#Compressed air dryer manufacturers

Explore tagged Tumblr posts

Text

The Importance of Air Dryer Compressors: A Comprehensive Guide

Air dryer compressors are vital in a wide range of industrial and commercial applications, delivering dry, clean, and efficient compressed air for optimal performance. By removing moisture and subtle impurities from the air, they help create a healthier and safer work environment. In humid conditions, compressed air dryers play an essential role in maintaining uninterrupted operations and preventing costly downtime. In this article, we will explore the importance of air dryer compressors, and their various types, highlight their applications, and offer practical tips for selecting the ideal system to meet specific needs.

What is an air dryer compressor?

An air dryer supplier is a specialised device or system designed to remove moisture from the air, ensuring the efficient process of compressed air systems. These systems are essential for facilities utilising compressed air, as compression significantly increases the relative humidity in a given space, potentially leading to operational challenges. Air dryer compressors serve using various methods, depending on the type of system in place. Regardless of the mechanism, their primary goal is to extract moisture from the air to prevent vapor condensation, allowing the system to work at peak efficiency. Common techniques employed by compressed air dryer manufacturers include adsorption, filtration, absorption, refrigeration, and diffusion, all of which work to eliminate excess moisture and maintain optimal performance.

Why is an air dryer supplier important?

Air dryer supplier is essential for well-functioning air compressor systems. Moisture is unavoidable with air compression — it’s a natural byproduct of the system, and without removal, your facility will soon have a moisture problem. Here are some of the advantages you can expect when you add air dryer compressors to the compression system:

Prevents freezing: If vapor condenses into water, the water can freeze in the face of low temperatures. Freezing can lead to jams in moving parts. It can also stash on process lines and interfere with process or product fluid movement.

Removes contamination: Contamination is a danger for industries using high-purity compressed air. Places like plasma generation, food and pharmaceutical products manufacturing, laser cutting and welding, painting, coating, and shot blasting all require pure compressed air to work. If water builds up, efficiency decreases, productivity slows or products get damaged.

Halts water buildup: Water will build up in small pockets within downstream equipment without moisture removal. Too much buildup can cause sensitive equipment to perform inaccurately, harming production quality and output.

Reduces microbial growth: The pharmaceutical and food and beverage industries use compressed air to mix and convey products. Water is prone to bacteria growth, and any water in the condensed air system can quickly lead to food and beverage spoilage or contamination. Additionally, small amounts of microbes in pharmaceutical plant products can result in entire batches being thrown out to avoid health risks.

Improves efficiency: If your facility uses air-powered equipment and tools powered by energy from compressed air systems, water will reduce its efficiency. It can damage internal parts and reduce the power delivered, impacting production.

Inhibits corrosion: Water is excellent at corroding steel. Components like pipes, drums, vessels, and tanks are commonly made from steel and will begin to break down when moisture buildup turns to water and corrosion. When corrosion conditions, process, and product streams can quickly become contaminated.

How does the air dryer supplier work?

At the most basic level, air dryer compressors separate moisture from industrial process air. Moisture is inherent to compressed air, so the air dryer must take that air and remove the excess moisture from it. This is done through diffusion, absorption, filtration, or refrigeration. Each method sends compressed air through the system, drawing out the water so that the system can work efficiently and without damage.

The action of an air dryer supplier and the way it protects compressed air from excess moisture will vary depending on the type of air dryer supplier used. The standard types of air dryer compressors include:

Refrigerated dryers: The most common type of air dryer compressors will see in an industrial compressed air system is the refrigerated dryers. These work by a simple mechanism of using one or more heat exchangers to cool down the hot compressed air, condense out the bulk of the water, and remove the water through a separator equipped with an automatic drain. If you are looking for a reasonably-priced dryer and do not need unusually high drying capabilities, these are often the best and most economical choices.

Desiccant dryers: If you are in a harsh situation where air is subject to very low temperatures or your products or environment cannot handle any moisture at all, a desiccant dryer may better serve you. These dryers use a material such as activated alumina to absorb water from the compressed air.

Specialty gas and liquid dryers: Water is not the only moisture-related contaminant that could impact on a facility. Many industries work with gases or liquids that might interfere with production. If your company works with exotic or dangerous gases or liquids that need drying, such as benzene, butane, hydrogen, or landfill gas, there are specialty dryers designed to safely remove moisture from these products. They work similarly to air dryers but focus on their specific gas or liquid removal instead of just water.

