#Concrete Machine Spare Parts Producer in India

Explore tagged Tumblr posts

Text

Concrete Machine Spare Parts Manufacturers in India

We are leading Concrete Machine Spare Parts Manufacturers in India. We understands the demands of the construction industry and strives to deliver spare parts that withstand the rigors of heavy-duty usage. Innovation is at the core of their manufacturing process, as they constantly explore new technologies and materials to enhance the performance of their products.

#Concrete Machine Spare Parts Producer in NCR#Concrete Machine Spare Parts Producer in India#Concrete Machine Spare Parts Producer#Machine Parts Supplier#Ram Babu Manufacturing#Concrete Machinery#Concrete Machine#Concrete Machine Parts

0 notes

Text

Efficient And Sustainable Mobile Concrete Batching Plant

Though the modern world of infrastructure development is moving forward at a fast pace there is a rising need for effective construction machinery that is flexible, compact, and portable. Of these, mobile concrete batching plants have turned out to be the most useful and effective new developments. These plants are exceptionally movable, and their erection is rather simple, so they are crucial to contemporary construction sites. This article explores the details of the mobile concrete batching plant, the benefits it offers, and the role that only some of the leaders of the road construction equipment manufacturers along with concrete batching plant manufacturers in India have to offer.

Features of Mobile Concrete Batching Plants

Mobile concrete batching plants are designed to have mobility features while at the same time having high production rates. These units are on wheels or trailers thus making it very easy to move from one construction site to another. Their key features include:

Compact Design: Mobile plants are particularly useful to projects that may only offer small spaces as they take minimal space.

Quick Installation: These plants can be established within a few hours of arrival and need very little setting up.

Customizable Capacity: Coming in different sizes, mobile concrete batching plants serve small construction projects to large construction projects in construction companies.

Automation: They incorporate sophisticated control procedures in the measurement and combination of the material.

Pros of Operating Mobile Concrete Batching Plants

The adoption of mobile concrete batching plants offers numerous benefits for construction companies:

Flexibility: Since they are not anchored structures, these plants do not require fixed installations that may be suitable for centralized utility but may be inconvenienced in remote or temporarily established facilities.

Cost-Effective: Since these plants minimize transportation expenses as well as provide concrete production at the site they help to cut several expenses at the construction site.

Time-Saving: Mobile batching plants help in faster construction through the supply of Hur concrete at the construction site.

Environmental Compliance: Today’s mobile plants are environmentally friendly; therefore, they will not harm the environment during their operation.

Mobile Managers In India: Overview of Solutions of Concrete

The construction industry in India has witnessed a rising demand for mobile concrete batching plants owing to the fast-growing infrastructure projects. Understanding this global demand, the leading Indian construction equipment manufacturers have been pioneers in innovations, manufacturing new-generation mobile batching solutions.

Being a premier road construction equipment manufacturer, India has several reputed concrete batching plant manufacturing companies that produce quality products according to various projects. These firms use sophisticated technology to make sure their equipment is the best in world standards in terms of efficiency and longevity.

Alfa Omega India: A Trusted Leader in Construction Equipment

Alfa Omega India has taken its place as the leading company in the construction equipment manufacturers sector. Being one of the leading global manufacturers of mobile concrete batching plants and other products, the company has earned its reputation for creating quality and efficient products for construction industries.

Alfa Omega India is a quality-conscious company and therefore, its equipment is long-lasting, owing to the new technologies used and high-quality requirements. Some of the designs by the company are environmentally conscious because they emit the least amount of emissions possible to the environment.

Further, Alfa Omega India offers excellent after-sale service for its customers and the spare parts for its machines are easily accessible thus making sure that its customers’ operations run smoothly. Being an offbeat company among the top construction equipment manufacturers in India, Alfa Omega India has still remained prominent in contributing to the developments of the nation.

Choosing the Right Manufacturer

Choosing the right concrete batching plant manufacturer in India is vital to the success of these ventures. When evaluating manufacturers, consider the following factors:

Experience and Reputation: Indeed, first-time positioners, who are generally new companies or smaller firms entering the industry after observing its growth, are relatively more likely to produce inferior equipment.

Product Range: Select a manufacturer with as many models of mobile batching plants as possible given the nature and sizes of the projects involved.

After-Sales Support: Accessibility to spare parts together with quality customer service is an important factor for smooth running operations.

Sustainability Practices: It is, therefore, advisable to work with those manufacturers whose products are environmentally friendly and energy efficient.

Conclusion

Mobile concrete batching plants have now advanced the construction industry by giving mobility, reliability, and technology. They still remain valuable since they are capable of producing high-performance concrete that will be needed on the construction site for infrastructural development. For this reason, road construction equipment manufacturers and concrete batching plant manufacturers in India will have more significant roles in meeting those demands. Thus, construction companies can establish their efficiency, cost savings, and effectiveness in implementing environmental measures by acquiring advanced equipment from reliable manufacturers.

#concrete batching plant#construction equipment manufacturers#mobile concrete batching plants#concrete batching plant manufacturing companies#road construction equipment manufacturers#concrete batching plant manufacturers

0 notes

Text

Why Jaypee® Concrete Mixer Machines are Perfect for Your Construction Needs in INDIA

Construction industry efficiency, durability and cost-effectiveness are essential considerations in India. Concrete mixers are indispensable tools on any construction site to produce consistent, high-quality mixtures requiring reliable machinery, such as Jaypee® concrete mixer machine - trusted for their affordability and superior performance. This blog will examine why Jaypee® concrete mixers may be perfect for your construction needs. It will explore their pricing, material quality, after-sales services, spare part availability, and various mixers that cover different applications.

Reasonably Priced Without Compromising Quality Jaypee® concrete mixer machines stand out for their competitive pricing without compromising performance compared to many international brands. While their prices may be less, their performance outshone even them! Here's why.

Jaypee® Industries employs economies of scale in its production process, leading to reduced manufacturing costs passed directly to customers. Plus, their Indian production is made possible by eliminating import duties, making their mixers more cost-effective for domestic buyers.

Streamlined Design: Our company's designs strive to strike a balance between functionality and material usage to maximize durability without unnecessary extravagance. Jaypee® mixers are affordable yet constructed to high-quality standards, guaranteeing efficient output efficiency and consistent performance.

Premium-Grade Materials to Maximize Durability: Durability is of the utmost importance in construction, so Jaypee® concrete mixers are built to last. Their strength lies in the premium-grade materials used: steel and plastic resin, to name just two.

High-Grade Steel: Our mixing drum and structural components are constructed of robust, corrosion-resistant steel for long-term reliability in even harsh environments. Heavy-Duty Bearings: Bearings and joints constructed of industrial-grade materials offer improved stress tolerance to reduce wear and tear over time.

Precision Manufacturing: Each part of a Jaypee® concrete mixer is assembled carefully, guaranteeing smooth operations and reduced breakdown chances. It focuses on high-grade materials, which results in a longer operational lifespan and decreases the frequency and cost of replacements or repairs over time. It is an investment that pays for itself in time.

Jaypee® takes pride in cultivating long-standing relationships with its customers. Its exceptional after-sales service is tailored to provide an effortless experience, making it the preferred choice among construction professionals across India.

Nationwide Support Network: Jaypee® offers an expansive service network, guaranteeing quick support regardless of your construction site. Skilled Technicians: Our knowledgeable technicians are on call 24x7, 365 Days to address operational issues quickly and minimize downtime.

