout of your workspace will influence the type of dust collector that fits best.

Maintenance Requirements: Consider the ease of maintenance and filter replacement. Some systems require more frequent servicing than others.

Budget: Dust collector systems come with different price tags. Evaluate the initial cost against long-term benefits and operational costs.

Conclusion

Dust collector systems play a pivotal role in maintaining a clean and safe working environment across various industries. By understanding the different types of dust collectors, how they work, and their benefits, you can make an informed decision that enhances both workplace safety and operational efficiency. Investing in a reliable dust collector system not only protects your workforce but also contributes to the overall success of your business.

If you’re considering upgrading or installing a dust collector system, consulting with a professional can help you determine the best solution tailored to your specific needs.

Related Products:-

Dust Collector System Centrifugal Blowers Cyclone Dust Collector Industrial Dust Collector Filter Bags Filter Bag

For more Information:- Contact us:- +91–9868621620 , +91–0120–4941514 Email:- [email protected], Address:- Khasra No-164, Pawan Puri Industrial Area, Abupur Muradnagar, Ghaziabad, U.P-201206

#Dust Collector Systems#Dust Collector Systems manfuacturer#Dust Collector manufacturer#Dust Collector manufacturer in India#Dust Collector Systems supplier#Dust Collector Systems supplier in India#akj industries

1 note

·

View note

Text

What Are Transmission Belts?

Transmission belts are continuous loop belts set between two ‘pulleys’ to transmit power through the transmission belting into the machinery the belting is situated.

Transmission belting is used across an array of industries, from automotive manufacturing and performance through to industrial belting production and manufacturing, as well as a source of motion

Positive Drive vs Friction Drive Transmission

Fundamentally there are two forms of transmission belting for power transmission. These are either friction drive or positive drive. Friction drive belts utilize the belt’s and pulley’s friction to transmit power. The friction drive belting requires balanced tension to maintain the right friction levels. These are traditionally flat belts.

Positive drive belts will rely on the engagement of what is referred to as ‘teeth’ on the belt within the grooves on the pulley(s). There is no slippage with this transmission belt unless the teeth between the grooves’ jump’.

website:

Office

Corkish & Layne India Pvt Ltd 209 AJC Bose Road, Kolkata 700 017

+91 334 601 2395

#dust collector filter bags#cartridge dust collector#cartridge dust collector filter#dust collector filter bags suppliers#filter bag suppliers#filter cage manufacturer#filter bag manufacturers in india#filter bag manufacturers in south africa

2 notes

·

View notes

Text

The Vital Role of Dust Collector Manufacturers in Keeping Our Air Clean

Dust may seem like an insignificant nuisance, but it's anything but. Microscopic particles can wreak havoc on our health, environment, and industrial processes. Fortunately, unsung heroes stand sentinel against this silent threat: dust collector manufacturers. These companies play a crucial role in safeguarding our air quality, and Intech Bulk Handling Systems Pvt. Ltd., a leading chain conveyor manufacturers in India, stands out as a prime example.

Invisible Hazards, Tangible Impact:

Dust exposure poses significant health risks, triggering respiratory problems like asthma and allergies. In industrial settings, it can also compromise product quality, damage equipment, and even escalate fire hazards. Dust collectors combat these issues by capturing and filtering dust particles, ensuring cleaner air for workplaces and communities.

How Dust Collectors Work:

These unsung heroes come in various configurations, each suited to specific applications. Common mechanisms include:

Cyclones: Utilizing centrifugal force, they separate heavier dust particles from air.

Bag filters: Air passes through fabric bags, trapping dust while clean air exits.

Cartridge filters: Similar to bag filters, but with pleated cartridges offering higher efficiency.

Wet scrubbers: Water sprays capture dust, often ideal for sticky or hazardous materials.

Intech's Contribution to Cleaner Air:

Intech Bulk Handling Systems, while specializing in chain conveyors, also recognizes the importance of dust control. They offer a range of dust collection systems tailored to various industries, including:

Cement: High-efficiency bag filters capture fine dust particles, protecting workers and the environment.

Pharmaceuticals: Dust-free environments are crucial for product purity. Intech's systems ensure compliance with strict regulations.

Food processing: Preventing dust contamination safeguards product quality and consumer health. Intech provides solutions for both dry and wet ingredients.

Beyond Individual Companies:

The efforts of dust collector manufacturers reach far and wide. They contribute to:

Improved public health: By reducing dust exposure, they help prevent respiratory illnesses and promote overall well-being.

Environmental protection: Dust collectors control air pollution, contributing to cleaner air and mitigating climate change effects.

