#ColdChainLogistics

Explore tagged Tumblr posts

Text

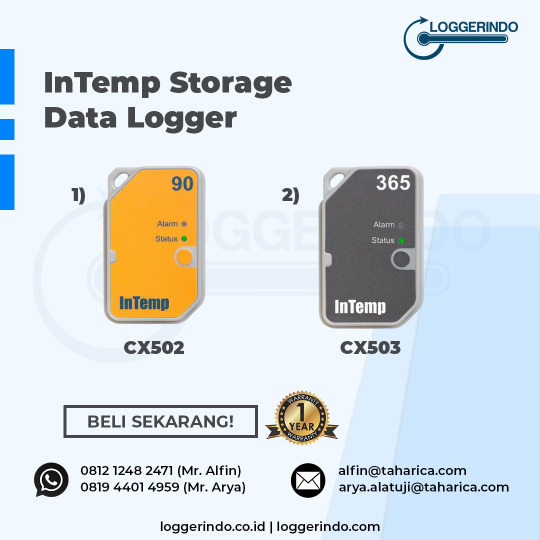

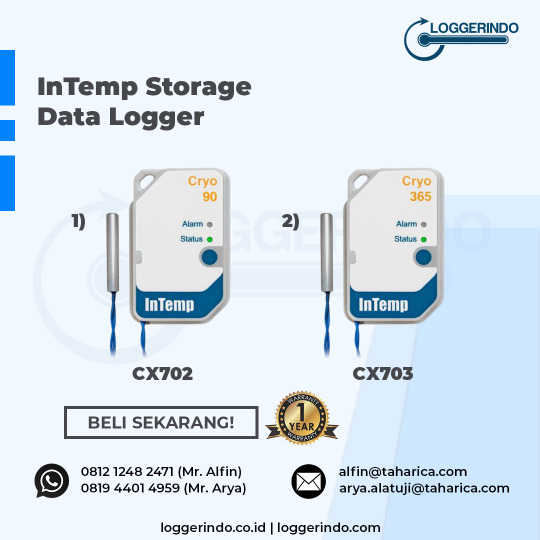

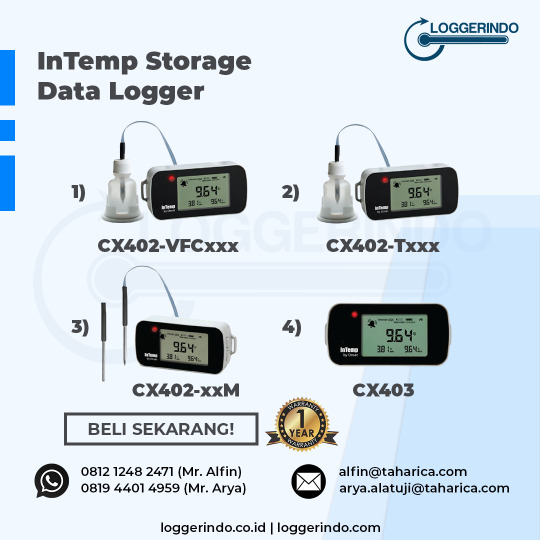

InTemp Storage Data Logger . Temukan variasi Storage Data Logger yang sesuai dengan kebutuhan anda disini! . . Ingin tau lebih lanjut? atau ingin bertanya? Silahkan hubungi kami melalui : -Whatsapp : 0812 1248 2471 (Mr. Alfin) / 0819 4401 4959 (Mr. Arya) -Email : alfin@taharica.com / arya.alatuji@taharica.com -Website : loggerindo.co.id / loggerindo.com

#coldchain#coldchainvaksin#coldchaindatalogger#coldchainmanagement#coldchainlogistics#distribusi#logistik#gudang#penyimpanangudang

#coldchain#coldchainvaksin#coldchaindatalogger#coldchainmanagement#coldchainlogistics#distribusi#logistik#gudang#penyimpanangudang

2 notes

·

View notes

Text

Trusted Reefer Repair Services: Keep Your Fleet Running Smoothly

For businesses relying on refrigerated transport, a malfunctioning reefer unit can cause significant disruptions. Whether you're in food distribution, pharmaceuticals, or logistics, maintaining your refrigerated truck or trailer is essential. If you're searching for Reefer Repair Services In Greater Landover, MD, working with experienced professionals ensures that your reefer units stay in top condition, minimizing downtime and protecting your cargo.

Why Reefer Repair Services Are Crucial

A faulty reefer unit can lead to:

Cargo spoilage – Perishable goods such as food, medicine, and chemicals require stable temperatures.

Regulatory violations – Many industries must comply with strict temperature control regulations.

