#Conveyor System Manufacturers in Maharashtra

Explore tagged Tumblr posts

Text

Conveyor System Manufacturers in India - Santek

At Santek Equipments Private Limited, we are not just manufacturers; we are creators of seamless motion in industries across India. With an unwavering commitment to excellence, we have earned our reputation as one of the leading Conveyor System Manufacturers in India.

#Conveyor System Manufacturers in India#Conveyor System Manufacturers in Pune#Conveyor System Manufacturers in Maharashtra#Conveyor System Manufacturers near me#Conveyor System

0 notes

Text

RCN Grading Machine: automatic kaju processing machine

Introduction

The cashew processing industry has witnessed remarkable technological advancements, aimed at enhancing efficiency, productivity, and product quality. Among these advancements, the RCN Grading Machine is a pivotal solution for effective cashew grading. This machine streamlines the sorting process, ensuring that cashew nuts are categorized according to size and quality, which is crucial for meeting market demands. In this comprehensive article, we will delve into the features and benefits of the RCN Grading Machine, explore its components, and discuss its significance in the context of modern cashew processing.

Understanding Cashew Grading

Cashew grading refers to the process of sorting cashew nuts based on various parameters, including size, shape, and quality. This grading process is essential for several reasons:

Quality Control: Proper grading ensures that only the best quality cashew nuts reach consumers, enhancing customer satisfaction and loyalty.

Market Value: Graded cashew nuts fetch higher prices in the market. Different grades can command different price points, so processors can optimize their profits by accurately grading their products.

Operational Efficiency: An efficient grading process allows for faster production cycles, reducing the time and labor required for sorting.

Packaging and Distribution: Grading facilitates better packaging, ensuring that nuts of similar sizes are packed together, which helps in maintaining quality during transportation.

The RCN Grading Machine is specifically designed to address these needs, making it an indispensable asset in the cashew processing industry.

Features of the RCN Grading Machine

1. Grading Conveyor System

At the heart of the RCN Grading Machine is its advanced grading conveyor system. This system plays a crucial role in the sorting process by ensuring smooth and efficient movement of cashew nuts during grading. The grading conveyor allows for the continuous flow of nuts, reducing bottlenecks and improving overall processing speed.

2. Belted Conveyor

The inclusion of a belted conveyor enhances the machine’s functionality. The belt transports cashews with minimal damage, maintaining their quality throughout the grading process. This is particularly important as cashew nuts can be delicate, and improper handling can lead to breakage or blemishes that reduce their market value.

3. Adjustable Conveyor

One of the standout features of the RCN Grading Machine is its adjustable conveyor. This feature allows operators to customize the machine settings based on the specific requirements of the cashew nuts being processed. Whether the nuts are large or small, the adjustable conveyor can be fine-tuned to optimize the grading process, ensuring accuracy and efficiency.

4. Versatility in Conveyor Systems

The RCN Grading Machine is part of a comprehensive suite of conveyor systems that can be integrated into any cashew processing setup. These conveyor systems are designed to work harmoniously with other machines in the processing line, such as automatic cashew peeling machines and automatic cashew cutting machines. This integration creates a seamless workflow, reducing downtime and maximizing productivity.

5. Durability and Low Maintenance

Constructed from high-quality materials, the RCN Grading Machine is built to withstand the rigors of continuous operation. Its robust design minimizes wear and tear, reducing maintenance needs and ensuring longevity. This durability makes it a cost-effective investment for cashew processors looking to enhance their operational capabilities.

6. User-Friendly Interface

The machine features a user-friendly interface that simplifies operation. Operators can easily adjust settings, monitor the grading process, and troubleshoot any issues that may arise. This ease of use reduces training time and enhances overall operational efficiency.

The Importance of Efficient Cashew Grading

As the demand for cashew nuts continues to rise globally, efficient cashew grading becomes increasingly important. The RCN Grading Machine addresses this need by providing processors with a reliable solution for sorting their products accurately and efficiently. Here are some of the key benefits of using this machine:

1. Increased Productivity

With its advanced grading conveyor system and seamless operation, the RCN Grading Machine significantly increases productivity. The continuous flow of cashews through the grading process allows processors to handle larger volumes in less time, meeting market demands more effectively.

2. Improved Quality Control

By accurately sorting cashews based on size and quality, the RCN Grading Machine enhances quality control measures. This leads to higher-quality products, which are essential for maintaining a competitive edge in the market. Consumers are increasingly discerning about the quality of the food products they purchase, and processors must respond accordingly.

3. Cost Efficiency

Investing in the RCN Grading Machine can lead to significant cost savings in the long run. By optimizing the grading process, processors can reduce labor costs, minimize product loss, and improve their overall operational efficiency. Additionally, better quality products can command higher prices, further enhancing profitability.

4. Scalability

As a processor’s business grows, the RCN Grading Machine can easily adapt to increased production demands. Its adjustable conveyor and integration with other automatic processing machines make it a versatile solution for businesses of all sizes.

The Role of RCN Grading Machine in Automatic Cashew Processing

The RCN Grading Machine plays a vital role in the broader context of automatic cashew processing. To fully appreciate its significance, it’s essential to explore how it fits into the overall production line.

1. Integration with Automatic Cashew Processing Machines

The RCN Grading Machine can be seamlessly integrated with various automatic cashew processing machines, such as:

Automatic Cashew Peeling Machine: This machine efficiently removes the outer shell of cashews, preparing them for the grading process. The RCN Grading Machine ensures that only the best-peeled nuts are sorted and packaged.

Automatic Cashew Cutting Machine: After grading, the RCN Grading Machine can direct cashews to the cutting machine for further processing. This integration creates a streamlined workflow that reduces manual handling and enhances efficiency.

Automatic Kaju Processing Machine: The RCN Grading Machine is part of a complete processing solution that includes automatic machines designed specifically for kaju processing, ensuring high quality at every stage.

