#Defoaming Agent Market report

Explore tagged Tumblr posts

Text

Defoaming Agent Market - Forecast 2024-2030

Defoaming Agent Market Overview

Defoaming Agent Market size is forecast to reach $10.13 billion by 2030 after growing at a CAGR of 4.1% during 2024-2030. Defoaming Agent is chemical additive that reduces the formation of foam in industrial process liquids. The growth of the market of Defoaming Agent is expected to be driven by the high demand from the food and beverages industry. A prominent trend in the Defoaming Agent market is the increasing demand for sustainable solutions. As industries prioritize environmental consciousness, there's a growing interest in Defoaming Agents derived from eco-friendly sources. Biodegradable and renewable Defoaming Agents, often plant-based, are gaining traction. Manufacturers are investing in research to develop formulations that provide effective foam control while aligning with sustainability goals, catering to environmentally conscious industries like food and beverage, pharmaceuticals, and wastewater treatment. Another trend involves technological advancements for precise foam control. Industries such as manufacturing, oil and gas, and chemical processing are seeking Defoaming Agents with improved efficiency and application precision. Innovations include the development of smart or responsive antifoaming solutions that can adapt to varying foam challenges dynamically. Nanotechnology is being explored to enhance the efficiency of Defoaming Agents. Nano-sized particles can offer improved dispersion and coverage, leading to enhanced foam control. This trend involves the development of nanomaterial-based Defoaming Agents with higher surface area and reactivity. The incorporation of nanotechnology also contributes to reducing the overall dosage of Defoaming Agents required for effective foam suppression. The use of Defoaming Agents is expanding beyond traditional industries. There is a growing demand for these agents in cosmetic and personal care product formulations where controlling foam is crucial for product stability and quality. As consumers become more discerning about the ingredients in personal care items, the market for Defoaming Agents in this sector is experiencing growth.

Defoaming Agent Market Report Coverage

The report: “Defoaming Agent Market -Forecast (2024-2030)”, by IndustryARC, covers an in-depth analysis of the following segments of Defoaming Agent industry.

By Type: Water Based, Oil Based, Silicone Based, Alkyd Based, Polymer Based and Others

By Application: Adhesives, Coatings, Detergents, Wood Pulp, Food Processing, Wastewater Treatment and Others.

By End Use: Oil and gas, Paint and coatings, Food and Beverages, Pharmaceuticals, Textile, Pulp and Paper, Industrial and Others.

Geography: North America, South America, Europe, APAC, and RoW.

Request Sample

Key Takeaways

APAC dominates the Defoaming Agent owing to increasing demand from Oil and gas sector.

Continues expanding application of Defoaming Agent will drive the growth of the market in the forecast period.

The formation of foam in industrial process liquids as it has an affinity to the air-liquid surface will hinder the growth of the market in the forecast period.

Defoaming Agent Market Segment Analysis - By Type

Silicone based Defoaming Agents held the largest share in the Defoaming Agents market in 2023. Silicone based Defoaming Agents have properties such as low surface tension, chemical inertness, thermal stability, and complete solubility in water. These Defoaming Agents have heavy duty type and are suitable for neutralizing surface foam and to release the entrained air in non-aqueous foaming applications. Hence, they have been finding preferential application in crude oil refineries. Silicone based Defoaming Agents contain less volatile organic compound due to the environmental regulation passed by the North America and Europe government. This Defoaming Agents are high in demand as compared to other chemicals due to its optimal reactivity with process ingredients and long operation life. This factor will drive the growth of market of silicone based Defoaming Agents in the forecast period.

Inquiry Before Buying

Defoaming Agent Market Segment Analysis - By Application

Food Processing held the largest share in the Defoaming Agents market in 2023. Food grade Defoaming Agents are used to reduce and prevent foam formation. Foam is a byproduct formed during processing of food. It is also used in the fermentation process in breweries to drain out the foam and offer optimize efficiency. The food processing industry is a mature sector that is undergoing a tumultuous phase due to rising global demands for food safety, increasing food insecurity and increasing customer demand for higher quality and sustainability. Today's food supply chain is more globalized, longer and more dynamic than ever before. With increasing imports and exports, processed foods rely on longer supply chains, which pose a major challenge to ensuring food safety.

Defoaming Agent Market Segment Analysis - By End Use

Pharmaceuticals sector held the largest share in the Defoaming Agents market in 2023 with a share of 7.3%. Defoaming Agent are used for pharmaceutic fermentation in antibiotics and enzymes. Among these the growing and aging population, rising prevalence of chronic diseases are major drivers in the growth of pharmaceutical sector globally. In the United States, overall spending growth in pharmaceutical is driven by a range of factors including new product uptake and brand pricing, while it is offset by patent expiries and generics. Pharmaceutical spending in China reached $7.1 billion in 2023. These factors will drive the growth of the market of pharmaceuticals in the forecast period.

The 2019–2020 coronavirus pandemic has had far-reaching consequences beyond the spread of the disease and efforts to quarantine it. As the pandemic has spread around the globe, concerns have shifted from supply-side manufacturing issues to decreased business. The current epidemic outbreak has deeply influenced consumers' daily life and in addition to the impact on pharmaceutical sector. About 90% of the needs of antibiotic makers in globally is fulfilled by China. Raw materials from China are used in making antibiotics, paracetamol, and diabetes and cardiovascular drugs, among others are not exported. This factor will hinder the growth of market for this year. But after the situation became normal it will grow at a steady rate in the forecast period.

Schedule a Call

Defoaming Agent Market Segment Analysis - By Geography

APAC dominates the Defoaming Agents market with a share of 48% followed by North America and Europe. The economy of APAC is mainly influenced by the economic dynamics of countries such as China and India, but with growing foreign direct investment for economic development of South East Asia, the current scenario is changing. Countries in South East Asia are witnessing high growth the oil and gas sector. Defoaming Agent are used in crude oil refinery as it helps in reducing frothy crude oil production by eliminating foam from tanks or gas scrubbers. The oil and gas sector plays a major role in influencing decision making for all the other important sections of the economy. According to the trade map the total export of light crude oil globally in the year 2023 was 102.2 mb/d. This factor will drive the growth of the market of oil and gas sector in the forecast period.

Defoaming Agent Market Drivers

High demand of crude oil across the world will drive the growth in the forecast period

High demand of crude oil across the world is expected to drive the global Defoaming Agent’s market growth. However, other non-renewable energy resources are not capable of fulfilling the growing demand. Oil and gas is one of the largest energy resources in the world; hence, it becomes essential to use and distribute crude oil in the productive and efficient way. This factor will drive the growth of market in the forecast period.

Rise in the Paint and coatings sector will drive the growth of market in the forecast period

The coatings industry is one of the most heavily regulated industries in the world, so producers have been forced to adopt low-solvent and solvent less technologies in the past 40 years, and will continue to do so. The number of coatings producers is large, but most are regional producers. This factor will drive the growth of market in the forecast period.

Buy Now

Defoaming Agent Market Restriction

Hike in the crude prices will hamper the growth of the market in the forecast period

Tremendous hike in the crude prices and global recession will hinder the growth of the market. This was on the back of a deepening slowdown in the world economy as the outbreak of novel coronavirus has spread across the globe and a price war between major oil producing countries like Saudi Arabia, Iran and Russia. These factor will hinder the growth of the market in the forecast period.

Defoaming Agent Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the Defoaming Agents market. Major players in the Defoaming Agents market are BASF, Evonik Industries, Air Products and Chemicals, Inc., Wacker Chemie AG, DOW Corning Corporation, and Others.

Acquisitions/Technology Launches/ Product Launches

In Oct 2023, Evonik Launches New Defoaming Agent that Combines the Best Properties of Silicone and Bio-Based Materials. The new product is targeted at water-based ink and coating applications, uses a unique new mixing technology, contains more than 50% bio-based materials in the solid content, and complies with multiple food contact regulations.

