#Dairy Products Processing Equipment Market Research

Explore tagged Tumblr posts

Text

Milton Orr looked across the rolling hills in northeast Tennessee. “I remember when we had over 1,000 dairy farms in this county. Now we have less than 40,” Orr, an agriculture adviser for Greene County, Tennessee, told me with a tinge of sadness.

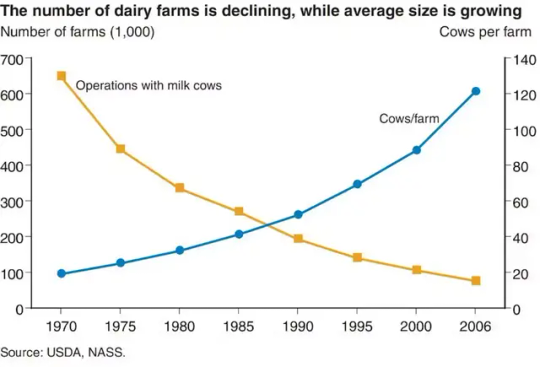

That was six years ago. Today, only 14 dairy farms remain in Greene County, and there are only 125 dairy farms in all of Tennessee. Across the country, the dairy industry is seeing the same trend: In 1970, more than 648,000 US dairy farms milked cattle. By 2022, only 24,470 dairy farms were in operation.

While the number of dairy farms has fallen, the average herd size—the number of cows per farm—has been rising. Today, more than 60 percent of all milk production occurs on farms with more than 2,500 cows.

This massive consolidation in dairy farming has an impact on rural communities. It also makes it more difficult for consumers to know where their food comes from and how it’s produced.

As a dairy specialist at the University of Tennessee, I’m constantly asked: Why are dairies going out of business? Well, like our friends’ Facebook relationship status, it’s complicated.

The Problem with Pricing

The biggest complication is how dairy farmers are paid for the products they produce.

In 1937, the Federal Milk Marketing Orders, or FMMO, were established under the Agricultural Marketing Agreement Act. The purpose of these orders was to set a monthly, uniform minimum price for milk based on its end use and to ensure that farmers were paid accurately and in a timely manner.

Farmers were paid based on how the milk they harvested was used, and that’s still how it works today.

Does it become bottled milk? That’s Class 1 price. Yogurt? Class 2 price. Cheddar cheese? Class 3 price. Butter or powdered dry milk? Class 4. Traditionally, Class 1 receives the highest price.

There are 11 FMMOs that divide up the country. The Florida, Southeast, and Appalachian FMMOs focus heavily on Class 1, or bottled, milk. The other FMMOs, such as Upper Midwest and Pacific Northwest, have more manufactured products such as cheese and butter.

For the past several decades, farmers have generally received the minimum price. Improvements in milk quality, milk production, transportation, refrigeration, and processing all led to greater quantities of milk, greater shelf life, and greater access to products across the US. Growing supply reduced competition among processing plants and reduced overall prices.

Along with these improvements in production came increased costs of production, such as cattle feed, farm labor, veterinary care, fuel, and equipment costs.

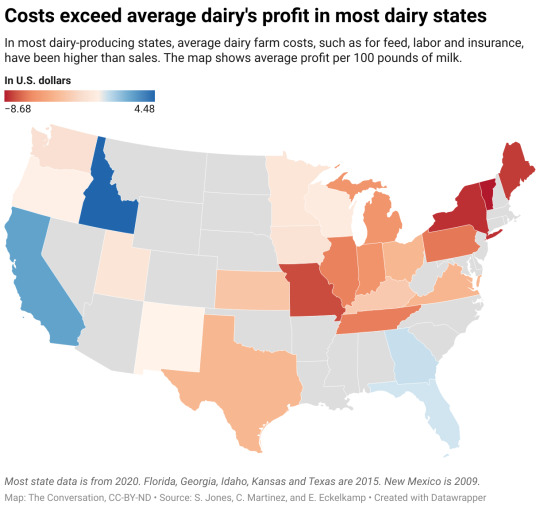

Researchers at the University of Tennessee in 2022 compared the price received for milk across regions against the primary costs of production: feed and labor. The results show why farms are struggling.

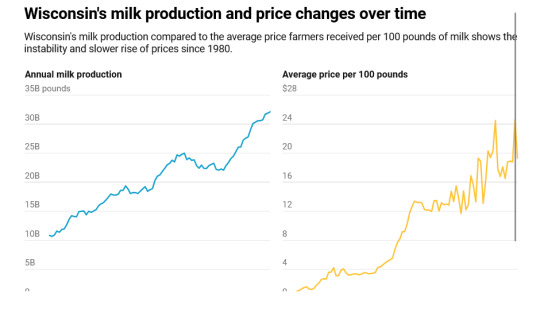

From 2005 to 2020, milk sales income per 100 pounds of milk produced ranged from $11.54 to $29.80, with an average price of $18.57. For that same period, the total costs to produce 100 pounds of milk ranged from $11.27 to $43.88, with an average cost of $25.80.

On average, that meant a single cow that produced 24,000 pounds of milk brought in about $4,457. Yet, it cost $6,192 to produce that milk, meaning a loss for the dairy farmer.

More efficient farms are able to reduce their costs of production by improving cow health, reproductive performance, and feed-to-milk conversion ratios. Larger farms or groups of farmers—cooperatives such as Dairy Farmers of America—may also be able to take advantage of forward contracting on grain and future milk prices. Investments in precision technologies such as robotic milking systems, rotary parlors, and wearable health and reproductive technologies can help reduce labor costs across farms.

Regardless of size, surviving in the dairy industry takes passion, dedication, and careful business management.

Some regions have had greater losses than others, which largely ties back to how farmers are paid, meaning the classes of milk, and the rising costs of production in their area. There are some insurance and hedging programs that can help farmers offset high costs of production or unexpected drops in price. If farmers take advantage of them, data shows they can functions as a safety net, but they don’t fix the underlying problem of costs exceeding income.

Passing the Torch to Future Farmers

Why do some dairy farmers still persist, despite low milk prices and high costs of production?

For many farmers, the answer is because it is a family business and a part of their heritage. Ninety-seven percent of US dairy farms are family owned and operated.

Some have grown large to survive. For many others, transitioning to the next generation is a major hurdle.

The average age of all farmers in the 2022 Census of Agriculture was 58.1. Only 9 percent were considered “young farmers,” age 34 or younger. These trends are also reflected in the dairy world. Yet, only 53 percent of all producers said they were actively engaged in estate or succession planning, meaning they had at least identified a successor.

How to Help Family Dairy Farms Thrive

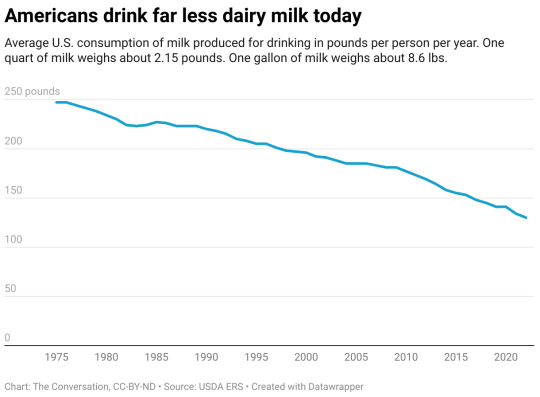

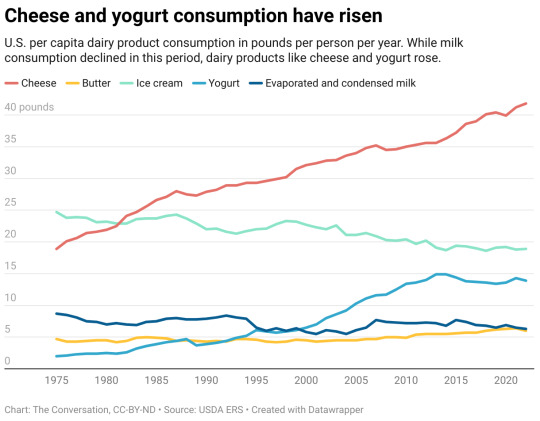

In theory, buying more dairy would drive up the market value of those products and influence the price producers receive for their milk. Society has actually done that. Dairy consumption has never been higher. But the way people consume dairy has changed.

