#Reverse air baghouse manufacturers

Explore tagged Tumblr posts

Text

cyclone dust collector manufacturers in Mumbai

We are leading manufacture dust collectors and multiclone dust collector for various industrial applications cyclone dust collector manufacturer,cyclone dust collector manufacturers In India.

#cyclone dust collector manufacturers#cyclone dust collector manufacturer in india#calciner manufacturers#cyclone dust collector Suppliers#cyclone dust collector Suppliers india#multiclone dust collector#centrifugal fan manufacturers in india#industrial blower manufacturers in india#tube axial fans manufacturers india#dust collector system manufacturer india#fume extraction system manufacturers#Cyclone dust collector#Reverse air baghouse manufacturers#scrubber manufacturers in india#venturi scrubber manufacturers#industrial fan manufacturers#axial fan manufacturers#bag filter manufacturers in india#bag filter manufacturers

0 notes

Text

Breathing Easy: Understanding Fabric Filters and Dust Extraction Systems

Dust. It's an unavoidable byproduct of many industrial processes, from manufacturing and construction to food processing and pharmaceuticals. While seemingly insignificant, dust can pose serious challenges:

Respiratory Hazards: Airborne dust can irritate the respiratory system, leading to health issues for workers.

Product Contamination: Dust can contaminate products, reducing quality and increasing waste.

Equipment Damage: Dust buildup can clog machinery, leading to reduced efficiency, increased maintenance costs, and even equipment failure.

Environmental Impact: Dust emissions can contribute to air pollution, negatively impacting the environment and potentially violating environmental regulations.

Fortunately, effective solutions exist to combat these challenges: fabric filters and dust extraction systems.

Fabric Filters: The Heart of Dust Collection

Imagine a giant sieve, but instead of holes, it has countless tiny fibers. That's essentially what a fabric filter, often referred to as a baghouse, is. These systems utilize a series of fabric bags to capture particulate matter from the air stream. As dust-laden air passes through these bags, the dust particles become trapped within the fabric's intricate network.

How Fabric Filters Work:

Air Intake: Dust-laden air is drawn into the fabric filter.

Filtration: As the air passes through the fabric bags, dust particles are captured.

Cleaning: To prevent excessive pressure buildup, the collected dust must be regularly removed. This is typically achieved through methods such as:

Shaking: Mechanically shaking the bags to dislodge dust.

Reverse Air: Briefly reversing the airflow to blow off dust.

Pulse Jet: Short bursts of compressed air are injected into the bags to dislodge dust.

Clean Air Exhaust: Clean air is then released back into the environment.

Dust Extraction Systems: A Comprehensive Approach

Fabric filters are often integrated into a larger dust extraction system, which comprises a network of components designed to capture and remove dust at its source.

Key Components of a Dust Extraction System:

Hoods and Enclosures: Capture dust at the point of generation, preventing it from spreading.

Ductwork: Transports the dust-laden air to the fabric filter.

Fabric Filter: Removes dust particles from the air stream.

Fan: Moves the air through the system.

Dust Collection Hopper: Collects the captured dust for proper disposal.

Benefits of Implementing Dust Extraction Systems:

Improved Air Quality: Reduces dust levels in the workplace, creating a healthier and safer environment for employees.

Enhanced Product Quality: Minimizes dust contamination, leading to improved product quality and reduced waste.

Equipment Protection: Protects machinery from dust buildup, extending equipment life and reducing maintenance costs.

Environmental Compliance: Helps businesses comply with environmental regulations by minimizing dust emissions.

Increased Productivity: A cleaner work environment can boost employee morale and productivity.

Choosing the Right System

Selecting the most appropriate dust extraction system requires careful consideration of several factors, including:

Type and volume of dust generated

Airflow requirements

Space constraints

Maintenance requirements

Budgetary considerations

Specific industry regulations

By carefully evaluating these factors and consulting with experts in the field, businesses can select a dust extraction system that effectively addresses their specific needs and contributes to a cleaner, safer, and more productive work environment.

In Conclusion

Fabric filters and dust extraction systems are essential tools for maintaining a clean and safe industrial environment. By effectively capturing and removing dust, they not only improve worker health and safety but also enhance product quality, protect equipment, and minimize environmental impact. Investing in these systems is an investment in a healthier, more efficient, and more sustainable future.

Disclaimer: This blog post provides general information and should not be considered professional advice.

0 notes

Text

Dust Collectors

Dust collectors are devices or systems designed to remove particulate matter (dust) from air or gas streams. They are commonly used in various industries to improve air quality, protect equipment, and ensure a safer working environment. Dust collectors come in different types and configurations, each suited for specific applications. Here are some common types of dust collectors:

Cyclone Dust Collectors:

These use centrifugal force to separate dust particles from the air stream. As the contaminated air enters a cyclone chamber, it swirls around, causing heavier particles to fall into a collection container.

Baghouse Dust Collectors:

Baghouses use fabric bags to capture dust. The contaminated air passes through the fabric bags, and the dust particles are collected on the surface. Periodically, the bags are cleaned using methods like reverse air or pulse-jet cleaning.

Cartridge Dust Collectors:

Cartridge collectors use cylindrical cartridges with filter media to capture dust. These collectors are compact and efficient, making them suitable for various industries.

