#Dairy Products Processing Equipment Market

Explore tagged Tumblr posts

Text

Data Bridge Market Research analyses that the dairy products processing equipment market is expected to reach the value of USD 13.37 billion by 2029, at a CAGR of 5.80% during the forecast period. Growth and expansion of the food and beverages industry, surge in the demand for dairy products, rising consumer consciousness towards high quality nutritional products, rising usage of automation process for production and growing personal disposable income by the major companies are the major factors attributable to

#Dairy Products Processing Equipment Market#Dairy Products Processing Equipment Market Demand#Dairy Products Processing Equipment Market Share#Dairy Products Processing Equipment Market Forecast#Dairy Products Processing Equipment Market Trend#Dairy Products Processing Equipment Market Segment#Dairy Products Processing Equipment Market Overview#Dairy Products Processing Equipment Market Growth

0 notes

Text

A2 COW MILK BUTTER

Why choose A2 Cow Milk Butter?

A2 cow milk butter is easier to digest

Easier on gut

Lower in fat, as compared to buffalo milk

0 notes

Text

Milton Orr looked across the rolling hills in northeast Tennessee. “I remember when we had over 1,000 dairy farms in this county. Now we have less than 40,” Orr, an agriculture adviser for Greene County, Tennessee, told me with a tinge of sadness.

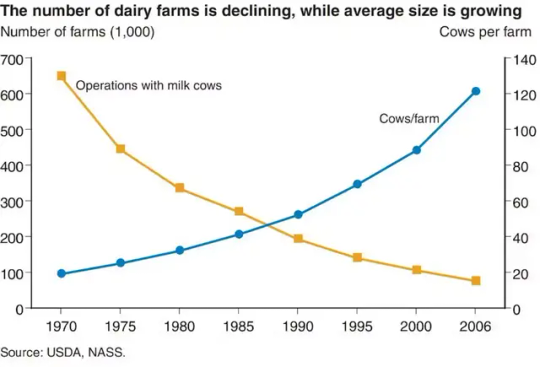

That was six years ago. Today, only 14 dairy farms remain in Greene County, and there are only 125 dairy farms in all of Tennessee. Across the country, the dairy industry is seeing the same trend: In 1970, more than 648,000 US dairy farms milked cattle. By 2022, only 24,470 dairy farms were in operation.

While the number of dairy farms has fallen, the average herd size—the number of cows per farm—has been rising. Today, more than 60 percent of all milk production occurs on farms with more than 2,500 cows.

This massive consolidation in dairy farming has an impact on rural communities. It also makes it more difficult for consumers to know where their food comes from and how it’s produced.

As a dairy specialist at the University of Tennessee, I’m constantly asked: Why are dairies going out of business? Well, like our friends’ Facebook relationship status, it’s complicated.

The Problem with Pricing

The biggest complication is how dairy farmers are paid for the products they produce.

In 1937, the Federal Milk Marketing Orders, or FMMO, were established under the Agricultural Marketing Agreement Act. The purpose of these orders was to set a monthly, uniform minimum price for milk based on its end use and to ensure that farmers were paid accurately and in a timely manner.

Farmers were paid based on how the milk they harvested was used, and that’s still how it works today.

Does it become bottled milk? That’s Class 1 price. Yogurt? Class 2 price. Cheddar cheese? Class 3 price. Butter or powdered dry milk? Class 4. Traditionally, Class 1 receives the highest price.

There are 11 FMMOs that divide up the country. The Florida, Southeast, and Appalachian FMMOs focus heavily on Class 1, or bottled, milk. The other FMMOs, such as Upper Midwest and Pacific Northwest, have more manufactured products such as cheese and butter.

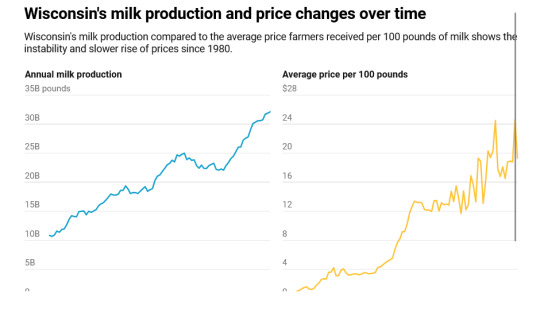

For the past several decades, farmers have generally received the minimum price. Improvements in milk quality, milk production, transportation, refrigeration, and processing all led to greater quantities of milk, greater shelf life, and greater access to products across the US. Growing supply reduced competition among processing plants and reduced overall prices.

Along with these improvements in production came increased costs of production, such as cattle feed, farm labor, veterinary care, fuel, and equipment costs.

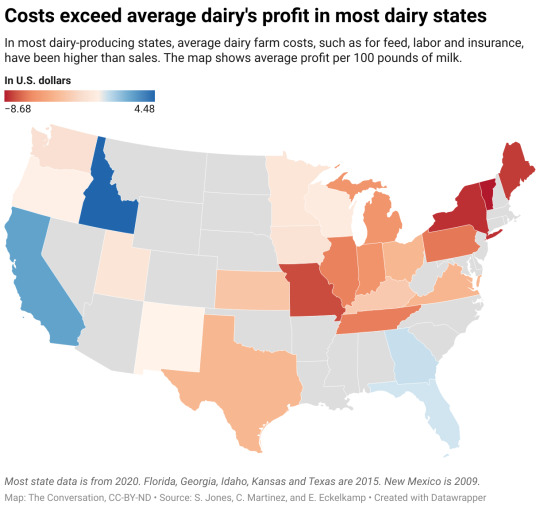

Researchers at the University of Tennessee in 2022 compared the price received for milk across regions against the primary costs of production: feed and labor. The results show why farms are struggling.

From 2005 to 2020, milk sales income per 100 pounds of milk produced ranged from $11.54 to $29.80, with an average price of $18.57. For that same period, the total costs to produce 100 pounds of milk ranged from $11.27 to $43.88, with an average cost of $25.80.

On average, that meant a single cow that produced 24,000 pounds of milk brought in about $4,457. Yet, it cost $6,192 to produce that milk, meaning a loss for the dairy farmer.

More efficient farms are able to reduce their costs of production by improving cow health, reproductive performance, and feed-to-milk conversion ratios. Larger farms or groups of farmers—cooperatives such as Dairy Farmers of America—may also be able to take advantage of forward contracting on grain and future milk prices. Investments in precision technologies such as robotic milking systems, rotary parlors, and wearable health and reproductive technologies can help reduce labor costs across farms.

Regardless of size, surviving in the dairy industry takes passion, dedication, and careful business management.