Americans eat a lot, and I mean a lot, of cheese. We also consume a good amount of ice cream, yogurt, and butter, but not as much milk as we used to.

Does this mean the US should change the way milk is priced? Maybe.

The FMMO is currently undergoing reform, which may help stem the tide of dairy farmers exiting. The reform focuses on being more reflective of modern cows’ ability to produce greater fat and protein amounts; updating the cost support processors receive for cheese, butter, nonfat dry milk, and dried whey; and updating the way Class 1 is valued, among other changes. In theory, these changes would put milk pricing in line with the cost of production across the country.

The US Department of Agriculture is also providing support for four Dairy Business Innovation Initiatives to help dairy farmers find ways to keep their operations going for future generations through grants, research support, and technical assistance.

Another way to boost local dairies is to buy directly from a farmer. Value-added or farmstead dairy operations that make and sell milk and products such as cheese straight to customers have been growing. These operations come with financial risks for the farmer, however. Being responsible for milking, processing, and marketing your milk takes the already big job of milk production and adds two more jobs on top of it. And customers have to be financially able to pay a higher price for the product and be willing to travel to get it.

33 notes

·

View notes

Text

Others have probably said this more eloquently than I, and I know I've griped about related issues in the past, but let me just say again, it is downright criminal how little food manufacturers and retailers care about people with food allergies.

My daughter has EOE. It's not life threatening in an anaphylactic sense, but it does severely limit quality of life for her, and impacts every facet of her existence. We're in the process of identifying her triggers, one of which we know for sure is dairy. The amount of stuff that's unnecessarily made with dairy is awful; it's even worse how much stuff gets casually contaminated, and companies aren't required to label it.

Those little "made in a facility with/that also processes" tags? The "may contain" warnings? Voluntary. Optional. So unless it's made in a dedicated dairy-free facility, it could have traces in it, and we simply wouldn't know unless they decide to be kind.

The worse part is, in our case, we don't always know what food did it. EOE is a delayed reaction. It could have been something from yesterday, or last week. Trying to pin down which foods are safe and which aren't becomes a billion times harder when we can't rely on labeling. Sure it doesn't contain milk or whey or caseinate or butter, but could it have been made in the same processing line? Who knows! The manufacturer didn't bother putting that on the label!

And grocery stores and restaurants aren't much better. Those deli meats are sliced on the same equipment as the block cheeses. The lettuce is right next to the shredded cheese at the taco bar. I watched an employee use the same serving utensils for the ice cream as the dairy free sorbet.

And we're lucky! Her allergy isn't going to kill her outright if she gets contaminated. But it is turning out to be extremely sensitive, so we're struggling. I spent two and a half hours the other day trying to shop for 10 things, because I had to keep researching the different brands' manufacturing processes and ingredient sources. I had to go to three different stores. Again, we're lucky; we live in an area with a pretty big market for vegan and "specialty" foods.

We're facing down the very real possibility of having to also eliminate soy and/or wheat in the near future, and I'm so exhausted just thinking about it. Soy is in everything. Wheat is in everything. Dairy is in everything. To avoid it, you either have to eat exclusively from the produce section and/or pay through the nose for one of about three specialty products that have an extremely limited distribution. Just going fully dairy free alone has almost doubled our grocery bill, and it's not like we were splurging before.

It's just frustrating. And if it's this bad for us, who have the luxury of not needing an epi pen and an emergency plan, I don't even want to imagine how bad it is for people with near-fatal or anaphylactic allergies. People shouldn't have to jump through a billion hoops and pay quadruple price for infinitely fewer options just to not die.

#food tw#food allergies#eoe#ranting#i'm off to the woods to build a neo-hippie agri commune who's in?

24 notes

·

View notes

Text

How to Start a Food Processing Business: A Complete Guide

Are you interested in launching a business that processes food because you have a strong passion for it? Starting a business that processes food is a terrific way to make your passion profitable. But launching a company that processes food can be challenging and needs careful planning and preparation. We will provide you a step-by-step explanation of how to launch a food processing business in this manual.

Introduction :

It's critical to comprehend what food processing is before getting into the technicalities of launching a firm in this industry. Processing food entails converting basic materials into finished goods. Cooking, baking, canning, freezing, and packing are some examples of this.

The food processing sector is significant and expanding, with a $4 trillion global market. The industry is divided into a number of subsectors, including those that prepare meat and poultry, dairy products, fruits and vegetables, and snack foods.

Market Research :

Before starting any business, it is important to conduct thorough market research to determine if there is a demand for your product. In the case of food processing, you will want to research the industry trends, consumer preferences, and competitors in your market.

Some key questions to consider during your market research include:

- What are the current trends in the food processing industry?

- Who are your competitors and what are their products and pricing strategies?

- Who are your target customers and what are their preferences?

- What are the regulatory requirements for starting a food processing business in your area?

Business Planning :

Once you have conducted your market research, it is time to develop a business plan. A business plan is a document that outlines your business goals, target market, products and services, marketing and sales strategies, financial projections, and more.

Your business plan should include the following sections:

- A concise explanation and description of your business and its goals

- Market research is the analysis of your competitors, target market, and current market trends.

Services and products a list of the products and services you provide

- Sales and marketing plans: How you plan to promote and market your products.

- Budgetary goals: a projection of your expenses and income for the ensuing three to five years.

Financing :

Starting a food processing business can be expensive, so it is important to have a solid financing plan in place. There are a variety of financing options available, including loans, grants, and investors.

Some key factors to consider when seeking financing include:

- How much capital do you need to start your business?

- What is your business credit score?

- Do you have collateral to secure a loan?

- Are there any grants or incentives available in your area?

Equipment and Supplies :

Once you have secured financing, it is time to purchase the equipment and supplies you will need to start your business. The specific equipment and supplies you will need will depend on the type of food processing business you are starting.

Some common equipment and supplies needed for a food processing business include:

- Processing equipment, such as ovens, mixers, and blenders

- Packaging equipment, such as sealers and labelers

- Storage equipment, such as refrigerators and freezers

- Ingredients and raw materials

Developing a Product Line :

Your ability to sell your products will have a big impact on how well your food processing company does. It's critical to have a product lineup that appeals to your target market and distinguishes you from your rivals.

Keeping the following things in mind will help you design your product line:

- Your target market's preferences and needs

- The price point of your products

- The packaging and labelling of your products

- The shelf life of your products

- The availability of ingredients and raw materials

Marketing and Sales :

Once you have developed your product line, it is important to develop a marketing and sales strategy to promote your products. Your marketing and sales strategy should be tailored to your target market and should aim to differentiate your products from those of your competitors.

Some key marketing and sales considerations include:

Developing a brand identity and messaging that resonates with your target market

Identifying your distribution channels, such as retail stores or online marketplaces

Developing a pricing strategy that is competitive but still profitable

Creating a promotional plan, such as social media advertising or email marketing campaigns

Legal Compliance and Safety :

The operation of a food processing firm requires adherence to numerous regulatory and safety requirements. Depending on the kind of food processing business you're beginning and where it's located, you'll need to adhere to a certain set of rules.