2. Ensuring Consistency in Quality

The integration of the RCN Grading Machine with other automatic machines ensures that quality control measures are maintained throughout the entire processing line. Consistent grading leads to uniformity in size and quality, which is crucial for packaging and distribution.

3. Minimizing Manual Labor

By automating the grading process, the RCN Grading Machine significantly reduces the need for manual labor. This not only decreases labor costs but also minimizes the risk of human error, leading to more accurate grading results.

Choosing the Best Automatic Cashew Processing Machine Supplier in India

When considering the investment in the RCN Grading Machine, it’s essential to select a reputable supplier. As the best automatic cashew processing machine supplier in India, we are committed to providing high-quality machinery that meets the specific needs of cashew processors. Here’s what to look for in a supplier:

1. Industry Experience

Choose a supplier with extensive experience in the cashew processing industry. A knowledgeable supplier will understand the unique challenges faced by processors and can offer tailored solutions.

2. Range of Products

The best suppliers offer a comprehensive range of machines, including the RCN Grading Machine, automatic cashew peeling machines, automatic cashew cutting machines, and more. This range ensures that processors can find all the equipment they need from a single source.

3. Quality Assurance

Look for a supplier that prioritizes quality assurance. High-quality machines are essential for ensuring consistent processing results and minimizing downtime due to maintenance issues.

4. After-Sales Support

Reliable after-sales support is crucial for maintaining the performance of processing machines. Choose a supplier that offers training, maintenance services, and readily available replacement parts.

5. Competitive Pricing

While cost should not be the sole factor in your decision, it is essential to find a supplier that offers competitive pricing without compromising on quality. Evaluate the overall value offered by the supplier in terms of machine features, performance, and support.

Conclusion

In conclusion, the RCN Grading Machine is a game-changer in the cashew processing industry. With its advanced features, including the grading conveyor, belted conveyor, and adjustable conveyor, it provides an efficient solution for cashew grading. The machine’s integration with other automatic processing machines ensures a streamlined workflow, enhancing overall productivity and product quality.

As the top cashew processing equipment supplier in India, we are committed to delivering the best automatic cashew processing machines to our customers. Our dedication to quality, innovation, and customer satisfaction sets us apart in the industry. By investing in the RCN Grading Machine and other automatic processing machines, cashew processors can optimize their operations, reduce costs, and meet the growing demands of the market.

Choose us as your partner in cashew processing and experience the difference that advanced technology can make. Elevate your production capabilities and ensure the highest quality products for your customers with our state-of-the-art machinery. Partner with us today to take your cashew processing operations to the next level!

#grading conveyor#conveyor#cashew grading#belted conveyor#adjustable conveyor#conveyor systems#"Cashew Processing Equipments#Automatic Cashew Processing Machine#Cashew Processing Machine#automatic cashew peeling machine supplier in india#Cashew Processing Equipments#Automatic Kaju Processing Machine#Fully Automatic Cashew Processing Machine#kaju processing machine#cashew nut peeling machine#cashew processing#kaju cutting machine#cashew manufacturers in maharashtra#automatic cashew nut cutting machine#cashew machine manufacturer#cashew processing machinery#cashew nut cutting machine

0 notes

Text

Mustard Oil / Edible Oil Bottle Filling Line

Company Overview: Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Mustard Oil / Edible Oil Bottle Filling Line in Ahmedabad, Gujarat, India. Shiv Shakti Machtech's Mustard Oil Bottle Filling Machine is crafted from top-notch materials, adhering to hygiene standards and facilitating easy cleaning. A Mustard Oil or Edible Oil Bottle Filling Line comprises a series of machines designed for filling, capping, and labeling bottles containing mustard oil or other edible oils. Filling Machine: Equipped to precisely fill bottles with desired quantities of mustard oil or edible oil. Features a conveyor belt system for bottle transportation, precision filling nozzles, and volume adjustment controls. Ensures uniform filling levels and reduces spillage or wastage of oil. Capping Machine: Responsible for securely sealing filled bottles with caps or lids. Utilizes various capping mechanisms (e.g., screw caps, press-on caps, snap-on caps) based on bottle and cap types. Ensures tight and consistent sealing to prevent oil leakage or contamination. Labeling Machine: Applies labels onto filled and capped bottles, providing product information, branding, and regulatory details. Operates with precision and consistency, even at high production speeds. Features may include label applicators, sensors, and controls for accurate label placement and alignment. Application: Food and beverage industry: Used in edible oil processing plants, bottling facilities, and packaging operations for Cooking Oil, Mustard Oil, Soybean Oil, Cottonseed Oil, Vanaspati Ghee, Rice Bran Oil, Sesame Oil, Palm Oil, Mustard Oil, Kachi Ghani Mustard Oil, Refined Oil, Coconut Oil, Sunflower Oil, Corn Oil, Olive Oil, Soya Oil, Canola Oil, Safflower Oil, Oil Spray, Avocado Oil, Rapeseed Oil, Nut Oils, Organic Safflower Oil, Palm Oil, Groundnut Oil, Edible Oil, Vegetable Oil. Geographical Coverage: Shiv Shakti Machtech serves as the Manufacturer and Supplier of Mustard Oil / Edible Oil Bottle Filling Line in Ahmedabad, Gujarat, India, and various locations across the country, including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal. For further details, interested parties can contact Shiv Shakti Machtech. Read the full article

#Ahmedabad#AndhraPradesh#ArunachalPradesh#Assam#Bihar#Chandigarh#Chhattisgarh#DadraandNagarHaveliandDamanandDiu#Delhi#Exporter#Goa#Gujarat#Haryana#HimachalPradesh#India#JammuandKashmir#Jharkhand#Karnataka#Kerala#Ladakh#MadhyaPradesh#Maharashtra#Manipur#Manufacturer#Meghalaya#MustardOil/EdibleOilBottleFillingLine#MustardOil/EdibleOilBottleFillingLineinGujarat#MustardOil/EdibleOilBottleFillingLineinIndia#Nagaland#Odisha

2 notes

·

View notes

Text

The Evolution and Growth of TPU Film in India: A Comprehensive Analysis

Introduction: Understanding the TPU Film Revolution

The Indian manufacturing sector has witnessed remarkable growth in recent years, with specialized materials like Thermoplastic Polyurethane (TPU) film emerging as a crucial component across various industries. As TPU film manufacturers in India continue to expand their operations, the country is positioning itself as a significant player in the global TPU market. This comprehensive analysis explores the current landscape, challenges, and opportunities within India's TPU film manufacturing sector.