Enhanced industrial efficiency: Cleaner work environments and protected equipment lead to improved productivity and reduced maintenance costs.

Conclusion:

Dust collector manufacturers may not grab the headlines, but their work is essential for our health, environment, and industrial well-being. Companies like Intech Bulk Handling Systems, with their commitment to innovative solutions, exemplify the critical role this industry plays in keeping our air clean. As we strive for a healthier and more sustainable future, appreciating and supporting these silent guardians of clean air becomes ever more important.

#dust collector manufacturers#clean air#Intech Bulk Handling#dust emissions control#CleanAir#DustControl#IndustrialSafety#HealthAndSafety#EnvironmentalProtection#AirQuality#DustCollection#Manufacturing#PublicHealth#CleanerEnvironment#Sustainability#WorkplaceSafety#IntechBulkHandling#ChainConveyors#India

3 notes

·

View notes

Text

Trusted Air Washer and Dust Collector Manufacturer in India

Ventilair India Pvt. Ltd., a name synonymous with quality and innovation, stands as a leader among Air Washer manufacturers in India, offering reliable solutions tailored to diverse industry needs.

Original Source By :- https://www.ventilair.in/your-trusted-air-washer-and-dust-collector-manufacturer-in-india-ventilair/

0 notes

Text

Bkair: Dust collector manufacturers and suppliers in India

Bkair stands as a beacon of innovation and reliability in the realm of dust collector manufacturing and supply in India. With a legacy steeped in excellence and a commitment to quality, Bkair has earned its place as a trusted partner for industries seeking effective solutions to their dust management needs.

#dust collector manufacturers#Dust collectors systems in India#dust collector manufacturers and suppliers in India

0 notes

Text

cyclone dust collector manufacturers in Mumbai

We are leading manufacture dust collectors and multiclone dust collector for various industrial applications cyclone dust collector manufacturer,cyclone dust collector manufacturers In India.

#cyclone dust collector manufacturers#cyclone dust collector manufacturer in india#calciner manufacturers#cyclone dust collector Suppliers#cyclone dust collector Suppliers india#multiclone dust collector#centrifugal fan manufacturers in india#industrial blower manufacturers in india#tube axial fans manufacturers india#dust collector system manufacturer india#fume extraction system manufacturers#Cyclone dust collector#Reverse air baghouse manufacturers#scrubber manufacturers in india#venturi scrubber manufacturers#industrial fan manufacturers#axial fan manufacturers#bag filter manufacturers in india#bag filter manufacturers

0 notes

Text

Dust Extraction Systems

The Dust Extraction System is basically developed and manufactured for the removal, and extraction the dust from the industrial area. The dust particles produced during the manufacturing process are totally removed ensuring a safe and healthy working environment by preventing the release of pollutants into the atmosphere.

If you're considering and willing to implement a Dust Extraction System in your industrial facility, StratGem Projects is here to help with your significant application with the best Dust Extraction System Manufacturers India. Contact us today to discuss your specific needs and explore the best dust extraction solution for your industry, factory, business, etc.

#dust extraction system#Dust Extraction System Manufacturers#Dust Extraction System Manufacturers India#dust collector machine#machine dust collector#dust collector#dust collector system#dust extraction#industrial dust collector#dust collector filter#dust collector filter bag#dust extractor machine#bag filter#dust remover#bag filter dust collector#dust collector bags#bag house filter#industrial dust extractor manufacturers#bag filtration#dust extraction system manufacturer#high efficiency particulate air filter#cyclone separator#rotary air lock valve

0 notes

Text

Single Belt Grinder with Dust Collector

Single belt grinder with a dust collector is a type of power tool used for material removal, grinding, and finishing processes while also having an integrated dust collection system. This combination provides a cleaner work environment by effectively capturing and containing dust and debris generated during grinding operations. The single belt grinder part of the tool works similarly to a regular single belt grinder, as mentioned in the previous response. It features a single abrasive belt running on a pulley system, which is used for tasks such as deburring, shaping, sharpening, and polishing various workpieces. The dust collector component is designed to remove dust and particulate matter produced during grinding to maintain a cleaner and healthier workspace. The dust collector typically consists of a suction mechanism that draws air and dust particles from the grinding area through a collection hood or exhaust port. The collected dust is then filtered, and the clean air is either recirculated into the workspace or discharged outside, depending on the design of the dust collector.