Some regions have had greater losses than others, which largely ties back to how farmers are paid, meaning the classes of milk, and the rising costs of production in their area. There are some insurance and hedging programs that can help farmers offset high costs of production or unexpected drops in price. If farmers take advantage of them, data shows they can functions as a safety net, but they don’t fix the underlying problem of costs exceeding income.

Passing the Torch to Future Farmers

Why do some dairy farmers still persist, despite low milk prices and high costs of production?

For many farmers, the answer is because it is a family business and a part of their heritage. Ninety-seven percent of US dairy farms are family owned and operated.

Some have grown large to survive. For many others, transitioning to the next generation is a major hurdle.

The average age of all farmers in the 2022 Census of Agriculture was 58.1. Only 9 percent were considered “young farmers,” age 34 or younger. These trends are also reflected in the dairy world. Yet, only 53 percent of all producers said they were actively engaged in estate or succession planning, meaning they had at least identified a successor.

How to Help Family Dairy Farms Thrive

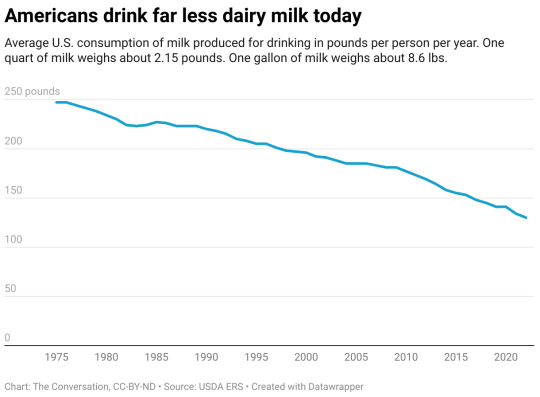

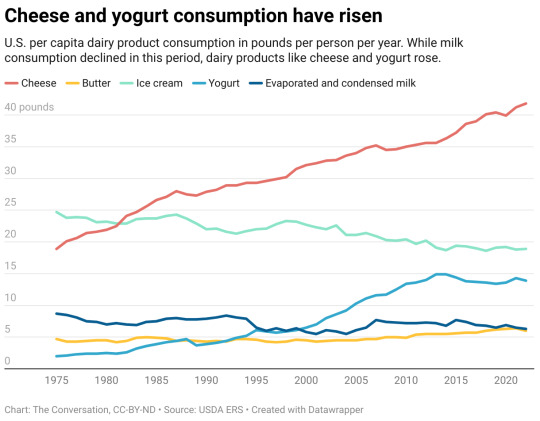

In theory, buying more dairy would drive up the market value of those products and influence the price producers receive for their milk. Society has actually done that. Dairy consumption has never been higher. But the way people consume dairy has changed.

Americans eat a lot, and I mean a lot, of cheese. We also consume a good amount of ice cream, yogurt, and butter, but not as much milk as we used to.

Does this mean the US should change the way milk is priced? Maybe.

The FMMO is currently undergoing reform, which may help stem the tide of dairy farmers exiting. The reform focuses on being more reflective of modern cows’ ability to produce greater fat and protein amounts; updating the cost support processors receive for cheese, butter, nonfat dry milk, and dried whey; and updating the way Class 1 is valued, among other changes. In theory, these changes would put milk pricing in line with the cost of production across the country.

The US Department of Agriculture is also providing support for four Dairy Business Innovation Initiatives to help dairy farmers find ways to keep their operations going for future generations through grants, research support, and technical assistance.

Another way to boost local dairies is to buy directly from a farmer. Value-added or farmstead dairy operations that make and sell milk and products such as cheese straight to customers have been growing. These operations come with financial risks for the farmer, however. Being responsible for milking, processing, and marketing your milk takes the already big job of milk production and adds two more jobs on top of it. And customers have to be financially able to pay a higher price for the product and be willing to travel to get it.

33 notes

·

View notes

Text

Key sectors in KSA manufacturing market:

Here’s a concise overview of the key sectors in Saudi Arabia's manufacturing market:

1. Petrochemicals

- Central to Saudi Arabia's manufacturing, leveraging vast oil and gas reserves to produce chemicals like ethylene and polypropylene.

- Major players include SABIC and Saudi Aramco.

2. Pharmaceuticals

- Rapidly expanding with a focus on local production of generics, vaccines, and biotech products.

- Supported by government initiatives to reduce import dependency.

3. Food and Beverage

- Vital for food security and economic growth, focusing on dairy, processed foods, beverages, and halal products.

- Expanding into regional and international markets.

4. Automotive

- Developing sector with a focus on assembling vehicles, manufacturing parts, and electric vehicles (EVs).

- Growing interest from global manufacturers.

5. Construction Materials

- Driven by mega-projects, producing cement, steel, aluminum, and sustainable materials.

- Key to supporting infrastructure development.

6. Metals and Mining

- Emerging sector with significant resources like gold, phosphate, and bauxite.

- Focus on extraction, processing, and downstream industries like aluminum smelting.

7. Textiles and Apparel

- Small but growing, with potential in high-quality textiles and traditional clothing.

- Opportunities in fashion and design.

8. Renewable Energy Equipment

- Focused on producing solar panels, wind turbines, and related components to support renewable energy projects.

- Significant growth potential aligned with sustainability goals.

9. Packaging

- Expanding due to growth in food, pharmaceuticals, and e-commerce.

- Innovation in sustainable packaging solutions is on the rise.

10. Defense and Aerospace

- Strategic priority with efforts to localize military equipment production.

- Supported by GAMI, focusing on parts manufacturing and maintenance services.

These sectors highlight Saudi Arabia's drive toward economic diversification, with strong government support and strategic investments fostering growth across the manufacturing industry.

#KhalidAlbeshri #خالدالبشري

#advertising#artificial intelligence#autos#business#developers & startups#edtech#education#finance#futurism#marketing

16 notes

·

View notes

Text

Others have probably said this more eloquently than I, and I know I've griped about related issues in the past, but let me just say again, it is downright criminal how little food manufacturers and retailers care about people with food allergies.

My daughter has EOE. It's not life threatening in an anaphylactic sense, but it does severely limit quality of life for her, and impacts every facet of her existence. We're in the process of identifying her triggers, one of which we know for sure is dairy. The amount of stuff that's unnecessarily made with dairy is awful; it's even worse how much stuff gets casually contaminated, and companies aren't required to label it.

Those little "made in a facility with/that also processes" tags? The "may contain" warnings? Voluntary. Optional. So unless it's made in a dedicated dairy-free facility, it could have traces in it, and we simply wouldn't know unless they decide to be kind.

