#Commercial Steel Fabricators

Explore tagged Tumblr posts

Text

Elevate Your Roofing Projects: The Importance of Roof Trusses in Melbourne.

Introduction: Roof trusses are a fundamental component of any roofing system, providing structural support and stability while also influencing the overall aesthetics and functionality of a building. In Melbourne, where diverse architectural styles and climatic conditions prevail, the role of roof trusses is paramount in ensuring the durability, efficiency, and aesthetic appeal of residential and commercial properties. Let's delve deeper into the significance of roof trusses in Melbourne and their impact on roofing projects across the city.

Structural Integrity and Support: Roof trusses serve as the backbone of a roofing system, transferring the weight of the roof to the walls and providing essential support and stability. Engineered to withstand various loads, including snow, wind, and seismic forces, roof trusses ensure the structural integrity of buildings, protecting occupants and assets from potential damage and collapse.

Customized Solutions for Melbourne's Varied Climate: In Melbourne, where weather conditions can be unpredictable and extreme, the design and selection of roof trusses play a crucial role in ensuring optimal performance and durability. Experienced roof truss manufacturers in Melbourne offer customized solutions tailored to the specific requirements of each project, taking into account factors such as roof pitch, span, load-bearing capacity, and environmental considerations.

Aesthetic Versatility and Design Flexibility: Beyond their functional role, roof trusses contribute significantly to the aesthetic appeal and architectural character of a building. In Melbourne, where architectural styles range from traditional to contemporary, roof trusses offer design flexibility and versatility, allowing for the creation of unique roof profiles, vaulted ceilings, and open living spaces that reflect the preferences and lifestyle of homeowners.

Efficiency and Cost-Effectiveness: By utilizing prefabricated roof trusses, builders and contractors in Melbourne can achieve greater efficiency and cost-effectiveness in roofing projects. Prefabricated trusses are precision-engineered off-site, minimizing waste, labor, and construction time while maximizing structural performance and consistency. This streamlined approach translates to savings in time and money, making roof trusses an attractive option for builders and homeowners alike.

Conclusion: In conclusion, roof trusses play a pivotal role in the construction and design of roofing systems in Melbourne, offering structural integrity, design versatility, efficiency, and cost-effectiveness. Whether for residential, commercial, or industrial projects, roof trusses are indispensable components that ensure the durability, safety, and aesthetic appeal of buildings across the city. Invest in quality roof trusses from reputable manufacturers in Melbourne, and elevate your roofing projects to new heights of excellence and innovation.

For More Information Visit - https://skybluesteel.com/

Contact US - Phone - 0418777345 Mail Id [email protected] Timings -9AM-5PM (monday-Friday)

#Commercial Steel Fabricators#Steel Stud Wall Framing#Engineered Floor Joists#Residential Structural Steel

0 notes

Text

Trending Stainless Steel and Structural Fabrication in the Heavy Metal Industry

Structural fabrication and stainless steel are essential for creating robust, long-lasting infrastructure and goods in the heavy metal sector. These fabrication techniques guarantee that industries like manufacturing, transportation, energy, and construction have the parts they need to operate, from complicated machinery to massive construction projects. However, the need for innovation has changed how structural fabrication and stainless steel are handled, so it’s critical to comprehend these hot-button developments in the industry. This blog is originally published here: https://crescocustommetals.com/trending-stainless-steel-and-structural-fabrication/

0 notes

Text

Steel fabricator in Peachtree Corners

Universal Steel of America is the leading design-build provider of prefab steel buildings and metal building construction. Our services and products include steel building kits and providing you with a construction management team to build the structure that you need. Our kits are designed to be used with all kinds of building materials, such as brick, glass, wood, stone, and more. There's nothing more important to our team than our structural integrity and giving you high-quality results, which is why we're the most trustworthy steel provider in the nation.