Comprehensive Maintenance Plans: Jaypee® offers comprehensive maintenance plans to keep your mixer operating at peak condition and extend its lifespan. At the same time, their efficient after-sales service gives customers peace of mind, making We an indispensable partner in their construction endeavors.

Easy Access to Spare Parts: When equipment breaks down, construction delays can be severely disrupted, so having quick access to spare parts is vital. Jaypee® excels in this respect: they offer fast shipping of replacements.

Jaypee® maintains an expansive spare parts inventory, allowing immediate repairs when required.

Affordable Spares: Our spare parts are priced competitively, so maintenance costs remain minimal. Spare parts produced domestically are readily accessible, eliminating delays caused by import logistics. This approach allows mixers to quickly return to full function without extensive downtime, even when they require part replacement.

Concrete Mixers and Their Applications: Jaypee® offers a selection of concrete mixers designed to meet various construction needs. Here is an overview of some of these types and their purposes:

Hand-Fed Concrete Mixers | PBS Contractors, LLC: These small portable mixers are great for small-scale construction tasks. They're manually fed with raw materials for limited concrete production. The drum capacity allows for limited concrete output. Applications: Hopper-Fed Concrete Mixers can be an ideal way to complete projects requiring limited space, from home renovations and repairs to repairs that involve limited access. Their automatic material-feeding hopper makes their operation more efficient while guaranteeing consistent mixing results. Applications: Ideal for medium-scale construction projects such as residential buildings and commercial complexes. Reversible Drum Mixers These advanced mixers allow mixing and discharging operations within the same drum, increasing efficiency while decreasing waste and productivity. Their unique reversible design also minimizes waste while increasing productivity. Applications: Hydraulic concrete mixers are ideal for infrastructure projects like roads, bridges, and irrigation works. Whilst they don't come cheap, they boast unmatched mixing efficiency while being designed for heavy-duty operations—something other mixers simply can't. Applications: Transit Mixers can be utilized in large-scale industrial and infrastructure projects requiring continuous mixing at high capacity. They feature truck-mounted mixers designed to transport ready-mix concrete across long distances while maintaining consistency. Applications: An essential tool in remote site construction, high-rise building construction and urban infrastructure projects. Jaypee® concrete mixer machines have earned an esteemed place among construction professionals across India. Thanks to their combination of affordability, efficiency, and durability, these concrete mixers make an excellent investment choice for projects of all sizes. High-grade materials and unrivalled after-sales support to ensure maximum value is received from every purchase.

We offers an extensive selection of concrete mixers designed to meet specific applications and diverse construction needs. Whether for residential construction, commercial property development, or large-scale infrastructure projects, We can find an appropriate mixer that ensures precision, cost-efficiency, and reliability throughout every phase.

#Concrete Mixer Machine#Concrete Processing#Concrete Mixer Machine Price#ConcreteMixer#ConstructionEquipment#BuildingSolutions#ConstructionMachinery#ConcreteTechnology#ConcreteMixingSolutions

0 notes

Text

How to Choose the Right Paver Block Making Machine in India

Choosing the right paver block making machine in India is crucial for businesses looking to enter or expand in the construction and paving industry. With the growing demand for interlocking tiles making machine in India and paver blocks, investing in a high-quality machine can significantly boost your productivity and profitability. This guide will help you navigate the process of selecting the ideal paver block making machine for your needs.

Understanding the Basics of Paver Block Making Machines

Before diving into the selection process, it's essential to understand what paver block making machines are and how they work. These machines are designed to produce various types of concrete blocks, including interlocking tiles making machine in India, paver blocks, and in some cases, fly ash brick making machine in India. They use a combination of vibration and compression to mold concrete or other materials into the desired shape and size.

Types of Paver Block Making Machines

1. Stationary Machines

Stationary paver block making machines are ideal for large-scale production facilities. They offer high output and are suitable for businesses with a dedicated production area.

2. Mobile Machines

Mobile or portable paver block making machines are perfect for on-site production or businesses that need flexibility in their operations. They can be easily transported to different locations as needed.

3. Automatic Machines

Automatic paver block making machines require minimal human intervention and are best for high-volume production. They often come with advanced features like automatic feeding and stacking systems.

4. Semi-Automatic Machines

Semi-automatic machines strike a balance between manual control and automation. They are suitable for medium-scale production and offer a good mix of efficiency and affordability.

Key Factors to Consider When Choosing a Paver Block Making Machine

1. Production Capacity

Consider your current and future production needs. BTM Product offers a range of machines with varying capacities to suit different business scales.

2. Types of Blocks Produced

Ensure the machine can produce the types of blocks you plan to offer. Some machines are versatile and can produce both interlocking tiles making machine in India and paver blocks, while others may specialize in specific types.

3. Quality of Output

The quality of the finished product is crucial. Look for machines that produce consistent, high-quality blocks with proper density and strength.

4. Energy Efficiency

Energy-efficient machines can significantly reduce your operating costs in the long run. Check the power consumption and efficiency ratings of different models.

5. Ease of Operation and Maintenance

User-friendly machines with simple controls and easy maintenance requirements can improve productivity and reduce downtime.

6. Durability and Build Quality

Invest in a machine built with high-quality materials to ensure longevity and reliability. BTM Product is known for its durable and robust machines.

7. Customization Options

Some manufacturers offer customization options to tailor the machine to your specific needs. This can be particularly useful if you have unique production requirements.

8. After-sales support and Spare Parts Availability

Choose a manufacturer that offers reliable after-sales support and easy access to spare parts. This can minimize downtime in case of any issues.

Assessing Your Business Needs

Before making a decision, carefully assess your business needs:

1. Production Volume

Estimate your daily or monthly production requirements to choose a machine with the appropriate capacity.

2. Available Space

Consider the space available in your production facility to ensure the machine fits comfortably and allows for efficient workflow.

3. Budget

Determine your budget, keeping in mind that investing in a high-quality machine can lead to better returns in the long run.

4. Workforce Skill Level

Consider the skill level of your workforce when choosing between automatic and semi-automatic machines.

5. Future Growth Plans

Think about your future expansion plans and choose a machine that can accommodate potential growth in production.

Comparing Different Brands and Models

When comparing different brands and models of paver block making machine in India, consider the following:

1. Technical Specifications

Compare the technical specifications of different machines, including production capacity, power consumption, and dimensions.

2. Customer Reviews and Testimonials

Look for customer reviews and testimonials to get real-world insights into the performance and reliability of different machines.

3. Brand Reputation

Choose reputable brands like BTM Product that have a proven track record in the industry.

4. Warranty and Support

Check the warranty terms and after-sales support offered by different manufacturers.

5. Price-to-Performance Ratio

Compare the features and capabilities of different machines relative to their price to ensure you're getting the best value for your investment.

The Importance of Proper Installation and Training

Once you've chosen your paver block making machine, proper installation and training are crucial for optimal performance:

1. Professional Installation

Ensure the machine is installed correctly by professionals to avoid issues and maximize efficiency.

2. Operator Training

Invest in comprehensive training for your operators to ensure they can use the machine effectively and safely.

3. Regular Maintenance Schedule

Implement a regular maintenance schedule to keep your machine in top condition and prevent unexpected breakdowns.