The worse part is, in our case, we don't always know what food did it. EOE is a delayed reaction. It could have been something from yesterday, or last week. Trying to pin down which foods are safe and which aren't becomes a billion times harder when we can't rely on labeling. Sure it doesn't contain milk or whey or caseinate or butter, but could it have been made in the same processing line? Who knows! The manufacturer didn't bother putting that on the label!

And grocery stores and restaurants aren't much better. Those deli meats are sliced on the same equipment as the block cheeses. The lettuce is right next to the shredded cheese at the taco bar. I watched an employee use the same serving utensils for the ice cream as the dairy free sorbet.

And we're lucky! Her allergy isn't going to kill her outright if she gets contaminated. But it is turning out to be extremely sensitive, so we're struggling. I spent two and a half hours the other day trying to shop for 10 things, because I had to keep researching the different brands' manufacturing processes and ingredient sources. I had to go to three different stores. Again, we're lucky; we live in an area with a pretty big market for vegan and "specialty" foods.

We're facing down the very real possibility of having to also eliminate soy and/or wheat in the near future, and I'm so exhausted just thinking about it. Soy is in everything. Wheat is in everything. Dairy is in everything. To avoid it, you either have to eat exclusively from the produce section and/or pay through the nose for one of about three specialty products that have an extremely limited distribution. Just going fully dairy free alone has almost doubled our grocery bill, and it's not like we were splurging before.

It's just frustrating. And if it's this bad for us, who have the luxury of not needing an epi pen and an emergency plan, I don't even want to imagine how bad it is for people with near-fatal or anaphylactic allergies. People shouldn't have to jump through a billion hoops and pay quadruple price for infinitely fewer options just to not die.

#food tw#food allergies#eoe#ranting#i'm off to the woods to build a neo-hippie agri commune who's in?

24 notes

·

View notes

Text

What are the Advantages of Mini Dairy Plant?

Advantages of Mini Dairy Plants

1. Local Sourcing and Freshness

One of the most significant advantages of mini dairy plants is their ability to source milk locally. This reduces transportation costs and ensures that milk is processed and distributed quickly, thereby preserving its freshness and nutritional value. Consumers today are increasingly conscious of where their food comes from and prefer products that are locally sourced and minimally processed.

2. Quality Control

With a mini dairy plant, producers have greater control over the entire production process. From milk collection to processing and packaging, every step can be closely monitored to maintain hygiene standards and ensure product quality. This level of control is crucial in meeting regulatory requirements and in building consumer trust.

3. Flexibility and Efficiency

Mini dairy plants are designed to be versatile and efficient. They can be set up in smaller spaces compared to traditional dairy facilities, making them ideal for rural areas or communities where space and resources may be limited. Moreover, these plants can often be operated with fewer staff, reducing labor costs and improving overall operational efficiency.

4. Support for Small-Scale Producers

For small-scale dairy farmers, mini dairy plants offer a viable solution to add value to their milk production. By processing their own milk into products like cheese or yogurt, farmers can increase their profitability and reduce dependency on volatile milk prices. This empowerment of local producers contributes to sustainable agricultural practices and strengthens rural economies.

What is a Mini Dairy Plant?

Challenges and Considerations

While mini dairy plants offer numerous benefits, there are some challenges to consider. Initial setup costs, regulatory compliance, and ensuring consistent product quality are among the primary concerns. However, with proper planning, investment, and adherence to industry standards, these challenges can be effectively managed.

Future Outlook

The future looks promising for mini dairy plants as consumer preferences continue to evolve towards healthier and locally sourced food options. Advances in technology and innovations in processing equipment are further enhancing the efficiency and sustainability of these facilities. Moreover, the ability of mini dairy plants to adapt to changing market demands and produce niche products presents exciting opportunities for growth and diversification within the dairy industry.

Conclusion

In conclusion, mini dairy plants represent a significant shift towards localized, sustainable, and high-quality dairy production. By bringing processing closer to the source, these plants not only ensure freshness and quality but also support local economies and empower small-scale producers. As we move towards a future that prioritizes transparency and sustainability in food production, the role of mini dairy plants is set to become increasingly pivotal in meeting consumer expectations and driving positive change in the dairy industry.

For more information, please visit our website:

Website : www.99businessvyapar.com

Contact No. : +91–9560336670, +91–8076381705, +91–9631021248

Email : [email protected], [email protected]

#Mini Dairy Plants#Mini Dairy Plants manufacturer#Mini Dairy Plants supplier in India#99 business vyapar

2 notes

·

View notes

Text

Export Import Products List

Exporting and importing products is a major part of the global economy. In 2022, the value of global merchandise trade was over $28 trillion. This means that businesses and consumers all over the world are exchanging goods and services on a massive scale.

There are a wide variety of products that are exported and imported, but some of the most common include:

Agricultural products: This category includes food crops, such as wheat, rice, and corn, as well as livestock and animal products, such as meat, dairy, and eggs.

Chemicals: This category includes a wide range of products, such as petrochemicals, pharmaceuticals, and fertilizers.

Electrical machinery and equipment: This category includes products such as generators, motors, and computers.

Food and beverages: This category includes processed foods and drinks, as well as fresh produce.

Machinery and equipment: This category includes products such as machine tools, engines, and construction equipment.

Manufactured goods: This category includes a wide range of products, such as textiles, clothing, and electronics.

Minerals and fuels: This category includes products such as crude oil, natural gas, and coal.

Other goods: This category includes products that do not fall into any of the other categories, such as furniture and toys.

Textiles and clothing: This category includes products such as yarn, fabric, and garments.

Transport equipment: This category includes products such as cars, trucks, and airplanes.

The specific products that are exported and imported vary from country to country. For example, the United States is a major exporter of agricultural products, machinery, and equipment, while China is a major exporter of manufactured goods and electronics.

Factors to Consider When Choosing Export Import Products

There are a number of factors that businesses should consider when choosing which products to export or import. These factors include:

Demand: Is there a strong demand for the product in the target market?

Competition: How much competition is there for the product in the target market?

Profitability: Is the product profitable to export or import?

Regulations: Are there any regulations that restrict the export or import of the product?

Logistics: How will the product be transported to and from the target market?

Benefits of Exporting and Importing Products

There are a number of benefits to exporting and importing products. For businesses, exporting can help to increase sales and profits, and it can also help to diversify the business's customer base. Importing can help businesses to access products that are not available domestically, and it can also help businesses to reduce costs.

For consumers, exporting and importing can help to lower prices and increase the availability of goods. For example, consumers in the United States can buy fresh produce from all over the world, and they can also buy electronics and other manufactured goods at lower prices because of imports.