Among the most important legal and safety factors are:

securing the authorizations and licences required to run your enterprise

observing food safety guidelines, such as those established by the FDA and USDA

planning a HACCP (Hazard Analysis and Critical Control Points) strategy

upholding sanitization and hygiene standards

ensuring that your staff is educated on proper food handling and safety practices

Conclusion :

Although it requires careful planning and preparation, starting a food processing business can be a rewarding and profitable venture. You can improve your chances of success by carrying out in-depth market research, creating a strong business plan, obtaining finance, buying the essential tools and materials, developing a product line, and putting a marketing and sales strategy into action. The health and safety of your clients and staff are also dependent on your ability to adhere to legal and safety requirements. You can convert your love of cooking into a successful business with the correct preparation and execution.

2 notes

·

View notes

Text

Forage Harvester Market Size, Share, Trends, Growth and Competitive Outlook

"Forage Harvester Market – Industry Trends and Forecast to 2029

Global Forage Harvester Market, By Type (Pull-Type Forage Harvester and Self-Propelled Forage Harvester), Application (Ranch, Farm and Others), Country (U.S., Canada, Mexico, Germany, France, U.K., Italy, Spain, Russia, Turkey, Belgium, Netherlands, Switzerland, Luxemburg, Rest of Europe, Japan, China, South Korea, India, Australia And New Zealand, Singapore, Thailand, Malaysia, Indonesia, Philippines, Rest of Asia-Pacific, Brazil, Argentina, Rest of South America UAE, Saudi Arabia, Egypt, Israel, South Africa, and Rest Of Middle East and Africa) Industry Trends and Forecast to 2029

Access Full 350 Pages PDF Report @

**Segments**

- **Type:** The forage harvester market can be segmented based on type into self-propelled forage harvesters and pull-type forage harvesters. Self-propelled forage harvesters are gaining popularity due to their efficiency, ease of operation, and advanced technological features. Pull-type forage harvesters, on the other hand, are relatively more affordable and suitable for small to medium-sized farms.

- **Application:** In terms of application, the market can be segmented into dairy farms, livestock farms, and other agricultural operations. Forage harvesters are essential equipment for dairy and livestock farms to ensure efficient feed processing and management. They are also used in other agricultural activities such as silage making and biomass collection.

- **Region:** Geographically, the forage harvester market can be segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. North America and Europe are anticipated to dominate the market due to the presence of large-scale commercial farms and the adoption of advanced farming technologies. The Asia Pacific region is witnessing rapid growth in the forage harvester market due to increasing mechanization in agriculture.

**Market Players**

- **AGCO Corporation:** AGCO Corporation is a prominent player in the forage harvester market, offering a wide range of advanced harvesting equipment for various agricultural applications. The company focuses on innovation and sustainability to meet the evolving needs of farmers worldwide.

- **CLAAS KGaA mbH:** CLAAS is known for its high-performance forage harvesters that are renowned for their efficiency and productivity. The company invests heavily in research and development to introduce cutting-edge technologies in its harvesting equipment.

- **CNH Industrial N.V.:** CNH Industrial is a key player in the forage harvester market, providing a comprehensive range of harvesting solutions for farmers globally. The company's forage harvesters are known for their reliability, performance, and technological advancements.

- **Deere & Company:** DeereDeere & Company is a significant player in the forage harvester market, known for its innovative agricultural machinery and equipment. They offer a diverse range of forage harvesters catering to the needs of farmers worldwide. Deere & Company focuses on incorporating advanced technologies into their products to enhance efficiency, productivity, and ease of operation for farmers. Their forage harvesters are designed to withstand rigorous agricultural tasks while providing optimal performance. The company's strong emphasis on research and development enables them to stay ahead in the market by introducing new features and improvements to meet the evolving demands of the agriculture industry.

AGCO Corporation has established itself as a leading player in the forage harvester market by delivering high-quality and reliable harvesting equipment. Their range of forage harvesters is designed to streamline the harvesting process, improve productivity, and ensure superior crop quality. AGCO Corporation continuously invests in research and development to introduce innovative solutions that address the specific needs of farmers. Their commitment to sustainability and environmental stewardship resonates with the growing trend towards eco-friendly agricultural practices. By offering a comprehensive lineup of forage harvesters, AGCO Corporation caters to a diverse customer base across various agricultural segments.

CLAAS KGaA mbH has a strong presence in the forage harvester market with its reputation for manufacturing high-performance harvesting equipment. Their forage harvesters are renowned for their cutting-edge technology, efficiency, and reliability. CLAAS KGaA mbH places a strong emphasis on product innovation and development to deliver top-of-the-line solutions that enhance farm operations. By focusing on customer requirements and industry trends, the company continuously evolves its product portfolio to stay competitive in the market. CLAAS KGaA mbH's commitment to quality and performance has solidified its position as a leading provider of forage harvesters globally.

CNH Industrial N.V. is a key player in the forage harvester market, offering a wide range of harvesting solutions designed to meet the diverse needs of farmers. Their for**Segments**

- **Type:** The forage harvester market can be segmented based on type into self-propelled forage harvesters and pull-type forage harvesters. Self-propelled forage harvesters are gaining popularity due to their efficiency, ease of operation, and advanced technological features. Pull-type forage harvesters, on the other hand, are relatively more affordable and suitable for small to medium-sized farms.

- **Application:** In terms of application, the market can be segmented into dairy farms, livestock farms, and other agricultural operations. Forage harvesters are essential equipment for dairy and livestock farms to ensure efficient feed processing and management. They are also used in other agricultural activities such as silage making and biomass collection.

- **Region:** Geographically, the forage harvester market can be segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. North America and Europe are anticipated to dominate the market due to the presence of large-scale commercial farms and the adoption of advanced farming technologies. The Asia Pacific region is witnessing rapid growth in the forage harvester market due to increasing mechanization in agriculture.

**Market Players**

- **AGCO Corporation:** AGCO Corporation is a prominent player in the forage harvester market, offering a wide range of advanced harvesting equipment for various agricultural applications. The company focuses on innovation and sustainability to meet the evolving needs of farmers worldwide.

- **CLAAS KGaA mbH:** CLAAS is

Global Forage Harvester Market survey report analyses the general market conditions such as product price, profit, capacity, production, supply, demand, and market growth rate which supports businesses on deciding upon several strategies. Furthermore, big sample sizes have been utilized for the data collection in this business report which suits the necessities of small, medium as well as large size of businesses. The report explains the moves of top market players and brands that range from developments, products launches, acquisitions, mergers, joint ventures, trending innovation and business policies.

The report provides insights on the following pointers:

Market Penetration: Comprehensive information on the product portfolios of the top players in the Forage Harvester Market.

Product Development/Innovation: Detailed insights on the upcoming technologies, R&D activities, and product launches in the market.

Competitive Assessment: In-depth assessment of the market strategies, geographic and business segments of the leading players in the market.

Market Development: Comprehensive information about emerging markets. This report analyzes the market for various segments across geographies.

Market Diversification: Exhaustive information about new products, untapped geographies, recent developments, and investments in the Forage Harvester Market.

The following are the regions covered in this report.

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

The Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Browse Trending Reports:

7g Substrate Materials Market Cloud Application Programming Interface Api And Management Platforms And Middleware Market Abscisic Acid Aba Market Benign Mesonephroma Market Cancer Supportive Care Products Market Data Center Interconnect Market Potash Fertilizers Market Private Label Food And Beverage Market Relational Database Market Commercial Lighting Market Ethoxylates Market Eclinical Solutions Market Vaccines Market Spark Plug Market High Visibility Clothing Market Gas Turbine Services Market Dessert Mix Market Lipid Nutrition Market Barrier Films Flexible Electronics Market Nasal Polyposis Drugs Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

Uses of Milk Processing Plant for Dairy Farm

Milk processing plants are essential for dairy farms as they transform raw milk into a variety of consumer-ready products like cheese, yogurt, and butter, significantly increasing profitability. These facilities extend the shelf life of milk through pasteurization and ensure high quality and safety standards, which are crucial for consumer trust. By processing milk, dairy farms can reach broader markets, enhance product nutritional value, and effectively manage waste by repurposing by-products. Additionally, modern automation improves efficiency, allowing farms to scale operations while complying with regulatory standards. Ultimately, investing in a milk processing plant supports local economies and fosters brand development, enabling dairy farms to thrive in a competitive market.