Increased costs – Repairs, fuel inefficiencies, and spoiled cargo can quickly add up.

Delayed deliveries – A broken reefer unit can disrupt schedules and impact customer trust.

By investing in quality reefer repair and maintenance, you ensure reliable performance and prevent costly breakdowns.

Common Reefer Unit Issues and How to Fix Them

Refrigerated transport units require regular maintenance to avoid common issues. Here are some typical problems and their solutions:

1. Reefer Unit Not Cooling Properly

Causes: Low refrigerant levels, dirty condenser coils, or malfunctioning sensors

Solution: Refill refrigerant, clean condenser coils, and test sensors for accuracy

2. Engine Won’t Start

Causes: Battery failure, faulty starter, or fuel system issues

Solution: Check battery voltage, inspect starter motor, and ensure fuel supply is clean

3. Compressor Failure

Causes: Overheating, worn-out parts, or oil leaks

Solution: Perform regular oil changes, monitor temperature levels, and replace damaged components

4. Temperature Fluctuations

Causes: Faulty thermostat, improper airflow, or blocked evaporator coils

Solution: Calibrate thermostat, check for blockages, and ensure proper ventilation

Benefits of Professional Reefer Repair Services

When you hire a trusted service for Reefer Repair Services In Greater Landover, MD, you get:

✅ Expert Technicians – Skilled professionals can quickly diagnose and repair problems. ✅ Emergency Repair Support – 24/7 service options to minimize downtime. ✅ Regulatory Compliance – Ensure your reefer units meet FDA and DOT standards. ✅ Long-Term Cost Savings – Preventative maintenance helps avoid major breakdowns.

How to Choose the Right Reefer Repair Service in Greater Landover, MD

Finding the best reefer repair provider requires careful consideration. Here’s what to look for:

🔹 Certified Technicians – Ensure they have experience with all major reefer brands. 🔹 Mobile Repair Services – On-site repairs save time and prevent delays. 🔹 Customer Reviews – Check ratings and feedback for reliability and quality of service. 🔹 Comprehensive Services – A full range of maintenance, diagnostics, and repairs ensures all needs are covered.

Pro Tips for Reefer Unit Maintenance

To extend the life of your reefer unit and avoid unexpected failures, follow these maintenance tips:

Inspect units regularly – Check for leaks, wear and tear, and unusual noises.

Monitor temperature settings – Ensure the reefer unit is maintaining the correct temperature.

Clean condenser and evaporator coils – Blockages reduce efficiency and can lead to overheating.

Use high-quality fuel and oil – Poor-quality fuel can damage the engine and affect performance.

Schedule preventative maintenance – Regular check-ups from Reefer Repair Services In Greater Landover, MD keep your unit in peak condition.

Conclusion

Refrigerated transport is essential for businesses dealing with perishable goods, and a well-maintained reefer unit ensures smooth operations. By choosing professional Reefer Repair Services In Greater Landover, MD, you can reduce downtime, protect your cargo, and keep your fleet running efficiently. Prioritize maintenance and repairs to avoid costly breakdowns and maintain the highest standards in refrigerated logistics.

Need a Reliable Reefer Repair Service?

Don’t wait for a breakdown—schedule a maintenance check today to keep your refrigerated truck in top condition!

0 notes

Text

Temperature Controlled Packaging Market Drivers Shaping the Future of Global Supply Chains

The temperature controlled packaging market is driven by several key factors that have made it an essential part of industries such as pharmaceuticals, food, and e-commerce. These drivers are shaping the market’s growth trajectory, making it one of the most critical segments in logistics and supply chain management.

Growing Demand for Perishable Goods As consumer demand for fresh and perishable products like fruits, vegetables, dairy, and meats increases, the need for effective temperature-controlled packaging solutions grows. The rise of global e-commerce platforms has made it easier for consumers to access perishable goods, further boosting this demand. To maintain freshness and prevent spoilage during transportation, businesses are turning to advanced packaging solutions that regulate temperature effectively.

Expanding Pharmaceutical Sector The pharmaceutical industry is one of the largest contributors to the temperature controlled packaging market. With an increasing number of biologics, vaccines, and temperature-sensitive medications being developed, the need for strict temperature control during storage and transit has become more critical. The pandemic emphasized the importance of maintaining specific temperatures for vaccines, pushing pharmaceutical companies to rely more on temperature-controlled solutions to preserve the integrity of these products.

Advances in Cold Chain Logistics The development and expansion of cold chain logistics are vital drivers in the temperature controlled packaging market. Cold chains involve temperature-regulated environments for transporting goods that must be kept within certain temperature ranges. Innovations in refrigerated transport and temperature-sensitive storage solutions are making it easier to move products globally without compromising quality. Improved cold chain infrastructure is enabling more companies to ensure products remain within required temperature ranges throughout the supply chain.

