#Copper Parts Manufacturers in India

Explore tagged Tumblr posts

Text

Top 8 Copper Parts Manufacturers in India

This Comprehensive Blog Delves Into the Crucial Role of Copper Parts Within India’s Industrial Sector, Showcasing Their Importance Across Various Industries Thanks to Their Exceptional Properties Like Conductivity and Corrosion Resistance. Highlighting the Top Manufacturers in India Such as Meck Industries, Hindustan Copper Limited, Bhagyanagar India Limited, Madhav Copper, Rajnandini Metal, Sterlite Copper, Gujarat Copper Alloy Ltd., and Kavya Metal, It Emphasizes Their Dedication to Precision Manufacturing and Superior Quality. With Insights Into Sustainability and Customization Options, This Guide Provides Valuable Information for Businesses Seeking Top-Notch Copper Components. Dive Deeper Into the Article for A Thorough Analysis and To Learn, How These Leading Manufacturers Are Shaping India’s Copper Industry.

Read More:��Top 8 Copper Parts Manufacturers in India

#Copper Parts Manufacturers in India#Copper Components Manufacturers in India#Top Copper Parts Manufacturers in India#Best Copper Parts Manufacturers in India#Top Copper Components Manufacturers in India#Best Copper Components Manufacturers in India

0 notes

Text

Top Brass Components Manufacturer in India

In today’s fast-evolving industrial landscape, innovation is key to staying ahead. One material that continues to play a crucial role in various sectors is brass. Known for its remarkable adaptability, durability, and resistance to corrosion, brass components are integral to modern industrial systems. From automotive and electrical to plumbing and machinery, brass is at the heart of many innovations. Among the leading manufacturers in this domain, Atlas Metal, based in Jamnagar, stands out as a pioneer in providing top-quality brass parts.

The Unique Properties of Brass

Brass, an alloy primarily composed of copper and zinc, is renowned for its versatility and performance. One of its most notable properties is its resistance to corrosion, making it ideal for use in environments exposed to moisture or chemicals. This characteristic is crucial for components used in plumbing, marine applications, and outdoor machinery, where exposure to elements is inevitable.

Additionally, brass possesses excellent thermal and electrical conductivity, making it a preferred material in the electrical and electronics industries. Its malleability allows for easy machining into precise components, while its inherent durability ensures longevity, even in demanding applications.

The ability of brass to withstand extreme temperatures without losing structural integrity further enhances its use in industries that rely on heavy-duty machinery and equipment. These unique properties have positioned brass as a key driver in numerous industrial innovations.

Brass Components Across Industries

Brass components find wide applications in several key industries:

Automotive Industry: Brass is commonly used in the production of engine parts, gears, and fuel connectors. Its resistance to heat and corrosion makes it ideal for ensuring the durability of these critical components.

Electrical and Electronics: Brass is widely used in earthing accessories, electrical connectors, terminals, and switchgear due to its superior conductivity and malleability, ensuring precision and reliability in complex electrical systems.

Plumbing and Sanitary Applications: Brass fittings, valves, and pipes are the backbone of modern plumbing systems. Its corrosion resistance ensures that brass parts last longer in both residential and industrial water systems.

Machinery and Heavy Equipment: Brass bushings, bearings, and fasteners are integral to many mechanical systems due to their durability and resistance to wear and tear.

Atlas Metal: A Leader in Brass Manufacturing

In Jamnagar, a city widely known as the brass manufacturing hub of India, Atlas Metal has carved a niche for itself as a leader in the production of high-quality brass components. With a focus on precision engineering, Atlas Metal offers a wide range of brass parts tailored to the specific needs of various industries.

The company’s commitment to innovation and quality is reflected in its use of advanced technology and stringent quality control processes. Atlas Metal produces everything from brass nuts, bolts, and fasteners to specialized fittings, terminals, and connectors that meet the demands of today’s high-performance industries.

What sets Atlas Metal apart is its emphasis on customization. Understanding that different industries require unique specifications, Atlas Metal works closely with its clients to deliver components that perfectly match their requirements, ensuring optimal performance and efficiency.

Why Choose Atlas Metal?

Quality Assurance: Atlas Metal places a high priority on quality control, ensuring that every component meets international standards.

Expertise and Experience: With years of experience in the brass manufacturing industry, Atlas Metal brings expertise and innovation to every project.

Advanced Manufacturing Techniques: The company uses cutting-edge technology to deliver precision-engineered parts.

Global Reach: Atlas Metal exports its products to clients worldwide, reflecting its reliability and reputation in the global market.

Conclusion

Brass components are indispensable to many industries, driving innovation with their versatility and durability. Atlas Metal, a leading brass parts manufacturer in Jamnagar, has been at the forefront of providing high-quality, precision-engineered components for global markets. With a commitment to quality, innovation, and customer satisfaction, Atlas Metal continues to be a trusted partner for industries seeking reliable brass solutions.

#brass parts manufacturer in Jamnagar#brass fitting manufacturers in india#pipe fittings manufacturers in india#brass conduit fittings in india#cable tie manufacturer in india#cable gland manufacturers in india#lugs manufacturers in india#cable lugs manufacturers in india#copper lugs manufacturers in india

1 note

·

View note

Text

where are 2 feet Narmadeshwar Shivling Found?

Narmadeshwar Shivling refers to a particular type of Shivling, a sacred symbol representing the Hindu deity Lord Shiva, sourced from the Narmada River in India. The Narmada River, considered one of the seven holy rivers in Hinduism, flows through the central part of India. The stones used to make these Shivlings are naturally occurring and typically found in the riverbed. Devotees believe that these Shivlings possess special spiritual significance and are considered highly auspicious for worship. They are often used in temples and homes for rituals and prayers dedicated to Lord Shiva.

In Hinduism, Shivling can be classified into various types based on their materials, shapes, and locations. Here are some common types:

Spatalinga: These are naturally occurring Shivlings found in the riverbeds, particularly in the Narmada River. Spatalingas are shaped by the flow of water and are considered highly propitious.

Parthiv Linga: Parthiv Lingas are made of clay or mud. They are often used in rituals and ceremonies, especially during festivals or when a temporary representation of Lord Shiva is needed.

Narmadeshwar Linga: Narmadeshwar Lingas are specifically sourced from the Narmada River. They are believed to possess special spiritual significance and are highly revered by devotees.

Sphatika Linga: Sphatika Lingas are made of quartz crystal. They are considered highly propitious and are believed to radiate positive energy. Sphatika Linga is often used in meditation and healing practices.

Banalinga: Banalingas are made of stone, typically carved from a single stone. They come in various shapes and sizes and are worshipped in temples and homes.

Ashtadhatu Linga: Ashtadhatu Lingas are made of eight metals, including gold, silver, copper, zinc, lead, tin, iron, and mercury. They are believed to possess unique spiritual properties.

Panchaloha Linga: Panchaloha Lingas are made of a blend of five metals, typically gold, silver, copper, iron, and zinc. They are considered auspicious and are used for worship and rituals.