What is a Milk Processing Plant?

A milk processing plant is a facility designed to handle, process, and package milk and dairy products. These plants employ various technologies and equipment to ensure the milk is pasteurized, homogenized, and packaged safely for consumption.

Types of Milk Processing Plants

Milk processing plants come in various capacities to cater to different production needs. Here’s a breakdown of common sizes and their associated costs:

100 Ltr Milk Processing Plant Cost: Ideal for small dairies or startups, this capacity is suitable for local markets and specialty products.

200 Ltr Milk Processing Plant Cost: Slightly larger, this plant can serve small businesses looking to scale up their production.

300 Ltr Milk Processing Plant Cost: Perfect for growing operations that need more flexibility in their product range.

500 Ltr Milk Processing Plant Cost: A mid-sized option that balances capacity with space requirements, suitable for small to medium-sized dairies.

1000 Ltr Milk Processing Plant Cost: This size is often used by medium enterprises aiming for higher production volumes.

5000 Ltr Milk Processing Plant Cost: Designed for larger operations, this capacity allows for extensive processing and product diversity.

10000 Ltr Milk Processing Plant Cost: Perfect for large-scale dairy operations that require significant output to meet market demands.

2000 Ltr Milk Processing Plant Cost: A popular choice for businesses looking to expand their production capabilities without going to the maximum scale.

Choosing a Right Milk Processing Plant Manufacturer

When selecting a milk processing plant manufacturer, it’s crucial to consider several factors:

Experience and Reputation: Look for manufacturers with a proven track record in the industry. Research reviews and testimonials to gauge their reliability.

Quality of Equipment: Ensure the manufacturer uses high-quality materials and adheres to industry standards for hygiene and safety.

Customization Options: A good manufacturer should be able to provide tailored solutions that meet your specific needs and production goals.

After-Sales Support: Check if the manufacturer offers installation, training, and maintenance support to keep your plant running smoothly.

Cost Efficiency: Compare prices among different milk processing plant manufacturers to find the best balance between quality and cost.

If you are looking for Best Milk Processing Plant Manufacturer in India, look no further than Pranamji Engineering Works, we are a leading Milk Processing plant manufacturer, supplier and exporter in India.

Conclusion

Investing in a milk processing plant can significantly enhance your business’s capacity to meet the growing demand for dairy products. Understanding the various sizes and their respective costs — ranging from the 100 ltr milk processing plant cost to the 10000 ltr milk processing plant cost — will help you make informed decisions.

By partnering with a reputable milk processing plant manufacturer, you can ensure your operation is efficient, compliant, and capable of producing high-quality dairy products. Whether you’re starting small with a 500 ltr milk processing plant or going big with a 5000 ltr milk processing plant, the right investment will pay off in the long run.

For more details, please contact us!

Website :- www.pranamjiengineering.com

Contact No. :- 09997737365, 7017598033

Email :- [email protected]

Address :- Khasra No 346, Jalapur, Raghunathpur Muradnagar, Ghaziabad Uttar Pradesh — 201206

#Milk Processing Plant#Milk Processing Plant manufacturer#Milk Processing Plant supplier#Milk Processing Plant manufacturer in India#Milk Processing Plant supplier in India#pranamji engineering works

1 note

·

View note

Text

India's Export Landscape: Key Insights and Major Exporters

India has firmly established itself as a prominent player in the global export market, thanks to its diverse range of products and robust industrial base. This article explores the key highlights of India's export performance, major exporters, and top export companies, shedding light on the factors that drive the country's trade success.

Key Highlights of India's Export Performance

In October 2023, India saw a notable increase in its total exports, reaching USD 62.26 billion, a 9.43% rise from USD 56.90 billion in October 2022. This growth underscores the resilience and expansion of India's export sector amid global economic uncertainties. The fiscal year 2023–2024 marked a record total export value of USD 778.2 billion, with a slight increase of 0.04% from the previous year.

However, while the overall export value has grown, there was a 3% decrease in the export of goods, which fell to USD 437.1 billion. Conversely, exports of services saw a significant rise to USD 341.1 billion, highlighting a shift towards service-based exports.

Exports by Major Products:

Leather and Its Products

Petroleum Products

Gems and Jewelry

Automobiles, Equipment Parts, and Electronic Goods

Pharmaceutical Products

Organic and Inorganic Chemicals

Dairy Products

Handloom and Cotton Yarns

Top Exporting Countries:

China - USD 3,380 billion

United States - USD 2,019 billion

Germany - USD 1,688 billion

Netherlands - USD 934 billion

Japan - USD 798 billion

Italy - USD 717 billion

France - USD 676 billion

South Korea - USD 648 billion

Mexico - USD 593 billion

Canada - USD 569 billion

Major Exporters in India

India's export sector is characterized by a few key players who dominate various industries. Here’s a closer look at some of the major exporters:

1. Reliance Industries

Reliance Industries is the largest exporter in India, contributing to 15% of the country's total exports. The company excels in refining and petrochemicals, exporting petroleum products such as chemicals, polymers, and refined fuels. Its primary markets include Europe, Africa, and the Americas.

2. Tata Steel

Tata Steel stands out for its extensive steel production capacity, with an annual output of 35 million metric tons. The company's operations span from mining to manufacturing and marketing finished products. Tata Steel exports its products to a diverse range of markets, including the United States, Vietnam, Iraq, Afghanistan, Korea, Jordan, and Qatar.

3. Sun Pharmaceutical Industries

Sun Pharma is a global leader in pharmaceutical exports, specializing in APIs, generic drugs, and specialty medications. The company’s research-driven approach has expanded its reach to markets such as the USA, Belarus, Sri Lanka, and Myanmar.

4. Rajesh Exports Limited

Rajesh Exports is unique in its complete integration across the gold value chain, from retail branding to mining. Processing about 35% of the world’s gold, the company exports gold and jewelry to over 60 countries, including the USA, UK, Singapore, and UAE.

5. Tata Motors

Tata Motors is a leading automaker known for its diverse range of vehicles, including electric, commercial, and passenger vehicles. The company’s export markets include Latin America, Africa, the Middle East, and Vietnam.

6. Vardhaman Textiles

As the largest vertically integrated textile manufacturer in India, Vardhaman Textiles exports a significant portion of its yarn production. Its major markets are South Asia, Europe, Africa, Japan, and the United States.

7. International Lace Trade Center

The ILTC facilitates the export of handmade lace products, showcasing Indian handicrafts to the global market. The center supports artisans and exporters by providing various facilities for exhibitions and craft bazaars.

8. Bajaj International Private Limited

Bajaj International Pvt. Ltd., part of the Bajaj Group, exports a range of electronic products, including irons, gas stoves, ceiling fans, and room heaters.

9. Arvind Mills

Arvind Mills is renowned for its textiles and denim, including brands like Flying Machine and licensed international labels. The company operates retail chains such as Megamart, Unlimited, and Arvind Store.

10. Kiran Gems Private Limited

Kiran Gems is the world’s largest producer of natural diamonds, known for its advanced manufacturing systems and broad product variety. The company exports diamonds globally, setting industry standards in quality and precision.

Conclusion

India's export sector demonstrates impressive growth and diversity, driven by a range of industries and key players. From refined petroleum and high-quality textiles to pharmaceuticals and automobiles, India's global trade footprint continues to expand. The country’s top exporters play a crucial role in shaping its economic landscape, leveraging technological advancements and market diversification to maintain their competitive edge.

For businesses and individuals interested in exploring India's export opportunities, platforms like ExportImportData.in offer comprehensive insights and data to facilitate informed decision-making.