E-commerce Growth E-commerce has dramatically influenced the demand for temperature controlled packaging. With the rise of online grocery shopping, food delivery services, and home delivery of pharmaceuticals, there is an increasing need for packaging solutions that can preserve product quality during transportation. E-commerce platforms are also leveraging temperature-controlled packaging to expand their reach to more remote locations, ensuring products are delivered fresh and safe. This has led to a boom in the demand for reliable and efficient temperature-controlled packaging options.

Environmental and Sustainability Concerns The push for sustainability has led to a surge in demand for eco-friendly and recyclable packaging solutions. Companies are becoming more aware of their environmental impact and are prioritizing sustainable alternatives, such as biodegradable packaging materials and reusable packaging systems. This growing awareness is driving innovations in temperature-controlled packaging that reduce reliance on non-recyclable materials and contribute to a more sustainable supply chain. Green initiatives and eco-friendly innovations are expected to continue shaping the market.

Technological Innovations in Packaging Materials Innovations in materials used for temperature controlled packaging are a significant driver of market growth. The development of advanced materials, such as phase change materials (PCMs) and vacuum insulated panels (VIPs), has improved the effectiveness of packaging solutions. These materials can maintain the required temperature over long periods, improving the reliability of temperature-controlled packaging for sensitive products. This has increased the market’s ability to serve a wider range of industries, from pharmaceuticals to fine wines.

Regulations and Standards in Food Safety Strict regulations and standards around food safety and product quality are pushing companies to adopt better temperature controlled packaging. Governments across the world are enforcing regulations that demand stringent temperature control in food and pharmaceutical transport, especially for international shipments. These regulations ensure that products meet safety standards and are free from contamination or degradation, further driving the adoption of temperature-controlled packaging solutions.

Customization of Packaging Solutions The increasing demand for tailored packaging solutions is another significant market driver. As different industries have varying requirements, companies are focusing on creating customized packaging solutions that can cater to the specific needs of their clients. Whether it's a certain temperature range or specific insulation properties, businesses are investing in innovative packaging solutions that offer maximum protection for products during transit. The need for flexible and customizable packaging options is expected to grow as industries require more personalized solutions.

Rise in Global Trade With the globalization of trade, companies are reaching new markets, and there is an increased need to transport products across long distances while maintaining quality. Temperature controlled packaging allows businesses to tap into new markets by ensuring their products remain viable, no matter the distance. This rise in global trade is particularly significant for the food and pharmaceutical sectors, which rely heavily on temperature-controlled logistics to maintain product quality.

Consumer Expectations for Quality and Freshness Today’s consumers demand higher standards of quality and freshness in the products they purchase. Whether it's fresh produce, dairy, or medicine, customers expect to receive goods that are in pristine condition. This increasing expectation of quality has forced companies to adopt more reliable temperature-controlled packaging solutions to ensure products meet customer demands. Meeting these consumer expectations is driving companies to invest more in better packaging technologies.

0 notes

Text

The Future of Cargo Aviation in India: Trends and Opportunities

Opportunities

India's cargo aircraft industry is expected to grow significantly because to a number of factors, including favorable government policies, infrastructure advancements, and rising e-commerce demand. It is imperative to comprehend the trends and prospects in cargo aviation as the nation strives to become a worldwide hub for logistics.

Trends Shaping Cargo Aviation in India

The Boom in E-Commerce :The Indian e-commerce market is expected to rise to $200 billion by 2026, a record amount given its rapid expansion. Due to the rise in online sales, there is a greater need than ever for effective air cargo services to guarantee prompt and dependable delivery within the nation and beyond Market Research Future

Advancement To increase cargo handling capacity, the Indian government is making significant infrastructural investments in airports. The objective of the UDAN (Ude Desh ka Aam Nagrik) initiative is to improve regional connectivity through the establishment of cargo terminals at multiple airports. To meet the rising demand, major airports like Delhi and Mumbai are also upgrading their cargo capabilities. Government of India's Ministry of Civil Aviation

.Technological Advancements The adoption of advanced technologies such as automation, AI, and IoT in cargo operations is revolutionizing the industry. These technologies enhance efficiency, reduce turnaround times, and improve tracking and monitoring of shipments. The implementation of the Air Cargo Community System (ACS) at major airports is a step towards creating a seamless digital ecosystem for cargo operations Airports Authority of India.

