#Core Cutter Machine Manufacturer India

Explore tagged Tumblr posts

Text

Save Time & Effort with a Reaper Attachment for Power Weeder

Farming in today’s modern world demands efficiency, precision, and a good deal of ingenuity. For many, the days of back-breaking labour and time-consuming methods are becoming a distant memory, thanks to the innovation of modern agricultural tools.

One such remarkable innovation is the Reaper Attachment for Power Weeder. If you’ve ever dreamed of enhancing your farming productivity while saving time and effort, this attachment could be your golden ticket. Let’s get to know what this tool is all about, how it works, and why it could be the exact thing you’ve been searching for.

What is a Reaper Attachment for Power Weeder?

The Reaper Attachment for Power Weeder is a specialised tool that transforms a standard power weeder into a powerful harvesting machine. This attachment is engineered to cut down crops quickly and efficiently, making the harvest season less of a chore. Suppose you have a piece of equipment that not only clears weeds but also brings in your harvest – this dual-functionality makes the Reaper Attachment invaluable for farmers and agricultural enthusiasts alike.

At its core, this attachment features sharp blades that are optimized for cutting through various types of crops. When mounted on a power weeder, the reaper becomes an all-in-one tool that saves time, reduces labour costs, and increases efficiency. This means you can spend less time in the fields and more time enjoying the fruits of your labour (or investing that time into expanding your agricultural practices).

How Does a Reaper Attachment Work with a Power Weeder?

The operation of a Reaper Attachment for Power Weeder is impressively straightforward. When attached to a power weeder, the reaper utilizes the same engine power that drives the weeding functions. As you guide the power weeder through your field, the attachment engages, and its sharp blades spin rapidly to slice through crops with precision.

Attachment Process:

This crop cutting attachment (katai machine) is designed for easy installation and removal, allowing you to switch between weeding and harvesting seamlessly. Most attachments can be fitted onto different brands of power weeders, ensuring versatility across various farming setups.

Cutting Mechanism:

Reaper Attachment for Power Weeder is a multi-crop harvesting machine that gets power through gears. A double-blade cutter bar is used in it which is capable of harvesting multiple crops including paddy, wheat, gram, and jowar.

Efficient Harvesting:

As you manoeuvre the power weeder, the reaper attachment clears the field in a linear pattern, cutting down crops in one swift motion. This method minimizes the need for manual labour and accelerates the harvesting process, ensuring that you can complete the task in a fraction of the time compared to traditional hand-harvesting methods.

Easy Attachment:

The Reaper Attachment for Power Weeder is very easy to assemble; it can be fitted easily compared to other attachments. Krishitek, being one of the leading reaper attachment manufacturers in India, provides all the attachments necessary to make your farming effortless.

What are the Benefits of Using a Reaper Attachment for Harvesting?

The benefits of using a Reaper Attachment for Power Weeder extend far beyond just saving time and effort. Here are some compelling reasons to consider this innovation:

Time Efficiency: Harvesting is often one of the most time-consuming tasks in farming. The reaper attachment allows you to finish this task swiftly, freeing up your schedule for other essential activities.

Labour Savings: Fewer hands are needed in the field when utilizing this power weeder attachment, which can be especially beneficial in areas facing labour shortages or where hiring additional help isn’t feasible.

Cost-Effective: Although the initial price of reaper attachment for power weeder may seem high, the long-term savings on labour costs and time make it a cost-effective solution for many farmers.

Improved Harvest Quality: The precision of the cutting blades ensures that crops are harvested cleanly and at the right height, improving the quality of your yield.

Versatility: The ability of a power weeder with a reaper function to switch between weeding and harvesting, and cutting multiple crops makes it a versatile tool for any farmer.

What Crops Can I Harvest Using a Reaper Attachment for Power Weeder?

The Reaper Attachment for Power Weeder is a highly versatile tool, making it an essential addition to various farming operations. It allows for efficient harvesting of a wide range of crops, including:

Wheat

Paddy

Millet

Bajra

Jowar

Soybean

Corn

Mustard

Gram

Mug

With the Reaper Attachment for Power Weeder, managing different crops in your fields becomes easier and more efficient, leading to a more productive harvest season.

Is the Reaper Attachment compatible with all power weeders?

The price of a self propelled power reaper in India can vary depending on factors like engine quality, type of mechanism, and overall design. Traditional models with a belt and pulley system might be cheaper, but they are often heavy, harder to operate, and require more maintenance. They also tend to be less efficient in cutting crops.

On the other hand, fully gear-driven power reapers are lighter, more balanced, easier to maintain, and highly efficient, making them a better long-term investment. The quality of the engine is crucial, so always ensure that the reaper you choose has a reliable and durable engine.

How Do I Maintain the Reaper Attachment?

To get the most out of your Reaper Attachment for Power Weeder, regular maintenance is crucial. Here are some tips to keep your attachment in top shape:

Clean After Use: Remove any debris or plant material after each use to prevent buildup that could hinder performance.

Inspect Blades: Regularly check the blades for sharpness and damage. Dull blades can decrease cutting efficiency, so sharpening them when necessary is essential.

Lubricate Moving Parts: Like any machinery, lubrication is key to smooth operation. Ensure all moving parts are properly lubricated according to the manufacturer’s recommendations.

Store Properly: When not in use, store the attachment in a dry place, preferably covered, to protect it from the elements and rust.

