#Cubic feet examples

Explore tagged Tumblr posts

Text

In this article, we will discuss the definition and formula of cubic feet, different conversion units of cubic feet, and calculating methods of cubic feet. In addition, with the help of detailed examples and their solution.

#allmathtricks#Cubic Feet Conversion#Cubic Yards to Cubic Feets#Cubic Centimeters to Cubic Feets#Cubical Storage Space#Cubic feet examples

0 notes

Text

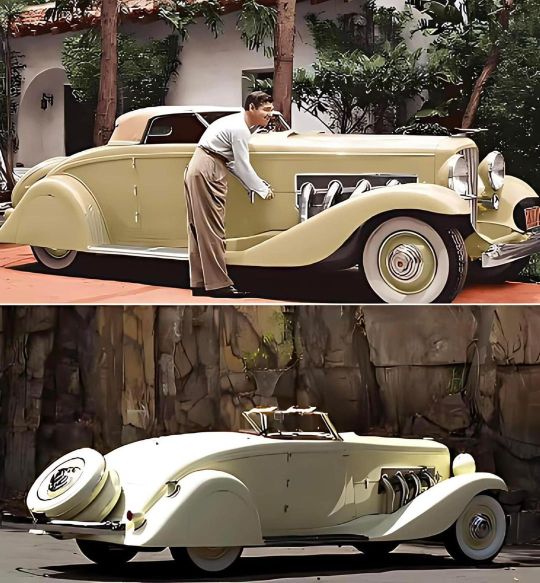

1935 Duesenberg

Clark Gable and his 1935 Duesenberg

His wife, Carole Lombard, had one too, which is now in a museum in NZ.

HOLLYWOOD, Calif.

Its 420-cubic-inch straight-8 pulled like a train; it was reputed to have a 115-m.p.h. top speed – “right off the showroom floor,” It could exceed 100 m.p.h. in the second of its three gears, boasted E. L. Cord, the company’s president at the time. Its wheelbase of nearly 12 feet gives the car a poised, unflappable ride. And its massive steering wheel guides the wheels straight and true – although its vacuum assisted drum brakes provide the car somewhat uncertain stopping power

Today, the car’s odometer shows 13,416 miles.

It was January 25, 1936 and Clark Gable had a new car to show off – to a new object of his affections. She was actress Carole Lombard, and the hostess of the lavish White Mayfair Ball, a formal Hollywood soiree, to which Gable drove his 1935 Duesenberg Model JN convertible that night.

The suave actor eventually convinced Miss Lombard to “take a spin around town” with him; when he invited her to his suite a few miles away at the Beverly Wilshire Hotel, she famously replied, “Who do you think you are? Clark Gable?”

They weren’t exactly strangers; they had already co-starred together in “No Man of Her Own”. After filming wrapped Miss Lombard presented Mr. Gable with a ham – with his picture on it! But their professional relationship went no further at that point; Miss Lombard was then married to William Powell (she divorced him a couple of years later).

Nevertheless, after they re-connected at the White Mayfair Ball, a scandalous affair ensued; Mr. Gable, still married, was often spotted traveling in the Duesenberg with Miss Lombard from her bungalow on Hollywood Blvd. to night spots, restaurants and hotels all over town. One of those places, The Georgian Hotel in nearby Santa Monica, now advertises the couple had trysts there often.

“This is nothing discreet about this car,” Mr. Gooding said as he pulled up in the glowing Duesenberg, in front of The Georgian. Not exactly the type of car for two famous stars to be seen in – when they are trying to downplay their affair!

. The car fairly screams “notice me!”. Even now the Duesenberg, which appeared in a couple of actual movies of its own, is a show-stopper.

“The record for an American car sold at public auction is $10.34 million, for a Duesenberg – the 1931 Whittell Coupe – which we sold last year,” Mr. Gooding said. “In many ways, however Gable’s 1935 JN is an even finer example.” It is undeniably rare; fewer than a dozen JNs were built – only four of which were convertibles. But no other Duesenberg is like this one. (I will update this post Aug. 19 with the sales price!)

And, then there is the consideration of its celebrity provenance. “I’ve never seen a car with a history behind it like this one,” Mr. Gooding said.

Its 420-cubic-inch straight-8 pulled like a train; it was reputed to have a 115-m.p.h. top speed – “right off the showroom floor,” Mr. Gooding said. It could exceed 100 m.p.h. in the second of its three gears, boasted E. L. Cord, the company’s president at the time. Its wheelbase of nearly 12 feet gives the car a poised, unflappable ride. And its massive steering wheel guides the wheels straight and true – although its vacuum assisted drum brakes provide the car somewhat uncertain stopping power.

A work of automotive art!

Of course, that has often been said about many great works of art – sculptures, paintings, and the like – but seldom about automobiles. Many collectors, however, consider the 18-foot-long Duesenberg, with its flamboyant, following lines, the epitome of automotive art.

The Model JN that Mr. Gable bought originally had a body by Rollston. Mr. Gooding noted, “It was a work of art already.” But Mr. Gable decided it wasn’t audacious enough for his tastes.

So he took it to master coachbuilders Bohman & Schwartz, in Pasadena, Calif., for a complete re-working. And besides, the convertible top leaked – which Miss Lombard reportedly thought amusing; Mr. Gable, however, was mortified.

Clark Gable shows off his beloved Duesenberg!

“Not only did Gable sketch out many of the changes he wanted himself,” Mr. Gooding said. “He also got hands-on with it, and worked on it himself. I don’t recall an example where a celebrity got so involved, and essentially helped craft the car.”

The modifications included body-colored radiator cowl and headlamp pods, raked windshield, extended hood with custom air scoops, re-location of the side-mounted spares to a double-deck “continental kit” at the rear, rear fender skirts, chrome side pipe exhausts (with a driver-controlled bypass lever), functional rumble seat, and a stowable convertible top – that no longer leaked!

It was also re-painted from a pale green to a luminous cream color that seems to glow – apropos of any star of stage, screen or even outer space.

Despite the fact Mr. Gable owned a large, discerning collection of other Duesenbergs, Packards, and Mercedes-Benzes, the JN remained the preferred ride of the inseparable lovers.

So public was their romance that Photoplay magazine ran a feature in December 1938 out-ing them as one of “Hollywood’s Unmarried Husbands and Wives.” Mr. Gable had also been linked in recent years with Joan Crawford, Jean Harlow and Loretta Young (with whom he fathered a love child) – among others. Producer David O. Selznick was ready to cast Gary Cooper as Rhett Butler in “Gone With The Wind” unless Mr. Gable cleaned up his personal life. So the studio reportedly helped pay for Mr. Gable’s costly divorce from heiress Ria Langham; he got the part. The rest, as they say, is history.

Gable got the part!

Mr. Gable and Miss Lombard (who lost out in casting for Scarlett O’Hara) eloped in March 1939. In 1941 the happy couple set off in the Duesenberg on an epic vacation – sort of a belated honeymoon – from their ranch in Encino, Calif., up the Pacific Coast to Vancouver, British Columbia. The trip was nearly 1,500 miles, on primitive roads.

It must have been quite a sight: two of Hollywood’s biggest stars pumping their own gas, fixing their own flats, even changing their own oil – the Gables didn’t want anyone else touching this car! – in a car easily worth $35,000 then (Mr. Gable made more than that in one month, in salary, in those years – and Miss Lombard made nearly as much).

“This was at a time you could buy a Ford for a few hundred dollars,” Mr. Gooding noted.

In Vancouver, the couple would see the Duesenberg for the final time. They stored it there, planning to return the next summer to drive it back to California. They took the train home.

Some months later, however, Miss Lombard was killed in a plane crash near Las Vegas, Nev. Gable, devastated, instructed an agent to sell the beloved Duesenberg – with the proviso that he never would see it again. He never did; he died in 1960.

The Duesenberg became a four-wheeled vagabond, crisscrossing the country, changing hands more than a dozen times. It was re-painted at least four different colors. Its engine was replaced in the 1950s. Parts went missing.

But the current owner, Mr. Gooding said, acquired it in 2006 and ordered a no-expense-spared restoration to its Gable-era glory.

