#Consolidated Lamp and Glass Co.

Explore tagged Tumblr posts

Photo

Vase by the Consolidated Lamp and Glass Co., 1929-30s, USA.

115 notes

·

View notes

Text

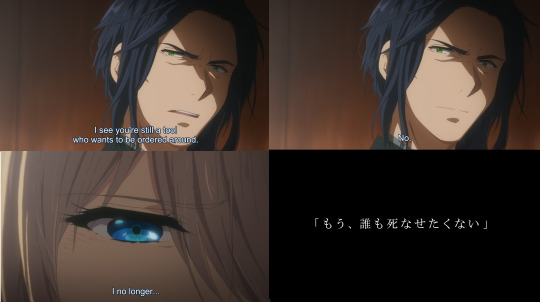

Burning as a Motif for Humanity in Violet Evergarden

I think, when watching Violet Evergarden, most of us picked up on fire as a motif for Violet’s trauma – the violence and destruction she witnessed in the war, and the violence and destruction she engendered with her own hands. I’m not going to go into this too much because it’s all pretty self-explanatory, if not trite, but here are some quick examples of fire as a motif for her trauma just to lay the groundwork for the rest of the essay:

In frame 1 (episode 8), Violet draws first blood on the battlefield, and the once contained fire from the felled soldiers’ lanterns spread quickly through the forest, a symbol for how one small act of violence can cascade into large scale destruction. In frame 2, Gilbert stares at the carnage in front of him, horrified. In frame 3, the major is shot, and all we get to see is a screen of flames. In frame 4 (episode 12), Merkulov stares into a fire as he schemes about re-kindling the war.

I want to follow this (well trodden) opinion up with a more encompassing statement. That is, fire, in Violet Evergarden, is not limited to representing the destructive power of violence and trauma. Instead, it is a motif for humanity itself – an embodiment of the full range of experiences and emotions that make us human.

To show this, I’m going to start off at the beginning of Violet’s journey, focusing on how her disconnect (from herself as well as others) is illustrated in episode one. For instance, her initial struggle to move her now mechanical arms as she sits in her hospital bed in the opening sequence is an excellent embodiment of her dissociation from her own body and lack of agency. I want to, however, focus on two scenes that are particularly relevant for our discussion:

First, the scene where Violet spills tea on her hand:

And second, the scene where Hodgins insists that Violet is burning:

These scenes are similar: in both, someone asserts that Violet must be in pain, specifically due to burning, and in both, Violet rejects that statement. In the first, however, that burning is physical. And in the second, that burning is emotional. Regardless, Violet is so removed from her own body that she is incapable of feeling either. Her mechanical hand is therefore an embodiment of her inhumanity (ie. her “dollness” or “weapon-ness”). Like her, it is cold, mechanical, insensitive, without life or agency. After all, up until now, all she’s been doing is killing on command, without the ability to think for herself, experience her own pain, or sympathize with her victims’ pain.

When the screen shows that Hodgins is indeed correct, that Violet is literally on fire (frame 1), that fire is depicted with restraint. Flames engulfs Violet’s body, but those flames are from a streetlamp enclosed in glass. It is controlled and distant. This encapsulates Violet’s current state; she is literally on fire, but that fire is so compartmentalized and suppressed, and she is so far removed from her own experience, that she is incapable of feeling it.

In frame 2, we are viewing Violet in a flashback, from Hodgin’s point of view. Although we’re offered a close up shot of her bloodied hands, we see, about two cuts later, that Hodgin is actually observing Violet from afar (frame 2.5). This distance demonstrates that he cannot bring himself to reach out to her, something that Hodgin confesses he feels guilty about literally 5 seconds later. They were, at that point in time, and perhaps even now, unable to connect.

In frames 3 and 4, Hodgin is speaking again. We get this super far shot of Violet’s body. The camera is straight on, objective, and unfeeling. This unsympathetic framing has two functions. First, it distances us from Violet. Our inability to see the details on her face and her relatively neutral body language gives us, the audience, no real way inidication her thoughts. Second, it distances Violet from herself. As someone who experiences dissociative symptoms from PTSD, this is a very poignant way of framing what it feels like to be removed from your own experience. Hodgin’s line, “You’ll understand what I’m saying one day. And, for the first time, you’ll notice all your burn scars,” further drives home the sense that Violet is completely estranged from herself. It almost feels like we are looking at her, from her own detached point of view.

We’re going to move on now, but we’ll get back to these frames later in the analysis, so hold onto them.

Throughout Violet’s journey, fire comes up again and again. Specifically, it shows up in moments of emotional intimacy, connection, and healing. Let’s see what I mean by this:

I have here a collection of moments that all occur at the same narrative point in their respective mini-stories: the moment where one character reaches out to another, sympathizes with them, and literally pulls them of their darkness. For example, frame 1 (episode 3) shows Violet bringing a letter from Luculia to her brother. It expresses Luculia’s gratitude and love for him, and ultimately mends their relationship. In frame 2 (episode 4), Violet and Iris share a moment of emotional intimacy and connection, which is the beginning of Iris’ story’s resolution. In frame 3 (episode 9), Violet’s suicidal despondency is interrupted by the mailman, bringing her a heartwarming letter from all her friends. In frame 4 (episode 11), Violet comforts a dying solder by a fireplace.

It’s not that other modes of lighting do not exist – modern looking lamps show up repeatedly in the show. Even Iris’ rural family has them, so I can reasonably assume that, no, the above moments do not all coincidentally use lamps because that’s all there is in this universe; the usage of fire during moments of catharsis is deliberate, and establishes that fire can also bring hope, kindness, and love.

Now that we’ve explored the dual nature of fire as both destructive/constructive, painful/cathartic, let’s go onto the thesis of my essay. Why do I say that being on fire is to be human? Let’s go back to the scene where Hodgin tells Violet she’s on fire (episode 1, on the left), and compare it to the scene where Violet finally realizes that Hodgin was right and that she is on fire (episode 7, on the right):

In these sequences, there is a notable shift in framing and perspective. In frame 1b, we finally get to see Violet’s blood-stained hands from her point of view, as opposed to from Hodgin’s point of view in 1a. Violet becomes aware of her past as an actual agent choosing to kill, shown through the first-person point of view. Similarly, the medium, straight on shot of Violet looking down at her hands (frame 2a) is replaced with an intimate first-person, close-up view (frame 2b). In shots 3a and 3b, the difference in framing is most pronounced. In 3a, we get this straight on, long shot. In frame 3b, the camera’s detachment is replaced by a claustrophobic closeness. While this framing does an excellent job at conveying the panicked feeling of “everything crashing down all at once”, it also demonstrates Violet’s new-found awareness of herself. While before, the camera was used to alienate, now it is used to create a sense of painful awareness and intimacy.

These series of shots are the first in the entire show, I believe, of Violet's body from her own point of view. Their co-incidence with her awakening self-awareness characterizes the state of “being in one’s body” as a precondition to self-connection, or more specifically, to Violet’s understanding of herself as neither a weapon nor a doll, but as a human. Correspondingly, this pivotal moment serves as a catalyst for her subsequent emotional development. From this episode on towards the finale, we’re launched into a heart wrenching sequence of events: Violet’s desperate grieving for Gilbert’s apparent death, her attempted suicide driven by newfound grief, and most importantly, Violet receiving her first written letter, an act that is strongly representative of genuine human connection. Following these events, Violet’s emotional connection to both herself and others only continues to grow; during her two final jobs of the story, she breaks down crying in response to the suffering of her clients, demonstrating a level of compassion—if not empathy—that she seems to have never been able to tap into before.

At the same time, Violet acquires a new sense of agency, making plot-driving decisions that no longer require other characters’ validations. Most poignantly, in episode 12, she chooses to stay on the train to fight Merkulov, explicitly going against Dietfried’s order for her to leave. Her reason?

She doesn’t want anyone to die anymore.

And it’s this moment, for me, that consolidated her as a character with true agency. Up until now, all her major decisions have been framed in relation to Gilbert: she killed in the war because Gilbert ordered her to, and she became an Auto Memories Doll because she wanted to understand Gilbert’s enigmatic “I love you”. Now, however, her motivation is purely her own—she fights, simply because she doesn’t want anyone else to die. It’s a line implies an intimate knowledge of loss. It’s a sentiment motivated by compassion. It’s a raw and extraordinarily human thing to say.

