#Cooling Tower Pump Manufacturers

Explore tagged Tumblr posts

Text

Everything You Should Know About Vagus Less Pump Manufacturers

Introduction

Vertical glandless pumps are essential components in various industrial applications, known for their efficiency and reliability. As a leading name among vertical glandless pump manufacturers, VND Plastico Pumps Pvt. Ltd. is dedicated to providing high-quality and innovative solutions tailored to meet the needs of our clients. This comprehensive guide covers everything you need to know about vertical glandless pumps, from their working principles and key features to their advantages and applications.

What is a Vertical Glandless Pump?

A vertical glandless pump is a type of centrifugal pump that operates without a gland or seal. Unlike traditional pumps that use mechanical seals or packing to prevent leakage, glandless pumps are designed to eliminate the need for these components. This design feature significantly reduces maintenance requirements and enhances the pump's reliability, particularly in applications involving aggressive or hazardous fluids.

Key Components of Vertical Glandless Pumps

Understanding the key components of vertical glandless pumps is crucial to comprehending their operation and benefits:

Impeller: The impeller is the rotating component that imparts kinetic energy to the fluid, facilitating its movement.

Motor: The motor drives the impeller, providing the necessary mechanical energy.

Pump Casing: The casing houses the impeller and directs the fluid flow, converting kinetic energy into pressure energy.

Shaft: The shaft connects the motor to the impeller, transmitting mechanical power.

Column Pipe: The column pipe supports the pump and houses the discharge pipe, ensuring efficient fluid transport.

Bearings: Bearings support the shaft and reduce friction, ensuring smooth operation.

Working Principle of Vertical Glandless Pumps

The working principle of vertical glandless pumps is based on centrifugal force. Here’s a step-by-step explanation:

Suction Stage: Fluid enters the pump through the suction inlet at the base.

Impeller Action: The motor drives the impeller, which imparts kinetic energy to the fluid, increasing its velocity.

Casing Conversion: The fluid moves into the pump casing, where the kinetic energy is converted into pressure energy.

Discharge Stage: The pressurized fluid is directed through the discharge pipe to its intended destination.

The absence of a gland or seal means there are fewer components that can wear out, resulting in a more robust and low-maintenance pump.

Advantages of Vertical Glandless Pumps

Vertical glandless pumps offer several advantages over traditional pumps, making them an attractive choice for various industries:

1. Reduced Maintenance

The elimination of mechanical seals or packing significantly reduces maintenance requirements. There are fewer components that can wear out or fail, leading to lower maintenance costs and less downtime.

2. Enhanced Reliability

Without seals or packing, there is a reduced risk of leaks and failures. This makes vertical glandless pumps highly reliable, especially in applications involving hazardous or aggressive fluids.

3. Improved Safety

The glandless design enhances safety by preventing leaks of hazardous fluids, protecting both personnel and the environment. This is particularly important in chemical processing and other industries handling dangerous substances.

4. Efficient Operation

Vertical glandless pumps are designed for efficient operation, providing consistent performance and high reliability. Their design minimizes energy losses, ensuring optimal energy use.

5. Compact Design

The vertical design of these pumps saves space, making them suitable for installations where floor space is limited. This is particularly beneficial in industrial plants with constrained layouts.

Applications of Vertical Glandless Pumps

Vertical glandless pumps are used in a wide range of applications across various industries. Some of the key applications include:

1. Chemical Processing

In the chemical industry, these pumps are used to handle corrosive and hazardous fluids. Their glandless design prevents leaks, ensuring safe and reliable operation in chemical processing plants.

2. Water and Wastewater Treatment

Vertical glandless pumps are widely used in water and wastewater treatment facilities. They handle various fluids, including sewage, sludge, and treated water, with high efficiency and reliability.

3. Power Generation

In power plants, these pumps are used for cooling water circulation, boiler feed water, and other critical processes. Their robust design ensures reliable operation under demanding conditions.

4. Oil and Gas Industry

The oil and gas industry relies on vertical glandless pumps for the safe and efficient handling of hydrocarbons, drilling fluids, and other substances. Their design minimizes the risk of leaks and enhances safety.

5. Food and Beverage Industry

In the food and beverage industry, vertical glandless pumps are used for processes such as mixing, transferring, and packaging. Their sanitary design ensures compliance with hygiene standards.

6. Pharmaceutical Industry

The pharmaceutical industry uses these pumps for the safe and efficient handling of sensitive and high-purity fluids. Their glandless design minimizes the risk of contamination, ensuring product integrity.

Choosing the Right Vertical Glandless Pump Manufacturers

Selecting the right manufacturer is crucial to ensuring the quality and reliability of your vertical glandless pump. Here are some factors to consider when choosing a manufacturer:

1. Experience and Expertise

Look for manufacturers with extensive experience and expertise in designing and manufacturing vertical glandless pumps. A company with a proven track record is more likely to deliver high-quality products.

2. Customization Capabilities

Different applications have unique requirements. Choose a manufacturer that offers customization options to tailor the pump to your specific needs.

3. Quality Assurance

Ensure that the manufacturer follows strict quality control procedures and uses high-quality materials. This guarantees the durability and reliability of the pump.

4. Technical Support

Technical support is essential for the installation, operation, and maintenance of the pump. Choose a manufacturer that provides comprehensive technical support and after-sales service.

5. Reputation

Check the manufacturer’s reputation by reading customer reviews and testimonials. A reputable manufacturer is more likely to provide reliable products and excellent customer service.

Why Choose VND Plastico Pumps Pvt. Ltd.?

VND Plastico Pumps Pvt. Ltd. stands out among vertical glandless pump manufacturers for several reasons:

1. Expertise

With years of experience in the industry, we have the expertise to design and manufacture high-quality vertical glandless pumps that meet the rigorous demands of various applications.

2. Innovation

We are committed to innovation, continuously improving our products to enhance performance, efficiency, and reliability. Our pumps incorporate the latest technologies and design advancements.

3. Quality

Quality is our top priority. We use high-quality materials and follow stringent quality control procedures to ensure that our pumps deliver exceptional performance and durability.

4. Customization

We understand that each application is unique. That’s why we offer customization options to tailor our pumps to your specific requirements, ensuring optimal performance.

5. Customer Support

Our dedicated customer support team is always ready to assist you with technical queries, installation, and maintenance. We are committed to ensuring your satisfaction and success.

Conclusion

Vertical glandless pumps are a vital component in various industrial applications, offering numerous advantages such as reduced maintenance, enhanced reliability, and improved safety. As one of the leading vertical glandless pump manufacturers and cooling tower pump manufacturers, VND Plastico Pumps Pvt. Ltd. is dedicated to providing high-quality, innovative, and reliable pumping solutions tailored to meet the specific needs of our clients.

0 notes

Text

Boilers and chillers Erection manufacturer and supplier

We have decades of experience servicing boilers and chillers for multiple commercial and industrial facilities as well as servicing other mechanical, electrical and plumbing systems.we provide Magnetic bearing chillers,Screw & scroll chillers,Reciprocating chillers,Steam & hot water boilers,Reciprocating chillers,Steam & hot water boilers,Chiller & boiler controls, System pumps and Cooling tower.

For more details please visit our website -

#boiler#chiller#erection#manufacturer#supplier#fabrication#hot water boiler#chiller boiler#system pumps#cooling tower

0 notes

Text

Cooling Tower Pump Manufacturers, Suppliers India from Pune

Cooling Tower Pump Manufacturers, Suppliers, Exporters - India in Pune, Mumbai, Nashik, Aurangabad, Goa, Kolhapur. Manufacturer of Cooling Tower Pumps

0 notes

Text

EPC company in Pune Maharashtra

Welcome to Veda Engg, your trusted partner for comprehensive engineering solutions in Maharashtra. As a premier EPC (Engineering, Procurement, and Construction) company, we specialize in utility engineering, serving a diverse range of industries. Explore our expertise as an authorized Thermax dealer, steam boiler and thermic fluid heater supplier, hot water generator manufacturer, cooling tower specialist, and provider of steam accessories and systems, along with reliable operation and Manning services throughout Maharashtra.