Sustainability Initiatives In line with the growing emphasis on sustainability on a worldwide scale, the Indian freight aviation industry is adopting environmentally friendly techniques. To lessen their carbon footprint, airports are implementing green initiatives and airlines are investing in fuel-efficient aircraft. The International Air Transport Association (IATA) reports that the government is pushing the use of biofuels and other sustainable energy sources in aviation.

Opportunities for Growth

Regional Connectivity Strengthening regional connectivity presents a significant opportunity for growth in the cargo aviation sector. The development of regional airports and airstrips can facilitate quicker movement of goods to and from remote areas, boosting local economies and enhancing overall logistics efficiency Economic Times.

International Trade As India strengthens its trade ties with various countries, there is a growing demand for air cargo services to facilitate international trade. The signing of trade agreements and the establishment of new trade routes are expected to drive growth in the cargo aviation sector Ministry of Commerce and Industry, Government of India.

Cold Chain Logistics The pharmaceutical and perishable goods sectors are driving demand for specialized cargo services, particularly cold chain logistics. The Indian government's focus on improving cold chain infrastructure offers significant opportunities for cargo airlines to expand their services in this niche market Frost & Sullivan.

Investment in Technology Continued investment in cutting-edge technologies will be crucial for the future of cargo aviation in India. Innovations in drone technology, blockchain for secure transactions, and AI-driven logistics planning can revolutionize the sector, making it more efficient and cost-effective Cargo Facts.

Government Support Favorable government policies and incentives play a critical role in the growth of the cargo aviation sector. Initiatives like the National Logistics Policy and the Air Cargo Policy aim to streamline regulations, reduce logistics costs, and enhance the competitiveness of the Indian logistics sector on a global scale Ministry of Commerce and Industry, Government of India.

Challenges and Solutions

Regulatory Challenges The cargo aviation industry in India faces several regulatory challenges, including stringent customs procedures and varying regulations across states. Streamlining these regulations and creating a unified framework can facilitate smoother operations and faster clearance of goods.

Infrastructure Bottlenecks Despite significant investments, infrastructure bottlenecks such as inadequate warehousing facilities and limited cargo handling capacity at smaller airports persist. Addressing these issues through public-private partnerships and continuous infrastructure upgrades is essential for sustained growth.

Skilled Workforce Shortage The rapid growth of the cargo aviation sector necessitates a skilled workforce. Investing in training programs and educational initiatives can bridge the skill gap and ensure a steady supply of qualified professionals.

Environmental Concerns The aviation industry is a significant contributor to greenhouse gas emissions. Adopting sustainable practices, such as using biofuels and implementing carbon offset programs, can mitigate environmental impacts and align with global sustainability goals

Conclusion

The future of cargo aviation in India looks promising, with numerous trends and opportunities paving the way for growth and innovation. By leveraging technological advancements, enhancing infrastructure, and capitalizing on government support, the sector is set to become a key driver of the Indian economy. As the demand for efficient logistics solutions continues to rise, the cargo aviation industry must adapt and evolve to meet the changing needs of the market.

#CargoAviationIndia#AirCargoTrends#ECommerceLogistics#SustainableAviation#CargoInfrastructure#AIInAviation#ColdChainLogistics#IndiaTradeRoutes#LogisticsSolutions#AviationTechnology#GreenAviation#AirCargoGrowth#FutureOfLogistics#GovernmentPolicies#AviationInnovation#CargoInChennai#AirFreightBangalore#LogisticsMumbai#AirCargoDelhi#ColdChainHyderabad#SustainableCargoIndia#UDANCargo#CargoAviationOpportunities

0 notes

Text

Your All-in-One Customised Logistics Service Provider - DahNAY Logistics

Move your cargo your way, with customised logistics service provider. All you need to do is partner with DahNAY. With dedicated account management and tailored solutions for your business needs.

Explore our blog - dahnay.com/the-crucial-role-of-cold-chain-logistics-in-the-food-beverage-industry/

To know more about DahNAY: dahnay.com/

#dahnaylogistics#logisticsserviceprovider#supplychainmanagement#freightforwarders#internationalfreightservice#customizedlogistics#freightforwarersinchennai#seafreightservice#airfreightservice#containerfreightstation#coldchainlogistics#foodandagrologistics#import#export

0 notes

Text

"Protecting Vaccines, Saving Lives: Innovations in Storage and Packaging"

📦💉 "Safe vaccines, safer lives! The Vaccine Storage and Packaging Market is evolving to ensure effective immunization globally. From innovative packaging to advanced cold chain logistics, explore how this market is reshaping public health."