Electrostatic Precipitators:

Electrostatic precipitators charge particles in the air and then collect them on oppositely charged plates. They are effective for removing both fine and coarse particles.

Wet Scrubbers:

Wet scrubbers use water or other liquid solutions to trap and remove dust particles from the air. They are often used when dealing with sticky or corrosive dust.

Portable Dust Collectors:

These are smaller, mobile units that can be moved to different locations as needed. They are often used in situations where a centralized dust collection system is not practical.

Downdraft Tables:

Downdraft tables are workstations with built-in dust collection systems. They are commonly used in woodworking and metalworking to capture dust generated during the manufacturing process.

sourcetec industries are help in dust collection is crucial for maintaining a healthy and safe work environment, complying with environmental regulations, and protecting machinery from the abrasive effects of dust. Choosing the right type of dust collector depends on factors such as the type of dust, volume of air, and the specific requirements of the industry or process. Regular maintenance is also essential to ensure the efficient operation of dust collectors.

0 notes

Text

How to choose the best Dust collector for your needs

Choices abound in life. Making sure to choose the right Dust collection system Manufacturers is the challenge. The "obvious solution" might not be the best choice based on your particular situation, depending on the problem.

Which of the two primary choices, dry dust collectors or wet dust collectors (scrubbers), is best for you in the case of dust collecting, for instance?

What should be the perfect choice? Dry dust collector or wet dust collector

The mechanisms used for gathering the dust for dry dust include reverse air cyclones, baghouse collectors, and cartridge collectors. For the heaviest dust loads, baghouse collectors are the recommended alternative. Cartridge dust collectors might be more suitable for dry, free-flowing dust, while reverse air collectors could be the best choice if you need to conserve energy or have restricted access to a reliable source of compressed air.

Wet scrubbers are a type of dust collector that uses liquid. These devices include adding the cleaning liquid—typically water—to a gas stream holding the dust particles. Increased dust removal efficiency results from increased gas and liquid stream interaction. Options for wet scrubbing include packed-tower, impingement, venturi, and educator scrubbers.

It's crucial to keep in mind that selecting between dry collecting of particles and wet scrubbing may not always be a simple binary choice. The application of the two categories' representatives in combination might be the most effective course of action in some circumstances.

Differentiating Factors

Even if you are completely knowledgeable about the type of dust you want to collect and are aware of the numerous wet and dry dust extraction methods and technologies readily accessible there can be tough situations waiting to catch the unwary.

You should always take expert opinions and consult a professional Dust collection system Manufacturers for a hassle-free service. B.D.FANS’ high effectiveness, minimal pressure drop multi-cyclone separators guarantee efficient dust particle collection at a cheap establishment cost. Visit our website and get in touch with us for further queries.

0 notes

Text

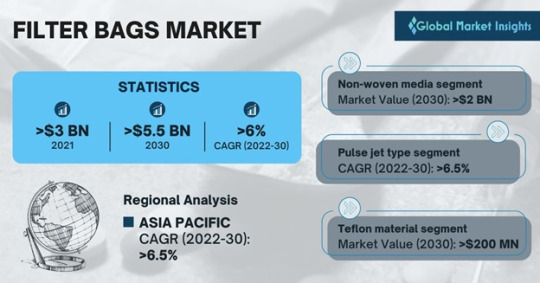

Filter Bags Market Trends, Segmentation and Registering a Strong Growth by 2030

The global filter bags market size is projected to expand considerably over 2022-2030, on account of the implementation of strict government regulations to limit plastics usage.

A notable example is the implementation of the Single-use Plastics Prohibition Regulations by the Canadian Government, to ban the manufacture, import, sale, and export of single-use plastic items from the country. Strict mandates like these are likely to encourage consumers to rely on paper for packaging and other applications.

Get sample copy of this research report @ https://www.gminsights.com/request-sample/detail/3152

Since filtration is an indispensable process in pulp and paper production processes, the prohibition of plastic usage and burgeoning paper production is expected to augment the use of filter bag systems. Apart from paper processing, filtration is a key requirement in textile, tire, and paints and dyes manufacturing, further supporting the growth of industrial filter bag manufacturers. The filter bags market is segregated based on type, media, material, application, and region.

In terms of type, the market value from the reverse air segment is slated to rise considerably over the next 8 years. The product is adopted in high-temperature and combustible dust applications, making it ideal for coal filtration. Other favorable properties such as low energy use, reliable and effective cleaning, and high performance will also escalate the consumption of reverse air filter bags in industrial sectors.

The filter bags market share from the woven media segment is anticipated to rise by 2030. The increasing reliance on coal-fired power plants to ease power supply disruptions in Europe is one of the key growth drivers. Apart from coal-fired utilities, filter baghouses are utilized in chemical processing. With the rapid expansion of chemical plants, the consumption of woven filter bags is likely to increase, especially in North America.

Based on the material, the market value from the polyester segment was over USD 800 million in 2021, owing to its applicability in elevated temperatures and its chemical resistance. Other key attributes including resistance to minerals and organic acids make the material ideal for use in chemical industry processes. The global adoption of polyester filter bags is expected to further grow, as a result of the strong demand from the plastics, detergents, and paints industries.