EPC Company in Pune, Maharashtra:

Veda Engg stands as a leading EPC company in Pune, Maharashtra, offering end-to-end engineering solutions. Our expertise spans across diverse sectors, providing innovative and customized solutions to meet the unique requirements of our clients.

Utility Engineering Company in Maharashtra:

With a commitment to excellence, Veda Engg excels as a utility engineering company in Maharashtra. Our solutions are tailored to optimize utility systems, enhancing efficiency, sustainability, and overall operational performance for industries across the region.

Authorized Thermax Dealer in Maharashtra:

As an authorized Thermax dealer, Veda Engg brings you cutting-edge technologies and solutions from one of the industry leaders. Our partnership with Thermax ensures that you receive high-quality products and services, meeting the highest standards of performance and reliability.

Steam Boiler Supplier/Manufacturer in Maharashtra:

Veda Engg takes pride in being a trusted steam boiler supplier and manufacturer in Maharashtra. Our steam boilers are designed to deliver optimal performance, efficiency, and safety, making them the ideal choice for various industrial applications.

Thermic Fluid Heater Supplier/Manufacturer in Maharashtra:

Count on Veda Engg as your reliable thermic fluid heater supplier and manufacturer in Maharashtra. Our heaters are crafted with precision, ensuring the smooth operation of your industrial processes with efficient heat transfer capabilities.

Hot Water Generator Supplier/Manufacturer in Maharashtra:

Experience uninterrupted hot water supply with Veda Engg as your preferred hot water generator supplier and manufacturer in Maharashtra. Our generators are designed to meet the diverse hot water requirements of industries, ensuring reliability and energy efficiency.

Cooling Tower Supplier/Manufacturer in Pune, Maharashtra:

For top-tier cooling tower solutions in Pune, Maharashtra, turn to Veda Engg. Our cooling towers are engineered to deliver superior heat dissipation, optimizing the performance of your industrial processes.

Steam Accessories & System in Maharashtra:

Veda Engg offers a comprehensive range of steam accessories and systems in Maharashtra, enhancing the efficiency and reliability of your steam-based operations. Trust us for cutting-edge solutions that meet the highest industry standards.

Operation & Manning Services in Maharashtra:

Ensure seamless operations with Veda Engg's operation and Manning services in Maharashtra. Our experienced team is dedicated to providing reliable and efficient services to keep your systems running smoothly.

Conclusion:

Choose Veda Engg as your preferred engineering partner in Maharashtra. With our expertise as an EPC company, authorized Thermax dealer, and supplier/manufacturer of various industrial solutions, we are committed to delivering excellence in every aspect of your project. Elevate your engineering experience with Veda Engg - where innovation meets reliability.

9130099434

#EPC company in Pune Maharashtra#Industrial pump dealers/ supplier in Pune/ Mumbai#Cooling tower supplier/manufacturer in Gujarat#Utility engineering company in Maharashtra

0 notes

Text

0 notes

Text

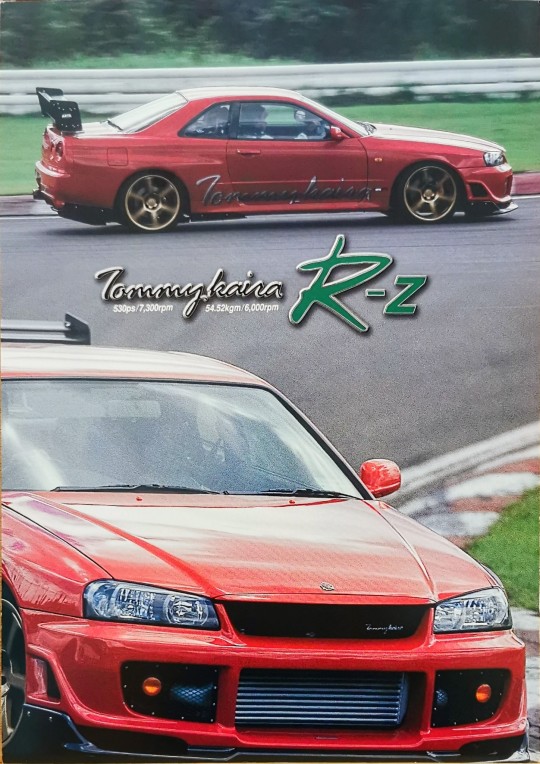

Tommykaira R-z brochure translation.

The wonders of Tommykaira Magic that you can experience while driving. R

Total balance with a high degree of perfection commensurate with 530ps.

The displacement has been increased to 2700cc, achieving a maximum output of 530 horsepower and a maximum torque of 54.52kgm. To achieve this, various types of tuning have been applied. For example, the crankshaft, which is the most important element for bringing out the best performance of the engine, is an original crankshaft manufactured by Fandon in the UK. Highly rigid full counter type provides excellent balance performance. Furthermore, the R-z uses an H-section connecting rod and forged aluminum piston, making it both highly rigid and lightweight. What's more, it achieves well-balanced tuning. In addition, the R-z uses metal head gaskets, high-lift camshafts, valve springs, and racing plugs to bring out the best in the pistons, connecting rods, and crankshafts that are the main moving parts. Composite Radiator Improves cooling effect by using NI water pump.

I got it.

Changes to the intake and exhaust system have resulted in a significant increase in efficiency through the use of a stainless steel exhaust system with suction from the front pipe and a racing type intercooler. By increasing the size of the fuel system parts and strengthening the drive system, you can enjoy ample torque even when driving at low rpm around town. What's more, the sense of power, extension, and revving at high rpm will captivate anyone sitting in the driver's seat.

suspension tuning is

"High ride comfort and handling"

Balance in Dimensions.” During normal driving

Passenger-friendly ride

While realizing the taste, wine day

It is sharp and has excellent turning performance when turning.

Tomita has achieved this goal and has received rave reviews from many quarters.

It's a magic called Kaira Magic.

The front brake has been strengthened to control the 530 horsepower. Uses AP 6-pot calipers, AP brake rotors, and PFC brake pads. This is a highly reliable braking system that responds precisely to the driver's wishes.

[mechanism]

engine body

・Cylinder head/port polishing

・Cylinder block/boring, internal polishing

・Original crankshaft made in UK Fandon

・Special H section connecting rod

・Special forged piston

・Titanium coated piston ring

・Metal head gasket

・High lift camshaft

・Reinforced valve spring, valve guide

・Racing plug

computer unit

・R-z dedicated computer unit

cooling system

・Large capacity water-cooled oil cooler

Water pump for high speed N1

Intake and exhaust system

・All exhaust system

・Large capacity intercooler

・Special turbine

fuel system

Large capacity air flow meter

large capacity injector

・Large capacity fuel pump

drive system

・Twin plate clutch

Reinforcement parts

・Strut tower bar (with master cylinder stopper)

・Reinforced engine mount

・Enhanced mission mount

[Suspension]

Brake system

・AP 6-pot caliper & rotor (F)

・PFC brake pad

suspension

・Bilstein original shock absorber

・Original spring (F)

Original double spring (R)

tires/wheels

・Forged magnesium cut wheel “PRO R” 9.5×19+22

・DUNLOP FORMULA FM901 275/30ZR19

Reinforcement parts

・Stainless mesh brake hose

・Front tension rod (pillow ball)

* [Exterior] and [Interior] are the same specifications as R-s.