Expanding Your Product Line

Consider machines that offer versatility in production. For example, some paver block making machine in India can also produce fly ash brick making machine in India, allowing you to diversify your product offerings. BTM Product offers machines capable of producing both paver blocks and fly ash bricks, providing flexibility for your business.

Conclusion

Choosing the right paver block making machine in India is a crucial decision that can significantly impact your business's success. By carefully considering factors such as production capacity, quality, energy efficiency, and after-sales support, you can make an informed choice that aligns with your business needs and goals.

Remember to thoroughly research different brands and models, including those offered by reputable manufacturers like BTM Product. Take the time to assess your current and future needs, and don't hesitate to seek expert advice if needed.

Investing in a high-quality interlocking tiles making machine in India or a versatile paver block making machine can set your business up for long-term success in the competitive construction and paving industry. With the right machine and proper maintenance, you'll be well-equipped to meet the growing demand for paver blocks and interlocking tiles in the Indian market.

0 notes

Text

EN1A square bright bar

EN1A square bright bars are steel rods used majorly in automotive and construction projects. The EN1A square bright bars are anti-abrasive and anti-corrosive, making them the correct match for joints in commercial medical environments such as hospitals. The most preferred applications include mounting decorative ironwork, gates, and safety barriers around various organizations.

If you are in search of the EN1A square bright bar of the highest quality, please look no further. Matta Drawing Works is among the leading organization well-known for the production and supply of high-quality special steel shapes, including the best quality EN1A square bright bar all over the country.

Why En1a square bright bar is so unique?

Several reasons make EN1A square bright bars irreplaceable. Even if concrete, wood, or other synthetic fibers can be found in the surrounding area, EN1A square bright bar’s anti-corrosion qualities, durability, strength, and dependability remain unmatched. EN1A square bright bars are often flat, round, hexagonal, or square in shape and their shape determines their application space. These bars are equipped with a variety of uses and are available in various grades.

Uses of En1a square bright bar

Depending upon the various grades of EN1A square bright bar, the uses and the applications in the industry also vary. One thing to note is that these EN1A square bright bars are used without any kind of heat treatment or with a limited amount of tempering in order to relieve the stress that can form during its production. In the industries, these EN1A square bright bars are used for making nuts, bolts, and spare parts for the automobile industries and for making some precision instruments or different kinds of instruments that are being used by several companies.

EN1A square bright bar is an important type of free-cutting steel shape that has made its way into the market. These are widely used by a wide range of industries for the use in the production of the above-mentioned instruments and parts. As this type of steel configures chips when it is worked on, they can take up only an average amount of heavy-duty items at a time. When EN1A square bright bars are sold in the market, the grade of the free cutting varies with its composition. Sulfur or phosphorous are the two major types of ingredients that are added to the steel, apart from some little amounts of carbon.

Some Properties Of En1a square bright bar

● Strength for withstanding any physical or chemical conditions.

● Resistance against uttermost climatic conditions.

● Cost-effective as well as durable.

Major Applications of En1a square bright bar:

● Automobile industries

● Fasteners

● Machining equipment

● Textile industries

● Machining Tools

● Heavy engineering

Features of En1a square bright bar:

● Unmatched quality

● Long work life

● High tensile strength

● 100% purity level

● Corrosion resistance

● Superior performance

● Chemical resistance

EN1A square bright bar isa strong and sturdy metal that is resistant to corrosion. They are also utilized for many purposes due to their flexibility and how easily they can be shaped.

The Bottom Line

Matta Drawing Works is a steel bright bar manufacturer that produces a wide variety of EN1A square bright bar. As a result of our more than a decade of expertise, we are able to deliver a high-quality assortment of EN1A square bright bars in a variety of grades and sizes to our clients.

After passing through the heat treatment, cold drawing, annealing, and tempering processes, our highly qualified production team develops EN1A square bright bar for our customers in a recently constructed facility. The state-of-the-art products produced at this facility allow them to produce EN1A square bright bars of world-class quality.

We are the most well-known EN1A square bright bar manufacturer in India for various applications. We also create advanced stainless steel bars and bright round, square and bright bars from high-quality steel and other raw materials. For more information, please visit our website and get the best quote on steel shapes today!

0 notes

Text

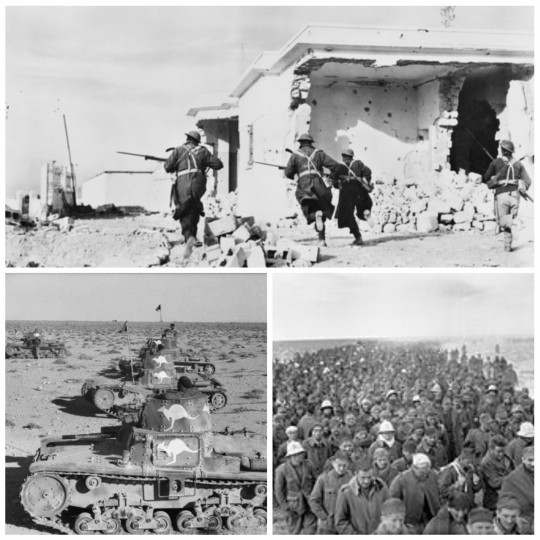

• Battle of Bardia

The Battle of Bardia was fought between January 3rd and 5th 1941, as part of Operation Compass, the first British military operation of the Western Desert Campaign of the Second World War.

Italy declared war on the United Kingdom on June 10th, 1940. Bordering on the Italian colony of Libya was the Kingdom of Egypt. Although a neutral country, Egypt was occupied by the British under the terms of the Anglo-Egyptian Treaty of 1936, which allowed British military forces to occupy Egypt if the Suez Canal was threatened. A series of cross-border raids and skirmishes began on the frontier between Libya and Egypt. On September 13th, 1940, an Italian force advanced across the frontier into Egypt, reaching Sidi Barrani on September 16th, where the advance was halted until logistical difficulties could be overcome. Italy's position in the centre of the Mediterranean made it unacceptably hazardous to send ships from Britain to Egypt via that route, so British reinforcements and supplies for the area had to travel around the Cape of Good Hope. For this reason, it was more convenient to reinforce General Sir Archibald Wavell's Middle East Command with troops from Australia, New Zealand and India. Nonetheless, even when Britain was threatened with invasion after the Battle of France. On December 9th, 1940 the Western Desert Force under the command of Major General Richard O'Connor attacked the Italian position at Sidi Barrani. The position was captured, 38,000 Italian soldiers were taken prisoner, and the remainder of the Italian force was driven back. The Western Desert Force pursued the Italians into Libya, and the 7th Armoured Division established itself to the west of Bardia, cutting off land communications between the strong Italian garrison there and Tobruk. On December 11th, Wavell decided to withdraw the 4th Indian Division and send it to the Sudan to participate in the East African Campaign. The 6th Australian Division (Major General Iven Mackay) was brought forward from Egypt to replace it and Mackay assumed command of the area on December 21st,1940.