Jyotirlinga: Jyotirlingas are a set of twelve sacred Linga spread across India, each representing a different manifestation of Lord Shiva. They are considered highly auspicious pilgrimage sites and are worshipped fervently by devotees.

The most famous size of Shivling is: 2 Feet Narmadeshwar Shivling

A 2 feet Narmadeshwar Shivling refers to a Shivling sourced from the Narmada River in India that measures approximately two feet (24 inches) in height. Narmadeshwar Shivlings are naturally occurring stones found in the riverbed of the Narmada River and are considered highly sacred in Hinduism.

A Shivling of this size, made from Narmadeshwar stone, would be quite substantial and would be likely to be used as a central object of worship in temples or sacred spaces. Devotees believe that Narmadeshwar Shivlings possess special spiritual significance and are revered for their connection to Lord Shiva.

Such large Narmadeshwar Shivlings are often the focus of elaborate rituals, prayers, and ceremonies, where devotees offer various sacred items such as water, milk, honey, and flowers as offerings. They are symbols of divine presence and are believed to radiate positive energy and strengthen the spiritual growth and well-being of those who worship them.

Manufacturer Websites:

Local spiritual or religious stores may carry Narmadeshwar Shivlings of various sizes. Visit them to inspect the stones in person and inquire about pricing. Some manufacturers or distributors sell 2 feet Narmadeshwar Shivlings directly to consumers through their websites. Check for pricing and shipping information on their platforms.

#narmada shivling#narmadeshwar shivling original#narmadeshwar shivling for home#narmadeshwar shivling online

2 notes

·

View notes

Text

Excellence in Non-Ferrous Forging & Casting in India

Non-ferrous forging and casting have emerged as critical processes in the manufacturing landscape, contributing significantly to India's industrial prowess. With a focus on metals like aluminum, copper, brass, and bronze, the country's expertise in non-ferrous forging and casting has reached new heights. Let's explore the excellence that India brings to these essential metallurgical processes.

Non-ferrous forging in India is marked by precision and skill, as manufacturers leverage advanced techniques to shape metals into components with superior mechanical properties. The forging process involves applying heat and pressure to mold metals into desired forms, enhancing their strength and durability. Indian forging facilities are equipped with state-of-the-art technology, ensuring the production of high-quality components that meet international standards.

Casting, another integral part of non-ferrous metal processing, is equally impressive in India. Foundries across the country use advanced casting methods to create intricate and complex shapes from molten non-ferrous metals. The attention to detail in the casting process is evident in the precision components that are vital to various industries.

Industries such as automotive, aerospace, and electronics in India benefit significantly from the excellence in non-ferrous forging and casting. The automotive sector, for instance, relies on these processes for manufacturing engine components, transmission parts, and lightweight structural elements. The use of non-ferrous metals contributes to fuel efficiency and sustainability, aligning with global trends.

In the aerospace industry, where precision and reliability are paramount, non-ferrous forging and casting play a crucial role. Components like aircraft engine parts and structural elements are crafted with meticulous attention to detail, ensuring the highest standards of performance and safety.

The electronics industry in India also reaps the rewards of non-ferrous forging and casting. The superior thermal conductivity of non-ferrous metals makes them ideal for applications such as heat sinks and connectors. The corrosion resistance of these metals ensures the longevity of electronic components in various environments.

As India continues to position itself as a global manufacturing hub, the excellence in non-ferrous forging and casting becomes a cornerstone of its industrial success. The commitment to quality, technological advancement, and sustainability places India at the forefront of non-ferrous metallurgy, contributing to the growth and competitiveness of its industries on the world stage. The journey of excellence in non-ferrous forging and casting in India is undoubtedly a testament to the nation's capabilities in shaping the future of manufacturing.

2 notes

·

View notes

Text

HOW NEHRU CAN TRULY BE CALLED 'THE ARCHITECT OF INDIA'S BIMARU ECONOMIC STRUCTURE'. ................................................................................. - HOW NEHRU INCOMPETENTLY, & PER MANY HISTORIANS, MALICIOUSLY, RUINED EASTERN INDIAN ECONOMIES, LIKE BENGAL, BIHAR, JHARKHAND, MADHYA PRADESH, CHHATTISGARH, & ORISSA, BY HIS ONE SIDED (SUBSIDIZED/EQUALIZED FREIGHT COST OF RAW MATERIAL ONLY & NOT FOR FINISHED GOODS) FREIGHT EQUALIZATION POLICY. - HOW NEHRU IN THE GARB OF A SOCIALIST INDIA, MANAGED TO CREATED A REGRESSIVELY CAPITALISTIC INDIA INSTEAD.

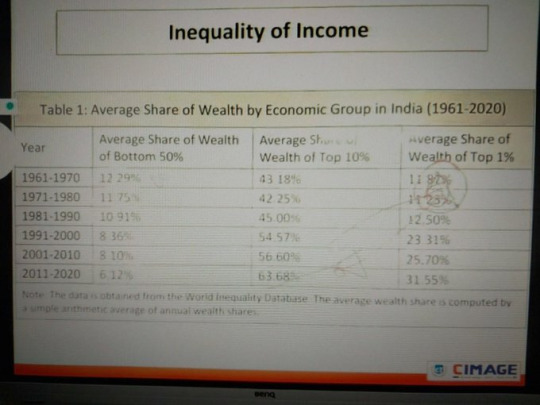

Here are India's 60 yr Share of Wealth stats, from 1961-2020, taken from the 'World Inequality Database'.

Looking at which, most would be forced to ask, why is it that in a wholly socialized state like India (& heavily publicized so at that for 60 yrs)....that our Top 1% 's share in wealth goes up 3 times, Top 10%'s share goes up 1.5 times, BUT SHARE OF THE BOTTOM 50% IS LITERALLY HALVED?

The answer to this lies largely in one man, Nehru, & his policies, either incompetently unintentional or maliciously intentional, policies directly responsible for creating a deeply disparate & heavily lopsided yet overall non-flourishing economic structure, for the entire first half century of the 'Dominion (of Britain) India'.

And the biggest mishap-causing misadventure, being 1951's infamous FREIGHT EQUALIZATION POLICY.

👇

https://en.wikipedia.org/wiki/Freight_equalisation_policy#:~:text=Freight%20equalisation%20policy%20was%20adopted,subsidised%20by%20the%20central%20government.

☝

Above is the Russian Govt+military reaction, to Indian 'independence' in mid 1947. This article was published in the Russian central military newspaper 'Red Star' on July 31, 1947, just 2 weeks before the official date of India's so-called Independence.

"Chief economic positions still remain in British hands–railways,marine transport,port economy,irrigation systems,finance,basic part of jute,industry,almost whole mining industry etc"

“The defence of economic positions and interests is not possible without political power. That power will be secured in the person of the capitalists, landowners and businessmen who are dependent upon British capital.”

“The partition, does not affect the feudal power of the Princes who have always supported British domination.”

"The British Govt plans to artificially separate industrial from agricultural areas,turning it to a agrarian & raw material appendage of Britain."

Exactly what Nehru's Freight Equalization Policy achieved 4 yrs later!