Tommykaira R-Z SPECIFICATION

PRICE ¥10,500,000-

PERFORMANCE

Max Output 530ps/7300rpm

Max Torque 54.52kgm/6000rpm

ENGINE

RB26DETT STRAIGHT-6 DOHC Turbo with multi-cup Intercooler

Piston Displacement: 2700cc

Bore x Stroke: 87.0mm x 75.7mm

BODY

Length: 4620mm

Width: 1785mm

Height: 1335mm

Wheelbase: 2665mm

Tread: Front 1496mm

Rear 1496mm

LAYOUT

4 Wheels Drive

Transmission: 6MT

Brakes:(F) 6 Piston Opposed Type Caliper + Ventilated Disc

Brakes:(R) 2 Piston Opposed Type Caliper + Ventilated Disc

Wheels: 9.5JJX 19 (Front&Rear)

Tire: 275/30ZR19 (Front&Rear)

Suspension : Original Shock absorber + Original Coil Spring

Steering: Rack & Pinion < SUPER HICAS >

*Price is vehicle price delivered at Kyoto store, registration fees and consumption tax not included US specifications, data, etc. are subject to change without notice. *Detailed options, equipment, body color, etc. are based on genuine Nissan. Catalog photos may look different from the actual products as they are printed materials. For inquiries and requests..

TOMITA

dream factory

http://www.tommykaira.com

18 notes

·

View notes

Text

Exploring Chilled Water Systems: Your Solution for Efficient Cooling

In the ever-evolving world of heating, ventilation, and air conditioning (HVAC), chilled water systems have emerged as a vital solution for providing efficient cooling in a variety of settings. From commercial buildings to industrial facilities, these systems utilize chilled water to absorb heat, ensuring a comfortable environment while optimizing energy use. This article will explore the components, benefits, and applications of chilled water systems to help you understand their significance in modern HVAC design.

What Are Chilled Water Systems?

Chilled water systems operate on a closed-loop system that circulates chilled water throughout a building. The primary components of these systems include:

Chillers: The heart of the system, chillers cool the water by removing heat through a refrigeration cycle. They can be classified as water-cooled or air-cooled, depending on the design and requirements.

Cooling Towers: Used in conjunction with chillers, cooling towers dissipate heat absorbed from the chilled water, enhancing the system's efficiency through evaporative cooling.

Pumps: Essential for circulation, pumps transport chilled water through the piping system, ensuring even distribution to various air handling units (AHUs) and fan coil units (FCUs).

Air Handling Units (AHUs): These units are responsible for conditioning the air by using chilled water to cool and dehumidify the indoor air before it is distributed throughout the building.

Piping and Ductwork: This network of pipes and ducts facilitates the transport of chilled water to different areas of the building and returns it to the chillers for re-cooling.

Benefits of Chilled Water Systems

Energy Efficiency: One of the standout advantages of chilled water systems is their energy efficiency. By centralizing the cooling process, these systems can significantly reduce energy consumption compared to individual air conditioning units. This efficiency translates into lower utility bills and a reduced carbon footprint.

Scalability: Chilled water systems can easily be scaled to accommodate varying cooling demands, making them suitable for both small offices and large industrial facilities. As the cooling requirements change, adjustments can be made without extensive modifications to the infrastructure.

Improved Indoor Air Quality: These systems contribute to better indoor air quality by controlling humidity levels and maintaining consistent temperatures. This is especially important in environments where sensitive equipment or health considerations are involved, as it helps prevent the growth of mold and mildew.

Enhanced Comfort: Chilled water systems provide reliable and consistent cooling, ensuring comfort in buildings regardless of external weather conditions. The ability to maintain stable temperatures is critical in many settings, including data centers and healthcare facilities.

Reduced Noise Levels: Compared to traditional air conditioning systems, chilled water systems operate more quietly. The centralized equipment minimizes noise pollution, creating a more pleasant indoor environment for occupants.

Applications of Chilled Water Systems

Chilled water systems are utilized in a wide range of applications, including:

Commercial Buildings: Offices, shopping malls, and hotels rely on chilled water systems to provide efficient cooling and comfort for tenants and guests.

Industrial Facilities: Factories and manufacturing plants often implement chilled water systems to maintain optimal temperatures for machinery and processes, preventing overheating and ensuring operational efficiency.

Data Centers: The high heat generated by servers necessitates efficient cooling solutions. Chilled water systems are essential for maintaining stable temperatures and preventing equipment failures in data centers.

Healthcare Facilities: Hospitals and medical centers depend on these systems to provide a comfortable environment for patients and staff while maintaining strict temperature controls for sensitive medical equipment.

Conclusion

In conclusion, chilled water systems are an integral part of modern HVAC solutions, providing energy-efficient and reliable cooling for a variety of applications. By understanding the components and benefits of these systems, facility managers and decision-makers can make informed choices to enhance comfort, improve air quality, and reduce energy consumption. Investing in a chilled water system not only ensures optimal indoor conditions but also contributes to sustainable practices in building management. As technology continues to advance, the role of chilled water systems will undoubtedly grow, solidifying their place in the future of efficient cooling solutions.

0 notes

Text

Machine Condition Monitoring Market Key Companies, Trends, Growth and Forecast Report, 2030

The global machine condition monitoring market size is expected to reach USD 5.46 billion by 2030, according to a new report by Grand View Research, Inc. The industry is anticipated to grow at a lucrative CAGR of 7.9% from 2023 to 2030. Exponential demand for monitoring services to avoid machinery failure will propel the penetration of condition-monitoring systems. End-users have exhibited an unprecedented demand for predictive maintenance tools to bolster asset life, minimize machine failure and reduce maintenance costs. Stakeholders envisage revenue-boosting potentials in maintaining machine health and reducing downtime with advanced software and tools. The emergence of the Industrial Internet of Things (IIoT) has propelled the measurements, such as pressure, vibration, and temperature.

Machine condition monitoring helps measure equipment, enhance production efficiency, and reduce unplanned downtime. Industrial IoT has provided promising growth potential following the growing footfall of smart sensors across North America, Europe, and the Asia Pacific. Leading companies are poised to prioritize vibration, torque, and temperature monitoring to foster monitoring processes. For instance, vibration diagnosis has gained ground to boost the detection of possible faults, mainly due to the adoption of IoT technology and advanced algorithms.

Gather more insights about the market drivers, restrains and growth of the Machine Condition Monitoring Market

Detailed Segmentation:

Market Dynamics

The widespread adoption of wireless technology in machine condition monitoring is revolutionizing industries by providing an affordable and easily implementable solution. Wireless sensors enable real-time monitoring, offering operators a comprehensive overview of machine health. This proactive approach allows for early problem identification and resolution, preventing costly downtime. The cost-effectiveness of wireless solutions, attributed to their avoidance of complex wiring infrastructure, significantly benefits small and medium-sized businesses, making this technology an accessible option.

Monitoring Technique Insights

The vibration monitoring segment led market in 2022, accounting for over 26% share of global revenue. The high share can be attributed to soaring demand to detect wear, imbalances, and misalignments. Rising penetration of monitoring vibration has played a pivotal role in offering insights into detecting faults at an early stage. Vibration monitoring solutions have witnessed an uptick in minimizing maintenance, integration, and operational complexities. Industry players have increased investments in continuously monitoring equipment, including cooling tower gearboxes, boiler feed pumps, steam turbines, and gas. End-users will likely embed vibration monitoring into their system to foster reliability and protect data. Technology will remain highly sought-after for diagnosing emerging issues and robust troubleshooting.

Component Insights

The hardware segment led the market in 2022, accounting for over 55% share of the global revenue. The high share can be attributed to increasing use of infrared sensors, ultrasonic detectors, vibration analyzers, and accelerometers. Technologies used in condition monitoring have specialized knowledge of areas where various types of failure can occur. Hardware or sensor manufacturers offer their products in two varieties, static and dynamic, depending on the different frequencies hardware or sensors have. Additionally, this allows manufacturers to minimize machine downtime and implement successful predictive maintenance.