In May 2023, Jio-bp launches new diesel that offers saving of Rs 1.1 lakh per truck annually. It is designed to work across a range of commercial vehicles, and with ongoing use it offers a variety of benefits to drivers and fleet owners. It contains an anti-foam agent that helps deliver cleaner, faster, and safer refuelling, so trucks can spend more time on the road and less time at the pump.

#Defoaming Agent Market#Defoaming Agent Market size#Defoaming Agent industry#Defoaming Agent Market share#Defoaming Agent top 10 companies#Defoaming Agent Market report#Defoaming Agent Market industry outlook

0 notes

Text

Acrylic Coating Additives Market – Industry Trends and Forecast to 2029 Trends: Growth, Share, Value, Size, and Analysis

"Acrylic Coating Additives Market Size And Forecast by 2032

According to Data Bridge Market Research Global acrylic coating additives market size was valued at USD 1.34 billion in 2024 and is projected to reach USD 1.94 billion by 2032, with a CAGR of 4.80% during the forecast period of 2025 to 2032.

Acrylic Coating Additives Market is making waves in the industry with its latest advancements and market-driven strategies. As a leading player, Acrylic-Based Paint Additives Market continues to push boundaries by offering cutting-edge solutions that cater to evolving consumer demands. With a strong focus on innovation, Acrylic Coating Additives Market has successfully expanded its global footprint, providing businesses with high-quality services and products. The rapid growth of Performance Coating Additives Market is fueled by technological advancements, customer-centric approaches, and strategic partnerships. As Acrylic Coating Additives Market strengthens its position, it remains committed to delivering value-driven solutions that enhance market efficiency and growth.

Surface Enhancer Chemicals Market's impact on the industry is undeniable, with continuous efforts to enhance product offerings and service quality. By leveraging data-driven insights and advanced technologies, Acrylic Coating Additives Market ensures it stays ahead of market trends. The adaptability of Waterborne Acrylic Additives Market has allowed it to address diverse industry challenges while maintaining a competitive edge. Companies relying on Acrylic Coating Additives Market benefit from its expertise, robust infrastructure, and commitment to excellence. With increasing global demand, Industrial Acrylic Coatings Market is poised for sustained growth, driving innovation and transformation across various sectors.

Our comprehensive Acrylic Coating Additives Market report is ready with the latest trends, growth opportunities, and strategic analysis. https://www.databridgemarketresearch.com/reports/global-acrylic-coating-additives-market

**Segments**

- **Type**: The global acrylic coating additives market can be segmented based on type into rheology modifiers, defoamers, dispersing agents, wetting agents, anti-foaming agents, and others. Rheology modifiers are anticipated to witness significant growth due to their ability to enhance the performance of acrylic coatings.

- **Application**: By application, the market can be segmented into automotive, architectural, industrial, wood & furniture, and others. The architectural segment is expected to dominate the market share as acrylic coatings are extensively used in construction activities for their durability and aesthetic appeal.

- **End-Use Industry**: In terms of end-use industry, the acrylic coating additives market can be segmented into construction, automotive, furniture, packaging, and others. The construction industry is expected to be a key driver for market growth due to the increasing demand for acrylic coatings in residential and commercial construction projects.

**Market Players**

- **BASF SE**: A leading player in the acrylic coating additives market, BASF SE offers a wide range of additives that improve the performance of acrylic coatings in various applications.

- **Eastman Chemical Company**: Eastman Chemical Company is another prominent player known for providing high-quality acrylic coating additives that enhance the durability and appearance of coatings.

- **DowDuPont**: DowDuPont is a key player in the market, offering a comprehensive portfolio of acrylic coating additives that cater to specific industry needs and regulatory requirements.

- **Arkema Group**: Arkema Group is a global supplier of acrylic coating additives, known for its innovative solutions that meet the evolving demands of the market.

- **Evonik Industries AG**: Evonik Industries AG is a major player in the market, focusing on developing sustainable and high-performance acrylic coating additives for various end-use industries.

The global acrylic coating additives market is witnessing significant growth driven by the increasing demand for high-performance coatings in various industries. Key players in the market are focusing on product innovation and strategic partnerships to gain a competitive edge. With the expanding construction and automotive sectors, the market is poised for further growth in the coming years.

https://www.databridgemarketresearch.com/reports/global-acrylic-coating-additives-Market The global acrylic coating additives market is expected to continue experiencing robust growth as industries increasingly demand high-performance coatings to meet varying needs. One key trend shaping the market is the growing focus on sustainability, with companies like Evonik Industries AG investing in developing eco-friendly and high-performance additives for acrylic coatings. This trend is driven by stricter regulatory requirements and an overarching shift towards environmentally friendly practices across industries. Additionally, the market is witnessing a rise in the adoption of innovative solutions, as seen with Arkema Group's commitment to offering cutting-edge products that align with the evolving demands of the market.

Another noteworthy development in the global acrylic coating additives market is the emphasis on customization and tailored solutions to meet specific industry requirements. Companies like DowDuPont are leveraging their comprehensive portfolio of additives to address specific needs in different sectors, such as construction and automotive. This approach allows market players to strengthen their position by providing value-added solutions that cater to a diverse range of applications. Additionally, partnerships and collaborations between key players, such as BASF SE, Eastman Chemical Company, and other industry leaders, are driving innovation and fostering market growth through shared expertise and resources.

The architectural segment is poised to maintain its dominance in the market, driven by the widespread use of acrylic coatings in construction activities for their durability and aesthetic appeal. As urbanization and infrastructure development continue to drive construction projects globally, the demand for high-quality coatings is expected to surge, further fueling market growth. Moreover, the automotive sector presents significant opportunities for market players, with a growing need for advanced coatings that improve performance and longevity in vehicles. By offering additives that enhance the durability and appearance of coatings, companies like Eastman Chemical Company are well-positioned to capitalize on this trend.

Looking ahead, the global acrylic coating additives market is forecasted to experience sustained growth as industries prioritize quality, performance, and sustainability in their coating applications. Market players will continue to invest in research and development to introduce innovative additives that meet evolving market demands and regulatory standards. The expansion of end-use industries, coupled with increasing infrastructure development and technological advancements, will drive further opportunities for growth and expansion in the acrylic coating additives market.**Segments**

Global Acrylic Coating Additives Market, By Formulation: - Water-Borne - Solvent-Borne - Powder-Based

Function: - Anti-Foaming - Wetting and Dispersion - Biocides - Rheology Modification - Impact Modification - Others

Application: - Automotive - Architectural Application - Industrial Application - Wood and Furniture - Others

Industry Trends and Forecast to 2032:

The global acrylic coating additives market is experiencing a significant shift towards sustainable and high-performance solutions to meet the evolving demands of various industries. The market segmentation based on formulation, function, and application provides a comprehensive overview of the diverse uses and requirements for acrylic coating additives. With the increasing focus on eco-friendly options like water-borne formulations and the rising demand for specific functions such as biocides and impact modification, the market is projected to witness robust growth and innovation in the coming years. Industries such as automotive, architectural, and industrial applications are expected to drive market growth, supported by advancements in formulation technologies and tailored solutions.

**Market Players**

- Akzo Nobel N.V. (Netherlands) - Ashland. (U.S.) - ELEMENTIS PLC (U.K.) - Evonik Industries (Germany) - Eastman Chemical Company (U.S.) - ANGUS Chemical Company (U.S.) - Cabot Corporation (U.S.) - K-TECH (INDIA) PVT. LTD. (India) - The Lubrizol Corporation (U.S.) - Byk-Chemie GmbH (Germany) - BASF SE (Germany) - Dow (U.S.) - Arkema (France) - Chemicals Mfg. Co., Ltd. (Japan) - Meilian Chemical Co., Ltd. (China) - Allnex GMBH (Belgium) - Asahi Kasei Corporation (Japan) - DIC CORPORATION (Japan)

The global acrylic coating additives market is driven by a diverse range of market players offering innovative solutions to meet industry demands. Companies like Evonik Industries and Eastman Chemical Company are focusing on sustainability and high-performance additives, while others like BASF SE and Dow are emphasizing customization and tailored solutions to cater to specific industry needs. With an increasing emphasis on collaboration and partnerships among key players, the market is witnessing a surge in product innovation and market expansion. The presence of prominent players from various regions underscores the global nature of the market and the need for customized solutions in different applications and industries. As the market continues to evolve, market players are expected to invest in research and development to introduce cutting-edge additives that align with market trends and regulatory requirements, ensuring sustained growth and competitiveness in the global acrylic coating additives market.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies in Acrylic Coating Additives Market : https://www.databridgemarketresearch.com/reports/global-acrylic-coating-additives-market/companies

Key Questions Answered by the Global Acrylic Coating Additives Market Report:

What is the current state of the Acrylic Coating Additives Market, and how has it evolved?