Follow Manufacturer Guidelines: Always refer to the manufacturer’s maintenance manual for specific instructions and recommendations to prolong the life of your reaper attachment for farming.

Where Can I Purchase a Reaper Attachment for Power Weeder?

If you’re looking to enhance your farming efficiency with a high-quality Reaper Attachment for Power Weeder, Krishitek is your go-to destination. Renowned as a leading reaper attachment manufacturer in India, Krishitek specializes in producing top-notch reaper attachments tailored to meet the needs of local farmers.

Key Features of Krishitek Reaper Attachment for Power Weeder

Lightweight Reaper Head:

The Krishitek 3 Feet Reaper Attachment boasts a lightweight reaper head design, making it incredibly easy to operate and manoeuvre. This feature is particularly beneficial for reducing operator fatigue and enhancing overall efficiency during crop cutting.

Gear Drive System:

Equipped with a robust gear drive system, our attachment delivers a powerful performance that can tackle even the toughest harvesting tasks. The gear drive ensures reliable operation, allowing you to harvest crops with ease and confidence.

Manufactured in India:

Proudly produced in India, the Krishitek Reaper Attachment for Power Weeder supports local industry while providing a product that meets the specific needs of Indian farmers. With a focus on quality and reliability, our indigenous attachment is designed to withstand the challenges of local farming conditions.

Availability of Spare Parts:

One of the common concerns with agricultural machinery is the availability of spare parts. With the Krishitek, you can rest assured that spare parts are readily available, ensuring minimal downtime.

Investing in a Krishitek Reaper Attachment for Power Weeder is a step towards modernizing your farming operations. With the lightweight design, powerful gear drive, local manufacturing, and easy availability of spare parts, it’s a purchase that promises to deliver efficiency and reliability. Enhance your harvesting experience – get your Krishitek Reaper Attachment today!

Conclusion

In summary, the Reaper Attachment for Power Weeder is an invaluable tool for farmers looking to save time, reduce labour, and boost efficiency. With its ability to handle various crops, ease of use, and dual-functionality, it offers a significant upgrade to traditional farming methods.

Choosing a high-quality Reaper Attachment for Power Weeder like Krishitek ensures powerful performance, durability, and easy maintenance, making it the perfect solution for enhancing your harvesting operations. Upgrade your farming experience today with Krishitek, and see the difference for yourself!

0 notes

Text

Machine Tooling Market - Forecast(2024 - 2030)

Machine Tooling Market Overview

The Machine Tooling Market is estimated to surpass $94.42 billion marks by 2026 growing at an estimated CAGR of more than 3.7% during the forecast period 2021 to 2026. Increasing demand for high efficiency in complex machining products is expected to drive the Machine Tooling Market. Rise in demand for low operating cost and high precision, along with technological advancement in production processes, is further resulting in the popularity of CNC machine tools. Moreover, development and launch of next-gen, cutting-edge machine products and solutions are the central focus areas for key players in this market. These players are continuously investing in R&D to create enhanced and sophisticated offerings to strengthen their portfolio and further entrench their position in the market.

Machine Tooling Market Report Coverage

The report: “Machine Tooling Market– Forecast (2021-2026)”, by IndustryARC covers an in-depth analysis of the following segments of the Machine Tooling Market.

By Type: CNC Machine Tools, Conventional Machine Tools

By Product Type: Metal Cutting Tools (Boring and Drilling, Milling, Finishing, Lathe, Machine Centers and Others), Metal Forming Tools (Rolling, Forging and Press, Extruding and Drawing, Punching and Blanking, Bending, Shearing, Casting and Others) and Special Machine Tools (EDM, EBM, PAM, LBM, USM, ECG, CM and Others)

By Sales Channel: Direct and Indirect

By End User Industry:�� Automotive, Healthcare, Mining and Metal, Aerospace and Defense, Construction, Electrical and Electronics, Energy and Power, Transportation and Others

By Geography - North America (U.S, Canada, Mexico), South America(Brazil, Argentina and others), Europe (Germany, UK, France, Italy, Spain, Russia and Others), APAC(China, Japan India, SK, Aus and Others), and RoW (Middle East and Africa).

Request Sample

Key Takeaways

End users in this market, typically prefer OEMs to provide maintenance support rather than going through a third party. Thus, driving a change in the market model prevalent in this segment.

CNC has various advantages over conventional machines. the various advantages of CNC machines, including high accuracy, safety, time efficiency, flexibility, and low maintenance, is further expected to drive the CNC machine tools market demand.

The core focus areas for leading players in this business are the technical advancement and introduction of next-gen, cutting-edge CNC machine products and solutions. In order to build enhanced and advanced offerings to improve their portfolio and further entrench their position in the industry, these players are actively investing in R&D.

Machine Tooling Market Segment Analysis - By Type

CNC Machine Tools significantly dominate the Machine tool sector accounting for nearly 80% of the market. CNC Machine Tool systems are generally categorised into Milling, Lathe, Drilling, Plasma Cutter, Grinder, Others. The rising demand for high performance in complex machining products is expected to boost the CNC sector. The growth in demand for low running costs and high accuracy, along with technical advances in manufacturing methods, is further contributing to the popularity of CNC machine tools. In addition, the increase in demand across industries particularly in the electronics and automotive sectors contributes positively to the development of the market for CNC machine tools. The core focus areas for leading players in this business are the technical advancement and introduction of next-gen, cutting-edge CNC machine products and solutions. In order to build enhanced and advanced offerings to improve their portfolio and further entrench their position in the industry, these players are actively investing in R&D. Nearly every OEM provides maintenance services to the end users. These end users prefer OEM led maintenance services rather than third parties due to the discounted maintenance services typically offered as well as reliability and improved component procurement policies. This is changing the business model typically utilized in the market.