After the disaster at Sidi Barrani and the withdrawal from Egypt, XXIII Corps (Generale di Corpo d'Armata (Lieutenant General) Annibale Bergonzoli) faced the British from within the strong defences of Bardia. Mussolini wrote to Bergonzoli, "I have given you a difficult task but one suited to your courage and experience as an old and intrepid soldier—the task of defending the fortress of Bardia to the last. I am certain that 'Electric Beard' and his brave soldiers will stand at whatever cost, faithful to the last." Bergonzoli replied: "I am aware of the honour and I have today repeated to my troops your message — simple and unequivocal. In Bardia we are and here we stay." Bergonzoli had approximately 45,000 defenders under his command. The Italian divisions defending the perimeter of Bardia included remnants of four divisions. Bergonzoli also had the remnants of the disbanded 64th "Catanzaro" Infantry Division, some 6,000 Frontier Guard (GaF) troops, three companies of Bersaglieri, part of the dismounted Vittorio Emanuele cavalry regiment and a machine gun company. These divisions guarded an 18-mile (29 km) perimeter which had an almost continuous antitank ditch, extensive barbed wire fence and a double row of strong points. The strong points were situated approximately 800-yard (730 m) apart. Each had its own antitank ditch, concealed by thin boards. They were each armed with one or two Cannone da 47/32 M35 (47 mm antitank guns) and two to four machine guns. The weapons were fired from concrete sided pits connected by trenches to a deep underground concrete bunker which offered protection from artillery fire.

Each post was occupied by a platoon or company. The inner row of posts were similar, except that they lacked the antitank ditches. The posts were numbered sequentially from south to north, with the outer posts bearing odd numbers and the inner ones even numbers. The actual numbers were known to the Australians from the markings on maps captured at Sidi Barrani and were also displayed on the posts themselves. The major tactical defect of this defensive system was that if the enemy broke through, the posts could be picked off individually from the front or rear. The defence was supported by a strong artillery component, yet the large number of gun models, many of them quite old, created difficulties with the supply of spare parts. The older guns often had worn barrels, which caused problems with accuracy. Ammunition stocks were similarly old and perhaps as many as two-thirds of the fuses were out of date, resulting in excessive numbers of dud rounds. Shortages of raw materials, coupled with the increased technological sophistication of modern weapons, led to production problems that frustrated efforts to supply the Italian Army with the best available equipment. As a "mobile reserve" there were thirteen M13/40 medium tanks and a hundred and fifteen L3/35 tankettes. The L3s were generally worthless, the M13/40s were effective medium tanks with four machine guns and a turret-mounted 47 mm antitank gun for its main armament that were "in many ways the equal of British armoured fighting vehicles". Bergonzoli knew that if Bardia and Tobruk held out, a British advance further into Libya eventually must falter under the logistical difficulties of maintaining a desert force using an extended overland supply line. Not knowing how long he had to hold out, Bergonzoli was forced to ration his stocks of food and water so that O'Connor could not simply starve him out. Hunger and thirst adversely affected the morale of the Italian defenders that had already been shaken by the defeat at Sidi Barrani.

On the Allied side, the 6th Australian Division had been formed in September 1939 as part of the Second Australian Imperial Force. Prime Minister Robert Menzies ordered that all commands in the division were to go to reservists rather than to regular officers, who had been publicly critical of the defence policies of right wing politicians. The result was that when war came, the Army's equipment was of World War I vintage and its factories were only capable of producing small arms. Fortunately, these World War I-era small arms, the Lee–Enfield rifle and the Vickers machine gun, were solid and reliable weapons that would remain in service throughout the war; they were augmented by the more recent Bren light machine gun. Most other equipment was obsolescent and would have to be replaced but new factories were required to produce the latest items, such as 3-inch mortars, 25-pounder field guns and motor vehicles; War Cabinet approval for their construction was slow in coming. The training of the 6th Australian Division in Palestine, while "vigorous and realistic", was therefore hampered by shortages of equipment. These shortages were gradually remedied by deliveries from British sources. Similarly, No. 3 Squadron RAAF had to be sent to the Middle East without aircraft or equipment and supplied by the Royal Air Force, at the expense of its own squadrons. Despite the rivalry between regular and reserve officers, the 6th Australian Division staff was an effective organisation. Brigadier John Harding, the chief of staff of XIII Corps, as the Western Desert Force was renamed on January 1st, 1941. Harding later considered the 6th Australian Division staff "as good as any that I came across in that war, and highly efficient." As it moved into position around Bardia in December 1940, the 6th Australian Division was still experiencing shortages. It had only two of its three artillery regiments and only the 2/1st Field Regiment was equipped with the new 25-pounders, which it had received only that month. Only A Squadron of the 2/6th Cavalry Regiment was on hand, as the rest of the regiment was deployed in the defence of the frontier posts at Al-Jaghbub and Siwa Oasis. The 2/1st Antitank Regiment had likewise been diverted, so each infantry brigade had formed an antitank company but only eleven 2-pounders were available instead of the 27 required. The infantry battalions were particularly short of mortars and ammunition for the Boys anti-tank rifle was in short supply.

To make up for this, O'Connor augmented Brigadier Edmund Herring's 6th Australian Division Artillery with part of the XIII Corps artillery: the 104th (Essex Yeomanry) Regiment, Royal Horse Artillery, equipped with sixteen 25 pounders. Italian gun positions were located using sound ranging by the 6th Survey Regiment, Royal Artillery. At a meeting with Mackay on Christmas Eve, 1940, O'Connor visited Mackay at divisional headquarters and directed him to prepare an attack on Bardia. O'Connor recommended that this be built around the 23 Matilda tanks of the 7th Royal Tank Regiment (Lieutenant Colonel R. M. Jerrram) that remained in working order. The attack was to be made with only two brigades, leaving the third for a subsequent advance on Tobruk. Mackay did not share O'Connor's optimism about the prospect of an easy victory and proceeded on the assumption that Bardia would be resolutely held, requiring a well-planned attack. The plan developed by Mackay and his chief of staff, Colonel Frank Berryman, involved an attack on the western side of the Bardia defences by 16th Australian Infantry Brigade (Brigadier Arthur "Tubby" Allen) at the junction of the Gerfah and Ponticelli sectors. Attacking at the junction of two sectors would confuse the defence. The defences here were weaker than in the Mereiga sector, the ground was favourable for employment of the Matilda tanks and good observation for the artillery was possible. Most of the artillery, grouped as the "Frew Group" under British Lieutenant Colonel J. H. Frowen, would support the 16th Australian Infantry Brigade; the 17th would be supported by the 2/2nd Field Regiment. Much depended on the Western Desert Force moving fuel, water and supplies forward. The 6th Australian Division Assistant Adjutant General and Quartermaster General (AA&QMG), Colonel George Alan Vasey said "This is a Q war".