Filter bags market value from metals applications is projected to register more than 6% CAGR through 2030, due to the applicability of high temperature-resistant Nomex filter bags in sponge iron, steel, aluminum, and non-ferrous metallurgical sectors. In recent years, the need for metals in the automotive industry has also surged, further asserting a positive influence on filter bag manufacturers.

Request for customization @ https://www.gminsights.com/roc/3152

From a regional frame of reference, the Latin American filter bags industry is poised to exhibit over 5.5% CAGR through 2030. The mounting production and export levels of steel and iron in countries including Brazil will proliferate the use of filter bags in smelters and coke ovens for metal working applications.

The growing awareness regarding the significance of hygiene has also fueled the production of soaps and detergents. These factors will stimulate the requirement for filtration solutions in material handling applications in the soap industry across the LATAM region.

Table of Contents (ToC) of the report:

Chapter 1 Methodology & Scope

1.1 Definitions

1.2 Base estimates & calculations

1.3 Forecast calculations

1.4 Data Sources

1.4.1 Primary

1.4.2 Secondary

1.4.2.1 Paid Sources

1.4.2.2 Public Sources

Chapter 2 Executive Summary

2.1 Global filter bags market 3600 synopsis, 2022 – 2030

2.1.1 Business trends

2.1.2 Regional trends

2.1.3 Type trends

2.1.4 Material trends

2.1.5 Media trends

2.1.6 Application trends

Browse complete Table of Contents (ToC) of this research report @ https://www.gminsights.com/toc/detail/filter-bags-market

HVAC & Construction Research Reports

Ice Maker Market

Rubber Conveyor Belt Market

Lawn & Garden Equipment Market

About Global Market Insights:

Global Market Insights, Inc., headquartered in Delaware, U.S., is a global market research and consulting service provider; offering syndicated and custom research reports along with growth consulting services. Our business intelligence and industry research reports offer clients with penetrative insights and actionable market data specially designed and presented to aid strategic decision making. These exhaustive reports are designed via a proprietary research methodology and are available for key industries such as chemicals, advanced materials, technology, renewable energy and biotechnology.

Contact Us:

Aashit Tiwari

Corporate Sales, USA

Global Market Insights Inc.

Toll Free: 1-888-689-0688

USA: +1-302-846-7766

Europe: +44-742-759-8484

APAC: +65-3129-7718

Email: [email protected]

#Filter Bags Market Analysis#Filter Bags Market by Type#Filter Bags Market Share#Filter Bags Market Development

0 notes

Text

Fabric Bag Dust Collector | Fabric Bag Dust Collector Manufacturer in India | Fabric Bag Dust Collector Supplier in India | Fabric Bag Dust Collector Price in India | Fabric Bag Dust Collector in India

Fabric Bag Dust Collectors, normally referred to as Bag Filters, Baghouse, are maximum usually used dirt collectors for massive dirt process applications. Bag filters use long cylindrical tubes of woven fabric material or non-woven felt fabric material bags of 05 - 12 inches diameter (130 - 300 mm), and 6.5 - 10 feet (2M - 3M) or more in length, open from one cease.

Some of the clear-out bag tubes are housed inside the dirt collector frame forming a matrix of rows, in reference to the total filter-out fabric area needed for the designed ability of a dirt collector. The high extent centrifugal blowers of designed pressure create required suction for Dust Collector from the source.

Working of Fabric Bag Dust Collector

Dust-laden air is drawn into the dust collector through the inlet due to suction created via exhaust fan and passes through material luggage. Heavier dirt particles fall into the hopper because of a loss of momentum. Finer dust gets deposited on the inner surface of material baggage and easy air passes across the outer surface of filter-out bags after which exit into atmosphere through the outlet. Baggage is wiped clean through the motorized shaking arrangement. When a motor is switched OFF, the shaking cycle receives activated automatically and baggage is shaken for the preset timer. Dust launched from filter out luggage slides downward into the hopper for in addition collection into the dustbin.

Features of Fabric Bag Dust Collector

· Low maintenance and replacement of fabric, bags is easy and quick

· Assures longer life of bags

· Fabric bags are normally of cotton woven satin cloth. However, other materials can be supplied to suit individual application

Motorized Shaking Fabric Bag Dust Collector

Motorized Shaking fabric Bag dust Collector or a shaker dust collector also referred to as shaker fabric filter out refers to a dirt collector using a shaker cleaning device to remove the collected dust particles from the floor of the filter out media via mechanically shaking the clear-out luggage with the help of a motor. This may be accomplished by way of two approaches either manually or through the use of a motor driving an eccentric which in turn has been linked to the filter out bags.

Applications of Motorized Shaking Fabric Bag Dust Collector

· Woodworking Dust Collection

· Sand Blasting Machines

· Shot Blasting Machines

· Metal Grinding

· Pharmaceutical

· Paper Core Grinding

· Grinding or Buffing Applications

Reverse Pulse Jet Fabric Bag Dust Collector

In reverse pulse jet fabric bag dirt collector, individual luggage is supported with the aid of a steel cage within the cloth bag that is mounted onto a mobile plate at the pinnacle of the bag clear out. Dirty gas enters from the bottom of the bag filter and flows from outside to in the bags. The metal cage prevents fall apart of the bag filter out.