Conclusion

Exporting and importing products is a vital part of the global economy. It helps businesses to grow and consumers to save money. If you are considering starting an export import business, there are a number of resources available to help you get started.

#Export Import Products List#export import products#export import data#exporter#bussiness#export#import#importers

2 notes

·

View notes

Text

How to Start a Food Processing Business: A Complete Guide

Are you interested in launching a business that processes food because you have a strong passion for it? Starting a business that processes food is a terrific way to make your passion profitable. But launching a company that processes food can be challenging and needs careful planning and preparation. We will provide you a step-by-step explanation of how to launch a food processing business in this manual.

Introduction :

It's critical to comprehend what food processing is before getting into the technicalities of launching a firm in this industry. Processing food entails converting basic materials into finished goods. Cooking, baking, canning, freezing, and packing are some examples of this.

The food processing sector is significant and expanding, with a $4 trillion global market. The industry is divided into a number of subsectors, including those that prepare meat and poultry, dairy products, fruits and vegetables, and snack foods.

Market Research :

Before starting any business, it is important to conduct thorough market research to determine if there is a demand for your product. In the case of food processing, you will want to research the industry trends, consumer preferences, and competitors in your market.

Some key questions to consider during your market research include:

- What are the current trends in the food processing industry?

- Who are your competitors and what are their products and pricing strategies?

- Who are your target customers and what are their preferences?

- What are the regulatory requirements for starting a food processing business in your area?

Business Planning :

Once you have conducted your market research, it is time to develop a business plan. A business plan is a document that outlines your business goals, target market, products and services, marketing and sales strategies, financial projections, and more.

Your business plan should include the following sections:

- A concise explanation and description of your business and its goals

- Market research is the analysis of your competitors, target market, and current market trends.

Services and products a list of the products and services you provide

- Sales and marketing plans: How you plan to promote and market your products.

- Budgetary goals: a projection of your expenses and income for the ensuing three to five years.

Financing :

Starting a food processing business can be expensive, so it is important to have a solid financing plan in place. There are a variety of financing options available, including loans, grants, and investors.

Some key factors to consider when seeking financing include:

- How much capital do you need to start your business?

- What is your business credit score?

- Do you have collateral to secure a loan?

- Are there any grants or incentives available in your area?

Equipment and Supplies :

Once you have secured financing, it is time to purchase the equipment and supplies you will need to start your business. The specific equipment and supplies you will need will depend on the type of food processing business you are starting.

Some common equipment and supplies needed for a food processing business include:

- Processing equipment, such as ovens, mixers, and blenders

- Packaging equipment, such as sealers and labelers

- Storage equipment, such as refrigerators and freezers

- Ingredients and raw materials

Developing a Product Line :

Your ability to sell your products will have a big impact on how well your food processing company does. It's critical to have a product lineup that appeals to your target market and distinguishes you from your rivals.

Keeping the following things in mind will help you design your product line:

- Your target market's preferences and needs

- The price point of your products

- The packaging and labelling of your products

- The shelf life of your products

- The availability of ingredients and raw materials

Marketing and Sales :

Once you have developed your product line, it is important to develop a marketing and sales strategy to promote your products. Your marketing and sales strategy should be tailored to your target market and should aim to differentiate your products from those of your competitors.

Some key marketing and sales considerations include:

Developing a brand identity and messaging that resonates with your target market

Identifying your distribution channels, such as retail stores or online marketplaces

Developing a pricing strategy that is competitive but still profitable

Creating a promotional plan, such as social media advertising or email marketing campaigns

Legal Compliance and Safety :

The operation of a food processing firm requires adherence to numerous regulatory and safety requirements. Depending on the kind of food processing business you're beginning and where it's located, you'll need to adhere to a certain set of rules.

Among the most important legal and safety factors are:

securing the authorizations and licences required to run your enterprise

observing food safety guidelines, such as those established by the FDA and USDA

planning a HACCP (Hazard Analysis and Critical Control Points) strategy

upholding sanitization and hygiene standards

ensuring that your staff is educated on proper food handling and safety practices

Conclusion :

Although it requires careful planning and preparation, starting a food processing business can be a rewarding and profitable venture. You can improve your chances of success by carrying out in-depth market research, creating a strong business plan, obtaining finance, buying the essential tools and materials, developing a product line, and putting a marketing and sales strategy into action. The health and safety of your clients and staff are also dependent on your ability to adhere to legal and safety requirements. You can convert your love of cooking into a successful business with the correct preparation and execution.

2 notes

·

View notes

Text

Gold Loans for Farmers-A Life Savior during Dire Neediness

Agriculture is the backbone of the Indian economy, and most farmers face financial challenges on account of unpredictable weather, fluctuating market prices, and increasing input costs. Gold loans have become a crucial financial source for farmers during such times. It allows access to cash in a faster manner and also does not compel them to liquidate their valuable possessions. Companies such as RUGR are at the heart of this change by offering a range of tailored financial solutions aimed at empowering rural farmers.

Understanding Gold Loans

Gold loans are a kind of secured loan where the borrower gives a pledge of their gold jewelry or ornaments as security. This facility is quite important for farmers who do not have access to advanced banking services or credit facilities. It is relatively simple: farmers can approach a lender and, presenting their gold assets, get a loan amount based on current market values. Normally, they offer an LTV of up to 75% under such loans, through which farmers may get substantial amounts in a very short time.

Speedy Disbursal

Gold loans have many advantages, among which the biggest factor is speedy access to credit. Unlike the regular loan products, which are mired in the long approval process and need much paperwork, this product can be sanctioned quickly owing to minimal documentation requirements. This quick processing is very important for farmers who may need instant funds for any urgent agricultural need, such as seeds, fertilizers, or equipment. Fintech solution providers such as RUGR make online gold loans easily accessible to farmers with their facilities for mobile banking in rural Bharat.

Flexible Repayment Options

Gold loans also offer flexibility in repayments, catering to the needs of farmers. Lenders also extend a number of repayment plans, including scattered payments and lengthened tenures, which let borrowers return the loan at their own convenience. This flexibility in repayments is very important to farmers whose incomes vary throughout the year, given the cyclicality of harvests. By easing the repayment burden, gold loans enable farmers to focus on their agricultural activities without financial stress.

Supporting Agricultural Activities

In turn, the gold loan can be invested in a series of agricultural intentions, ranging from crops to the addition of livestock-even assuring allied proposals in the arena of dairy and aquaculture, accordingly. This expansive set of alternatives that allows farmers not only to invest in long-term growth but simultaneously satisfy immediate investment needs is further buttressed by extending crop insurance.