A series of air raids were mounted against Bardia in December, in the hope of persuading the garrison to withdraw. Once it became clear that the Italians intended to stand and fight, bombing priorities shifted to the Italian airbases around Tobruk, Derna and Benina. Air raids on Bardia resumed in the lead-up to the ground assault, with 100 bombing sorties flown against Bardia between December 31st, 1940 and January 2nd, 1941, climaxing with a particularly heavy raid by Vickers Wellington bombers of No. 70 Squadron RAF and Bristol Bombay bombers of No. 216 Squadron RAF on the night of January 3rd, 1941. A naval bombardment was carried out on the morning of the 3rd by the Queen Elizabeth-class battleships HMS Warspite, Valiant and Barham and their destroyer escorts. The aircraft carrier HMS Illustrious provided aircraft for spotting and fighter cover. They withdrew after firing 244 15-inch (380 mm), 270 6-inch (150 mm) and 240 4.5-inch (110 mm) shells. The assault troops rose early on January 3rd, 1941. The leading companies began moving to the start line at 0416. The artillery opened fire at 0530. On crossing the start line the 2/1st Infantry Battalion, under the command of Lieutenant Colonel Kenneth Eather, came under Italian mortar and artillery fire. The lead platoons advanced accompanied by sappers of the 2/1st Field Company carrying Bangalore torpedoes—12-foot (3.7 m) pipes packed with ammonal—as Italian artillery fire began to land, mainly behind them. An Italian shell exploded among a leading platoon and detonated a Bangalore torpedo, resulting in four killed and nine wounded. The torpedoes were slid under the barbed wire at 60-yard (55 m) intervals. A whistle was blown as a signal to detonate the torpedoes but could not be heard over the din of the barrage. Eather became anxious and ordered the engineering party nearest him to detonate their torpedo. This the other teams heard, and they followed suit. The infantry scrambled to their feet and rushed forward, they advanced on a series of posts held by the 2nd and 3rd Battalions of the Italian 115th Infantry Regiment. Posts 49 and 47 were rapidly overrun, as was Post 46 in the second line beyond. Within half an hour Post 48 had also fallen and another company had taken Posts 45 and 44. The two remaining companies now advanced beyond these positions towards a low stone wall as artillery fire began to fall along the broken wire.

The Italians fought from behind the wall until the Australians were inside it, attacking with hand grenades and bayonets. The two companies succeeded in taking 400 prisoners. The 2/2nd Infantry Battalion (Lieutenant Colonel F. O. Chilton) found that it was best to keep skirmishing forward throughout this advance, because going to ground for any length of time meant sitting in the middle of the enemy artillery concentrations that inflicted further casualties. The Australian troops made good progress, six tank crossings were readied and mines between them and the wire had been detected. Five minutes later, the 23 Matildas of the 7th Royal Tank Regiment advanced, accompanied by the 2/2nd Infantry Battalion. Passing through the gaps, they swung right along the double line of posts. The Italian defenders were cleared with grenades. By 0920 all companies were on their objectives and they had linked with 2/1st Infantry Battalion. However, several Bren gun carriers encountered problems as they moved forward during the initial attack. One was hit and destroyed in the advance and another along the Wadi Ghereidia. The 2/3rd Infantry Battalion was now assailed by half a dozen Italian M13/40 tanks who freed a group of 500 Italian prisoners. The tanks continued to rumble to the south while the British crews of the Matildas "enjoying a brew, dismissed reports of them as an Antipodean exaggeration". Finally, they were engaged by an antitank platoon of three 2 pounders mounted on portees. By midday, 6,000 Italian prisoners had already reached the provosts at the collection point near Post 45, escorted by increasingly fewer guards whom the rifle companies could afford to detach. The Italian perimeter had been breached and the attempt to halt the Australian assault at the outer defences had failed. Major H. Wrigley's 2/5th Infantry Battalion of Brigadier Stanley Savige's 17th Infantry Brigade, reinforced by two companies of Lieutenant Colonel T. G. Walker's 2/7th Infantry Battalion, now took over the advance. The battalion's task was to clear "The Triangle", a map feature created by the intersection of three tracks north of Post 16. Wrigley's force had a long and exhausting approach, and much of its movement forward to its jump off point had been under Italian shellfire intended for the 16th Infantry Brigade. Awaiting its turn to move, the force sought shelter in Wadi Scemmas and its tributaries. Wrigley called a final coordinating conference for 1030, but at 1020 he was wounded by a bullet and his second in command, Major G. E. Sell took over.

The artillery barrage came down at 1125, and five minutes later the advance began. The sun had now risen, and Captain C. H. Smith's D Company came under effective fire from machine guns and field artillery 700 yards (640 m) to the north east. Within minutes, all but one of the company's officers and all its senior non-commissioned officers had been killed or wounded. Meanwhile, Captain D. I. A. Green's B Company of the 2/7th Infantry Battalion had captured Posts 26, 27 and 24. After Post 24 had been taken, two Matildas arrived and helped to take Post 22. As the prisoners were rounded up, one shot Green dead, then threw down his rifle and climbed out of the pit smiling broadly. He was immediately thrown back and a Bren gun emptied into him. Upon hearing of the losses to the 2/5th Infantry Battalion, Brigade Major G. H. Brock sent Captain J. R. Savige's A Company of the 2/7th Infantry Battalion to take "The Triangle". Savige gathered his platoons and, with fire support from machine guns, attacked the objective, 3,000 yards (2,700 m) away. The company captured eight field guns, many machine-guns and nearly 200 prisoners on the way, but casualties and the need to detach soldiers as prisoner escorts left him with only 45 men at the end of the day. That evening, Brigadier Savige came forward to the 2/5th Infantry Battalion's position to determine the situation, which he accurately evaluated as "extremely confused; the attack was stagnant." Meanwhile, Captain G. H. Halliday's D Company moved southwards against Post 19. He drew the defenders' attention with a demonstration by one platoon in front of the post while the rest of the company moved around the post and attacked silently from the rear. This maneuver took the defenders by surprise and D Company captured the post—and 73 prisoners—at 0230. Although the Australian progress had been slower than that achieved during the break-in phase, the 17th Infantry Brigade had achieved remarkable results. Another ten posts, representing 3 kilometres (1.9 mi) of perimeter had been captured, the Switch Line had been breached, and thousands of Italian defenders had been captured. For the Italians, halting the Australian advance would be an immensely difficult task.

On the afternoon of January 3rd, Berryman met with Allen, Jerram and Frowen at Allen's headquarters at Post 40 to discuss plans for the next day. It was agreed that Allen would advance on Bardia and cut the fortress in two, supported by Frowen's guns, every available tank, MacArthur-Onslow's Bren gun carriers and the 2/8th Infantry Battalion, which Mackay had recently allocated from reserve. That evening, Berryman came to the conclusion that unless the Italian defence collapsed soon, the 16th and 17th Infantry Brigades would become incapable of further effort and Brigadier Horace Robertson's 19th Infantry Brigade would be required. The 2/1st Infantry Battalion began its advance on schedule at 0900, but the lead platoon came under heavy machine gun fire from Post 54, and Italian artillery knocked out the supporting mortars. The 3rd Regiment Royal Horse Artillery engaged the Italian guns and the platoon withdrew. The Italian guns were silenced when an Australian shell detonated a nearby ammunition dump. The Australians then captured the post. About a third of its defenders had been killed in the fighting. The remaining 66 surrendered. This prompted a general collapse of the Italian position in the north. Posts 56 and 61 surrendered without a fight and white flags were raised over Posts 58, 60, 63 and 65, and the gun positions near Post 58. By nightfall, Eather's men had advanced as far as Post 69 and only the fourteen northernmost posts still held out in the Gerfan sector. The advance resumed, only to come under machine gun and artillery fire from Wadi el Gerfan. The brigade major, Major I. R. Campbell, ordered MacArthur-Onslow, whose carriers were screening England's advance, to seize Hebs el Harram, the high ground overlooking the road to the township of Bardia. By the end of the second day, tens of thousands of defenders had been killed or captured. The remaining garrisons in the Gerfan and Ponticelli sectors were completely isolated. The logistical and administrative units were being overrun. Recognising that the situation was hopeless, General Bergonzoli and his staff had departed on foot for Tobruk during the afternoon, in a party of about 120 men.