The Rise of TPU Film Manufacturing in India

India's journey in TPU film production began modestly but has grown exponentially over the past decade. With increasing domestic demand and export opportunities, numerous manufacturers have established state-of-the-art facilities across industrial hubs in Gujarat, Maharashtra, and Tamil Nadu. These manufacturers have invested heavily in research and development, leading to innovative products that meet international standards while maintaining cost-effectiveness.

Understanding Thermoplastic in India

The best Thermoplastic polyurethane in India has evolved from being primarily import-dependent to having a robust domestic manufacturing base. The versatility of TPU as a material has driven its adoption across multiple sectors, from automotive to electronics. Indian manufacturers have mastered the art of producing different grades of TPU, catering to varied industrial requirements while maintaining high-quality standards.

Applications and Market Segments

Industrial Applications

The industrial sector remains the largest consumer of TPU films, utilizing them for:

Machine part protection

Conveyor belt systems

Industrial packaging

Anti-corrosion coatings

Consumer Electronics

The booming electronics industry has created substantial demand for TPU protective film, particularly in:

Smartphone screen protectors

Laptop covers

Tablet accessories

Wearable device protection

Automotive Sector

Modern vehicles incorporate TPU films in various applications:

Paint protection films

Interior surface protection

Undercarriage protection

Dashboard and console protection

Manufacturing Excellence and Technology

Advanced Production Techniques

Indian manufacturers have adopted cutting-edge technologies, including:

Precision extrusion systems

Advanced quality control mechanisms

Automated production lines

Clean room facilities for specialized products

Quality Control and Standards

The industry maintains strict quality parameters through:

ISO certifications

International testing standards

Regular quality audits

Advanced testing laboratories

Market Dynamics and Growth Factors

Economic Drivers

Several factors contribute to the sector's growth:

Increasing industrial automation

Growing electronics manufacturing

Rising automotive production

Export opportunities

Regulatory Environment

The government has supported the industry through:

Make in India initiatives

Industrial corridors development

Export promotion schemes

Quality standard implementation

Innovation and Research Development

Product Development

Indian TPU film manufacturers focus on:

Custom formulations

Enhanced durability

Improved clarity

Environmental sustainability

Sustainable Manufacturing

Sustainability initiatives include:

Reduced energy consumption

Waste reduction programs

Recycling initiatives

Eco-friendly formulations

Supply Chain and Distribution

Raw Material Sourcing

Manufacturers have developed robust supply chains through:

Local supplier development

International partnerships

Quality raw material sourcing

Strategic inventory management

Distribution Networks

Efficient distribution is achieved via:

Pan-India presence

Strategic warehousing

Just-in-time delivery

Digital tracking systems

Future Prospects and Challenges

Growth Opportunities

The sector shows promising growth potential in:

Electric vehicle components

Smart device protection

Medical device protection

Sustainable packaging

Industry Challenges

Manufacturers must address:

Raw material price fluctuations

Technology upgradation costs

International competition

Quality consistency

Environmental Considerations

Sustainable Practices

The industry is adopting:

Energy-efficient production

Water conservation

Waste reduction

Green technology integration

Regulatory Compliance

Manufacturers ensure:

Environmental clearances

Pollution control measures

Waste management systems

Safety protocols

Investment and Financial Aspects

Capital Requirements

The industry requires investments in:

Modern machinery

Research facilities

Quality control systems

Skilled workforce development

Return on Investment

Investors can expect:

Growing market share

Export opportunities

Technology valorization

Sustainable growth

Human Resource Development

Skill Development

Companies focus on:

Technical training programs

Quality control expertise

Research capabilities

Management skills

Employment Generation

The sector contributes through:

Direct employment

Indirect job creation

Skill enhancement

Career development

Market Competition and Positioning

Competitive Advantage

Indian manufacturers leverage:

Cost-effective production

Quality standards

Technical expertise

Customer service

Market Differentiation

Companies focus on:

Product specialization

Custom solutions

Value-added services

Technical support

Customer Service and Support

Technical Assistance

Manufacturers provide:

Application guidance

Problem-solving support

Product selection assistance

Installation support

After-Sales Service

Services include:

Product warranties

Technical support

Replacement policies

Customer feedback systems

Industry Collaborations and Partnerships

Research Institutions

Partnerships exist with:

Technical institutes

Research laboratories

Testing facilities

Innovation centers

International Collaborations

Companies maintain:

Technology transfers

Joint ventures

Export partnerships

Knowledge exchange

Quality Assurance and Testing

Testing Protocols

Manufacturers implement:

Material testing

Performance testing

Durability testing

Environmental testing

Certification Standards

The industry maintains:

ISO certifications

Industry standards

Environmental compliance

Safety certifications

Market Expansion Strategies

Domestic Growth

Companies focus on:

Regional expansion

Market penetration

Product diversification

Customer base expansion

Export Markets

Opportunities exist in:

Southeast Asia

Middle East

Africa

South America

Conclusion

The TPU film manufacturing sector in India represents a dynamic and growing industry with significant potential for further expansion. As manufacturers continue to invest in technology, quality, and sustainability, the sector is well-positioned to meet both domestic and international demand. The industry's commitment to innovation, quality, and customer service ensures its continued growth and success in the global market.

Frequently Asked Questions (FAQs)

What makes TPU film different from other protective films?

TPU film offers superior elasticity, durability, and scratch resistance compared to other materials. It has excellent optical clarity, self-healing properties for minor scratches, and maintains its protective properties even under extreme conditions. Unlike other films, TPU can be easily applied without bubbles and doesn't yellow over time.