#Steel fabricator in Peachtree Corners#Metal Buildings#Metal fabricator USA#Framing Systems#Steel Building Kits Georgia#Commercial Steel Buildings products#Building Supplies Georgia#Roof Panels#Wall Panel#Prefabricated metal#Metal fabricator in Peachtree Corners#Steel fabricator near me in Georgia#Metal fabricator

1 note

·

View note

Text

Best Pre-Engineered Steel Buildings | PEB Structures Solutions

#Pre-engineered steel buildings#PEB structures#Pre-fabricated steel structures#Industrial steel buildings#Commercial steel buildings#Pre-engineered constructed buildings#https://primainfracorp.com/pre-engineered-steel-buildings

0 notes

Text

The Role of Structural Beams in Home Construction: Insights and Tips for Nottingham Residents

When it comes to home construction and renovation, selecting the right materials and professionals is crucial. One of the most critical elements in any home construction project is the structural beams. These beams provide the necessary support and stability to your home, ensuring safety and durability. If you're located in Nottingham or its surrounding areas, you might find yourself searching for "structural steel fabricators near me" or "structural steel beams" to ensure your project is in good hands. This guide will help you navigate the process of choosing the right structural steel fabricators and understanding the importance of structural beams for your home.

The Importance of Structural Beams in Home Construction

Structural beams are the backbone of any building. They support the weight of the structure, distributing loads evenly and maintaining the integrity of the building. In homes, structural beams are often used in the construction of floors, ceilings, and roofs. The use of high-quality structural steel beams is essential to ensure that the structure is strong and can withstand various stresses over time.

Types of Structural Steel Beams

There are several types of structural steel beams used in construction, each with its specific applications and benefits:

I-Beams (H-Beams)

Shape and Design: Named for their I or H shape, these beams are commonly used due to their strength and efficiency in load-bearing.

Applications: Ideal for supporting heavy loads, I-beams are often used in the construction of bridges, buildings, and other large structures.

T-Beams

Shape and Design: These beams have a T-shape, offering high strength in one direction.

Applications: Frequently used in floor construction, T-beams provide excellent support and are often used in conjunction with other beams for added stability.

L-Beams (Angle Beams)

Shape and Design: L-beams have an L-shape, making them perfect for supporting structures at right angles.

Applications: Commonly used in the construction of frames and trusses, L-beams provide critical support in corners and junctions.

C-Beams (Channel Beams)

Shape and Design: These beams have a C-shape, providing good resistance to bending.

Applications: Used in building frames and support structures, C-beams are versatile and essential for many construction projects.

Choosing the Right Structural Steel Fabricators Near Me

Finding the right structural steel fabricators is vital to ensure the quality and durability of the beams used in your home construction. Here are some tips to help you choose the best fabricators near you:

Experience and Expertise

Look for fabricators with extensive experience in the industry. Experienced professionals are more likely to understand the specific requirements of your project and provide high-quality products.

Reputation and Reviews

Check online reviews and ask for references from past clients. A reputable fabricator will have positive feedback and a proven track record of delivering quality work.

Certifications and Standards

Ensure that the fabricators comply with industry standards and have the necessary certifications. This guarantees that the materials used are of high quality and meet safety regulations.

Customization and Flexibility

Choose fabricators who offer customization options and are flexible to meet your specific needs. This is particularly important for unique or complex projects.

Pricing and Quotations

Request detailed quotations from multiple fabricators. Compare the pricing and services offered to ensure you get the best value for your money.

Structural Beams for Homes in Nottingham: Local Fabricators

If you're based in Nottingham, several local fabricators can provide high-quality structural steel beams for your home construction project. Here are a few recommended fabricators:

Nottingham Steel Fabricators

With years of experience in the industry, Nottingham Steel Fabricators offer a wide range of structural steel products, including I-beams, T-beams, L-beams, and C-beams. Their team of experts ensures that every product meets the highest standards of quality and safety.

Midlands Structural Steel

Known for their exceptional craftsmanship and attention to detail, Midlands Structural Steel specializes in customized steel solutions for residential and commercial projects. They offer competitive pricing and excellent customer service.

Eastwood Steel Fabrications

Eastwood Steel Fabrications provides reliable and durable structural steel beams for various construction projects. Their experienced team works closely with clients to deliver tailored solutions that meet specific requirements.

Conclusion

Choosing the right structural beams and fabricators is crucial for the success of your home construction project. By understanding the different types of structural steel beams and following the tips for selecting reputable fabricators, you can ensure that your home is built with the highest quality materials and craftsmanship. If you're in Nottingham, consider reaching out to local fabricators to discuss your project needs and find the best solutions for your home. Investing in high-quality structural steel beams and working with experienced fabricators will provide you with peace of mind, knowing that your home is safe, durable, and built to last. Whether you're renovating an existing structure or building a new home, make sure to prioritize the quality of the materials and the expertise of the professionals you choose to work with.