When Violet embarks on her journey to decipher Gilbert’s love, she is devoid of many traits we consider inherent and possibly even unique to being human—suffering, compassion, altruism, love, agency, and the interplay between them. As an Auto Memories Doll, she learns to live, experiencing all these emotions she had never had the luxury to experience before, and we quickly realize that she cannot know what love is without simultaneously wrestling with her trauma. She learns that yes, sometimes the fire destroys and sometimes it burns, but sometimes it thaws too, and you cannot have one without the other. You cannot choose what the fire does to you; you cannot choose what you want to feel. Thus, to be on fire is to know the anguish of its destruction, but it is also, and more importantly, to know the catharsis of human connection, to be the warm flame that pulls someone else out of the dark, to be pulled out of the dark yourself. To be on fire is to be human.

#violet evergarden#violet evergarden analysis#anime analysis#anime#anime essay#anime meta#violet evergarden meta#analysis#w.writing#w.analysis

49 notes

·

View notes

Photo

“Ruba Rombic” Perfume Bottle 1928–32 Glass Designer: Reuben Haley (American; 1872–1933) Manufacturer: Consolidated Lamp & Glass Co. Carnegie Museum of Art, Pittsburgh, Pennsylvania

#perfume#perfume bottles#toiletries#bottles#decorative arts#glassware#Reuben Haley#Haley#American design#Art Deco#Art Deco design#American artists#American decorative arts#American Modernism#lilac#Ruba Rombic#mold-blown glassware#modern art#modern design#modernist design#modern American design#Consolidated Lamp and Glass Company#Consolidated Lamp and Glass Co.#1920s#1930s#20th-century design#1920s design#1930s design#American Art Deco#Ruba Rombic glassware

587 notes

·

View notes

Text

Excited to share the latest addition to my #etsy shop: 1926 Consolidated Lamp & Glass Co, Martelé Line Art Glass Chickadee Vase, #2589 Shape, Tri-Color Bird Decor, 6.5"H #consolidatedglass #marteleline #consolidatedvase #consolidatedmartele #chickadee #glassbird #bird https://etsy.me/3JkZSq6

0 notes

Text

Ethylene propylene diene monomer (EPDM) market to reach ~ us$ 6.2 bn by 2027

Ethylene Propylene Diene Monomer (EPDM) Market: Key Highlights

The global ethylene propylene diene monomer (EPDM) market was valued at ~ US$ 3.8 Bn in 2018, and is anticipated to expand at a CAGR of ~ 6% during the forecast period.

The global ethylene propylene diene monomer market is driven by the rise in the demand for EPDM in automotive applications such as rear-lamp gaskets, hoses, tire sidewalls, inner tire tubes, front and rear bumpers, and braking systems.

Asia Pacific accounts for a major share of the global ethylene propylene diene monomer market, led by an increase in the demand for EPDM for use in thermoplastics modification in the region.

Request a Sample –

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=1285

Key Drivers of the EPDM Market

Ethylene propylene diene monomer, a type of synthetic rubber, is primarily used in automotive, roofing, and plastic modification applications. Ethylene propylene diene monomer is extensively employed in the automotive industry, owing to its chemical properties such as high temperature sustainability, and resistance to heat, harsh weather conditions, ozone, and steam.

Highly volatile prices of natural rubber is a major factor that has compelled rubber consumers across the globe to shift from natural rubber toward synthetic rubber such as ethylene propylene diene monomer.

Ethylene propylene diene monomer is widely used in the construction and civil engineering sector in applications such as mounting structures, bridge bearings, expansion joints, pipe couplings, water barriers, roofing membranes, rubberized asphalt, and concrete texturing.

Building & Construction Sector to Offer Attractive Opportunities

Ethylene propylene diene monomer is an extremely durable, synthetic-rubber, roofing membrane that is widely used in low-slope buildings across the globe. Its two primary ingredients, i.e. ethylene and propylene, are derived from oil and natural gas.

Ethylene propylene diene monomer is widely used in the building & construction industry, due to its properties such as resistance to cracks, water, and temperature. Thus, it is suitable to be used in roofing solutions in the construction industry.

Ethylene propylene diene monomer offers properties such as high electric resistance and excellent electric insulation. Thus, it is used in various applications in the electric industry. EPDM is widely employed in the manufacture of low- and medium-voltage cable insulations, wires, and submersible water pumps, due to its water-repellent property.

In the automotive industry, EPDM is used in hydraulic brake systems, wire and cable harnesses, tubing, window spacers, radiators, belts, weather stripping and seals, glass-run channels, and door, window, and trunk seals.

Buy now-

https://www.transparencymarketresearch.com/checkout.php?rep_id=1285<ype=S

High Risk of Substitution to Hamper EPDM Market Growth

The inert nature of EPDM, which reduces the adherence of the material when used in automotive and plastic applications, and high costs of installation of EPDM roofing systems are expected to hamper the demand for ethylene propylene diene monomer in these applications during the forecast period. Furthermore, ethylene propylene diene monomer exhibits unsatisfactory compatibility with most oils, kerosene, gasoline, aromatic and aliphatic hydrocarbons, concentrated acids, and halogenated solvents.

The above-mentioned disadvantages of EPDM augment the usage of other elastomers, including NBR, polyurethane-based, and HNBR elastomers, in various applications.

Furthermore, the oversupply of ethylene propylene diene monomer led by the rise in production capacities acts as a major restraining factor for players operating in the global ethylene propylene diene monomer market. EPDM remains oversupplied in Asia Pacific, with most plants in the region running at reduced pace. Major suppliers had to cut the prices of EDPM to boost buying sentiments. In China, ethylene propylene diene monomer prices have dropped by 8.5% since early October 2018, to reach US$ 2,150/ton on December 19, 2018.

Request for covid19 impact analysis –

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=1285

Asia Pacific a Prominent EPDM Market

Asia Pacific dominated the global ethylene propylene diene monomer market in 2018. Growth of the automotive industry in developing economies such as China and India is likely to propel the ethylene propylene diene monomer market in the region during the forecast period.

The ethylene propylene diene monomer market in North America is expected to expand at a significant pace during the forecast period, due to the high demand for lubricant additives, and rapid growth of the plastic, rubber, and automotive industries in the U.S. and Canada.

The demand for EPDM roofing is rising in Spain, Italy, the U.K., and countries in Western Europe, due to the increasing demand for waterproofing solutions for use in non-residential and commercial buildings in these countries.

Increasing demand for eco-friendly products as substitutes for PVC is projected to drive the TPE sector in North America. This, in turn, is likely to fuel the ethylene propylene diene monomer market in the region from 2019 to 2027.

Top Few Players Accounted for ~ 50% of EPDM Market Share in 2018

The global EPDM market is dominated by a few major players, and is consolidated in nature. The top six manufacturers - LANXESS AG, ExxonMobil Chemical Company, Kumho Polychem, Mitsui Chemicals, The Dow Chemical Company, and Lion Copolymer LLC - held ~ 70% of the market share in 2018. Other key companies that manufacture ethylene propylene diene monomer are Sumitomo Chemical Co. Ltd., Versalis S.p.A., SK Global Chemical Co. Ltd., and Johns Manville Inc.

In April 2015, Lanxess started production of EPDM at its new plant at Changzhou in the Jiangsu province of China. The new plant, with 160,000 tons of annual production capacity, is located in Changzhou Yangtze Riverside Industrial Park. The plant produces ten premium grades of EPDM, tailored to the requirements of customers in Asia, especially China. However, in 2016, Lanxess AG planned to stop the production of EPDM rubber at its facility in Marl, the U.K.

Companies in the Ethylene Propylene Diene Monomer (EPDM) market have increasingly shifted gears with wide application of digital technology across the continuum, from raw material sourcing to manufacturing to generation of final output, to warehousing to final distribution operations. Among the various affects, the market is witnessing new growth economics due to thinning of line between specialty and commodity businesses that are associated with the larger ecosystem. At the same time, new growth parameters are being vigorously being debated as industry stakeholders put greater emphasis on the circular economy processes.