What are the key drivers behind the growth of the Acrylic Coating Additives Market?

What challenges and barriers do businesses in the Acrylic Coating Additives Market face?

How are technological innovations impacting the Acrylic Coating Additives Market?

What emerging trends and opportunities should businesses be aware of in the Acrylic Coating Additives Market?

Browse More Reports:

https://www.databridgemarketresearch.com/reports/global-medical-aesthetics-markethttps://www.databridgemarketresearch.com/reports/global-identity-verification-markethttps://www.databridgemarketresearch.com/reports/global-premium-wine-markethttps://www.databridgemarketresearch.com/reports/global-blockchain-markethttps://www.databridgemarketresearch.com/reports/global-shampoo-market

https://www.databridgemarketresearch.com/reports/europe-driving-footwear-markethttps://www.databridgemarketresearch.com/reports/asia-pacific-driving-footwear-markethttps://www.databridgemarketresearch.com/reports/middle-east-and-africa-driving-footwear-markethttps://www.databridgemarketresearch.com/reports/north-america-driving-footwear-markethttps://www.databridgemarketresearch.com/reports/europe-plant-based-beverages-market

Data Bridge Market Research:

☎ Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 988

✉ Email: [email protected]"

#Acrylic-Based Paint Additives Market#Performance Coating Additives Market#Surface Enhancer Chemicals Market#Waterborne Acrylic Additives Market#Industrial Acrylic Coatings Market#Polymer Coating Enhancers Market#Acrylic Resins Market#Protective Coating Additives Market#High-Performance Acrylic Finishes Market#Decorative Coating Solutions Market

0 notes

Text

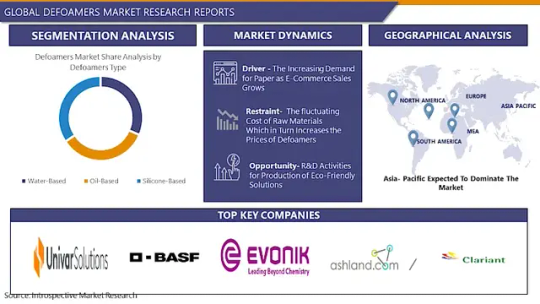

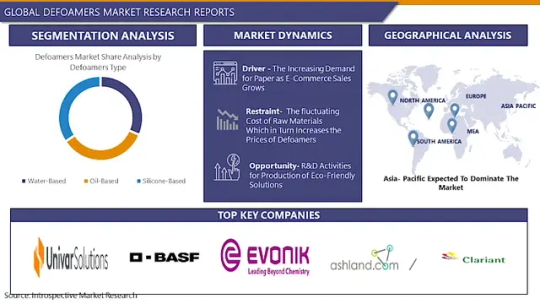

Defoamers Market Size, Share, and Competitive Landscape

Increasing Demand for Foam Control Solutions Across Industries Drives Growth in the Defoamers Market.

The Defoamers Market Size was valued at USD 3.6 billion in 2023, and is expected to reach USD 5.6 billion by 2032, and grow at a CAGR of 5.1% over the forecast period 2024-2032.

The Defoamers Market is driven by increasing demand for foam control solutions across various industries, including pulp & paper, wastewater treatment, food & beverages, paints & coatings, and pharmaceuticals. Defoamers, also known as anti-foaming agents, help in preventing and reducing foam formation, improving process efficiency, product quality, and operational stability. With growing industrialization and stricter environmental regulations, the market for eco-friendly and silicone-based defoamers is expanding rapidly.

Key Players in the Market

The global Defoamers market is highly competitive, with major industry players investing in product innovation, sustainable formulations, and advanced application technologies. Leading companies include:

The major key players are BASF SE, Clariant AG, Merck KGaA, Ashland Inc., Dow Corning Corporation, Evonik Industries AG, Shin-Etsu Chemical Co. Ltd., Kemira Oyj, Baker Hughes, Eastman Chemical Company, Air Products and Chemicals, and other key players mentioned in the final report.

These companies are focusing on developing biodegradable, silicone-free, and high-efficiency defoamers to cater to various industrial applications while ensuring environmental safety.

Future Scope and Emerging Trends

The Defoamers Market is set for steady expansion due to increasing demand for high-performance, non-toxic, and regulatory-compliant defoaming agents. The pulp & paper industry remains a major consumer, as foam control is essential in paper production and wastewater management. Additionally, the wastewater treatment sector is witnessing increased adoption of defoamers, driven by strict environmental regulations and industrial water reuse initiatives.

In the food & beverage industry, the demand for FDA-approved defoamers is on the rise for applications in brewing, dairy processing, and food manufacturing. The paints & coatings sector is also seeing growth in defoamer usage, ensuring smooth application and improved finish quality. Furthermore, advancements in nanotechnology and bio-based defoamers are creating new opportunities, making products more effective and sustainable.

Key Market Points:

✅ Growing Demand from Pulp & Paper Industry: Essential for foam control in paper manufacturing and wastewater treatment. ✅ Expansion in Wastewater Treatment Applications: Increased use due to strict environmental regulations and water conservation initiatives. ✅ Rising Adoption in Food & Beverages: Demand for safe and food-grade defoamers in dairy, beverages, and food processing industries. ✅ Advancements in Sustainable Solutions: Development of biodegradable, non-toxic, and silicone-free defoamers. ✅ Technological Innovations: Growth in nanotechnology-based and highly efficient defoaming agents for industrial applications.

Conclusion

The Defoamers Market is on a growth trajectory, driven by industrial expansion, regulatory compliance, and demand for high-performance foam control solutions. As companies shift towards sustainable, biodegradable, and innovative defoamer formulations, manufacturers investing in eco-friendly and technologically advanced solutions will have a competitive edge in the market.

Read Full Report: https://www.snsinsider.com/reports/defoamers-market-3911

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Defoamers Market#Defoamers Market Size#Defoamers Market Share#Defoamers Market Report#Defoamers Market Forecast

0 notes

Link

0 notes

Text

Powdered Defoamer Market, Global Outlook and Forecast 2025-2032

Powdered defoamers are chemical additives designed to control or eliminate foam in industrial processes. These defoamers are widely used in industries such as papermaking, textile printing and dyeing, petrochemicals, construction, cleaning agents, printing ink, and wastewater treatment. Their ability to provide long-lasting defoaming effects at low concentrations makes them a preferred choice for various applications.

Market Size

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/287156/global-powdered-defoamer-forecast-market-2025-2032-313

0 notes

Text

A Deep Dive into the Industrial Water Treatment Chemicals Market: Insights and Analysis

The global industrial water treatment chemicals market size is expected to reach USD 21.23 billion by 2030, registering a CAGR of 4.9% during the forecast period, according to Grand View Research, Inc. The growth is majorly driven by growing demand for freshwater and favorable regulatory support for water treatment.

High requirement for drinkable water across the world has surged demand for the chemicals that are utilized in cleaning. The environment is seriously endangered by company waste. Due to accelerating urbanization, a rising economy, and expanding industrial activity, freshwater is witnessing high demand.