Product Type Insights

The motors segment led the market in 2022, accounting for over 17% of global revenue. Growth is attributed to rising demand for motors in key industries like oil and gas, automotive, and manufacturing. Ensuring motors are in their optimal condition is essential to prevent failures, boost operational efficiency, and minimize downtime, thereby driving the growth of motors segment in machine condition monitoring. As demand for motors in various industries continues to increase, motors segment is anticipated to maintain its growth trajectory in foreseeable future.

Application Insights

The turbines & generators segment led the market in 2022, accounting for over 16% of global revenue. Escalating demand for preventive maintenance in the power generation industry drives the segment's growth. These components are crucial for power plants, and early identification of potential issues through machine condition monitoring helps prevent costly outages. Segment's growth is further fueled by increasing use of renewable energy sources, necessitating advanced monitoring solutions and the adoption of predictive maintenance strategies to optimize costs and uptime. Moreover, development of new technologies, such as vibration analysis and infrared thermography, provides more accurate and detailed data on condition of turbines and generators, boosting the segment's prominence.

Architecture Type Insights

The on-premises segment led the market in 2022, accounting for over 34% of global revenue. On-premises is often managed or self-hosted and ensures organizations meet specific market requirements, enabling teams to optimize their workload and create highly customizable environments. To ensure machines are operating efficiently, engineers need the ability to keep track and monitor status and enable teams to pinpoint long running or inefficient machines easily. Furthermore, the cost-effectiveness of on-premises solutions significantly contributed to their widespread adoption. With businesses keen on budget optimization, the affordability of these solutions rendered them highly attractive, offering access to robust monitoring capabilities without straining financial resources.

Plant Type Insights

Brownfield plant segment held the largest revenue share of over 70% in 2022. This is because brownfield plants are older, nearing the end of their lifespan, and face a higher risk of failures and downtime, creating a pressing need for condition monitoring. Factors such as increased safety focus in the industrial sector, regulatory compliance requirements, and higher probability of equipment problems in older setups contribute to a larger market share for machine condition monitoring in brownfield plants. Proactive monitoring in these environments is crucial for businesses to ensure operational efficiency, minimize risks, and avoid costly disruptions.

Monitoring Process Insights

The online condition monitoring segment held the largest revenue share of over 51% in 2022. Growth is attributed to soaring demand for data monitoring and management to reduce downtime and defects and bolster machine life. Leading manufacturers are poised to prioritize advanced monitoring systems to expand penetration across untapped regions. The need for real-time metrics and alert notifications has triggered demand for online monitoring systems to boost machines' health information. For instance, in July 2022, Valmet, supplier and developer of automation systems, stated that online condition monitoring systems are typically used in industries like oil & gas, power generation, and metals & mining. Demand for online condition monitoring is high as portable monitoring procedures are challenging to use in production plants located in remote areas.

End-use Industry Insights

The power generation segment dominated the market in 2022 and accounted for a revenue share of over 15%. Growth is attributed to high failure rates for some components, such as increased repair costs, entire system overhauls, and unsafe work environments in the power and generation industry. As this industry is product-intensive, it requires continuous machinery maintenance. Further, the oil and gas segment will acquire significant market share due to bullish demand for oil analysis, thermography, and vibration monitoring. The industry has witnessed unprecedented demand for condition monitoring to keep up with demand for sensor applications to boost efficiency and productivity.

Regional Insights

North America dominated the market in 2022, accounting for over 36% share of global revenue. U.S. and Canada are slated to provide promising growth opportunities against bullish demand from power generation, aerospace, oil & gas, marine, and food & beverages industries. The trend for vibration monitoring has become pronounced for oil condition monitoring in oil and gas platform machinery lubricants. With a surge in offshore oil exploration across North America, forward-looking companies could strengthen their position in the regional market. Oil condition monitoring is poised to receive an uptick in predictive maintenance and reliability.

Browse through Grand View Research's Next Generation Technologies Industry Research Reports.

• The global neural processor market size was estimated at USD 237.6 million in 2023 and is projected to grow at a CAGR of 19.3% from 2024 to 2030.

• The global service virtualization market size was valued at USD 786.0 Million in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 17.4% from 2024 to 2030.

Key Companies & Market Share Insights

Incumbent players and startups are poised to emphasize organic and inorganic strategies, including mergers & acquisitions, product offerings, technological advancements, innovations, and geographical expansion. Trend for predictive maintenance and growing footfall of IoT will serve as catalysts to expand their footprint across untapped areas. For instance, in February 2023, Seed Group partnered with Samotics, a provider of asset health monitoring, to introduce condition monitoring services to the Middle East. With Samotics' SAM4 technology utilizing electrical signature analysis (ESA) to monitor critical assets, the partnership aims to cater to a growing demand for advanced condition monitoring solutions in the region's thriving industrial sector.

Some of the prominent players in the global machine condition monitoring market include:

• ALS

• Emerson Electric Co.

• General Electric

• Honeywell International Inc.

• Megget PLC

• NATIONAL INSTRUMENTS CORP

• Parker Hannifin

• Rockwell Automation, Inc.

• SKF

• Schaeffler AG

Machine Condition Monitoring Market Segmentation

Grand View Research has segmented the global machine condition monitoring market based on monitoring technique, component, product type, application, architecture type, plant type, monitoring process, end-use industry, and region:

Machine Condition Monitoring Technique Outlook (Revenue, USD Billion, 2017 - 2030)

• Torque Monitoring

• Vibration Monitoring

• Oil Analysis

• Thermography

• Corrosion Monitoring

• Others

Machine Condition Monitoring Component Outlook (Revenue, USD Billion, 2017 - 2030)

• Hardware

• Portable/Handheld Condition Monitoring Units

• Software

• Services

Machine Condition Monitoring Product Type Outlook (Revenue, USD Billion, 2017 - 2030)

• Valves

• Compressors

• Turbines

• Gearbox

• Motors

• Bearings

• Couplings

• Others

Machine Condition Monitoring Application Outlook (Revenue, USD Billion, 2017 - 2030)

• HVAC Systems

• Turbines & Generators

• Material Handling

• Conveyors

• Pump Systems

• Sprockets

• Bushings & Hubs

• Control Cabinet Monitoring

• Paper Presses

• Storage Rooms

• Motor Control

• Lubricant Level Monitoring on CNC Machines

• Others

Machine Condition Monitoring Architecture Type Outlook (Revenue, USD Billion, 2017 - 2030)

• Public Cloud

• Edge Platform

• Hybrid Cloud

• On-premises

Machine Condition Monitoring Plant Type Outlook (Revenue, USD Billion, 2017 - 2030)

• Greenfield Plant

• Brownfield Plant

Machine Condition Monitoring Process Outlook (Revenue, USD Billion, 2017 - 2030)

• Online Condition Monitoring

• Portable Condition Monitoring

Machine Condition Monitoring End-use Industry Outlook (Revenue, USD Billion, 2017 - 2030)

• Mining

• Primary Metals

• Power Generation

• Automotive

• Oil & Gas

• Aerospace

• Food & Beverages

• Chemicals

• Marine

• Pharmaceutical

• Pulp & Paper

• Others

Machine Condition Monitoring Regional Outlook (Revenue, USD Billion, 2017 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o U.K.

o Germany

o France

• Asia Pacific

o China

o Japan

o India

• Central & South America

o Brazil

• MEA

Order a free sample PDF of the Machine Condition Monitoring Market Intelligence Study, published by Grand View Research.