Application of Reverse Pulse Jet Fabric Bag Dust Collector

· Woodworking Dust

· Sand Blasting

· Shot and grit blasting

· Ceramics

· Pharmaceuticals

· Chemicals

· Activated Carbon

· Food Processing

· Rubber

Reverse Pulse Jet Pleated Filter Dust Collector

Reverse Pulse Jet Pleated filter a dust Collector is a unit of dirt collector that is maximum typically utilized in industries or factories. An excessive stress blasting of air is done to put off dust from the Pleated filter bag. The blasted air enters from the top of the Pleated filter bag tube, quickly stopping the go with the flow of grimy air. The unexpected surprise of air causes a wave of expansion to journey down the pleated clear-out bag.

Applications of Reverse Pulse Jet Pleated Filter Dust Collector

· Sand Blasting, shot, or grit blasting machines

· Metalizing spray Booth

· Powder Coating Booth

· Pharmaceuticals

· Cement

· Powder & Coating

· Metals & Minerals

· Chemicals

· Steel & Power

Fabric Bag Dust Collector Manufacturer in India

We are the leading Fabric Bag Dust Collector manufacturer in India. Blast Room is the best supplier and exporter of Pleated Filter Bag Dust Collector, sand blasting machine, grit blasting machine, shot blasting machine, Dust Collector, abrasive media, thermal spray gun, sand blasting nozzles, sand blasting cabinets, etc.

Shot Blasting Machine | Sand Blasting Machine | Portable Sand Blasting Machine | Sand Blasting Cabinet

#Fabric Bag Dust Collector Supplier in India#Fabric Bag Dust Collector Manufacturer#Fabric Bag Dust Collector Price in India

0 notes

Text

Baghouse Market Augmented Expansion to be Registered until 2025

Baghouse Market

The research report on Baghouse Market analyzes the entire production and supply chain of the market and provides data as per the various situations. Then again, the report likewise gives the data related to price, cost, value, volume, pay, income, and net revenue of the market utilized in different fields, which are in high demand in the major regions and by various organizations. In this manner, filling in as a precious source of guidance for readers, covers an analytical overview of the industry chain of the global market and discusses key elements related with it, including driving purchasers, driving crude material suppliers, and suppliers of manufacturing equipment.

Our analysis involves the study of the market taking into consideration the impact of the COVID-19 pandemic on Baghouse Market. Please get in touch with us to get your hands on an exhaustive coverage of the impact of the current situation on the market. Our expert team of analysts will provide as per report customized to your requirement. For more connect with us at [email protected] or call toll free: +1-800-910-6452.

Request a in-depth Sample Copy of This Report Including: TOC, Table and Figures @ https://www.bigmarketresearch.com/request-sample/4065463

Scope of the Reports:

A portion of the real key players working in the Baghouse Market Report include , Babcock & Wilcox , Pall , Thermax , Eaton , Mitsubishi Hitachi Power Systems , Parker Hannifin , General Electric , Camfil Farr , BWF Envirotech , W.L. Gore & Associates , Lenntech , Rosedale Products , Donaldson Company,

Basis of Product types

Mechanical Shaker Bag Filter Reverse Air Bag Filter Pulse Jet Bag Filter

Basis of applications

Steel Mills Power Plants Chemicals Pharmaceutical Food Others

Regional Analysis of the Global Baghouse Market:-

North America (United States, Canada, Mexico)

South America ( Brazil, Argentina, Ecuador, Chile)

Asia Pacific (China, Japan, India, Korea)

Europe (Germany, UK, France, Italy)

Middle East Africa (Egypt, Turkey, Saudi Arabia, Iran) and More.

The report analyses the past, present and future performance of the market in the industry. The report also sheds light on the prevalent business models, competitive scenario, growth drivers and restrains, production value, cost structure, branding and labelling, advertising and marketing strategies, market share, market size, key market players, barriers and challenges and other important segments of the market.

Significant Questions Covered in this Report: 1. What will the market size be in 2025? 2. What are the key factors driving the global market? 3. What are the challenges to market growth? 4. Who are the key players in the market? 5. What are the market opportunities and threats faced by the key players? 6. What will be the growth rate in 2025? 7. Which strategies are used by top players in the Baghouse market?

This report provides:

An in-depth overview of the global market for Baghouse.

Assessment of the global industry trends, historical data from 2015, projections for the coming years, and anticipation of compound annual growth rates (CAGRs) by the end of the forecast period.

Discoveries of new market prospects and targeted marketing methodologies for Global Baghouse Market.

Discussion of R&D, and the demand for new products launches and applications.

Wide-ranging company profiles of leading participants in the industry.

The composition of the market, in terms of dynamic molecule types and targets, underlining the major industry resources and players.

The growth in patient epidemiology and market revenue for the market globally and across the key players and market segments.

Study the market in terms of the generic and premium product revenue.

Determine commercial opportunities in the market sales scenario by analyzing trends in authorizing and co-development deals.