Text via John Piazza

Credit: Respective Owner ( DM for credit or removals )

141 notes

·

View notes

Text

The Red Sea might just be history’s most contested body of water. It has been the site of imperial or great-power competition for at least 500 years, from the Portuguese search for the sea route to Asia all the way to the Cold War. It remains the most important trade link between Asia and Europe. The Suez Canal at its northern egress has been displaced by the Singapore Strait as the world’s most important chokepoint, but it’s still the second-most vital; 30 percent of global container ship traffic moves through that canal. Container ships are to globalization what eighteen-wheelers are to the United States—the workhorses of trade. And there are important energy flows here: 7.1 million barrels of oil and 4.5 billion cubic feet of natural gas transit the Bab el-Mandeb (the southern entrance to the Red Sea) every day, per the U.S. Energy Information Administration.

So attacks by Houthi forces on “Israeli” shipping in recent days have the potential for major disruption. “Israeli” is in quotes because commercial shipping ownership is complicated and opaque: Ship ownership, ship operation, and flag of registry often differ, and none necessarily has any bearing on the ownership or destination of the cargo on board or the nationality of the crew. What’s more, Houthi attacks have quickly morphed from semi-targeted at ships nominally linked to Israel to more indiscriminate. The world’s most important container shipping firms—including MSC, Maersk, Hapag-Lloyd, and Cosco—have paused on sending ships through these waters for fear of loss of life or damage.

Enter a new U.S.-led task force with the somewhat on-the-nose moniker Operation Prosperity Guardian, a naval coalition to protect commercial shipping from Houthi attacks. It will operate under the aegis of a preexisting mechanism, the Combined Maritime Forces, a counterpiracy and counterterrorism naval coalition (the world’s largest, by far) that operates out of Bahrain. So far, nine countries have signed up officially (though some with very modest contributions—Canada, for example, is sending three staff officers and no ships yet); there are reports that others have quietly agreed to participate or contribute. India, which has a lot at stake here (especially in the disproportionate number of Indian nationals among the crews of major commercial lines), is not part of the coalition but is independently contributing two vessels to the effort.

The United States and France have long had bases in Djibouti to project power across the Red Sea, recently joined by Japan and China, and the European Union operates out of the French base to support Operation Atalanta, a counterpiracy task force that protects trade in the nearby Gulf of Aden (alongside the U.S.-led Combined Task Force 151, which has the same mission). But this skirmish is an astonishingly asymmetric fight. With a handful of missiles and drones, the Houthis have succeeded in placing at risk one of the most important arteries of the global economy.

The asymmetry has caused some of the debate to focus on the cost of the drones versus the cost of the missiles being used to defend the ships. It’s the wrong metric. The right calculation is cost of the missile versus cost of the target. If a drone attack succeeds, it could wreck a ship worth anywhere upwards of $50 million and carrying trade goods likely in the $500 million range—and in some cases, roughly double those amounts.

The real problem of volume is a different one. The primary ships being used for these operations—for the United States, Arleigh Burke-class destroyers; for the United Kingdom, the Daring class—sail with an arsenal of roughly 60 missiles that are useful for shooting down drones or missiles. (They carry other types of missiles as well, rounding out the complement of armaments, but not ones germane to this fight.) At the pace at which the Houthis have been conducting attacks, a single ship would expend its relevant armaments in a couple of weeks and need to be rotated out; there’s no way to replenish these missiles at sea. If the Houthis keep up the pace of attacks and have a steady supply of drones and missiles (which seems likely), the cost of maintaining a naval escort operation—including the costs of operating the ships at distance—will rapidly rise into the tens of billions of dollars.

The West faces three options, all with serious downsides.

First, reroute the shipping. For now, until the task force is assembled, shippers are switching routes between the Red Sea and the long voyage around the Cape of Good Hope off southern Africa. It’s been done before, when the Suez Canal was closed as a result of Arab-Israeli wars in the late 1960s and early ’70s. But global trade then was a fraction of global trade now. Rerouting via the Cape of Good Hope would add roughly 60 percent of the transit time (and fuel cost) from Asian ports to European ones, not just adding costs to shippers (who would pass those costs onto consumers) but more importantly gumming up the works in global just-in-time manufacturing. While this is an acceptable option for a week or two, any longer and the disruption to global sea-based supply chains would be significant.

Second, attack the missiles and drones at the source, either to eradicate the armaments or deter the attacks. Already there’s a drumbeat of criticism that U.S. President Joe Biden hasn’t yet authorized this course. Easily said but less easily achieved. It would not be too hard for Houthi forces to hide both themselves and a stockpile of drones and missiles from U.S. targeting, so any attacks—from two U.S. carrier strike groups in nearby waters—would have to be pretty wide-ranging and even then are likely to miss pockets of weaponry. Would Iran—the Houthis’ primary backers—be thus deterred? It’s unclear how or why; Iran is surely willing to allow the Houthis to sustain substantial casualties for the “win” of harassing “the West” in the Red Sea. Attacking Iran itself is the next logical step and may prove necessary, but that carries its own major risk of escalation while Israel is grappling with the missile threat from Hezbollah on its northern border with Lebanon.

Third, widen the coalition. So far, Germany has not joined in, to some criticism but with good reason. There are mounting demands on Germany’s modest navy in Northern European waters, where the Russians are flexing their subsea muscles. Australia was asked to join but made the counterargument that its modest naval capacity is better deployed in the Western Pacific. Japan could contribute, especially since it has a base in Djibouti. Another potential contributor is China, which has a base nearby and a long track record of contributing to counterpiracy operations in the Indian Ocean. There’s a dilemma here for the West, though: Do the Western powers prefer to (a) pay the price of protecting global sea-based trade, of which China is the largest source and arguably primary beneficiary, or (b) help facilitate China’s growing capacity to project naval power across the high seas?

The entire episode highlights this point: There’s a deepening contradiction between the reality of globalization, heavily dependent on sea-based trade and on China, and the reality of geopolitical contest, in which naval power is rapidly emerging as a central dimension. Tensions and bad choices abound in the Red Sea—but they are also a harbinger of tougher choices and turbulent waters ahead.

7 notes

·

View notes

Text

Understanding Ventilation Power: Selecting the Ideal CFM for Your Kitchen Exhaust Hood Installation

When it comes to kitchen exhaust hood installation, one of the most crucial factors to consider is the ventilation power, measured in cubic feet per minute (CFM). Choosing the right CFM ensures your kitchen remains free from smoke, grease, and odors, providing a safe and comfortable environment. This guide will help you understand how to select the appropriate CFM for your kitchen exhaust hood, enhancing both functionality and compliance with safety standards.

Why CFM Matters in Kitchen Exhaust Hood Installation

CFM, or cubic feet per minute, measures the volume of air a hood can exhaust in one minute. The right CFM is essential for effective ventilation, determining how quickly and efficiently smoke, steam, and grease are removed from your kitchen. An inadequate CFM can lead to poor air quality and increased fire hazards, while an excessively high CFM can be unnecessarily noisy and energy-consuming.

Calculating the Right CFM for Your Kitchen

The size of your cooking area and the type of cooking you do significantly impact the CFM requirements. For standard cooking ranges, a basic rule of thumb is 100 CFM per linear foot of cooktop. For example, a 30-inch range would need a hood with at least 250 CFM. For more intensive cooking methods, such as grilling or frying, you may need a higher CFM to ensure adequate ventilation.

Factors Influencing CFM Requirements

Several factors influence the CFM requirements for your kitchen exhaust hood installation:

Cooking Style: Heavy cooking styles like frying or grilling produce more smoke and grease, requiring higher CFM.

Kitchen Size: Larger kitchens may need more powerful hoods to ensure complete ventilation.

Ductwork Length: Longer duct runs can reduce efficiency, necessitating higher CFM to maintain performance.

Hood System Installation

Proper hood system installation is key to maximizing the effectiveness of your kitchen exhaust hood. Professional installation ensures your hood is correctly positioned and ducted, optimizing airflow and ventilation. Experts can assess your specific kitchen layout and recommend the best system and CFM for your needs, ensuring safety and compliance with local regulations.