More Trending Reports-

https://www.prnewswire.com/news-releases/players-in-bovine-colostrum-market-likely-to-gather-exceptional-demand-opportunities-from-medical-nutritional-food-producers-highlights-tmr-301331454.html

0 notes

Text

Ethylene Propylene Diene Monomer (EPDM) Market expand at a CAGR of ~ 6%

Ethylene Propylene Diene Monomer (EPDM) Market: Key Highlights

The global ethylene propylene diene monomer (EPDM) market was valued at ~ US$ 3.8 Bn in 2018, and is anticipated to expand at a CAGR of ~ 6% during the forecast period.

The global ethylene propylene diene monomer market is driven by the rise in the demand for EPDM in automotive applications such as rear-lamp gaskets, hoses, tire sidewalls, inner tire tubes, front and rear bumpers, and braking systems.

Asia Pacific accounts for a major share of the global ethylene propylene diene monomer market, led by an increase in the demand for EPDM for use in thermoplastics modification in the region.

Request A Sample –

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=1285

Key Drivers of the EPDM Market

Ethylene propylene diene monomer, a type of synthetic rubber, is primarily used in automotive, roofing, and plastic modification applications. Ethylene propylene diene monomer is extensively employed in the automotive industry, owing to its chemical properties such as high temperature sustainability, and resistance to heat, harsh weather conditions, ozone, and steam.

REQUEST FOR COVID19 IMPACT ANALYSIS –

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=1285

Highly volatile prices of natural rubber is a major factor that has compelled rubber consumers across the globe to shift from natural rubber toward synthetic rubber such as ethylene propylene diene monomer.

Ethylene propylene diene monomer is widely used in the construction and civil engineering sector in applications such as mounting structures, bridge bearings, expansion joints, pipe couplings, water barriers, roofing membranes, rubberized asphalt, and concrete texturing.

Building & Construction Sector to Offer Attractive Opportunities

Ethylene propylene diene monomer is an extremely durable, synthetic-rubber, roofing membrane that is widely used in low-slope buildings across the globe. Its two primary ingredients, i.e. ethylene and propylene, are derived from oil and natural gas.

Ethylene propylene diene monomer is widely used in the building & construction industry, due to its properties such as resistance to cracks, water, and temperature. Thus, it is suitable to be used in roofing solutions in the construction industry.

Ethylene propylene diene monomer offers properties such as high electric resistance and excellent electric insulation. Thus, it is used in various applications in the electric industry. EPDM is widely employed in the manufacture of low- and medium-voltage cable insulations, wires, and submersible water pumps, due to its water-repellent property.

In the automotive industry, EPDM is used in hydraulic brake systems, wire and cable harnesses, tubing, window spacers, radiators, belts, weather stripping and seals, glass-run channels, and door, window, and trunk seals.

High Risk of Substitution to Hamper EPDM Market Growth

The inert nature of EPDM, which reduces the adherence of the material when used in automotive and plastic applications, and high costs of installation of EPDM roofing systems are expected to hamper the demand for ethylene propylene diene monomer in these applications during the forecast period. Furthermore, ethylene propylene diene monomer exhibits unsatisfactory compatibility with most oils, kerosene, gasoline, aromatic and aliphatic hydrocarbons, concentrated acids, and halogenated solvents.

The above-mentioned disadvantages of EPDM augment the usage of other elastomers, including NBR, polyurethane-based, and HNBR elastomers, in various applications.

Furthermore, the oversupply of ethylene propylene diene monomer led by the rise in production capacities acts as a major restraining factor for players operating in the global ethylene propylene diene monomer market. EPDM remains oversupplied in Asia Pacific, with most plants in the region running at reduced pace. Major suppliers had to cut the prices of EDPM to boost buying sentiments. In China, ethylene propylene diene monomer prices have dropped by 8.5% since early October 2018, to reach US$ 2,150/ton on December 19, 2018.

Asia Pacific a Prominent EPDM Market

Asia Pacific dominated the global ethylene propylene diene monomer market in 2018. Growth of the automotive industry in developing economies such as China and India is likely to propel the ethylene propylene diene monomer market in the region during the forecast period.

The ethylene propylene diene monomer market in North America is expected to expand at a significant pace during the forecast period, due to the high demand for lubricant additives, and rapid growth of the plastic, rubber, and automotive industries in the U.S. and Canada.

The demand for EPDM roofing is rising in Spain, Italy, the U.K., and countries in Western Europe, due to the increasing demand for waterproofing solutions for use in non-residential and commercial buildings in these countries.

Increasing demand for eco-friendly products as substitutes for PVC is projected to drive the TPE sector in North America. This, in turn, is likely to fuel the ethylene propylene diene monomer market in the region from 2019 to 2027.

Top Few Players Accounted for ~ 50% of EPDM Market Share in 2018

The global EPDM market is dominated by a few major players, and is consolidated in nature. The top six manufacturers – LANXESS AG, ExxonMobil Chemical Company, Kumho Polychem, Mitsui Chemicals, The Dow Chemical Company, and Lion Copolymer LLC – held ~ 70% of the market share in 2018. Other key companies that manufacture ethylene propylene diene monomer are Sumitomo Chemical Co. Ltd., Versalis S.p.A., SK Global Chemical Co. Ltd., and Johns Manville Inc.

0 notes

Text

EPDM Market - Industrial Forecast on Global Industry Analysis and Trends till 2027

Ethylene Propylene Diene Monomer (EPDM) Market: Key Highlights

· The global ethylene propylene diene monomer (EPDM) market was valued at ~ US$ 3.8 Bn in 2018, and is anticipated to expand at a CAGR of ~ 6% during the forecast period.

· The global ethylene propylene diene monomer market is driven by the rise in the demand for EPDM in automotive applications such as rear-lamp gaskets, hoses, tire sidewalls, inner tire tubes, front and rear bumpers, and braking systems.

· Asia Pacific accounts for a major share of the global ethylene propylene diene monomer market, led by an increase in the demand for EPDM for use in thermoplastics modification in the region.

Is something restraining your company’s growth in the EPDM market? Ask for the report brochure here

Key Drivers of the EPDM Market

· Ethylene propylene diene monomer, a type of synthetic rubber, is primarily used in automotive, roofing, and plastic modification applications. Ethylene propylene diene monomer is extensively employed in the automotive industry, owing to its chemical properties such as high temperature sustainability, and resistance to heat, harsh weather conditions, ozone, and steam.

· Highly volatile prices of natural rubber is a major factor that has compelled rubber consumers across the globe to shift from natural rubber toward synthetic rubber such as ethylene propylene diene monomer.

· Ethylene propylene diene monomer is widely used in the construction and civil engineering sector in applications such as mounting structures, bridge bearings, expansion joints, pipe couplings, water barriers, roofing membranes, rubberized asphalt, and concrete texturing.

Building & Construction Sector to Offer Attractive Opportunities

· Ethylene propylene diene monomer is an extremely durable, synthetic-rubber, roofing membrane that is widely used in low-slope buildings across the globe. Its two primary ingredients, i.e. ethylene and propylene, are derived from oil and natural gas.

· Ethylene propylene diene monomer is widely used in the building & construction industry, due to its properties such as resistance to cracks, water, and temperature. Thus, it is suitable to be used in roofing solutions in the construction industry.

· Ethylene propylene diene monomer offers properties such as high electric resistance and excellent electric insulation. Thus, it is used in various applications in the electric industry. EPDM is widely employed in the manufacture of low- and medium-voltage cable insulations, wires, and submersible water pumps, due to its water-repellent property.

· In the automotive industry, EPDM is used in hydraulic brake systems, wire and cable harnesses, tubing, window spacers, radiators, belts, weather stripping and seals, glass-run channels, and door, window, and trunk seals.

Stuck in a neck-to-neck competition with other brands? Request a custom report on competition on EPDM market here

High Risk of Substitution to Hamper EPDM Market Growth

· The inert nature of EPDM, which reduces the adherence of the material when used in automotive and plastic applications, and high costs of installation of EPDM roofing systems are expected to hamper the demand for ethylene propylene diene monomer in these applications during the forecast period. Furthermore, ethylene propylene diene monomer exhibits unsatisfactory compatibility with most oils, kerosene, gasoline, aromatic and aliphatic hydrocarbons, concentrated acids, and halogenated solvents.

· The above-mentioned disadvantages of EPDM augment the usage of other elastomers, including NBR, polyurethane-based, and HNBR elastomers, in various applications.