Avail 10% Discount on this Research report@ https://www.bigmarketresearch.com/checkout/sales/22136 [Coupon Code = ORG128KS]

About Us: Big Market Research has a range of research reports from various domains across the world. Our database of reports of various market categories and sub-categories would help to find the exact report you may be looking for.

We are instrumental in providing quantitative and qualitative insights on your area of interest by bringing reports from various publishers at one place to save your time and money. A lot of organizations across the world are gaining profits and great benefits from information gained through reports sourced by us.

Contact Us: Mr. Abhishek Paliwal 5933 NE Win Sivers Drive, #205, Portland, OR 97220 United States Direct: +1-971-202-1575 Toll Free: +1-800-910-6452 E-mail [email protected]

0 notes

Text

Working principle of baghouse dust collectors

Air treatment devices are widely used in industry for accurate cleaning of ventilation air from dust particles, as well as for industrial and sanitary cleaning of gas emissions. Baghouse dust collectors are regarded as the most widespread in the industry for dry air treatment of gas emissions from impurities.

The baghouse dust collector for ventilation and air treatment is one of the most effective air treatment devices capable of catching air pollutants and used for cleaning gases and gas mixtures. The air treatment system can be used both as part of an internal ventilation system that returns air to the premises and for removal dust contaminants from the air from buildings.

The design and principle of baghouse collector operation offer several functional and technological advantages:

easy installation and operation of the air treatment system;

continuous operation as part of the ventilation system;

easy maintenance and minimal maintenance costs;

effective air treatment from pollution with simultaneous and cyclical cleaning of the dust collector from accumulated material.

These advantages explain the prevalence of baghouse dust collectors in the industry. Catching and removing air pollutants ranging in size from 0.1 to 100 micrometers in the circulation or output mode is an opportunity to ensure the maintenance of a safe mode operation and reduce the impact on the environment.

The design of the baghouse collector is developed to allow a large amount of air or gas passing through it, which is sent to the baghouses of dust collectors that hold dust particles. Depending on the type of installation, the baghouse dust collectors can also be installed horizontally so that the maximum amount of air passes through them. Dust, soot and other air pollutants pass through the tissue and do not pass further, in the direction of the outlet for clean air.

The vast majority of bag type air treatment devices consists of several modules:

body frame with filter elements;

inlet shutter for air-gas mixture;

groups of baghouses or individual baghouses;

outlet shutter with automatic pressure monitoring;

regeneration system - devices for quick cleaning of baghouse dust collectors from accumulated dust.

Such features as the simplicity of the design and the ability to effectively collect dust, soot, and partially small teardrop-shaped contaminants make the baghouse dust system used in industries where the technological process is associated with the constant leakage of small contaminants and a dusting of air.

Fields of application and features of operation

The need for continuous air treatment from a large number of small particles from materials and products is experienced by a wide range of industries. This is the reason why baghouse dust collectors are commonly used:

in the chemical and food industry;

in mining and processing production;

in foundry production, in metallurgy;

at flour mills, elevators and other enterprises where the processing and storage of raw materials remains a source of dust;

on production sites and in painting shops.

Depending on the requirements for air purity and the characteristics of technological processes, baghouse collectors can be equipped with baghouses from different materials - these are both natural and synthetic woven and non-woven cloths rolled into baghouses. The effectiveness of air treatment from certain types of air pollution can be improved by using porous materials or fabrics with relieved fibers and its synthetic analogs.

Baghouse collector design allows its installation in different ways. As a rule, the service life of one baghouse dust collector lasts several years. In the absence of aggressive air pollution that destroys the structure of the fabric, the regeneration system copes with its task and maintains the throughput of the dust collector throughout the entire operation cycle.

Baghouse collector cleaning or baghouse regeneration can be performed using two principles of action to accumulated particles. Depending on the dust types, it can be removed in two main ways:

intensive shaking of the baghouse, in which the particles fall and are sent to the hopper for removal;

pulsed blowdown of the baghouse dust collector with a reverse current of air or a gas-air mixture, "knocking out" particles from the pores of the fabric.

A combined technique can be used in individual air treatment systems, but this is not always effective; the choice of solution depends on the characteristics of production and the properties of pollutants.

The regeneration of the baghouses turns on automatically - as dust accumulates on the surface of the dust collector, its throughput decreases, the air pressure at the outlet drops, and the sensing system responds by activating a reverse blow or a shaking mechanism. The most effective technique is the baghouse arrangement, it means that there are three baghouses in the active zone of the collector, herewith, one of the dust collectors is regenerated, and two other continue to operate in the cleaning mode.

Efficiency and productivity of baghouse dust collectors

The general design and principle of baghouse system operation for air treatment allows organizing a consistent process. Several baghouses are installed in series, catching various types of air pollution. If we take into account that such a system is usually mounted at the stage of mechanical air treatment, then its effectiveness determines the success of the whole air treatment systems in industries.

Baghouses for dust collector are manufactured at specialized enterprises and are regarded as standardized parts. They can be selected by capacity, degree of treatment, size of filtering pores and fibers, design of the fastener. Baghouse dust collectors are designed to treat dust and gas flows with temperatures up to +260 ° C and initial dust content of up to 100 g/m³.