Inquiry Before Buying

Machine Tooling Market Segment Analysis - By Product Type

The Milling segment held among the highest market share in 2020. Milling machines tools are primarily used in metal grinding processes across a variety of industries. The positive acceleration of the metalworking process industries in the world has ignited the market for milling machines tools. Milling machines tools are extremely flexible and can perform a wide range of functions, such as filling, spinning, chamfering, drilling, gear cutting, and so on. These devices can also render numerous incisions by using multiple cutters.

Moreover, Lathe segment is anticipated to witness significant market growth during the forecast period 2021-2026. Lathe is a tool that rotates every workpiece on its axis in order to execute a wide variety of operations. Automation is the key factor likely to fuel the expansion of the global demand for lathe machines tools. Manufacturers have begun to simplify their manufacturing procedures in order to improve efficiency. The incorporation of the Internet of Things (IoT) into manufacturing (Smart Manufacturing) is one of the latest market trends that will give the business sufficient momentum in the years ahead.

Machine Tooling Market Segment Analysis - By Geography

APAC accounted for the largest share of the Machine tool market. The significant demand from automotive and aerospace sector in China, India and South-East Asia, in particular, is driving market growth. Geographically, RoW (Middle East and Africa) region is anticipated to witness the significant market growth during the forecast period 2021-2026 with a CAGR of 5.22%. The market growth is due to the rising demand of the CNC machine tools from the end-users including automobile, food & beverage, aerospace, construction and others. Growing automotive production primarily in Kuwait, Jordan, and others is projected to boost the market growth. Israel is home to robust mining and manufacturing sector. The country’s manufacturing sector is booming with effective diamond cutting/polishing technologies, aviation and space products, and food processing. These provide promising growth prospects for the machine tool market in the country.

Schedule a Call

Machine Tooling Market Drivers

Rising Adoption of Internet of Things (IoT) Technologies to Fuel Growth

One of the most prominent machine tools market trends is expected to be the increasing uptake of IoT in the manufacturing sector. This will be a result of escalating demand for information and access to information. Furthermore, producers are looking to bring down their production costs, streamline processes, and raise the safety quotient in their units. As a result, there is growing investment in IoT by manufacturers for improved management and control, which is propelling the machine tool market, especially CNC Machine tools. For instance, it is predicted that by 2020, the manufacturing sector will receive an investment of USD 267 billion for IoT integration. Studies have shown that close to 31% of manufacturing operations are already IoT-enabled, which augurs well for this market.

Adoption of CNC Machine Tools in Medical Sector

The medical industry greatly benefits from the efficiency, speed, and accuracy of CNC machining. According to a report by Teton Machine, the number of Americans aged 65 and older is projected to double between 2019 and 2060 95 million. Due to the growth of aging population, the need for precision machining services in the medical industry is growing as well. CNC machines are capable of producing sophisticated surgical instruments, tiny screws and everything in between. In addition medical machined parts for the most complex devices require tight tolerances, which is capable through CNC machine tools. Adding to this, multi-tool and multi-axis machines, such as CNC Swiss turning centers, improve the manufacturing of medical parts with shorter cycle times and owing to the features allowing versatility during production. Moreover several medical equipment manufacturers such as Pulse systems, are focusing on adopting CNC machine tools for advancements in manufacturing. In 2019, Pulse Systems acquired additional CNC (computer numerical control) machine tools to support the company's rapid growth, and has expanded its facilities space to accommodate the newly-added capital equipment. Hence these rising adoption will drive the market growth in the forecast period 2021-2026.

Buy Now

Machine Tooling Market Challenges

High Maintenance Costs and Lack of Training to Hinder Growth of the Market

Generally, CNC machines are costlier than the manually-operated machines. However, with time, the cost is estimated to reduce effectively. Furthermore, to maintain the proper functioning of the machines, regular maintenance of the high-tech pieces is essential by the manufacturers. Apart from this, the focus in the current market is on deploying cheaper machine tools, especially in developing nations. While this saves on initial investment, these machine tools have higher long-term maintenance, parts replacement and other costs, apart from the limited functionality. Besides that appropriate training and machinists need to get acquainted with the professional skills necessary to operate these machines. Hence high maintenance costs and lack of skilled workers will restrict the market growth in the forecast period 2021-2026.

Machine Tooling Market Landscape

Product launches, acquisitions, and R&D activities are key strategies adopted by players in the Machine Tooling Market. Dalian, Amada, JTEKT, Trumpf, Shenyang Machine Tool (SMTCL), Philips Machine Tools, KRC Machine Tool Services, Optimation Technology Inc., Troy Industrial Services, MIC Group and others are considered to be the key players of the Machine Tooling Market.

Acquisitions/Technology Launches/Partnerships

In December 2019, DMG MORI, a leading machine tool manufacturer launched LASERTEC 125 3D hybrid, a new hybrid additive manufacturing system. The LASERTEC 125 is a 5-axis laser deposition welding (LDW) system designed for the maintenance, repair and production of significantly larger parts

IN February 2019, Okuma America Corporation, a world leading builder of CNC machine tools, partnered with Jergens, a superior manufacturer of workholding solutions for machine tools. This partnership was aimed to provide the best possible integrated solutions to the end-user. Such partnerships and Product launches positively impacts the market growth.

#Machine Tooling Market#Machine Tooling Market Share#Machine Tooling Market Size#Machine Tooling Market Forecast#Machine Tooling Market report#Machine Tooling Market Growth

0 notes

Text

Fiber Laser Cutting Machine: The must-have machine for high-efficiency manufacturing capability

In a constantly evolving manufacturing environment, it is necessary to adopt cutting-edge technology to stay ahead of the competition. One such revolutionary tool that has become essential for Fiber Laser Cutting Machine manufacturers in Faridabad, the center of industrial activity, fiber laser cutting machines are transforming the way businesses operate. A leading name in the industry, weldarc India is a state-of-the-art fiber laser welding and cutting solutions provider. In this article, we explore why fiber laser cutters are essential for manufacturers in Faridabad, focusing on their unparalleled benefits and weldarc India's expertise in the field.

The Power of Fiber Laser Cutting Machines

Accuracy and Speed

Fiber laser cutting machines are known for their accuracy and speed. Unlike traditional cutting methods, fiber lasers use a focused beam of light to cut materials with exceptional precision. This precision is crucial for manufacturers in Faridabad, where complex designs and tight tolerances are often required. Whether cutting sheet metal for automotive parts or creating detailed patterns for industrial equipment, fiber laser cutting machines deliver unparalleled results.

The speed at which these machines operate is another game changer. Fiber lasers can cut materials at a significant speed, which significantly reduces production time. Increased efficiency means higher productivity and faster delivery times for manufacturers, allowing them to easily meet tight deadlines and customer requirements.

Versatility

One of the distinguishing features of fiber laser cutting machines is their versatility. They can cut a variety of materials including stainless steel, aluminum, brass, copper, and more. This versatility makes them an ideal choice for manufacturers in Faridabad who often deal with different materials in their production processes. Whether manufacturing parts for the automotive industry, creating components for machinery, or creating complex designs for the electronics industry, fiber laser cutting machines can do it all with precision and ease.

Cost Effectiveness

Investing in a fiber laser cutting machine can result in significant savings in the long run. These machines are very efficient and consume less energy than traditional cutting methods. In addition, their quick operation and low maintenance requirements reduce operating costs. Fiber laser cutting machines offer an excellent return on investment for manufacturers in Faridabad where cost efficiency is key.

weldarc India: A Leader in Fiber Laser Cutting Technology

As a leading fiber laser cutting machine manufacturer in Faridabad, weldarc India is committed to providing cutting-edge solutions to the diverse needs of manufacturers. Our machines are designed with the latest technology to ensure accuracy, speed, and reliability. Here's why weldarc India stands out in the industry:

Cutting Edge Technology

At weldarc India, we use the latest advances in fiber laser technology to produce machines that set new standards in performance. Our fiber laser cutting machine is equipped with high-power laser sources, advanced control systems, and robust construction to ensure smooth and precise cutting results. Our machines enable manufacturers in Faridabad to achieve exceptional quality and efficiency in their manufacturing processes.

Customization and Support

We understand that every manufacturer has unique requirements. That's why we offer solutions adapted to your needs. Whether you need a machine for mass production or specialized cutting applications, weldarc India has the expertise to provide a complete solution. Our team of experts works closely with customers to understand their requirements and provide personalized support throughout the process, from installation to maintenance.

Commitment to Quality

Quality is the core of our business at weldarc India. Our fiber laser cutting machines undergo rigorous testing and quality control to ensure they meet the highest standards of performance and reliability. We are committed to providing machines that not only meet but exceed the expectations of manufacturers in Faridabad. With our focus on quality, you can trust weldarc India with state-of-the-art solutions that drive your business forward.

Wider Impact of Fiber Laser Technology

Laser Welding Equipment Manufacturers in India

Apart from fiber laser cutting machines, weldarc India is also a major player among Laser welding machine manufacturers in India. Our laser welding machines provide precise and efficient welding solutions for various industries. The integration of laser welding technology completes our fiber laser cutting equipment, providing manufacturers in Faridabad with a wide range of advanced tools to meet their manufacturing needs.

Promotes Innovation and Growth

The adoption of fiber laser cutting and welding technology promotes innovation and growth of industries in Faridabad. Manufacturers can improve their skills, improve product quality, and make their operations more efficient. This in turn contributes to the general growth of the industrial sector in the region. The partnership with weldarc India gives manufacturers access to the latest technology and expertise, enabling them to remain competitive in the global market.

Conclusion

Fiber laser cutting machines have become a key tool for manufacturers in Faridabad, offering unmatched accuracy, speed, and versatility. As a leading fiber laser cutting machine manufacturer in Faridabad, weldarc India is committed to providing cutting-edge solutions that drive innovation and growth. Our focus on quality, customization, and support ensures that manufacturers have the tools they need to succeed. By investing in fiber laser cutting technology, manufacturers in Faridabad can streamline their operations and stay ahead of the rapidly evolving industry.

#FiberLaserCuttingMachines#ManufacturingTechnology#IndustrialAutomation#PrecisionCutting#WeldarcIndia#LaserCutting#IndustrialEquipment#FiberLaserCuttingMachinesFaridabad

0 notes

Text

The Purpose of RCC Road-Cutting Machine

RCC road-cutting machines serve a crucial role in construction and road maintenance. These machines are specifically designed to cut through reinforced concrete, providing a precise and efficient method for various applications. Here's an overview of the purpose and functionality of RCC road-cutting machines:

1. Construction and Road Maintenance:

RCC road-cutting machines are extensively used in the construction industry for tasks like creating expansion joints, removing damaged pavement sections, or modifying existing concrete structures. In road maintenance, these machines are vital for repairs and alterations, ensuring the integrity of the road infrastructure.

2. Depth and Precision:

One of the primary features of RCC road-cutting machines is their ability to cut with precision and at specific depths. This is crucial in construction projects where accurate cuts are necessary for the installation of utilities or modifications to existing structures.

3. Versatility:

RCC cutting machines are versatile tools that can handle a range of materials, including reinforced concrete. This versatility makes them suitable for various applications, from cutting through thick pavements to creating fine grooves for specific purposes.

4. Efficiency and Speed:

These machines enhance efficiency and speed in construction projects. The powerful motor and advanced cutting mechanisms allow for quick and effective operations, reducing project timelines and labor costs.

5. Safety:

RCC road-cutting machines are designed with safety features to protect operators and bystanders during operations. This includes features such as blade guards and ergonomic designs, ensuring a safe working environment.

Now, regarding Bharat Saw as the best website to buy RCC cutters in India:

Bharat Saw stands out as a reliable source for RCC cutting machines and related tools. The company offers a diverse range of products, including cutting blades, core bits, and diamond segments. Here's why Bharat Saw is considered a top choice:

1. Product Quality:

Bharat Saw is known for manufacturing high-quality cutting blades and tools. Their RCC cutters are durable and designed to withstand the rigors of construction and roadwork.

2. Variety of Products:

The company provides a comprehensive range of cutting solutions, catering to different project requirements. This variety ensures that customers can find the right tool for their specific needs.

3. Industry Experience:

Bharat Saw, based in Jaipur, Rajasthan, has established itself as a reputable player in the industry. With experience and expertise, they understand the demands of the construction sector.

4. Customer Reviews:

Positive customer reviews and testimonials indicate the satisfaction of buyers with Bharat Saw's products and services.

In conclusion, RCC road-cutting machines play a vital role in construction and road maintenance, offering precision, efficiency, and versatility. Bharat Saw emerges as a reliable choice for procuring quality RCC cutters in India.

0 notes

Link

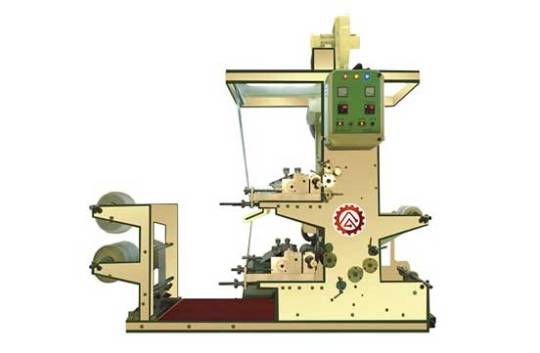

Core Cutter Machine Manufacturer India, Paper Core Cutting Machine, Core Cutter Machine for BOPP Tape Cutting with the desired size up to 1200 mm. User friendly Core Cutting Machine Manufacturers with the accurate cutting system and high-quality knife and cutter blades for long lasting production requirement. This core cutting machine can also be used to set large-diameter anchors and reinforce bars. We are Core Cutter Machine Manufacturer supported by our experienced and skilled professionals that assist us to offer an immaculate paper core cutting machine products.

#Core Cutter Machine#Core Cutter Machine Manufacturer#Core Cutter Machine Manufacturer India#Core Cutting Machine#Core Cutting Machine Manufacturer#Core Cutting Machine Manufacturer India#Paper core cutting machine#Manual core cutting machine#Cutting machine

1 note

·

View note

Photo

We are able to effectively offer a wide range of Paper Core Cutting Machine. Our Paper Core Cutter Machines are user friendly, easy to install and maintain. Automatic Paper Core Cutting Machine manufacturer Also, wide range of different type of core cutter machines, paper core cutter, core cutting for BOPP tape, BOPP tape mini slitting, slitter rewinder machine manufacturer for cello tape with high performance materials manual core cutting machines.

#Paper Core Cutting Machine#Paper Core Cutting Machine Manufacturer#Automatic Paper Core Cutter#Automatic Paper Core Cutter Machine#Core Cutting Machine#Core Cutting Machine Manufacturer#Core Cutter Machine#Core Cutter Machine Manufacturer#Core Cutter Machine Manufacturer India#BOPP Tape Core#BOPP Tape Core cutter machine

0 notes

Link

Door Wrapping Machine Manufacturer, Pallet Wrapping Machine for heavy duty process, Stretch Wrappers, Reel Wrapping, Door Wrap Machine Manufacturer India. Roll Wrapping Machine, Reel Wrapping Machine, Mini Roll Wrapping Machine, Heavy Duty Roll Wrapping Machine, Jumbo Roll Wrapping Machine, Ring Wrapping Machine, Stretch Film Wrapping Machine, Core Cutter Machine, Carton Box Stretch Wrapping Machine. We have designed Door Wrapping Machine to wrap with Heavy duty Rubber Roller for Wrap Machine and flexible packaging machinery.

#Door Wrapping Machine#Door Wrapping Machine Manufacturer#Door Wrap Machine Manufacturer India#Roll Wrapping Machine#Roll Wrapping Machine Manufacturer#roll wrapping#Pallet Wrapping Machine#Pallet Wrap Machine#Heavy Duty Roll Wrapping Machine#Stretch Film Wrapping Machine#Stretch Film Wrap Machine#Core Cutter Machine#Carton Box Stretch Wrapping Machine#Ring Wrapping Machine#Jumbo Roll Wrapping Machine#Reel Wrapping Machine#Mini Roll Wrapping Machine

0 notes

Text

Annular Cutter: For Precision Drilling on Hard Metals

DIC is a leading Annular Cutter Manufacturer in India. It is used in Metal Manufacturing industries, Heavy Industries, and Mechanical processing industries. Annular Cutter is also known as Core Drill, Broach Cutter. Customer satisfaction and quality of tools are our prime focus.

► TCT Annular Cutters

Also called a Core Drill or Broach Cutter. Mainly used in metal manufacturing industries, heavy industries, and mechanical processing industries. These Cutters are specially designed to drill very hard materials. TCT Annular Cutter is a form of Core Drill frequently used to create holes in metal. The multi-cut geometry design of the cutter results in increased chip removal.

► Annular Cutter Set

These Sets contain multiple bits for making holes in various diameters. The Annular Cutter Set in HSS and Carbide in all sizes are available. The Set contains 6 piece sets and 10 piece sets with one pilot pin. DIC Annular Cutters feature unique tooth geometry and provide clean cutting at a fast feed rate.

► TCT Rail Cutters

Specially made for cutting rail tracks, these Rail Cutters are specified to drill the world’s toughest trail track. These Annular Cutters are mainly produced on modern CNC-controlled grinding centres. It is also available in various drill depths to pierce through heavy rail metal grades. TCT Rail Cutters are supplied in various Shank Types and cutting depths.

► HSS Rail Cutters

DIC HSS Rail Cutters are equipped with high-precision Weldon shanks. It is suitable for arbour connectors with two-point perpendicular positioning. These annular cutters are also appropriate for machining fine-grained steels and rustproof materials. This Cutter is made from high-performance power metallurgy high-speed steel. Moreover, it is suitable for all kinds of steel rail drilling machines. HSS Annular Cutter, TCT Annular Cutter, Rail Cutters manufacturers and Suppliers

► TCT Annular Cutters with Weldon Shank

Also called TCT Broach Cutter or TCT core bit, TCT hole saw. It is made from a special Tungsten Carbide that reduces the damage of tips and better endurance. TCT Annular Cutter is available in various cutting depths and shanks depending on their usage. Various Shanks include Weldon Shank, One Touch Shank, Fein Shank and so on.

► TCT Annular Cutter with One Touch Shank

DIC is a Manufacturer & Supplier of TCT Annular Cutter with One Touch Shank in India which cuts holes in the steel accurately and safely. This cutter is made from high-grade Tungsten Tipped Carbide material which is acquired from reliable vendors in the market and provides long-term performance.

► TCT Annular Cutter with Fein Shank

Manufacturer of TCT Annular Cutter with Fein Shank. These Cutters drill holes 3 times faster than twist drills. Fein Shank Annular Cutter is suitable for various materials with high speed.

► TCT Annular Cutters with Thread Shank

It has unique types of geometry and random-space tips. It provides clear-cutting, fast feed rate, less vibration, smooth hole surface. The effectiveness of drilling with thread shank is much better and quicker than the common drills. The cutter diameter is 12mm-100mm.

► TCT Annular Cutters with Universal Shank

Also known as multi-shank or one-touch shank. It is suitable for hole cutting and the process of annular groove on various magnetic drills and press. The Annular Cutters are available in various cutting depths and shanks depending on their use. Various Shanks include Weldon Shank, One Touch Shank, Fein Shank, Threaded Shank and so on. We can supply all these cutters in customized as well as standard forms.

► HSS Annular Cutter

Designed to drill holes on mild to hard steels. These Cutters are more effective for mild steel application. Moreover, it can also be re-sharpened to increase the cutter’s life. For the Excellent performance of the cutters, the fluid should be used to extend cutter life. The Cutter diameter ranges from 12mm to 60mm.

► TIN Coated HSS Annular Cutter

DIC is a Manufacturer of Tin Coated HSS Annular Cutter in India. TIN-Coated HSS Annular cutters are made from HSS in grades M2, M35, M42. TIN Coating is provided on these cutters for longer tool life and efficient usage. These cutters are more effective for mild steel applications and can be re-sharpened also to increase the cutter life.

https://www.mrjourno.com/business/a-comprehensive-guide-to-about-keyway-broaches-1628678420.html

#annularcutter#tct annular cutter#hss annular cutter#annular cutter set#annular cutter for hand drill#high speed steel annular cutter#annular cutter manufacturers#annular cutter suppliers

1 note

·

View note

Link

We have been successfully manufacturing, exporting & supplying all types of Paper Core Cutting Machine like Fully Automatic Paper Core Cutting Machine, Semi-Automatic Paper Core Cutting Machine, Manual Paper Core Cutting Machine, etc. KEW Manufacturers, exports & supplies Paper Core Cutter Machine with high production output & efficient function with more than 2000 installation in place all over India. Specially cutting in different sizes from 12mm to 1000mm. We designed both fully automatic and semi-automatic core cutter machine India.

#Folding Open Machine#Folding Open Machine Manufacturer#Core Cutting Machine#Core Cutting Machine Manufacturer#Core Cutting#Core Cutter Machine#Core Cutter Machine Manufacturer#Core Cutter Machines#Paper Core Cutting Machine#Manual Paper Core Cutting#Manual Paper Core Cutting Machine#Paper Core Cutting#Manual Paper Core#Manual Paper Core Cutter#Manual Paper Core Cutter Machine

1 note

·

View note

Link

Shivshakti Metal is well known leading high quality Duplex Filler Wire, Aluminium Filler Wire, Filler Wire Tig/Mig Stainless Steel, Flux Cored Wire, Mild Steel & Low Alloy Steel Welding Filler Wire, Nickel & High Nickel Alloy Filler Wire, Stainless Steel Rod, Titanium Alloy Filler Wire, Tungsten Rods manufacturers, Suppliers And Exporters Company in Ahmedabad, Bangalore, Chennai, Mumbai, Surat, Vadodara, Gujarat And all over India.

Shivshakti Metal manufactured different Cutting Equipment Manufacturers like Handheld Air Plasma Cutters, CNC Plasma Cutting Tables, Pipe And Tube Cutting Machines, High Definition Plasma Cutting, Structural Steel Fabrication, Shape Cutting Controllers, Retrofit Solutions, Handheld Plasma Torches & Consumables, Mechanized Plasma Torch Consumables also provide Welding Equipment Manufacturers like Mig Welders, Saw Welders, Stick Welders (SMAW), Tig Welders manufacturers, Suppliers And Exporters Company in Ahmedabad, Bangalore, Chennai, Mumbai, Surat, Vadodara, Gujarat And all over India.

Our Products

Duplex Filler Wire Manufacturers Aluminium Filler Wire Manufacturers Filler Wire Tig/Mig Stainless Steel Manufacturers Flux Cored Wire Manufacturers Mild Steel & Low Alloy Steel Welding Filler Wire Manufacturers Nickel & High Nickel Alloy Filler Wire Manufacturers Stainless Steel Rod Manufacturers Titanium Alloy Filler Wire Manufacturers Tungsten Rods Manufacturers

Cutting equipment

Handheld Air Plasma Cutters Manufacturers CNC Plasma Cutting Tables Manufacturers Pipe And Tube Cutting Machines Manufacturers High Definition Plasma Cutting Manufacturers Structural Steel Fabrication Manufacturers Shape Cutting Controllers Manufacturers Retrofit Solutions Manufacturers Handheld Plasma Torches & Consumables Manufacturers Mechanized Plasma Torch Consumables Manufacturers

Welding Equipment

Mig Welders Manufacturers Saw Welders Manufacturers Stick Welders (SMAW) Manufacturers Tig Welders Manufacturers

1 note

·

View note

Photo

KEW India, Core Cutting Machine manufacturer, exporting all type of Paper Core Cutter Machine like automatic and manual core cutters designed accurate cutting machine. A various application like Automatic Core Cutting Machine, BOPP Tape Slitting Machine, Semi Core Cutting Machine, Manual Core Cutter manufacturers, BOPP Tape Cutting Machine. Paper core thickness 12 mm with Semi and Fully Automatic Core Cutting Machine for the packaging industry.

#Core Cutting Machine#Paper Core Cutter Machine#Paper Core Cutting Machine#BOPP Tape Cutting Machine#packaging#manufacturer

3 notes

·

View notes

Text

Construction Machinery Market Analysis, Size, Growth, Competitive Strategies, and Worldwide Demand

Latest Report Available at Advance Market Analytics, “Construction Machinery Market” provides pin-point analysis for changing competitive dynamics and a forward looking perspective on different factors driving or restraining industry growth. The global Construction Machinery- market focuses on encompassing major statistical evidence for the Construction Machinery- industry as it offers our readers a value addition on guiding them in encountering the obstacles surrounding the market. A comprehensive addition of several factors such as global distribution, manufacturers, market size, and market factors that affect the global contributions are reported in the study. In addition the Construction Machinery- study also shifts its attention with an in-depth competitive landscape, defined growth opportunities, market share coupled with product type and applications, key companies responsible for the production, and utilized strategies are also marked. Some key players in the global Construction Machinery- market are Caterpillar Inc. (United States),Komatsu Ltd. (Japan),Xuzhou Construction Machinery Group (China),Sany Heavy Industries (China),Zoomlion (China),CNH Industrial NV (United Kingdom),Deere & Company (United States),JCB India Limited (India),Volvo Group (Sweden),Doosan Infracore (South Korean)

Construction machinery is mechanized equipment that is used to carry out construction tasks. Certain construction machines carry out a set of activities in a specific order to attain a specific goal. Excavating, roading, drilling, pile-driving, reinforcement, roofing, and finishing machinery, concrete-working machinery, and preparatory work machinery are the core groups of construction machinery. Loosening the soil and cleaning the area of bushes, trees, and rocks are all part of the preparation process. Construction machines placed on crawler-tractor chassis, such as rippers, brush cutters, and stump pullers, execute it. These machines typically include interchangeable, mounted equipment that is appropriate for the sort of work being done. Mechanical shovels and multi-bucket excavators, trench diggers, single-bucket loaders, and hydro mechanization equipment are among the machines employed. To compact earth in embankments and materials in roadbeds, vibration rollers and static road rollers with metal rolls and pneumatic tires are utilized.

What's Trending in Market: Growing adoptions of AI-powered machines

Challenges: Lack of harmonized emission regulations globally

Market Growth Drivers: Adoption of advanced construction machinery

Increasing construction and infrastructure investment

The Global Construction Machinery- Market segments and Market Data Break Down by Type (Articulated Dump Truck, Asphalt Finisher, Backhoe Loader, Mini Excavator, Compactor, Road Roller, Other), Application (Commercial, Residential, Infrastructure), Category (Earthmoving, Material Handling, Concrete Mixing and transporting, Heavy Construction Vehicle, Other), Fuel Type (Diesel, CNG/LNG/RNG) Presented By

AMA Research & Media LLP

0 notes

Text

All India Machinery - Plastic Blown Film Extruders, Flexo & Rotogravure Printing Machines Manufacturer, Exporter and Supplier

All India Machinery is a renowned and world-class manufacturer, exporter, and supplier of Plastic Blown Film Extruders, Flexo and Rotogravure Printing machines. The company was established in 2017 and is based in Mumbai and has enjoyed the pinnacle of success in the world of blown film and printing machinery industries. With an experience of over 25 years and expertise in manufacturing lifecycles, sales, integrated marketing, creating events, boosting performance, and enhanced professional consultation, this organization has everything which enables it to have its presence in more than 25 countries including export to Qatar, Bahrain, Kenya, Saudi, Canada, Peru, Morocco, Italy, Mexico, Tanzania etc.

All India Machinery strives to be the largest company of offline and online printing machinery in the world by 2025 with its core values of constant innovation, collaboration, result orientation, honesty, and trustworthiness in place. With all the leadingtechnological know-how, All India machinery has participated in worldwide business meetings on how to increase profitability. Reusing and recycling plastic has been made much easier and the company focuses on total quality control. This superlative performance is because of the state of art manufacturing practices adopted that aim at precision and perfection. The team is a comprehensive one that offers solutions for all the client needs and has the ISO 9001- 2015 certification.

All India Machinery is a one-stop solution for all Blown film extruders and Flexographic and Roto Gravure printing machines with models that give an exemplary performance. The wide range of products with advanced technology enables this company to have a total grip over the market needs. Any impediment in the machinery operation is taken care of and various variants are suggested to cater to the specified needs of clients. An Outstanding bag making system is also guaranteed owing to the years of expertise in the field. We ensure that all our clients get the utmost satisfaction and end-to-end services with the best quality.

The range of Products at All India Machinery includes-

Flexo Printing Machines Flexo printing machines come in various models like the two colors high-speed Flexographic printing machine, the medium Flexo printing machine, and the mini Flexo printing machine. These machines offer a very easy installation and operation with superlative printing results. Flexographic printing machinery offers consistent quality and great durability.

Roto Printing Machines

These models include the online and the inline Roto Gravure Printing Machine, the single and two color floor mounted Roto printing machines which are greatly user-friendly and offer hassle-free operation. Any kind of wastage is reduced and production costs also are significantly curbed. The rotogravure is a cost-efficient printing process and the production speed is exemplary.

Tubing Machines

The long-lasting maintenance-free life offered by the Blown film extrusion machines which come in various mm’s offer tremendous versatility with speed. The output is voluminous depending on the size and gauge of the material and can be used to produce t-shirt bags, garbage bags, carry bags, grocery bags, and much more. The models like ABA Two layer Extruder runs electricity while the Corona treater machine offers a uniform treatment throughout the web width.

Sealing and Cutting Machine

The Bottom Sealing and cutting machine is a microprocessor-controlled one that has its speed synchronized with the stroke and size. There is a side sealing and cutting machine which has a silicon sealing roller driven by servo and has a sealer and cutter logic embedded. They offer a very good sealing effect and is simple to operate. Its efficiency makes it popular and much demanded.

Recycling Machines

The recycling machines include a vertical mixture with dryers and are suitable for light and semi-dense materials. These machines have minimalist power consumption and the high-speed mixers offer the efficiency of batch times of 10 to 15 minutes per batch.

1 note

·

View note

Link

We have been manufacturing, exporting & supplying all types of Paper Core Cutter Machine. Automatic, Manual, Semi-Auto Core Cutter Machine Manufacturer India, a wide range of Core Cutting Machine, Manual Core Cutting Machine, Paper Core Cutter Machine. Paper Core Cutter Machine, Core cutting machine, Paper core cutter for BOPP Tape with International Standards. We are also manufacturer of BOPP tape slitting machine, BOPP Tape Mini Slitting Machine and many more on custom requirement.

#Core Cutter Machine Manufacturer India#Core Cutter Machine Manufacturer#Core Cutter Machine Manufacturers#Core Cutter Machine#Core Cutter Machines#Paper Core Cutting Machine#Paper Core Cutting Machine Manufacturer#BOPP Tape Core#Core Cutting Machine#Core Cutting Machine Manufacturer#Core Cutting Machines#BOPP Tape Cutting Machine#BOPP Slitting Machine#Automatic Core Cutter Machine#Fully Automatic Core Cutter Machine#Semi Automatic Core Cutter Machine#Manual Core Cutter Machine

0 notes