Membrane dryers: Membrane dryers are very efficient dryers that dehumidify and depress the dew point as the air comes into the system. These dryers have an absorbent membrane that allows water vapor to pass through. The membrane catches the water vapor, lowering the dew point temperature so condensation cannot occur. They are becoming increasingly popular as they require no electricity, have a low installation cost, are easy to maintain, and perform quietly.

Deliquescent dryers: Deliquescent dryers are another brand of electricity-free, economical air dryer compressors. They work using a pressure vessel containing dissolving salt tablets that absorb water vapor. Compressed air runs through the dryer, and the salt pulls all the water out. The salt dissolves with the water, turning into a brine that collects in a special tank. Meanwhile, the air passes out through the system moisture-free.

How to choose the right air dryer compressor

Understand your requirements

Evaluate the desired dew point for your application.

Identify the airflow rate (CFM) needed for your operations.

Consider the environment

Evaluate the ambient temperature and humidity levels of your workspace.

Choose an air dryer supplier that can handle these conditions effectively.

Energy efficiency

Opt for energy-efficient models to save operational costs.

Look for features like automatic drain valves to reduce wastage.

Space constraints

Consider the size of the equipment, especially for smaller facilities.

Compact options like membrane air dryers may be ideal.

Budget and maintenance

Balance initial costs with long-term savings from reduced maintenance and energy consumption.

Check for easy access to replacement parts and reliable service support.

Maintenance tips for air dryers recommended by compressed air dryer manufacturers

Regular filter replacement: Prevent clogging by replacing air filters frequently.

Monitor dew point: Ensure the system is delivering the required air quality.

Inspect drains: Keep drain valves clean and operational to avoid water build-up.

Scheduled servicing: Conduct routine maintenance checks to identify and address potential issues.

Wrapping up:

Air dryer compressors are vital in ensuring the efficiency, reliability, and longevity of industrial processes. Investing in the right type and maintaining it properly, can protect the equipment, improve product quality, and achieve cost savings. Whether you’re in manufacturing, healthcare, or construction, choosing the right air dryer supplier tailored to your needs is key to optimizing your operations. By partnering with reliable compressed air dryer manufacturers, can ensure that your systems remain efficient and the operations run smoothly.

0 notes

Text

Air Dryer manufacturers

Air Dryer manufacturers are essential devices used to remove moisture and contaminants from compressed air systems. They play a crucial role in ensuring the quality and reliability of compressed air for various industrial applications. Air dryer manufacturers design and produce a wide range of air dryers tailored to meet the diverse needs of industries such as manufacturing, automotive, pharmaceutical, food and beverage

0 notes

Text

What are some tips for using an air compressor?

Air compressors are essential tools for many manufacturing businesses. They can be used for various tasks, including inflating tires, cleaning equipment, and operating pneumatic tools. However, air compressors can be dangerous if they are not used properly. Here are some tips for using an Air dryer for air compressor manufacturers safely and effectively:

Read the owner's manual. This is the most important tip! The owner's manual will provide all the information you need about your specific air compressor, including how to operate it safely and properly.

Use the correct safety equipment. Wear safety glasses when you are operating an air compressor. You might also wish to wear gloves and a dust mask depending on your tasks.

Never overload the compressor. Ensure you do not exceed the maximum pressure or flow rate specified by the manufacturer. Overloading the compressor can damage it and could lead to serious injury.

Keep the compressor clean. Clean the air filter and coils of the compressor regularly to avoid dust and debris accumulation. This will help to keep the compressor running efficiently and prevent damage.

Store the compressor properly. Store it in a dry, cool place when not using the compressor. By doing this, corrosion and damage can be avoided.

Air Dryers for Air Compressor Manufacturers

Air dryers are an important part of any air compressor system. They remove moisture from the compressed air, preventing damage to equipment and improving the air quality. Trident Pneumatics offers a variety of air dryers for air compressor manufacturers, including:

Refrigerated air dryers: These air dryers use refrigeration to remove moisture from the air. They are a good choice for applications requiring high-quality, dry air.

Desiccant air dryers: These air dryers use a desiccant material to remove moisture from the air. They are a good choice for applications where a lower cost or a smaller footprint is required.

Trident Pneumatics can help you choose the right Air dryer for air compressor manufacturers. Contact us today to learn more.

Additional Tips

Here are a few more things you can do to maintain your air compressor operating safely and properly besides the advice provided above

Inspect the compressor regularly for leaks. If you discover a leak, get it checked right away. Leaks can waste air and can also be dangerous.

Change the oil in the compressor regularly. The oil helps to lubricate the compressor and prevent wear.

Have the compressor serviced regularly by a qualified technician. This will help to ensure that the compressor is running properly and that it is safe to use.