These dust collectors belong to the "dry" type of dust-collecting equipment. Baghouse collectors demonstrate a higher efficiency of gas treatment in comparison with any types of electrostatic scrubbing systems and gas wet scrubbers. The residual dust content at the outlet after baghouse dust collectors is usually not more than 10 mg/m³ (there are modifications of dust collectors with a lower residual dust content up to 1 mg/m³). Baghouse collectors can be equipped with filter bags made from high-temperature filter materials (polytetrafluoroethylene, polyimide) with operating temperatures up to +260 °C.

The dust collectors are designed for both flue gas air treatment and aspiration emissions from enterprises in various industries:

ferrous metallurgy;

nonferrous metallurgy;

building materials industry;

engineering;

foundry;

metalworking;

glass industry;

chemical industry;

mining industry;

food industry;

woodworking and furniture industry;

energy.

Baghouse dust collectors are the most universal type of dust and gas air treatment devices, as they are able to reliably and efficiently operate in almost all dust-emitting technological processes. Baghouse systems are able to operate continuously and do not require constant maintenance.

The versatility of baghouse collectors can also include the fact that a dust collector with specified characteristics can be manufactured in several designs, with different overall dimensions. In most cases, it is possible to select (or develop) the design of a baghouse collector, taking into account the size and limitations of the existing space for installing the scrubbing system.

The air treatment material and its processing (antistatic, water-oil-repellent, etc.) are selected depending on the operating conditions of the dust collector and the properties of the captured dust.

Two designs of the baghouse dust collector are applied:

round design (Ø135 mm) for collectors with vertical baghouses;

the elliptical design used for both horizontal and vertical baghouses.

The service life of baghouses in baghouse dust collectors averages 2-3 years, and in some cases can reach 6 or more years of effective operation. Timely replacement of baghouses is a guarantee of the effective dust collector operation, and the emergence of more modern air treatment materials helps to ensure the relevance of the baghouse dust collectors while reducing environmental standards for residual dust in the future.

The autonomy of the operation and the performance of baghouse collectors are provided by a regeneration system of treatment elements.

The disadvantages of baghouse dust collectors include:

- high cost compared to cyclone scrubbers;

- the complexity of the air treatment device, which requires qualified service personnel;

- operation in conditions of limited dust concentrations in the air stream;

- variable hydraulic resistance. Nevertheless, this disadvantage is compensated by effective methods of regeneration (cleaning) of air treatment elements.

Therefore, wet scrubbing systems remain the most commonly used air treatment devices that allow complying with air pollution control regulations. If you search the best air treatment device to improve air quality at the industry, you can buy a high-tech completely new type of wet air scrubber – a Multi-Vortex wet air scrubber produced by Optromix company.

0 notes

Text

cyclone dust collector manufacturers

CYCLONE & MULTICYCLONE

#cyclone dust collector manufacturers#cyclone dust collector manufacturer in india#calciner manufacturers#cyclone dust collector Suppliers#cyclone dust collector Suppliers india#multiclone dust collector#centrifugal fan manufacturers in india#industrial blower manufacturers in india#tube axial fans manufacturers india#dust collector system manufacturer india#fume extraction system manufacturers#Cyclone dust collector#Reverse air baghouse manufacturers#scrubber manufacturers in india#venturi scrubber manufacturers#industrial fan manufacturers#axial fan manufacturers#bag filter manufacturers in india#bag filter manufacturers#id fan manufacturers#centrifugal fan manufacturers#industrial blower manufacturers#tube axial fan manufacturers#dust collection system manufacturers#dust collector system#fume extraction system#pyrolysis plant manufacturers in india#pyrolysis plant#cartridge filter manufacturers in india#baghouse manufacturers india

1 note

·

View note

Text

Fabric Filters: Efficient Dust Collectors for Cleaner Operations

In many industrial processes, dust particles are generated as a byproduct, posing significant risks to worker health, equipment, and the environment. Dust collection systems are crucial for capturing these particles and ensuring a safe and efficient operating environment. Among these systems, fabric filters stand out as a highly effective and versatile solution.

How Fabric Filters Work

Fabric filters, often referred to as "baghouses," utilize a network of fabric bags to capture dust particles from the air stream. As contaminated air passes through these bags, dust particles become trapped within the fabric's fibers. This process effectively removes particulate matter from the air stream, ensuring cleaner emissions and a healthier working environment.

Key Advantages of Fabric Filters:

High Efficiency: Fabric filters are renowned for their high efficiency in capturing a wide range of particulate matter, including fine dust particles.

Versatility: Suitable for a broad spectrum of industrial applications, from manufacturing and processing to power generation.

Cost-Effectiveness: While initial investment may vary, fabric filters often demonstrate lower operating costs compared to some other dust collection technologies.

Adaptability: Fabric filter systems can be customized to accommodate various dust types, gas flow rates, and specific application requirements.

Types of Fabric Filters

Pulse Jet Filters: Utilize short bursts of compressed air to dislodge dust from the filter bags, ensuring continuous operation.

Reverse Air Filters: Employ a reverse flow of air to clean the filter bags, dislodging the captured dust.

Shaker Filters: Utilize mechanical shaking to dislodge dust from the filter bags.