#structural steel fabricators near me#structural steel beams#Structural Beams for Homes in Nottingham#commercial

0 notes

Text

The Future of Manufacturing: Integrating Commercial Laser Cutting and Bespoke Metal Fabrications

As the manufacturing landscape continues to evolve, the integration of commercial laser cutting and bespoke metal fabrications is setting new standards for precision, efficiency, and customisation. This synergy is driving innovation across various sectors, from automotive to aerospace, architecture, and beyond.

The Evolution of Laser Cutting Technology

Commercial laser cutting has come a long way since its inception. Early laser cutting systems were limited in power and precision, but advancements in technology have significantly enhanced their capabilities. Modern laser cutters are equipped with fibre lasers and CO2 lasers that offer superior cutting speeds, accuracy, and versatility.

Fibre Lasers: Known for their efficiency and precision, fibre lasers are ideal for cutting thin to medium-thickness metals. They offer faster cutting speeds and lower operating costs compared to traditional CO2 lasers.

CO2 Lasers: These lasers are versatile and can cut a wide range of materials, including non-metals like wood and acrylic. They are particularly effective for thicker materials and offer high-quality edge finishes.

Benefits of Integrating Laser Cutting with Bespoke Fabrications

The integration of commercial laser cutting with bespoke metal fabrications offers numerous benefits, making it an indispensable combination for modern manufacturing.

Unmatched Precision: Laser cutting provides unparalleled precision, ensuring that each component is cut to exact specifications. This level of accuracy is essential for bespoke fabrications, where custom designs and tight tolerances are required.

Enhanced Creativity: The ability to cut complex shapes and intricate designs opens up new possibilities for creativity. Designers and engineers can push the boundaries of what’s possible, creating unique and innovative products.

Improved Efficiency: Laser cutting is significantly faster than traditional cutting methods. This speed translates to higher productivity and shorter lead times, which are crucial for meeting the demands of bespoke projects.

Cost Savings: Despite the initial investment in laser cutting equipment, the long-term cost savings are substantial. Reduced material waste, lower labour costs, and increased production efficiency all contribute to a more cost-effective manufacturing process.

Applications Across Various Industries

Automotive: In the automotive industry, bespoke metal fabrications are used to create custom car parts and modifications. Laser cutting ensures that these components fit perfectly and perform optimally, enhancing both aesthetics and functionality.

Aerospace: Precision is critical in aerospace manufacturing. Laser cutting allows for the creation of lightweight, high-strength components that meet stringent safety and performance standards.

Architecture: From decorative panels to structural elements, bespoke metal fabrications play a vital role in modern architecture. Laser cutting enables the production of intricate designs that add aesthetic value and functionality to buildings.

Art and Design: Artists and designers use laser cutting to create detailed metal artworks and installations. The precision of laser cutting allows for the creation of intricate patterns and shapes that would be challenging to achieve with traditional methods.

Future Trends and Innovations

The future of commercial laser cutting and bespoke metal fabrications looks promising, with several trends and innovations on the horizon:

3D Laser Cutting: Advancements in 3D laser cutting technology are enabling the creation of complex, multi-dimensional shapes. This innovation is expected to revolutionise industries such as aerospace and automotive, where complex geometries are common.

Integration with AI and Automation: The integration of artificial intelligence (AI) and automation is set to enhance the efficiency and accuracy of laser cutting processes. AI-powered systems can optimise cutting paths and adjust parameters in real-time, reducing errors and improving productivity.

Sustainable Manufacturing: As industries strive for more sustainable practices, laser cutting is becoming increasingly popular due to its efficiency and minimal waste generation. The development of eco-friendly materials and techniques is expected to further drive this trend.

In conclusion, the integration of commercial laser cutting and bespoke metal fabrications is transforming the manufacturing landscape. This powerful combination offers unmatched precision, efficiency, and creativity, enabling the production of custom solutions across various industries. As technology continues to advance, the future holds exciting possibilities for innovation and sustainability, solidifying the role of laser cutting and bespoke fabrications in modern manufacturing.

#laser cutting#commercial laser cutting#laser fabrication#laser cutting technology#bespoke metal fabrication#metal fabrication#steel metal fabrication

0 notes

Text

#saudi arabia#commercial#industrial design#kitchen#saudiarbia#laundry#steel#fabrication#stainless steel

0 notes

Text

MIG and TIG Welding: Unraveling the Secret Techniques of Commercial Metal Fabrication

Welding, an integral process in commercial metal fabrication, has come a long way since its inception. With many methods available today, MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding stand out for their versatility and efficiency, making them popular in manufacturing industries.