On the morning of January 5th, the 19th Infantry Brigade launched its attack on the Meriega sector, starting from the Bardia road and following a creeping barrage southward with the support of six Matilda tanks, all that remained in working order. The others had been hit by shells, immobilised by mines, or had simply broken down. The company commanders of the lead battalion, the 2/11th Infantry Battalion, did not receive their final orders until 45 minutes before start time, at which point the start line was 3 miles (4.8 km) away. As they advanced, they came under fire from the left, the right, and in front of them, but casualties were light. Most positions surrendered when the infantry and tanks came close, but this did not reduce the fire from posts further away. Meanwhile, the Italian garrisons in the north were surrendering to the 16th Infantry Brigade and the Support Group of the 7th Armoured Division outside the fortress; the 2/8th Infantry Battalion had taken the area above Wadi Meriega; and the 2/7th Infantry Battalion had captured Posts 10, 12 and 15. The only post still holding out was now Post 11. The 2/6th Infantry Battalion renewed its attack, with the infantry attacking from the front and its carriers attacking from the rear. They were joined by Matildas from the vicinity of Post 6. At this point the Italian post commander, who had been wounded in the battle, lowered his flag and raised a white one. Some 350 Italian soldiers surrendered at Post 11. Godfrey sought out the Italian post commander—who wore a British Military Cross earned in the First World War—and shook his hand. "On a battlefield where Italian troops won little honour", Gavin Long later wrote, "the last to give in belonged to a garrison whose resolute fight would have done credit to any army."

The victory at Bardia enabled the Allied forces to continue their advance into Libya and capture almost all of Cyrenaica. As the first battle of the war to be commanded by an Australian general, planned by an Australian staff and fought by Australian troops, Bardia was of great interest to the Australian public; congratulatory messages poured in and AIF recruitment surged. In the United States, newspapers praised the 6th Division. An estimated 36,000 Italian soldiers were captured at Bardia, 1,703 (including 44 officers) were killed and 3,740 (including 138 officers) were wounded A few thousand (including General Bergonzoli and three of his division commanders) escaped to Tobruk on foot or in boats. The Allies captured 26 coastal defence guns, 7 medium guns, 216 field guns, 146 anti-tank guns, 12 medium tanks, 115 L3s, and 708 vehicles. Australian losses totalled 130 dead and 326 wounded. Bardia did not become an important port as supply by sea continued to run through Sollum but became an important source of water, after the repair of the large pumping station that the Italians had installed to serve the township and Fort Capuzzo. Axis forces reoccupied the town in April 1941, during Operation Sonnenblume, Rommel's first offensive in Cyrenaica. Bardia changed hands again in June 1942, being occupied by Axis forces for a third time and was re-taken for the last time in November unopposed, following the Allied victory at the Second Battle of El Alamein.

#second world war#world war 2#world war ii#wwii#military history#history#long post#british history#italy in ww2#italian history#north africa#australian history

22 notes

·

View notes

Text

Concrete Machine Spare Part Supplier in Delhi NCR

Choosing the right concrete machine spare parts Supplier in Delhi NCR is a pivotal decision that can impact the success of your construction projects. At Ram Babu Manufacturing, we take pride in our industry experience, commitment to quality, and technological advancements that set us apart as a trusted partner in the realm of concrete machine spare parts.

#Concrete Machine Spare Parts Producer in India#Concrete Machine Spare Parts Manufacturers in India#Concrete Machine Spare Parts Supplier in India#Concrete Machine Spare Parts Producer in Delh#Concrete Machine Spare Parts Producer in NCR

0 notes

Text

nail making machine price in China

What is the nail making machine price in china? Our nail making machine is strengthened type. The frame is heavier to ensure the fixedness after tension. we paid more attention to the details of every small part, all these small details ensure the best quality of the nail producing machines. So it can run for many years without any problems.

VIDEO OF NAIL MAKING MACHINE TESTING

HOW CAN GET NAIL MAKING MACHINE PRICE IN CHINA

The function of the Z94 nail machine is to make the nails into different sizes by adjusting the nails making machine. It needs to put the suitable wire diameter into the entrance of the nail making machine. Then start the nail making machine, the machine will produce wood nails automatically. China’s price is not higher than the India machine. We really hope, clients can visit us if come to Hebei Province. Then we can show you what is the quality of Made in China.

Why do we need to know the nail making machine price? Z94 type nails producing machines have different size, some can make big nails, some can make small nails. The performance of Automatic Z94 Type C New Generation Nail Making Machine is High-Speed and low Noise. Do you know how to operate an automatic Z94-C type nail making machine and the machine price & worker salary? (nail machine, nail making machine, China nail making machine price).

LIST OF NAIL MAKING MACHINE PRICE IN CHINA

TESTING OF NAIL MAKING MACHINE BEFORE DELIVERY

WIRE POINTING MACHINE OPERATING VEDEO

BUTT WELDING MACHINE FOR WIRE DRAWING

GRINDERING MACHINE FOR NAIL CUTTER

Above is the related video of NAIL MAKING MACHINE PRICE IN CHINA. Now hope you already know how to operate these nail making machine and AUXILIARY EQUIPMENT. Following, we introduce some spare parts of nail making machine.

SAPREPARTS FOR SMALL WIRE NAIL MAKING MACHINE

Sharpening dies: this machine is to sharpen the head of steel wire before it is feed into the wire drawing machine, the principle of the drawing machine is that using different size of drawing dies, for example, to draw steel wire of 6.5 mm to 3.8 mm, we can use a drawing die of 3.8mm, sharpen the head of 6.5mm steel wire less than 3.8 mm first, then put the head into the die, then fix the head of the wire to the wire drawing machine, then start pulling. After the wire comes through the die, all the wire becomes the diameter of 3.8mm.

Nail knife grinder: because after 1-2 days cutting, the nail knife installed on the wire nail making machines will become blunt, then you can use the nail knife grinder to grind the nail knife to make it sharp again.

Gripping Dies: Machines are provided with round dies having 8 or 10 nail holding grooves

Cutting Die: For cutting nails and making point after the head & shank are formed Diamond, Chisel, Round, Long or Blunt shaped Points can be made by grinding the tools appropriately

Header Dies: Used for forming a nailhead Chequered or Plain Heads can be formed with these dies

Nail Cutter and Die Grinder (supplied with a motor, Emery wheels and Pedestal Stand)

Optional Accessories: Additional sets of Tooling (Set of Gripping Dies, Cutting Tools and Header Dies)

Standard Accessories: Electric Motor, Starter, Belts, One set of Tooling, Wire Stand and Hand Operated Lubricating Pump

Further is the NAIL MAKING MACHINE PRICE IN CHINA.

AUXILIARY EQUIPMENT FOR NAILS MAKING MACHINE

Punch pin and nail Moulds.

Connecting welding machine: in case the wire breaks during drawing, you can use the butt welding machine to weld the broken wire together, then continue the drawing. without this machine, if the wire breaks, you need to sharpen the wire head again and do all things from the start.

Nail Polishing Drums (with a motor, starter, and belts)

Wire Drawing Machine (WE OFFER A COMPLETE WIRE DRAWING LINE TO DRAW NAIL WIRE IN VARIOUS DIAMETERS FROM 6 mm or 5.5 mm WIRE RODS)

HOW TO GET RAW MATERIALS

Normally, you can buy from the local market or steel company.

If they can sell low carbon iron wire rod Q195,6.5mm/5.5mm. You can buy and use a wire drawing machine to draw to the thickness you need.