The U.S. Environmental Protection Agency (EPA) establishes national standards to ensure that consumption by humans is safe while considering the country's available technology and associated costs. The Safe Drinking Water Act and its amendments set up the fundamental framework for safeguarding the solution used by public systems in the U.S. This law specifies the requirements for guaranteeing the security of the nation's municipal drinking supplies. Systems that regularly serve 25 or more people per day or that have at least 15 service connections are considered public drinking sources.

In response to COVID-19, the governments of the affected economies have resorted to lockdowns and social distancing that have impacted the global supply chains. Several manufacturing activities were suspended which in turn, to resulted in the decline in sales of oil & gas and other industrial products. Moreover, due to the supply disruption, the price of raw materials increased significantly which in turn, was followed by an increase in the cost of treatment chemicals.

Gather more insights about the market drivers, restrains and growth of the Industrial Water Treatment Chemicals Market

Industrial Water Treatment Chemicals Market Report Highlights

• Effluent water treatment application is expected to witness the fastest growth rate of 5.1% on account of stringent wastewater disposal limitations imposed by the major international as well as regional regulatory bodies

• Raw treatment is also estimated to witness a notable growth rate. Due to the presence of suspended particles and heavy metals, the demand for pretreated industrial water is anticipated to increase especially in key countries such as the U.S., China, India, the UK, Germany, and Brazil

• During the forecasted years, it is anticipated that the presence of manufacturing facilities in the chemical, pharmaceutical, food & beverage, and automotive sectors in the U.S. and Canada would play a significant role in driving up demand for treatment services, thus triggering demand in the North America region

• Key players in the market are engaged in R&D activities coupled with mergers & acquisitions to gain a higher share of the market. For instance, Ecolab purchased Purolite a purification and separation life science solution provider in October 2021

Industrial Water Treatment Chemicals Market Segmentation

Grand View Research has segmented the global industrial water treatment chemicals market report based on the application and region:

Industrial Water Treatment Chemicals Application Outlook (Revenue, USD Million; Volume, Kilotons; 2018 - 2030)

• Raw Water Treatment

o Deoiling Polyelectrolytes (DOPE)

o Organic Coagulants

o Flocculants

o Filtration Aids

o Dewatering Aids

o Others

• Water Desalination

o Biocides

o Cleaning Agents

o Carbonates

o Sulfates

o Metal Oxides

o Silica

o Chelating Agents incl. NaOH

o Biofilms

o Others

o Antiscalants

o Flocculants

o Defoaming Agents

o Others

• Cooling & Boilers

o Sludge Controllers

o Antifoams

o Antiscalants

o Oxygen Scavengers

o Others

• Effluent Water Treatment

o Deoiling Polyelectrolytes (DOPE)

o Organic Coagulants

o Flocculants

o Filtration Aids

o Dewatering Aids

o Others

• Others

Industrial Water Treatment Chemicals Regional Outlook (Revenue, USD Million; Volume, Kilotons; 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o UK

o France

o Italy

o Spain

o Belgium

o Sweden

o Austria

o Finland

o Poland

o Turkey

• Asia Pacific

o China

o Japan

o South Korea

o India

o Singapore

o Indonesia

o Thailand

o Vietnam

o Australia

o New Zealand

o CIS

o Indonesia

o Rest of Asia Pacific

• Latin America

o Brazil

o Argentina

o Chile

• Middle East & Africa

o South Africa

Order a free sample PDF of the Industrial Water Treatment Chemicals Market Intelligence Study, published by Grand View Research.

#Industrial Water Treatment Chemicals Market#Industrial Water Treatment Chemicals Market Size#Industrial Water Treatment Chemicals Market Share#Industrial Water Treatment Chemicals Market Analysis#Industrial Water Treatment Chemicals Market Growth

0 notes

Text

How industries utilize silicone oils in its regular operations?

Industries worldwide depend upon innovative solutions to maintain efficiency and quality in their operations. Among various materials, Silicone oils have become a cornerstone in modern industrial applications, thanks to their unique properties and unparalleled versatility. From manufacturing units to specialized sectors, these fluids are trusted across sectors to enhance performance and streamline processes. Chemtex Speciality Ltd. offers a premium range of silicone oils, including Silicone Oil 350 cSt, Silicone Oil 1000 cSt, and Silicone Oil Lubricants, designed to meet diverse industrial requirements. Discover how silicone oils are utilized across industries and how we can help redefine operational excellence.

Applications of Silicone Oils Across Industries

Textile and Garment Industry Silicone oils serve as softeners and lubricants, improving the texture and feel of fabrics. Distributors can position these oils as essential solutions for enhancing fabric durability and performance.

Personal Care and Cosmetics Found in hair conditioners, skin creams, and deodorants, silicone oils ensure smooth application and lasting effects. Dealers can highlight their hydrophobic and non-greasy nature to attract clients in this fast-growing sector.

Automotive Sector Silicone oils, such as Silicone Oil 1000 cSt, are used in polishing agents, brake fluids, and lubricants for superior performance. Distributors can showcase these oils as reliable products that reduce wear and extend the lifespan of automotive components.

Electronics and Electricals Silicone oils act as insulators and thermal transfer fluids, ensuring reliability in critical applications. Dealers can tap into the growing demand for high-performance electrical solutions.

Industrial Manufacturing Used as mold release agents and anti-foaming agents; silicone oils facilitate smooth operations. Distributors can leverage their chemical stability and operational benefits to capture a larger market share.

Benefits of Silicone Oils for Distributors and Dealers

Broad Application Range: Serve clients across multiple industries with one versatile product.

Reliable Performance: Offer products that withstand extreme temperatures and chemical conditions.

Effective defoaming at lower dosage

Low viscosity ensures rapid spread on foam

Why Chemtex Silicone Oil?

At Chemtex, we understand the diverse needs of industries and offer silicone oils that cater to a wide range of applications. Here's why distributors and dealers should choose Chemtex:

Unmatched Quality: Chemtex Silicone Oils are formulated to meet the highest industry standards, ensuring superior performance and reliability.

Wide Range: We offer silicone oils suitable for various industries, providing tailored solutions for specific applications.

Sustainability Focus: Our products are environmentally friendly, aligning with global sustainability goals and enhancing your market reputation.

Profitability: Chemtex offers competitive pricing, enabling distributors and dealers to maximize margins while maintaining affordability for end-users.

Availability of Silicone Oil - 350 cSt, 1000 cSt, 5000 cSt, 125000 cSt, and custom grades tailored to industry requirements

Ease of Collaboration: Our seamless logistics, dedicated support, and marketing assistance ensure a hassle-free partnership experience.

Testimonials and Success Stories

Many of our distributors and dealers have witnessed exponential growth by using Our Silicone Oils for their clientele. One of our partners in the textile sector reported, “Chemtex's Silicone Oil 350 cSt completely transformed our fabric finishing process.”

"Switching to Chemtex's Silicone Oil 1000 cSt was a game-changer for us. Our rubber components now last longer, reducing warranty claims and boosting our reputation in the market." -Automotive Parts Supplier

Such testimonials reinforce the value we bring to our collaborators.

Unlock New Opportunities with Chemtex Silicone Oils

By adding Our silicone oils to your product lineup, you open doors to:

Capturing new markets with high-demand products.

Strengthening customer loyalty through quality offerings.

Elevating your brand’s position in the competitive landscape.

Join hands with us today to discuss distributorship opportunities and explore how our products can add value to your business. Let’s grow together—reach out now and join hands with a trusted leader in specialty chemicals!

0 notes

Text

Silicone Surfactant Market Growth Trends: Share, Size, and Industry Insights by 2031

Straits Research, a leading global market research firm, has released its latest research report on the silicone surfactant market, forecasting a steady growth trajectory in the coming years. The global silicone surfactant market was valued at USD 2.4 billion in 2023 and is expected to expand from USD 2.524 billion in 2024 to USD 4 billion by 2032, growing at a compound annual growth rate (CAGR) of 5.1% during the forecast period (2024–2032).