0 notes

Text

Keeping your cold storage inventory fresh and operations smooth has never been easier. Our advanced cold storage management system offers real-time monitoring, optimized logistics, and seamless inventory control. Whether you're managing large warehouses or small facilities, our system ensures efficiency at every step. ❄️📊

#ColdStorage#InventoryManagement#BusinessEfficiency#SmartStorage#TechSolutions#ColdChainLogistics#SupplyChainOptimization#WarehouseTech

1 note

·

View note

Text

#SpecialtyPharmaPackaging#TemperatureControlledShipping#ColdChainLogistics#PharmaPackaging#TemperatureSensitiveProducts#PharmaceuticalLogistics

0 notes

Text

Last-Mile vs. Hub-to-Distributor: Decoding Healthcare Cold Chain Logistics with Cardinal Health, Envirotainer, FedEx & More!

Investment opportunities in healthcare cold chain logistics as of July 2024 | Comparison of Last-Mile Delivery and Hub-to-Distributor models, highlighting growth projections, emerging trends like blockchain integration and AI, and innovations

Healthcare Cold Chain Logistics: Last-Mile Delivery vs. Hub-to-Distributor – The Investment Opportunities The healthcare cold chain logistics market is experiencing significant growth, driven by the increasing demand for temperature-sensitive pharmaceuticals, vaccines, and biologics. Within this market, two key delivery segments dominate: Last-Mile Delivery and Hubs-to-Distributor. As an…

View On WordPress

#artificialintelligence#BlockchainIntegration#ColdChainLogistics#ColdChainSolutions#HealthcareColdChain#HealthcareInnovation#IoT#LastMileDelivery#LogisticsTechnology#MedicalLogistics#PharmaLogistics#PharmaSupplyChain#SupplyChainManagement#TemperatureMonitoring

0 notes

Text

Cold Chain Logistics: Ensuring The Integrity Of Temperature-Sensitive Products

In the intricate web of global supply chains, one critical component stands out for its pivotal role in preserving the integrity of temperature-sensitive products: the cold chain. From pharmaceuticals and vaccines to perishable foods and biologics, the cold vaccine serves as a lifeline, maintaining optimal temperature conditions from production to distribution, ensuring product safety and efficacy. In this article, we explore the intricacies of cold chain logistics, its significance across various industries, and the challenges and innovations driving its evolution.

Understanding A Complex Journey

It refers to a series of interconnected processes and infrastructure designed to maintain specific temperature ranges for the transportation, storage, and handling of temperature-sensitive products. These products, which include vaccines, blood products, fresh produce, dairy products, and certain medications, require precise temperature control to prevent spoilage, degradation, or loss of efficacy.

The journey of a temperature-sensitive product through the chain begins at the point of manufacture or production, where it is carefully packaged and stored under controlled conditions. From there, the product is transported via refrigerated trucks, ships, or planes to distribution centers, warehouses, and ultimately to end-users or consumers. At each stage of the cold chain, temperature monitoring and control mechanisms are employed to ensure compliance with specified temperature requirements and regulatory standards.

Significance Across Industries: From Pharmaceuticals to Food

The cold chain logistics plays a critical role in various industries, each with its unique set of temperature-sensitive products and requirements:

Pharmaceuticals and Biologics: Pharmaceutical products, including vaccines, biologics, and certain medications, are highly sensitive to temperature fluctuations. Deviations from recommended temperature ranges can compromise product efficacy and safety, leading to potential health risks for patients. The cold chain is essential for maintaining the potency and stability of pharmaceutical products throughout their lifecycle, from manufacturing to distribution and administration.

Food and Beverage: Perishable foods, including fresh produce, dairy products, meat, and seafood, require refrigeration or freezing to maintain quality and safety. The cold chain logistics ensure that these products remain fresh and free from contamination during transportation and storage, reducing the risk of foodborne illnesses and spoilage. Additionally, the cold chain enables the global trade of perishable foods, allowing consumers to access a diverse range of fresh products year-round.

Biotechnology and Life Sciences: Temperature-sensitive biologics, such as enzymes, antibodies, and reagents used in research and diagnostics, require stringent temperature control to preserve their activity and stability. The cold chain is essential for maintaining the integrity of biological products, ensuring reliable results, and reproducibility in scientific experiments and clinical assays.

Chemicals and Industrial Products: Certain industrial products, chemicals, and materials may also be sensitive to temperature variations and require specialized cold chain logistics solutions to prevent degradation or alteration of their properties. From electronic components to adhesives and coatings, maintaining consistent temperature conditions is essential for ensuring product quality and performance.