Factors Affecting Fabric Filter Performance

Several factors can influence the performance of fabric filters:

Particle size and distribution: The size and concentration of particles in the air stream.

Gas flow rate and temperature: The volume and temperature of the gas passing through the filter.

Filter media selection: The choice of filter fabric is crucial, as it must be compatible with the specific dust type and operating conditions.

Maintenance: Regular maintenance, including filter bag cleaning and replacement, is essential for optimal performance.

Intensiv-Filter Himenviro: A Partner in Dust Collection Solutions

Intensiv-Filter Himenviro is a leading provider of industrial dust collection systems, including advanced fabric filter solutions. They offer:

Customized solutions: Tailored fabric filter systems to meet specific application requirements.

High-quality products: Durable and efficient fabric filter systems.

Expert support: Comprehensive installation, maintenance, and repair services.

Energy efficiency: Systems designed to minimize energy consumption.

Environmental compliance: Solutions that help meet stringent environmental regulations.

Conclusion

Fabric filters are a cornerstone of effective dust collection in many industrial settings. By investing in high-quality fabric filter systems and partnering with experienced providers like Intensiv-Filter Himenviro, businesses can ensure a clean and safe working environment, improve product quality, and minimize their environmental impact.

Disclaimer: This information is for general knowledge and informational purposes only. It is not intended as professional advice. For specific applications and requirements, consult with qualified professionals and experts in the field of air pollution control.

0 notes

Text

Baghouse Performance Monitoring For Reduced Operating Costs

March 19, 2019

Process Industry Informer

For optimum performance, fabric filter baghouses require correct and timely maintenance. ENVEA’s UK business (formerly PCME) manufacture a range of particulate monitoring systems, from simple leak to QAL1 certified measurement instruments providing Process Operators with an improved understanding of their baghouse operation.

Designed to monitor dust releases from single or multiple filter compartment baghouses, sensors installed in the clean gas output of each filter chamber are able to detect leaks as they develop, even down at very low emission concentrations.

Knowing where leaks are developing enables process stoppages and maintenance times to be scheduled saving time and resources by highlighting which bags require changing prior to potential emission limit excursions.

In addition, ENVEA now provide sensors to warn of hopper blockages, often a cause of bag filter abrasion and which can potentially result in explosions within the filter. For Combustion applications which require sorbent injection such as lime or activated carbon, PicoFlow sensors are available to measure the quantity of injected sorbent.

Ensuring the correct amount is injected maintains acidic conditions in the filter at the desired level preventing costly damage to the baghouse and also helps to prevent sorbent over usage and consequent wastage.

Further details of ENVEA’s range of Particulate Emission and Solids Flow instrumentation can be found at www.enveauk.global

Process Industry Informer

Summarization of Filtration Products Website: Filtration Products page reports on the just out knowledge, research and filter products direct from the treatment field. Filtration-Products keeps you familiar on treatment and all the main professional events including string wound depth filtration, pleated elements, meltblown depth cartridges, bag filters, reverse osmosis filtration, from brands such as Culligan needed for air filtration, and anything else the filter biz has to present.

from Filtration Products https://ift.tt/2JqzGzd

0 notes

Text

Baghouse Filters Market 2025: Analysis by Material, Application & Geography - by Million Insights

22 October 2018 - Global Baghouse Filters Market is expected to grow at a significant CAGR in the upcoming years as the scope and its applications are rising enormously across the globe. Baghouse filters are also termed as fabric filters or dust collectors. These are the devices manufactured for nearly any dust producing application by changing size and bag types. It uses envelopes, fabric filter tubes, or cartridges to capture or separate dust and other particulate matter. These are most effective air pollution control instruments that work by eliminating particles from the electrical production processes or gas stream of industrial processes. Baghouse filters are exclusively known to remove 99.99% stubborn submicron particles.

The factors that are playing a major role in the growth of Baghouse Filters Industry are rising demand and popularity of hybrid electrostatic filters, rise in packaged food retail manufacturers, preservation of food products, and growing popularity of snack food products, frozen food products, and ready-to-cook food products. Baghouse Filters Market is segmented based on types, fiber type, applications, and region. Types such as Pulse Jet, Shaker, and Reverse classify Baghouse Filters Market.

View Full Report with TOC @ https://www.millioninsights.com/industry-reports/baghouse-filters-market

The shaker segment accounts the largest market share of Baghouse Filters Market and is estimated to lead the overall market in the upcoming years. The reason being, low-pressure drop, the capability to assimilate strong woven bags, and the ease of operation. Fiber type such as Fiberglass, Cotton, PVC, Polypropylene, Nylon, Homopolymer Acrylic, Polyester, PPS, Aramid, Polyimide, and PTFE classify Baghouse Filters Market.

Applications into Flooring, Veneer, Industrial Woodworking, Lumber, Architectural Woodworking, Composite Panel, Furniture & Fixture, Cabinetry, and others classify Baghouse Filters Industry. Baghouse Filters Market is segmented geographically into Americas (North America, South America), Europe (Eastern Europe, Western Europe), Asia Pacific, Latin America, Middle East and Africa. Globally, Asia Pacific accounts for the largest market share of Baghouse Filters Industry in terms of revenue and is estimated to lead the overall market in the years to come. This is mainly due to the, growing demand for processed food in the emerging countries like China and India and the growth in disposable incomes of people.