If better, you can get the thickness nails making wire you need.

And if local no wire rod and nails making wire, better import from China for any type of them.

What should import, depend on how is the quantity you want to produce daily output.

If quantity not much, you can just import nails making wire.

But if your quantity huge, better buy a wire drawing machine to draw for yourself using.

Then you can start a Fully automatic nail making machine to make nails.

What is the profit in wire nail making process?

Nail making business is profitable in Africa and Mid East, South Asia. The cost of wire nail making machines is not higher much. there are 8 types, different type can produce different sizes of nails. from 3/4inch, 1inch, 2inch, 2.5inch to 10 inch.

1 inch machine is cheaper, About USD2000–2500/Set,

2.5inch and 3 inch is middle, About USD5000–6000USD,

4–10inch nail making machine is much expensive, about usd7000–9000/Set, but very less clients need it.

If you buy raw materials, the import duty is different with finished products. Some West Africa countries rised the tax to support the local company to set up nails making factory. so this is the good project to catch the developing speed.

As for the profit, I think at least USD50/T for the importers,

And they sell to distributors, who need profit also, right?

so the reasonable profit is not less USD70/Ton for nails making factory.

If you catch the right time with lower materials, profit not less than USD100–150/Ton.

If you have more machines, then daily output is not only 1 ton right? so the profit you can imagine now. We are in China, have a branch in Africa, offer train and install service after the sale. If you want to know more about how to earn profit in setting nail making factory, catch us to further talk. Above is some of the “Questions about Nail making machine at Quora”

How much is barbed wire machine and nail making machine? How long does it take for the investment to break even?

Barbed wire making machine cost abut USD3100/Set. The iron wire nail making machine price in China is not higher. There are 8 types, different type can produce different sizes nails. from 3/4inch, 1inch, 2inch, 2.5inch to 10 inch.

1 inch machine is cheaper, About USD2000–2500/Set,

2.5inch and 3 inch is middle, About USD5000–6000USD,

4–10inch nail making machine is much expensive, about usd7000–9000/Set, but very less clients need it.

Daily output steady, workers working well. 1 year is enough get some profit also. We are in China, have a branch in Africa, offer train and install service after the sale. If you want to know more about the price of wire nail making machine, catch us to further talk.

Where can I find a wire nail making machine? How much does it approximately cost?

you can buy from local market, or by the second hand nails making machine.

import from China, if your company can import, or your can get a help for your forwarder agent.

and you can contact us for further inquiry, we have Branch in Africa for nails making business, we can offer you whole unit nails making equipments, such as nails making machine, wire drawing machine, polishing machine, etc.

meanwhile, we can supply you raw materials, Q195 low carbon wire rod, or nails making wire with different thickness you need.

Meanwhile we also can send our Chinese master to train your team and install your nail making plant .With us ,your nail making business will success in short time.

The price of wire nail making machine is not higher much. there are 8 types, different type can produce different sizes nails. from 3/4inch, 1inch, 2inch, 2.5inch to 10 inch.

QUOTATION OF NAIL MAKING MACHINE PRICE IN CHINA

The 1-inch machine is cheaper, About USD2000–2500/Set,

2.5inch and 3 inch is middle, About USD5000–6000USD,

4–10inch nail making machine is much expensive, about usd7000–9000/Set, but very less clients need it.

If you want to know more about the price of wire nail making machine, catch us to further talk. We are in China, have a branch in Africa, offer train and install service after the sale.

How do I find a quality Chinese nail supplier?

which kind of nail supplier are you looking for? You can search by google website, also use google image to checking. and some B2B websites, like Indiamart, TradeIndia, etc, google is more famous. In Guangzhou, there is a fair named “CANTON FAIR”, twice a year, in April and Oct, each time has three phases, different industries. Hardware, building material, handtool, Lighting, machinery, chemical, etc. we are in Common nails, concrete nails, roofing nails, and related nails making machines, etc. Any further questions, contact us freely. We can offer you Nail making machine price in china.

How much I can earn from setup of one nail making machine?

Nail making business is profitable in Africa and Mid East, South Asia. The cost of wire nail making machines is not higher much. there are 8 types, a different type can produce different sizes of nails. from 3/4inch, 1inch, 2inch, 2.5inch to 10 inches. We can offer you Nail making machine price in china.

1 inch machine is cheaper, About USD2000–2500/Set,

2.5inch and 3 inch is middle, About USD5000–6000USD,

4–10inch nail making machine is much expensive, about usd7000–9000/Set, but very less clients need it.

If you buy raw materials, the import duty is different with finished products. Some West Africa countries rised the tax to support the local company to set up nails making factory. so this is the good project to catch the developing speed.

As for the profit, I think at least USD50/T for the importers,

And they sell to distributors, who need profit also, right?

so the reasonable profit is not less USD70/Ton for nails making factory.

If you catch the right time with lower materials, profit not less than USD100–150/Ton.

If you have more machines, then daily output is not only 1 ton right? so the profit you can imagine now. We are in China, have a branch in Africa, offer train and install service after the sale. If you want to know more about how to earn profit in setting nail making factory. catch us to further talk.

What is Nail making machine price in china?

The cost of wire nail making machines is not higher much. there are 8 types, the different type can produce different sizes of nails. from 3/4inch, 1inch, 2inch, 2.5inch to 10 inches. The 1-inch machine is cheaper, About USD2000–2500/Set, 2.5inch and 3 inch is middle, About USD5000–6000USD, 4–10inch nail making machine is much expensive, about usd7000–9000/Set, but very fewer clients need it. If you want to know more about the cost of wire nail making machine, catch us to further talk. We are in China, have a branch in Africa, offer train and install service after the sale.

What is the price of the wire nail machine?

The price of wire nail making machines is not higher much. there are 8 types, the different type can produce different sizes of nails. from 3/4inch, 1inch, 2inch, 2.5inch to 10 inches. The 1-inch machine is cheaper, About USD2000–2500/Set, 2.5inch and 3 inch is middle, About USD5000–6000USD, 4–10inch nail making machine is much expensive, about usd7000–9000/Set, but very fewer clients need it. If you want to know more about the price of wire nail making machine, catch us to further talk. We are in China, have a branch in Africa, offer train and install service after the sale.

Do you know how to set up a nail making factory in Africa?

Can we know which type of nails you are going to make? if common nails, that is easy. Other a little hard for galvanized umbrella head Roofing nails, Galvanized concrete nails, U type nails, etc. IN China, people normally use Z94–3C, Z94–4C. Do you want to know more Questions about Nail making machine at Quora? We have a branch in East Africa for nails making business years. So we can help you to build your own nails making plant with Chinese Masters, including training and installing nails making machine.

What is Nail Making Machine price in China?

The nail making machine is used to make different types of nails, such as galvanized umbrella head Roofing nails, Galvanized concrete nails, Common iron wire nails, U type nails, etc. IN China, people normally use Z94–3C, Z94–4C. We have a branch in East Africa for nails making business years. So we can help you to build your own nails making plant with Chinese Masters, including training and installing nails making machine. Below are our main business countries. If you have interesting, contact us freely. We will continue to update some useful Questions about Nail making machine at Quora for you.