Benefits of Choosing the Right CFM

Selecting the appropriate CFM for your kitchen exhaust hood offers several benefits:

Improved Air Quality: Efficient ventilation removes contaminants, keeping the air fresh and clean.

Enhanced Safety: Proper ventilation reduces the risk of grease fires and improves overall kitchen safety.

Energy Efficiency: Choosing the right CFM ensures your hood operates efficiently, saving on energy costs.

Noise Reduction: An appropriately powered hood operates more quietly, creating a more pleasant cooking environment.

Professional Kitchen Exhaust Hood Installation

Opting for professional kitchen exhaust hood installation guarantees your hood system is tailored to your kitchen’s specific needs. At Red Eagle – Kitchen Hood Services LA, we specialize in providing expert installation services. Our experienced team will help you choose the right CFM and ensure your hood is installed for maximum efficiency and safety.

#Kitchen Hood Installation#Commercial Vent Hood#Restaurant Hood Installation#Kitchen Ventilation#Exhaust Hood System#Kitchen Ventilation Installation#Professional Hood Installation#Range Hood Installation#Type 2 Hood Installation#Kitchen Exhaust Fan#Commercial Kitchen Hood#Vent Hood Services#Kitchen Hood Ventilation#CFM Calculation#Kitchen Exhaust System#Kitchen Hood Maintenance#Ventilation Power#Air Quality Improvement#Fire Safety#Energy Efficiency

2 notes

·

View notes

Quote

Efficiency vs. Effectiveness - They are Not the Same Over the past 3+ years there has been a sharp rise in interest related to indoor air cleaners. I have consistently seen confusion over the terms efficiency and effectiveness. This thread is about the difference. 1/

Richard Corsi, PhD, PE (Texas) on Twitter

A helpful & clear explanation! Some excerpts:

As an example, consider an air cleaner that removes close to 100% of particles that enters it, but that only has 1 cubic feet per minute (cfm) of air passing through it. 4/

In this example, the air cleaner has a Clean Air Delivery Rate (CADR) of only 1 cfm. In a typical K-12 classroom (say, 700 square feet with 9 ft ceiling height) this would yield an equivalent of only about 0.01 additional air changes per hour. 6/

So, 100% “efficient” may do very little to clean the air if the air flow rate through the device is small. This was the case for many quiet and non-filter-based air cleaners that were marketed in the 1990s and 2000s. 7/

On the other hand, it is possible to have a particle removal efficiency of, say, only 50%, e.g., only half of the particles (or particle mass) that enter the device are actually captured by the device, but to have that air cleaner be quite effective. What? 9/

Imagine a device that is only 50% effective at removing aerosol particles from indoor air (fraction removal efficiency = 0.5). Now, if the air flow rate though that device is 800 cfm it will have a CADR = 400 cfm (800 x 0.5). 10/

This is greater than most off-the-shelf HEPA air cleaners on the market and far greater than many other air cleaners. In this case, for the classroom described above the air cleaner would yield an equivalent of about 3.8 additional air changes per hour. 11/

This is why the Clean Air Delivery Rate (CADR) is a much better metric than filter removal efficiency when comparing air cleaners. 12/

3 notes

·

View notes

Text

It's an interesting tale, but it fails to take into account that the obsolescence and inaccesibility of braille is really its expense and size. For example, a Bible is 600-1000 dollars and is 6 cubic feet. Most people simply aren't interested in keeping a whole warehouse for their books when they could just have a Kindle or w/e.

Embossed braille should be standard on computer keyboards.

It would raise braille literacy more than anything else I could imagine - among both the blind and the sighted. Currently braille is actually vanishing due to an increasing reliance on audiobooks and screen readers.

I think that braille has a lot of potential use among non-blind groups. As an alternative to traditional writing for dyslexics. As a way to help photosensitive people type with their eyes closed. Or simply as a means to help sighted people find things without needing the lights on all the time!

87K notes

·

View notes

Text

OVERVIEW OF MEDICAL GAS MANIFOLDS

What is a Medical Gas Manifold? Unlike Medical Air Compressors and Vacuum Pumps that generate gas on-site, many gases used in healthcare settings are delivered to the facility in different types of containers and use manifolds to distribute into the rooms. Gases that can be delivered:

Oxygen – delivery pressure of 50psi Nitrous Oxide – delivery pressure of 50psi Medical Air – delivery pressure of 50psi Carbon Dioxide – delivery pressure of 50-100psi HeliOX blends – delivery pressure of 50psi Nitrogen – delivery pressure of 180psi Instrument Air – delivery pressure of 180psi The 2021 edition of the NFPA99 has the most recent developments in medical equipment and processes as well as new methods to reduce fire, explosion, and electrical hazards.

What Containers are used with Manifolds? Bulk tanks and micro-bulk tanks are gas containers that get refilled on-site. These are used for large applications and require additional equipment. Sometimes, these are collectively called a tank farm and the pad – which allows access for a truck with cryogenic gas to pull in and fill the tanks. Liquid Dewars and high-pressure cylinders are the types of gas containers that are delivered and replaced when empty. For example, there is an “H-type” high pressure cylinder, which is primarily hooked up to a high-pressure manifold in the healthcare setting. These are very common for ambulatory surgery centers and small outpatient facilities, most of the gases listed above outside of oxygen, still use this type.

Micro-Bulk Tank

Bulk Tank

High Pressure and Liquid Medical Gas Manifold Installation Discussing high pressure and liquid medical gas manifolds located indoors, the number one aspect is that it has to be a separate secured room with one hour fire rating used for no other purpose. Your manifold room can only have the manifolds and the container that is being replaced. You can store and keep connected what you’re actually using.

For example, if you have Dewars, you are only able to store Dewars, and then your high-pressure cylinders (H tanks) can go in there. Sometimes people put the vacuum pump and the oxygen manifold in the same room – that is not allowed and very expensive change order. Remember, your manifolds must be in a room all by themselves and be properly labeled.

Although this blog discusses the most common practices, Pattons Medical advises you to always work with your local municipality and local verifier to ensure that your design complies with your interpretation of whichever code they’re working on. Additionally, please note that any electrical devices in this room must be situated above five feet, and relief valves must be installed with copper piping that extends outside the room. The discharge should be turned down and screened for safety. Another important consideration is having a source valve located near the manifold.

When it comes to the insulation of the room, there are several other factors to take into account. Firstly, the temperature inside the room should not exceed 125 degrees. Additionally, ventilation must be carefully planned and implemented to ensure optimal conditions. You are able to naturally ventilate the room if your total gas falls below 3000 cubic feet. You can access gas volume charts on the Pattons Medical website.

Reference NFPA 99 5.1.3.3.2 (1-9) for design and construction details for locations of central supply systems and storage of positive pressure gases.

Indoor rooms can be heated by indirect means using steam or hot water if needed. The common rule of thumb for your liquid containers, your Dewars, is depending on the gas, it could be between 12 and 16 H cylinders. You will know where you are in that 3000 cubic feet threshold by the math and whether you want to do the mechanical versus the natural.

Liquid Dewars

High Pressure Cylinders

How do Medical Gas Manifolds Work? With medical gas manifolds, you will have two banks; the primary and the secondary, and they are required to be equal. In regards to space, the primary bank is the one currently supplying the gas, and then the secondary bank will be ready when the primary is depleted. The manifold is required to be fully automatic. Referring to the NFPA applications, the switchover must occur within the manifold, semi-automatic.

Discussing the manifold and the header bars, the header bars will need to be equipped with high-pressure shutoff valves outside the cabinet to allow for emergency isolation. You also will need to have integral check valves for each station. The header bar is going to be CGA gas specific. This means your H cylinder (your Dewar), has a certain threaded connection – similar to the header bar. The goal is to prevent a nitrogen, H cylinder from being hooked up to an oxygen manifold. With the CGA fittings, the manifold is equipped with pressure transduced – which will send information to the main circuit board for a remote signal. This is how it will talk to your master alarms. Since you will need to place this outdoors, the NEMA four gives you some weatherproofing. You will need to make it a NEMA four cabinet if you are going to do it outside. Pattons Medical recommends putting a cover or shelter over it.