And to add to what y'all I assume would already have read from above, as to it's evil designs & effects, it created a reverse-reward scenario, whereby all the resource-rich states were essentially penalized for their natural advantages, by taking away all incentive for processing-industries & final transportation industries, that are a logical next step from the extraction industries, to germinate & set base in these places. Thereby creating a scenario where the South-western & western coastal states like Maharashtra, Gujarat & Tamil Nadu, & parts of Punjab in North India, were able to find logical easy base for all the processing & transportation industries in their states, for industries like steel, cement, heavy manufacturing, & power, all enabled via raw materials from the other far-off states, like iron ore, coal, limestone, bauxite, copper etc, even w/o any personal natural resources to rely on themselves, merely by virtue of being easy locations to set up ports in for exports, & w/o industries having to compromise on higher transportation & value-added processing costs, that cost aspect equalized & protected for all distances from the resource point. All this, with resource states not finding even some respite in terms of return benefits from any possibly subsidized finished product costs, finished goods not covered by this policy!

These 4-5 states effectively thus became the parasites, for atleast 7 of the traditionally god-gifted states of today like Bihar, Jharkhand, Madhya Pradesh, Chhattisgarh, Orissa, Bengal & Uttar Pradesh, killing all their hope at industrial development & economic progress, & where there is economic (or lotsa times attached) spiritual hopelessness, springs leftism in all it's devious forms, giving birth to intense communism & it's shameful offsprings of caste-divide & gang-culture, literally turning these states HOUSING HALF OF INDIA'S POPULATION, into the pot-holes of the Indian Union -the BIMARU (for Bihar, Madhya Pradesh, Rajasthan, Uttar Pradesh) states of India.

Now in all of this, it's not as if the above-mentioned coastal states were turning themselves into heavens of prosperity either, merely relatively well-off & with a hopeful disposition of the future, that in itself enough to attract large-scale migration from the above BIMARU states, particularly Maharashtra with a more traditionally Hindi-friendly ambience, but also in TN, creating a new urban housing problem, giving birth anew to Mumbai's infamously gargantuan chawl (dingy hutment) lifestyle.

And the reasons for these states, given all these special privileges, not able to take off well enough, aren't directly visible, yet that we can now, on basis of our analysis of Nehru & his so-called Independent India, over innumerable blogs prior, safely interpret, to be an India yet functioning in 1950s & till mid-1960s as some sort of a vassal state of Britain. Only natural then for a supreme state in such a relationship, to not be assumed to desire nations other than itself any sorta economic or strategic base in it's territory, thus curtailing more robust foreign economic to-and-fro.

A utterly class-subservient bent, not seen just for the British race, but per historians, eg Kanchan Gupta, in his hateful sense of complex & hatred of dark-skinned & skinny Bengali community, even worse passionate Hindu Durga-lovers, & per many, all largely borne of his hatred for Bose.

And thus ends yet another inglorious chapter from the life of the self-confessed Last British Ruler of India.

The Tale of the Internal Destruction of India, & it's Premier at it.

2 notes

·

View notes

Text

What is African wax print fabric?

African wax print fabric is a 100% cotton fabric most popular in West African countries, including. Nigeria, Ghana, Senegal, Gambia, Kenya and Tanzania.

History

African wax print fabric has its roots in Indonesian batik, which was brought to Africa by Dutch traders in the 19th century. The designs were initially produced in Holland and exported to the Dutch colonies in Indonesia, but were eventually brought to West Africa where they became popular.

In the early 20th century, European textile manufacturers began producing the fabric in Europe and exporting it to Africa. However, the fabric was not widely accepted by Africans until it was adapted to suit local tastes and needs. African entrepreneurs, particularly in Ghana and Nigeria, began producing their own versions of the fabric, incorporating local designs and motifs.

Today, the fabric is produced and worn throughout Africa, and has become an important part of African fashion. It is used to make traditional clothing such as dresses, skirts, and head wraps, as well as modern clothing such as shirts, pants, and even shoes.

BASIC STEPS IN AFRICAN WAX PRINT FABRIC PRODUCTION

1. Preparation

2. Raw cotton fibres

3. Spinning the cotton to make yarn

4. Using the yarn to produce grey cloth

- Design

- Wax Printing

- Indigo Dyeing

- Crackling Effect

- Colouration

- Washing

- Finishing

Production

African wax print fabric is produced through a process called wax-resist dyeing. The fabric is first washed and bleached, then a wax design is stamped or printed onto the fabric using a copper stamp or roller. The fabric is then dyed, and the wax is removed, leaving a design that is resistant to the dye. This process can be repeated multiple times to create intricate and colorful designs.

Symbolism

African wax print fabric has a rich symbolic meaning in African culture. The patterns and colors used in the fabric often have specific meanings related to cultural traditions, spirituality, and social status. For example, some patterns may be associated with specific tribes or regions, while others may be worn for special occasions such as weddings or funerals.

The fabric has also become a symbol of African identity and resistance, particularly during the colonial era. It was often worn as a symbol of African pride and cultural independence, and was even used as a form of protest against colonial rule.

Conclusion

African wax print fabric is a beautiful and important part of African culture and fashion. Its complex history and rich symbolism make it a fascinating subject of study, and its vibrant colors and designs make it a popular choice for clothing and accessories. Whether worn as a traditional garment or incorporated into modern styles, African wax print fabric in Rajkot, Gujarat will continue to be a symbol of African culture and identity for generations to come.

For more:

Where Can I Get Authentic African Fabric Supplier In India?

Why You Should Pay Attention To African Printed Fabric?

African Fabric Supplier In Zambia

1 note

·

View note

Text

India’s Top-Quality Shim Manufacturers- United Stainless LLP

United Stainless LLP stands-out as one of the best quality Shim Manufacturers in India. There are several grades, forms, sizes, and standards available for our Shims. Indian shim makers are crucial to the ability to supply high-quality shims to a range of industries, including equipment, construction, automotive, and manufacturing. Shim Manufacturers are tiny, expertly crafted parts used to seal gaps or crevices between parts to guarantee that machinery is stable, balanced, and aligned correctly.

Shim suppliers in India provide a wide range of shims for different uses, including bespoke shims to meet specific needs. These manufacturers use advanced technology and premium-grade materials such as stainless steel, brass, copper, and aluminum to produce shims that meet industry standards. We also provide Stainless Steel Sheet Manufacturers in India

The presence of reliable Shim Suppliers in India guarantees that businesses can obtain high-quality parts that enhance production and efficiency. India is a major global center for the manufacturing and supply of shims because Indian manufacturers have established a solid reputation for providing long-lasting, accurate, and reasonably priced solutions.Visit our website to learn more in-depth information: unitedstainlessllp.com

#Shim Manufacturers in India#Shim Suppliers in India#shim manufacturers#Shim suppliers#Stainless Steel Sheet Manufacturers in India

0 notes

Text

Round Bars: Applications, Advantages, and Types

Nova Steel Corporation is a significant Round Bar manufacturer in India. We specialize in producing high-quality round bars that meet industrial specifications. These Round Bars are available in a variety of sizes, forms, and dimensions, and may also be customized to meet our clients' exact needs. Our high-quality Round Bars are specifically designed for steel manufacturing facilities, the petrochemical industry, fire prevention systems, synthetic enterprises, shipping and delivery organizations, and so on. As a leading round bar manufacturer in India, we offer a wide range of round bar solutions to fulfill a variety of requirements.