#Major Exporters in India#largest exporter in India#Indian Exporters List#top export companies in India#top exporters in India

0 notes

Text

A Comprehensive Guide to ESMA Registration for Businesses in Abu Dhabi

Navigating the regulatory landscape is a critical aspect of establishing a business in Abu Dhabi, particularly when it comes to ensuring your products meet the highest standards of safety, quality, and performance. The Emirates Authority for Standardization and Metrology (ESMA) plays a pivotal role in setting these standards, and obtaining ESMA Registration is essential for businesses looking to thrive in the UAE market. This comprehensive guide will walk you through everything you need to know about ESMA Registration and how to achieve it for your business in Abu Dhabi.

What Is ESMA Registration?

ESMA Registration is a mandatory certification process implemented by the UAE government to ensure that products sold within the country adhere to stringent safety, quality, and performance standards. ESMA oversees this process, ensuring that all products meet the necessary criteria before they can be marketed and sold in the UAE.

Why ESMA Registration Is Important:

Regulatory Compliance: Ensures that your products comply with UAE’s technical and safety standards.

Market Access: Legally allows your products to be sold in Abu Dhabi and across the UAE.

Consumer Trust: Builds confidence among consumers regarding the safety and quality of your products.

Types of Products Requiring ESMA Registration

ESMA Registration covers a wide range of products, including but not limited to:

Electronics and Electrical Equipment: Appliances, lighting, and other electronic devices.

Automotive Products: Tires, spare parts, and safety equipment.

Food and Beverages: Packaged foods, dairy products, and bottled water.

Cosmetics and Personal Care Products: Skincare, haircare, and hygiene products.

Children’s Products: Toys, clothing, and childcare items.

Construction Materials: Cement, steel, and other building materials.

Step-by-Step Process for Achieving ESMA Registration

1. Determine Applicable Standards

Overview: The first step in the ESMA Registration process is identifying the specific standards and regulations applicable to your product. ESMA has established detailed standards for various product categories.

Action Steps:

Research ESMA Standards: Review the ESMA website or consult with a regulatory expert to identify relevant standards.

Assess Product Requirements: Determine which specific requirements your product must meet.

Example: An electronics manufacturer would need to understand standards related to electrical safety, electromagnetic compatibility (EMC), and energy efficiency.

2. Prepare Necessary Documentation

Overview: Comprehensive documentation is crucial for ESMA Registration. This includes technical files that provide detailed information about the product.

Required Documents:

Product Description: Detailed information about the product, including specifications and components.

Test Reports: Results from the product testing, demonstrating compliance with ESMA standards.

Safety Data Sheets (SDS): For chemical products, providing information on hazards and safe handling.

Example: A cosmetics company would need to prepare ingredient lists, safety data sheets, and test reports.

3. Conduct Product Testing

Overview: Products must undergo rigorous testing to verify their compliance with ESMA standards. Accredited testing labs in Abu Dhabi can conduct these tests.

Testing Categories:

Safety Testing: Ensures the product does not pose any harm to users.

Performance Testing: Verifies that the product performs as advertised.

Quality Testing: Confirms that the product meets the required quality standards.

Example: A toy manufacturer must conduct safety tests to ensure the product is safe for children.

4. Submit Application and Documentation

Overview: Once all necessary documentation and test reports are prepared, the next step is to submit your application to ESMA.

Action Steps:

Complete the Application Form: Fill out the ESMA application form with accurate information.

Submit Documentation: Provide all required documents, including test reports and technical files.

Example: An automotive parts manufacturer would submit test reports, safety data sheets, and a completed application form.

5. Factory Inspection (If Required)

Overview: For certain product categories, ESMA may require factory inspections to verify that manufacturing processes comply with regulatory standards.

Inspection Focus:

Quality Management Systems: Ensures that manufacturing processes consistently produce high-quality products.

Production Environment: Verifies that the factory environment is safe and hygienic.

Record Keeping: Checks that proper records are maintained for production and quality control.

Example: A food manufacturing plant might be inspected to ensure hygiene standards are met and quality control processes are in place.

6. Obtain ESMA Certificate of Conformity

Overview: Upon successful completion of the application process and any required inspections, ESMA will issue a Certificate of Conformity.

Benefits:

Legal Compliance: Certifies that your product meets all regulatory requirements.

Market Access: Allows your product to be sold in Abu Dhabi and throughout the UAE.

Example: A construction materials company receives a Certificate of Conformity, allowing them to market and sell their products in the UAE.

Benefits of Partnering with an Accredited Testing Lab

1. Expertise in ESMA Standards

Overview: Accredited testing labs have in-depth knowledge and understanding of ESMA standards and regulations, ensuring that your product meets all necessary requirements.

Benefits:

Regulatory Insight: Labs provide detailed guidance on specific ESMA standards applicable to your product.

Compliance Assurance: Expert advice ensures that your product complies with all relevant standards, minimizing the risk of non-compliance.

Example: A cosmetics manufacturer can benefit from the lab’s expertise in ESMA’s safety and quality standards for personal care products.

2. Comprehensive Testing Services

Overview: Accredited testing labs offer a wide range of testing services to evaluate the safety, quality, and performance of your product.

Benefits:

Safety Testing: Ensures the product does not pose any harm to users.

Performance Testing: Verifies that the product performs as advertised.

Quality Testing: Confirms that the product meets the required quality standards.

Example: An electronic device can undergo electrical safety tests, electromagnetic compatibility (EMC) tests, and performance evaluations in a single facility.

3. Streamlined Documentation Process

Overview: Proper documentation is crucial for ESMA Registration. Accredited testing labs assist in preparing and reviewing the necessary documents to ensure they meet ESMA’s requirements.

Benefits:

Technical Documentation: Labs help compile detailed technical files required for certification.

Document Review: Thorough review of documents to ensure accuracy and completeness.

Example: A food manufacturer can rely on the lab to prepare safety data sheets, ingredient lists, and test reports.

4. Efficient Labeling and Marking Compliance

Overview: Accredited labs ensure that your product’s labeling and marking meet ESMA requirements, which is essential for certification.

Benefits:

Label Review: Checking product labels for compliance with ESMA requirements.

Marking Verification: Ensuring the correct use of ESMA compliance marks.

Example: A toy manufacturer can get assistance with ensuring labels show age recommendations, safety warnings, and the ESMA mark.

5. Support During Factory Inspections

Overview: For certain products, ESMA may require factory inspections. Accredited testing labs can provide support to ensure that your manufacturing processes comply with regulatory standards.

Benefits:

Pre-Inspection Audits: Labs conduct audits to prepare for ESMA factory inspections.

Inspection Assistance: Support during the actual inspection process.

Example: A medical device manufacturer can get help preparing for and passing an ESMA factory inspection.

6. Ongoing Compliance and Certification Renewal

Overview: ESMA Registration requires ongoing compliance. Accredited testing labs offer services to support continuous compliance and certification renewal.

Benefits:

Regular Testing: Periodic testing to ensure continued compliance.

Renewal Support: Assistance with the certification renewal process.

Example: A construction material manufacturer can benefit from regular testing services and support for renewing certification.

Conclusion

Achieving ESMA Registration is crucial for any business aiming to sell products in Abu Dhabi and the wider UAE market. By understanding the process and partnering with an accredited testing lab, businesses can ensure their products meet all regulatory standards, gain market access, and build consumer trust. Accredited labs offer invaluable support through their expertise, comprehensive testing services, and efficient documentation processes, making them an essential partner in your journey to ESMA Registration.