Market Definition

Silicone surfactants are a class of surfactants that are derived from silicone, a synthetic material that is known for its unique chemical structure and properties. These surfactants are used in various industrial applications to reduce surface tension, improve stability, and enhance the performance of other products. They find wide applications in industries such as personal care, agriculture, construction, paints and coatings, and textiles due to their superior performance in enhancing wetting, foaming, emulsification, defoaming, and dispersing properties.

Get a Full PDF Sample Copy of the Report @ https://straitsresearch.com/report/silicone-surfactant-market/request-sample

Market Dynamics

The silicone surfactant market is experiencing steady growth driven by several trends, market drivers, and emerging opportunities:

Key Trends:

Growing Demand for Sustainable Products: There is an increasing focus on sustainability and the need for environmentally friendly surfactants. Silicone surfactants are considered a greener alternative to conventional surfactants, as they are biodegradable and non-toxic, meeting the growing demand for eco-friendly solutions. This trend is propelling the adoption of silicone surfactants in various industries.

Technological Advancements in Silicone Chemistry: Recent technological advancements in silicone chemistry have led to the development of innovative and high-performance silicone surfactants. These innovations are enhancing the efficiency and effectiveness of silicone surfactants in diverse applications, including personal care, paints, and coatings, driving the market's growth.

Key Market Drivers:

Rising Demand from the Personal Care Industry: Silicone surfactants are increasingly being used in personal care products, such as shampoos, conditioners, and skincare products, due to their ability to enhance product performance. They are prized for their ability to provide superior conditioning, smooth texture, and long-lasting effects, making them a preferred choice for cosmetic manufacturers.

Expanding Agricultural Applications: Silicone surfactants are increasingly utilized in agriculture, particularly in agrochemical formulations, to improve the wetting, spreading, and absorption of pesticides and fertilizers. The growing need for efficient agricultural practices to boost crop yield and reduce environmental impact is driving the demand for silicone surfactants in this sector.

Key Market Opportunities:

Expansion in Emerging Economies: As industries in emerging economies such as India, China, and Brazil continue to grow, there is increasing demand for silicone surfactants across various sectors, including agriculture, construction, and textiles. These regions present significant opportunities for market expansion, with rising industrialization and awareness of product performance.

Increased Adoption in Green Technologies: With the global shift toward sustainability and the adoption of green technologies, silicone surfactants are well-positioned to capitalize on this trend. Their eco-friendly properties make them ideal for use in applications that focus on reducing environmental impact, presenting substantial growth opportunities for manufacturers.

Market Segmentation

The silicone surfactant market is segmented by application, end-use industry, and geography. Below are the key segments:

By Application:

Wetting Agents

Foaming Agents

Emulsifiers

Defoaming Agents

Dispersants

Others

By End-Use Industry:

Agriculture

Paints and Coatings

Construction

Textile

Personal Care

Others

For a detailed breakdown of the market segmentation, visit https://straitsresearch.com/report/silicone-surfactant-market/segmentation

Key Players

The silicone surfactant market features several key players who are dominating the global landscape. These players are focusing on expanding their product portfolios, developing innovative solutions, and capitalizing on emerging market opportunities:

Dow Inc.

Innospec

Momentive

Elkem Silicones

Shin-Etsu Chemical Co.Ltd.

Evonik Industries AG

Andisil

Supreme Silicones

Siltech Corporation

Silibase Silicone New Material Manufacturer Co. Ltd.

Jiangsu Maysta Chemical Co., Ltd.

Elkay Chemicals Pvt. Ltd.

Hangzhou Ruijiang Performance Material Science Co., Ltd.

Harcros Chemicals Inc.

SST Australia Pty Ltd

Dominated Region and Fastest Growing Region

Asia-Pacific dominates the silicone surfactant market, owing to its well-established industrial sectors, including textiles, paints and coatings, and personal care. The region's rapid industrialization, particularly in countries like China, India, and Japan, is a significant factor contributing to the market's dominance. Additionally, the increasing demand for high-performance products in emerging markets fuels growth in the region.

North America is the fastest-growing region in the silicone surfactant market, driven by strong demand from the personal care, paints and coatings, and construction industries. The region’s increasing focus on sustainable solutions and high-performing, eco-friendly chemicals is expected to drive further growth in the silicone surfactant market in North America.

Conclusion

The silicone surfactant market is expected to grow steadily over the next several years, driven by increasing demand for high-performance, sustainable surfactants across a variety of industries, including agriculture, personal care, paints and coatings, and textiles. Technological advancements, along with a rising focus on eco-friendly and innovative solutions, will continue to fuel the market's growth. With Asia-Pacific dominating the market and North America emerging as the fastest-growing region, the global silicone surfactant market is projected to reach USD 4 billion by 2032.

For more information, queries, or to customize the report before purchasing, visit https://straitsresearch.com/buy-now/silicone-surfactant-market

About Us:

StraitsResearch.com is a leading market research and market intelligence organization, specializing in research, analytics, and advisory services along with providing business insights & market research reports.

Contact Us:

Email: [email protected] Tel: +1 646 905 0080 (U.S.), +44 203 695 0070 (U.K.) Website: https://straitsresearch.com/

#Silicone Surfactant Market#Silicone Surfactant Market Share#Silicone Surfactant Market Size#Silicone Surfactant Market Research

0 notes

Text

Wood Coating Additives Market-Industry Forecast, 2024–2030

Wood Coating Additives Market Overview

Request Sample Report :

COVID-19 Impact

Various countries have declared a complete national lockdown as a result of the corona virus 2019 (COVID-19) outbreak. These decisions have restricted the movement of people and resulted in a complete shutdown of many businesses across many sectors. The construction industry, as a significant growth driver of the economy with no exception, has also been completely shut down. All the developments and projects were postponed until further notice. For instance, the construction output in Great Britain fell by a record 35.0% in Quarter 2 (Apr to June) 2020 compared with Quarter 1 (Jan to Mar) 2020. This value decline was due to the Corona Virus pandemic. With the decrease in building and construction operation, the demand for furniture has significantly fallen, which is having a major impact on the wood coating additives market.

Report Coverage

The report: “Wood Coating Additives Market — Forecast (2021–2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the wood coating additives Industry.

By Formulation: Water Based System, Solvent Based System, Radiation Cured System, and Others.

By Type: Dispersing Agents, Rheology Modifiers, Defoamers, Micronized Waxes, Emulsions, Wetting & Leveling Agents, Surface Modifiers, and Others.

By End-Use Industry: Food Industry (Trays, Pallets, and Others), Building and Infrastructure (Residential, Commercial, and Industrial), Furniture (Outdoor, and Indoor), and Others.

By Geography: North America (U.S., Canada, and Mexico), Europe (U.K, Germany, France, Italy, Netherland, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East, and Africa).

Inquiry Before Buying:

Key Takeaways:

Asia-Pacific dominates the wood coating additives market, owing to the increasing building & infrastructure activities in the APAC due to various government initiatives such as “100 smart cities” and “Housing for all by 2022”.

The primary purpose of using coating additives in wood is to manufacture superior quality wood surfaces. Additives are often used in wood coatings for a variety of purposes such as better stabilization, hygiene, and decoration of wood.

The coating additives also add some extensive properties to the wooden material such as moisture-resistant, anti-bacterial solution, improved hardness, better appearance, and more. These enhanced properties of wood coating additives are projected to increase the market growth.

However, high regulation on coatings due to its high emission of volatile organic compounds and awareness on damage for deforestation is projected to hinder the growth of wood coatings, which indirectly affects the demand for wood coating additives.

Due to the Covid-19 pandemic, most of the countries have gone under lockdown, due to which various building and construction operations are disruptively stopped, which is hampering the wood coating additives market growth.