Challenges and Innovations in Cold Chain Logistics Management

Despite its critical importance, the cold chain presents numerous challenges and complexities that require innovative solutions and continuous improvement:

Temperature Monitoring and Control: Accurate temperature monitoring and control are paramount in cold chain management to prevent temperature excursions and ensure product quality and safety. Advances in sensor technology, data analytics, and real-time monitoring systems have enhanced visibility and control over temperature-sensitive products, enabling proactive intervention and response to temperature deviations.

Infrastructure and Logistics: The effective management of cold chain logistics relies on robust infrastructure, including refrigerated storage facilities, transportation equipment, and cold chain packaging solutions. However, inadequate infrastructure, especially in remote or developing regions, can pose challenges to maintaining the integrity of the cold chain and distributing temperature-sensitive products safely and efficiently.

Regulatory Compliance: Regulatory requirements and standards governing cold chain logistics vary across industries and regions, adding complexity to cold chain management. Ensuring compliance with Good Distribution Practices (GDP), Good Manufacturing Practices (GMP), and other regulatory frameworks is essential for safeguarding product quality, meeting customer expectations, and avoiding regulatory penalties or sanctions.

Sustainability and Environmental Impact: The cold chain consumes significant energy and resources, contributing to environmental degradation and greenhouse gas emissions. Sustainable cold chain practices, such as energy-efficient refrigeration technologies, optimized transportation routes, and recyclable packaging materials, are essential for minimizing the environmental footprint of cold chain logistics and promoting sustainable development.

Conclusion

In conclusion, the cold chain is a vital component of modern supply chains, ensuring the integrity and safety of temperature-sensitive products across various industries. From pharmaceuticals and biologics to food and beverages, cold chain logistics plays a critical role in preserving product quality, efficacy, and safety from production to consumption. However, the complexity of the cold chain presents challenges that require innovative solutions and collaboration across stakeholders to overcome. By embracing technology, adopting best practices, and prioritizing sustainability, we can enhance the resilience and efficiency of the cold chain, ensuring the uninterrupted flow of temperature-sensitive products to meet the needs of consumers worldwide.

#ColdChainLogistics#TemperatureSensitiveProducts#SupplyChainManagement#InnovationInLogistics#SustainableSupplyChain#GlobalTrade

0 notes

Text

Peran Vital Cold Chain dalam Distribusi Vaksin . Dalam era modern ini, vaksinasi menjadi salah satu kunci utama untuk mengatasi penyebaran penyakit yang dapat dicegah. Namun, keberhasilan vaksinasi tidak hanya bergantung pada pengembangan vaksin yang efektif, tetapi juga pada kemampuan untuk mendistribusikannya dengan aman dan efisien.

Di sinilah peran vital dari cold chain, atau rantai dingin, muncul sebagai faktor kunci dalam memastikan bahwa vaksin mencapai tujuannya dengan keamanan dan kualitas yang terjaga.

Cold chain adalah sistem manajemen logistik yang dirancang untuk memastikan produk-produk yang sensitif terhadap suhu, seperti makanan segar, vaksin, dan obat-obatan, tetap terjaga dalam suhu yang terkendali selama proses produksi, penyimpanan, transportasi, dan distribusi.

Tujuannya adalah untuk memastikan kualitas, keamanan, dan efektivitas produk-produk ini tetap terjaga dari produsen hingga konsumen akhir.

Cold chain data logger adalah perangkat elektronik yang dirancang khusus untuk memonitor dan merekam suhu serta kondisi lingkungan selama transportasi, penyimpanan, dan distribusi dalam rantai dingin.

Fungsi utama cold chain data logger adalah untuk memastikan bahwa produk-produk yang sensitif terhadap suhu, seperti makanan segar, vaksin, dan obat-obatan, tetap terjaga dalam kondisi yang sesuai selama seluruh perjalanan mereka. . Baca selengkapnya di : https://loggerindo.co.id/2023/11/peran-vital-cold-chain-dalam-distribusi-vaksin/ . . Ingin tau lebih lanjut? atau ingin bertanya? Silahkan hubungi kami melalui : -Whatsapp : 0812 1248 2471 (Mr. Alfin) / 0819 4401 4959 (Mr. Arya) -Email : alfin@taharica.com / arya.alatuji@taharica.com -Website : loggerindo.co.id / loggerindo.com

#coldchain#coldchainvaksin#coldchaindatalogger#coldchainmanagement#coldchainlogistics#distribusi#logistik#gudang#penyimpanangudang #penyimpanandingin #gudangdingin #transportasi #datalogger #sensor #detektor #instrumentasi #loggerindo #taharica

#coldchain#coldchainvaksin#coldchaindatalogger#coldchainmanagement#coldchainlogistics#distribusi#logistik#gudang#penyimpanangudang#penyimpanandingin#gudangdingin#transportasi#datalogger#sensor#detektor#instrumentasi#loggerindo#taharica

1 note

·

View note

Text

The Future of Cold Storage Warehouses: Automation, AI, and Beyond

In a world that's continually advancing, the future of cold storage warehouses is being shaped by cutting-edge technologies. These innovations not only improve efficiency and sustainability but also redefine how we think about preserving perishable goods. EPACK Prefab, a leading manufacturer and supplier, is at the forefront of this transformation, spearheading the adoption of automation, AI, and other groundbreaking solutions in cold storage warehouse construction.