#manufacture#industrial equipment#manufacturer#metallurgical#metallographicequipments#belt grinder#single belt grinder#single belt grinder with dust collector#single belt grinder supplier#single belt grinder manufacture#single belt grinder specifiation#single belt grinder price#single belt grinder cost#single belt grinder supplier in india#single belt grinder manufacture in india#single belt grinder supplier in delhi ncr#single belt grinder manufacture in delhi ncr#single belt grinder supplier in uttar pradesh#single belt grinder manufacture in uttar pradesh

1 note

·

View note

Text

Why Trimech India is the Best Lime Handling System Manufacturer

When it comes to handling lime in industrial processes, having the right equipment is essential for efficiency and long-term success. Trimech India has established itself as the best lime handling system manufacturer in the market, thanks to its commitment to quality, innovation, and customer satisfaction. With years of experience and a dedicated team, Trimech India delivers top-tier solutions for lime handling, ensuring that industries benefit from durable, efficient, and technologically advanced systems.

Trimech India: A Legacy of Excellence

Founded in 2008, Trimech India has grown to become a leading lime handling system supplier. The company was built on a vision to provide innovative technology to industries, and since its inception, it has become synonymous with cutting-edge engineering and top-quality equipment. Trimech’s diverse range of products, including lime handling systems, screw conveyors, dust collectors, and more, serve industries such as cement plants, power plants, and fertilizer manufacturing.

Expertise in Lime Handling Systems

One of the core strengths of Trimech India is its specialization in manufacturing lime handling systems. Whether it’s a lime stone handling unit for cement production or a sophisticated system for industrial use, Trimech delivers solutions that meet the unique needs of various industries. The company’s lime handling systems are designed to handle lime’s abrasive nature, ensuring that the material is transported, stored, and processed safely and efficiently.

Trimech India’s extensive knowledge of lime handling applications allows the company to provide systems that offer maximum durability, minimal maintenance, and high operational efficiency. This makes Trimech India the best lime handling system manufacturer for businesses looking for reliable and robust solutions.

Why Trimech India Stands Out

1. Innovative Solutions

Trimech India prides itself on its continuous innovation. The company consistently invests in research and development to ensure that its lime handling systems remain at the forefront of technology. By combining the latest technological advancements with proven design principles, Trimech India ensures that its systems offer exceptional performance in demanding environments.

2. Customization

No two businesses are the same, and neither are their lime handling requirements. Trimech understands this, which is why they offer customized solutions to meet the unique needs of each client. Whether you require a compact lime stone handling unit or a large-scale lime handling system, Trimech’s engineering team works closely with clients to design systems tailored to their specific operational needs.

3. Quality Assurance

As the best lime handling system supplier, Trimech India is committed to delivering equipment that meets the highest quality standards. Each lime handling system undergoes rigorous testing and quality control to ensure that it performs reliably and efficiently under all conditions. This focus on quality ensures that Trimech India’s systems are durable, safe, and cost-effective.

4. Global Support and Service

Trimech India isn’t just a lime handling system manufacturer; it’s a partner to businesses around the world. With a strong focus on customer satisfaction, Trimech provides exceptional after-sales support, including maintenance services, consultancy, and technical assistance. This ensures that clients get the most out of their lime handling systems, with minimal downtime and maximum productivity.

Industries Served

Trimech India’s lime handling systems are used in a wide range of industries that rely on lime for various processes. Some of the key industries include:

Cement Plants: Efficient lime handling is crucial for cement production, and Trimech provides tailored systems that ensure smooth, continuous operations.

Power Plants: Trimech’s lime handling systems are designed to withstand harsh conditions, ensuring reliable performance even in the most demanding environments.

Fertilizer Industries: Lime plays an important role in fertilizer production, and Trimech ensures that its systems meet the specific needs of this sector.

Conclusion

Trimech India’s reputation as the best lime handling system manufacturer is built on its commitment to quality, innovation, and customer satisfaction. The company’s expertise in designing and manufacturing lime handling systems makes it the preferred choice for industries around the world. With a focus on providing durable, efficient, and customizable solutions, Trimech India ensures that its clients receive top-quality lime handling systems that deliver optimal performance for years to come.Whether you are looking for a lime stone handling unit for a large-scale industrial setup or a customized system for a specialized application, Trimech India is the lime handling system supplier you can trust for all your lime handling needs.

#lime handling system#lime handling system supplier#lime handling system manufacturers#lime handling unit

1 note

·

View note

Text

Exporter of Multi Effect Evaporator in Zambia Drytech Engineering Systems is a trusted Exporter of Multi Effect Evaporator in Zambia.

We are located in Ahmedabad, Gujarat, India.