Fintech for Financial Inclusion

Fintech companies like RUGR are the need of the hour in enhancing financial inclusions for rural farmers. By leveraging technology and mobile banking solutions, they provide easy access to gold loans and other financial products. The ability to apply for loans online and receive instant approvals empowers farmers who may otherwise be excluded from traditional banking systems. In addition, these digital platforms offer educational resources about financial management and investment strategies that help farmers make informed decisions.

Challenges and Considerations

Despite all the advantages, a number of challenges are associated with gold loans that one has to confront. Most farmers will not understand anything about gold loans or would have cultural beliefs about gold and hence may avoid leveraging their assets as such. This also requires ensuring transparency in valuations and lending practices so that fairness to farmers will be maintained.

Conclusion

In other words, gold loans have become the lifesaver of farmers in India at a time of distress. Quick disbursal, flexible repayments, and the efficiency to manage the funds by the farmer allow farmers to reinvest in their agriculture effectively. Supported by fintech solutions such as RUGR, coupled with an increase in mobile banking in rural Bharat, farmers are accessing such vital financial resources. It can therefore be seen that with growing awareness and reduced barriers, gold loans will remain an integral constituent in the life of the rural Indian farmer: serving as a supporting mechanism over hard times into secured futures.

0 notes

Text

Best Agriculture Loan Services in Navsari, Gujarat: A Comprehensive Guide

Agriculture is the backbone of Gujarat's economy, and Navsari, located in the southern part of the state, is no exception. The region boasts a rich agricultural landscape, with farmers engaged in cultivating crops such as rice, sugarcane, cotton, and various fruits and vegetables. However, farming is not without its challenges. From unpredictable weather patterns to fluctuating market prices, farmers often require financial assistance to ensure smooth operations and growth. This is where the Best Agriculture Loan Services in Navsari, Gujarat come into play.

Understanding the Importance of Agriculture Loans

Agriculture loans are crucial for farmers to finance their agricultural activities, whether it’s for purchasing seeds, fertilizers, machinery, or even for covering labor costs. In Navsari, where farming is a predominant occupation, access to affordable and flexible loans can make a significant difference in the success of farming ventures. These loans help farmers expand their land, improve crop quality, and invest in modern farming techniques.

Types of Agriculture Loans Available in Navsari, Gujarat

The best agriculture loan services in Navsari, Gujarat offer a variety of loan products to cater to the diverse needs of farmers. Some of the common types include:

Crop Loans: These loans are designed to meet the short-term needs of farmers for purchasing seeds, fertilizers, pesticides, and other inputs required for crop cultivation. Crop loans are typically repaid after the harvest.

Kisan Credit Card (KCC): A Kisan Credit Card is a popular option among farmers in Gujarat. It provides farmers with access to short-term credit for crop production and other agricultural activities. The credit limit is based on the farmer's landholding and past financial history.

Farm Equipment Loans: For farmers looking to purchase modern equipment such as tractors, harvesters, and irrigation systems, farm equipment loans are the ideal choice. These loans help reduce dependency on manual labor and improve productivity.

Agri-Processing Loans: These loans are available for farmers who wish to invest in agricultural processing units. They can use these funds to set up facilities for processing fruits, vegetables, grains, or dairy products.

Long-Term Agriculture Loans: For farmers interested in expanding their agricultural business, long-term loans can help finance large-scale projects such as land acquisition, irrigation infrastructure, or setting up greenhouses.

Key Factors to Consider When Choosing Agriculture Loan Services in Navsari

When looking for the Best Agriculture Loan Services in Navsari, Gujarat, it is important to consider several factors to ensure that you get the most favorable loan terms. Here are some essential aspects to keep in mind:

Interest Rates: The interest rate is one of the most important factors to consider when taking out an agriculture loan. The lower the interest rate, the more affordable the loan will be in the long run. Look for services that offer competitive interest rates.

Repayment Terms: Flexible repayment options can make it easier for farmers to repay their loans. Some agriculture loans offer seasonal repayment schedules, allowing farmers to pay after their crops are harvested and sold.

Loan Amount: The loan amount should be sufficient to meet the farmer’s requirements. Whether it's a small loan for purchasing inputs or a larger loan for machinery or land, the best loan services will offer tailored loan amounts based on the farmer’s needs.

Processing Time: Timely disbursal of loans is crucial for farmers, especially during the planting season. Look for loan services that have a quick and efficient loan approval process to ensure funds are available when needed.

Eligibility Criteria: Different loan providers may have different eligibility criteria. Ensure that you meet the requirements, such as land ownership, credit score, or agricultural experience, before applying.

Government Schemes: In addition to commercial agriculture loans, several government schemes in Gujarat offer subsidized loans to farmers. These schemes often come with lower interest rates and more lenient terms. It’s worth checking if the loan provider is affiliated with government programs.

Why Navsari is Ideal for Agriculture Loans

Navsari, known for its fertile soil and favorable climate, is a hub for agricultural activities. The region is home to several small and large-scale farmers who play a key role in the state's agricultural output. With the growing need for financial support, agriculture loan services in Navsari are continuously evolving to cater to the needs of the farming community.

The local banks, cooperatives, and financial institutions in Navsari have recognized the importance of agriculture and are now offering specialized loan products to meet the diverse needs of farmers. Additionally, with the government’s support and focus on agricultural development, farmers in Navsari are better equipped to access financial assistance.

How to Apply for Agriculture Loans in Navsari

Applying for an agriculture loan in Navsari is a straightforward process. Farmers can approach banks, cooperative societies, or private financial institutions offering agriculture loans. Most loan providers will require the following documents:

Proof of identity (Aadhar card, voter ID, etc.)

Proof of land ownership or tenancy

Agricultural income proof

Bank account details

Loan application form

After submitting the required documents, the loan provider will assess the application, and upon approval, the loan amount will be disbursed. It is essential to read and understand the loan terms before signing the agreement.

Conclusion

Access to Best Agriculture Loan Services in Navsari, Gujarat is essential for farmers looking to enhance their productivity and overcome financial challenges. With the right loan services, farmers can invest in better technology, improve crop yields, and ensure a sustainable farming business. Whether you are a small-scale farmer or looking to expand your agricultural operations, finding the right financial support is the key to success. Always compare different loan options, consider interest rates, repayment terms, and eligibility criteria to choose the best service that suits your needs.

0 notes

Text

What is air freight: Meaning, benefits, and suitability

The world has become smaller. Products once considered exotic are now delivered to your doorstep within days — thanks to the wonders of air freight and air shipping.

More info Door To Door Shipping

But what exactly are these terms, and are they different? Let’s understand the world of air freight logistics, meaning, benefits, when you should opt for shipping air freight, and more.