Here are some additional tips that can help you get the most out of your air compressor:

Use the right size air compressor for the job. A too-small compressor will not be able to provide enough air for the task at hand, while a too-large compressor will be overkill and waste energy.

Use the right air pressure for the job. Too much air pressure can damage equipment, while too little air pressure is ineffective.

Use the right air tools for the job. Air tools are designed to operate at specific air pressures. Using an air tool at the wrong pressure can damage the tool or the compressor.

0 notes

Text

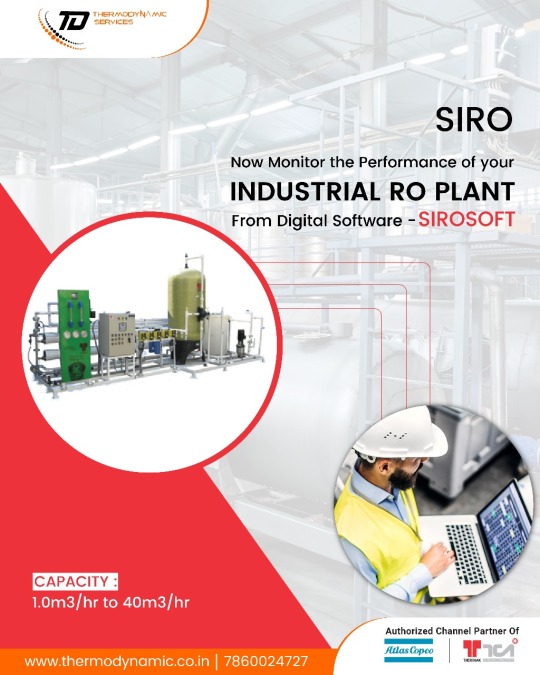

Atlas Copco Air Compressor Dealer in Uttar Pradesh - Thermodynamic Services

Welcome to Thermodynamic Services, your trusted partner for top-notch industrial air compressors and compressed air solutions in Uttar Pradesh. As the premier Atlas Copco dealer in the region, we take pride in delivering cutting-edge technology and reliable products to meet your diverse compressed air needs.

Atlas Copco Air Compressors in Uttar Pradesh:

At Thermodynamic Services, we specialize in offering a comprehensive range of Atlas Copco air compressors in Uttar Pradesh. Our commitment to quality and efficiency ensures that your industrial operations run smoothly with the most advanced and reliable compressed air solutions.

Atlas Copco Dealer in Kanpur:

If you are based in Kanpur and searching for a reliable Atlas Copco dealer, look no further than Thermodynamic Services. We bring you the latest models of Atlas Copco air compressors, combining innovation and durability to enhance your industrial processes.

Industrial Air Compressor Manufacturer & Supplier in Kanpur:

As a leading industrial air compressor manufacturer and supplier in Kanpur, Thermodynamic Services provides customized solutions tailored to meet the unique requirements of your business. Our state-of-the-art compressors are designed to optimize energy efficiency and minimize downtime.

Atlas Copco Compressed Air Dryer Dealer in Uttar Pradesh:

Thermodynamic Services is your go-to Atlas Copco compressed air dryer dealer in Uttar Pradesh. Our range of air dryers ensures that your compressed air is free from moisture, contaminants, and impurities, guaranteeing the longevity and efficiency of your equipment.

Unmatched Quality and Reliability:

When you choose Thermodynamic Services, you invest in unparalleled quality and reliability. Our partnership with Atlas Copco, a global leader in compressed air technology, ensures that you receive products that adhere to the highest industry standards.

Customer-Centric Approach:

At Thermodynamic Services, customer satisfaction is our priority. Our team of experienced professionals is dedicated to understanding your specific needs and providing tailored solutions. We believe in building lasting relationships with our clients through exceptional service and support.

Conclusion:

For all your industrial air compressor needs in Uttar Pradesh, Thermodynamic Services stands as the preferred choice. As the foremost Atlas Copco dealer in the region, we guarantee top-quality products, unmatched reliability, and a customer-centric approach. Elevate your industrial processes with Thermodynamic Services – your trusted partner for compressed air solutions.

conatct us on 91 78600 24711

#industrial air compressor dealer in uttar pradesh#Atlas Copco Air Compressor#Atlas Copco Air Compressors in Uttar Pradesh:#Atlas Copco Dealer in Kanpur#Industrial Air Compressor Manufacturer & Supplier in Kanpur:#Atlas Copco Compressed Air Dryer Dealer in Uttar Pradesh:#industrial air compressor needs in Uttar Pradesh