In this blog post, we will look closer at MIG and TIG welding techniques used by commercial steel fabrication companies and why metal fabrication professionals in Orange County, CA, and beyond prefer these methods.

MIG vs. TIG: What's the Difference?

Let's first differentiate the two and understand why they're so popular in commercial metal fabrication.

MIG Welding

Also known as Gas Metal Arc Welding (GMAW)

Utilizes a consumable electrode wire and an inert shielding gas

The electrode wire is continuously fed through a welding gun

Suitable for a wide range of metal types and thicknesses

Metal fabrication companies near you commonly use MIG welding, and have earned a reputation for being a fast and efficient solution for joining metal pieces. Cresco Manufacturing's primary advantage is its adaptability to various metals, making it a top choice for custom metal cutting services.

TIG Welding

Also known as Gas Tungsten Arc Welding (GTAW)

Employs a non-consumable tungsten electrode and an inert shielding gas

It requires higher precision and more skill from the welder

Produces exceptionally clean and high-quality welds

TIG welding is favored in more specialized metal fabrication projects, such as welding thinner metals or more complex joints. The resultant welds often have better strength and durability, making TIG welding a preferred process in critical applications such as aerospace or automotive components.

Why Choose MIG and TIG Welding for Your Commercial Metal Fabrication Needs?

Now that we've listed the key characteristics of MIG and TIG welding let's explore some reasons why these methods find widespread usage in commercial steel fabrication:

Efficiency: MIG welding offers speed and efficiency that few other welding methods can match. Due to the constant wire feed, MIG welding minimizes downtime and increases productivity.

Versatility: As mentioned earlier, both MIG and TIG welding can accommodate a wide range of metals and projects, making them practical choices in diverse industries.

Quality: TIG welding, in particular, produces high-quality welds that are aesthetically pleasing, strong, and reliable. High quality is crucial in custom metal cutting and high-precision projects.

Cost-effectiveness: Thanks to the efficiency and versatility of these techniques, MIG and TIG welding can contribute to cost savings in the long run.

Finding the Right Metal Fabrication Company in California

When you need high-quality commercial metal fabrication solutions in California, look no further than Cresco Custom Metals. Servicing Orange County and beyond, we offer a range of services, including MIG and TIG welding and other state-of-the-art metal fabrication techniques.

#Commercial Steel Fabrication#Metal Fabrication Companies Near Me#Commercial Metal Fabrication#Welding Orange County Ca#Cresco Custom Metals

1 note

·

View note

Text

Bollards Melbourne | IMSpro

Bollards Melbourne: Safety, Aesthetics, and Urban Functionality

Bollards may seem like unassuming features of a city's landscape, but in Melbourne, Australia, they have evolved into significant elements that contribute to safety, aesthetics, and the overall urban functionality. Bollards are short, sturdy, vertical posts often used to control traffic flow, provide security, and enhance the visual appeal of public spaces. In Melbourne, these unassuming structures have taken on a life of their own, reflecting the city's unique character and commitment to creating safe, inviting urban environments.

One of the primary functions of bollards in Melbourne is traffic management. They are strategically placed to regulate the flow of vehicles, demarcate pedestrian zones, and deter unauthorized access to certain areas. Whether they are guiding vehicles along designated paths, preventing cars from entering pedestrian zones, or safeguarding public spaces, bollards play a vital role in maintaining order and ensuring road safety in Melbourne's bustling streets.

In recent years, Melbourne, like many major cities around the world, has recognized the importance of "hostile vehicle mitigation." This approach involves using bollards and other security measures to protect public spaces from the potential threat of vehicle-based attacks. Bollards, when properly designed and installed, can act as physical barriers to prevent vehicles from entering pedestrian malls, government buildings, and event spaces. They enhance security while maintaining the city's open and welcoming atmosphere, allowing people to enjoy public spaces without undue concern for their safety.

Melbourne's bollards also serve as canvases for artistic expression. They have become integral components of the city's urban art scene. These functional elements have been transformed into colorful designs, sculptures, and installations, breathing life and character into the city's streets. These artistic bollards serve as both visual delights and conversation starters, capturing Melbourne's creative spirit and encouraging community engagement. They offer a unique way to express the city's vibrant culture and showcase the talents of local artists.