What’s Inside a HP Manifold? The manifold is going to come equipped with a three-quarter inch shutoff valve, which makes up a manifold for high pressure. At the bottom of the diagram, is the pressure transducers that are telling you what pressure is happening in each side, your left and right bank, and your primary and secondary. Then, we go into the left and right bank dome regulators. The important part about using the dome biased regulators is that it’s what holds the pressure to allow the whole thing to work off pressure differential.

Above those, are the first line regulators. Then, the bank gauges at the top tell you what's going on in these headers. After that, there’s the pilot regulator, which is feeding pressure into the dome bias, so your dome bias regulator is about 25 – 30 PSI higher than the one that it’s currently feeding.

When a facility gets gas delivered to their site, they are paying for gas at a certain purity, when the gas gets delivered on site, there is no way to make it pure. Manifolds can affect the purity of the gas, so if you’re not using high quality regulators that are made for NFPA applications, then there is potential through the regulator to introduce some impurities into the gas as it flows through the manifold. The left bank is feeding the facility, but when it drops to 250 PSI, it is no longer satisfying the dome biased, then it’ll switch to the secondary bank.

In our second “true” line regulators, which is where it gets put it into the building. All of these regulators are preset at the factory depending on the gas. Discussing the delivery pressure being different depending on the gas, your bank of H cylinders is going to have different, depending on the gas. For example, a bank of oxygen, H cylinders track about 2200 PSI, but a bank of nitrous oxide cylinders only track about 750 PSI. So, these regulators all come preset from the factory gas specific. Then you go through the line regulator. The image shows both regulators being open, but when you are truly feeding the facility, only one regulator will be open.

The manual purge valve will test for purity. The pressure relief valve is there to let you know if something is wrong and it will relieve off. When you are determining the flow through the manifold, some spec sheets give you the flow with both your left line regulator and your right line regulator being open, flowing through both, but this is not accurate for an NFPA application. For maintenance, the left line regulator will be manually turned off and then the right line regulator will need to be turned on. That is strictly to keep the wear and tear equal within the manifold.

There are manifolds on the market that use what’s called a “switching,” which is when it switches to where the pressure is after one side no longer has any pressure. The issue with this is that they leak and cause a waste of gas. The other caveat is that they fail frequently in the middle, so they haven’t closed the left bank but they opened the right bank. So, you end up using both banks at once with no warning.

Heaters CO2 and nitrous are two gases that can potentially freeze up a manifold. This is caused by a pressure drop and flow across the regulators in the orifice in the manifold. If you’re going to use a manifold with a shuttle valve, you must have a heater for CO2 and nitrous oxide because they leak. Then, you will be left with a slow flow the eventually freezes, so you’ll need to use a heater. We have a high flow dome bias regulator in our manifold, our specification sheets do not specify a heater with a Pattons Medical manifold. It isn’t needed because Pattons Medical picked a regulator that would give us high flow. Pattons Medical also wanted to make it so that heaters weren’t needed because they add to the room which causes another fail point. The heaters basically work by switching on when the room temperature drops below 75 degrees.

Liquid x Liquid Manifold In larger facilities, the number of high-pressure cylinders required to meet the demand can become very high resulting in a huge space requirement and a very labor-intensive change out. In those instances, cryogenic containers become advantageous. If using cryogenic containers, there are options pertaining to the primary and secondary banks. If using a liquid manifold, a HP reserve manifold is required as back-up.

IntelliSwitch Manifold The IntelliSwitch manifold is the product we will need to use if you are using a liquid-by-liquid application or high pressure. One of the unique features of the IntelliSwitch manifold is the flexibility.

When you push the button on the front, it allows you to identify what is being connected to this manifold. What this manifold's able to do is when you tell it what is connecting to it, it will understand what pressure is supposed to see based on the containers being attached.

When you liquefy the gas in the container, it introduces some challenges with the gas being in a cryogenic state. IntelliSwitch is able to address some of those challenges. One of the first features is the economizer function. For this example, we will say, that this bank is feeding the facility. When this bank is feeding the facility, this container is generating head pressure because the gas does not want to be in a liquid state. When it generates too much head pressure, that's when you're going to pop your pressure relief valve to protect the container. In a traditional liquid by liquid manifold, it blows off into the room.

The IntelliSwitch is able to monitor the pressure on the bank, feeding the facility. Still, it’s also monitoring the pressure of the bank, not feeding the facility when it starts to register, that the head pressure is getting to. The economizer feature just bleeds some of that gas off so that it's able to be used downstream and you don't waste it. All of this happens in reverse with the lookback feature.

The lookback feature will do a soft switchover, and start drawing some of the gas from this bank, but then it keeps looking back. When this generates enough head pressure, it uses it. If it notices that there is no type of gas or that its completely empty, it’ll switch to the alternative. So instead of wasting 30% of gas in the container, only 5% will be wasted. The majority of verifiers say that this is a safer product because you are constantly getting readouts from both, meaning you know exactly what the pressure is.

Working with a verifier is essential. Take into consideration whether they are truly third parties or selling products as well.

Alarms For the manifold, there are local and master alarms. The local alarms are physically on the cabinet and are going to have either green or red lights. These lights will be next to a few phrases; ready, in-use, and replace.

For reference, you should have two green lights for ready, which means you now have a demand. For this example, let’s say this is your primary bank. When it’s depleted, the red light will be next to “replace” and the green light will be next to “ready” and “in-use.”

At your master alarm, you have a low-pressure line, high-pressure line, and reserve in use. They are actually being read by the main line pressure switch downstream of the source valve, but then you have your changeover alarm. Similarly to the local alarm, if the red light for “replace,” it is telling you to change over. You will need to address getting the bank changed out within a specified timeframe.

For liquid by liquid, we have those same three alarm points at the master, but we also have to have two more points at the master alarm, called reserve in use. As mentioned, for liquid-by-liquid applications, you have your two cryogenics and your high pressure. If your cryogenic containers have both failed, we will take off our “reserve-in-use” for the high-pressure reserves. The reserve manifold will trigger an alarm at the master.

0 notes

Text

New Human Species with Orange-Size Brain Discovered

First published 10 September 2015 (scroll down to see the UPDATE)

A newly discovered extinct human species may be the most primitive unearthed yet, with a brain about the size of an orange. But despite its small brain size, the early human performed ritual burials of its dead, researchers say.

This newfound species from South Africa, named Homo naledi, possessed an unusual mix of features, such as feet adapted for a life on the ground but hands suited for a life in the trees, that may force scientists to rewrite their models about the dawn of humanity.

Although modern humans are the only human lineage alive today, other human species once walked the Earth. These extinct lineages were members of the genus Homo just as modern humans are. The earliest human specimens found yet are about 2.8 million years old.

Though the researchers aren't sure how far back this human relative dates, it is the newest addition to the genus Homo. "It's a very exciting finding," said paleoanthropologist Ian Tattersall at the American Museum of Natural History, who did not participate in this research.

However, Tattersall suggested these new hominins might not belong to genus Homo. "I'm a great advocate for the notion that the genus Homo has been made overinclusive," he said. "I don't like to stuff new things in old pigeonholes. I don't think we have the vocabulary needed to describe the diversity we're seeing in early hominins."

Underground astronauts

Two cavers, Rick Hunter and Steven Tucker, discovered the new fossila in 2013 in a cave known as Rising Star, locatedin the Cradle of Humankind World Heritage Site about 30 miles (50 kilometers) northwest of Johannesburg in South Africa. The species is named after the cave; "naledi" means "star" in Sesotho, a South African language.

The fossils were recovered in two missions in 2013 and 2014 dubbed the Rising Star Expeditions. The bones lay in a chamber now named Dinaledi, meaning "many stars," located about 300 feet (90 meters) from the entrance of Rising Star.

Getting into Dinaledi required a steep climb up a sharp limestone block called "the Dragon's Back" and then down a narrow crack only 7 inches (18 centimeters) wide. A global call for researchers who could fit through this chute resulted in six women chosen to serve as what the researchers called "underground astronauts."

"They risked their lives on a daily basis to recover these extraordinary fossils," study lead author Lee Berger, a paleoanthropologist at the University of the Witwatersrand in Johannesburg, told Live Science.