#Machine Condition Monitoring Market#Machine Condition Monitoring Market size#Machine Condition Monitoring Market share#Machine Condition Monitoring Market analysis#Machine Condition Monitoring Industry

0 notes

Text

Center Enamel Provides Custom Solutions of Industrial Containers and Process Equipment for Every Industry

Center Enamel Provides Custom Solutions of Industrial Containers and Process Equipment for Every Industry

Shijiazhuang Zhengzhong Technology Co., Ltd. is a trusted name in the design, manufacturing, and installation of industrial containers and process equipment. With over 30 years of expertise, we deliver tailored solutions for various sectors, including petrochemical, pharmaceutical, food, textile, and energy industries. Our product range includes pressure vessels, reactors, heat exchangers, and towers—each built to meet stringent national and international standards, ensuring safety, durability, and optimal performance.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, welded steel tanks ,pressure vessels and storage tanks roof, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs Solution

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Industry-Leading Design Standards

Our commitment to quality and safety is demonstrated by our adherence to industry-leading design standards. Every piece of equipment is carefully engineered to meet strict regulatory requirements, ensuring that it performs reliably and efficiently under all conditions.

Key design standards include:

GB150-2011: Pressure Vessel

JB/T4735-1997: Steel Welded Atmospheric Pressure Vessel

GB6789-1997: Food Machinery Hygiene

HG/T 20569-1994: Mechanical Mixing Equipment

GB/T151-2014: Heat Exchanger

NB/T 47041-2014: Tower Container

NB/T47003.1-2009: Steel Welded Atmospheric Pressure Vessel

GB48069-2016: Food Safety National Standard for Metal Materials in Food Contact

These standards guarantee the safety, compliance, and durability of our industrial containers and process equipment, making us a trusted partner for industries across the globe.

Our Comprehensive Product Range

1. Pressure Vessels

Pressure vessels are critical for safely containing gases or liquids under pressure. Our pressure vessels are designed and manufactured to suit the needs of industries such as petrochemical, energy, and manufacturing. Made from high-quality materials like stainless steel and carbon steel, our vessels are durable, reliable, and built to meet the toughest regulatory requirements. We provide custom design, manufacture, installation, and testing to ensure each pressure vessel fits the unique needs of your operation.

2. Reactors

Our reactors are designed for processes involving heating, cooling, evaporation, and mixing. Serving industries such as petrochemical, pharmaceutical, food, and beverage, our reactors are customized for optimal efficiency. We specialize in designing reactors that meet your specific process requirements, ensuring high performance and longevity in demanding applications.

3. Heat Exchangers

Heat exchangers play a pivotal role in transferring heat between fluids in industrial processes. We design and manufacture customized heat exchangers for chemical, pharmaceutical, biotechnology, food processing, and many other industries. Our heat exchangers are built to enhance efficiency while maintaining safety, ensuring that they meet your operational needs.

4. Towers

Towers are used for physical processes like separation and absorption in gas and liquid mixtures. As a well-known tower manufacturer, we offer a range of equipment including distillation towers, adsorption columns, scrubbing towers, and more. All of our towers are designed and manufactured to meet ASME specifications and are customized based on the specific requirements of your process.

Advantages of Our Industrial Containers and Process Equipment

High Strength and Durability

Our products are made from premium materials, such as stainless steel and carbon steel, providing excellent corrosion resistance and long-term stability. This ensures that our industrial containers and process equipment perform reliably even under harsh operating conditions.

Safety Assurance

Our equipment is designed to meet the highest safety standards and regulations, ensuring secure and dependable operation. Safety devices and stringent quality checks are implemented throughout the production process to minimize risks.

Reliability and Stability

We maintain strict control over the design and manufacturing processes to guarantee the reliability and stability of our products. From material selection to final quality inspections, every stage is monitored to ensure optimal performance over the long term.

Economic Benefits

Our industrial containers and process equipment provide excellent return on investment by reducing operational costs, enhancing process efficiency, and minimizing downtime. The durability of our products ensures long-term savings for our clients.

Applications Across Key Industries

Our industrial containers and process equipment are designed to serve a broad range of industries, including:

Petrochemical Industry

Energy Industry

Pharmaceutical Industry

Food Industry

Textile Industry

Environmental Protection Industry (wastewater treatment, waste gas treatment, garbage disposal)

Aerospace

Metallurgical Industry

0 notes

Text

The V SMSR Gearbox: Revolutionizing Power Transmission in Industry

Introduction

In the world of industrial machinery, the efficiency and reliability of power transmission systems are crucial. Among the various types of gearboxes available, the V SMSR Gearbox (Shaft Mounted Speed Reducer) stands out for its innovative design and performance. This article delves into the features, benefits, and applications of the V SMSR Gearbox, highlighting why it is a preferred choice for many industrial applications.

Understanding the V SMSR Gearbox

The V SMSR Gearbox, or Shaft Mounted Speed Reducer, is a compact and efficient gearbox designed to provide speed reduction and increased torque in industrial machinery. Unlike traditional gearboxes that require a base or foundation for mounting, the SMSR gearbox is directly mounted onto the driven shaft, eliminating the need for additional support structures. This design simplifies installation and maintenance, making it a popular choice for various applications.

Key Components and Design Features

Gear Assembly: The core component of the V SMSR Gearbox is the gear assembly, which typically includes helical gears. Helical gears are known for their smooth and quiet operation, thanks to their angled teeth that gradually engage with each other.

Shaft Mounting: The defining feature of the SMSR gearbox is its shaft-mounted design. The gearbox is directly mounted onto the driven shaft, which simplifies the alignment process and reduces the need for additional components.

Torque Arm: The torque arm is an essential part of the SMSR gearbox. It prevents the gearbox from rotating and ensures that the torque is effectively transmitted to the driven equipment. The torque arm is usually adjustable, allowing for flexibility in installation.

Bearings and Seals: High-quality bearings and seals are used to ensure smooth operation and protect the internal components from contaminants. These elements are crucial for maintaining the longevity and performance of the gearbox.

Housing: The housing of the V SMSR Gearbox is typically made from robust materials such as cast iron or aluminum. It provides structural support and protection to the internal components, ensuring the gearbox can withstand harsh industrial environments.

Functionality and Operation

The V SMSR Gearbox operates by reducing the input speed from the motor and increasing the torque transmitted to the driven equipment. The helical gears within the gearbox mesh smoothly, providing efficient power transmission and minimizing energy losses. The shaft-mounted design ensures that the gearbox is directly aligned with the driven shaft, reducing misalignment issues and enhancing overall efficiency.

Applications of V SMSR Gearboxes

The versatility of the V SMSR Gearbox makes it suitable for a wide range of industrial applications. Some of the common applications include:

Conveyors: SMSR gearboxes are widely used in conveyor systems for material handling. Their compact design and efficient power transmission make them ideal for use in industries such as mining, aggregate processing, and manufacturing.

Crushers: In the mining and quarrying industry, SMSR gearboxes are used in crushers to provide the necessary torque for crushing operations. Their robust construction ensures reliable performance even in demanding environments.

Mixers and Agitators: SMSR gearboxes are employed in mixers and agitators used in chemical processing, food production, and wastewater treatment. Their ability to provide precise speed control and high torque is crucial for these applications.

Pumps: In various industrial processes, SMSR gearboxes are used to drive pumps. Their efficient power transmission ensures consistent fluid flow and reliable operation.

Cooling Towers: SMSR gearboxes are used in cooling towers to drive the fans that dissipate heat. Their compact design and reliable performance make them suitable for use in HVAC systems and power plants.

Advantages of V SMSR Gearboxes

Ease of Installation: The shaft-mounted design of the SMSR gearbox eliminates the need for additional support structures, simplifying the installation process. This design also reduces the time and labor required for setup.

Compact Design: The SMSR gearbox is compact and space-saving, making it ideal for applications with limited space. Its streamlined design also reduces the overall weight of the system.