· Furthermore, the oversupply of ethylene propylene diene monomer led by the rise in production capacities acts as a major restraining factor for players operating in the global ethylene propylene diene monomer market. EPDM remains oversupplied in Asia Pacific, with most plants in the region running at reduced pace. Major suppliers had to cut the prices of EDPM to boost buying sentiments. In China, ethylene propylene diene monomer prices have dropped by 8.5% since early October 2018, to reach US$ 2,150/ton on December 19, 2018.

Asia Pacific a Prominent EPDM Market

· Asia Pacific dominated the global ethylene propylene diene monomer market in 2018. Growth of the automotive industry in developing economies such as China and India is likely to propel the ethylene propylene diene monomer market in the region during the forecast period.

· The ethylene propylene diene monomer market in North America is expected to expand at a significant pace during the forecast period, due to the high demand for lubricant additives, and rapid growth of the plastic, rubber, and automotive industries in the U.S. and Canada.

· The demand for EPDM roofing is rising in Spain, Italy, the U.K., and countries in Western Europe, due to the increasing demand for waterproofing solutions for use in non-residential and commercial buildings in these countries.

· Increasing demand for eco-friendly products as substitutes for PVC is projected to drive the TPE sector in North America. This, in turn, is likely to fuel the ethylene propylene diene monomer market in the region from 2019 to 2027.

Buy this report @ https://www.transparencymarketresearch.com/checkout.php?rep_id=1285<ype=S

Top Few Players Accounted for ~ 50% of EPDM Market Share in 2018

The global EPDM market is dominated by a few major players, and is consolidated in nature. The top six manufacturers - LANXESS AG, ExxonMobil Chemical Company, Kumho Polychem, Mitsui Chemicals, The Dow Chemical Company, and Lion Copolymer LLC - held ~ 70% of the market share in 2018. Other key companies that manufacture ethylene propylene diene monomer are Sumitomo Chemical Co. Ltd., Versalis S.p.A., SK Global Chemical Co. Ltd., and Johns Manville Inc.

· In April 2015, Lanxess started production of EPDM at its new plant at Changzhou in the Jiangsu province of China. The new plant, with 160,000 tons of annual production capacity, is located in Changzhou Yangtze Riverside Industrial Park. The plant produces ten premium grades of EPDM, tailored to the requirements of customers in Asia, especially China. However, in 2016, Lanxess AG planned to stop the production of EPDM rubber at its facility in Marl, the U.K.

About Us

Transparency Market Research is a next-generation market intelligence provider, offering fact-based solutions to business leaders, consultants, and strategy professionals.

Our reports are single-point solutions for businesses to grow, evolve, and mature. Our real-time data collection methods along with ability to track more than one million high growth niche products are aligned with your aims. The detailed and proprietary statistical models used by our analysts offer insights for making right decision in the shortest span of time. For organizations that require specific but comprehensive information we offer customized solutions through adhoc reports. These requests are delivered with the perfect combination of right sense of fact-oriented problem solving methodologies and leveraging existing data repositories.

TMR believes that unison of solutions for clients-specific problems with right methodology of research is the key to help enterprises reach right decision.

Contact Mr. Rohit Bhisey Transparency Market Research State Tower, 90 State Street, Suite 700, Albany NY - 12207 United States Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Email: [email protected] Website: http://www.transparencymarketresearch.com Research Blog: http://www.europlat.org/

0 notes

Text

Algaecide Market Poised to Expand at a Robust Pace by 2027

Ethylene Propylene Diene Monomer (EPDM) Market: Key Highlights

The global ethylene propylene diene monomer (EPDM) market was valued at ~ US$ 3.8 Bn in 2018, and is anticipated to expand at a CAGR of ~ 6% during the forecast period.

The global ethylene propylene diene monomer market is driven by the rise in the demand for EPDM in automotive applications such as rear-lamp gaskets, hoses, tire sidewalls, inner tire tubes, front and rear bumpers, and braking systems.

Asia Pacific accounts for a major share of the global ethylene propylene diene monomer market, led by an increase in the demand for EPDM for use in thermoplastics modification in the region.

Key Drivers of the EPDM Market

Ethylene propylene diene monomer, a type of synthetic rubber, is primarily used in automotive, roofing, and plastic modification applications. Ethylene propylene diene monomer is extensively employed in the automotive industry, owing to its chemical properties such as high temperature sustainability, and resistance to heat, harsh weather conditions, ozone, and steam.

Highly volatile prices of natural rubber is a major factor that has compelled rubber consumers across the globe to shift from natural rubber toward synthetic rubber such as ethylene propylene diene monomer.

Ethylene propylene diene monomer is widely used in the construction and civil engineering sector in applications such as mounting structures, bridge bearings, expansion joints, pipe couplings, water barriers, roofing membranes, rubberized asphalt, and concrete texturing.

Building & Construction Sector to Offer Attractive Opportunities

Ethylene propylene diene monomer is an extremely durable, synthetic-rubber, roofing membrane that is widely used in low-slope buildings across the globe. Its two primary ingredients, i.e. ethylene and propylene, are derived from oil and natural gas.

Ethylene propylene diene monomer is widely used in the building & construction industry, due to its properties such as resistance to cracks, water, and temperature. Thus, it is suitable to be used in roofing solutions in the construction industry.

Ethylene propylene diene monomer offers properties such as high electric resistance and excellent electric insulation. Thus, it is used in various applications in the electric industry. EPDM is widely employed in the manufacture of low- and medium-voltage cable insulations, wires, and submersible water pumps, due to its water-repellent property.

In the automotive industry, EPDM is used in hydraulic brake systems, wire and cable harnesses, tubing, window spacers, radiators, belts, weather stripping and seals, glass-run channels, and door, window, and trunk seals.

To obtain all-inclusive information on forecast analysis of Global Market , request a PDF brochure here.

High Risk of Substitution to Hamper EPDM Market Growth

The inert nature of EPDM, which reduces the adherence of the material when used in automotive and plastic applications, and high costs of installation of EPDM roofing systems are expected to hamper the demand for ethylene propylene diene monomer in these applications during the forecast period. Furthermore, ethylene propylene diene monomer exhibits unsatisfactory compatibility with most oils, kerosene, gasoline, aromatic and aliphatic hydrocarbons, concentrated acids, and halogenated solvents.

The above-mentioned disadvantages of EPDM augment the usage of other elastomers, including NBR, polyurethane-based, and HNBR elastomers, in various applications.

Furthermore, the oversupply of ethylene propylene diene monomer led by the rise in production capacities acts as a major restraining factor for players operating in the global ethylene propylene diene monomer market. EPDM remains oversupplied in Asia Pacific, with most plants in the region running at reduced pace. Major suppliers had to cut the prices of EDPM to boost buying sentiments. In China, ethylene propylene diene monomer prices have dropped by 8.5% since early October 2018, to reach US$ 2,150/ton on December 19, 2018.

Asia Pacific a Prominent EPDM Market

Asia Pacific dominated the global ethylene propylene diene monomer market in 2018. Growth of the automotive industry in developing economies such as China and India is likely to propel the ethylene propylene diene monomer market in the region during the forecast period.

The ethylene propylene diene monomer market in North America is expected to expand at a significant pace during the forecast period, due to the high demand for lubricant additives, and rapid growth of the plastic, rubber, and automotive industries in the U.S. and Canada.

The demand for EPDM roofing is rising in Spain, Italy, the U.K., and countries in Western Europe, due to the increasing demand for waterproofing solutions for use in non-residential and commercial buildings in these countries.

Increasing demand for eco-friendly products as substitutes for PVC is projected to drive the TPE sector in North America. This, in turn, is likely to fuel the ethylene propylene diene monomer market in the region from 2019 to 2027.

Top Few Players Accounted for ~ 50% of EPDM Market Share in 2018

The global EPDM market is dominated by a few major players, and is consolidated in nature. The top six manufacturers – LANXESS AG, ExxonMobil Chemical Company, Kumho Polychem, Mitsui Chemicals, The Dow Chemical Company, and Lion Copolymer LLC – held ~ 70% of the market share in 2018. Other key companies that manufacture ethylene propylene diene monomer are Sumitomo Chemical Co. Ltd., Versalis S.p.A., SK Global Chemical Co. Ltd., and Johns Manville Inc.