For More Details on This Report — Request for Sample

Wood Coating Additives Market Segment Analysis — By Formulation

The solvent based system segment held the largest share in the wood coating additives market in 2020 and is growing at a CAGR of 6% during 2021–2026. A solvent based wood coating additives system offers a liquid protective layer that is primarily composed of organic compounds and applied to a material’s surface to prevent corrosion. They are typically more resilient than water based wood coating additives system coatings during the curing time. These coatings have one major advantage over water based wood coating additives systems i.e. they are less susceptible to environmental conditions such as temperature and humidity during the curing phase. Humidity can prevent the water in a water-based system from evaporating, making them impractical in some climates. Thus, solvent based wood coating additives systems are preferred for applications in humid environments. All these superior properties of the solvent based system are the key factor anticipated to boost the demand for wood coating additives during the forecast period.

Wood Coating Additives Market Segment Analysis — By Type

The Rheology modifier segment held a significant share in the wood coating additives market in 2020. For the optimal application of coatings on wood, it is necessary to adjust the rheology profile of the coating with the help of rheology modifiers. This can be managed by using associative thickeners based on polyurethanes. Polyurethane thickeners can be used solely or in combination with each other as well as with other types of thickeners (e.g. polyacrylates or cellulose ethers). In addition, rheology modifiers enable formulators to adjust the flow behavior of coatings, owing to which the wood coatings benefit from improved viscosity. Furthermore, it reduces dripping and a spattering of paint during roller or brush application, which is the major driving factor for the Rheology modifier additives during the forecast period.

Schedule A Call:

Wood Coating Additives Market Segment Analysis — By End-Use Industry

The furniture segment held the largest share in the wood coating additives market in 2020 and is growing at a CAGR of 5% during 2021–2026, owing to the increasing usage of wood in the manufacturing of the furniture industry. This exceptionally versatile material is commonly used as a building material as it is a natural resource, which makes it readily available and economically feasible. It is remarkably strong in relation to its weight, provides good insulation from the cold, and can be fabricated into all kinds of shapes and sizes to fit practically any construction need. Pinewood and whatman filter paper are common substrates used in furniture fungal resistance. Also, wood is an environmentally sustainable product, biodegradable, renewable, and carries the lowest carbon footprint of any comparable building material. In addition, no high-energy fossil fuels are required to produce wood, unlike other common building materials such as brick, steel, or plastic owing to which wood is widely used in the manufacturing of furniture. And wood furniture requires preservation for which coating additives are extensively used over wood, which is the major factor driving the demand for wood coating additives in the furniture industry during the forecast period.

Wood Coating Additives Market Segment Analysis — By Geography

Asia-Pacific region held the largest share in the wood coating additives market in 2020 up to 36%, owing to the increasing demand for furniture in the region. The key factors driving the increase in demand for furniture are the growth of housing and commercial construction and also the increase in income levels that influence customers to adopt global lifestyle options, especially in urban affluent Indians. According to the Trade Promotion Council of India (TPCI), the Indian domestic furniture market is expected to expand at a CAGR of 12.91% from 2020 through 2024. It has been observed that for 2018 and from 2014–18, India’s furniture exports surged at CAGRs of 15% & 8.8% respectively, which is way higher than the world average. According to the United States Department of Agriculture (USDA), China remains the largest wood-based panel producer in the world, accounting for roughly half of global production. Production in 2019 was approximately 325 million meter cube, nine percent higher than in 2018 (299 million meter cube), driven by strong demand from decoration facilities. Thus, with an upsurge in the demand for furniture, the demand for wood coating additives will also subsequently increase to preserve the wooden furniture, which is anticipated to eventually drive the wood coating additives market in the APAC region during the forecast period.

Wood Coating Additives Market Drivers

Flourishing Food Industry

Products derived from wood are widely used in the packaging of food in the form of paper and cardboard. Paper is a very cheap, lightweight product with excellent printing capacity. Although it is very sensitive to moisture, it can be corrected with a combination of paper and other materials such as plastic or paraffin. The wooden packaging is specially designed for cooking or reheating in traditional ovens or microwave ovens. According to the International Trade Administration (ITA), there was an increase of 4.7% in food production in Russia. According to the United States Department of Agriculture (USDA), in 2018, the total value of all retail food and beverage sales in Japan was $479.29 billion (¥53,339 billion), an overall increase of 2.3 percent. According to the United States Department of Agriculture (USDA), China’s food processing industry continued to grow in 2017. Revenue climbed to $1.47 trillion, an increase of 6.3 percent compared with the previous year. The rising disposable income has resulted in the increasing demand for the food industry in various regions, which is further driving the growth of the food packaging industry market. And since additives improve or maintain the food’s nutritive value, make food last longer, make food stay fresh for much longer owing to which the demand for coating additives in wood-based food packaging is increasing. Thus, the expanding food industry acts as a driver for the liquid nitrogen market.

Buy Now :

Increasing Government Initiative Bolstering the Growth of building and infrastructure Industry In Various Regions

The building and construction industry is flourishing in countries such as India, and Singapore as governments are spending heavily on expanding the building and construction industry. The A government-wide program for a Circular Economy, aimed at developing a circular economy in the Netherlands by 2050 is boosting the construction sector in the country. The infrastructure sector has become the biggest focus area for the Government of India. India plans to spend US$ 1.4 trillion on infrastructure during 2019–23 to have a sustainable development of the country. The Government has suggested investment of Rs. 5,000,000 crore (US$ 750 billion) for railways infrastructure from 2018–30. And wood-based products such as furniture are often used in the construction industry. And these wood products to be durable and resistant require coating additives. Hence, with the increase in construction activities across the globe, the demand for wood coating additives will be foreseen to grow enormously. Thus, such government investments and initiatives in the construction industry act as a driver for the market.

Wood Coating Additives Market Segment Analysis Challenges

Presence of Other Substitute Materials

Most wood coatings are done either in a short-term artificial weathering chamber or long-term on an outdoor rack/fence. In both cases, the coatings are exposed to both ultraviolet radiation and water. As moisture is absorbed into the wood structure, the wood swells in proportion to the volume of water absorbed. As moisture is lost, the wood shrinks in proportion to the volume of the water lost. Thus, moisture in the wood end grain is responsible for coating failures. Also, the wood material may be too hard or rough for products like soft fruits, and therefore liners of soft material may be needed, which further increases the expenses owing to which polymeric materials are gaining popularity. Moreover, the continuous manufacturing of wooden-based products such as furniture, crates, pallets, containers, and more have put an extra claim on the natural forest resources, leading to deforestation. All these disadvantages of wood-based products are unlatching doors for other immediate substitute materials such as metal, polymer, composites, and more. Thus, the demand for wood may see a downfall, which may hinder the wood coating additives market growth during the forecast period.

Wood Coating Additives Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the wood coating additives market.

The Top 5 companies in the are: Wood coating additives market

BYK Additives & Instruments

Arkema S.A.

Sherwin-Williams Company

Akzo Nobel N.V.

PPG Industries, Inc.

Acquisitions/Technology Launches

In November 2019, AkzoNobel invested $55 million to transform its wood coatings facility in High Point, North Carolina, and further strengthen the company’s market position in North America.

In October 2019, BASF introduced a new silicone wetting agent-“Hydropalat® WE 3225”, which combines excellent substrate wetting with pronounced defoaming performance. It is designed for use in high-end water-based industrial and automotive coatings and especially wood coatings that require excellent wood grain accentuation.

In October 2019, BASF launched a new high molecular weight dispersing agent-“Dispex® Ultra PX 4290”. Dispex® Ultra PX 4290 in response to surging market demand for a dispersing agent, which enables broad applicability in both inorganic and organic pigments and fillers used in water-based automotive OEM and refinishes coatings, industrial coatings, and wood coatings.

For more Chemicals and Materials Market reports — Please click here

#WoodCoatings#WoodFinish#CoatingAdditives#WoodProtection#WoodCare#SurfaceFinishing#EcoFriendlyCoatings

0 notes

Text

Textile Chemicals Market Is Experiencing Healthy Growth Worldwide

Textile Chemicals Industry Overview

The global textile chemicals market size is expected to reach USD 36.14 billion by 2030, registering a CAGR of 4.5% from 2024 to 2030, according to a new report by Grand View Research, Inc. The growth is majorly driven by increasing demand for textile products from major applications including apparel, home furnishing, technical textiles, and others.