5 notes

·

View notes

Text

Comprehensive Solutions in Thermodynamic Services: A Leading Partner in Uttar Pradesh

Introduction: In the bustling industrial landscape of Uttar Pradesh, Thermodynamic Services emerges as a beacon of excellence, catering to a diverse range of thermodynamic needs. With a rich history of collaboration with industry giants like Thermax Limited, Atlas Copco (India) Limited, and Buhler India Pvt. Limited, Thermodynamic Services stands as a trusted partner offering comprehensive solutions. Specializing in industrial air compressors, compressed air dryers, thermic fluid heaters, industrial water treatment plants, STP plants for hospitals, and ETP plants for industrial use in Kanpur and beyond, Thermodynamic Services is committed to addressing the most challenging issues in heat, energy, air, water, solar, and grain processing.

Industrial Air Compressor Manufacturer & Supplier in Kanpur: As a premier industrial air compressor manufacturer and supplier in Kanpur, Thermodynamic Services delivers top-of-the-line equipment tailored to meet the rigorous demands of modern industries. Drawing from years of expertise and partnerships with leading manufacturers, we provide cutting-edge solutions that ensure optimal performance and efficiency for our clients' operations.

Compressed Air Dryer / Refrigerated Air Dryer Supplier in Kanpur: Recognizing the critical importance of quality compressed air in industrial processes, Thermodynamic Services offers premium compressed air dryers and refrigerated air dryers. Our products guarantee the delivery of clean, dry air, free from moisture and contaminants, thereby safeguarding the integrity of our clients' operations and prolonging the lifespan of their equipment.

Thermic Fluid Heater Supplier/Manufacturer in Uttar Pradesh: In the realm of thermic fluid heating systems, Thermodynamic Services stands as a distinguished supplier and manufacturer in Uttar Pradesh. Our thermic fluid heaters are engineered to deliver efficient heat transfer, ensuring consistent performance and reliability across various industrial applications. With a focus on innovation and quality, we empower our clients to optimize their processes while minimizing energy consumption.

Industrial Water Treatment Plants Supplier/Manufacturer in Uttar Pradesh: Water is a precious resource, and Thermodynamic Services is committed to its responsible management through advanced water treatment solutions. As a leading supplier and manufacturer of industrial water treatment plants in Uttar Pradesh, we offer customized systems designed to meet the unique needs of each client. From filtration to purification, our solutions ensure the availability of clean water for industrial processes, enhancing productivity and sustainability.

STP Plant for Hospitals: Ensuring safe and sustainable wastewater management is imperative for healthcare facilities, and Thermodynamic Services provides tailored solutions with our STP (Sewage Treatment Plant) plants for hospitals. Compliant with regulatory standards and designed for efficiency, our STP plants effectively treat wastewater, mitigating environmental risks and promoting a healthier community.

ETP Plant for Industrial Use in Kanpur: Industries in Kanpur rely on efficient wastewater treatment, and Thermodynamic Services meets this demand with our ETP (Effluent Treatment Plant) plants for industrial use. Through advanced technologies and expert engineering, our ETP plants efficiently remove pollutants from industrial effluents, ensuring compliance with environmental regulations and fostering sustainable industrial practices.

Conclusion: Thermodynamic Services stands as a testament to excellence in thermodynamic solutions, driven by a commitment to innovation, quality, and customer satisfaction. With a proven track record of serving esteemed clients and addressing complex challenges, we continue to be the preferred partner for industries across Uttar Pradesh. Whether it's industrial air compressors, compressed air dryers, thermic fluid heaters, water treatment plants, or wastewater management solutions, Thermodynamic Services remains at the forefront, empowering industries to thrive in an ever-evolving landscape.

#Industrial air compressor manufacturer & supplier in kanpur#Air compressor dealers in Kanpur/ Uttar Pradesh#compressed air dryer / refrigerated air dryer supplier in kanpur#STP plant for hospitals#ETP Plant for industrial use in kanpur

0 notes

Text

#Air dryer compressor#Compressed Air Piping#Pressure Vessels#Pressure Vessel Manufacturers#Plate type heat exchangers

0 notes

Text

Improve Efficiency with F&D Machines: Fluid Bed Drying and Granulation Solutions

In today's fast-paced manufacturing world, efficiency is key. Whether you're in pharmaceuticals, chemicals, or food processing, optimizing your production process can significantly impact your bottom line. This is where F&D machines come in, offering innovative solutions for drying and granulation needs.

What are F&D Machines?