REQUEST FOR COVID19 IMPACT ANALYSIS –https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=18218

Explore Transparency Market Research’s award-winning coverage of the global Chemicals and Materials Industry:https://www.prnewswire.co.uk/news-releases/single-walled-carbon-nanotube-market-to-touch-valuation-of-us-5-bn-by-2027-commercializing-depends-on-cost-effective-fabrication-methods-transparency-market-research-879370332.html

0 notes

Text

ETHYLENE PROPYLENE DIENE MONOMER (EPDM) MARKET TO REACH ~ US$ 6.2 BN BY 2027

Ethylene Propylene Diene Monomer (EPDM) Market: Key Highlights

The global ethylene propylene diene monomer (EPDM) market was valued at ~ US$ 3.8 Bn in 2018, and is anticipated to expand at a CAGR of ~ 6% during the forecast period.

The global ethylene propylene diene monomer market is driven by the rise in the demand for EPDM in automotive applications such as rear-lamp gaskets, hoses, tire sidewalls, inner tire tubes, front and rear bumpers, and braking systems.

Asia Pacific accounts for a major share of the global ethylene propylene diene monomer market, led by an increase in the demand for EPDM for use in thermoplastics modification in the region.

Request A Sample – https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=1285

Key Drivers of the EPDM Market

Ethylene propylene diene monomer, a type of synthetic rubber, is primarily used in automotive, roofing, and plastic modification applications. Ethylene propylene diene monomer is extensively employed in the automotive industry, owing to its chemical properties such as high temperature sustainability, and resistance to heat, harsh weather conditions, ozone, and steam.

Highly volatile prices of natural rubber is a major factor that has compelled rubber consumers across the globe to shift from natural rubber toward synthetic rubber such as ethylene propylene diene monomer.

Ethylene propylene diene monomer is widely used in the construction and civil engineering sector in applications such as mounting structures, bridge bearings, expansion joints, pipe couplings, water barriers, roofing membranes, rubberized asphalt, and concrete texturing.

Building & Construction Sector to Offer Attractive Opportunities

Ethylene propylene diene monomer is an extremely durable, synthetic-rubber, roofing membrane that is widely used in low-slope buildings across the globe. Its two primary ingredients, i.e. ethylene and propylene, are derived from oil and natural gas.

Ethylene propylene diene monomer is widely used in the building & construction industry, due to its properties such as resistance to cracks, water, and temperature. Thus, it is suitable to be used in roofing solutions in the construction industry.

Ethylene propylene diene monomer offers properties such as high electric resistance and excellent electric insulation. Thus, it is used in various applications in the electric industry. EPDM is widely employed in the manufacture of low- and medium-voltage cable insulations, wires, and submersible water pumps, due to its water-repellent property.

In the automotive industry, EPDM is used in hydraulic brake systems, wire and cable harnesses, tubing, window spacers, radiators, belts, weather stripping and seals, glass-run channels, and door, window, and trunk seals.

High Risk of Substitution to Hamper EPDM Market Growth

The inert nature of EPDM, which reduces the adherence of the material when used in automotive and plastic applications, and high costs of installation of EPDM roofing systems are expected to hamper the demand for ethylene propylene diene monomer in these applications during the forecast period. Furthermore, ethylene propylene diene monomer exhibits unsatisfactory compatibility with most oils, kerosene, gasoline, aromatic and aliphatic hydrocarbons, concentrated acids, and halogenated solvents.

The above-mentioned disadvantages of EPDM augment the usage of other elastomers, including NBR, polyurethane-based, and HNBR elastomers, in various applications.

Furthermore, the oversupply of ethylene propylene diene monomer led by the rise in production capacities acts as a major restraining factor for players operating in the global ethylene propylene diene monomer market. EPDM remains oversupplied in Asia Pacific, with most plants in the region running at reduced pace. Major suppliers had to cut the prices of EDPM to boost buying sentiments. In China, ethylene propylene diene monomer prices have dropped by 8.5% since early October 2018, to reach US$ 2,150/ton on December 19, 2018.

Request For Brochure @

Asia Pacific a Prominent EPDM Market

Asia Pacific dominated the global ethylene propylene diene monomer market in 2018. Growth of the automotive industry in developing economies such as China and India is likely to propel the ethylene propylene diene monomer market in the region during the forecast period.

The ethylene propylene diene monomer market in North America is expected to expand at a significant pace during the forecast period, due to the high demand for lubricant additives, and rapid growth of the plastic, rubber, and automotive industries in the U.S. and Canada.

The demand for EPDM roofing is rising in Spain, Italy, the U.K., and countries in Western Europe, due to the increasing demand for waterproofing solutions for use in non-residential and commercial buildings in these countries.

Increasing demand for eco-friendly products as substitutes for PVC is projected to drive the TPE sector in North America. This, in turn, is likely to fuel the ethylene propylene diene monomer market in the region from 2019 to 2027.

Top Few Players Accounted for ~ 50% of EPDM Market Share in 2018

The global EPDM market is dominated by a few major players, and is consolidated in nature. The top six manufacturers – LANXESS AG, ExxonMobil Chemical Company, Kumho Polychem, Mitsui Chemicals, The Dow Chemical Company, and Lion Copolymer LLC – held ~ 70% of the market share in 2018. Other key companies that manufacture ethylene propylene diene monomer are Sumitomo Chemical Co. Ltd., Versalis S.p.A., SK Global Chemical Co. Ltd., and Johns Manville Inc.

In April 2015, Lanxess started production of EPDM at its new plant at Changzhou in the Jiangsu province of China. The new plant, with 160,000 tons of annual production capacity, is located in Changzhou Yangtze Riverside Industrial Park. The plant produces ten premium grades of EPDM, tailored to the requirements of customers in Asia, especially China. However, in 2016, Lanxess AG planned to stop the production of EPDM rubber at its facility in Marl, the U.K.

0 notes

Text

Global UV Curing System Market Company Profiles, Segments, Landscape, Size, Industry Growth and Demand by Forecast to 2025

The global UV curing system market accounted for USD 2.78 billion in 2017 and is projected to grow at a CAGR of 10.8% during the forecast period of 2018 to 2025. The upcoming market report contains data for historic years 2016, the base year of calculation is 2017 and the forecast period is 2018 to 2025.

Market Definition

This market report defines the market trends and forecast the upcoming opportunities and threats of the UV curing system market in the next 8 years. Ultraviolet (UV) curing is a photochemical procedure in which high power UV light is being utilized to immediately cure and for adhesives as well as coatings. It helps in decreasing dismiss rates, encourage unrivaled holding, increase production speed, enhance scratch and dissolvable protection and others. UV curing system creates no ecological pollutants, no dissolvable to dissipate, covering thickness and volume loss. This outcome in energy utilization is higher within short span of time along with decrease in waste and pollutant emissions. Rising environmental concerns and strict regulation by the government agency is one of the factors which help in driving the UV curing system market. (VOC) Volatile Organic Compounds content of coatings is being calculated or determined by Environmental Protection Agency (EPA) Reference Test Method 24 which states different standard method such as ASTM D 1475-60, ASTM 4457-85, ASTM D 5403-93 and others. ASTM D 5403-93 states that amount of UV ink or coating being applied to the substrate should be less than 0.2 grams and the substrate sample area would be greater than or equal to 225 cm2. Thus, it is considered as a thin-film UV radiation-cured coating for the application in the manufacturing companies. Another factor which led to the increase in UV curing system market is various product launches made by different companies so as to overcome from the traditional UV system. For instance, Nordson Corporation manufactures CoolWave 306 System which delivers easy maintenance and improved flexibility for industrial curing applications.

Get exclusive PDF sample report@ http://databridgemarketresearch.com/request-a-sample/?dbmr=global-uv-curing-system-market

This Report Consists of –

· No of pages: 350, No of Figures: 60, No of Tables: 220

Global UV Curing System Market, By Type (Flood Cure, Spot Cure, Focused Beam), By Technology (UV LED, Mercury Lamp), By Pressure Type (Low, Medium, High), By Application (Bonding & Assembling, Printing, Disinfection, Coating), By Industry (Automotive, Aerospace, Construction, Medical), By Geography (North America, Europe, Asia-Pacific, Europe, South America, Middle East & Africa)– Industry Trends and Forecast to 2025

Note: If you have any special requirements, please let us know and we will offer you the report as you want.