High Efficiency: The use of helical gears in the SMSR gearbox ensures smooth and efficient power transmission. The gradual engagement of the gears reduces energy losses and enhances overall efficiency.

Low Maintenance: The robust construction and high-quality components of the SMSR gearbox result in low maintenance requirements. The direct shaft mounting also reduces the risk of misalignment and associated wear.

Versatility: The adjustable torque arm and flexible mounting options make the SMSR gearbox suitable for a wide range of applications. It can be easily adapted to different setups and operational requirements.

Maintenance and Care

To ensure the optimal performance and longevity of V SMSR Gearboxes, regular maintenance is essential. Here are some maintenance tips:

Lubrication: Regularly check and maintain the appropriate oil levels. Proper lubrication is crucial for reducing friction and wear between the gears and bearings.

Inspection: Periodic inspections of the gearbox can help identify potential issues early. Look for signs of wear, leaks, and unusual noises that may indicate problems.

Cleaning: Keep the gearbox and its surroundings clean to prevent dust and contaminants from entering the gearbox. This can help prevent damage to the gears and bearings.

Alignment: Ensure that the gearbox is properly aligned with the driven shaft during installation. Misalignment can lead to excessive wear and reduced efficiency.

Torque Arm Adjustment: Periodically check and adjust the torque arm to ensure it is properly positioned and securely fastened. This will prevent unnecessary stress on the gearbox and enhance its performance.

Innovations and Future Trends

The field of gearbox technology is continuously evolving, and the V SMSR Gearbox is no exception. Several innovations and trends are shaping the future of these gearboxes:

Advanced Materials: The use of advanced materials, such as composite materials and high-strength alloys, is enhancing the performance and durability of SMSR gearboxes.

Precision Manufacturing: Advances in manufacturing techniques, such as 3D printing and CNC machining, are enabling the production of gears with higher precision and tighter tolerances, resulting in improved performance.

Smart Gearboxes: The integration of sensors and IoT technology is leading to the development of smart gearboxes that can monitor their own performance and provide real-time data for predictive maintenance, reducing downtime and improving efficiency.

Energy Efficiency: As industries strive for greater energy efficiency, gearboxes are being designed to minimize energy losses and improve overall system efficiency. Innovations in lubrication and materials are contributing to this goal.

Conclusion

The V SMSR Gearbox is a vital component in many industrial applications, offering ease of installation, high efficiency, and reliable performance. Its unique shaft-mounted design and robust construction make it suitable for a wide range of uses, from conveyors and crushers to mixers and pumps. By understanding its design, functionality, and applications, industries can leverage the benefits of the V SMSR Gearbox to enhance their operations and achieve greater efficiency.

For more information about the V SMSR Gearbox and to explore our range of products, visit Cherry Belts.

0 notes

Text

Boilers and chillers Erection manufacturer and supplier

We have decades of experience servicing boilers and chillers for multiple commercial and industrial facilities as well as servicing other mechanical, electrical and plumbing systems.we provide Magnetic bearing chillers,Screw & scroll chillers,Reciprocating chillers,Steam & hot water boilers,Reciprocating chillers,Steam & hot water boilers,Chiller & boiler controls, System pumps and Cooling tower.

For more details please visit our website -

#boiler#chiller#erection#boiler manufacturer#supplier#hot water boiler#steam boiler#system pumps#Cooling tower

0 notes

Text

Flexible Service Solutions to Fit Your HVAC Needs

Partner with Carrier BluEdge for Your Service and Lifecycle Needs

Our best-in-class lifecycle service solution protects you and your investment from your start-up through customizable plans to mid-life upgrades, all to ensure your equipment’s peak performance and longevity. And all backed by unmatched expertise and the latest technology for years to come.

WE SERVICE ALL BRANDS OF EQUIPMENT We have extensive experience servicing all major heating, ventilation and cooling manufacturers’ equipment, as well as excellent technical understanding of HVAC systems including:

Air and water cooled chillers

packaged unitary Equipment

Air Handling Unit

cooling Tower

Building Controls

Heat Exchangers

Boilers

Split System

Pumps

Variable Refrigerant Flow (VRF)

Carrier is Here to Support You & Your HVAC System

Whether you are an engineer, contractor, architect, manager or owner, you can count on Carrier’s expertise and offerings to help you get the most from your HVAC system from start-up through the entire lifecycle.

#air quality#commercial ac#hvac services#hvac solutions#hvac repair#ac maintenance#indoor air quality#air conditioner maintenance#healthy buildings programs#air cooled

0 notes

Text

Vertical turbine pumps happen to be one of the most usually used deep well pumps. They are used in a wide range of applications such as water treatment in industries, in cooling towers of power plants, for pumping water into fields for irrigation purposes, etc. Yet, not many people are aware of the incredible features and working capacity of these pumps. As among the foremost vertical sump manufacturers in India, Flowmore happens to be here to guide you with the working attitude of these pumps and how to choose the vertical pumps that best suit your application requirements.

What is a vertical turbine pump?

A vertical turbine pump is a subcategory of centrifugal pumps. These pumps are specially designed to pump water from deep reservoirs and underground borewells. They are also known as shaft turbo pumps, sump pumps or deep-sea turbo pumps. These pumps are connected to the engine at ground level by a long vertical shaft, hence the name vertical turbine pumps. It transports fluid/water from deep groundwater reservoirs to ground level. Vertical turbine pumps are used in a wide range of industrial environments and are proven pumps. The efficiency and ease of maintenance of these pumps make them an excellent choice for various industrial requirements. These pumps are mainly used in chemical processing, petrochemical, power generation, oil and gas exploration, mining and seawater desalination industries.

How do vertical turbine pumps work? The Principle of functioning

Vertical turbine pumps move in a specific direction and cause gas molecules to collide with moving solid surfaces. These pumps have a fast-spinning fan that hits the gas molecules and blows them from the inlet to the outlet. This action happens to cause a vacuum-like status inside the pump chamber. Most Vertical turbine Pumps India have manifold stages. Each stage has two blades: a rotor blade that spins at high speed and a stator blade. This mechanical action of the blade transfers kinetic energy to the gas molecule. The gas molecule hits the rotor surface again and moves towards the exit.

Structure of vertical turbine pumps

Vertical turbine pumps happen to be designed with open and closed impellers. The diffuser bowl bearings are lubricated by the transferred liquid.

0 notes

Text

Why Industrial Chillers are Essential for UAE Industries

Industrial chillers are used to chill industrial equipment or processing. They are applications used to pump cooled water or other liquid through an industrial process such as laser welding, concrete batching, machine tooling, chemical processing, plastic injection and blow molding. Industrial chillers maintain temperature control of the equipment to save production time, increase production quality and avoid sudden breakdowns. This type of technology is necessary for particular industry applications to prevent heat damage to the manufacturing system during production.

Industrial chiller, is a specialized category of equipment, sometimes referred to as a chiller air cooled or chiller water cooled. This cooling system is extremely important in the food and beverage processing industry, vacuum systems, x-ray diffraction, power generation stations, analytical equipment, semiconductors, gas cooling as well as MRI machines and lasers. Industrial chillers are specifically engineered to prevent downtime during the production process.

Industrial water chillers are designed to assist in the creation of a safe, smooth and efficient application when it comes to temperature control. Whether using an air or water industrial chiller, the overall costs in energy can be significantly reduced benefiting not only the organization but the impact on the environment is greatly reduced as well. Industrial water chillers come in either central chillers for large plant environments or portable industrial chillers for precision applications. Portable industrial chillers on wheels are a convenient and cost effective way to ensure temperature regulation on sensitive applications that need closer attention to prevent unexpected problems like critical government communication heat loads.

In specific industries where cooling is required in the manufacturing or storage of products, a chiller is the solution for stability of production. Grocery distribution warehouses, fruit vegetable storage and loading docks all depend on industrial chillers for the preservation of their products.