The Evolution of Cold Storage Warehouses

Cold storage warehouses have long been vital for preserving and distributing temperature-sensitive products, from fresh produce to pharmaceuticals. In earlier times, cold storage warehouses were essentially spacious, heavily insulated enclosures fitted with refrigeration systems. Nevertheless, with the advancement of technology, our ability to transform these facilities into more efficient and effective spaces has significantly expanded.

The Role of Automation

Automation is one of the most significant advancements in the cold storage industry. Automated systems are capable of optimizing various processes within the warehouse, from goods reception and placement to retrieval and dispatch. This not only reduces the need for manual labor but also enhances the precision of operations.

EPACK Prefab's Automation Expertise

EPACK Prefab has embraced automation in the design and construction of cold storage warehouses. They understand that automated systems can significantly reduce operational costs, improve inventory management, and enhance overall efficiency. Their expertise in integrating automation technologies into warehouse design is revolutionizing the industry.

The Power of AI and Machine Learning

Artificial intelligence (AI) and machine learning are increasingly being harnessed to make cold storage warehouses smarter. These technologies can predict temperature fluctuations, detect equipment malfunctions before they occur, and optimize energy consumption. In essence, they provide a level of proactive management that was previously impossible.

Sustainability as a Driving Force

As the world confronts pressing environmental issues, sustainability emerges as a pivotal aspect in shaping the future of cold storage. The refrigeration systems within these facilities are undergoing a transformation towards greater energy efficiency and eco-friendliness. EPACK Prefab is unwavering in its commitment to constructing cold storage warehouses that incorporate sustainable technologies. These not only contribute to reducing their environmental impact but also translate into enduring cost savings for their clients.

The Future of Cold Storage Warehouses with EPACK Prefab

EPACK Prefab's dedication to innovation and quality makes them a natural leader in the construction of cold storage warehouses that are ready for the future. Their commitment to integrating automation, AI, and sustainable solutions ensures that clients receive state-of-the-art facilities that meet the demands of a rapidly evolving industry.

Whether it's automated retrieval systems, smart monitoring and control, or energy-efficient refrigeration, EPACK Prefab is equipped to provide clients with the latest technological advancements. Their team of experts collaborates closely with clients to design and construct cold storage warehouses that are tailored to their specific requirements.

Also Read: PRE ENGINEERED COLD STORAGE ROOMS – COST EFFECTIVE AND QUICK TO BUILD!

The future of cold storage warehouses is being shaped by automation, AI, sustainability, and an unwavering commitment to innovation. EPACK Prefab, as a top manufacturer and supplier, is leading the way by integrating these technologies into their construction projects. The result is a new generation of cold storage warehouses that are more efficient, eco-friendly, and prepared to meet the demands of a changing world.

Under the leadership of EPACK Prefab, the outlook for the future of cold storage warehouses is bright, guaranteeing the continued delivery of perishable goods to consumers in impeccable condition, all while diminishing our environmental footprint.

#ColdStorageSolutions#PEBColdStorage#EfficientColdStorage#GreenBuildingTechnology#PEBConstruction#SmartColdStorage#ColdChainLogistics#EPACKPrefab#PEBSolution#SteelStructure