0 notes

Text

Raw and Real or Refined and Restricted? Market Growth of Food Starches Caught in a Processing Paradox

The global food starch market is projected for growth, driven by the expanding food processing and food service industries. However, the increasing availability of substitutes may pose a challenge. To navigate this landscape, Infinium Global Research offers a recent report with a deep dive into market segments and sub-segments, both globally and regionally. The report analyzes the impact of various short- and long-term factors, including drivers, restraints, and macro indicators, influencing the market's trajectory. It provides a comprehensive overview of current trends, forecasts, and dollar values for the global food starch market. This valuable resource can equip stakeholders with the insights needed to make informed decisions in this evolving market

To Get More Business Strategies for Request Sample Report @: https://www.infiniumglobalresearch.com/reports/sample-request/20722

Consumers around the world are increasingly seeking high-quality food and beverages that are both delicious and nutritious. This trend is driving a shift away from basic staples towards more enhanced food products. As a result, the demand for starch in the food and beverage industry is growing.

Starch is a versatile ingredient prized for its thickening, emulsifying, texturizing, gelling, stabilizing, and adhesive properties. It also boasts rheology modifying properties, making it a highly adaptable ingredient for a wide range of food applications. Bakery products, confectionery, sauces, processed meats, noodles, pasta, dry mixes, soups, salad dressings, puddings, and pie fillings all rely heavily on starch. Furthermore, advancements in starch modification have led to improved heat, temperature, pH, and rheological resistance, further expanding its global appeal and boosting the food starch industry.

Market Dynamics

The food starch market is experiencing a confluence of driving forces and potential challenges.

On the positive side, consumer demand for high-quality, nutritious food and beverages is translating into a preference for enhanced food products, which often rely heavily on starch for thickening, texture, and other functionalities. Starch's versatility extends beyond food processing, with applications in adhesives (particularly packaging) and various industrial products. This widespread use, coupled with its role as a thickening agent, binder, stabilizer, and emulsifier, fuels market growth. the growing trend of biofuels and biomaterials creates additional demand for industrial starch. The paper and textile industries are also significant consumers of corn starch, contributing further to market expansion.

Market Segmentation

Type:

Native Starch: This includes unmodified starch extracted directly from plants like corn, wheat, potato, and tapioca. It offers thickening and texturizing properties.

Modified Starch: This category encompasses starch that has undergone various treatments to enhance specific functionalities like heat resistance, gelling, or emulsification, making it suitable for diverse food applications.

Starch Derivatives: This segment includes products derived from starch through further processing, such as glucose syrups, maltodextrins, and cyclodextrins. These derivatives offer a wider range of functional properties for specialized uses in the food industry.

Applications:

The report explores the various sectors that utilize food starch, including:

Baked Goods: Starch plays a crucial role in baked goods for thickening, texturizing, and creating desired crumb structures.

Dairy Products: Starch is used in dairy products like yogurt and cheese to improve texture, stability, and mouthfeel.

Beverages: Starch finds application in thickening beverages, stabilizing emulsions, and enhancing mouthfeel.

Confectionery: Starch is a vital ingredient in candies and sweets, contributing to texture, sweetness, and binding properties.

Meat Products: Starch can be used in processed meats as a binder, thickener, and extender.

Other Applications: Starch has additional uses in var

Regional Impact:

North America (Dominant Market Share): This region is expected to hold the largest market share throughout the forecast period. Several factors contribute to North America's leading position:

Development of Modified Starch: North American producers are at the forefront of modified starch innovation, offering a wider range of functional starches for diverse applications.

Presence of Large Producers: Established players in the region cater to both domestic and international demand for food starch.

Asia-Pacific (High Growth Potential): The Asia-Pacific region is anticipated to witness significant growth with a healthy CAGR. This expansion can be attributed to:

Rising Maize (Corn) Use: The growing use of maize as a raw material for starch production fuels market expansion in this region.

Europe (Focus on Alternative Starches): Europe presents promising growth opportunities driven by:

Shifting Raw Material Preferences: European producers are increasingly utilizing potato and wheat alongside traditional sources like corn, catering to specific consumer demands.

Rest of the World (Emerging Markets): The ROW market holds potential for future growth as developing economies prioritize food processing advancements. However, factors like limited infrastructure and fragmented markets in some regions may pose challenges.

Request full Report: https://www.infiniumglobalresearch.com/reports/global-food-starch-market

Competitive landscape

Cargill Inc.

National Starch Food Innovation

Tereos Syral SAS

Tate & Lyle PLC

Roquette Freres SA

Grain Processing Corporation

Agrana Group

Qingdao Nutrend Biotech Co., Ltd.

SPAC Starch Products Ltd.

Sonish Starch Technology Co., Ltd.

Future outlook and conclusion:

The future of the food starch market appears bright, driven by a confluence of trends. Consumers' desire for high-quality, nutritious, and convenient food products positions starch as a valuable ingredient due to its versatility and functionality.

Beyond food processing, starch finds applications in adhesives, biofuels, and biomaterials, further expanding its market reach. However, the increasing availability of substitutes presents a potential challenge.

Innovation will be key for market leaders. Continued development of modified starches with enhanced properties and exploration of alternative raw materials can help the industry stay ahead of the curve. the food starch market offers a dynamic landscape with both opportunities and challenges. By staying abreast of consumer trends, embracing innovation, and exploring new applications, market players can capitalize on the potential for sustained growth in the years to come.

0 notes

Text

Is Food Technology a Good Career Option?

In today's rapidly evolving world, food technology has emerged as a dynamic and promising field that bridges the gap between traditional food processing and modern technological advancements.

This interdisciplinary domain combines principles of food science, microbiology, chemistry, engineering, and nutrition to innovate and improve the way food is produced, processed, preserved, packaged, and distributed.

With increasing global focus on food safety, quality, and sustainability, the demand for skilled professionals in food technology is on the rise, making it a lucrative and rewarding career choice.

Understanding Food Technology

Food technology involves the application of scientific and technological principles to the processing, preservation, packaging, and distribution of food. It encompasses a wide range of activities, from developing new food products and enhancing food safety protocols to optimizing manufacturing processes and ensuring compliance with regulatory standards. Professionals in this field work to create healthier, safer, and more sustainable food options for consumers.

Food Technology Courses and Education

For those who have completed their higher secondary education, enrolling in a B.Sc. or B.Tech program in food technology is a popular choice. Additionally, diploma courses and certification programs in food technology are available for students seeking specialized knowledge and skills. To embark on a career in food technology, aspiring students can pursue various educational pathways, including:

B.Sc. Food Technology: This undergraduate program typically spans three years and provides a comprehensive understanding of food science, nutrition, microbiology, food chemistry, and food processing technologies. It equips students with the foundational knowledge and practical skills needed to excel in the food industry.

B.Tech Food Technology: A four-year engineering degree, B.Tech in Food Technology delves deeper into the technical and engineering aspects of food production and processing. This program covers subjects like food engineering, quality control, packaging technology, and industrial microbiology.

Scope of Food Technology

The scope of food technology is vast and ever-expanding, driven by the need for innovation in food production and processing. Key areas within the field include:

Food Production and Processing: Developing new methods and technologies to enhance the efficiency and quality of food production. This includes improving techniques for processing fruits, vegetables, dairy products, meat, and grains.

Food Safety and Quality Assurance: Ensuring that food products meet stringent safety and quality standards. Professionals in this area work to prevent contamination, improve shelf life, and maintain nutritional value.

Research and Development: Innovating new food products, flavors, and ingredients. This involves conducting research to understand consumer preferences and developing products that cater to market demands.

Packaging and Preservation: Developing advanced packaging solutions to extend the shelf life of food products and reduce waste. This includes creating sustainable packaging materials and methods.

Regulatory Affairs: Ensuring compliance with national and international food safety regulations. This involves staying updated with changing regulations and implementing necessary changes in production processes.

Career Opportunities in Food Technology

A degree in food technology opens up a wide range of career opportunities in various sectors, including:

Food Technologist: Food technologists are responsible for developing new food products, improving existing ones, and ensuring that food processing methods are safe and efficient. They work in food manufacturing companies, research institutions, and government agencies.

Quality Assurance Manager: These professionals oversee the quality control processes in food production, ensuring that products meet safety and quality standards. They implement testing procedures, manage quality control teams, and handle compliance with regulatory requirements.