Our skilled engineers are always here to help in various cooling system requirements to ensure stable cooling and high performance.

Our industrial chiller lines can support various industrial processes but not limited to those applications, so if you have any question about cooling, get in contact with us and we will get back to you with reliable cooling solutions.

Industrial Chiller Types

Air-Cooled Chillers: Dissipate heat by using the surrounding air. ideal for settings with limited or expensive water resources.

Water-Cooled Chillers: Displace heat with water by using a cooling tower. more efficiency than air-cooled chillers, particularly in warm regions.

Evaporative Condensed Chillers: Combining water and air cooling, evaporative condensed chillers can provide great efficiency in certain applications.

Applications

Plastic Industry: The plastics industry uses cooling molds and machinery to improve production speed and product quality.

Food and Beverage Industry: Keeping production, storage, and transit areas at safe temperatures is the responsibility of the food and beverage industry.

Pharmaceuticals: Accurate temperature regulation throughout the production and storage of medications.

HVAC systems: Supplying big business and industrial facilities with reliable cooling.

Laser cutting: Maintaining the ideal temperature for laser equipment to guarantee accuracy and effectiveness.

Advantages

Energy Efficiency: Newer chillers are made to use less energy, which lowers their running expenses.

Reliability: Designed to run continuously with little maintenance and downtime.

Flexibility: Offered in a range of configurations to accommodate diverse industry requirements and scales.

Selecting the Appropriate Chiller

Think about things like chilling capacity, energy efficiency, installation space, and particular process needs when choosing an industrial chiller. Finding the ideal chiller type and configuration for your requirements might be facilitated by consulting with an expert.

Visit MTECH CHILLER for more thorough details and expert advice on choosing and setting up industrial chillers.

1 note

·

View note

Text

Veda Engineering: Leading EPC And Utility Engineering Company In Pune, Maharashtra

Veda Engineering is a shining beacon of excellence for Engineering, Procurement, and Construction in the vibrant industrial landscape that is Pune, Maharashtra. Veda Engineering is a leading utility engineering company in Maharashtra. It has always been at the forefront when it comes to delivering innovative solutions for industries throughout the region.

Veda Engineering is a trusted engineering partner because of its commitment to quality, customer satisfaction and reliability.

Comprehensive EPC Solutions Veda Engineering is a specialist in EPC solutions that are tailored to meet the needs of each client. Veda Engineering provides seamless project execution from conception and design through procurement, construction and commissioning.

Utility Engineering Services Veda Engineering is a leading utility company in Maharashtra. It offers a variety of services to optimize utility systems at industrial facilities. Veda Engineering offers cutting-edge solutions for steam boilers and thermic fluid heating systems, as well as hot water generators and cooling towers.

Authorized Thermax Dealer Thermax Limited is a global leader of energy and environmental solutions. Veda Engineering leverages this partnership to offer a comprehensive range Thermax solutions and products that meet the needs of clients in a variety of industries.

Steam Boiler Manufacturer and Supplier Veda Engineering is a reliable steam boiler manufacturer and supplier in Maharashtra. Veda Engineering offers high-quality steam solutions for any industrial application.

Supplier and manufacturer of Thermic fluid heaters Veda Engineering is a specialist in the supply and manufacture of thermic liquid heaters. These are essential for applications that require indirect heating. Veda Engineering thermic heaters are trusted across Maharashtra for their efficiency, durability and reliability.

Supplier and manufacturer of Hot Water Generator Veda Engineering provides innovative hot water generators designed to meet the needs of different industrial processes. Veda Engineering hot water generators are designed with energy efficiency and reliability in mind. They provide consistent performance for clients and help them save money.

Cooling Tower Suppliers and Manufacturers Veda Engineering cooling towers can be used for HVAC systems, industrial process, or power plants.

Comprehensive Steam Accessories and Systems Veda Engineering offers a wide range of steam systems and accessories to complement the equipment it supplies and manufactures. Veda Engineering integrates steam systems seamlessly, from valves and pumping systems to control systems and instruments.

Customer satisfaction is our top priority at Veda Engineering. Our team of professionals is dedicated to exceeding client expectations with innovative solutions, impeccable workmanship, and unmatched service. Veda Engineering is the leading provider of EPC and utility engineering services in Pune, Maharashtra and beyond.

Visit our website for more information on our products and services, or contact us directly. Veda Engineering is your trusted partner in engineering excellence.

0 notes

Text

Unlocking the Magic of Mono Ethylene Glycol (MEG): From Production to Limitless Possibilities!

Mono ethylene glycol (MEG), also known as MEG or ethylene glycol, might sound like something yummy, but don't be deceived! This popular industrial chemical is a colorless, odorless liquid with a large number of applications. The MEG is involved in many things in our everyday life like keeping your car from freezing in winter to the comfy fleece jackets you love. But is MEG safe? How is it made? And what precisely are all those various applications? In this blog post, we will explore the world of mono ethylene glycol, the fact from the fiction and the science behind this amazing chemical.

𝗖𝗹𝗶𝗰𝗸 𝗛𝗲𝗿𝗲 𝗙𝗼𝗿 𝗙𝘂𝗹𝗹 𝗥𝗲𝗽𝗼𝗿𝘁 𝗮𝘁 𝗠𝗼𝗻𝗼 𝗘𝘁𝗵𝘆𝗹𝗲𝗻𝗲 𝗚𝗹𝘆𝗰𝗼𝗹 (𝗠𝗘𝗚): https://www.chemanalyst.com/Pricing-data/mono-ethylene-glycol-4

Introduction

Mono ethylene glycol (MEG), also known by various names like EG, 1,2-ethanediol, or 1,2-Dihydroxyethane, is a clear, colorless liquid with a slightly syrupy texture. Despite its sweet taste, it has almost no smell. This versatile industrial workhorse is easily mixed with water, alcohols, and many other organic compounds. Its biggest jobs? Making polyester fibers for clothing and forming the base for antifreeze, coolants, and aircraft de-icing fluids.

Manufacturing Process

EO REACTION, EO AND CO SCRUBBING SECTION

Ethylene, oxygen, and methane/nitrogen ballast gas are introduced from the battery limits and blended with lean cycle gas before entering a preheating unit, known as the Gas-Gas Exchanger. From there, the gas mixture proceeds to the EO Reactor/Gas Coolers, where approximately 9.6% of the ethylene undergoes conversion per pass. At the start-of-run (SOR), the selectivity of ethylene to ethylene oxide stands at 83.4%. The reactors generate ethylene oxide, which is then extracted from the exit gas of the EO Reactor/Gas Coolers using lean cycle water, with the resulting rich cycle water directed to the EO Stripping Section. The scrubbed cycle gas is directed through the CO2 Contactor Section of the Wash Tower to eliminate carbon dioxide produced in the EO Reactor/Gas Coolers. The gas, now depleted of CO2, is recompressed and returned to the EO Reactor/Gas Coolers. Heat generated by the reaction is dissipated by boiling water on the shell side of the multi-tubular reactors, facilitated by thermo-syphon action driving water circulation through the reactors' shell side. The steam-water mixture from the reactors' shell side is directed to steam drums, where makeup boiler feed water is preheated and steam is separated from water, subsequently being routed to the steam header.

CO2 REMOVAL SYSTEM SECTION

The concentrated carbonate solution from the Carbonate Solution Exchanger, which is part of the EO and CO2 Scrubbing Section, undergoes regeneration at nearly atmospheric pressure through the use of stripping steam. Following regeneration, the revitalized lean carbonate solution is reintroduced into the CO2 Contactor Section of the Wash Tower within the EO and CO2 Scrubbing Section, where it resumes its role in absorbing CO2.