What Are Round Bars?

Round bars are solid cylindrical rods made from various materials, primarily metals. They are produced through different processes, including hot rolling, cold rolling, or forging, depending on the material and the intended application. These bars are available in a wide range of diameters and lengths, making them suitable for diverse industrial and commercial purposes.

Types of Round Bars

Stainless Steel Round Bars: These are known for their corrosion resistance, strength, and aesthetic appeal. They are widely used in industries like construction, marine, and food processing.

Mild Steel Round Bars: These are cost-effective and have good machinability, making them ideal for applications requiring moderate strength and flexibility.

Aluminum Round Bars: Lightweight and corrosion-resistant, aluminum round bars are commonly used in aerospace, automotive, and construction industries.

Copper Round Bars: Copper bars are prized for their excellent electrical and thermal conductivity, making them indispensable in electrical applications.

Brass Round Bars: With their combination of strength, machinability, and corrosion resistance, brass bars are often used in plumbing, fittings, and decorative applications.

We are Round Bars Supplier In:

Round Bars Supplier in Hyderabad

Round Bars Supplier in Bangalore

Round Bars Supplier in Chennai

Round Bars Supplier in Mumbai

Round Bars Supplier in Gujarat

Applications of Round Bars

Round bars find extensive use across various sectors due to their adaptability. Some of the most common applications include:

Construction: Round bars are frequently used as structural reinforcements in buildings and infrastructure projects. They are also employed in the creation of metal frameworks, railings, and fencing.

Machinery and Equipment: These bars are vital in the manufacturing of shafts, fasteners, and gears, offering the necessary strength and precision for mechanical components.

Automotive Industry: Round bars are used in the production of axles, crankshafts, and other critical automotive parts, ensuring performance and durability.

Aerospace Industry: Lightweight materials like aluminum round bars are crucial for aerospace applications, providing strength without adding excessive weight.

Electrical Industry: Copper round bars are essential for creating efficient electrical systems, including wiring, busbars, and connectors.

Decorative and Artistic Use: Brass and stainless steel round bars are often used in crafting ornamental designs, furniture, and other decorative elements.

Benefits of Using Round Bars

Versatility: Available in various materials and sizes, round bars can be tailored to meet specific needs, making them suitable for an array of industries.

Strength and Durability: Metal round bars provide excellent strength and resistance to wear and tear, ensuring longevity in demanding applications.

Ease of Fabrication: Round bars are easy to machine, weld, and cut, simplifying the manufacturing process and reducing production time.

Aesthetic Appeal: Stainless steel and brass round bars add a polished and modern look to decorative applications.

Corrosion Resistance: Materials like stainless steel and aluminum offer exceptional resistance to rust and corrosion, making them ideal for harsh environments.

Round Bar Manufacturer in India

Our round bars come in a variety of materials, including stainless steel, carbon steel, alloy steel, and aluminum, with varying diameters, lengths, and surface treatments. When you pick us as your Round Bars Supplier in India, you can be sure that you will receive high-quality products. Our round bars go through rigorous quality control methods to ensure dimensional correctness, mechanical characteristics, and consistent surface polish. We are also a leading provider of MS plate weight charts.

#Round Bars Manufacturer in India#Round bars suppliers#Round bars suppliers in India#ms plate weight chart

0 notes

Text

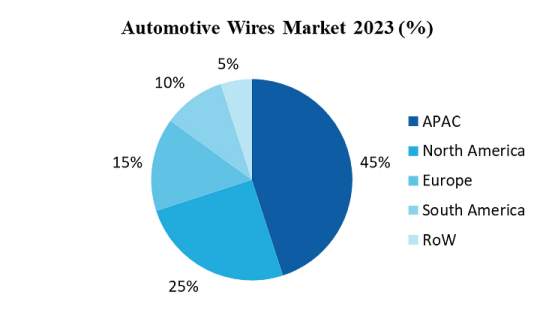

Automotive Wires Market-Industry Forecast, 2024–2030

Automotive Wires Market Overview:

Request Sample :

Automotive wire demand is expected to rise due to the growing trend of lightweight passenger automobiles as a means of reducing carbon emissions. In response to stringent regulations aimed at reducing carbon emissions from automobiles, manufactures will concentrate on producing aluminium automotive wires to reduce the vehicle’s overall weight. This is going to help in achieving the new regulations criteria. The rising focus on enhancing the standards for automotive wire will give opportunities for market expansion. For instance, according to US Auto Outlook 2024, light vehicle sales to grow 3.7% above last year’s level, rising to 16.1 million units. Additionally, the demand for automotive wires is expected to rise in parallel with the volume of vehicles being produced and the increasing demand from customers for better comfort, safety, and convenience.

Market Snapshot:

Automotives Wires Market — Report Coverage:

The “Automotive Wires Market Report — Forecast (2024–2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Automotives Wires Market.

AttributeSegment

By Material

· Copper

· Aluminium

· Others

By Vehicle Type

· Passenger Vehicles

· Light Commercial Vehicles

· Heavy Commercial Vehicles

By Propulsion

· ICE Vehicles

· Hybrid Vehicles

· Pure Electric Vehicles

By Transmission Type

· Electric wiring

· Data Transmission

By Application

· Engine wires

· Chassis wires

· Body and Lighting wires

· HVAC wires

· Dashboard / Cabin wires

· Battery wires

· Sensor wires

· Others

By End User

· OEM

· Aftermarket

By Geography

· North America (U.S., Canada and Mexico)

· Europe (Germany, France, UK, Italy, Spain, Russia and Rest of Europe),

· Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand and Rest of Asia-Pacific),

· South America (Brazil, Argentina, Chile, Colombia and Rest of South America)

· Rest of the World (Middle East and Africa).

COVID-19 / Ukraine Crisis — Impact Analysis:

The COVID-19 pandemic disrupted global supply chains, leading to delays in production and sales of automobiles which led to decrease in automotive wire manufacturing. Governments worldwide imposed lockdowns and restrictions, which led to shut down of mines, factories, and transportation networks, thus disrupting the supply of raw materials such as copper and aluminum, that are used in making automotive wires.

The Russia-Ukraine war had a huge impact on the global automotive wires market. Ukraine is a major manufacturer of copper, a material used as an automotive wiring component. The war has led to mining disruptions, which in turn has caused the shortages and increase in prices globally.

Key Takeaways:

Copper wires segment is Leading the Market

Copper wires segment holds the largest share in the automotive wires market with respect to market segmentation by material. Electrification will be the biggest driver to copper demand for vehicles. Copper is used throughout electric vehicle powertrains, from foils in each cell of the battery to the windings of an electric motor. In total, each electric vehicle can generate over 30kg of additional copper demand. According to a report by IDTechEx, the demand for copper from the automotive industry was just over 3MT in 2023 but is set to increase to 5MT in 2034. Because of its electrical and chemical characteristics, copper is used in every part of the battery. There are lot of tiny cells in the battery, and each one has a copper foil to carry electricity out of the cell. Large copper bars placed throughout the battery also convey the energy from each cell to the high-voltage connections, which in turn power the motor and electronics. Such parts and components with the copper are driving the market growth of copper wires in automotive wires market.