F&D machines refer to a range of equipment designed for fluid bed processing, a versatile technique used across various industries. These machines utilize the principle of fluidization, where a bed of solid particles is lifted and agitated by an upward flow of air. This creates a fluid-like state, allowing for efficient heat and mass transfer.

Two Key Applications:

FBD Fluid Bed Dryer: FBD Fluid Bed Dryer. These machines are highly effective in drying powders, granules, and crystals. The fluidization process ensures uniform drying by exposing each particle to the drying air, resulting in consistent moisture content and improved product quality. FBDs are particularly beneficial for heat-sensitive materials as the controlled environment prevents overheating and degradation.

Fluid Bed Processor for Granulation: Fluid bed processors can also be used for granulation, a process of creating granules from fine powders. This is achieved by spraying a binding solution onto the fluidized bed of particles. The controlled environment and efficient mixing ensure uniform granule formation, resulting in improved flow properties, compressibility, and solubility.

Benefits of Using F&D Machines:

Increased Efficiency: F&D machines offer faster drying and granulation times compared to traditional methods, leading to increased throughput and reduced production costs.

Improved Product Quality: The uniform processing environment ensures consistent particle size distribution, moisture content, and other critical quality attributes.

Enhanced Process Control: Precise control over parameters like temperature, airflow, and spray rate allows for reproducible results and minimized batch-to-batch variability.

Versatility: F&D machines can handle a wide range of materials, from fine powders to coarse granules, making them suitable for diverse applications.

Reduced Labor Costs: Automated operation and minimal manual intervention translate to lower labor costs and improved workplace safety.

Applications Across Industries:

Pharmaceutical Industry: Drying and granulation of drug formulations, excipients, and intermediates.

Chemical Industry: Processing of chemicals, catalysts, and polymers.

Food Industry: Drying of food products like coffee, tea, and spices; granulation of sugar, salt, and other ingredients.

Choosing the Right F&D Machine:

Selecting the appropriate F&D machine depends on several factors, including:

Material properties: Particle size, density, and heat sensitivity.

Production capacity: Batch size and throughput requirements.

Process requirements: Drying or granulation, desired particle size distribution.

Budget and space constraints: Cost of the equipment and available floor space.

It's crucial to consult with experienced equipment manufacturers to determine the best solution for your specific needs. They can provide guidance on machine selection, process optimization, and ongoing support.

Conclusion:

F&D machines, including FBD fluid bed dryers and fluid bed processors for granulation, offer significant advantages in terms of efficiency, product quality, and process control. By adopting this technology, businesses can optimize their production processes, reduce costs, and enhance their competitive edge in the market.

0 notes

Text

Desiccant dryers in Los Angeles are crucial for industries requiring high-quality compressed air systems that are free from moisture. These dryers utilize desiccant materials to effectively adsorb water vapor, ensuring that compressed air remains dry and protected from the damaging effects of moisture. Desiccant compressed air dryers are ideal for environments where low dew points are critical, such as in pharmaceutical, food processing, and electronics manufacturing

0 notes

Text

Air Dryer Manufacturer

Discover high-quality air dryers from a trusted Air Dryer Manufacturer at Air Care Equipment. We offer efficient air drying solutions designed to enhance performance and reduce moisture in compressed air systems, ensuring reliability in various industries.

Visit: https://www.aircareequipment.co.in/air-dryer-gurgaon/

Add: Khewat No. 197/202, Khasra No. 13/11, Village Garauli Khurd, Gurgaon- 122001

Ph: +91-9599293541, +91-9871793228

Email: [email protected] , [email protected]

0 notes

Text

Welcome to Roteck Compressor

With close to 28 years of experience in manufacturing of screw air compressors, Roteck Equipment Ltd. is a global leader in providing sustainable compressed air solutions. Roteck designs and manufactures an extensive range of innovative and technologically advanced compressed air solutions for a variety of industry applications. Throughout the years, Roteck has earned worldwide applause for designing customer centric, compressed air solutions which are sustainable, and helping the companies to achieve their productivity goals while ensuring a lower total cost of ownership. Besides, we are delivering superior quality compressed air dryer, Screw compressor, compressed air filters, and oil filter elements at the best prices. We are exporting the products to 6 countries globally. All products are guaranteed to equal or exceed the corresponding OEM Parts and are manufactured and supplied in strict accordance with ISO 9001:2015 quality standards. Roteck compressor is offering overhauling elements of screw compressor and all types of air compressor for those companies which are using the air compressors of these Brands. Atlas Copco, Ingersoll-Rand, ELGI, C.P.T. Kirloskar, Kaeser air compressor.