EO STRIPPING AND EO REABSORPTION SECTION

The concentrated solution of ethylene oxide in the rich cycle water undergoes preheating prior to its introduction into the Stripping Column, where the ethylene oxide is separated. Subsequently, the depleted or lean cycle water is pumped through a sequence of heat exchangers to cool it down before being returned to the Scrubber Section of the Wash Tower within the EO and CO2 Scrubbing Section. A portion of this water is diverted as a bleed stream and directed to the glycol unit to eliminate the glycol accumulated in the cycle water loop. The ethylene oxide present in the vapor overhead from the Stripping Column is reabsorbed through contact with chilled process water in the Reabsorber. The vapor recovered from the Reabsorber is compressed back into the cycle gas system by the Reclaim Compressor, while the remaining liquid is transferred to the Glycol Feed Stripper in the Glycol Reaction Section.

GLYCOL REACTION AND GLYCOL EVAPORATION SECTION

The ethylene oxide solution retrieved from the Re-absorber is directed to the Glycol Feed Stripper to eliminate CO2. The resulting CO2-free stream is then heated and introduced into the Glycol Reactor. The output from the reactor is channeled into the initial stage of a Seven Effect Evaporator System. The bleed from the cycle water and the MEG Column Condenser blow down are treated in a Cycle Water Treating Unit before being utilized in the evaporator system as reflux. The condensate produced by the evaporator reboilers is employed to heat the feed for the Glycol Reactor before being transferred to the Recycle Water Tank. The vapor discharged from the Fifth Effect Evaporator, known as extraction steam, is utilized in the Regenerator Extraction Re-boiler. The vapor from the Sixth Effect Evaporator serves as stripping steam for both the Stripping Column and Glycol Feed Stripper, also assisting in reboiling the Sixth Effect Evaporator bottoms and heating the feed for the Glycol Reactor. The vapor from the Vacuum Effect Evaporator is condensed, with a portion returning to the column as reflux, another portion serving as reflux for the Drying Column within the Glycol Drying Section, and the rest directed to the Recycle Water Tank. The concentrated glycol extracted from the Vacuum Effect Evaporator is pumped into the Drying Column for the removal of residual water.

GLYCOL DRYING AND GLYCOL PURIFICATION SECTION

• The raw moist glycol undergoes drying via vacuum distillation within the Drying Column. The residue from the Drying Column is directed to the MEG Column, where a high-quality fiber-grade mono-ethylene glycol product is extracted as a side stream near the upper part of the column. This product is then cooled and stored in the MEG Rundown Tanks before being subsequently transferred to storage. • The residual glycol from the MEG Column is routed to the MEG Splitter, where any remaining MEG is separated from the heavier glycols and returned to the Vacuum Effect Evaporator for recycling. The bottom output from the MEG Splitter is transferred to the DEG Column within the DEG and TEG Purification Section for the separation of Diethylene Glycol (DEG) and triethylene glycol (TEG).

DEG AND TEG PURIFICATION SECTION

The heavier glycols present in the bottom stream of the MEG Splitter undergo distillation in the DEG Column, where the Diethylene Glycol (DEG) product is collected as the overhead stream. Following collection, the DEG product is cooled and stored in the DEG Rundown Tanks before being pumped to storage. The residue from the DEG Column is then directed to the TEG Column for further distillation, where the triethylene glycol (TEG) product is obtained as the overhead stream. Once collected, the TEG product is cooled and stored in the TEG Rundown Drums prior to pumping to storage. The bottom output from the TEG Column, which contains the poly-glycols, is stored in the PEG Drum

𝗚𝗲𝘁 𝗥𝗲𝗮𝗹-𝗧𝗶𝗺𝗲 𝗣𝗿𝗶𝗰𝗲𝘀 𝗙𝗼𝗿 𝗠𝗼𝗻𝗼 𝗘𝘁𝗵𝘆𝗹𝗲𝗻𝗲 𝗚𝗹𝘆𝗰𝗼𝗹 (𝗠𝗘𝗚): https://www.chemanalyst.com/Pricing-data/mono-ethylene-glycol-4

Major Applications of Mono Ethylene Glycol

1. Chemical Intermediates

MEG, a crucial component for Polyethylene Terephthalate (PET) production, plays a vital role in manufacturing PET items like Polyester film and PET bottles, commonly utilized in food and beverage packaging. These PET products boast complete recyclability and are certified safe for food and beverage use. The purity of MEG directly impacts PET quality, and GC-produced MEG stands out with an impressive purity level of 99.9% by weight, ensuring the production of premium PET material.

2. Polyester Fibres

Monoethylene glycol (MEG) is the essential building block for polyester fibers, commonly used in clothing and textiles. The purity of MEG significantly impacts the quality of the final polyester fiber. High-purity MEG, like that produced by GC Glycol (at 99.9% wt), is key to creating top-quality polyester fibers. These polyester fibers are known for their strength and comfortable wear. They are also easy to care for, wrinkle-resistant, and can be blended with other fibers to add specific properties as needed.

3. Coolants

Monoethylene glycol (MEG) plays a critical role in engine coolant formulations. By significantly elevating the boiling point of the water mixture, MEG enhances the cooling system's ability to regulate engine temperature. This dual functionality safeguards the engine from overheating in hot weather and freezing in cold climates, ensuring optimal performance and longevity.

4. De-icing and Coolants

Monoethylene glycol (MEG) finds critical application within the industrial sector, particularly in antifreeze formulations. Its exceptional ability to depress the freezing point of water makes MEG a key component in coolants, aircraft anti-icers, and deicers. This ensures optimal performance and protection in environments susceptible to freezing temperatures.

Market Outlook

Mono Ethylene Glycol (MEG) market is driven by its remarkable versatility and high demand across various industries. Renowned for its durable, hydrophobic, and tenacious properties, MEG serves as a pivotal ingredient or feedstock in the production of Polyester Fibers, Polyester Films, Polyethylene Terephthalate (PET), antifreeze products, Coolants, solvents, and more. Its humectant nature also finds application in paper, printing inks, leather, fibers treatment, and cellophane industries. With a broad spectrum of end-use sectors including Textile, Packaging, Cosmetics, Pharmaceuticals, Food and Beverage, Automobile, Chemicals, Adhesives & Sealants, and others, MEG plays a vital role. Majority of the globally produced MEG contributes significantly to Polyester Fibers, closely followed by Polyethylene Terephthalate (PET) and Polyester films, cementing its status as a cornerstone of industrial chemistry, fostering innovation, and driving growth across diverse markets.

Mono Ethylene Glycol Major Global Players

Significant players in the Global Mono Ethylene Glycol market are Nan Ya Plastics, Mitsubishi Chemical Corporation, Reliance Industries Limited, Eastern Petrochemical Company (SHARQ, Shell Chemicals, MEGlobal, Huntsman Corporation, Lianyungang Petrochemical, Hengli Petrochemicals Co.,Ltd, Jubail United Petrochemical company, INEOS and Others

Conclusion:

In conclusion the Mono Ethylene Glycol (MEG) market is likely to grow because of its versatility and numerous applications in different industries. MEG is a very important ingredient in the production of Polyester Fibres, Polyester Films, Polyethylene Terephthalate (PET), antifreeze products, Coolants, solvents, and more due to its properties such as durability, hydrophobicity, and tenacity. Its humectant property makes it even more useful in the industries like paper, printing inks, leather, fibres treatment, and cellophane manufacturing. As a key ingredient or feedstock, MEG has become an indispensable part of sectors such as Textile, Packaging, Cosmetics, Pharmaceuticals, Food and Beverage, Automobile, Chemicals, Adhesives & Sealants, and others. The large worldwide need for MEG proves its importance in the innovation and growth of these industries. The market structures are still changing, and MEG is still the main industry of industrial chemistry, which is ready to face the challenges and opportunities of the future markets.

0 notes