Frequently Asked Questions?

· What will the market size be in 2025?

· What are the key factors driving the global market?

· What are the challenges to market growth?

· Who are the key players in the market?

· What are the market opportunities and threats faced by the key players?

· What will be the growth rate in 2025?

· Which strategies are used by top players in the Global UV Curing System Market?

For Customized Reports and Discounts, Mail us @ [email protected]

Major Market Drivers & Market Restraint

· Growing acceptance of bio based products and resins

· Rising environmental concerns and strict regulation

· Better performance and high speed and consistency over traditional system

· Bounded depth of curing

Market Segmentation of

The global UV curing system market is segmented based on type, technology, pressure type, application, industry and geographical segments.

Based on type, the global UV curing system market is segmented into

· flood cure,

· spot cure,

· focused beam

On the basis of technology, the global UV curing system market is segmented into

· UV LED and

· Mercury Lamp

Mercury lamp is sub segmented into microwave lamp and arc lamp.

On the basis of pressure type, the global UV curing system market is segmented into

· low,

· medium and

· high pressure

On the basis of application, the global UV curing system market is segmented into

· bonding and assembling,

· printing,

· disinfection,

· coating and finishing and others

Other type of application includes temporary masking, sealing and potting.

On the basis of industry, the global UV curing system market is segmented into

· automotive and transportation,

· aerospace and defense,

· construction and architectural,

· industrial and machinery,

· consumer electronics,

· semiconductor,

· medical,

· energy,

· marine and others

Inquire before buying @ http://databridgemarketresearch.com/inquire-before-buying/?dbmr=global-uv-curing-system-market

Automotive and transportation is sub segmented into cables and wire harness, decorating interior vehicle assemblies, music system, radio and navigation consoles, markings on glass, logos and coating on lenses, headlight and mirrors. Aerospace and defense is sub segmented into aircraft and weapon coating. Construction and architectural is sub segmented into sealants and adhesives for commercial buildings, tunnels, highways, construction projects and others; filling cracks and sealing joints. Industrial and machinery is sub segmented into machinery and equipment. Consumer electronics is sub segmented into coating on plastic parts of electronics and displays of electronic devices. Semiconductor is sub segmented into printed circuit boards (PCBS), wafer processing and electronics assembly. Medical is sub segmented into medical electronics assembly and equipment such as needle bonder, tube set, catheter, anesthesia mask and others. Energy is sub segmented into oil and gas pipelines. Marine is sub segmented into barges, yachts, water line, canal boats.Others are sub segmented into air and water filtration and agriculture.

Based on geography, the global UV curing system market report covers data points for 28 countries across multiple geographies such as

· North America,

· South America,

· Europe,

· Asia-Pacific and

· Middle East and Africa

Some of the major countries covered in this report are U.S., Canada, Germany, France, U.K., Netherlands, Switzerland, Turkey, Russia, China, India, South Korea, Japan, Australia, Singapore, Saudi Arabia, South Africa, and Brazil among others.

Competitive Landscape

The global UV curing system market is consolidated due to the presence of limited number of players concentrated in few countries. These major players have adopted various organic as well as inorganic growth strategies such as mergers & acquisitions, new product launches, expansions, agreements, joint ventures, partnerships, and others to strengthen their position in this market.

Call Our Analyst @ http://databridgemarketresearch.com/speak-to-analyst/?dbmr=global-uv-curing-system-market

Top Competitors of Market

· Heraeus Holding,

· Honle,

· Baldwin Technology,

· Panasonic Corporation,

· IST METZ GmbH.,

· Phoseon Technology,

· Excelitas Technologies Corp.,

· Nordson Corporation,

· Delo,

· Dymax Corporation,

· American Ultraviolet,

· BASF SE,

· Nippon Gohsei,

· Jiangsu Sanmu Group Corporation,

· DSM AGI Corporation,

· Toagosei Co. Ltd,

· Wanhua Chemical Group Co. Ltd.,

· Heraeus Noblelight America,

· Benford UV,

· Uvexs Inc.,

· GEW,

· Miltec UV,

· Hanovia Ltd and

· Hoya Corporation

Visit Report @ http://databridgemarketresearch.com/reports/global-uv-curing-system-market/

About Data Bridge Market Research:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

0 notes

Text

Development and Trend of High Efficiency LED Lighting Application

Shenzhen Risen OPTO Co.,Ltd,led flood light supplier,Aluminum Alloy Flood Light Manufacturers,waterproof led lamps supplier china. The global LED lighting market in the market mature period, part of the field showing the state of consolidation, according to the state set LED research center (LEDinside) data, 2016 global LED lighting market size reached 29.6 billion US dollars, 2017 is expected to grow to 331 100 million US dollars, LED lighting penetration rate is 52% of the degree, the future is still quite play space, but the low-end market prices and competition, not the international manufacturers are happy to see some of the more powerful and product technology threshold Of the first-tier manufacturers, will be efficient LED lighting and niche market to go And benefited from the development of regional lighting market, 2016 European LED lighting accounted for 23%, followed by North America and China market, the overall growth rate of the Asia-Pacific lighting market the fastest. LEDinside visits lighting manufacturers with major LED suppliers to explore new markets in the market for high efficiency LED lighting. US lighting market to attract manufacturers to push high efficiency LED lamp The US market economic policy affects the development of the North American lighting industry, the United States is promoting the localization of LED lighting fixtures, will be more satisfied with the local market segments, expand the size of the local market. LEDinside that this will produce similar to the previous US local solar installation services industry, the rise of the effect, led more US LED lighting engineering team was born to deal with the new installation of the project and replace the traditional lamps, the first generation of LED lights and other business, increase more Local job opportunities in the United States. The major US manufacturers are actively developing LED lighting business, LED lighting products continue to rise, LED commercial lighting / engineering lighting needs are strong in the US market. Among them, Troffer, flat lights, tunnel lights, patio light market demand to grow the most rapid, and accelerate to the wisdom and optical communications and other fields. LEDinside said that in 2017 the global LED commercial lighting (mainly including lamp, Toffer and panel lights), the output value of 6.347 billion US dollars, 2016-2020 compound annual growth rate of 12%. North American market LED lamp demand is very high, in the DLC 4.0 specifications come out, many manufacturers and standard contracting units are more in line with DLC 4.0 related specifications of the product, which LED lamp design and cost structure, manufacturers use LED What is the effect of the chip's choice? High current density with low current use of LED components to choose philosophy At this stage because the market and the application of different lighting manufacturers must be careful in the choice of LED chips and LED components. At present the mainstream of the new application of the market, divided into "high current density" and "low current use" of these two LED chip design and selection philosophy. International LED epitaxial manufacturers Crystal Marketing Center Director Lin Zi Yuan pointed out that the demand for high-efficiency LED, LED chip prices have been reduced to sweet points, the lighting manufacturers, the choice of less with the LED chip, so that They work with a higher current density, to Over Drive the way to achieve the cost of lighting fixtures, which is the general way of LED lights or LED bulb, the pursuit of lm per dollar, but with the appropriate cooling module, there are quite The cost of cooling materials, although the current market mainstream, but the light quality, product life, in fact, subject to many challenges. For example, the high current density design of the LED package in the LED tube is too small, it will show the spotlight on the LED lamp lighting quality, heat caused by the negative impact. Another way to succeed is "low current use", that is, in high-quality and efficient LED lamp, the use of more stars, to avoid the negative problems. The philosophy of low current use is to drive the LED chip with a lower current specification, and to put enough LED in a lamp and look better. In the case of the formation of the whole glass lamp, gradually replace the semi-plastic lamp case, low current use of high efficiency LED chip, not only improve the lighting effect, product life, quality and stability are better, but also meet US DLC 4.0 high efficiency specifications, to achieve the whole lamp 150lm / w above the high efficiency. In the case of the entire group of LED lamps to improve the efficiency of light, the appropriate LED chip design, coupled with heat, Blaster, glass lamp structure, it will be the higher price of high quality and high efficiency products, but also in line with market expectations. High efficiency LED lamp components need to carefully selected a patent supplier Crystal is currently in the United States customers have been successfully in the hospital, public buildings, buildings and other areas into the market, and actively T8, T5 traditional fluorescent tube replacement to LED lamp. At the same time, US manufacturers in the United States to create a trend, the owner and the market acceptance is higher than in the past. A high-efficiency LED lamp required LED chip is not less, is the general low-cost LED bulb several times to ten times as much. Crystal in the LED chip research and development not only has many years of experience, there are a lot of own LED patents and cooperation authorized patents, products exported to Europe and North America and other customers customers, will be more willing to choose crystal power solution Program, crystal power can be large and stable supply is the main advantage. In addition to the North American market, the crystal also cut into the quality of the Japanese market, the recent response to the 2010 Tokyo Olympic Games, there are many times the next generation of LED lighting needs. Overall, some of the market needs to be able to operate at low current, but can achieve high efficiency LED products, low current high-quality solutions, has become a first-line lighting manufacturers focus on the goal. More information please enter:http://www.outdoorlightingsupplier.com/

0 notes

Text

Ethylene propylene diene monomer (EPDM) market to reach ~ us$ 6.2 bn by 2027

Ethylene Propylene Diene Monomer (EPDM) Market: Key Highlights

The global ethylene propylene diene monomer (EPDM) market was valued at ~ US$ 3.8 Bn in 2018, and is anticipated to expand at a CAGR of ~ 6% during the forecast period.