0 notes

Text

Air Compressor Parts and Accessories-Evergreen

Evergreen Compressed Air and Vacuum offers reliable and genuine OEM parts & accessories for all major brands of Air Compressors, Vacuum Pumps and Air Dryers at reasonable cost. We offer services in the state of Washington — Seattle, Tacoma, Everett, Kent, Mount Vernon, Olympia, Auburn. Our air compressor parts such as lubricants, valves, separators, belts, couplings, drains and filters are designed to keep your compressor and vacuum systems running at peak performance and reduce the cost of ownership of your compressed air system. Getting air compressor parts you need is as easy as contacting our team of dedicated service engineers. They are trained to solve problems quickly and efficiently.

Brands we offer

ELGi

Sullivan-Palatek

Sullair

Gardner Denver

Quincy

CP

Rogers

FS-Curtis

Ingersoll Rand

Atlas Copco

Vac-u-lok

DV

Saylor-Beall

Champion

Airtech

Beacon Medaes

Busch

Why do you need to buy air compressor spare parts from OEMs?

Every component within an air compressor has a designated service life and undergoes wear and tear over time, necessitating regular maintenance to ensure optimal performance and longevity. While aftermarket replacement parts may be enticing due to lower costs, it’s essential to prioritize sourcing from Original Equipment Manufacturers (OEMs). OEM air compressor parts ensure proper performance levels and minimize equipment failure risk .

OEM air compressor spare parts offer the following benefits

Durability OEM replacement components offer premium quality assurance and guarantee longevity. Using OEM parts minimises the risk of equipment failure and production performance decline, ensuring consistent performance.

Improved Safety OEMs adhere to industry safety standards, providing enhanced protection for users and minimizing occupational hazards. Third party air compressor spare parts may compromise safety and pose risks to health and the environment.

Efficiency OEM air compressor parts deliver optimal performance over a longer period, reducing downtime and the need for frequent repairs. Investing in OEM parts ensures uninterrupted operation and reduces maintenance demands.

Stringent Quality Standards OEM parts undergo rigorous endurance tests and quality inspections to ensure consistent performance and reliability. Choosing OEM air compressor parts guarantees adherence to quality standards and reliable operation.

Warranty Protection OEM parts ensure warranty coverage and protect your investment. Other parts may void warranties and leave you vulnerable to costly repairs and downtime.

Air compressor parts that need replacement include

Dust filters and oil separators These components are crucial in safeguarding the compressor against damage and performance degradation caused by internal contaminants. Dust particles from inlet pose a significant threat to compressor rotors, leading to reduced efficiency and premature wear.

Air filter Swapping your air compressor’s line filter cartridge with counterfeit alternatives compromises filtration efficiency, resulting in pressure drops and compromised air quality. Genuine airline filters ensure optimal filtration, reducing the need for frequent replacements and minimizing lifecycle costs.

Lubricating oil Lubricating oil is essential for maintaining system efficiency and preventing equipment breakdowns. Poor-quality oil can lead to sediment buildup and corrosion risks, undermining compressor performance. Using genuine oil supplied by the manufacturer ensures effective lubrication and maximises equipment longevity.

It’s essential to procure spare parts and air compressor accessories exclusively from OEMs and reputable suppliers and maintain a service kit containing essential tools for safe part replacement. Talk to our parts specialist today.

Other products

Air Compressors

Vacuum Pumps

Air Dryers

0 notes

Text

Founded in 1989 and based in Coimbatore, Tamil Nadu, India, United Cooling Systems Pvt. Ltd. is a respectable producer of cooling and heat transfer equipment. Heat exchangers, air fin coolers, oil coolers, and compressed air dryers are just a few of the cooling solutions that the company specializes in designing and manufacturing. These goods have vital uses in a number of sectors, including petrochemicals, power production, oil and gas, and pharmaceuticals.

United Cooling Systems is renowned for its excellent quality control and engineering standards. The company's dedication to producing dependable and effective goods is demonstrated by its significant certifications, which include ISO 9001:2015 and ASME (U, U2, R, NB). The business also concentrates on sustainable and energy-efficient cooling solutions that satisfy industry demands while reducing their negative effects on the environment.

United Cooling Systems has established a great reputation for offering robust and efficient cooling technologies that satisfy the various needs of its clients across the globe by putting a strong emphasis on innovation.

1 note

·

View note

Text

What are air dryer manufacturers?