Rapidly growing demand from the apparel industry is anticipated to propel the demand for the product during the forecast period. Home furnishing, specifically in developing economies, demanding modern and attractive furniture products is expected to have a positive impact on the growth of the market.

Numerous chemicals are used in the fabric manufacturing industry to offer a wide range of performance features during the production process, which are known as process chemicals. These end products include biopolishing enzymes, desizing enzymes, flame retardants, antiviral/antimicrobial agents, lubricating/anti-crease agents, water and oil repellents, printing auxiliaries, and softening agents.

Gather more insights about the market drivers, restrains and growth of the Textile Chemicals Market

Based on existing operations and technologies, new application areas for textile chemicals are being developed, wherein these products can help improve efficiency, promote cost reduction, reduce environmental impacts, and ensure the performance of formulations. Application sectors for the product include apparel, home furnishing, technical textiles, and others. STYLUS APPAREL; HYAK DESIGN GROUP; Suuchi Inc.; TechniTextile Québec; and Stafford Textiles Limited are some of the major end-users in the market.

The manufacturing of textile chemicals is highly dependent on abundant availability and favorable costs of raw materials. In this market, successful commercialization of products such as yarn lubricants, finishing agents, coating & sizing agents, and others and investments in production capacity are some of the key strategies of the market players.

The market is highly competitive owing to the presence of a large number of manufacturers with a global presence. The leading product manufacturers include Dow, Huntsman International LLC, The Lubrizol Corporation, Archroma, Evonik Industries AG, and Solvay S.A.

Browse through Grand View Research's Specialty Polymers Industry Research Reports.

The global aseptic packaging market size was valued at USD 77.1 million in 2024 and is projected to grow at a CAGR of 10.8% from 2025 to 2030.

The global fluoropolymer films market size was valued at USD 1.09 billion in 2023 and is projected to grow at a CAGR of 12.9% from 2024 to 2030.

Textile Chemicals Market Segmentation

Grand View Research has segmented the global textile chemicals market based on process, product, application, and region:

Textile Chemicals Process Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Pretreatment

Bleaching Agents

Desizing Agents

Scouring Agents

Others

Coating

Anti-Piling

Protection

Water Proofing

Water Repellant

Others

Treatment Of Finished Products

Softening

Stiffening

Others

Textile Chemicals Product Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Coating & Sizing Chemicals

Colorants & Auxiliaries

Dispersants/levelant

Fixative

UV absorber

Others

Finishing Agents

Antimicrobial or anti-inflammatory

Flame retardants

Repellent and release

Others

Surfactants

Detergents & Dispersing Agents

Emulsifying Agents

Lubricating Agents

Wetting Agents

Denim Finishing Agents

Anti-back Staining Agents

Bleaching Agents

Crush Resistant Agents

Defoamers

Enzymes

Resins

Softeners

Others

Textile Chemicals Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Apparel

Innerwear

Outerwear

Sportswear

Others

Home Furnishing

Carpet

Drapery

Furniture

Others

Technical Textiles

Agrotech

Buildtech

Geotech

Indutech

Medtech

Mobiltech

Packtech

Protech

Others

Other Applications

Textile Chemicals Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

Turkey

Italy

UK

France

Russia

Spain

Poland

Asia Pacific

China

India

Japan

South Korea

Vietnam

Indonesia

Central & South America

Brazil

Argentina

Middle East and Africa

Saudi Arabia

South Africa

Morocco

Tunisia

UAE

Kenya

Key Companies profiled:

AB Enzymes

Archroma

BASF SE

BioTex Malaysia

Dow

Ethox Chemicals, LLC

Evonik Industries AG

Fibro Chem, LLC

German Chemicals Ltd.

Govi N.V.

Huntsman International LLC

Kemira Oyj

Kiri Industries Ltd.

LANXESS

OMNOVA Solutions Inc.

Omya United Chemicals

Organic Dyes and Pigments

Resil Chemicals Pvt. Ltd.

Solvay S.A

The Lubrizol Corporation

Key Textile Chemicals Company Insights

Some of the key players operating in the global textile chemicals market include Kiri Industries Ltd., AB Enzymes, Dow, BASF SE, The Lubrizol Corporation, Kemira Oyj, and Evonik Industries AG, among others.

AB Enzymes is a biotech company that develops and manufactures enzyme preparations for a wide range of applications such as baking, fruit juice processing, grains processing, animal feed, paper, textiles, and laundry.

BASF SE operates through six business segments, including chemicals, industrial solutions, materials, surface technologies, nutrition and care, and agricultural solutions. The chemical segment's product portfolio includes intermediates, monomers, petrochemicals, and catalysts. The company provides non-halogenated flame-retardants for several end-use industries, including the textile market.

Evonik Industries AG is a global manufacturer of specialty chemicals. It operates through four business segments: Specialty Additives, Nutrition and care, Smart Materials, and Performance Materials. Under the Performance Materials segment, the company offers performance intermediates such as large-volume additives and intermediates, along with functional solutions such as polymer additives, potassium derivatives, cyanuric chloride, alkyl chlorides, and alkoxides.

Kemira Oyj is a global chemical manufacturer with business operations in pulp & paper, water, oil & gas, metals & mining, food, and energy industries. For textile processing, the company offers oil-based foam control products and dry powder flocculants. Oil-based foam control products (defoamers) are active dispersions in mineral oil that can be used for persistent foam reduction applications. They are cost-efficient and well-suited for high temperatures. Their primary applications include textiles and wastewater treatment. Dry powder flocculants, such as nonionic polyacrylamides, offered by the company are effective in textile processing applications such as the flocculation of negatively charged particles.

Recent Developments

In January 2024, Devan Chemicals, a provider of sustainable textile finishes, is excited to announce its upcoming participation in Heimtextil 2024. Devan invites attendees to visit their booth in Hall 11.0, booth A21, to experience firsthand the latest sustainable textile finishes they have developed.

In April 2024, BASF SE announced its portfolio of polyamides for the textile industry. The company’s sustainable polyamide PA6 and PA6.6 product range have been certified under the Recycled Claim Standard (RCS) for textile applications. This certification allows BASF SE to market textiles produced using recycled raw materials.

In May 2023, Dystar announced its eco-advanced indigo dyeing, which aims to reduce energy consumption by up to 30% and water usage by up to 90% during the production process.

In November 2023, Solvay introduced a textile fiber that decomposes rapidly in the oceans, minimizing the environmental impact of microplastics. The new textile polyamide, set to be manufactured at the company's industrial facility in Brazil, will decrease oceanic impact by roughly 40 times compared to traditional fibers. This product development aligns with the global trend of rising demand and market shifts toward more sustainable textile solutions.

Order a free sample PDF of the Textile Chemicals Market Intelligence Study, published by Grand View Research.

0 notes

Text

0 notes

Text

Water Treatment Additives Market - Forecast(2024 - 2030)

Water Treatment Additives Market Overview

The water treatment additives market size is forecasted to reach US$35.0 billion by 2027, after growing at a CAGR of around 4.1% from 2022 to 2027. The water treatment additives are chemical products added as conditioners that purify the water and improve the quality. The water treatment additives such as corrosion inhibitors, disinfectants, defoamers, coagulants, and others are used in the water purification and treatment applications across various industries. The growing demand of water treatment additives in major end-use industries such as chemical, food and beverage, water and wastewater treatment, and others is creating a drive in the market. Furthermore, the water scarcity concerns will offer major demand in the water treatment additives market and growth opportunities during the forecast period.