Air freight and air shipping: Understand the difference

Air freight and air shipping are essentially two terms for the same concept: transporting goods by air. While they’re often used interchangeably, it has a minor yet critical difference:

Air Shipping: Refers to all goods transported by air, including luggage on passenger flights, parcels sent through express services, and large shipments in cargo planes.

Air Freight: Refers specifically to the commercial transportation of goods by air, including the costs, logistics, and regulations involved.

In this article, we’ll talk specifically about air freight. We’ll also use the terms air freight, air shipping, and air freight shipping interchangeably in the same context.

What are the most common products shipped by air?

With a market size of more than US $175 billion, the air cargo industry has become a powerhouse for global trade, especially with the rising e-commerce. These industries and products often rely on air freight due to its quick delivery timelines:

E-commerce: Facilitates expedited shipping for high-value goods such as electronics, luxury, and high-demand fashion items.

Manufacturing: Ships time-sensitive components critical for production lines to enable just-in-time inventory management.

Humanitarian aid: Delivering relief supplies to disaster zones, including medicines, food, water, and shelter materials, enabling quick response during emergencies.

Aerospace and defence: Supply of avionics, aircraft engines, and military equipment and armaments like missiles and drones, crucial for armed forces.

Perishables: Produce, seafood, dairy items, chemical materials, plants, and flowers are quickly transported to the market, reducing spoilage and preserving freshness.

Pharmaceutical companies: Transporting temperature-sensitive immunisations worldwide, crucial during health crises like the COVID-19 pandemic.

Compared to other freight transportation modes, air freight is the fastest mode of long-distance shipping, making it crucial for businesses dealing with time-sensitive goods.

Typical journey of your air freight shipment

Air freight, though seemingly straightforward, involves a complex process. From pre-shipment prep to delivery, air cargo undergoes numerous stages, including:

Booking & Planning: Secure the best rate and logistics with a carrier.

Prepping & Packing: Goods get packaged securely and compliant with regulations, along with the necessary shipping documentation.

Collection & Consolidation: Your shipment is picked up and combined with others for efficient transport.

Customs Clearance: Both import and export requirements must be met, including inspections and potential duties.

Air Travel: Your shipment takes flight on a dedicated cargo plane chosen based on size, weight, and urgency.

Arrival & Delivery: Customs clearance at the destination airport precedes final delivery to your desired location.

0 notes

Text

Soy Protein Isolate Prices, News, Trend, Graph, Chart, Forecast and Historical

Soy Protein Isolate is a highly refined form of soy protein and is widely used in the food and beverage industry, as well as in the nutritional supplement sector. Over recent years, the soy protein isolate market has experienced notable fluctuations in pricing, influenced by various factors such as supply and demand dynamics, raw material availability, production costs, and market trends. These fluctuations are significant for both manufacturers and consumers who rely on soy protein isolate for its high nutritional content and functional properties. The price of soy protein isolate is largely determined by global agricultural conditions, the cost of raw soybeans, and processing technologies. Soybeans, the primary raw material used to produce soy protein isolate, are subject to weather patterns, particularly in key production regions such as the United States, Brazil, and Argentina. Any disruptions in soybean production due to adverse weather conditions or supply chain disruptions can lead to a rise in the cost of soy protein isolate.

In addition to the direct impact of soybean prices, processing costs also play a vital role in determining the final price of soy protein isolate. The refining process involved in extracting soy protein from raw soybeans requires advanced technologies, such as water or alcohol-based extraction, ultrafiltration, and drying. The energy-intensive nature of these processes, combined with labor and equipment costs, means that producers must account for these expenses when pricing the end product. As demand for plant-based protein sources continues to grow, driven by the rise in vegetarian, vegan, and flexitarian diets, the demand for soy protein isolate has also surged. This increased demand has put upward pressure on prices, as manufacturers work to meet the needs of a rapidly expanding market. Additionally, as more consumers seek alternatives to animal-based proteins, soy protein isolate’s use in protein bars, meal replacements, plant-based meat substitutes, and dairy alternatives is expected to increase. The rise in popularity of these products has led to a shift in the pricing strategies of soy protein isolate suppliers, particularly in response to heightened competition within the plant-based protein market.

Get Real time Prices for Soy Protein Isolate: https://www.chemanalyst.com/Pricing-data/soy-protein-isolate-1578

While demand is increasing, market players must also deal with the fluctuations in global trade dynamics. Tariffs and trade agreements, particularly between major soybean producers like the United States and China, can significantly impact the price of soy protein isolate. For example, trade wars and the imposition of tariffs on soybeans or soy-based products can result in price volatility. Similarly, changes in government policies or subsidies related to the agricultural sector can influence the availability and pricing of soybeans, further affecting soy protein isolate prices. Another factor influencing soy protein isolate prices is the increased awareness of sustainability and the environmental impact of food production. Consumers and manufacturers are increasingly prioritizing sustainably sourced ingredients, which may drive up costs as producers adopt more sustainable agricultural practices. This shift towards sustainability can also encourage innovation in alternative protein sources, such as pea protein or rice protein, which may compete with soy protein isolate and affect its pricing. Despite these challenges, soy protein isolate remains one of the most cost-effective plant-based protein options available, particularly when compared to animal-derived protein sources. Its high protein content, neutral flavor, and versatility make it an attractive choice for food manufacturers, particularly in applications such as protein shakes, energy bars, and plant-based meat alternatives.

As the market for plant-based proteins continues to evolve, the pricing structure of soy protein isolate is expected to remain influenced by a range of external factors. Over time, advancements in production technologies may help reduce processing costs and improve the overall efficiency of soy protein isolate production, potentially leading to more stable prices. Additionally, the growth of regional markets, especially in emerging economies, may further diversify the supply chain and impact global pricing trends. One important development that may affect the price of soy protein isolate is the increasing adoption of genetically modified (GM) soybeans. These genetically modified crops have been designed to increase yield and resistance to pests, which could make soybeans more abundant and potentially lower prices. However, the growing concern over the environmental impact and health implications of genetically modified crops could lead to varying market dynamics and regulatory changes, particularly in countries with strict GMO regulations.

In summary, the market for soy protein isolate is shaped by a complex interplay of agricultural conditions, production costs, demand from the plant-based food sector, and trade factors. While prices have seen an upward trend due to increased demand and supply chain challenges, advances in technology and sustainable practices could help stabilize or even reduce prices in the future. As the plant-based protein market continues to evolve, manufacturers and consumers alike will need to stay informed about these factors to make the best decisions regarding pricing and sourcing of soy protein isolate.