The scientists recovered more than 1,550 bones and bone fragments, a small fraction of the fossils believed to remain in the chamber. These represent at least 15 different individuals, including infant, child, adult and elderly specimens. This is the single largest fossil hominin find made yet in Africa. (Hominins include the human lineage and its relatives dating from after the split from the chimpanzee lineage.)

"With almost every bone in the body represented multiple times, Homo naledi is already practically the best-known fossil member of our lineage," Berger said.

"We will be trying to extract DNA from these fossils," Berger added.

A weird mix

On average, Homo naledi stood about 5 feet (1.5 m) tall and weighed about 100 lbs. (45 kilograms). It had a tiny brain, only about 30.5 cubic inches (500 cubic centimeters) in size, making the organ about as large as the average orange. That's smaller than the modern human brain, which is about 73 to 97 cubic inches (1,200 to 1,600 cubic cm), but comparable in size to the brain of Austrolopithecus sediba. Australopithecines are likely the ancestors of the human lineage.

Homo naledi was a surprising blend of primitive and modern hominin. For example, "the hands suggest tool-using capabilities," study co-author Tracy Kivell of the University of Kent in England said in a statement. Many scientists have long believed that tool use accompanied a boost in brain size, but Homo naledi's brain was rather small.

In addition, its feet are virtually indistinguishable from those of modern humans. This, together with its long legs, suggest the species was adapted for a life on the ground involving long-distance walking. However,; its fingers were extremely curved, more curved than those of nearly any other species of early hominin, which hints at a life suited for climbing trees.

"Modern humans are really unusual in that walking on two legs is pretty much all we do," study co-author Will Harcourt-Smith, a paleoanthropologist at Lehman College in the Bronx and the American Museum of Natural History in New York, told Live Science. "Homo naledi probably spent most of its time walking on two legs, but also spent some proportion of its time up in trees — whether to escape predators or nest at night, we don't know."

Furthermore, Homo naledi's small teeth, slender jaws and many skull features are similar to those of the earliest known members of Homo, but its shoulders are more similar to those of apes.

"The combination of anatomical features we see in this creature is not like any we've ever seen before," study co-author John Hawks, a paleoanthropologist at the University of Wisconsin–Madison, told Live Science.

Death rituals

Intriguingly, this primitive human species may have disposed of its dead repeatedly, a ritualized behavior previously confirmed only in modern humans.

"Homo naledi is a primitive member of our genus, perhaps the most primitive we've ever seen, but it had the capacity both mentally and behaviorally to dispose of remains in a ritual fashion," Berger said.

Dinaledi is an isolated part of the Rising Star cave system that was never open directly to the surface and attracted only a few accidental visitors. Of the more than 1,550 bones and bone fragments recovered from Dinaledi so far, only about a dozen are not hominin. These include the remains of small animals such as birds and mice.

There is no evidence that flowing water or mud washed these bones into Dinaledi, nor are there bite marks suggesting that predators or scavengers carried the remains into the chamber, nor cut marks suggesting cannibalism. Instead, the researchers suggest, these remains were brought into this remote spot intentionally over time.

Prior research had uncovered another possible instance of an extince human species disposing of its dead, in Atapuerca in Spain. This site also contained remains thrown to the bottom of a cave. "Those hominins were much larger-brained, much closer to modern humans in brain size," Harcourt-Smith said. "There's debate as to which species was at Atapuerca — probably Homo heidelbergensis, a close relative of Neanderthals."

However, this is the first time such behavior with the dead has been seen with such a primitive hominin— that is, one dating back so early in the human family tree. "It's just an extraordinary discovery, a game-changer to see this very advanced behavior used back then," Harcourt-Smith said.

It remains unknown why Homo naledi disposed of its dead in this way. "We can spin a lot of yarns," Harcourt-Smith said. Maybe it buried the dead out of reverence, he said, or "maybe to get rid of things that were smelling. Maybe another species was throwing them down."

Uncertain place in the family tree

The age of the fossils remains uncertain, since the chamber lacks many of the features that scientists normally rely on to date fossils. As such, scientists can't yet say where Homo naledi fits on the human family tree. Depending on its age, it could be a direct ancestor to Homo sapiens, or the ancestor of the species that gave rise to Homo sapiens. "At this stage, all we know is that it's reasonably primitive," Harcourt-Smith said.

The researchers did note that both Homo naledi and the "hobbit" Homon floresiensis had similarly tiny brains. Although the scientists said they could not as yet speculate on any evolutionary links between those two species, the researchers new findings revealed that small-brained, primitive-looking human species with fairly modern features did exist in the past. This suggests that the hobbit is no longer an anomaly, the researchers said.

The scientists detailed their findings online 10 Sept in two papers published in the journal of eLife, and reported their work in the cover story of the October issue of National Geographic magazine, as well as the NOVA/National Geopgraphic Special "Dawn of Humanity" premiering 16 Sept.

UPDATE

#new human species#orange-size brain#South Africa#LiveScience.com#Homo naledi#orange#Trump#Trump unhinged#Donald Trump

0 notes

Text

Buy Range Hoods Like a Pro: Avoid These Common Mistakes

When it comes to outfitting your kitchen with essential appliances, a range hood is often one of the most important yet overlooked items. A good range hood plays a crucial role in maintaining air quality in your kitchen by venting out smoke, steam, and odors from cooking. However, buying the right range hood can be overwhelming due to the variety of options available. Whether you're renovating your kitchen or simply replacing an old unit, understanding the common mistakes to avoid can help you make an informed purchase that suits your needs and enhances your kitchen environment.

Here are some key considerations to ensure you buy a range hood like a pro, along with common mistakes to avoid.

1. Choosing the Wrong Size

One of the most common mistakes people make when purchasing a range hood is not selecting the correct size. The size of your range hood should correspond to the size of your cooktop or range. A range hood that is too small will struggle to adequately ventilate the kitchen, while one that is too large can dominate the space and be unnecessarily noisy or inefficient.

How to Avoid This Mistake:

To determine the appropriate size, measure the width of your cooktop. The range hood should be at least as wide as your stove or slightly wider. If your stove is 30 inches, a 30-inch range hood is a good choice. However, for larger stoves or ranges, like those with six or more burners, you may want to opt for a larger hood for optimal air circulation.

Additionally, the depth of the hood should ideally match the depth of the range or cooktop. For example, a 24-inch deep cooktop requires a deeper hood to capture all the smoke and steam effectively.

2. Ignoring Airflow Capacity (CFM)

The airflow capacity of a range hood is measured in cubic feet per minute (CFM). CFM indicates how much air the range hood can move to eliminate smoke, steam, and odors. Choosing a range hood with insufficient CFM can lead to poor ventilation, while a unit with too high a CFM might be excessively loud and expensive.

How to Avoid This Mistake:

A general rule of thumb for determining the right CFM is to choose a range hood with at least 100 CFM for every 12 inches of cooktop width. So, for a 30-inch cooktop, look for a range hood with a CFM between 250 and 400.

Keep in mind that the cooking style and frequency will also affect CFM needs. If you regularly cook with high heat, such as frying or grilling, you might need a higher CFM to keep up with the smoke and steam. Similarly, if you have a large family or entertain frequently, you may want to invest in a more powerful range hood.

3. Neglecting Noise Levels

Many buyers overlook the noise level when shopping for a range hood, only focusing on style, size, and performance. However, the noise produced by a range hood can be quite noticeable, especially in open-concept kitchens or small spaces. A loud range hood can detract from the cooking experience and disrupt conversations.

How to Avoid This Mistake:

Check the noise level of the range hood, often indicated in sones or decibels (dB). A quieter unit will be rated between 1-3 sones, while a noisier model may reach 5 or more sones. If noise is a concern, look for models that advertise quiet operation, or opt for a range hood with multi-speed settings, allowing you to adjust the power and noise level according to your needs.

Another consideration is the placement of the range hood. A hood placed too close to the ceiling or the walls might amplify sound, while a well-placed, higher-end unit with sound-dampening features will produce less noise.

4. Not Considering Venting Options

Range hoods come in two basic types of ventilation systems: ducted and ductless (also known as recirculating). Ducted systems expel air outside the home through a vent, while ductless systems filter the air using charcoal filters and return it to the kitchen. While ducted hoods are more efficient, they require installation of venting ducts, which can be complicated and costly.