Preserving Melbourne's rich heritage is another role bollards play. The city is known for its historical architecture and landmarks, and bollards are used to protect these treasures from accidental damage caused by vehicles. Whether it's guarding the grandeur of Parliament House or the Victorian-era buildings in the central business district, bollards blend seamlessly into their surroundings, preserving Melbourne's architectural heritage for generations to come.

0 notes

Text

Best Steel Fabricator Melbourne

Specialise in making commercial stainless steel fabrication, including exhaust canopy, Exhaust duct, Stainless Steel Sink, Stainless Steel Benches/Shelving and other Custom Stainless Steel products and the best Steel Fabricator Melbourne.

Reach us at +61 03 9348 9938 / 0422 247 437 today for any queries.

#Steel Fabricator Melbourne#stainless sink#stainless steel benches#stainless steel sink#commercial stainless steel sink#stainless steel benches melbourne#stainless steel sinks#cgc stainless steel#stainlesssteelbenchesmelbourne#stainless steel sink melbourne#commercial stainless steel benches

1 note

·

View note

Text

Glass and Glazing Work from Rajasthan India

A wide variety of glass railing is exported by Fabiron in Dubai. For both private residences and business structures, we provide glass railing. Get in contact with us if you need assistance creating stunning aesthetics for your businesses.

Our designers develop ideas while considering your aesthetic and financial preferences. We passionately believe in offering distinctive design alternatives that are specifically catered to your needs.

Get more information or purchase this product by contacting us today. Call us on : +91 9636699999, +91 9166988888 or get in touch via e-mail - [email protected]

#Fabiron#Rajasthan#Ajmer#Kota#Jaipur#Manufacturer#Exporter#Architecture#Interiordesign#Homdecor#Commercial#steel#welding#doors#fabrication#construction#wroughtiron#railings#glassrailings#ironrailings#customrailings#aluminumrailings#railingstainless#modernrailings

0 notes

Text

Mastering Structural Integrity: Engineered Floor Joists in Modern Construction.

Introduction: In the realm of modern construction, engineered floor joists stand as a testament to innovation and efficiency. These structural components play a vital role in supporting floors and distributing loads, revolutionizing the construction industry with their superior strength and versatility.

The Evolution of Engineered Floor Joists: Engineered floor joists have evolved significantly over the years, replacing traditional solid timber joists with engineered wood products such as laminated veneer lumber (LVL) and I-joists. This evolution has led to lighter, stronger, and more consistent floor systems, offering architects and builders greater flexibility in design and construction.

Benefits of Engineered Floor Joists:

Enhanced Strength and Stability: Engineered floor joists are engineered to provide exceptional strength and stability, making them ideal for supporting heavy loads and spanning longer distances without the need for intermediate supports. This strength allows for larger open spaces and more creative architectural designs.

Consistency and Predictability: Unlike traditional timber joists, engineered floor joists exhibit uniformity and predictability in their performance. Manufactured under controlled conditions, these joists have consistent dimensions, moisture content, and structural properties, ensuring reliable performance in every application.

Cost-Effectiveness: While engineered floor joists may have a higher upfront cost compared to traditional timber joists, their long-term benefits often outweigh the initial investment. Their lightweight construction reduces labor and installation time, resulting in overall cost savings during construction.

Environmental Sustainability: Engineered floor joists are often made from sustainably sourced wood products, making them an environmentally friendly choice for builders and homeowners. By utilizing wood efficiently and minimizing waste, these joists contribute to the conservation of natural resources and the reduction of carbon emissions.

Applications of Engineered Floor Joists: Engineered floor joists find widespread applications in various construction projects, including residential homes, commercial buildings, and industrial facilities. Whether used in single-family homes or multi-story structures, these joists offer structural integrity, durability, and design flexibility to meet the demands of modern construction.

Conclusion: Engineered floor joists represent a paradigm shift in construction methodology, offering unparalleled strength, stability, and versatility. With their exceptional performance, cost-effectiveness, and environmental sustainability, these joists continue to shape the future of construction, providing builders and architects with the tools they need to create safe, efficient, and aesthetically pleasing spaces.

For More Information Visit - https://skybluesteel.com/

Contact US - Phone - 0418777345 Mail Id [email protected] Timings -9AM-5PM (monday-Friday).