Inquiry Before Buying :

Passenger Vehicles are Leading the Market

Passenger Vehicles segment is leading the Automotive Wires Market by Application. The passenger vehicle category is currently holding the largest share in the automotive wires market because of a combination of factors including large production volumes, a wide range of wiring requirements, technological developments, and the increasing adoption of electric vehicles. For instance, according to Global and EU Auto industry 2023 report by The European Automobile Manufacturers’ Association (ACEA), European car production grew substantially, reaching nearly 15 million units, marking a significant year-on-year improvement of 12.6%. The growing popularity of electric vehicles (EVs) is also contributing to the growth of the passenger vehicle segment in the automotive wires market. EVs have more complex wiring systems due to the integration of batteries, motors, and charging infrastructure.

Integration of Smart Systems in Automobiles

Global demand for automotive wires is primarily driven by the integration of smart systems in automobiles. Modern automobiles have more wires because electronic control units (ECUs) are becoming more and more popular. Each ECU has been connected to a variety of sensors, actuators, and other ECUs through a complex network of connections. Automotive manufacturers are using sophisticated wiring solutions, such as light-weight harnesses, insulated cables and high-temperature-resistant wires to manage the rising number of connections and ensure reliable performance. For instance, In July 2024, Compal Electronics Inc, a leading contract electronics manufacturer from Taiwan, announced plans to build its first European factory in Poland. The company intends to invest more than $15.4 million to target automotive electronics clients. This strategic move marks Compal’s expansion into the European market. The need for complex and more advanced wiring solutions will continue to grow as automobiles become more technologically advanced, fueling the worldwide automotive wires market’s expansion.

Schedule A Call :

Fluctuating cost of materials to hamper the market

The market for automotive wires is significantly impacted by the price fluctuations of raw materials, particularly copper and aluminum. These materials are necessary for making automobile wires, and the market’s ability to expand may be severely hindered by their price instability. For instance, vehicle automation requires multiple sensors, as well as additional on-board computers. A standard autonomous system, with 12 cameras, seven Light Detection and Ranging sensors (LiDARs), eight radars and one automated driving control unit, will all depend on copper connections to function safely and reliably.

Buy Now :

For more details on this report — Request for Sample

Key Market Players:

Product/Service launches, approvals, patents and events, acquisitions, partnerships, and collaborations are key strategies adopted by players in the Automotive Wires Market. The top 10 companies in this industry are listed below:

Aptiv plc

Yazaki Corporation

Furukawa Electric Co., Ltd

Sumitomo wiring systems

Nexans SA

Fujikura Ltd

Samvardhana Motherson International Ltd

Leoni AG

Lear Corporation

THB Electronics

Scope of the Report:

Report MetricDetails

Base Year Considered

2023

Forecast Period

2024–2030

CAGR

5.7%

Market Size in 2030

$ 6.8 Billion

Segments Covered

By Material, By Vehicle Type, By Propulsion, By Transmission Type, By Application, By End User and By Geography.

Geographies Covered

North America (U.S., Canada and Mexico), Europe (Germany, France, UK, Italy, Spain, Russia and Rest of Europe), Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand and Rest of Asia-Pacific), South America (Brazil, Argentina, Chile, Colombia and Rest of South America), Rest of the World (Middle East and Africa).

Key Market Players

1. Aptiv plc

2. Yazaki Corporation

3. Furukawa Electric Co., Ltd

4. Sumitomo wiring systems

5. Nexans SA

6. Fujikura Ltd

7. Samvardhana Motherson International Ltd

8. Leoni AG

9. Lear Corporation

10. THB Electronics

For more Automotive Market reports, please click here

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Instant Water Heater Tap Electric Water Heater Tap Hot Water Tap Instant Hot Water Tap Instant Hot Water Heater Electric Tap Heater Tankless Water Heater Tap Instantaneous Water Heater On-Demand Water Heater Instant Water Heater for Kitchen Product Dimensions : 20 x 12 x 10 cm; 250 g Date First Available : 9 December 2024 Manufacturer : EVIE HOUSE ASIN : B0DPWG3GGQ Item part number : 457WH Country of Origin : India Manufacturer : EVIE HOUSE Packer : EVIE HOUSE Item Weight : 250 g Item Dimensions LxWxH : 20 x 12 x 10 Centimeters Net Quantity : 250.0 gram Generic Name : WAtEr-HEAtEr-TAp Support and well-being of dual-use electric faucet, while heated, the water, the lower the temperature, whereas the smaller the flow, the higher the temperature. Quick Electric Hot Water Tap Heating tube: high-purity copper liner heating element Rated voltage: 220V/50HZ Rated Power: 3000W Power unified are the 3000-watt, 5 seconds fast heat! Your hands won't feel cold when washing dishes or doing the laundry or washing vegetables. Of course, washing face and brushing teeth with warm water every morning are great enjoyments. When you receive Dr Water tankless instant electric tap water heater, please do not test it in your hands, you need install it well and then test, or it will be dangerous. Please operate it according to the instructions. Your hands won't feel cold when washing dishes or doing the laundry. Of course,washing face and brushing teeth with warm water every morning are great enjoyments. When you receive the water heater, please do not test it in your hands, you need install it well and then test, or it will be dangerous. Please operate it according to the instructions. [ad_2]

0 notes

Text

A Deep Dive into the Precious Metals E-Waste Recovery Market: Insights and Analysis

The global precious metals e-waste recovery market size is anticipated to reach USD 8.75 billion by 2030, registering a CAGR of 5.0% from 2024 to 2030, according to a new report by Grand View Research, Inc. The demand for precious metals, including gold, silver, palladium, and platinum in industrial applications is projected to benefit the market growth. Gold is used in electronics, medical treatments, and aerospace applications. Silver has applications in the electronics, antibiotics, photography, cutlery, and energy sectors. Platinum and palladium have applications in the electronics, catalytic conversion, computer parts, medicine, and oil refining sectors, among others. Consumer electronics, such as cell phones, laptops, etc., have a short life span.

These products are updated regularly by manufacturing companies, and thus, new models are released in the market. This generates a high volume of end-of-life electronic products that contain high-value metals. This has boosted the recovery of precious metals as many companies have realized the potential of such electronic waste. The recycling rate in North America and Asia Pacific is very low compared to European countries. This represents an opportunity for market participants, as these two regions also have high e-waste generation in the world. Many companies have started investing in precious metals e-waste recovery as the value of metals obtained after recycling is very high.

For instance, Hindalco Industries Ltd. announced an investment of USD 240.9 million for e-waste and copper recycling in India. The rising awareness about sustainability across different end-use industries has been a pivotal factor driving the adoption of recycled precious metals. One key aspect of this awareness is the realization that traditional metal production, which involves extracting and refining raw ore, is resource-intensive and contributes significantly to carbon emissions. This fuels the demand for recycled metals as they mitigate the requirement for such energy-intensive processes. These metals align with principles of circular economy wherein materials can be reused and recycled, thereby reducing the overall environmental footprint.