How to Avoid This Mistake:

Before you purchase a range hood, assess your kitchen’s layout and the possibility of installing a ducted system. If your kitchen is located near an exterior wall or has easy access to ventilation ducts, a ducted hood is likely the best option. Ducted hoods offer better performance and are particularly suitable for larger kitchens or those with heavy cooking needs.

On the other hand, if you live in an apartment or a space where installing ducts is not feasible, a ductless range hood can be a good alternative. While less effective than ducted systems, modern ductless range hoods have improved filtration technologies, making them suitable for smaller kitchens.

5. Overlooking Design and Aesthetics

A range hood is a central feature of your kitchen’s design. An appliance that doesn’t complement the style of your kitchen can clash with the overall decor. However, many people focus only on functionality and forget to consider how the range hood fits into the aesthetic of the room.

How to Avoid This Mistake:

Choose a range hood that suits both your cooking needs and the style of your kitchen. For modern kitchens, a sleek, stainless steel hood may fit well, while for traditional kitchens, a more classic or decorative range hood design might be more appropriate. Range hoods come in many styles, including wall-mounted, under-cabinet, island, and downdraft models, so consider which design works best for your kitchen’s layout.

Additionally, take the color and finish of the range hood into account. Stainless steel is the most popular finish due to its durability and ease of cleaning, but there are also options in matte black, copper, and even custom colors that can match your kitchen’s aesthetic.

6. Forgetting About Maintenance and Cleaning

Like any kitchen appliance, range hoods require regular maintenance and cleaning to keep them working efficiently. Grease and dust accumulate on the filters, which can reduce the unit’s effectiveness over time. Many buyers neglect to consider the ease of cleaning when choosing a range hood.

How to Avoid This Mistake:

Choose a range hood with easy-to-clean filters and surfaces. Many hoods come with dishwasher-safe filters, making it easy to keep them clean. For the exterior, look for a model with a smooth surface that can be wiped down without difficulty. If you opt for a ductless hood, remember that the charcoal filters need to be replaced periodically, so consider the cost and availability of replacement filters when making your decision.

Additionally, consider the overall construction of the range hood. Hoods with smooth, curved lines are often easier to clean than those with more intricate designs, which may trap grease and dust.

7. Skipping Professional Installation

While installing a range hood may seem straightforward, it’s essential to ensure proper installation to guarantee that the unit functions efficiently. Improper installation can lead to airflow issues, noise problems, and even safety concerns. Many homeowners attempt to install their range hoods themselves, leading to suboptimal performance.

How to Avoid This Mistake:

For ducted range hoods, it’s advisable to hire a professional to install the unit, particularly if it requires ductwork. A qualified technician will ensure the correct placement, proper sealing of ducts, and compliance with local building codes. Even for ductless models, a professional installer can help with mounting and positioning to ensure optimal performance.

Conclusion

Buy range hoods is a critical decision that affects both the functionality and aesthetics of your kitchen. By avoiding common mistakes such as choosing the wrong size, neglecting airflow capacity, or overlooking noise levels, you can make a well-informed decision that meets your cooking needs and complements your kitchen design. Consider your venting options, ease of maintenance, and the importance of professional installation to ensure the longevity and effectiveness of your range hood. With careful planning, you’ll have a kitchen that’s not only cleaner but more enjoyable to cook in.

0 notes

Text

Oven - All types, varieties and features explained

Modern microwave ovens have cutting-edge functions like grilling, convection, and steaming to prepare delicious meals quickly. However, buying a microwave is necessary for most people, whether it is for your first home because your previous one is broken or your kitchen requires an upgrade. Once you have made up your mind that you need a microwave oven in your kitchen, you must do a little homework to get the best use for your money. This post will provide a microwave oven buying guide and discuss the styles, configurations available, and things to keep in mind while buying a microwave oven.

Difference Between a Convection Oven and OTG

An OTD is used for testing and grilling. For example, you can quickly grill meat and toast bread. A convection microwave oven can perform all these functions and can also reheat, cook and de-freeze, which an OTG cannot do.

Some of the differences are given below:

Heating method: An OTG oven can cook juicy and crispy food like kebabs, meats, and tikkas. When cooking with an OTG, heat radiated from the coil and is absorbed by the food. A fan is present, but most of the heat is dissipated directly under the coils. Convection uses a microwave with a fan for heating purposes.

Capacity: The capacity of an OTG may go up to 60 litres, whereas a convection microwave's capacity reaches just 32 litres. Therefore, OTG might be the better option for large batches of food.

Preheating: An OTG oven can take up to ten to fifteen minutes to preheat; a convection microwave only takes five minutes. This can reduce the cooking time considerably.

Cost: Although an OTG has a lower initial cost, the energy efficiency of a microwave oven is higher. A microwave oven saves money over time by using 20% less energy than an OTG.

How to Choose a Microwave

Average Cost of a Microwave: Small models of microwave start at around 4000 Rs, and mid-sized models start at a range of around 9000 to 22000 Rs, but most tested ones cost 35000 Rs and up. Models designed to make up about 22000 and up in cabinetry or wall cost only.

Space and Location: Before you buy a microwave, please look over where the microwave works best for you and the space available. For example, medium-sized models are usually over 18 inches deep and 20 inches wide, and large microwaves can be an inch or two larger. You will also want to factor in height, but a countertop model should fit well unless you have very low cabinets.

Type: Countertop microwaves are the most widely sold. OTP models are that: they are set up on the range. The built-in category includes models that are designed to be surrounded by cabinetry or built into a wall. This category comprises microwave drawers, which can be installed beneath a countertop or under a wall oven. Additionally, specific countertop models-but not all-can be transformed into built-ins with a kit.

Microwave Types

There are five different types of microwaves.

Countertop Microwaves: You can place them on any flat surface, making them easy to reach, move around, and take with you. Some can even be installed into a cabinet with additional trim kits for a built-in look. Countertop microwaves come in various sizes, features, and price points. For example, the Panasonic countertop microwave offers a greater capacity of 2.2 cubic feet of cooking space.

Over-the-Range Microwave Ovens: These microwaves are installed between the cabinets above your range to free up counter space. They also act as a vent, filtering smoke and steam from the ceiling. These popular models often come with the latest features, although back-to-basics microwaves are also available.

However, over-the-range microwaves may be suitable if you have limited room on the counter or enjoy a centralized workspace with the microwave and range in the same area. If you want a two-in-one appliance, choose an over-the-range microwave that removes the cooking smell from the kitchen.

Low-Profile Over-the-Range Microwave: An over-the-range microwave is an ideal option for some kitchen layouts. However, some models do not fit well in some range hoods. A low-profile over-the-range microwave designed for a slim space without sacrificing capability. Some models are fully vented and can work in place of a full range hood. They can easily replace an existing over-the-range microwave that is hanging too low.

Built-In Microwaves: Built-in microwaves are installed right into pre-existing cabinetry, bringing clean lines and a modern look to the kitchen. The microwave door usually opens from the top, not the side, like an oven. Several people place the built-in microwave above their wall oven to maximize space and provide easy access to both.

Moreover, built-in microwaves offer premium features and finish at potentially higher price points than a countertop and over-the-range options. If you like the idea of a built-in microwave over a wall oven, consider a wall oven microwave combo.

Microwave Drawers: As the name suggests, microwave drawers slide out for use and are installed on the countertop or under a wall oven. The location of this microwave makes it a more convenient and safer option for all family members.

Features to Focus On

Turntables and Trays: As one of the most convenient and common ways to increase temperature uniformity, a turntable is used in the microwave oven as a tray to carry and rotate the heated material to improve the temperature uniformity microwave could.

Quick Keys: The 1-minute or 30-second key requires just one tap to increase the preset cooking time, whatever power you select. It also allows quick adjustments to your previous setting-pressing the button more than once multiplies the time extension.

Racks: These let you expedite things up and cook multiple dishes at once. They also improve convection cooking by allowing heat to build up beneath the cooking vessel. But you may also have trouble fitting a coffee mug into some models unless you remove the rack, so check when you shop.