0 notes

Text

Doing Abrasive Blasting Los Angeles CA

By Sharon Nelson

Sand strokes measuring unit similar to crushing strokes. Sand strokes. Basically it is the approach that unambiguously stimulates a floor stream. This sand stroke is made to scrub under the heavy duty of a sound floor or to create a ground, but does not bother or prevent contaminants from occurring. Sand strokes strategies are combined with perforation, fragile liquid and punching. Abrasive blasting Los Angeles CA accessible to various variants in recent times, you wind surge, you need to know and possess gifts and weaknesses of substances. You have to know if you have a sand stroke profile or a threat that essentially ensures a company that shares a terribly comparable technique. The technique is charged by this fluid directly or by way of a better pressed liquid gas. For this process, the abrasive sandblasting media for this process are generally associated with many generic terms. Water driven, most often water fuelled method for preparing bricks or concrete surfaces, is used to reduce surface deterioration. The air assembled process is ideal for metal surfaces, preventing moisture build up and preventing intrusion of surface water. Abrasive blasting employs several materials to strip surface flakes, paints, rust and other pollutants. This is a vital step in the preparation of surface coatings, because substrate cleanses and creates a protected surface. Dynamically engaged purifying techniques, as an example link brushing or sanding, quadrate measure realized by suggests that of brushing and up to seventy five percent will revive the surface course of action method. At the purpose once all is expressed in done, grinding media square measure poor and there quadratic area numerous reusable kinds. Additional financial gifts provided by technique for poignant, considering surfaces of the quadratic area best and swifter over ordinarily happening techniques usefully cleansed. Metal surfaces are removed from rust to boot ground breaking. Harsh poignant capability gets ready securing surfaces. During this technique it prevail imperative that short climatically management arrangements quadratic area known with oust excess suddenness that suppose application and dry security so as to minimize relative dampness and temperatures. It transpires not suitable for cleaning up smooth surfaces due to the application of abrasives. So, instead of sandblasting, you can use soda blasting that also works similarly in preparation on the surface but in several ways. The abrasives used in the process of sand storming are very rough. Thus, if it prevails used regularly for a specific surface preparation, the surfaces of the details are removed. Because of its various health hazards, it was banned in most countries, including India. Much caution is needed to prevent various types of hazards during this process. Besides this, at the time span of the process an operator must cover all its body parts. In the mean solar time, you would like to equally point out the simplest producer of sandblasters in Republic of India. The central issue of great price Spare is India own riding maker of sand stroke objects brooding about that machines have an important have an effect on in every quite sand stroke assignment. They understand however unreasonable the shop bearing limit will is that is created open for all supporter machinery and shipments that they offer best ends up in floor composition. Today several people select the arrangements on DIY that incorporate real master works out, for example, the processing of sand. Amazing property and YouTube accounts rectilinear reach accessible that impacts it to look to be essential and basic, nonetheless it transpire too straightforward to ever be amazing regarding this golf shot regarding your own capability to figure with no coaching or inclusion with exceptional new equipment. Basic botches of sand stroke occur. For a WHO person, it is important or possibly is on a point of the handle to get an eye on and say that the risk measurement unit remedies. The inability to undertake and do so will harm people and make the calculation devilish. However, there is no question that even now and over again capable pros will yield hustling botches or will involve themselves with outstanding elements of an essential endeavor. Stucco, rust and clear substances are only conceivable, which defile metals, concrete, pickets or the factory own greatest mistakes. As far as the danger is concerned, you should be able to essentially blow the safety of all equipment in particular, the command itself. It does not matter if you cannot get the welfare indicators you want or if your merchandise ends in disgrace. Unfortunately, not all take the right precautions to speed up more the process. But ignorance, which stops a working day, does not exist. It prevails very much necessary to recognize that abrasive particles are shot at a very high speed to sand stroke, so you can bounce backwards. There is a reason why covers have become the attraction for many manufacturing industries, the automotive industry and others. A robust fabric is the ideal way to keep your entire skin and clothes from oil of the motor to sciatic sores. This is particularly important when small particles are sand stroke when the exposed flesh cannot only abrade it, they can also be lodged in normal clothing seams and cracks. It prevails important. If you have no access then there could be a heavy jean for some reason It happens that you make your confrontation bound to the base of the hazard in stressful high speed particles. Sand storming is crucial. In a perfect world it can often be a seriously organized way to avoid working several days and may have to do the main thing, which is to pass terribly persevering eye damage. The real opposite is that one can fly quickly even in your eyes. With the plastic drawing you will ask to estimate, you can complete the exceptional machine for that work. For 2 reasons, each glove area is the first basic unit to be covered. Pores and skin have been found to make sure you do not face particles. The 2d is, in any case, a conventional safety show. When using an appliance, you also have to secure your gloves. The higher the cowhide guides are the standard for this measurement unit. In a great way with long calfskin gloves, you will ensure your decaying hands will also be tucked into your sleeves.

About the Author:

You can find a summary of the advantages you get when you use professional abrasive blasting Los Angeles CA services at http://bit.ly/2inmzPq today.

Doing Abrasive Blasting Los Angeles CA from 10 first best of http://bit.ly/2DIaD4u via IFTTT

0 notes

Link

Gurukrupa Industries has the required specialization and expertise in making Wire Nail Machine, Nail Making Machine, Wire Nail Making Machine, Common Nail Making Machine, Concrete Nail Making Machine, Coil Nail Making Machine, Nail Machine, Roofing Nail Making Machine, Nail Making Machine Price In Rajkot-India of different configurations. All our engineers are highly qualified and experienced who properly manage the every step of production in obtaining the finest product in the market. All our machines can easily cut the wire coils of different dimension and depth to obtain delicate nail headed wire at a good speed without producing much noise.

About Team

We ensure swift delivery of ordered items within stipulated time period. Our sincerity and hard work have helped us to gain the status of one of the leading Nail Making Machine Manufacturers In India. Our inspection staffs thoroughly checks the performance and working of these devices delivering them to the international clients. Our sales staffs will always reply to your queries within short period of time.

Why Choose Us

We use updated and latest accessories and spare parts into our nail making machine so that they can always offer impressive performance in any industrial environment. Our Wire Nail Making Machine has the capacity to produce nails of top quality with certain important accessories. These machines have good demand in construction industry due to improvement of science and technology. All our machines come with decent period of warranty to serve the customers fluently without any technical defect.

What Is Wire Nail Making Machine

Our Wire Nail Machine arrives with different configurations and to know more about them customers can visit our official website. We always upgrade the features and specs of these machines to keep pace with latest technology. These machines come with simple look and can be operated either manually or using automotive switches. These machines can work for a long period of time without increasing the consumption of electrical energy. These devices offer less vibration and are based on a latest system of feeding for cutting large bundle of wire.

0 notes

Text

Order Concrete Machine Spare Parts Supplier in India

Ram Babu Manufacturing is a reliable source of concrete machine spare parts manufacturing and supplying in India. We offer a wide range of spare parts that keep all kinds of concrete machines working without any issues.

#Concrete Machine Spare Parts Manufacturers in India#Spare Parts Manufacturers in India#Concrete Machine Spare Parts Supplier#Concrete Machine Spare Parts Supplier in India#Concrete Machine Spare Parts Producer in India#Spare Parts Producer

0 notes

Text

High-quality Concrete Machine Spare parts Manufacturer in India

Ram Babu Manufacturing specializes in producing high-quality concrete machine spare parts manufacturer in India. Our products are meticulously crafted using top-grade materials and advanced manufacturing techniques to ensure superior performance and durability.

0 notes