Research Scientist: Research scientists in food technology conduct experiments and studies to develop new food products, improve processing methods, and enhance nutritional value. They work in research and development departments of food companies, universities, and research organizations.

Food Safety Officer: Ensuring that food products are safe for consumption, food safety officers inspect food processing facilities, conduct audits, and implement safety protocols. They work for government agencies, food safety organizations, and private companies.

Product Development Manager: These professionals lead the development of new food products from concept to market. They work closely with marketing, production, and quality assurance teams to create innovative products that meet consumer demands.

Benefits of a Career in Food Technology

High Demand and Job Security: The food industry is a crucial sector that continues to grow, ensuring a steady demand for skilled professionals in food technology. This translates to job security and numerous employment opportunities.

Diverse Career Paths: The interdisciplinary nature of food technology offers diverse career paths in areas such as research and development, quality assurance, food safety, and product development. This allows professionals to explore various roles and find their niche.

Innovation and Creativity: A career in food technology provides opportunities to innovate and create new food products, processes, and solutions. This creative aspect can be highly rewarding and satisfying for individuals passionate about food and technology.

Contribution to Public Health: By ensuring the safety and quality of food products, professionals in food technology play a vital role in protecting public health and promoting nutrition. This sense of contribution can be fulfilling and impactful.

Shoolini University's School of Biotechnology and Food Technology is renowned for its cutting-edge curriculum, experienced faculty, and state-of-the-art facilities. Students at Shoolini University receive hands-on training and exposure to the latest advancements in food technology, preparing them for successful careers in the industry. Shoolini University shares the prestigious title of joint No. 1 private university in India according to the QS World University Rankings 2024.

The B.Sc. and B.Tech programs in food technology at Shoolini University cover a wide range of subjects, including food science, microbiology, food chemistry, food engineering, and quality assurance. The university emphasizes practical learning through internships, industry projects, and collaborations with leading food companies. This holistic approach ensures that graduates are well-equipped to meet the demands of the food industry and excel in their careers.

With a strong foundation in scientific principles and practical skills, professionals in this field can contribute to the development of safe, nutritious, and sustainable food products. Pursuing a degree in food technology opens up diverse career paths in areas such as food production, quality assurance, research and development, and packaging.

The demand for skilled food technologists is on the rise, driven by the need for innovation in food processing and preservation. This ensures job security and attractive salary prospects for professionals in the field. Additionally, the interdisciplinary nature of food technology allows for creativity and innovation, making it a fulfilling career choice for individuals passionate about food and technology.

Shoolini University, with its comprehensive programs and industry-oriented approach, provides an excellent platform for aspiring food technologists to gain the knowledge and skills needed to succeed in the industry. The university's focus on practical learning and industry collaborations ensures that graduates are well-prepared to meet the challenges of the food industry and make meaningful contributions to public health and nutrition.

Overall, a career in food technology offers a blend of scientific rigor, creativity, and societal impact, making it a smart and rewarding choice for students seeking a dynamic and fulfilling career path.

1 note

·

View note

Text

The Role of Agriculture in Turlock's Economy.

Turlock, a city located in the heart of California's Central Valley, has long been known for its agricultural prowess. This region, with its fertile soil and favorable climate, has become one of the most productive agricultural areas in the United States. Agriculture in Turlock is not just a part of the local economy; it is the lifeblood that sustains the community, providing employment, fostering local businesses, and contributing significantly to the region's economic output.

Historical Context and Agricultural Evolution

California, Turlock's history is deeply intertwined with agriculture. Since its founding in the late 19th century, the city has evolved from a small farming community to a major hub of agricultural production. Early settlers were drawn to the area by the promise of rich farmland, and over the decades, advancements in farming technology and irrigation have allowed for a dramatic increase in agricultural productivity. This evolution has not only sustained Turlock's economy but has also positioned it as a critical player in California's agricultural sector.

Economic Impact

Agriculture is the cornerstone of Turlock's economy. The sector generates substantial revenue, with local farms producing a diverse array of crops and livestock. Key commodities include almonds, dairy products, poultry, and a variety of fruits and vegetables. The almond industry, in particular, has seen significant growth, with Turlock contributing a sizeable portion of California's almond production. This industry alone brings millions of dollars into the local economy annually, supporting numerous ancillary businesses such as processing plants, packaging facilities, and transportation services.

Employment is another critical aspect of agriculture's role in Turlock. The sector provides jobs for thousands of residents, ranging from field laborers and equipment operators to managers and agricultural scientists. This employment is not limited to direct agricultural activities; many jobs are also created in related industries, including food processing, distribution, and retail. Seasonal employment opportunities, although variable, also contribute to the local job market, offering work to both permanent residents and migrant laborers.

Supporting Local Businesses

The agricultural sector in Turlock supports a wide range of local businesses. Farm equipment suppliers, seed and fertilizer companies, and irrigation specialists all thrive due to the demand generated by local farms. Additionally, the success of agriculture fuels the growth of local restaurants, grocery stores, and farmers' markets, which rely heavily on fresh, locally sourced produce. These businesses, in turn, contribute to the overall economic health of Turlock by providing goods, services, and employment to the community.

Educational and Research Contributions

Turlock is also home to California State University, Stanislaus, which plays a significant role in supporting the agricultural sector. The university's agricultural programs offer education and training to future generations of farmers, agronomists, and agricultural business professionals. Research conducted at the university helps to advance farming techniques, improve crop yields, and develop sustainable practices that benefit the local and global agricultural community. This symbiotic relationship between education and agriculture ensures that Turlock remains at the forefront of agricultural innovation.

Challenges and Future Prospects

Despite its many strengths, the agricultural sector in Turlock faces several challenges. Water scarcity is a persistent issue in California, and the Central Valley is no exception. Sustainable water management practices are crucial to ensuring the long-term viability of agriculture in the region. Additionally, labor shortages and fluctuating commodity prices can impact the stability of the agricultural economy. Addressing these challenges requires ongoing collaboration between farmers, policymakers, and researchers.

Looking ahead, the future of Turlock's agricultural sector appears promising. Innovations in technology, such as precision farming and advanced irrigation systems, hold the potential to enhance productivity and sustainability. Furthermore, the growing demand for organic and locally sourced produce presents new opportunities for Turlock's farmers. By continuing to adapt and innovate, Turlock can maintain its position as a leader in California's agricultural landscape.

Conclusion

Agriculture is more than just an economic activity in Turlock; it is a way of life. The sector's contributions to the local economy are vast, from generating revenue and providing employment to supporting local businesses and fostering educational growth. While challenges exist, the resilience and adaptability of Turlock's agricultural community ensure that it will continue to thrive, sustaining the city and contributing to the broader Central Valley and California economies.

0 notes

Text

Automated Material Handling Equipment Market Overview: Evaluating Size, Share, Trends, and Future Growth

The global automated material handling equipment market size is anticipated to reach USD 114.45 billion by 2030, projected to grow at a CAGR of 9.7% from 2024 to 2030, according to a new report by Grand View Research, Inc. The increasing labor costs in many countries are driving the demand for AMH equipment, which is replacing manual labor. It helps companies save costs by reducing the need for manual labor and increasing productivity. Further, e-commerce has created a need for faster and more efficient material handling systems. Automated Material Handling (AMH) equipment is used in e-commerce warehouses to handle large volumes of orders to ensure products are delivered to customers quickly and accurately. Technological advances have also made it possible to develop more sophisticated AMH equipment that is fast, accurate, and reliable. These systems use sensors, artificial intelligence, and machine learning to automate material handling tasks.

Automated Material Handling Equipment Market Report Highlights

The robots segment led the market in 2023, accounting for over 24% share of the global revenue owing to the integration of artificial intelligence and machine learning technologies in robotic systems.