Child Lock: If you have kids and want a hassle-free cooking experience, remember to buy a microwave that allows you to set a passcode to unlock the device. That way, you can be sure that your kids won’t be exposed to any unfortunate risks.

Convection Cooking, Grilling, and Browning: These characteristics give your kitchen the appeal of a second oven. But none of the tested models provides the results you will get from a regular oven or grill.

Sizes and Cooking Capacity: Exterior dimensions are essential when installing or replacing a built-in microwave or over-the-range. However, full-size countertop units take up a lot of counter space. Allow extra space on all sides. Check the product description of each microwave oven before buying.

For convenient access, you need at least 66 inches from the floor to the bottom of the cabinet when measuring for over-the-range microwave ovens. Moreover, at least 30 inches gap must be between the cooktop surface and the bottom of the cabinet.

Be sure your new microwave will meet your cooking needs. Cooking capacity refers to the internal area. It ranges from 0.7 cubic feet, excellent for small spaces and basic reheating, to 2 cubic feet or larger for full cooking capability.

Energy Savings: There are currently no energy-saving certified microwaves on the market, but you can still find ways to save time or energy. Look for a microwave with variable power settings for better cooking performance while using less energy.

Popular Microwave Features

Below are listed 13 popular features of microwaves.

Smart Technology: Several new microwaves have smart compatibility so that you can control the device via an app, Bluetooth, or voice assistant. These features help you multitask while you cook or monitor the cooking process.

Convection: Convection cooking uses a fan to circulate hot air around the dish, resulting in more evenly cooked food.

Speed Cook: Speed cooking combines the functionality of convection cooking with microwaving. You will get the results of a conventional oven at the speed of a microwave.

Sensors: To avoid overcooking, microwave oven sensors automatically change time and temperature as needed. Moreover, sensors measure the emitted steam to determine when the food is at the optimum temperature.

Non-stick Interior: Non-stick interior coatings make cleaning easy. Simply wipe down the plastic interiors with a damp cloth. In addition, stainless steel interiors also wipe clean and do not absorb odours.

Turntables, Trays, and Removable Racks: The turntable in a microwave rotates the food while it's cooking to ensure even heating. A tray can be used to catch any drips or spills that may occur during cooking.

Moreover, a removable rack can be used to elevate food and allow for more even heating or to cook multiple items at once. All of these features can be useful in improving the cooking process and making it easier to use a microwave.

High Wattage: Using a high wattage setting on a microwave means that the appliance is operating at a higher power level, which results in food heating up more quickly. Microwaves typically have power settings ranging from 600 to 1200 watts, with some models offering even higher wattage levels.

When using a higher wattage setting, it's essential to be mindful of the cooking time, as the food may cook faster than expected. It's also crucial to ensure that the food is evenly distributed in the microwave to avoid overcooking or undercooking certain areas.

Additionally, high-wattage microwaves can be more expensive and consume more energy, so it's essential to consider your cooking needs and energy usage when selecting a microwave.

Filters: If you use your microwave without a range hood, prefer a charcoal or recirculating filter to reduce cooking odours.

Preset Cooking Times: With this feature, you just press a button to start cooking. Designed to defrost or cook dishes for the optimal amount of time, you can often find options for pizza, popcorn, potatoes, and frozen dinners.

Inverter Technology: Engineered to provide steady heat over a short range, the inverter technology maintains an even percentage of power. Several microwaves alternate between low and high heat when you heat something at less than 100% power.

With the constant temperature of inverter technology, it is possible to make better-quality poached fish and omelets. Panasonic, Farberware, LG, and Samsung offer microwaves with inverter technology.

Grilling: By surrounding the food with intense heat, a grill option sears the outside of the food and prevents the rubbery texture that sometimes results from cooking meat in a microwave. Samsung offers a slim fry feature that combines grilling with hot air circulation to create crispy food inside and out without added oil.

Steam: Streaming is a convenient way to quickly prepare foods such as vegetables and fish; the steaming option keeps food moist without adding fat. This handsome cooking method also allows you to poach eggs in your microwave.

Top Microwave Brands

● Samsung

● Panasonic

● LG

● Bajaj

● IFB

● Morphy

● Lifelong

● Godrej

● Whirlpool

● Pigeon

● Inalsa

● American Micronic

● Agaro

0 notes

Text

How to Calculate the Right Amount of Cement and Concrete for Your Project

Properly estimating the amount of cement and concrete required for your construction project is crucial to avoid material wastage, prevent shortages, and ensure that your project proceeds smoothly. Overordering can lead to unnecessary costs, while underordering can cause delays and project disruptions. In this blog, we’ll guide you through the process of calculating the right amount of cement and concrete you’ll need for your project.

At AHM Building Materials LLC, we are committed to providing construction professionals and DIY enthusiasts with the tools and resources they need to succeed. Our extensive range of cement and concrete products, paired with expert guidance, ensures that you have everything you need to make your construction project a success.

Why Accurate Calculations Matter

Construction projects, whether big or small, come with their own set of challenges, and estimating the required materials is one of the most critical aspects. Incorrect calculations can have a significant impact on your budget, project timeline, and overall construction quality. The goal is to ensure you order the correct quantity of materials based on your project’s requirements, reducing waste and avoiding project delays.

Avoiding Cost Overruns

Ordering more cement and concrete than needed may seem harmless, but it can lead to substantial cost overruns. Cement and concrete are significant components of the total project cost, and buying more than you need could tie up funds that could be allocated elsewhere.

Preventing Material Shortages

On the other hand, underestimating the required amount of cement or concrete can result in material shortages, halting work on your project until the next batch arrives. These delays can extend the timeline of your project, leading to increased labor costs and further budget complications.

How to Calculate the Right Amount of Cement and Concrete

Calculating the amount of cement and concrete needed is straightforward once you understand the measurements and quantities involved. Here’s how you can calculate the right amount for your project:

Cement Calculation for Concrete Mixes

Concrete is typically made from a mixture of cement, sand, aggregates (gravel or crushed stone), and water. The ratio of these components can vary depending on the desired strength of the concrete. In most cases, a standard mix ratio of 1:2:3 (1 part cement, 2 parts sand, and 3 parts aggregate) is used for general construction purposes.

To calculate the amount of cement required for your concrete mix:

Step 1: Calculate the volume of the concrete needed (in cubic meters or cubic feet).

Step 2: Determine the mix ratio and the proportion of cement in the mix. For a 1:2:3 mix, the cement represents 1 part of the total 6 parts (1 + 2 + 3).

Step 3: Multiply the volume of concrete by the cement ratio to calculate the amount of cement required.

For example, if you need 10 cubic meters of concrete, the total mix is 1 part cement, 2 parts sand, and 3 parts aggregate, totaling 6 parts. The amount of cement needed would be:Cement required=16×Total concrete volume\text{Cement required} = \frac{1}{6} \times \text{Total concrete volume}Cement required=61×Total concrete volume

For 10 cubic meters of concrete:Cement required=16×10=1.67 cubic meters of cement\text{Cement required} = \frac{1}{6} \times 10 = 1.67 \text{ cubic meters of cement}Cement required=61×10=1.67 cubic meters of cement

Once you have the cement volume in cubic meters, convert it to bags (usually 50 kg per bag). For instance, one cubic meter of cement weighs around 1,500 kg. So for 1.67 cubic meters, you would need approximately:1.67 m3×1500 kgm3÷50 kg/bag=50.1 bags of cement1.67 \text{ m}^3 \times \frac{1500 \text{ kg}}{\text{m}^3} \div 50 \text{ kg/bag} = 50.1 \text{ bags of cement}1.67 m3×m31500 kg÷50 kg/bag=50.1 bags of cement

Concrete Volume Calculation for a Slab, Column, or Beam

Calculating the volume of concrete required for a slab, beam, or column is fairly simple if you have the correct dimensions. Concrete volumes are typically calculated in cubic meters. Here are the basic formulas for different concrete elements:

Slab: Length × Width × Thickness

Beam: Length × Width × Height

Column: Length × Width × Height

For example, if you’re pouring a concrete slab that is 10 meters long, 4 meters wide, and 0.15 meters thick, the volume calculation would be:Volume=10×4×0.15=6 cubic meters of concrete\text{Volume} = 10 \times 4 \times 0.15 = 6 \text{ cubic meters of concrete}Volume=10×4×0.15=6 cubic meters of concrete

Consider Concrete Mix Type

The strength and type of the concrete mix you need may affect the amount of cement required. Standard concrete mixes for general construction typically use a ratio of 1:2:3 (cement:sand:aggregate), but certain projects may require a higher-strength mix, such as a 1:1.5:3 ratio, or even a special mix for foundations or heavy-duty structures.