COVID-19 Impact

The water treatment additives industry was majorly impacted by the global slowdown during the covid-19 outbreak. The water treatment additives have high demand in chemical, oil and gas, and other sectors. The oil and gas industry was majorly impacted and faced major disruption in the pandemic. The factors such as demand and supply gap, closure of oil and gas production and exploration plants, and volatility and oil prices led to a major decline in the growth prospects for oil and gas sector. Moreover, slowdown in production activities, falling demand, and supply chain disturbances impacted the growth in the market. According to the International Energy Association (IEA), the global oil demand stood at 99.9 million barrels per day in 2020, showing a decline of 90,000 barrels per day from 2019. The fall in growth of oil and gas sector led to decline in the application of water treatment additives and demand in the market. Thus, with restricted demand and applications in major end use industries, the water treatment additives market faced major slowdown in the covid-19 outbreak.

Request Sample

Report Coverage

The “Water Treatment Additives Market Report– Forecast (2022-2027)” by IndustryARC covers an in-depth analysis of the following segments of the water treatment additives industry.

By Type: Coagulants, Corrosion Inhibitors, Disinfectants, Dechlorinating Agent, pH Conditioners, Defoamer, and Other By Form: Solid and Liquid By Application: Drinking Water Purification, Sewage Systems, Steam Boilers, Cooling Water Systems, and Other By End Use Industry: Food and Beverage (Whiskey, Juices, and Others), Power Industry, Oil & Gas, Water and Wastewater Treatment Industry, Paper & Pulp, Mining, Chemicals Industry, And Others By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia, and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Middle East (Saudi Arabia, UAE, Israel, Rest of the Middle East) and Africa (South Africa, Nigeria, Rest of Africa)

Key Takeaways

The water treatment additives market size will increase owing to its growing application for water and wastewater treatment, drinking water purification, sewage systems treatment, and others during the forecast period.

The Asia Pacific is the fastest growing region in the water treatment additives industry owing to flourishing emphasis on clean drinking water.

The demand of coagulants as major water treatment additives is rising due to its application in water treatment and purification in major industries such as oil and gas, chemical, and others.

Inquiry Before Buying

Water Treatment Additives Market Segment Analysis – By Type

By type, the coagulant is the fastest growing segment and is expected to grow with a CAGR of around 5.2% during the forecast period. The growing usage of coagulants for water and wastewater treatment applications, sewage systems, industrial water treatment, and others is offering high demand in the market. The demand of coagulants in water treatment plants is growing owing to its usage in removal of solid waste from the water and oil purification across various end-use industries, majorly oil and gas. Moreover, the growing development in the oil and gas plants across the world is boosting the demand of coagulants for water treatment applications and oil purifications. According to the U.S. Energy Information Administration (EIA), around 1.9 million barrels per day consumption of liquid fuels and petroleum is estimated for 2023 to average 101.5 million barrels per day. Thus, with increasing demand of water treatment additives, majorly coagulants for solid waste removal and purification across major industries, the water treatment additives market will grow rapidly during the forecast period.

Water Treatment Additives Market Segment Analysis – By End-Use Industry

By end-use industry, the water and wastewater treatment segment held the largest water treatment additives market share in 2021, with a share of over 24.0%. The high demand of water treatment additives in the water and wastewater treatment sector is influenced by growing awareness for wastewater recycling, safe drinking water scarcity, and increasing usage of clean water across various industries. The treatment additives such as defoamers, corrosive inhibitors, biocides, coagulants, disinfectants, sodium bicarbonate, and others are widely used in treating the municipal wastewater, sewage water distribution, and others. Moreover, growing wastewater plants set-up across the globe is propelling the growth of water treatment additives. According to the United Nations Water, around 56% of household wastewater flows were treated in the year 2020 globally. Thus, with increasing application of water treatment additives in water and wastewater treatment sector for offering clean and safe drinking water, the global water treatment additives market will grow rapidly during the forecast period.

Schedule a Call

Water Treatment Additives Market Segment Analysis – By Geography

By geography, the Asia Pacific is the fastest-growing region in the water treatment additives market and is expected to grow with a CAGR of around 5.9% during the forecast period. The high demand of water treatment additives in this region is influenced by its growing demand for water purification, and treatment procedures across various end-use industries such as wastewater, oil and gas, chemical, and others. Furthermore, the rise in demand of water treatment additives in the chemical processing sector is propelling the growth in the market. According to the European Chemical Industry Council (CEFIC), the chemical output growth in China accounted for 2.9% in 2020. Moreover, the development in the wastewater treatment and clean drinking water projects in APAC region is boosting the demand of water treatment additives. Thus, with a flourishing emphasis on water purification and treatment applications across major industries such as chemical, oil & gas, power, and others, the water treatment additives industry will grow rapidly during the forecast period.

Water Treatment Additives Market– Drivers

Favorable regulations for water and wastewater treatment

The water scarcity and limited availability of purified water is accelerating the growth of water treatment additives. The requirement of clean water across various end-use industries is influencing the growth of water treatment chemicals and additives. The strict regulations by government to recycle the wastewater and treat contaminated water is offering a major drive in the market, thereby boosting the application of water treatment chemicals and additives such as chlorine dioxide, algicide, biocides, disinfectants, and others. According to the Organization for Economic Co-Operation and Development (OECD), around 92.86% of the public in Australia is connected to a wastewater treatment in 2020. Thus, with increasing concerns for the treatment of water and wastewater, the water treatment additives industry is experiencing major growth.

High demand in the oil and gas sector

The water treatment additives such as chlorine dioxide, coagulants, corrosion inhibitors, disinfectants, and others have major demand in the oil and gas sector. The petroleum refineries use water and steam for various processes such as FCC, cooling towers, steam generators, and others. The rising scarcity of clean water in oil and gas is propelling the demand for water treatment additives. Furthermore, the demand of water and wastewater treatment in onshore as well as offshore sector is riding. According to the India Brand Equity Foundation (IBEF), the oil demand in India is expected to reach 11 million barrels per day by the year 2045. Thus, with major application and flourishing demand or water treatment additives and chemicals in oil and gas sector, the water treatment additives market is experiencing a major growth.

Buy Now

Water Treatment Additives Market– Challenges

Hazardous nature of water treatment additives and alternate treatment technologies

The water treatment additives have a growing demand for treatment of the water and purification systems. However, the health hazards associated with various additives and chemicals such as chlorine dioxide, biocides, and others is offering a major challenge in the market. The risks of health hazards such as respiratory system irritation, skin issues, nervous system complications, gastrointestinal tract issues, and other creates a hamper. Moreover, the availability of alternative water treatment technologies such as RO filtration, UV disinfection, and others creates challenge in the market. Thus, with regulations on the hazardous water treatment chemicals and availability of eco-friendly alternatives is leading to slowdown and restricted growth for the water treatment additives industry.

Water Treatment Additives Industry Outlook

The water treatment additives top 10 companies include:

1. BASF SE 2. Kemira OYJ 3. Aqua Tech International 4. TG Water Additives LLC 5. RX Marine International 6. Suez S.A. 7. Solenis LLC 8. Ecolab Inc. 9. 3M Purification 10. GE Water & Process Technologies

Recent Developments

In November 2021, the Platinum Equity completed the acquisition of Solenis LLC, a leading water treatment chemical company. Thus, this acquisition will provide growth and diverse portfolio in the water treatment additives industry.

In October 2021, the Usalco, LLC, a leading producer of water treatment chemicals announced the acquisition of the water treatment business of Altivia for municipal and wastewater and industrial applications. This acquisition expanded the coagulant product offering in the market.

In June 2021, the Kemira announced two major investments for expanding the capacity of water treatment chemicals at Yangzhou site in China for serving growth in the water treatment in the Asia Pacific region.

#Water Treatment Additives Market#Water Treatment Additives Market Share#Water Treatment Additives Market Size#Water Treatment Additives Market Forecast#Water Treatment Additives Market Report#Water Treatment Additives Market Growth

0 notes

Link

0 notes

Text

Defoamers Market: Global Industry Analysis and Forecast 2023 – 2030

Defoamers Market Size Was Valued at USD 3.91 Billion in 2022, and is Projected to Reach USD 6.09 Billion by 2030, Growing at a CAGR of 5.7% From 2023-2030.