Gather more insights about the market drivers, restrains and growth of the Precious Metals E-Waste Recovery Market

Precious Metals E-Waste Recovery Market Report Highlights

• The consumer electronics segment dominated the market with a revenue share of more than 40% in 2023

• The segment is expected to benefit from rising per capita income and resultant increased demand for products, such as cell phones, headphones, wearables, etc.

• The household appliances segment is expected to register the second-fastest CAGR from 2024 to 2030

• Demand for products, such as refrigerators, washing machines, stoves, and air conditioners, is expected to result in e-waste generation, thus positively influencing segment growth

• Gold is likely to emerge as the largest segment, primarily due to the high value, and difficulty in extraction of metal

• Asia Pacific is expected to remain the fastest-growing region over the forecast period. Most of the countries in the region have informal markets; however, rising awareness of recycling is likely to benefit industry growth

Precious Metals E-Waste Recovery Market Segmentation

Grand View Research has segmented the global precious metals e-waste recovery market on the basis of metal, source, and region:

Precious Metals E-Waste Recovery Metal Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

• Gold

• Silver

• Others

Precious Metals E-Waste Recovery Source Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

• Household Appliances

• IT & Telecommunication

• Consumer Electronics

• Others

Precious Metals E-Waste Recovery Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o Belgium

o UK

o Italy

o Sweden

• Asia Pacific

o Japan

o China

o India

o South Korea

o Malaysia

• Latin America

o Brazil

• Middle East & Africa

o South Africa

o UAE

o Egypt

Order a free sample PDF of the Precious Metals E-Waste Recovery Market Intelligence Study, published by Grand View Research.

#Precious Metals E-Waste Recovery Market#Precious Metals E-Waste Recovery Market Size#Precious Metals E-Waste Recovery Market Share#Precious Metals E-Waste Recovery Market Analysis#Precious Metals E-Waste Recovery Market Growth

0 notes

Text

E-waste, or electronic waste, refers to discarded electronic devices such as old computers, mobile phones, televisions, and other electronic gadgets that have reached the end of their useful life. With rapid technological advancements and the continuous upgrading of electronic devices, e-waste has become a significant environmental concern worldwide. India, with its growing population and increasing consumer demand for electronics, is facing a mounting challenge in managing e-waste.

In this blog, we will explore the role of e-waste management companies in India and how they contribute to reducing the environmental impact of discarded electronics. One such leading company in the field is E Waste Material, which is dedicated to providing sustainable solutions for e-waste disposal and recycling.

The Growing E-Waste Crisis in India

E waste management companies in india,India is one of the largest producers of e-waste globally. According to estimates, the country generates over 3 million tons of e-waste annually, and this number is expected to rise with the growing consumption of electronics. E-waste contains a variety of hazardous materials like lead, mercury, cadmium, and flame retardants, which, if not properly managed, can cause severe environmental damage and pose health risks to humans.

The improper disposal of e-waste, such as burning or dumping in landfills, releases toxic substances into the air, soil, and water. These chemicals can contaminate natural resources and harm wildlife, leading to long-term ecological damage. Furthermore, informal recycling practices, which are common in many parts of India, often involve manual dismantling of electronic devices without proper safety measures, exposing workers to hazardous substances.

The Role of E-Waste Management Companies

E-waste management companies play a crucial role in addressing these challenges by providing responsible and eco-friendly solutions for the disposal and recycling of electronic waste. These companies follow strict guidelines and regulations to ensure that e-waste is processed in a way that minimizes environmental harm and maximizes resource recovery.

E Waste Material, a prominent e-waste management company in India, offers a range of services to tackle the growing e-waste problem. They provide e-waste collection, transportation, segregation, and recycling services, ensuring that the hazardous components of electronic devices are safely disposed of or recycled.

Services Offered by E Waste Material

E-Waste Collection and Pickup: E Waste Material offers door-to-door collection services for businesses, organizations, and households, making it convenient for people to dispose of their old electronics responsibly.

E-Waste Recycling: The company uses advanced technologies to recycle electronic devices, extracting valuable metals such as gold, silver, copper, and palladium. These metals can be reused in manufacturing new products, reducing the need for mining and conserving natural resources.

Safe Disposal of Hazardous Materials: E Waste Material ensures that hazardous components such as batteries, circuit boards, and cathode ray tubes (CRTs) are disposed of safely, preventing contamination of the environment.

Data Destruction: For businesses and individuals concerned about data security, E Waste Material provides certified data destruction services. They ensure that all sensitive information is permanently erased from electronic devices before disposal.

Consultation and Awareness: The company also works to raise awareness about the importance of responsible e-waste management. They offer consultation services to help businesses and individuals develop e-waste management plans in compliance with local regulations.

The Importance of Responsible E-Waste Recycling

Responsible e-waste recycling not only helps prevent environmental degradation but also contributes to the circular economy by recovering valuable materials from old electronics. Recycling reduces the demand for raw materials, conserves energy, and minimizes the carbon footprint associated with manufacturing new electronic products.

In addition to environmental benefits, proper e-waste management also supports the economy by creating jobs in the recycling and waste management sectors. By partnering with e-waste management companies like E Waste Material, businesses and individuals can contribute to a more sustainable future and reduce their environmental impact.

Conclusion

As the e-waste crisis continues to grow in India, the role of e-waste management companies becomes increasingly vital. E waste management companies in india like E Waste Material are leading the way in providing effective, environmentally-friendly solutions for the disposal and recycling of electronic waste. By embracing responsible e-waste management practices, we can ensure a cleaner, safer environment for future generations while promoting sustainability and resource conservation.

0 notes

Text

Top Features to Look for in Metal Bending Machines

Metal bending machines are the unsung heroes of modern manufacturing, shaping metals into precision parts for industries ranging from construction to aerospace. But what exactly should you look for in a metal bending machine? Whether you're a seasoned manufacturer or new to the field, understanding the features that matter can save you time, money, and stress.

1. Understanding Metal Bending Machines

Metal bending machines are designed to shape metal sheets and plates into various forms, such as cylinders or cones. They are indispensable in manufacturing processes that require precision and efficiency. Think of them as sculptors, turning raw metal into masterpieces.

2. Types of Rolling Machines

Metal bending machines come in different types, each suited for specific tasks:

2-Roll Machines: Ideal for simple bending operations.

3-Roll Machines: Perfect for pre bending and symmetrical shapes.

4-Roll Machines: Offer enhanced precision and automation, a popular choice for advanced manufacturing.

Profile Bending Machines: Designed for bending beams, pipes, or angles.

Knowing the type of machine that fits your needs can make all the difference in your production line.

3. Key Features to Look For

When evaluating metal bending machines, prioritize these features:

Bending Capacity: Ensure the machine can handle your required plate thickness and length.

Ease of Operation: Look for intuitive controls and user-friendly interfaces.

Precision: Advanced machines with CNC systems offer unmatched accuracy.