Incorporate Wastage Allowance

Even with accurate calculations, there’s always a possibility of wastage during the mixing, transportation, and pouring processes. A common practice is to add an allowance of 10-15% to account for wastage.

For example, if you’ve calculated that you need 6 cubic meters of concrete, adding 10% for wastage would result in:6 cubic meters×1.1=6.6 cubic meters of concrete required6 \text{ cubic meters} \times 1.1 = 6.6 \text{ cubic meters of concrete required}6 cubic meters×1.1=6.6 cubic meters of concrete required

How AHM Building Materials Can Help

At AHM Building Materials LLC, we provide expert assistance to help you calculate the correct quantity of cement and concrete for your project. Our team of experts is available to guide you through the process, ensuring you order the right amount of materials based on your project’s specific requirements.

We also offer a comprehensive range of high-quality cement and concrete products, including Ordinary Portland Cement (OPC), Portland Pozzolana Cement (PPC), and ready-mix concrete, all of which come with clear product descriptions and detailed specifications. Our goal is to make sure that you receive the right materials, in the right quantities, to ensure your construction project runs smoothly from start to finish.

Tips to Help You Order the Right Amount of Cement and Concrete

Plan Ahead: Make sure to calculate the required quantity before starting the project. Keep in mind any future stages of construction that will also require cement or concrete.

Consult with Experts: If you’re unsure about your calculations, consult with construction professionals or suppliers like AHM Building Materials, who can help you determine the correct quantities.

Use Concrete Calculators: Many online concrete calculators are available to help you estimate the required volume of concrete for specific projects.

Order in Bulk: If your project requires large quantities of cement or concrete, consider bulk purchasing. Not only can this save you money, but it also ensures you’ll have enough materials to complete the job without delays.

Conclusion

Calculating the right amount of cement and concrete for your construction project is a critical task that can significantly impact your budget, timeline, and overall success. By following the guidelines above, you can make accurate estimates and avoid unnecessary wastage or shortages.

At AHM Building Materials LLC, we are here to support your construction needs by providing high-quality cement and concrete products, expert advice, and exceptional customer service. Whether you are a contractor, builder, or DIY enthusiast, we make sure you get the right materials in the right quantities to bring your project to life. With our reliable delivery service and competitive pricing, you can trust us to be your partner in building success.

0 notes

Text

How to take up perfect the Right Industrial Air Compressor

In industrial operations, efficiency and reliability are essential to success. A well-chosen industrial air compressor can greatly improve productivity while reducing downtime and costs. But how do you choose the right industrial air compressor for your needs? With the various technologies and different types of compressors available, choosing the correct one can be confusing and oftentimes overwhelming. Selecting the perfect industrial air compressor for your application requires careful consideration of several factors. These include the required air pressure, the air volume based on airflow and pressure needs, the level of air quality demanded by your application, energy efficiency requirements, the operating environment, and the intended use in industrial processes. Whether you’re a factory owner, a workshop manager, or involved in heavy-duty applications, understanding these factors will help you get the most out of your investment. Let’s take a look in depth!

What is an industrial air compressor?

An industrial air compressor is a versatile machine that converts power into compressed air, providing energy for various tools, machines, and systems. From powering pneumatic tools to aiding in assembly lines, these compressors are the backbone of many industries. Industrial compressor manufacturers facilitate different types of compressors and sizes, each tailored to specific needs. Understanding their features and benefits is essential for selecting the right one.

A comprehensive guide to choosing the right industrial air compressor

Understand your operational needs

The first step in selecting the perfect industrial air compressor is determining your operational requirements. Ask yourself the following:

What is the intended application? Different tasks require varying levels of compressed air. For example, painting jobs may need steady air pressure, while heavy machinery might require high-flow capabilities.

How much air do you need? Air volume, measured in Cubic Feet per Minute (CFM), determines the compressor’s ability to sustain operations. Calculate the total CFM required by all tools and add a buffer for future needs.

What pressure is necessary? Air pressure, measured in Pounds per Square Inch (PSI), must meet or exceed the requirements of your tools or machines. Industrial applications generally require higher PSI levels.

Types of industrial air compressors

Industrial air compressors come in several types. Choosing the right one depends on your specific use case:

Reciprocating compressors

Ideal for smaller-scale or intermittent applications.

Use pistons to compress air.

Affordable but may require frequent maintenance.

Rotary screw compressors

Best for continuous, high-demand operations.

Use two rotors for air compression.

Low maintenance and energy-efficient.

Centrifugal compressors

Suitable for large-scale industries.

Use impellers for compression, offering high flow rates.

Highly durable but costly upfront.

Consider energy efficiency

Energy costs contribute to the overall expenses of operating an industrial air compressor. Opting for energy-efficient models can help reduce long-term costs.

Variable speed drives (VSDs): Compressors with VSDs adjust motor speed to match air demand, saving energy during low-demand periods.

Energy certifications: Look for certifications that show compliance with energy-saving standards.

Oil-free vs. oil-lubricated compressors

Choosing between oil-free and oil-lubricated compressors depends on the nature of your industry:

Oil-lubricated compressors:

Robust and ideal for heavy-duty tasks.

Require regular oil changes and maintenance.

Commonly used in automotive and manufacturing industries.

Oil-free compressors:

Deliver contaminant-free air, making them essential for food processing, pharmaceuticals, and electronics.

Lower maintenance costs but may have a higher initial investment.

Size and storage capacity

An appropriately sized air compressor ensures optimal performance without unnecessary energy consumption. Consider the following:

Tank size:

Larger tanks are better for applications requiring continuous air supply.

Smaller tanks are suitable for short, periodic tasks.

Space restrictions:

Ensure the compressor fits within your workspace without compromising accessibility for maintenance.

Noise levels and workplace environment

Industrial air compressors can be noisy. If your operations are in a noise-sensitive environment, look for models with sound-dampening features or low-noise ratings. Some industrial compressor manufacturers offer chambers to reduce noise without affecting performance.

Maintenance and availability of air compressor parts

Regular maintenance is essential for the longevity and efficiency of your air compressor. When selecting a model, consider:

Ease of maintenance:

Choose a design with easily available air compressor parts.

Ensure that the industrial compressor manufacturers provide detailed maintenance guides.

Availability of air compressor parts:

Check the local availability of spare parts.

Work with industrial compressor manufacturers that offer strong after-sales support.

Budget and cost calculation

Balancing initial investment with long-term costs is important:

Initial cost: While high-quality compressors may cost more upfront, they often have better efficiency and durability.

Operating costs: Energy consumption, maintenance, and repairs can add to the overall cost.

Warranty and service plans: A comprehensive warranty can protect your investment.

Industry-specific needs

Certain industries have unique requirements for air compressors:

Food and beverage: Oil-free compressors to prevent contamination.

Automotive: High-pressure compressors for spray painting and tire inflation.

Manufacturing: Reliable, continuous-duty compressors to power assembly lines.

Contact with industrial compressor manufacturers

When in doubt, reach out to reputable industrial compressor manufacturers like www.indoair.com. They can provide expert advice, tailored solutions, and meetups to ensure the chosen compressor meets your needs.

Wrapping up:

Choosing the right industrial air compressor is about understanding your needs, evaluating the options, and balancing cost with functionality. By considering factors such as application requirements, energy efficiency, compressor type, and maintenance needs, you can make an informed decision. Partnering with reliable industrial compressor manufacturers ensures you receive a product that enhances productivity and reduces operational challenges. With the right industrial air compressor, your operations will be smoother, more efficient, and ultimately more profitable. Start exploring your options today and invest in a solution that powers your success.

0 notes

Text