#Commercial Steel Fabricators#Residential Steel Fabricators#Steel Stud Wall Framing#Floor Joists For Sale#Commercial Steel Construction

0 notes

Text

Cresco Manufacturing | Professional Quality

At Cresco, We offer metal fabrication services such as: Sheet Metal Shearing and Cutting, Milling, Assemble Services, Wrought iron design & fabrication, automatic Fiber Laser Cutting, Turret Punching (auto), Press brake, Line graining, Pem hydraulic press, Robotic welding, Mig & tig welding, Automatic band saw cutting and more! For more details visit https://www.4shared.com/office/jm2bky30jq/Cresco_Manufacturing_Professio.html

0 notes

Text

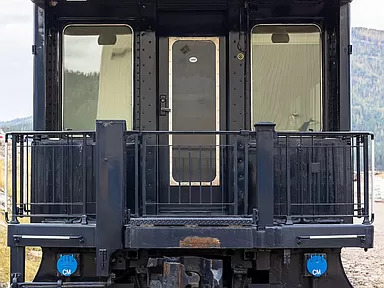

Found another of my former posts that didn't sell. This is a 1925 Pullman railroad car converted to a home. I think that the problem is that it's out in the middle of nowhere and it has to be moved. I have no idea how you would transport it, but the seller is willing to help facilitate the move. Right now the 3bd, 3ba home is in Bonner, MT. It comes furnished and is $249K.

It's got a western theme. The shades have cowboys on bucking broncos, and I love the soft velvet furniture. Look at the chairs w/scenes on the fabric.

This sofa is an original train seat.

Now, here we have a beautiful desk that looks like it could be original & a chair, plus another vintage bench seat with storage drawers.

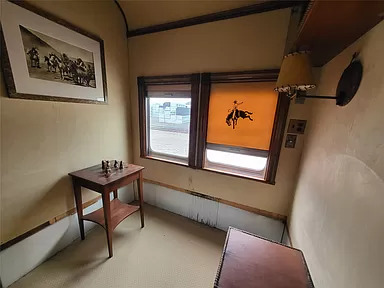

Small room flex space.

Outside this bedroom there's wallpaper and a shower curtain with a barbed wire print.

I like the stainless steel shower (there are 3 of them, one for each bedroom). There's also a very private toilet in each bedroom next to the chest of drawers.

Above the toilet is a clever unit with a mirrored medicine chest and a pull down sink.

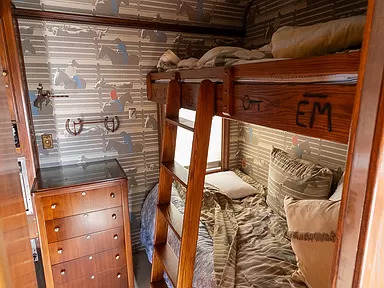

Cute room with bunks and vintage cowboy wallpaper.

The bedroom toilet units and chest of drawers must be original b/c they're built-in. They probably had bunk beds, but these wouldn't be the originals.

The dining room fits 6 in comfy upholstered chairs.

An antler chandelier matches the smaller antler sconces around the home. On the right is the hall to the bedrooms and showers.

A nice built-in serving cabinet has cowboy stained glass to match the window shades.

The kitchen also looks original. It's completely stainless steel and commercial. I trust that all of this works

At the end of the car is this cute little original seating area.

I'm not sure if even a small chair can fit out here, but it sure is cute.

https://www.zillow.com/homedetails/Nhn-Nka-Bonner-MT-59823/2054689249_zpid/

163 notes

·

View notes

Text

Best Pre-Engineered Steel Buildings | PEB Structures Solutions

#Pre-engineered steel buildings#PEB structures#Pre-fabricated steel structures#Industrial steel buildings#Commercial steel buildings#Pre-engineered constructed buildings#https://primainfracorp.com/pre-engineered-steel-buildings

0 notes

Text

The Essential Guide to Welding and Metal Fabrication

Whether you're a seasoned professional or a DIY enthusiast, our essential guide to welding and metal fabrication covers everything you need to know to succeed. From detailed explanations of different welding techniques to the best practices for metal fabrication, this comprehensive resource is designed to enhance your skills and knowledge. Discover the tools and materials you'll need, safety tips, and step-by-step instructions to help you achieve professional results in your welding and metal fabrication projects.

#commercial#entrepreneur#steel construction#local metal fabricators#welding and metal fabrication in Nottingham#welding metal fabrication

0 notes