The global ethylene propylene diene monomer market is driven by the rise in the demand for EPDM in automotive applications such as rear-lamp gaskets, hoses, tire sidewalls, inner tire tubes, front and rear bumpers, and braking systems.

Asia Pacific accounts for a major share of the global ethylene propylene diene monomer market, led by an increase in the demand for EPDM for use in thermoplastics modification in the region.

Request a Sample –

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=1285

Key Drivers of the EPDM Market

Ethylene propylene diene monomer, a type of synthetic rubber, is primarily used in automotive, roofing, and plastic modification applications. Ethylene propylene diene monomer is extensively employed in the automotive industry, owing to its chemical properties such as high temperature sustainability, and resistance to heat, harsh weather conditions, ozone, and steam.

Highly volatile prices of natural rubber is a major factor that has compelled rubber consumers across the globe to shift from natural rubber toward synthetic rubber such as ethylene propylene diene monomer.

Ethylene propylene diene monomer is widely used in the construction and civil engineering sector in applications such as mounting structures, bridge bearings, expansion joints, pipe couplings, water barriers, roofing membranes, rubberized asphalt, and concrete texturing.

Building & Construction Sector to Offer Attractive Opportunities

Ethylene propylene diene monomer is an extremely durable, synthetic-rubber, roofing membrane that is widely used in low-slope buildings across the globe. Its two primary ingredients, i.e. ethylene and propylene, are derived from oil and natural gas.

Ethylene propylene diene monomer is widely used in the building & construction industry, due to its properties such as resistance to cracks, water, and temperature. Thus, it is suitable to be used in roofing solutions in the construction industry.

Ethylene propylene diene monomer offers properties such as high electric resistance and excellent electric insulation. Thus, it is used in various applications in the electric industry. EPDM is widely employed in the manufacture of low- and medium-voltage cable insulations, wires, and submersible water pumps, due to its water-repellent property.

In the automotive industry, EPDM is used in hydraulic brake systems, wire and cable harnesses, tubing, window spacers, radiators, belts, weather stripping and seals, glass-run channels, and door, window, and trunk seals.

Buy now-

https://www.transparencymarketresearch.com/checkout.php?rep_id=1285<ype=S

High Risk of Substitution to Hamper EPDM Market Growth

The inert nature of EPDM, which reduces the adherence of the material when used in automotive and plastic applications, and high costs of installation of EPDM roofing systems are expected to hamper the demand for ethylene propylene diene monomer in these applications during the forecast period. Furthermore, ethylene propylene diene monomer exhibits unsatisfactory compatibility with most oils, kerosene, gasoline, aromatic and aliphatic hydrocarbons, concentrated acids, and halogenated solvents.

The above-mentioned disadvantages of EPDM augment the usage of other elastomers, including NBR, polyurethane-based, and HNBR elastomers, in various applications.

Furthermore, the oversupply of ethylene propylene diene monomer led by the rise in production capacities acts as a major restraining factor for players operating in the global ethylene propylene diene monomer market. EPDM remains oversupplied in Asia Pacific, with most plants in the region running at reduced pace. Major suppliers had to cut the prices of EDPM to boost buying sentiments. In China, ethylene propylene diene monomer prices have dropped by 8.5% since early October 2018, to reach US$ 2,150/ton on December 19, 2018.

Request for covid19 impact analysis –

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=1285

Asia Pacific a Prominent EPDM Market

Asia Pacific dominated the global ethylene propylene diene monomer market in 2018. Growth of the automotive industry in developing economies such as China and India is likely to propel the ethylene propylene diene monomer market in the region during the forecast period.

The ethylene propylene diene monomer market in North America is expected to expand at a significant pace during the forecast period, due to the high demand for lubricant additives, and rapid growth of the plastic, rubber, and automotive industries in the U.S. and Canada.

The demand for EPDM roofing is rising in Spain, Italy, the U.K., and countries in Western Europe, due to the increasing demand for waterproofing solutions for use in non-residential and commercial buildings in these countries.

Increasing demand for eco-friendly products as substitutes for PVC is projected to drive the TPE sector in North America. This, in turn, is likely to fuel the ethylene propylene diene monomer market in the region from 2019 to 2027.

Top Few Players Accounted for ~ 50% of EPDM Market Share in 2018

The global EPDM market is dominated by a few major players, and is consolidated in nature. The top six manufacturers - LANXESS AG, ExxonMobil Chemical Company, Kumho Polychem, Mitsui Chemicals, The Dow Chemical Company, and Lion Copolymer LLC - held ~ 70% of the market share in 2018. Other key companies that manufacture ethylene propylene diene monomer are Sumitomo Chemical Co. Ltd., Versalis S.p.A., SK Global Chemical Co. Ltd., and Johns Manville Inc.

In April 2015, Lanxess started production of EPDM at its new plant at Changzhou in the Jiangsu province of China. The new plant, with 160,000 tons of annual production capacity, is located in Changzhou Yangtze Riverside Industrial Park. The plant produces ten premium grades of EPDM, tailored to the requirements of customers in Asia, especially China. However, in 2016, Lanxess AG planned to stop the production of EPDM rubber at its facility in Marl, the U.K.

Companies in the Ethylene Propylene Diene Monomer (EPDM) market have increasingly shifted gears with wide application of digital technology across the continuum, from raw material sourcing to manufacturing to generation of final output, to warehousing to final distribution operations. Among the various affects, the market is witnessing new growth economics due to thinning of line between specialty and commodity businesses that are associated with the larger ecosystem. At the same time, new growth parameters are being vigorously being debated as industry stakeholders put greater emphasis on the circular economy processes.

More Trending Reports-

https://www.prnewswire.com/news-releases/players-harnessing-nanotechnologies-to-meet-expanding-industrial-demands-in-global--us-graphite-coatings-market-valuation-projected-to-expand-at-cagr-of-7-5-during-2020-2030-tmr-301284397.html

0 notes

Text

Ethylene Propylene Diene Monomer (EPDM) Market : Industry Outlook by 2027

Ethylene Propylene Diene Monomer (EPDM) Market: Key Highlights

· The global ethylene propylene diene monomer (EPDM) market was valued at ~ US$ 3.8 Bn in 2018, and is anticipated to expand at a CAGR of ~ 6% during the forecast period.

· The global ethylene propylene diene monomer market is driven by the rise in the demand for EPDM in automotive applications such as rear-lamp gaskets, hoses, tire sidewalls, inner tire tubes, front and rear bumpers, and braking systems.

· Asia Pacific accounts for a major share of the global ethylene propylene diene monomer market, led by an increase in the demand for EPDM for use in thermoplastics modification in the region.

Request A Sample @ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=1285

Key Drivers of the EPDM Market

· Ethylene propylene diene monomer, a type of synthetic rubber, is primarily used in automotive, roofing, and plastic modification applications. Ethylene propylene diene monomer is extensively employed in the automotive industry, owing to its chemical properties such as high temperature sustainability, and resistance to heat, harsh weather conditions, ozone, and steam.

· Highly volatile prices of natural rubber is a major factor that has compelled rubber consumers across the globe to shift from natural rubber toward synthetic rubber such as ethylene propylene diene monomer.