4. Automation and Control Systems

Automation has revolutionized metal bending. Machines equipped with CNC (Computer Numerical Control) systems allow for precise, repeatable results. For instance, a CNC plate rolling machine can program complex bends effortlessly, saving valuable time and reducing errors.

5. Material Compatibility

A versatile machine is essential for handling different materials such as steel, aluminum, or copper. Check the machine's specifications to ensure compatibility with the metals you use most frequently.

6. Safety Precautions in Rolling Machines

Safety is non-negotiable in metal bending operations. Look for these key safety features:

Emergency stop buttons.

Protective guards.

Automated shut-offs in case of malfunctions.

Following safety guidelines reduces risks and ensures a safer workplace for operators.

7. Understanding the Rolling Process

The rolling process involves shaping metal by passing it through rollers. Depending on your needs, this can be a simple task or a complex sequence involving multiple passes. Visualize it like rolling out dough for baking—except with metal, precision is critical.

8. Choosing the Right Rolling Type

Not all rolling processes are created equal. Here are common rolling types:

Hot Rolling: Ideal for large-scale production, involves shaping metal at high temperatures.

Cold Rolling: Ensures better surface finish and tighter tolerances.

Selecting the right rolling type affects the quality and efficiency of your operations.

9. Durability and Maintenance

Durable machines are long-term investments. Features like robust construction and wear-resistant rollers ensure longevity. Regular maintenance, such as lubrication and inspections, keeps machines running smoothly and minimizes downtime.

10. Why Choose Himalaya Machinery?

Himalaya Machinery, a leading plate rolling machine manufacturer in India, offers top-notch solutions tailored to the needs of metal manufacturers. Their machines are renowned for precision, reliability, and innovation, making them a trusted partner for businesses worldwide.

11. Applications of Metal Bending Machines

Metal bending machines are used in a variety of industries:

Automotive: Manufacturing components like exhaust pipes and chassis parts.

Construction: Creating beams and structural elements.

Aerospace: Shaping lightweight metal for aircraft parts.

12. Cost vs. Performance

Balancing cost and performance is crucial. While high-end machines may seem expensive, their efficiency and precision often justify the investment. Calculate ROI (Return on Investment) to determine the best value for your money.

13. Emerging Trends in Metal Bending

The metal bending industry is evolving with:

Smart Machines: Incorporating IoT for real-time monitoring.

Energy Efficiency: Reducing power consumption without compromising performance.

AI Integration: Enhancing precision and automation.

14. Tips for Optimal Machine Usage

To get the most out of your machine:

Train operators thoroughly.

Conduct regular inspections.

Use quality raw materials to prevent damage.

These steps ensure efficient operations and prolonged machine life.

15. Conclusion and FAQs

Metal bending machines are the backbone of modern manufacturing. By understanding the essential features and choosing a reliable manufacturer like Himalaya Machinery, you can optimize your production and stay ahead of the competition.

FAQs

1. What are the main types of metal bending machines? 2-roll, 3-roll, 4-roll, and profile bending machines are the primary types, each suited for specific tasks.

2. Why is material compatibility important in metal bending machines? Material compatibility ensures the machine can handle various metals without compromising performance or safety.

3. What safety precautions should operators follow? Operators should use machines with emergency stops, wear safety gear, and follow manufacturer guidelines.

4. How does CNC improve metal bending processes? CNC systems enhance precision, automate complex bends, and minimize human error.

0 notes

Text

Discovering Round Bars' Strength and Adaptability in Construction

Rajkrupa Metal Industries is a top-notch Round Bars Manufacturers in India. We have established ourselves as one of the top brands in the Round Bars sector. With significant commercial and technical personnel skills, Rajkrupa Metal Industries has strategically positioned itself as a top Round Bar manufacturer. Round bars are essential in forming our urban landscapes, from tall skyscrapers to elaborate bridges. Let's examine the benefits they provide, their structural strength, and the various ways they support building projects.

Types Of Round Bar by Rajkrupa Metal Industries

Lead Tin Bronze Round Bars: Lead Tin Bronze Round Bars are corrosion-resistant alloys primarily composed of copper, tin, and lead, offering excellent machinability, wear resistance, and durability for applications like bushings, bearings, and marine components.

Aluminium Bronze Round Bar: An Aluminium Bronze Round Bar is a cylindrical metal bar made from an alloy of copper and aluminum, known for its exceptional strength, corrosion resistance, and durability, commonly used in marine, aerospace, and industrial applications.

Phosphor Bronze Round Bar: Phosphor Bronze Round Bar is a durable, corrosion-resistant alloy made primarily of copper, tin, and phosphorus, commonly used in electrical, marine, and industrial applications for its strength, wear resistance, and machinability.

SMO 254 Round Bars: SMO 254 Round Bars are high-alloy austenitic stainless steel bars known for their exceptional corrosion resistance, high strength, and excellent performance in harsh environments, such as seawater and chemical processing industries.

Various Uses of Round Bars

1. Construction and Infrastructure

One of the most prominent uses of round bars is in the construction sector. They are frequently used as reinforcement bars (rebar) in concrete structures to improve tensile strength. Round bars provide support to buildings, bridges, and other structures, ensuring they withstand heavy loads and environmental stresses.

Reinforcement in Foundations: Round bars act as reinforcements for concrete in foundations, preventing cracking and structural damage over time.

Handrails and Guardrails: Round bars made of stainless steel or other durable materials are used to create handrails, balustrades, and guardrails for staircases and walkways.

Fabrication of Frames: In large-scale construction projects, round bars serve as integral components for fabricating structural frames and beams.

2. Manufacturing and Machinery

In the manufacturing sector, round bars play a crucial role in producing machine parts, tools, and industrial equipment. They are often used as raw materials for turning, milling, and machining operations.

Shafts and Rotors: Round bars are extensively used to manufacture shafts for motors, pumps, gear systems, and other mechanical components that require precision and strength.

Fasteners and Fixtures: From bolts and screws to nuts and rivets, round bars serve as raw materials for creating essential fasteners that hold structures and machinery together.

Tools and Dies: High-strength alloy and stainless steel round bars are ideal for creating tools, dies, and molds used in heavy industries and manufacturing processes.

The versatility of round bars in this sector is unmatched, as they ensure durability, reliability, and operational efficiency for machinery and tools.

3. Automotive and Transportation

The automotive industry relies heavily on round bars for both structural and mechanical purposes. Their strength, resistance to wear and tear, and precision make them an ideal choice for manufacturing critical automobile components.

Axles and Drive Shafts: Round bars are used to produce axles and shafts that form the backbone of vehicle drivetrain systems.

Chassis Components: Round bars contribute to the strength and stability of vehicle frames and chassis components.

Suspension Systems: In suspension systems, round bars help absorb shocks and provide stability to the vehicle while driving on uneven surfaces.

4. Oil and Gas Industry

The oil and gas sector demands materials that can withstand harsh environmental conditions, pressure, and corrosion. Round bars, especially those made of stainless steel and high-grade alloys, meet these requirements perfectly.

Pipeline Construction: Round bars are used in the construction of pipelines and other infrastructure for transporting oil, gas, and other fluids.