Drytech Engineering Systems specializes in a wide range of drying and processing equipment, including Flash Dryers, Spray Dryers, Spin Flash Dryers, Fluid Bed Dryers, Evaporator Dryers, Rotary Valves, Rotary Atomizers, Hot Air Generators, Centrifugal Blowers, and Dust Collector Systems.

A Multi-Effect Evaporator (MEE) is a highly efficient system designed to concentrate solutions by removing water or solvents. It is commonly used in industries such as food and beverage, pharmaceuticals, and chemicals.

The system operates on a thermal separation principle, utilizing multiple evaporation stages where the steam generated in one stage is used to heat the next, leading to significant energy savings.

Types of Multi-Effect Evaporators: Fully Automatic Multi Effect Evaporators Semi-Automatic Multi Effect Evaporators

Features: Energy Efficiency: MEEs dramatically reduce energy consumption by utilizing multiple evaporation stages compared to single-effect evaporators.

Compact Design: We engineer the system to optimize space usage, making it perfect for facilities with limited space.

Automated Control Systems: Advanced monitoring and control features improve operational efficiency, ensuring consistency and high-quality output.

Versatility: We can customize MEEs to handle various feed types and capacities, making them adaptable to different applications.

Robust Construction: We build MEEs with premium materials, designing them to endure demanding operating conditions and ensure long-lasting performance.

Advantages of Multi-Effect Evaporators: Custom Solutions: Tailored to meet specific operational needs, ensuring optimal performance. Expertise and Experience: Backed by years of industry experience to deliver reliable and efficient systems. High Efficiency: Significantly reduces energy costs while maximizing output. Sustainability Focus: Designed to minimize environmental impact through energy and resource efficiency. Comprehensive Support: From design to installation and after-sales service, we provide full support for a seamless operation.

Applications: Food & Beverage Processing Pharmaceutical Manufacturing Chemical Processing Wastewater Treatment Pulp and Paper Production

Drytech Engineering Systems is an Exporter of Multi Effect Evaporator in Zambia including locations Lusaka, Kitwe, Ndola, Chipata, Livingstone, Kasama, Kabwe, Chingola, Choma, Luanshya, Kafue, Mongu, Chinsali, Mazabuka, Mwinilunga, Solwezi, Mufulira, Kapiri Mposhi, Chililabombwe and Mansa.

Contact Us today for your multi effect evaporator solutions!

0 notes

Text

Cyclone Dust Collector

Are You Looking for Cyclone Dust Collector in India? AKJ Industries is a leading manufacturer and supplier of Cyclone Dust Collectors in India, specializing in efficient dust collection systems for various industries. Their Cyclone Dust Collectors are designed to handle heavy-duty applications, effectively removing large particles and dust from industrial processes. These systems are durable, easy to maintain, and offer high performance for factories, workshops, and processing plants. AKJ Industries focuses on providing energy-efficient and cost-effective dust management solutions that help industries comply with environmental regulations, ensuring cleaner air and a safer work environment. For more details Contact us@+91-9868621620

0 notes

Text

Unleashing Efficiency with ClipOn: Your Sustainable Material Handling Partner

Removal of particulate matter (PM) from flue gases

Bag filters are specifically crafted to trap PM particles, thereby preventing their release into the atmosphere. This crucial function enhances air quality and mitigates the potential health risks of PM exposure.

Increase boiler efficiency

By eliminating particulate matter from flue gases, bag filters can enhance boiler efficiency by decreasing the energy needed to heat the flue gases.

Protection of boiler components from damage

Bag filters effectively prevent the accumulation of particulate matter (PM) on boiler components, thereby safeguarding their efficiency and preventing damage. They achieve this by removing PM from the flue gases before they reach the boiler.

Extension of boiler lifespan

By safeguarding boiler components from harm, bag filters can effectively prolong the boiler's lifespan.

Office

Corkish & Layne India Pvt Ltd 209 AJC Bose Road, Kolkata 700 017

+91 334 601 2395

#dust collector filter bags#filter bag suppliers#filter bag manufacturers in india#polyester filter bags#nomex filter bag#high temperature filter bags#boiler bag filter manufacturers#bag filter for boiler#pleated bag filter#fiberglass filter bags

0 notes

Text

Top Industrial Air Pollution Control Equipment Manufacturers in India | Par Boiler

Par Boiler is a trusted name in air pollution control equipment manufacturing in India. We offer advanced industrial solutions like eco-friendly boilers, dust collectors, and emission control systems to ensure cleaner and greener operations.