How long does TPU protective film typically last?

The lifespan of TPU film varies depending on usage conditions and quality, but high-quality TPU protective films can last between 3-5 years under normal conditions. Industrial-grade TPU films used in heavy-duty applications may have even longer lifespans when properly maintained and installed.

Is TPU film environmentally friendly?

Modern TPU films are increasingly being manufactured with environmental considerations in mind. Many TPU film manufacturers in India now produce recyclable variants and use eco-friendly production processes. While traditional TPU is not biodegradable, newer formulations are being developed with enhanced environmental properties.

What thickness of TPU film is ideal for electronic device protection?

For electronic devices, TPU film thickness typically ranges from 0.1mm to 0.3mm. The ideal thickness depends on the specific application: screen protectors usually use 0.1-0.15mm film for better touch sensitivity, while back covers might use 0.2-0.3mm for enhanced protection. Custom thicknesses are available for specific requirements.

0 notes

Text

Rotary / Linear Vibrator Controller, Rotary / Linear Vibrator Controllers, Manufacturer, Supplier, India

We are Manufacturer, Supplier, Exporter of Rotary / Linear Vibrator Controller, Rotary / Linear Vibrator Controllers from Pune, Maharashtra, India.

Proximity Sensor, Proximity Sensors, Proximity Switch, Proximity Switches, AC Proximity Switch, AC Proximity Switches, Addressable Pull Cord Switch, Addressable Pull Cord Switches, Belt Loading Monitor, Belt Loading Monitors, Belt Monitoring Switch, Belt Monitoring Switches, Belt Rupture Switch, Belt Rupture Switches, Belt Sway Switch, Belt Sway Switches, Belt Tear Switch, Belt Tear Switches, Capacitive Proximity Sensor, Capacitive Proximity Sensors, Capacitive Proximity Switch, Capacitive Proximity Switches, Chute Jam Switch, Chute Jam Switches, Compact Pull Cord, Compact Pull Cords, DC Proximity Switch, DC Proximity Switches, Digital Frequency Controller, Digital Frequency Controllers, Electromagnetic Vibrator Controller, Electromagnetic Vibrator Controllers, Electronic Speed Monitoring Switch, Electronic Speed Monitoring Switches, Electronic Speed Switch, Electronic Speed Switches, Electronic Zero Speed Switch, Electronic Zero Speed Switches, Frequency Controllers For Bowl Feeder, Heavy Duty Limit Switch, Heavy Duty Limit Switches, Heavy Duty Pull Cord Switch, Heavy Duty Pull Cord Switches, Inductive Proximity Sensor, Inductive Proximity Sensors, Inductive Proximity Switch, Inductive Proximity Switches, Infrared Sensors Light Carton, Infrared Sensors Light Cartons, Level Switch, Level Switches, Magnetic Proximity Sensor, Magnetic Proximity Sensors, Magnetic Proximity Switch, Magnetic Proximity Switches, Optical Proximity Sensor, Optical Proximity Sensors, Optical Proximity Switch, Optical Proximity Switches, Position Sensor, Position Sensors, Position Switch, Position Switches, Pull Cord Switch, Pull Cord Switches, RF Admittance Level Sensor, RF Admittance Level Sensors, RF Admittance Type Level Switch, RF Admittance Type Level Switches, Rotary Paddle Type Switch, Rotary Paddle Type Switches, Rupture Switch, Rupture Switches, Safety Switch, Safety Switches, Safety Switches For Conveyor, Special Pull Cord Switch, Special Pull Cord Switches, Tilt Switch, Tilt Switches, Trip Indication System, Trip Indication Systems, Vibrating Fork Type Level Switch, Vibrating Fork Type Level Switches, Vibrator Controller, Vibrator Controllers, Vibratory Feeder Controller, Vibratory Feeder Controllers, Voltage Regulators For Vibratory Feeder, Manufacturer, Supplier, Exporter, Pune, Maharashtra, India.

0 notes

Text

Screw Conveyor Manufacturer in Maharashtra, India

Screw Conveyor Manufacturer in Maharashtra, India. these manufacturers offer robust and efficient screw conveyors tailored to your specific needs. Dust Extraction System.

#phengicon#ScrewConveyor#ConveyorManufacturer#IndustrialConveyor#MaharashtraManufacturing#MaterialHandling#EngineeringSolutions#IndustrialEquipment#ConveyorSystems#ScrewConveyorMaharashtra#IndianManufacturers

0 notes

Text

Fabricator and Engineers in Navi Mumbai

Navi Mumbai, a hub of industrial activity in Maharashtra, India, plays host to numerous Fabricator and Engineers in Navi Mumbai who contribute significantly to the region’s infrastructure development and manufacturing ecosystem. These businesses provide a wide range of services, catering to the diverse needs of various industries.

Types of Fabrication and Engineering Services

Fabricators and engineers in Navi Mumbai offer a comprehensive range of services, including:

Structural Fabrication: Fabrication of steel structures, such as beams, columns, and bridges, for buildings, bridges, and industrial facilities.

Platework Fabrication: Fabrication of metal plates and sheets into vessels, tanks, and other components used in chemical, pharmaceutical, and oil and gas industries.

Machinery Fabrication: Design and fabrication of custom machinery, including conveyors, packaging machines, and process equipment.

Rail and Automobile Manufacturing: Fabrication of rail coaches, wagons, and automobile components for the transportation sector.

Pipeline Fabrication: Fabrication and installation of pipelines for various applications, such as water supply, sewage systems, and oil and gas transportation.

Key Industries Served

The fabricators and engineers in Navi Mumbai cater to a wide range of industries, including:

Construction: Structural fabrication for residential, commercial, and industrial buildings.

Infrastructure: Fabrication of bridges, elevated roads, and flyovers.

Manufacturing: Fabrication of machinery, components, and vessels for Petrochemicals and Energy: Fabrication of pipelines, tanks, and other equipment for oil and gas industries.

Transportation: Fabrication of rail coaches, wagons, and automobile components.