A system or piece of equipment called an air drier is used to remove moisture from the air, significantly compressed air. The relative humidity of ambient air is usually between 30 and 50%. However, air that has been compressed has more moisture in a smaller volume. As a result, the surplus moisture that cannot be retained condenses, raising the relative humidity to 100%.

The high moisture content of air harms plant performance and the dependability of equipment downstream. It may cause equipment corrosion, early instrument failure and wear, contaminating the process stream, and other issues.

Moisture removal is needed for various processes, not just air compression. Dewatering, baking, industrial drying, food dehydration, steam heating, and cleaning are a few other industrial and manufacturing techniques that make it easier to remove water. These procedures require various dryers, primarily employed to eliminate moisture from a product or mass to render it dry, solid, and pure. The air dryer manufacturers used in these applications to transfer heat use the fundamental concepts of conduction, convection, and radiation. Air drying differs from other methods of removing moisture because it uses cooling, adsorption, absorption, diffusion, and filtration.

Importance of Air Dryers-

A vital part of compressed air systems is an air dryer manufacturer. Air compression inevitably produces moisture and condensation. Within the compressor unit, as well as to the equipment and processes downstream, water can condense and build. Here are a few benefits of using air dryers.

Removes water contamination-

In high-purity compressed air-using industries, including laser cutting and welding, plasma generation, microelectronics manufacturing, the production of food and pharmaceutical products, shot blasting, painting, and coating, water contamination is a significant issue. Using compressed air differently can have different impacts on water and other pollutants. As an illustration, consider laser cutting, which uses air to cool the resonator, which produces intense light beams. Using water-contaminated air reduces cooling efficiency, which causes overheating and energy loss.

Prevents water build-up-

In high-purity compressed air-using industries, including laser cutting and welding, plasma generation, microelectronics manufacturing, the production of food and pharmaceutical products, shot blasting, painting, and coating, water contamination is a significant issue. Using compressed air differently can have different impacts on water and other pollutants. As an illustration, consider laser cutting, which uses air to cool the resonator, which produces intense light beams. Using water-contaminated air reduces cooling efficiency, which causes overheating and energy loss.

Abates corrosion-

Steel surfaces may corrode if water is present inside of the apparatus. Internals of mixing equipment such as pipes, tanks, drums, and containers can collect water from the condensation of saturated air. This might encourage corrosion on the equipment's inside surfaces, contaminating the product or process stream.

Prevents freezing-

In compressed air systems, precipitated water can freeze. They can jam the moving parts of pneumatic actuators for valves and measuring equipment. The accumulated water on process lines freezes and can obstruct the product or process fluid flow.

Improves efficiency of air-powered or pneumatic equipment-

Compressed air powers air motors or turbines in air-powered tools and machinery. Pneumatic grinders, drills, jackhammers, etc., are examples of these. These devices' internals may become fouled with water, which reduces the power the air motor can deliver.

#Air dryer for air compressor manufacturers#Compressed air dryer manufacturers#air dryer manufacturers

0 notes

Text

Air Dryer manufacturers

The Air Dryer manufacturers are manufactured by Trident. Air dryer for air compressor Manufacturers develops dryers with the highest quality performance which is also cost-effective, reliable, and provides 100% clean dry.

0 notes

Text

Keeping It Cool: How Industrial Air Dryers Improve Efficiency and Equipment Longevity

In industrial settings, maintaining the integrity of compressed air systems is crucial. Industrial air dryers play a vital role in this maintenance by removing moisture from the compressed air, which can lead to significant operational issues if left unchecked. Moisture in compressed air can cause corrosion, reduce the efficiency of pneumatic tools, and compromise product quality. This blog explores the functionality, types, benefits, and selection criteria for industrial air dryers, highlighting their importance in various manufacturing applications.

0 notes

Text

How to Maintain and Extend the Lifespan of Your Pneumatic Dot Peen Marker

Pneumatic dot peen markers are widely used for the permanent marking of parts and materials, providing an efficient way to etch serial numbers, barcodes, logos, and other information onto metal, plastic, and other hard surfaces. Regular maintenance is essential to keep your pneumatic dot peen marker running smoothly and ensure its longevity. Here's how you can maintain and extend the lifespan of your machine, ensuring it delivers precise, high-quality marks for years to come.

1. Regular Cleaning of Components

One of the simplest yet most effective ways to maintain your pneumatic dot peen marker is regular cleaning. The marking process can generate debris such as metal shavings, dust, and other contaminants that can accumulate on critical components.

Cleaning the stylus: The stylus is responsible for making the physical impact that creates the dot marks. Over time, it can collect dirt and metal particles. Wipe it clean regularly using a soft cloth to ensure it stays sharp and functional.