· Ethylene propylene diene monomer is widely used in the construction and civil engineering sector in applications such as mounting structures, bridge bearings, expansion joints, pipe couplings, water barriers, roofing membranes, rubberized asphalt, and concrete texturing.

Building & Construction Sector to Offer Attractive Opportunities

· Ethylene propylene diene monomer is an extremely durable, synthetic-rubber, roofing membrane that is widely used in low-slope buildings across the globe. Its two primary ingredients, i.e. ethylene and propylene, are derived from oil and natural gas.

· Ethylene propylene diene monomer is widely used in the building & construction industry, due to its properties such as resistance to cracks, water, and temperature. Thus, it is suitable to be used in roofing solutions in the construction industry.

· Ethylene propylene diene monomer offers properties such as high electric resistance and excellent electric insulation. Thus, it is used in various applications in the electric industry. EPDM is widely employed in the manufacture of low- and medium-voltage cable insulations, wires, and submersible water pumps, due to its water-repellent property.

· In the automotive industry, EPDM is used in hydraulic brake systems, wire and cable harnesses, tubing, window spacers, radiators, belts, weather stripping and seals, glass-run channels, and door, window, and trunk seals.

High Risk of Substitution to Hamper EPDM Market Growth

· The inert nature of EPDM, which reduces the adherence of the material when used in automotive and plastic applications, and high costs of installation of EPDM roofing systems are expected to hamper the demand for ethylene propylene diene monomer in these applications during the forecast period. Furthermore, ethylene propylene diene monomer exhibits unsatisfactory compatibility with most oils, kerosene, gasoline, aromatic and aliphatic hydrocarbons, concentrated acids, and halogenated solvents.

· The above-mentioned disadvantages of EPDM augment the usage of other elastomers, including NBR, polyurethane-based, and HNBR elastomers, in various applications.

· Furthermore, the oversupply of ethylene propylene diene monomer led by the rise in production capacities acts as a major restraining factor for players operating in the global ethylene propylene diene monomer market. EPDM remains oversupplied in Asia Pacific, with most plants in the region running at reduced pace. Major suppliers had to cut the prices of EDPM to boost buying sentiments. In China, ethylene propylene diene monomer prices have dropped by 8.5% since early October 2018, to reach US$ 2,150/ton on December 19, 2018.

Asia Pacific a Prominent EPDM Market

· Asia Pacific dominated the global ethylene propylene diene monomer market in 2018. Growth of the automotive industry in developing economies such as China and India is likely to propel the ethylene propylene diene monomer market in the region during the forecast period.

· The ethylene propylene diene monomer market in North America is expected to expand at a significant pace during the forecast period, due to the high demand for lubricant additives, and rapid growth of the plastic, rubber, and automotive industries in the U.S. and Canada.

· The demand for EPDM roofing is rising in Spain, Italy, the U.K., and countries in Western Europe, due to the increasing demand for waterproofing solutions for use in non-residential and commercial buildings in these countries.

· Increasing demand for eco-friendly products as substitutes for PVC is projected to drive the TPE sector in North America. This, in turn, is likely to fuel the ethylene propylene diene monomer market in the region from 2019 to 2027.

Buy this report @ https://www.transparencymarketresearch.com/checkout.php?rep_id=1285<ype=S

Top Few Players Accounted for ~ 50% of EPDM Market Share in 2018

The global EPDM market is dominated by a few major players, and is consolidated in nature. The top six manufacturers - LANXESS AG, ExxonMobil Chemical Company, Kumho Polychem, Mitsui Chemicals, The Dow Chemical Company, and Lion Copolymer LLC - held ~ 70% of the market share in 2018. Other key companies that manufacture ethylene propylene diene monomer are Sumitomo Chemical Co. Ltd., Versalis S.p.A., SK Global Chemical Co. Ltd., and Johns Manville Inc.

· In April 2015, Lanxess started production of EPDM at its new plant at Changzhou in the Jiangsu province of China. The new plant, with 160,000 tons of annual production capacity, is located in Changzhou Yangtze Riverside Industrial Park. The plant produces ten premium grades of EPDM, tailored to the requirements of customers in Asia, especially China. However, in 2016, Lanxess AG planned to stop the production of EPDM rubber at its facility in Marl, the U.K.

About Us

Transparency Market Research is a next-generation market intelligence provider, offering fact-based solutions to business leaders, consultants, and strategy professionals.

Our reports are single-point solutions for businesses to grow, evolve, and mature. Our real-time data collection methods along with ability to track more than one million high growth niche products are aligned with your aims. The detailed and proprietary statistical models used by our analysts offer insights for making right decision in the shortest span of time. For organizations that require specific but comprehensive information we offer customized solutions through adhoc reports. These requests are delivered with the perfect combination of right sense of fact-oriented problem solving methodologies and leveraging existing data repositories.

TMR believes that unison of solutions for clients-specific problems with right methodology of research is the key to help enterprises reach right decision.

Contact Mr. Rohit Bhisey Transparency Market Research State Tower, 90 State Street, Suite 700, Albany NY - 12207 United States Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Email: [email protected] Website: http://www.transparencymarketresearch.com Research Blog: http://www.europlat.org/

0 notes

Text

UV curing system market Key Trends, Growth, Analysis and forecast Report 2025

The global UV curing system market accounted for USD 2.78 billion in 2017 and is projected to grow at a CAGR of 10.8% during the forecast period of 2018 to 2025. The upcoming market report contains data for historic years 2016, the base year of calculation is 2017 and the forecast period is 2018 to 2025.

Market Definition

This market report defines the market trends and forecast the upcoming opportunities and threats of the UV curing system market in the next 8 years. Ultraviolet (UV) curing is a photochemical procedure in which high power UV light is being utilized to immediately cure and for adhesives as well as coatings. It helps in decreasing dismiss rates, encourage unrivaled holding, increase production speed, enhance scratch and dissolvable protection and others. UV curing system creates no ecological pollutants, no dissolvable to dissipate, covering thickness and volume loss. This outcome in energy utilization is higher within short span of time along with decrease in waste and pollutant emissions. Rising environmental concerns and strict regulation by the government agency is one of the factors which help in driving the UV curing system market. (VOC) Volatile Organic Compounds content of coatings is being calculated or determined by Environmental Protection Agency (EPA) Reference Test Method 24 which states different standard method such as ASTM D 1475-60, ASTM 4457-85, ASTM D 5403-93 and others. ASTM D 5403-93 states that amount of UV ink or coating being applied to the substrate should be less than 0.2 grams and the substrate sample area would be greater than or equal to 225 cm2. Thus, it is considered as a thin-film UV radiation-cured coating for the application in the manufacturing companies. Another factor which led to the increase in UV curing system market is various product launches made by different companies so as to overcome from the traditional UV system. For instance, Nordson Corporation manufactures CoolWave 306 System which delivers easy maintenance and improved flexibility for industrial curing applications.

Get exclusive PDF sample report@ http://databridgemarketresearch.com/request-a-sample/?dbmr=global-uv-curing-system-market

This Report Consists of –

No of pages: 350, No of Figures: 60, No of Tables: 220

Global UV Curing System Market, By Type (Flood Cure, Spot Cure, Focused Beam), By Technology (UV LED, Mercury Lamp), By Pressure Type (Low, Medium, High), By Application (Bonding & Assembling, Printing, Disinfection, Coating), By Industry (Automotive, Aerospace, Construction, Medical), By Geography (North America, Europe, Asia-Pacific, Europe, South America, Middle East & Africa)– Industry Trends and Forecast to 2025

Note: If you have any special requirements, please let us know and we will offer you the report as you want.

Frequently Asked Questions?

What will the market size be in 2025?

What are the key factors driving the global market?

What are the challenges to market growth?

Who are the key players in the market?

What are the market opportunities and threats faced by the key players?

What will be the growth rate in 2025?

Which strategies are used by top players in the Global UV Curing System Market?

To Avail 10% Discount On This Report Mail us on @ [email protected]

Major Market Drivers & Market Restraint

Growing acceptance of bio based products and resins

Rising environmental concerns and strict regulation

Better performance and high speed and consistency over traditional system

Bounded depth of curing

Market Segmentation of

The global UV curing system market is segmented based on type, technology, pressure type, application, industry and geographical segments.

Based on type, the global UV curing system market is segmented into

flood cure,