Advantages of Hiring Fabricators and Engineers in Navi Mumbai

There are several advantages to partnering with fabricators and engineers in Navi Mumbai:

Proximity to Industrial Hubs: Navi Mumbai is strategically located close to major industrial areas in Maharashtra, providing easy access to raw materials and skilled workforce.

Competitive Pricing: The abundance of fabricators and engineers in the region fosters competition, resulting in competitive pricing and cost optimization.

Skilled Workforce: Navi Mumbai is home to a highly skilled workforce with expertise in fabrication and engineering, ensuring high-quality workmanship.

Project Management Capabilities: Reputable fabricators and engineers offer comprehensive project management services, including design, fabrication, installation, and maintenance.

Certifications and Standards: Most fabricators and engineers in Navi Mumbai comply with industry standards and certifications, ensuring the reliability and safety of their products.

Conclusion

Fabricators and engineers play a crucial role in the industrial ecosystem of Navi Mumbai. Their expertise in fabrication and engineering services supports the development of infrastructure, manufacturing, and various other industries. The region’s abundance of skilled workforce, competitive pricing, and proximity to industrial hubs make it an attractive destination for companies seeking reliable fabrication and engineering solutions.

0 notes

Text

Are you looking for best Industrial Roller Manufacturer in India?

Industrial rollers is a cylindrical or cylindrical-like component used in various industrial applications. Industrial rollers are used in a variety of situations, including conveyor systems, printing presses, feeding machines, bending machines, and stamping presses. These rollers come in different shapes, sizes, materials, and designs, used for its specific industrial application, processes and requirements.

We are Leading manufacturer of rollers, Industrial Rollers. We are Supplier and Exporter of Conveyor Rollers, Conveyor Accessories, Conveyor Idler Roller, Taper Roller, Rubber Rollers, Teflon Roller, PP Coated Roller, Food Grade Coated Roller, Polyurethane Rollers, Nylon Roller, Textile Roller, Sugar Mill Roller, Paper Mill Roller, Silicone Rubber Coated Roller, Sponge Roller (Paint Roller), Plastic Roller (PVC Roller), Idler Rollers, Natural Rubber Roller, Ebonite Rubber Rollers, Hard Chrome Plated Roller. Industrial Rollers Supplier and Exporter in Noida, Bengaluru, Coimbatore, Maharashtra, Punjab, Rajasthan, Gujarat, Goa, Chhattisgarh, Madhya Pradesh, South Africa, Oman, US, UK.

For More Details Click here: https://www.jekminindustries.com/

0 notes

Text

Welcome to Santek Equipments, your premier destination for top-quality conveyor systems in India. With years of expertise and a commitment to excellence, we pride ourselves on being one of the leading conveyor system manufacturers in the country.

#Conveyor System Manufacturers in India#Conveyor System Manufacturers in Pune#Conveyor System Manufacturers in Maharashtra#Conveyor System Manufacturers near me#Conveyor System#Conveyor System Manufacturer

0 notes

Text

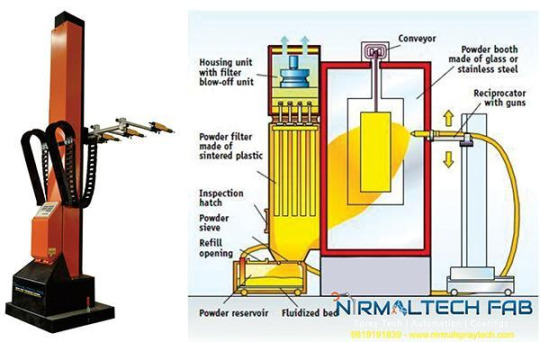

Five Axis Auto Spray System Manufacturer in Mumbai

https://nirmalspraytech.com/about-us/

“Established in the year 2008 in Maharashtra, “Nirmal Tech Fab” is a Sole Proprietorship based firm, engaged as the foremost Manufacturer of Industrial Oven, Perfume glass bottle décor coating plants, Paint Booths, Powder Coating Plants, UV vacuum metalizing plants, Powder recovery Booth, Automatic Spray booth, Conveyorized Oven, etc. These products are offered by us most affordable rates. Our products are high in demand due to their premium quality, seamless finish, different patterns, and affordable prices. Furthermore, we ensure to timely delivery of these products to our clients, and through this, we have gained a huge client base in the market. We also provide Fabrication Services.