#AirPollutionControlIndia#CleanAirSolutions#EnvironmentalProtection#IndustrialAirPurifiers#SustainableManufacturing#GreenTechnology#PollutionControlEquipment#IndustrialFiltration#EcoFriendlyIndustries#AirQualityManagement#EmissionControl#IndustrialHygiene#CleanTechIndia#SustainableIndustry#AirPurification#IndustrialSafety#EnvironmentalEngineering#GreenManufacturing#AirPollutionSolutions#IndustrialPollutionControl

0 notes

Text

Dust Collector Manufacturers in India - Ventilair India Pvt. Ltd.

If you are searching # No1 Industrial Dust Collector Machine Manufacturers & Suppliers in India Then Ventilair India is Best Choice for you Industrial dust collector system

Website:-https://www.ventilair.in/dust-collector-manufacturers-india/

0 notes

Text

Bkairwasher: Top dust collector manufacturers and suppliers in india

Bkairwasher is one of the leading dust collector manufacturers and suppliers in India. Based in New Delhi with over 25 years of experience, Bkairwasher designs and manufactures a wide range of industrial dust collection systems to help companies effectively control air pollution. Their product range includes bag filter dust collectors, cyclone separators, cartridge dust collectors, wet scrubbers, and vehicle exhaust extraction systems.

https://www.bkair.in/dust-collector/

0 notes

Text

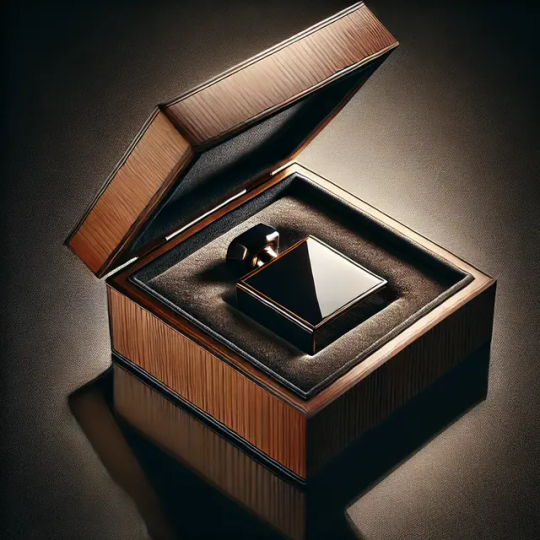

Wooden Gift Company “Wooden Gift Company” is a Brand of Pravat Timbers. Started in 1965, WGC has been one of the pioneers in Imaging, Customizing, Manufacturing, Distribution, and Exporting of Wooden Products.

Product Description:

Elevate the art of perfume storage with our exquisite Luxury Wooden Perfume Box, expertly crafted to pamper your senses. This stunning, fully customizable box is the perfect gift for perfume connoisseurs, luxury enthusiasts, and anyone deserving of elegance.

Features:

- Premium Materials: Handcrafted from high-quality wood, ensuring durability and sophistication.

- Customizable: Personalize with names, initials, or messages to make it unique.

- Spacious Interior: Stores multiple perfume bottles, keeping them organized and protected.

- Soft-Close Lid: Smooth, effortless opening and closing.

- Velvet Interior: Luxurious fabric cradles your precious perfumes.

Design Options:

- Wood Finishes: Choose from rich walnut, elegant cherry, or sleek ebony.

- Engraving Styles: Select from modern, classic, or script fonts.

- Custom Colors: Match your brand or personal style.

Perfect For:

- Luxury gifts

- Perfume collectors

- Home decor enthusiasts

- Special occasions (weddings, anniversaries, birthdays)

Care Instructions:

- Dust with a soft cloth

- Avoid direct sunlight

- Handle with care

Order Now and indulge in the art of luxury perfume storage!

Make this New Year truly special, Order now to get the best price

Contact Email ID: [email protected]

Contact Number: +91–90510 51051 (INDIA)

Select Your Design or Decide a Design: Decide the shape, size, and finish that fits your decor style. Customize Colors & Finish: Pick from various colors and wood finishes. Add Personalization: Include names, dates, or any unique message to make it yours & an Example Product.

#home & lifestyle#wooden perfume box#luxury wooden products#interior decorating#living room#interior decor#decor#home decorating#business#luxury wooden perfume box#customizable gift#perfume storage#wooden gift box#high-end home decor#personalized gift#LuxuryPerfumeBox#WoodenPerfumeBox#WeddingGifts#AnniversaryGifts#BirthdayGifts#WoodenFurniture#CustomDesign#PersonalizedGifts#ElegantHome#SophisticatedStyle#ClassicDesign#HomeDecorEnthusiasts#LuxuryLiving#GiftGivingIdeas#ShopNow

1 note

·

View note