Get Real time Prices for Soy Protein Isolate: https://www.chemanalyst.com/Pricing-data/soy-protein-isolate-1578

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Soy Protein Isolate#Soy Protein Isolate Prices#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Understanding the Benefits of Using a Modern Khoya Machine in Dairy Production

Khoya, additionally called khoa or mawa, is a critical aspect in lots of Indian chocolates and dairy merchandise. Traditionally made by way of manner of boiling milk for hours to reduce it right into a thickened robust, khoya manufacturing has been a labor-significant system for generations. However, with improvements in technology, the arrival of current-day khoya machines has revolutionized dairy production, making it extra green, hygienic, and worthwhile.

This article explores the benefits of using current-day khoya machines and the way they make a contribution to enhancing dairy manufacturing.

The Traditional Khoya-Making Process

Traditionally, khoya have turn out to be made by means of manner of way of heating milk in huge open pans over a flame, constantly stirring to prevent burning. While this technique produces splendid khoya, it demands huge time, strive, and labor. Moreover, the tool calls for consistent hobby, and any deviation can purpose waste or inconsistencies in top notch.

In nowadays rapid-paced global, depending totally on traditional techniques can limit productivity and profitability for dairy corporations. This is wherein current khoya machines step in to bridge the gap.

What is a Modern Khoya Machine?

A khoya device is a mechanized machine designed to automate the manner of milk evaporation and thickening. These machines use superior era to warmth milk evenly, stir it automatically, and supply normal outcomes. Available in severa sizes and capacities, they cater to small-scale manufacturers and big dairy industries alike.

Key Benefits of Using Modern Khoya Machines

1. Enhanced Efficiency

One of the most massive advantages of a present day-day khoya tool is its capacity to provide khoya in a fraction of the time as compared to traditional techniques. Automated heating and stirring mechanisms make sure the milk is processed speedy without compromising great. This prolonged overall performance lets in agencies to supply large portions, assembly market needs correctly.

2. Consistent Quality

Consistency is critical inside the food organisation. Modern khoya machines are equipped with particular controls to hold uniform temperature and stirring, resulting in khoya of regular texture and flavour. This ensures consumer pride and builds believe on your brand.

3. Time and Labor Savings

Manual khoya manufacturing requires expert hard paintings and hours of hard work. A khoya tool automates pretty a few the way, notably reducing exertions expenses and releasing up assets for one-of-a-type duties. Dairy manufacturers can attention on scaling their organisation in desire to being tied to extended manufacturing cycles.

4. Hygiene and Safety

Modern khoya machines are designed with meals-grade stainless-steel and adhere to stringent hygiene requirements. The enclosed tool minimizes the risk of infection, ensuring the very last product is cozy for consumption. Additionally, automatic machines lessen human intervention, in addition improving cleanliness.

5. Cost-Effective Operations

While making a funding in a khoya gadget may furthermore look like a enormous fee to start with, the lengthy-term economic financial savings in tough paintings, fuel, and time make it a rate-effective preference. Higher production volumes and decreased wastage moreover make a contribution to better profitability.

6. Versatility

Many cutting-edge khoya machines are bendy and may be used to prepare one-of-a-kind dairy products which encompass rabri, basundi, and condensed milk. This versatility makes them a valuable asset for dairy corporations looking to diversify their offerings.

7. Energy Efficiency

Modern machines are designed to optimize strength utilization, consuming an awful lot plenty much less fuel or strength in comparison to standard strategies. This not simplest reduces operational charges however moreover aligns with sustainable practices, which may be an increasing number of valued with the beneficial resource of customers and corporations alike.

How to Choose the Right Khoya Machine

When choosing a khoya gadget in your dairy commercial business enterprise, bear in mind the following elements:

Capacity: Choose a device that suits your manufacturing requirements, whether or not or no longer small-scale or big-scale.

Material: Opt for machines made from long lasting, food-grade materials to make sure hygiene and durability.

Automation Level: Machines with higher automation reduce manual intervention and tough work necessities.

Energy Consumption: Look for electricity-green fashions to shop on operational prices.

Maintenance: Select a system that is easy to easy and keep, making sure extended-time period reliability.

Conclusion

The adoption of contemporary khoya machines marks a transformative shift in dairy production. These machines no longer high-quality decorate ordinary performance and productivity however additionally ensure consistent tremendous and hygiene, meeting the evolving needs of the industry. By making an investment in a modern khoya tool, dairy producers can streamline operations, reduce prices, and growth their marketplace attain.

Whether you are a small-scale producer or a large dairy producer, integrating a cutting-edge khoya device into your operations can enhance your corporation to new heights. As the selection for for first rate dairy products maintains to develop, embracing technological upgrades is the crucial element to staying competitive and thriving within the marketplace.

0 notes

Text

Optimizing Agriculture with Stationary Specialized Machines | KYUNGNONG

KYUNGNONG Industry is a leading global provider of high-quality agricultural solutions and services. They offer a range of products like rechargeable sprayers, electric trimmers, agricultural skid loaders, fuel dispensers, and advanced cold storage solutions, designed to enhance productivity and simplify agricultural tasks. Here the stationary professional machines are equipped for agricultural, industrial, and professional settings. These portable specialized machines are essential for enhancing production efficiency in the agricultural and food industries.

Freshness Maintainer

The freshness maintainer machines are used in agriculture and food industries to maintain the quality and nutritional value of perishable goods. They regulate temperature and airflow, reducing waste, extending shelf life, and supporting export-ready goods with optimal freshness.

Agricultural Dryer

These agricultural dryers are essential for preventing spoilage and improving storage conditions for crops like grains, seeds, and herbs. They remove excess moisture, enhance storage life, and improve crop preparation for further processing, minimizing energy consumption and maximizing productivity.

Cold Storage

Cold storage systems are crucial for industries handling temperature-sensitive products, ensuring optimal storage conditions for dairy, meat, seeds, and flowers. It has efficient cooling mechanisms and customizable storage configurations.

Odor Remover

These systems are essential for maintaining a clean and pleasant working environment in agricultural and industrial spaces, ensuring better air quality and comfort for workers in poultry and livestock farms, agricultural processing plants, and food waste management facilities.

Chili Washer

The chili washers are specialized machines that remove dirt and debris from chilies, preserving their integrity and freshness. They save time, maintain produce quality, and prepare chilies for further processing like drying or grinding.

Multipurpose Workbench

A multipurpose workbench is a versatile tool for agricultural and industrial operations, providing durability and functionality for repairs, assembly, equipment maintenance, packaging, and sorting, and providing a versatile workspace for diverse operations.

Agricultural Sorter

The agricultural sorters utilize advanced technologies like optical sensors and AI to classify products based on size, shape, color, or quality, improving product uniformity, marketability, and waste reduction, and enhancing efficiency in large-scale agricultural operations.