0 notes

Text

Bottle Filling Line Automation Solution

Company Overview: Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Bottle Filling Line Automation Solution in Ahmedabad, Gujarat, India Our Manufacturer Unit is in Ahmedabad, Gujarat, India. The Bottle Filling Line Automation Solution offers a state-of-the-art, automated system for filling, capping, labeling, and packaging bottles across various industries. How Does Bottle Filling Line Automation Work? A typical bottle-filling line automation system consists of several key components that work in synergy: Bottle Feeding System: Bottles are automatically fed into the filling station from the conveyor belt. Filling Machine: This part of the system fills each bottle to the desired level based on preset parameters. Capping and Sealing: After filling, caps are automatically placed and sealed to ensure the bottle is ready for distribution. Labeling: A labeling machine attaches labels to each bottle, ensuring correct branding and product information. Packaging: Finally, we package the filled and labeled bottles for distribution, making them ready to reach consumers. Applications: Food and Beverage Pharmaceuticals Cosmetics and Personal Care Chemicals Agricultural Products What types of liquids can be filled using this automation system? Our automation solutions can fill a wide range of liquids, from thin solutions like water and beverages to thicker liquids such as oils, syrups, and pharmaceutical medicines. Can the filling line handle different bottle sizes? Yes, Shiv Shakti Machtech’s automated bottle-filling lines are highly customizable and can handle various bottle sizes and types, ensuring versatility in your production process. Shiv Shakti Machtech is a Supplier of Bottle Filling Line Automation Solution in Ahmedabad, Gujarat, India Including Kathwada, Vadodara, Changodar, Gota, Naroda, Nikol, Mehsana, Palanpur, Deesa, Patan, Vapi, Surendranagar, Bhavnagar, Jamnagar, Junagadh, Rajkot, Amreli, Mahuva, Surat, Navsari, Valsad, Silvassa, Porbandar, Mumbai, Vasai, Andheri, Dadar, Maharashtra, Aurangabad, Kolhapur, Pune, Rajasthan, Jaipur, Udaipur, Kota, Bharatpur, Ankleshwar, Bharuch, Ajmer, Delhi, Noida, Baddi, Solan, Himachal Pradesh, Una, Jammu Kashmir, Haryana, Hisar, Gurgaon, Gurugram, Madhya Pradesh, Indore, Bhopal, Ratlam, Jabalpur, Satna, New Delhi, Kolkata, West Bengal, Assam, Asansol, Siliguri, Durgapur, Bhubaneswar, Odisha, Brahmapur, Puri, Goa, Amaravati, Andhra Pradesh, Visakhapatna, Hyderabad, Guntur, Chittoor, Kurnool, Vizianagaram, Srikakulam, Karimnagar, Ramagundam, Suryapet, Telangana, Medak, Bengaluru, Bangalore, Mangaluru, Hubballi, Vijayapura, Davanagere, Kalaburagi, Chitradurga, Ballari, Kolar, Chennai, Coimbatore, Madurai, Tiruchirapalli, Tiruppur, Salem, Erode, Tirunelveli, Tamil Nadu, Kerala, Kochi, Thiruvananthapuram, Kozhikode, Thrissur, Kollam, Alappuzha, Kottayam, Kannur, Malappuram, Bharatpur, Jodhpur, Bikaner, Alwar, Bhilwara, Nagpur, Amravati, Solapur, Malegaon, Navi Mumbai, Thane, Wardha, Vasai-Virar, Gondia, Hinganghat, Barshi, Ulhasnagar, Nandurbar, Bhusawal, Pimpri-Chinchwad, Kalyan, Satara, Yamuna Nagar, Chhachhrauli. For more information or to request a quote, please reach out to us. Read the full article

1 note

·

View note

Text

Industrial Automation Rotary Encoder, Industrial Automation Rotary Encoders, Manufacturer, Supplier, India

We are Manufacturer, Supplier, Exporter of Industrial Automation Rotary Encoder, Industrial Automation Rotary Encoders from Pune, Maharashtra, India.

Proximity Sensor, Proximity Sensors, Proximity Switch, Proximity Switches, AC Proximity Switch, AC Proximity Switches, Addressable Pull Cord Switch, Addressable Pull Cord Switches, Belt Loading Monitor, Belt Loading Monitors, Belt Monitoring Switch, Belt Monitoring Switches, Belt Rupture Switch, Belt Rupture Switches, Belt Sway Switch, Belt Sway Switches, Belt Tear Switch, Belt Tear Switches, Capacitive Proximity Sensor, Capacitive Proximity Sensors, Capacitive Proximity Switch, Capacitive Proximity Switches, Chute Jam Switch, Chute Jam Switches, Compact Pull Cord, Compact Pull Cords, DC Proximity Switch, DC Proximity Switches, Digital Frequency Controller, Digital Frequency Controllers, Electromagnetic Vibrator Controller, Electromagnetic Vibrator Controllers, Electronic Speed Monitoring Switch, Electronic Speed Monitoring Switches, Electronic Speed Switch, Electronic Speed Switches, Electronic Zero Speed Switch, Electronic Zero Speed Switches, Frequency Controllers For Bowl Feeder, Heavy Duty Limit Switch, Heavy Duty Limit Switches, Heavy Duty Pull Cord Switch, Heavy Duty Pull Cord Switches, Inductive Proximity Sensor, Inductive Proximity Sensors, Inductive Proximity Switch, Inductive Proximity Switches, Infrared Sensors Light Carton, Infrared Sensors Light Cartons, Level Switch, Level Switches, Magnetic Proximity Sensor, Magnetic Proximity Sensors, Magnetic Proximity Switch, Magnetic Proximity Switches, Optical Proximity Sensor, Optical Proximity Sensors, Optical Proximity Switch, Optical Proximity Switches, Position Sensor, Position Sensors, Position Switch, Position Switches, Pull Cord Switch, Pull Cord Switches, RF Admittance Level Sensor, RF Admittance Level Sensors, RF Admittance Type Level Switch, RF Admittance Type Level Switches, Rotary Paddle Type Switch, Rotary Paddle Type Switches, Rupture Switch, Rupture Switches, Safety Switch, Safety Switches, Safety Switches For Conveyor, Special Pull Cord Switch, Special Pull Cord Switches, Tilt Switch, Tilt Switches, Trip Indication System, Trip Indication Systems, Vibrating Fork Type Level Switch, Vibrating Fork Type Level Switches, Vibrator Controller, Vibrator Controllers, Vibratory Feeder Controller, Vibratory Feeder Controllers, Voltage Regulators For Vibratory Feeder, Manufacturer, Supplier, Exporter, Pune, Maharashtra, India.

0 notes

Text

Global Brush Motor Control Unit Market

Global Brush Motor Control Unit Market

size was valued US$ XX Mn. in 2019 and the total revenue is expected to grow about 4.8% from 2020 to 2027, reaching nearly US$ XX Mn.

To know about the Research Methodology :-

Request Free Sample Report

Global Brush Motor Control Unit Market: Overview

The Brush motor is used for various applications in automotive industry such as power window, motorized toys, Computer Peripherals, seats, and other purposes. Also, industries use these motors for driving conveyor belt and other system & equipment. These motors have low cost and simple in design. The motor is made up of components like commutator, armature, axle, stator, magnets, and brushes. The Brush Motor Control Unit is used to control the motor. The motor output is controlled by controlling input electric power, the torque and speed of motor is precisely controlled.