The unit load material handling segment held the largest revenue share in 2023 due to its ability to streamline supply chain operations and move materials more efficiently across long distances.

The e-commerce segment led the market in 2023. The adoption of AMH equipment in the e-commerce industry is expected to increase significantly in the coming years as companies such as Amazon, eBay, and Alibaba strive to remain competitive and meet customer expectations.

The Asia Pacific region held the largest revenue share, over 39%, in 2023. The region's flourishing manufacturing and automobile sectors are expected to spur the demand for automated material-handling equipment.

For More Details or Sample Copy please visit link @:Automated Material Handling Equipment Market Report

Automated storage and retrieval systems can significantly reduce variable costs by eliminating the need for manual labor for tasks such as assembly, picking, storing, and inventory replenishment. Warehouses and distribution centers require the regular replenishment of raw materials, work-in-progress, and finished goods inventories to maintain uninterrupted processes, making shelf arrangement and grouping critical. Efficient space utilization is vital for the bottom line of warehouses and distribution centers. For instance, in September 2022, Aurora Organic Dairy, a producer of organic milk and butter for U.S. retailers, sought the help of Westfalia Technologies Inc. to design an AS/RS solution for a significant warehouse addition. The AS/RS enabled the company to build a highly automated warehouse adjacent to the milk plant to accommodate growth in a limited square footage area while recasting the whole warehousing process from production to shipping to staging.

Labor shortages are compelling organizations to seek robots to ensure their stability. Industries such as janitorial services, commercial and home delivery, food and beverage, healthcare, and manufacturing are expected to benefit from autonomous mobile and collaborative robots. Technologically advanced countries such as South Korea and Japan are at the forefront of manufacturing next-generation AMH equipment. For instance, in March 2023, THIRA Robotics launched a new generation of autonomous mobile robots (AMRs) designed to operate in harsh facility conditions, previously unsuitable for automation. This development is likely a significant advancement in the automation industry. The company aimed to present five models and demonstrations of AMR operating on sloped and uneven flooring at Promat.

#MaterialHandling#WarehouseAutomation#IndustrialAutomation#AutomationTechnology#AutomationEquipment#SupplyChainManagement#LogisticsSolutions#AutomatedSystems

0 notes

Text

Beverage Carton Packaging Machinery Market Global Trends, and Opportunities Forecast by 2031

Beverage Carton Packaging Machinery Market ReportScope & Overview

The Beverage Carton Packaging Machinery Market Report research report delivers critical information by utilizing effective methods such as primary and secondary research. The research has been emphasized based on historical data, present statistics, and projections for the future. In addition to this, the financial overview and recent changes are properly discussed to provide greater insights for business success. The most recent research focuses on the domestic and international economic growth of the sector.

The research report includes historical data, current conditions, and forecasts for the Beverage Carton Packaging Machinery industry. To audit the target market, many market evaluation approaches are researched during the complete process. It solves difficulties using methodical techniques. It investigates effective strategies, market shares, company products, and market investments in depth. While curating the study, several perspectives such as economic issues, politics, and culture are taken into account.

Get a Sample Report https://www.snsinsider.com/sample-request/3071

Market Key Players:

Jacob White Packaging Ltd, Douglas Machine Inc, Krones AG, Tishma Technologies, Cariba S.r.l, R.A. Jones, Mpac Group plc, Syntegon Technology GmbH, Bradman Lake Group Ltd, KHS GmbH

Market Segmentation Analysis

The research report covers research studies on current trends in several areas based on their coverage. This report's analyst focuses on the industries' static and dynamic pillars for a basic grasp of the strategies. The global Beverage Carton Packaging Machinery market is divided into segments based on market participants, geographic regions, application kinds, and other variables.

By Type

Top Load Cartoner

Horizontal End Side-Load Cartoner

Wraparound Cartoner

Others

By Function

Automatic

Semi-automatic

By Application

Alcoholic Beverages

Non-alcoholic Beverages

Dairy Beverages

Regional Outlook

The Beverage Carton Packaging Machinery market research focuses on the world's major regions and countries, completely examining the most important regional market circumstances. The inquiry included a SWOT analysis of a new project, an evaluation of an investment's viability, and an estimate of the investment return.

Competitive Analysis

The research identifies the drivers and possibilities for business development. Furthermore, it focuses on constraints to examine challenges from existing company plans. It focuses on numerous topics such as application areas, platforms, and top players operating globally. The research report offers an in-depth analysis of the Beverage Carton Packaging Machinery market, as well as information on a variety of industry participants and the competitive landscape, potential threats, and future development possibilities.

Key Reasons to Buy Beverage Carton Packaging MachineryMarket Report

Determine the sector's primary motivators and constraints, as well as their impact on the worldwide market.

Understanding the most essential industry-specific driving and restraining forces, as well as their global consequences.

The research examines market participants, raw material and equipment suppliers, end users, traders, distributors, and other key stakeholders.

Examine the marketing strategies used by the most successful organizations in the target market.

Conclusion

Through in-depth market analysis, you will gain a complete understanding of the global market and its commercial landscape. The reader will have a strong understanding of the worldwide Beverage Carton Packaging Machinery market and its business environment after a detailed market analysis.

Buy the Research Report Now https://www.snsinsider.com/sample-request/3071

About Us:

SNS Insider is one of the leading Market Size research and consulting agencies that dominates the Market Size research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate Market Size data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

0 notes

Text

Dairy Processing Equipment Market Outlook for Forecast Period (2023 to 2030)

The Global Dairy Processing Equipment Market size is expected to grow from USD 10834.56 million in 2022 to USD 16754.16 million by 2030, at a CAGR of 5.6% during the forecast period (2023-2030).

Growing the dairy processing equipment market across the globe due to the high preference for the packaged and nutritional dairy products by the consumers. The application of dairy processing equipment to produce numerous products such as processed milk, cream, yogurt, butter, and others. In addition, the key drivers of this market include growth in dairy production and switching in taste & preferences by the consumers. Increasing the health consciousness and demand for healthy products with low fat and cholesterol, low sugar, and new taste and flavor among the consumers, growing the market rapidly. Furthermore, growth in the incorporation of milk products in daily diet owing to high nutritive value will turn the market size. Changing dietary patterns by the consumers and demand for a product such as cheese, cream, and yogurt for making nutritious dishes may boost the demand for dairy processing equipment.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/15815

Leading players involved in the Dairy Processing Equipment Market include:

SPX FLOW Inc, Tetra Laval International S.A., GEA Group, Van Den Heuvel Dairy, Food Equipment Dairy, Krones AG, Alfa Laval Corporates, John Bean Technologies Corporation, IDMC Ltd., Scherjon Dairy Equipment Holland B.V., Coperion GmbH., IMA Industria Machine Automatiche SPA, Paul Mueller Company, Feldmeier Equpment Inc., Caloris Engineering LLC and other Major Players.

The latest research on the Dairy Processing Equipment market provides a comprehensive overview of the market for the years 2023 to 2030. It gives a comprehensive picture of the global Dairy Processing Equipment industry, considering all significant industry trends, market dynamics, competitive landscape, and market analysis tools such as Porter's five forces analysis, Industry Value chain analysis, and PESTEL analysis of the Dairy Processing Equipment market. Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years. The report is designed to help readers find information and make decisions that will help them grow their businesses. The study is written with a specific goal in mind: to give business insights and consultancy to help customers make smart business decisions and achieve long-term success in their particular market areas.

If You Have Any Query Dairy Processing Equipment Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/15815

Segmentation of Dairy Processing Equipment Market:

By Product Type

Membrane Filtration Equipment

Homogenizers

Separators

Mixing and Blending Equipment

Pasteurizers

Churning Equipment

Evaporators and Dryers

Other

By Operation

Automatic

Semi-Automatic

By Application

Milk Powders

Cream

Processed Milk

Cheese

Protein Concentrates

Yogurt

Other