Drilling Equipment: Heavy-duty round bars are essential for manufacturing drilling tools, rigs, and other equipment.

Support Structures: Round bars are used as reinforcement in offshore platforms, ensuring they can withstand extreme weather and pressure conditions.

We are also top quality Aluminium Bronze Round Bar Manufacturer In India. We have established ourselves as one of the market's top names in Aluminium Bronze Round Bar. Rajkrupa Metal Industries has deliberately positioned itself as a top-tier manufacturer and retailer worldwide. Aluminium Bronze Round Bar Suppliers are well-known for their excellent strength, resistance to corrosion, and thermal and electrical conductivity.

Website: rajkrupametal.com

Source: Round Bars Manufacturer in India

#RoundBarsManufacturersinIndia#RoundBarsManufacturers#RoundBars#AluminiumBronzeRoundBarManufacturerInIndia#AluminiumBronzeRoundBarManufacturer#AluminiumBronzeRoundBar#AluminiumBronzeRoundBarSuppliers

0 notes

Text

The Growing Role of an Indian Attar Manufacturer and Supplier in the Global Fragrance Industry

Attar, a traditional and natural form of perfume, has been a part of Indian culture for centuries. Made from pure essential oils derived from flowers, herbs, and spices, attars have a rich history of use in religious ceremonies, personal grooming, and as an integral part of various cultural practices. Today, the role of an Indian attar manufacturer and supplier has expanded globally as demand for these natural perfumes continues to rise. In this article, we will explore the significance of Indian attar manufacturers and suppliers, their contribution to the fragrance industry, and why their products are increasingly sought after.

The Essence of Attar: A Natural Fragrance

Attar is a fragrant oil extracted through a meticulous distillation process, often without the use of alcohol, making it distinct from modern perfumes. The traditional method of creating attars involves steam distillation, where plant materials such as flowers, herbs, and spices are placed in large copper vessels. This process allows for the purest extraction of oils, which are then blended to create a rich, long-lasting scent. Unlike synthetic perfumes, attars are free from chemicals, which makes them appealing to consumers seeking natural and eco-friendly alternatives.

As the demand for natural, chemical-free products grows worldwide, attars have found favour not only in India but also in international markets. The role of an Indian attar manufacturer and supplier has become increasingly important, as they cater to both local and global demand for these high-quality, artisanal perfumes.

Crafting Quality Attar: The Manufacturing Process

The process of manufacturing attar is a delicate and highly skilled craft that requires expertise in the selection of raw materials and distillation techniques. An Indian attar manufacturer and supplier sources high-quality natural ingredients, such as roses, sandalwood, jasmine, and oud, which are essential for producing a superior fragrance. The purity and authenticity of these ingredients play a critical role in determining the quality of the final product.

The Growing Global Demand for Attars

In recent years, there has been a significant shift towards natural products in the fragrance industry. Consumers are becoming more conscious of the ingredients in their perfumes and are moving away from synthetic, alcohol-based products. This shift has contributed to the increasing popularity of attars. As a result, Indian attar manufacturers and suppliers are now exporting their products worldwide, from the Middle East to Europe and the United States.

Why Choose an Indian Attar Manufacturer and Supplier?

India has long been known as the birthplace of attars, and Indian manufacturers have perfected the craft over generations. The knowledge, experience, and attention to detail that go into creating each bottle of attar make Indian products highly sought after. Moreover, these manufacturers are committed to producing high-quality attars using sustainable and ethical methods. Many Indian attar manufacturers and suppliers also prioritize eco-friendly practices, ensuring that the production of attars does not harm the environment. This commitment to sustainability, coupled with the natural, chemical-free nature of attars, makes them an attractive option for consumers who value both quality and environmental responsibility.

#indian attar manufacturer and supplier#agarwood products wholesale supplier#agarwood products manufacturer#Buy Agarwood Products online#best quality absolute oils manufacturer#Buy Indian Attar online#saffron wholesale supplier#Fragrance oils for soap and candles manufacturer#Buy floral water online#essential oils manufacturer and wholesale supplier#Carrier Oils Manufacturer

0 notes

Text

Maximizing Durability and Strength with Aluminium Alloy 7075 Round Bars

When it comes to demanding applications that require exceptional strength, lightweight properties, and high durability, Aluminium Alloy 7075 Round Bars stand out as the material of choice. Recognized for its superior strength-to-weight ratio and resistance to fatigue, Aluminium 7075 is used extensively in industries such as aerospace, automotive, military, and manufacturing. As one of the most robust aluminium alloys available, Aluminium Alloy 7075 Round Bars Manufacturers in India provide this high-performance material to meet global industrial demands. In this article, we’ll explore how Aluminium Alloy 7075 Round Bars are maximizing durability and strength in various industries.

Product Overview

Aluminium Alloy 7075 is primarily composed of zinc, magnesium, and copper, making it one of the strongest aluminium alloys available. Aluminium Alloy 7075 Round Bars are supplied in various heat-treated conditions, including T6 and T651, to optimize mechanical properties like tensile strength, hardness, and resistance to stress. The alloy’s strength is comparable to that of steel, yet it is much lighter, making it ideal for applications that require both strength and reduced weight.

Manufacturers, particularly those in India, play a crucial role in providing these high-quality round bars, ensuring they meet stringent specifications for industries that demand precision and performance. These bars are used in critical components, including aircraft structures, automotive parts, military equipment, and high-performance machinery, where durability and strength are non-negotiable.

Advantages of Aluminium Alloy 7075 Round Bars

Exceptional Strength and Durability: The strength of Aluminium Alloy 7075 rivals that of many steels, making it ideal for use in high-stress environments where components must resist deformation and failure.

Lightweight for Enhanced Performance: Despite its strength, Aluminium 7075 is lightweight, offering significant weight reduction without compromising strength—essential for industries like aerospace and automotive where weight savings are critical for performance.

Fatigue and Stress Resistance: The alloy’s excellent fatigue resistance ensures that parts exposed to repetitive loading, such as in aerospace and automotive applications, maintain their integrity and longevity.

Corrosion-Resistant: Aluminium 7075’s corrosion-resistant properties ensure that components last longer in challenging environments, reducing maintenance needs and improving the service life of parts.

Precision and Machinability: The machinability of Aluminium Alloy 7075 Round Bars allows for the production of high-precision parts, essential for applications that require exact specifications and tight tolerances.

Conclusion

Aluminium Alloy 7075 Round Bars are the perfect material for demanding industries that require high strength, exceptional durability, and reduced weight. With their superior mechanical properties, including unmatched strength-to-weight ratio, fatigue resistance, corrosion resistance, and machinability, these round bars are transforming industries such as aerospace, automotive, military, and manufacturing. Aluminium Alloy 7075 Round Bars Manufacturers in India play a pivotal role in supplying this advanced material, ensuring that industries worldwide have access to the performance materials they need to drive innovation and maintain safety and efficiency in their operations. As these industries continue to evolve and push the boundaries of engineering, Aluminium 7075 will remain a key material in the creation of cutting-edge, high-performance components.

0 notes