Global Brush Motor Control Unit Market: Drivers and Restraints

Demand for fuel efficient vehicle is increasing in recent few years; constantly fuel reserve level is also going down which is driving the market for Global Brush Motor Control Unit Market. The manufacturers are trying to reduce cost of production to couple with increasing demand for cost-efficient automotive parts and are contributing to the growth of Brush Motor Control Unit Market. Increasing Pollution control rules and trend towards use of clean fuel globally is the main motive force for use of electric vehicle, results in market growth of Global Brush Motor Control Unit. High initial investment needed to incorporate this system is the major restraint in market growth. The hydraulic steering system performance is challenge for electronic steering system. The brushless motor is getting more popular because they have low maintenance which is the major threat in development of Brush Motor Control Unit Market. The Brush Motor Control Unit needs timely maintenance for proper functioning and the motor’s brush is to be changed when worn out.

Global Brush Motor Control Unit Market: Regional Overview

The Global Brush Motor Control Unit Market is segmented into regions such as North America, Europe, Middle East & Africa, South America, and Asia Pacific. North America and Europe have dominance over the Global Brush Motor Control Unit Market. The eco-friendly parts and equipment are increasing and also showing significant growth during the recent years. Development activities are increasing in the sector of electronic system in atomization in industries which is majorly driving the Brush Motor Control Unit Market. Asia Pacific region is also increasing market capture owing to high quality automobile demand increase.

Global Brush Motor Control Unit Market: Segmentation

The Global Brush Motor Control Unit Market is segmented by End Use (Series wound Brush Motor Control Unit, Aerospace, Shunt wound Brush Motor Control Unit, Other End Use), Versions (First generation, Second generation), Vehicle Type (Commercial Vehicles, Passenger Vehicles), and Region (North America, Europe, Middle East & Africa, South America, Asia Pacific). The report also helps in understanding Brush Motor Control Unit Market dynamics, structure by analyzing the market segments and projects the Brush Motor Control Unit Market size. Clear representation of competitive analysis of key players by Application, price, financial position, Product portfolio, growth strategies, and regional presence in the Brush Motor Control Unit Market make the report investor’s guide.

For more informaion visit@ https://www.maximizemarketresearch.com/market-report/global-brush-motor-control-unit-market/72631/

Scope of the Brush Motor Control Unit Market: Inquire before buying

Brush Motor Control Unit Market, by End Use

• Automobile • Aerospace • Electronics • Other End Use

Brush Motor Control Unit Market, by Versions

• First generation • Second generation

Brush Motor Control Unit Market, by Vehicle Type

• Commercial Vehicles • Passenger Vehicles

Brush Motor Control Unit Market, by Region

• Asia Pacific • North America • Europe • South America • Middle East & Africa

Key players operating in Brush Motor Control Unit Market

• Mitsubishi Electric Corporation • Woodward • ORIENTAL MOTOR USA CORP. • Moog Inc. • General Electric • Maxon Motor AG • Roboteq • Texas Instruments Incorporated.

This report submitted by Maximize market Research Company

Customization of the report:

Maximize Market Research provides free personalized of reports as per your demand. This report can be personalized to meet your requirements. Get in touch with us and our sales team will guarantee provide you to get a report that suits your necessities.

About Maximize Market Research:

Maximize Market Research provides B2B and B2C research on 20,000 high growth emerging opportunities & technologies as well as threats to the companies across the Healthcare, Pharmaceuticals, Electronics & Communications, Internet of Things, Food and Beverages, Aerospace and Defense and other manufacturing sectors.

Contact info:

Name: Lumawant Godage

Organization Address: MAXIMIZE MARKET RESEARCH PVT. LTD.

Email: [email protected]

Address: Omkar Heights, Sinhagad Road, Manik Baug, Vadgaon Bk,Pune, Maharashtra 411051, India.

Contact: +919607195908

1 note

·

View note

Text

Impression Systems & Engineers stands among the top Warehouse Transfer Systems company. Contact us to learn about our approach and expertise.We are a Leading Manufacturer, Supplier, Exporter of Warehouse Transfer Systems and Warehousing Automation Products like Conveyors, Gates Conveyors, Overhead Transfer Systems, RGV - Rail Guided Vehicles, IoT, Inventory Management Systems, and our setup is located in Pune, Maharashtra, India.

0 notes

Text

PVC conveyor belt food gradesugar conveyor belt - Die Cutting Sanding Machine Conveyor PVC Belt Produced by HIC

Oil and Heat Resistant 100 degree C pvc conveyor belts manufactured in GREEN or BLACK color, used by die cutting parts collection conveyor-system manufacturers and woodworking sanding machine manufacturers of HIC make Universal brand pvc belt located in Birmingham England UK, Taipei Taiwan, Kowloon Hong Kong, Shanghai China, Rome Italy, Kuala Lumpur Malaysia, Frankfurt Germany, Tokyo Japan, Spain, Texas USA, Ohio United States, Latin America, Yangon Myanmar, Phuntsholing Bhutan, Bengaluru Karnataka India, Mumbai Maharashtra, Kolkata West Bengal, Ahmedabad Gujarat-India.

Food Quality PVC non-toxic conveyor belt manufactured conforming FDA WHITE color, used by seafood conveying equipment manufacturers of HIC-make Universal brand pvc belt located in Hong Kong, Malaysia, Thailand, China, UK, USA, Pakistan, Myanmar, Singapore, Goa India, West Bengal, Tamil Nadu, Kerala, Maharashtra, Odisha-India for fish, meat conveying.

PVC food belt also used by fruit vegetable dryer belt-conveyor manufacturers of HIC-make Universal brand pvc belt located in Wellington New Zealand, Nevada USA, Surrey UK, Beijing China, Brussels Belgium, Vienna Austria, Hamburg Germany, Srinagar Jammu Kashmir India, Solan Himachal, Navi Mumbai Maharashtra, Noida Uttar Pradesh, Patna Bihar-India for fruit drier and vegetable washer dryer conveying system pvc-conveyor belting.