Click here to contact to know more information about stationary specialized machines from KYUNGNONG

View more: Optimizing Agriculture with Stationary Specialized Machines | KYUNGNONG

0 notes

Text

Optimizing Agriculture with Stationary Specialized Machines | KYUNGNONG

KYUNGNONG Industry is a leading global provider of high-quality agricultural solutions and services. They offer a range of products like rechargeable sprayers, electric trimmers, agricultural skid loaders, fuel dispensers, and advanced cold storage solutions, designed to enhance productivity and simplify agricultural tasks. Here the stationary professional machines are equipped for agricultural, industrial, and professional settings. These portable specialized machines are essential for enhancing production efficiency in the agricultural and food industries.

Freshness Maintainer

The freshness maintainer machines are used in agriculture and food industries to maintain the quality and nutritional value of perishable goods. They regulate temperature and airflow, reducing waste, extending shelf life, and supporting export-ready goods with optimal freshness.

Agricultural Dryer

These agricultural dryers are essential for preventing spoilage and improving storage conditions for crops like grains, seeds, and herbs. They remove excess moisture, enhance storage life, and improve crop preparation for further processing, minimizing energy consumption and maximizing productivity.

Cold Storage

Cold storage systems are crucial for industries handling temperature-sensitive products, ensuring optimal storage conditions for dairy, meat, seeds, and flowers. It has efficient cooling mechanisms and customizable storage configurations.

Odor Remover

These systems are essential for maintaining a clean and pleasant working environment in agricultural and industrial spaces, ensuring better air quality and comfort for workers in poultry and livestock farms, agricultural processing plants, and food waste management facilities.

Chili Washer

The chili washers are specialized machines that remove dirt and debris from chilies, preserving their integrity and freshness. They save time, maintain produce quality, and prepare chilies for further processing like drying or grinding.

Multipurpose Workbench

A multipurpose workbench is a versatile tool for agricultural and industrial operations, providing durability and functionality for repairs, assembly, equipment maintenance, packaging, and sorting, and providing a versatile workspace for diverse operations.

Agricultural Sorter

The agricultural sorters utilize advanced technologies like optical sensors and AI to classify products based on size, shape, color, or quality, improving product uniformity, marketability, and waste reduction, and enhancing efficiency in large-scale agricultural operations.

Click here to contact to know more information about stationary specialized machines from KYUNGNONG

View more: Optimizing Agriculture with Stationary Specialized Machines | KYUNGNONG

0 notes

Text

The Industrial Food Milling Machine Market is projected to grow from USD 201.3 million in 2024 to an estimated USD 290.68 million by 2032, with a compound annual growth rate (CAGR) of 4.7% from 2024 to 2032. The industrial food milling machine market plays a pivotal role in the global food processing industry, facilitating the production of high-quality, uniform, and processed food products. As consumer demand for processed and packaged food grows, the need for efficient and versatile milling solutions has become more pronounced.

Browse the full report https://www.credenceresearch.com/report/industrial-food-milling-machine-market

Market Overview

Industrial food milling machines are used to grind, crush, or pulverize food materials into fine powders or granules for applications across various food industries, including bakery, confectionery, beverages, dairy, and pet food. These machines range from roller mills and ball mills to pin mills and hammer mills, each designed to meet specific production requirements.

The market is witnessing rapid growth due to the increasing need for consistency in food production and the rising demand for products like powdered spices, flours, and processed cereals. In 2023, the global industrial food milling machine market was valued at approximately $XX billion, and it is projected to grow at a compound annual growth rate (CAGR) of X% over the next five years.

Key Market Drivers

Rising Demand for Processed Food: With urbanization and changing lifestyles, consumers are leaning towards ready-to-eat and processed food products. This shift is driving demand for advanced milling equipment capable of producing high-quality products.

Technological Advancements: Innovations such as automated milling systems, precision grinding, and energy-efficient machinery have revolutionized the milling industry. These technologies enhance productivity and reduce operational costs, making them attractive to manufacturers.

Stringent Food Safety Regulations: Governments and regulatory bodies are enforcing stricter food safety standards, encouraging manufacturers to adopt state-of-the-art milling machines that ensure contamination-free processing.

Growth in Emerging Economies: Countries in Asia-Pacific, Africa, and Latin America are witnessing a surge in food production and consumption, creating opportunities for the expansion of the industrial milling machine market.

Challenges Facing the Market

Despite its promising growth, the industrial food milling machine market faces several challenges:

High Initial Investment: Advanced milling machines often come with a hefty price tag, which can be a deterrent for small and medium-sized enterprises (SMEs).

Maintenance Costs: The need for regular maintenance and skilled technicians to operate and repair machines can add to operational expenses.

Competition from Traditional Milling Methods: In some regions, especially rural areas, traditional milling methods still dominate due to their lower costs and ease of use.

Environmental Concerns: Energy-intensive milling processes and waste generation are raising concerns about the environmental impact of the industry.

Future Outlook

The industrial food milling machine market is poised for significant growth in the coming years, fueled by advancements in technology, increasing consumer demand, and expanding global food markets. To stay competitive, manufacturers will need to focus on innovation, sustainability, and cost-effective solutions.

As the food industry continues to evolve, industrial milling machines will remain at the forefront, enabling the production of high-quality, safe, and diverse food products that meet the changing tastes and preferences of consumers worldwide.

Key Player Analysis:

Erich NETZSCH GmbH and Co. Holding KG

FRITSCH GmBH

FUCHS Maschinen AG

Glen Mills Inc.

Hosokawa Micron Corp.

Alapala

Alvan Blanch Development Co.

Beccaria S.r.l.

Brabender GmbH and Co. KG Buhler AG

IDEX Corp.

Kice Industries Inc.

Mill Powder Tech Co. Ltd.

Omas Srl

ProXES GmbH

IKA Werke GmbH and CO. KG

Isimsan Muh. San ve Tic. A.S.

Jas Enterprises

Royal Duyvis Wiener BV

Satake Corp

Segmentation:

By Product Type:

Rice Mill

Corn Mill

Wheat Flour Mill

Roll Flour Mill

Food Processing Mill

Spices Mill

Grain Mill

Cereals Mill

By Application:

Commercial Purpose

Industrial Purpose

By Distribution Channel:

Online

Offline

By Region:

North America

United States

Canada

Europe

United Kingdom

Germany

France

Asia-Pacific

China

India

Japan

Latin America

Brazil

Mexico

Middle East and Africa

South Africa

United Arab Emirates

Browse the full report https://www.credenceresearch.com/report/industrial-food-milling-machine-market

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes