#Automatic Core Cutter Machine

Explore tagged Tumblr posts

Link

KEW ENGG. & MFG. PVT Ltd. Is a leading fully automatic Core Cutter Machine manufacturer, and automatic core cutter machine exporter. Designed and built to use per your requirement in Parent Core Length Range, Core Diameter Range, Wall Thickness, Cut Length Range, Maximum Length, and Cut Length Tolerance. Specially designed with featuring Electrical System Controls, a Stroke Limit, and a Large Core Diameter with accuracy and speed. Fully automatic machine built for Fast, precise, and accurate cuts with the smallest piece possible or per requirements. For more information:

Website: kew.net.in

Email: [email protected]

Contact Us: +91-7940085305

YouTube: https://www.youtube.com/watch?v=U2Qx8AqalAw

#Core Cutter Machine#Core Cutting Machine Price#Automatic Core Cutting Machine Price#Manual Core Cutter#Automatic Core Cutter#Manual Core Cutter Machine#Paper Core Cutter Machine#Paper Core Cutter

1 note

·

View note

Text

So, for Christmas break, I've been staying with a very considerate older couple. When I got here, I found out that they're also...comfortably wealthy. I wish I could have been live-blogging my stay here, but this summary post will have to suffice.

MOSS'S MUSINGS: HOUSEGUEST EDITION.

-Ask which dishes you are allowed to use. I didn't know this would even be a question--I grew up with one set of dishes--but it matters. The dishes we've been using are red with snowmen on them. Tonight I put my soup in a red bowl with Christmas trees around the edge. That was wrong and bad. I have been told that they "prefer I not use that" because it is "for special occasions," and was told to "set it aside so I can hand-wash it." Side note, rich people also own things that can't go in the dishwasher. Thankfully they told me about this ahead of time.

-In general, they make requests when they mean to give you instructions. "I'm having some ladies over tonight, so if you'd like to clean the bathroom, that would be fine." = I, Moss, need to clean the bathroom before I leave for work this morning. They're secret instructions--instructions in a suggestion-shaped suit. I like to think of it as a secret code that I'm very smart for solving. It helps me to not tear my hair out.

-House thing that shook me to the core: They have heat vents on the floors under the sinks! So you can wash your hands or wash dishes and your feets don't get cold!

-Speaking of heat: heated mattress pads exist! It's like a heating pad for your whole body. High settings are nice for muscle aches; low settings are so cozy to sleep on.

-Speaking of mattresses: The guest room has a Sleep Number mattress. I think it's a scam. It's a balloon under your mattress to adjust the firmness/softness. I am 240 lbs. If it isn't over half inflated, my butt's on the bedframe.

-They are weird about trash. All food waste is handled separately and taken straight to the bin in the garage so it doesn't smell. The kitchen trash can lid has a motion sensor. It's automatic. Scared the daylights out of me when I first walked past it to get water at night.

-Speaking of water, ask what water you should use. Tap is not acceptable to some! My hosts have a fridge dispenser. Unfortunately it dispenses cold water. I have worked around this by getting water in advance of my needs and letting it change toward room temp. Also, you can't put drinks on the furniture! Wood is different from the plastic-coated OSB furniture that I grew up with. I must remember now to use coasters because any spills or drips can leave white marks.

-When they start discussing money, try not to let your mouth drop open at the amount of zeroes. One host bought a new car and was bragging to me about how he only paid $28,000, and that was actually $5,000 off for having a certain type of credit card. I just worked the mental math for the discount percentage to keep my brain from exploding. $5k is more than I paid for my entire car. My family motto is "Buy used and drive it 'til the wheels fall off." I did not say so.

-Most importantly, they've been extremely kind and generous to me. They dropped my rent for the month down to almost nothing. They bought any groceries I expressed interest in. I'm going back to campus with some of the best homemade soup of my life, and a coupon for an oil change, and a new appreciation for dark chocolate almonds. When I got here, my hostess had set up a desk for my sewing machine in her sewing room (!! a whole room for sewing!!) and taught me to use a rotary cutter and an iron that's entirely too complex.

tl;dr rich-ish people are super weird about some things you wouldn't expect, and your head will explode a few times, but they're still people and my overall experience has been great.

40 notes

·

View notes

Text

SP Ultraflex’s live demonstration at drupa 2024

Visitors to SP Ultraflex’s stand (hall no-11, stand no D12) at drupa 2024 will witness the live demonstration of the Roboslit Plus series 1000 mpm dual turret slitter rewinder. Expressing his excitement about drupa 2024, Biku Kohli said, “We are always on the lookout for new vendors, experts in their respective fields, to support us in our innovation projects, and drupa is known to host many such vendors.”

Kohli's participation in the show is fueled by his firm belief in the capability of the technologically advanced slitter rewinding machine, and that it will attract vendors for discussions rather than the team of SP Ultraflex seeking them out.

The machine on display has an operational speed of 1000 MPM. It has a fully automatic job set-up that encompasses the positioning of the web guide sensor, cutters, trim extraction nozzles, and rewind cores, effectively minimizing setup time, material consumption, and operator dependency.

According to Kohli, drupa being the largest exhibition in the printing industry, provides an unparalleled opportunity to maximize global exposure while presenting the latest technology. He said, “drupa 2024 will play a vital role in facilitating our company's growth trajectory by providing a platform for strategic engagement, collaboration, and continuous learning within the dynamic landscape of the flexible packaging and converting industry.”

Apart from new inquiries and projects through showcasing, the latest innovations, Kohli expects to strengthen existing relationships with their valued existing customers a drupa 2024.

0 notes

Text

A small paper tube cutting machine is a specialized piece of equipment designed to cut paper tubes or cores into precise lengths. This machine is essential in various industries, including textile, paper, printing, packaging, and more.

Here's a brief overview of its functionality:

Material Loading: The process begins by loading the paper tube or core into the machine. This can be done manually or automatically, depending on the machine model.

Setting the Length: The operator sets the desired length for the cut. Most machines have a digital control panel where you can input the exact measurements, ensuring high precision in every cut.

Cutting Process: The machine uses a sharp, durable blade to cut the paper tube. The cutting can be done either by a rotating blade, a guillotine-style blade, or a saw blade, depending on the machine model and the thickness of the paper tube.

Collection: After the tubes are cut, they are collected in a bin or on a conveyor belt. Some machines also have an automatic sorting feature that separates the tubes based on their sizes.

Quality Control: Many machines come with built-in quality control features that check for any irregularities or defects in the cut tubes.

The Paper Tube Cutting Machine is known for its efficiency, accuracy, and speed, capable of producing large quantities of cut tubes in a short time. It's a valuable asset for businesses looking to streamline their production process and improve productivity. The paper tube machine's robust construction also ensures long-term durability, making it a worthwhile investment.

Adaptable Designs and Customization Options of Paper Tube Cutting Machine

Paper Tube Cutting Machines are not only efficient and precise but also highly adaptable and customizable. They are designed to cater to a wide range of industries and applications, making them a versatile choice for businesses of all sizes. Here’s a look at the adaptable designs and customization options of these machines:

Size and Capacity: Paper Tube Cutting Machines come in various sizes and capacities to accommodate different production needs. Whether you need to cut small paper cores for thermal rolls or large paper tubes for industrial packaging, there’s a machine designed to meet your specific requirements.

Cutting Mechanism: Depending on the thickness and material of the paper tube, you can choose from different cutting mechanisms. These include rotating blades, guillotine-style blades, or saw blades. Some machines even offer interchangeable blades for added flexibility.

Control System: Most paper core machine feature a digital control system that allows you to set the exact length for the cut. Some advanced models may also offer programmable controls, where you can save your settings for future use.

Automation Level: From semi-automatic to fully automatic models, you can choose the level of automation that suits your production process. Fully automatic machines can load, cut, and sort the tubes with minimal human intervention, saving time and labor costs.

Custom Features: Many manufacturers offer custom features to meet unique business needs. These may include special safety features, dust extraction systems, automatic sorting mechanisms, and more.

With these adaptable designs and customization options, Paper Tube Cutting Machines can be tailored to fit your business needs perfectly. They offer a practical and efficient solution to cut paper tubes or cores accurately and quickly, enhancing your production efficiency and profitability.

Advanced Cutting Mechanisms in Our Paper Tube Cutting Machine

Our Paper Tube Cutting Machine stands as a pinnacle of precision and efficiency with its advanced cutting mechanisms. Specifically engineered for cutting paper tubes or cores into exact lengths, this specialized equipment plays a pivotal role across diverse industries. From textiles to paper, printing, and packaging, its versatility meets the demands of varied applications. The machine incorporates cutting-edge technology, ensuring accuracy and reliability in every operation. Whether crafting customized tubes for packaging or contributing to the seamless production processes in printing, our Paper Tube Cutting Machine signifies a commitment to excellence, streamlining workflows and enhancing overall productivity across multiple sectors.

0 notes

Text

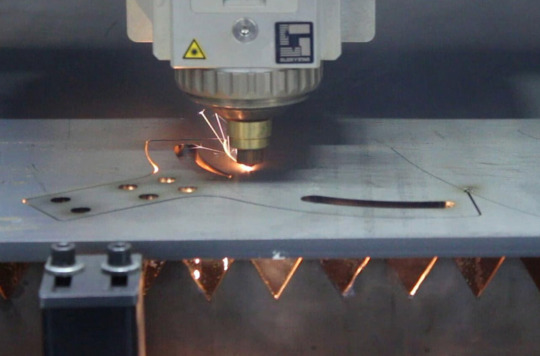

Laser cutting machine - a good helper for cutting pipes

youtube

1. Automatic laser cutting and blanking of metal tubes in full stroke.

According to the technical requirements of full-stroke automatic laser cutting materials for large-length metal pipes, the mechanical structure adopts a unique dual-drive pneumatic chuck rotation mechanism (driving shaft W, driven shaft W1), and the left driving shaft W-axis pneumatic chuck rotation mechanism A unique double-drive pneumatic chuck rotation mechanism is used to realize the axial movement of large-sized metal pipes.

2. CNC cutting process.

CNC cutting is a high-volume, high-efficiency, high-quality cutting production method, and its core is the CNC cutting system. The quality problems existing in the current laser pipe cutting process include: excessive cutting point of parts, high corner, deflection of cutting surface, circular deformation or inability to close, etc., which directly cause serious waste of pipe fittings and low cutting production efficiency.

CNC cutting technology refers to the advanced cutting technology and rich cutting experience provided by the cutting control software of the CNC system, so that the cutter can obtain high-quality and high-efficiency CNC cutting by skillfully using the control system.

3. A complete set of professional material technology.

Laser CNC cutting has high efficiency and complex programming materials. Improper use will waste piping and reduce cutting efficiency. On the computer, the NC cutting program is generated through professional pipe cutting software drawing, package and segment programming to realize full-stroke automatic laser cutting of large-length metal pipes. The special pipe sleeve software is the basis and premise to realize mass production, high efficiency and high quality blanking.

4. Pipe cutting process.

Because of pipe cutting (especially for small square pipes), slag adheres to the pipe wall, and most of the heat generated by cutting is absorbed by the workpiece. When the cutting density is high, the angle of the pipe is often overheated and the four angles of the square pipe are overheated, which seriously affects the cutting quality, and even cannot be cut.

To address these issues:

(1) The laser cutting head has a height sensing follow-up system, which can ensure that the height of the cutting nozzle is consistent with the surface of the workpiece during the cutting process (the focus remains unchanged), so that the cutting effect is not affected by the change of the surface of the workpiece;

(2) The method of increasing the oxygen pressure (6-8Mpa);

(3) Use software to increase the speed of sharp corner synthesis.

0 notes

Text

Japan Silica Coating Market 2023 Comprehensive Strategic Report with "Velox Sand, Wacker Chemie AG, Zeke, KEIM, BEECK"

https://theprose.com/post/713970/europe-carbide-tipped-hole-cutters-market-2029-new-research-reporthttps://theprose.com/post/713971/usa-induction-holding-furnaces-market-leading-countries-landscape-analysis-applicationhttps://theprose.com/post/713973/europe-core-induction-furnaces-market-2023-regions-type-application-2029https://theprose.com/post/713975/usa-protamine-sulfate-injection-market-2023-top-trends-segments-analysis-2029https://theprose.com/post/713977/europe-3d-printers-in-eyewear-market-2023-development-growth-trends-2029https://theprose.com/post/713980/usa-benchtop-torque-testers-market-2023-latest-trends-with-advancementhttps://theprose.com/post/713981/europe-industrial-insulation-resistance-meters-market-is-expected-to-grow-at-an-active-cagrhttps://theprose.com/post/713983/usa-semi-automatic-tube-filling-machines-market-size-2023-shares-growth-cost-structureshttps://theprose.com/post/713985/europe-bluetooth-antennas-market-2023-growth-trends-size-share-2029https://theprose.com/post/713987/usa-iot-antennas-in-electronic-devices-market-share-size-trends-growth-2023-to-2029https://theprose.com/post/713989/europe-rugged-embedded-systems-in-oil-and-gas-market-to-witness-astonishing-growthhttps://theprose.com/post/713991/europe-laboratory-stability-test-chambers-industry-statistics-market-analysis-2029https://theprose.com/post/713993/europe-data-center-security-solutions-market-2023-data-analysis-brief-reviewhttps://theprose.com/post/713995/europe-trawler-yachts-market-2023-projected-industry-growths-to-2029https://theprose.com/post/713997/usa-center-console-boats-market-2023-new-study-report-2029https://theprose.com/post/713999/europe-pontoon-boats-market-future-demand-market-analysis-2029https://theprose.com/post/714001/europe-adventure-boats-market-overview-demand-size-analysis-2029https://theprose.com/post/714003/europe-electric-inflatable-boats-market-2023-new-comprehensive-study-by-key-playershttps://theprose.com/post/714005/europe-mainsails-market-2029-new-research-reporthttps://theprose.com/post/714006/usa-boat-blocks-market-leading-countries-landscape-analysis-applicationhttps://theprose.com/post/714008/europe-boat-ratchet-blocks-market-2023-regions-type-application-2029https://theprose.com/post/714010/usa-boat-winch-handles-market-2023-top-trends-segments-analysis-2029https://theprose.com/post/714018/europe-helm-wheels-market-2023-development-growth-trends-2029https://theprose.com/post/714019/usa-boat-multi-purpose-gps-instruments-market-2023-latest-trends-with-advancementhttps://theprose.com/post/714021/europe-marine-chronometers-market-is-expected-to-grow-at-an-active-cagrhttps://theprose.com/post/714022/usa-water-jet-propulsion-device-market-size-2023-shares-growth-cost-structureshttps://theprose.com/post/714023/europe-boat-stern-tubes-market-2023-growth-trends-size-share-2029https://theprose.com/post/714024/usa-boat-steering-wheels-market-share-size-trends-growth-2023-to-2029https://theprose.com/post/714027/europe-boat-ladders-market-to-witness-astonishing-growthhttps://theprose.com/post/714029/europe-boat-grab-rails-industry-statistics-market-analysis-2029

0 notes

Link

#Semi-Automatic Core Cutter Machine Manufacturer#Semi-Automatic Core Cutter Machine#Automatic Core Cutter Machine#Paper Core Cutter Machine#Core Cutting Machine#Core Cutters

0 notes

Link

#Semi-Automatic Core Cutter Machine#Semi-Automatic Core Cutter Machine Manufacturer#Core Cutter Machine#Automatic Core Cutter Machine

1 note

·

View note

Link

We are able to effectively offer a wide range of Paper Core Cutting Machine. Krishna Engineering Works manufactures, exports & supplies Paper Core Cutter Machine with high production. Our Paper Core Cutter Machines are user friendly, easy to install and maintain. Automatic Core Cutter Machine Manufacturer, a different type of automatic paper core cutting machine, ready in a stock of automatic core cutter machine.

#Automatic Core Cutter Machine#BOPP Tape Cutting Machine#automatic core cutter#automatic core cutting machine#automatic paper core cutting machine#Automatic core cutting machine price#Core Cutter Machine

1 note

·

View note

Link

Krishna Engineering Works behaviour on manufacturing and exporting Fully Automatic Paper Core Cutting Machine. Our machines are designed with wide order of standard for long lasting heavy duty process, specially for cutting in different sizes from 12 mm to 1000 mm. Leading Manufacturer of automatic paper core cutter machine, automatic Paper Core Cutting Machine, pneumatic core paper cutter machine, heavy paper core cutting machine, multiple paper core cutter machine and paper core cutter machine etc.

#Jumbo Core Cutter Machine Manufacturer#Semi-Automatic Paper Core Cutting Machine#Heavy Duty Paper Core Cutting Machine#Manual Paper Core Cutting Machine#Mild Steel Paper Core Cutting Machine#Used Paper Core Cutting Machine#Automatic Paper Core Cutting Machine#Paper Core Cutting Machine Price#Paper Core Cutter#Paper Core Cutting Machine

4 notes

·

View notes

Text

Live at drupa 2024 — SP Ultraflex' Roboslit plus series

At drupa 2024 in Dusseldorf, SP Ultraflex, a specialist in Converting Slitter Rewinders, will conduct a live demonstration of its Roboslit plus series 1000 mpm dual turret slitter rewinder. Biku Kohli, CEO of SP Ultraflex, said, “This model, positioned right at the top of our extensive range, includes a host of features that take output, quality, and operator convenience to the next level within a safe and automated environment that includes end-to-end integrated material handling.”

The machine, which will be on display in hall no-11, stand no D12, has an operational speed of 1000 MPM. It has a fully automatic job set-up that encompasses the positioning of the web guide sensor, cutters, trim extraction nozzles, and rewind cores, effectively minimizing setup time, material consumption, and operator dependency.

Other features include a newly developed low-noise trim extraction system that allows a safer and more comfortable working environment; an automatic off-loader with a secondary pusher that reduces manual effort and enhances workflow efficiency, enabling continuous operation without interruptions; and robust safety features, including an area scanner, doors and guard interlocking, and CCTV cameras to ensure a secure working environment for operators.

Kohli explained the automatic job set-up feature. "It involves the simultaneous alignment of the unwind, cutting, and rewind sections of the machine to the package design through the use of servo-driven pick-and-place mechanisms for the components in the respective sections.” He believes this feature will be one of the key attactions for visitors, who are overwhelmed by the size changes required on their slitter rewinders.

The SP Ultraflex team says the newly designed trim extraction is far more efficient than its predecessor and, as such, can produce the desired suction power at a fraction of the power consumed by a regular trim extraction blower.

Kohli says the printing industry is undergoing rapid and significant changes. In the evolving landscape, he expressed confidence that his team is ready to deliver for converters who demand more efficient solutions with minimal set-up wastage and reduced dependency on operator skills.

He feels drupa 2024 is the largest exhibition in the industry and offers an opportunity to maximize the global exposure of any company. “It will play a vital role in facilitating our company's growth trajectory by providing a platform for strategic engagement, collaboration, and continuous learning within the dynamic landscape of the flexible packaging and converting industry.”

0 notes

Link

KEW ENGG MFG PVT LTD transaction on manufacturing and exporting Core Cutter Machine. An Effective specialized supplier. We are manufactures, exports & supplies Core Cutting Machine for cutting of paper core. Different types of Core Cutting Machine. Automatic Core Cutter used for Bopp tape, even manufacturer of BOPP tape Slitter Rewinder Machine with International Standards. Core Cutter Manufacturer for custom desired size and extent of machine and paper core we are also manufacturer of different type of BOPP Tape Cutting Machine.