The key players of Baghouse Filters Market are DBA AGET Manufacturing Company, Aircon Corporation, Amerair Industries, Airex Industries, Baghouse America, Nederman Mikropul, Baghouse America, Griffin Filters, Camcorp, Imperial Systems, Scientific Dust Collectors, Gencor Industries, Kelin Environmental Protection Equipment, SLY, U.S. Filtration, and FUJIAN LONGKING. These players are concentrating on inorganic growth to sustain themselves amongst fierce competition. As such, mergers, acquisitions, and joint ventures are the need of the hour.

Market Segment:

The major manufacturers covered in this report

• Baghouse America

• Camcorp

• Donaldson Company

• Aquest Corporation

• Scientific Dust Collectors

• W.L. Gore & Associates, Inc.

• Gencor Industries

• Airex Industries

• IAC

• AGET

• Tarmac International

• Mac Process

• FLSmidth

Geographically, this report studies the top producers and consumers, focuses on product capacity, production, value, consumption, market share and growth opportunity in these key regions, covering

• North America

• Europe

• China

• Japan

• Southeast Asia

• India

Request Sample Copy of This Report @ https://www.millioninsights.com/industry-reports/baghouse-filters-market/request-sample

#Baghouse Filters Market Report#Baghouse Filters Market Demand#Baghouse Filters Market Segment#Baghouse Filters Market Forecast#Baghouse Filters Market Growth#Baghouse Filters Industry

0 notes

Text

Baghouse Filters Market to Witness an Outstanding Growth by ‘2025’

This report studies the global Baghouse Filters market status and forecast, categorizes the global Baghouse Filters market size (value & volume) by manufacturers, type, application, and region. This report focuses on the top manufacturers in North America, Europe, Japan, China, and other regions (India, Southeast Asia, Central & South America, and Middle East & Africa). The global Baghouse Filters market is valued at million US$ in 2017 and will reach million US$ by the end of 2025, growing at a CAGR of during 2018-2025.

Get Sample Request @ http://www.reportsintellect.com/sample-request/33670 The major manufacturers covered in this report Baghouse America Camcorp Donaldson Company Aquest Corporation Scientific Dust Collectors W.L. Gore & Associates, Inc. Gencor Industries Airex Industries IAC AGET Tarmac International Mac Process FLSmidth Imperial Systems Clarcor Industrial Air Staclean Diffuser Company Griffin Filters Nederman Mikropul Aircon Corporation Geographically, this report studies the top producers and consumers, focuses on product capacity, production, value, consumption, market share and growth opportunity in these key regions, covering North America Europe China Japan Southeast Asia India We can also provide the customized separate regional or country-level reports, for the following regions: North America United States Canada Mexico Asia-Pacific China India Japan South Korea Australia Indonesia Singapore Rest of Asia-Pacific Europe Germany France UK Italy Spain Russia Rest of Europe Central & South America Brazil Argentina Rest of South America Middle East & Africa Saudi Arabia Turkey Rest of Middle East & Africa On the basis of product, this report displays the production, revenue, price, market share and growth rate of each type, primarily split into Pulse Jet Reverse Air Shaker On the basis of the end users/applications, this report focuses on the status and outlook for major applications/end users, consumption (sales), market share and growth rate for each application, including Veneer Lumber Composite Panel Cabinetry Furniture & Fixture Architectural Woodworking Industrial Woodworking Flooring

Get Discount Report @ http://www.reportsintellect.com/discount-request/33670

The study objectives of this report are: To analyze and study the global Baghouse Filters capacity, production, value, consumption, status (2013-2017) and forecast (2018-2025); Focuses on the key Baghouse Filters manufacturers, to study the capacity, production, value, market share and development plans in future. Focuses on the global key manufacturers, to define, describe and analyze the market competition landscape, SWOT analysis. To define, describe and forecast the market by type, application and region. To analyze the global and key regions market potential and advantage, opportunity and challenge, restraints and risks. To identify significant trends and factors driving or inhibiting the market growth. To analyze the opportunities in the market for stakeholders by identifying the high growth segments. To strategically analyze each submarket with respect to individual growth trend and their contribution to the market To analyze competitive developments such as expansions, agreements, new product launches, and acquisitions in the market To strategically profile the key players and comprehensively analyze their growth strategies. In this study, the years considered to estimate the market size of Baghouse Filters are as follows: History Year: 2013-2017 Base Year: 2017 Estimated Year: 2018 Forecast Year 2018 to 2025 For the data information by region, company, type and application, 2017 is considered as the base year. Whenever data information was unavailable for the base year, the prior year has been considered. Key Stakeholders Baghouse Filters Manufacturers Baghouse Filters Distributors/Traders/Wholesalers Baghouse Filters Subcomponent Manufacturers Industry Association Downstream Vendors Available Customizations With the given market data, Reports Intellect offers customizations according to the company's specific needs. The following customization options are available for the report: Regional and country-level analysis of the Baghouse Filters market, by end-use. Detailed analysis and profiles of additional market players.

Get Purchase Report @ http://www.reportsintellect.com/inquire-before-buying/33670

0 notes