Check the air filter: As pneumatic systems rely on compressed air, it's essential to keep the air filter clean to prevent debris from entering the system. Inspect the air filter periodically and clean or replace it if it appears clogged.

Surface maintenance: Wipe down other machine surfaces, especially around the marking head and carriage, to remove dirt and prevent any buildup that could interfere with the machine's movement.

2. Lubricate Moving Parts

Pneumatic dot peen markers have moving components, such as linear rails, bearings, and gears, that need proper lubrication to function effectively. Lack of lubrication can cause friction and wear, leading to premature component failure.

Use appropriate lubricants: Follow the manufacturer’s recommendations on which lubricant to use for your specific model. Apply the lubricant sparingly but consistently to the rails and any moving parts.

Inspect for wear: While lubricating, check the parts for signs of wear or damage. Early detection can prevent bigger, more costly repairs down the line.

3. Maintain Air Pressure Levels

A pneumatic dot peen marker relies on compressed air to drive the stylus. Ensuring that the air pressure is consistent and within the recommended range is crucial for accurate marking and preventing damage to internal components.

Check the pressure regulator: Make sure the air pressure regulator is set to the manufacturer’s specified level. Too much pressure can cause excessive wear on the stylus and other components, while too little pressure may result in weak or inconsistent marks.

Monitor air supply quality: Use clean, dry air in the system. Moisture in the compressed air can cause corrosion and damage internal parts. Installing an air dryer or filter can help prevent this.

4. Inspect and Replace the Stylus as Needed

The stylus in your dot peen marker is a high-wear part, especially when marking hard materials such as steel or titanium. Over time, the tip can become dull, which affects marking depth and clarity.

Monitor stylus condition: Inspect the stylus regularly for signs of wear or damage. A dull or chipped stylus should be replaced immediately to maintain the quality of the marks.

Replace with manufacturer-approved parts: When replacing the stylus, always use genuine parts from the manufacturer to ensure compatibility and performance. Using lower-quality or incompatible parts can lead to reduced performance and potential machine damage.

5. Calibrate the Machine Periodically

Over time, the accuracy of your dot peen marker may drift due to normal wear or changes in operating conditions. Regular calibration ensures that your marks remain consistent and precise.

Follow the calibration procedure: Most manufacturers provide a step-by-step guide for calibrating the machine. This process typically involves checking the alignment of the marking head, adjusting the height of the stylus, and verifying the marking depth.

Test before production runs: After calibration, run test marks on a sample piece to ensure everything is functioning correctly before marking production parts.

6. Perform Routine Software Updates

Modern dot peen markers often include a software interface for controlling the marking process, especially in automated or CNC-integrated systems. Keeping the software up-to-date ensures that your machine benefits from the latest features, bug fixes, and performance improvements.

Check for updates: Regularly visit the manufacturer’s website or contact customer support to check if any software updates are available for your model.

Back up settings: Before performing any updates, back up your machine's settings and configurations to avoid losing custom parameters.

7. Establish a Preventive Maintenance Schedule

The best way to ensure your pneumatic dot peen marker stays in top condition is by adhering to a regular maintenance schedule. This includes both daily checks and more thorough inspections at set intervals.

Daily checks: Inspect the machine for any obvious signs of damage, debris, or unusual sounds. Make sure the air pressure is correct and the machine is properly lubricated.

Monthly or quarterly maintenance: Depending on usage, perform a deeper inspection of all moving parts, check the air supply system, and calibrate the machine if needed. Keep a log of all maintenance activities for future reference.

8. Train Operators on Proper Use

Proper handling of the machine by operators can significantly impact its lifespan. Ensure that all users are trained on how to operate the machine correctly, including setup procedures, maintenance requirements, and troubleshooting steps.

Avoid mishandling: Improper use, such as running the machine at incorrect air pressures or overloading the stylus, can cause damage. Educate your team on how to avoid these issues.

Encourage regular inspections: Train operators to perform quick daily inspections before starting a shift to catch any potential problems early.

Conclusion

Maintaining and extending the lifespan of your pneumatic dot peen marker requires regular care, attention to detail, and adherence to manufacturer guidelines. By cleaning the machine, lubricating moving parts, managing air pressure, inspecting the stylus, and calibrating the system periodically, you can ensure that your marker operates efficiently and lasts for years. A preventive maintenance schedule and proper operator training are also key components in getting the most out of your investment. With these best practices, your pneumatic dot peen marker will continue to deliver precise, high-quality marks in even the most demanding environments.

0 notes