#Automatic Core Cutter#Automatic Core Cutting Machine Price#Paper Core Cutter Machine#Paper Core Cutting Machine Price#Paper Core Cutter#Manual Paper Core Cutting Machine#Automatic Paper Core Cutting Machine#Core Cutting Machine#Mild Steel Paper Core Cutting Machine#Industrial Core Cutting Machine#Semi-Automatic Core Cutting Machine#BOPP Tape Paper Core Cutting Machine

1 note

·

View note

Link

Exclusive Core Cutter Machine Manufacturer India with International Standards, Paper Core Cutting Machine, Heavy Duty Fully Automatic Core Cutter Machine ready in stock. Manufacturer of Paper Core Cutter Machine - Automatic Paper Core Cutter Machine, Automatic Paper Core Cutting Machine, Pneumatic Core Paper Cutter. Convertors are in constant need of different type of cores according to the size of prints or slitted material. KEW Make Core Cutting Machine Serves this purpose.. Compact body, easily movable, safety guards for cutter & movable parts. Drive chrome plated spindle, maximum length 400 mm. Maintenance & hassle free, easy cantilevered operation, perfect cut Edges. Single knife speedy production. Technical Information is. Maximum width of cut : 450 mm. Minimum width of cut : 12 mm.Paper core inside diameter : 76 mm.Paper core thickness : 12 mm.Round Blade Diameter : 150 mm.Electric Motor : - H.P. A.C.

#Paper Core Cutting Machine#Core Cutter Machine Manufacturer#Core Cutter Machine#Core Cutting Machine#Automatic Paper Core Cutting#Flexible Packaging Machinery#Tyre Cord Machinery#Technical Textiles Machinery#plastic Cutter Machine#semi-automatic Core Cutter#Slitter Cutter Machine.

0 notes

Link

KEW ENGG. & MFG. PVT Ltd. manufacturer and exporter of Manual Core Cutter Machine. Ability to cut both cardboard and plastic cores with accurate and quality. Core Cutters are Easy to change-over for multiple core diameters and many more features in Manual Paper Core Cutting Machine. Our team of diligent engineers, technicians and designers strive to achieve excellence in size, dimensions, blade diameter, motor, etc. It is best Manual Core Cutter Machine in its class.

#Manual Core Cutter Machine#Manual Core Cutter#Manual Core Cutting Machine#Core Cutter Machine#Core Cutting Machine Price#Automatic Core Cutting Machine#Automatic Core Cutter#Automatic Core Cutter Machine#Accurate Manual Core Cutting Machine#Manual Paper Core Cutter Machine#Semi-Automatic Core Cutting Machines#Semi-Automatic Paper Core Cutting Machine

1 note

·

View note

Link

We are Manufacturer, Exporter & Supplier all types of Core Cutting Machine from the following type of Core Cutter Machines, Fully Automatic Core Cutter Machine, Paper Core Cutting Machine, Semi-Automatic Core Cutting Machine, Manual Core Cutter Machine, BOPP Tape Cutting Machine, BOPP Tape Slitting Machine, Core Cutter Machine, Heavy Duty Paper Core Cutting, Automatic Cardboard Core Cutter, BOPP Tape Cutting, Manual Core Cutter, Paper Core Cutter, all Client’s Requirement.

#Core Cutting Machine#Core Cutting Machine Manufacturer#Core Cutter Machine#Core Cutter Machine Manufacturer#Fully Automatic Core Cutter Machine#Fully Automatic Core Cutter#Paper Core Cutting Machine#Paper Core Cutting#Semi-Automatic Core Cutting Machine#Semi-Automatic Core Cutting#Manual Core Cutter Machine#Manual Core Cutter#BOPP Tape Cutting Machine#BOPP Tape Cutting#Tape Cutting Machine

0 notes

Link

We are leading manufacturers of Automatic Core Cutter Machine. Leading Manufacturer of Automatic Core Cutter Machine, automatic paper core cutting machine, pneumatic core paper cutter machine, heavy paper core cutting machine, multiple paper core cutter machine and paper core cutter machine. For more information visit our website: krishnaengineeringworks.com or Contact us: [email protected]

#Automatic Core Cutter Machine#BOPP Tape Cutting Machine#Automatic Paper Core Cutter Machine#Automatic Paper Core Cutting Machine#Pneumatic Core Paper Cutter Machine#Heavy Paper Core Cutting Machine#Multiple Paper Core Cutter Machine#Paper Core Cutter Machine#Fully Automatic Core Cutter Machine#Pneumatic Core Cutter Machine#Air Pneumatic Core Cutting Machine#Semi-Automatic Paper Core Cutting Machine#Paper Core Cutting Machine#Manual Core Cutter Machine

1 note

·

View note