Food grade PVC conveyor belting also used by sugar processing conveyor-system manufacturers of HIC-make Universal brand pvc belt located in Ningbo China, Washington USA, Port Louis Mauritius, Cheshire UK, Auckland New Zealand, Singapore, Doha Qatar, Gauteng South Africa, Nairobi Kenya, Kathmandu Nepal, Vadodara Gujarat India, Guwahati Assam, Vasco da Gama Goa, Navi Mumbai Maharashtra, Hardwar Uttarakhand, Kolkata West Bengal, Chennai Tamil Nadu, Muzaffarnagar Uttar Pradesh-India for sugar granulator toxic-free non-smelling sugar transport pvc conveyor-belt

Bakery Confectionery quality PU conveyor-belt glossy WHITE color, used by biscuits confectionery cooling conveyor-system manufacturers of HIC make Universal brand pu belt located in England UK, Spain, Germany, USA, Switzerland, UAE United Arab Emirates, China, Andhra Pradesh India, West Bengal, Maharashtra, New Delhi of India and bread bakery conveyor machine manufacturers of HIC make Universal brand located in Lebanon, Italy, Mexico, France, United Kingdom, Scotland, China, United States of America, Thailand, Maharashtra, Gujarat, Delhi, Punjab of India, advantage being non-toxic leaving no odour on conveyed foodstuffs

Click here to Learn more about PVC conveyor belt food gradesugar conveyor belt

66 notes

·

View notes

Text

Automated Material Handling Market: 3 Bold Projections for 2027 | Major Giants

Market Overview

In its new research report, Market Research Future (MRFR), highlights that the global automated material handling market 2020 is expected to grow exponentially over the review period, securing a considerable market valuation and a substantial CAGR over the review period.

Drivers and Restraints

Such equipment has grown dramatically over the last few years, experiencing several notable transformations with the introduction of technology. Manufacturers are clearly the guiding force to carry these changes in. Keeping the three goals in mind, they have established a range of automated equipment such as conveyors, elevators, cranes, lift and lift truck track cranes, stackers, bridge cranes and monorails, gantry cranes and helicopter lifts, etc. Technological developments that prevailed in this sector have gradually taken advantage of functional and cost-effective approaches leading to the automation of these equipment. These innovations have accompanied their market value to an unprecedented level, making these devices popular and widely adopted.

Get Free Sample Report @ https://www.marketresearchfuture.com/sample_request/1029

Other factors that contribute to the growth of the market include rising automation across production industries. The ever-growing need for resource utilization and consumption of raw materials drives the demand & adoption of Automated Material Handling equipment. In addition to factors such as continuous technical progress, the modernization of the manufacturing plants, and the expansion of the industrial base in developing countries, Automated Material Handling equipment is providing fuel for business development.

Industrial Internet of Things (IIoT) proliferation driven by new automation projects pursued by manufacturers moving towards Industry 4.0 revolution has shaped business growth, enhancing their operations. Extensive analytics take-up will allow the industry to experience a tremendous change in the coming years.

Regional Analysis

The geographical synopsis of the global market has been analyzed in four major regions, including North America, Europe, the Asia Pacific, and the rest of the world.

Due to the presence of numerous manufacturing plants in the various countries in the region, the Asia-Pacific region dominates the Automated Material Handling industry. Many of the APAC nations are in their growth process and are therefore available to foreign investors, thereby allowing multi-domain international players to available the production unit in these countries. The Asia-Pacific region is also expected to grow substantially in the Power Quality Equipment (PQE) space. In addition, automated material handling facilitates the distribution and production of materials, mainly in the e-commerce sector. Thereby, booming eCommerce and the PQE industry will provide a great incentive to the development of the APAC market of Automated Material Handling.

Europe is the second-largest Automated Material Handling market in terms of sales and market size. A resurgent economy coupled with the booming regional industrial sector combined with increased security concerns in the workplace, especially in the automotive, food & beverage, and metal & heavy industries will drive regional market growth.

On the other hand, North America, due to the presence of multiple manufacturing plants, mainly in the U.S., represents the third-largest market for automated material handling. The proliferation and uptake of advanced technology mostly stimulate market growth.

Segmental Analysis

Segmentation by Operation: storage & transportation, Packaging & distribution, assembly, waste management, among others.

Segmentation by Software & Services comprises Services- (Maintenance & repairs, training, and software up-gradation), Software (TMS- Transportation management system, WMS- Warehouse management system).

Segmentation by Application includes e-commerce, foods & beverages, healthcare, automotive, chemicals, aviation, semiconductors, and electronics, among others.

Segmentation by Automated Equipment comprises Automated guided vehicles, automated cranes, robotics systems, automated storage and retrieval system, conveyors, among others.

Competitive Analysis

The major market players operating in the global market as acknowledged by MRFR are Schaefer Holding International (Germany), Daifuku Co. Ltd (Japan), Dematic (U.S.), Murata Machinery (Japan), Mecalux (Spain), Vanderlande Industries (U.S.), BEUMER Group (Germany), Swisslog AG (Switzerland), Kardex (Switzerland), Intelligrated (U.S.) among others.

Get Complete Report @ https://www.marketresearchfuture.com/reports/automated-material-handling-market-1029

About Us

Market Research Future (MRFR) is an esteemed company with a reputation of serving clients across domains of information technology (IT), healthcare, and chemicals. Our analysts undertake painstaking primary and secondary research to provide a seamless report with a 360 degree perspective. Data is compared against reputed organizations, trustworthy databases, and international surveys for producing impeccable reports backed with graphical and statistical information.

We at MRFR provide syndicated and customized reports to clients as per their liking. Our consulting services are aimed at eliminating business risks and driving the bottomline margins of our clients. The hands-on experience of analysts and capability of performing astute research through interviews, surveys, and polls are a statement of our prowess. We constantly monitor the market for any fluctuations and update our reports on a regular basis.

Media Contact:

Market Research Future

Office No. 528, Amanora Chambers

Magarpatta Road, Hadapsar,

Pune - 411028

Maharashtra, India

+1 646 845 9312

Email: [email protected]

0 notes