0 notes

Link

🚚🧊🍎 Refrigerated vans are essential for businesses that need to transport perishable goods. These vehicles are equipped with a cooling system that maintains a consistent temperature, ensuring that the products arrive fresh and in good condition. 🚚🧊🍓 The use of refrigerated vans is not limited to the food industry. Pharmaceutical companies, florists, and other businesses that deal with temperature-sensitive products also rely on these vehicles to transport their goods. 🚚🧊🥩 Investing in a refrigerated van can be a game-changer for businesses that need to transport perishable goods. With the right vehicle, companies can expand their reach and offer their products to a wider audience without compromising on quality.1. The Importance of Refrigerated Vans for Food Delivery ServicesRefrigerated vans are crucial for food delivery services to ensure food safety and quality. They keep food at the right temperature, preventing spoilage and bacterial growth. 🌡️ 🍔🍟🍕 🚚 Without refrigerated vans, food may arrive at its destination in poor condition, leading to customer dissatisfaction. Refrigerated vans also allow for longer delivery distances and more flexible delivery schedules. 🌎 🕰️ Investing in refrigerated vans can save money in the long run by reducing food waste and spoilage. It also shows customers that you prioritize their health and safety. 💰 👩👧👦 Overall, refrigerated vans are essential for food delivery services to maintain food quality and customer satisfaction.2. Understanding the Mechanics of Refrigerated VansRefrigerated vans are specialized vehicles used to transport temperature-sensitive goods such as food, medicine, and chemicals. They are equipped with a refrigeration unit that maintains a specific temperature range. The refrigeration unit can be powered by a generator or the vehicle's engine. The insulation of the van is crucial to keep the temperature constant. The walls, ceiling, and floor are made of materials that prevent heat transfer. The doors are also insulated and have a tight seal to prevent warm air from entering the van. The refrigeration unit uses a compressor, condenser, and evaporator to maintain the desired temperature. The compressor compresses the refrigerant gas, which then flows to the condenser where it is cooled. The cooled refrigerant then flows to the evaporator, where it absorbs heat and cools the air inside the van. The temperature inside the van can be adjusted depending on the type of goods being transported. For example, frozen goods need to be kept at -18°C, while fresh produce needs to be kept between 0°C and 5°C. The temperature can be monitored and controlled remotely using a telematics system. Refrigerated vans come in different sizes and configurations to suit different needs. They can be customized with features such as shelving, lighting, and ventilation. They are essential for businesses that need to transport temperature-sensitive goods and ensure their quality and safety. 🚛❄️3. Factors to Consider When Choosing a Refrigerated Van for Your BusinessWhen selecting a refrigerated van for your business, there are several factors to consider: Size: Ensure the van is large enough to accommodate your products. Temperature range: Choose a van that can maintain the required temperature range for your products. Insulation: Look for a van with high-quality insulation to keep your products fresh. Refrigeration unit: Select a van with a reliable refrigeration unit that can handle your product's cooling needs. Accessibility: Consider the ease of loading and unloading your products. Cost: Determine your budget and choose a van that fits within it. Maintenance: Choose a van that is easy to maintain and repair. Ultimately, the right refrigerated van for your business will depend on your specific needs and budget. Take the time to research and compare different options to find the best fit. 🚚🧊💸4. Maintenance Tips for Keeping Your Refrigerated Van in Top ConditionRegular maintenance is key to keeping your refrigerated van in top condition. Here are some tips: Check the refrigerant levels regularly and top up if necessary. Clean the condenser coils and fan blades to prevent overheating. Inspect the door seals for wear and tear, and replace if necessary. Keep the interior clean and dry to prevent mold and bacteria growth. Check the temperature control settings and calibrate if needed. Replace the air filter regularly to maintain good air quality. Inspect the tires and brakes for wear and tear, and replace if necessary. Have a professional technician perform a thorough inspection at least once a year. By following these maintenance tips, you can ensure that your refrigerated van stays in top condition and performs at its best. 👍 Happy maintenance! 👍5. Common Challenges Faced by Refrigerated Van Operators and How to Overcome ThemRefrigerated van operators face common challenges that can affect their business. Here are some of these challenges and how to overcome them: Temperature Control: Maintaining the right temperature inside the van can be difficult. Use a reliable refrigeration system and monitor the temperature regularly. Fuel Costs: Refrigerated vans consume more fuel than regular vans. Plan your routes efficiently and use fuel-efficient vehicles to save on costs. Cargo Security: Refrigerated vans carry valuable cargo that can be stolen. Install security systems and use GPS tracking to ensure cargo safety. Cargo Damage: Cargo can be damaged during transportation. Use proper packaging and secure the cargo to prevent damage. Regulatory Compliance: Refrigerated van operators must comply with regulations on food safety and transportation. Stay updated on regulations and ensure compliance. Overcoming these challenges requires planning, investment, and attention to detail. With the right strategies, refrigerated van operators can run a successful business. 👍6. Innovations in Refrigerated Van Technology: What the Future HoldsRefrigerated van technology is constantly evolving to meet the demands of the market. Here are some of the innovations that we can expect to see in the future: 🚚 Smaller, more efficient refrigeration units that use less fuel and take up less space 🔋 Electric-powered refrigeration units that reduce emissions and noise pollution 📱 Advanced telematics systems that monitor temperature, location, and vehicle performance in real-time Other potential innovations include: 🤖 Autonomous refrigerated vans that can drive themselves, reducing the need for human drivers 🌡️ Temperature-controlled packaging that can maintain the temperature of goods during transit 🌍 Sustainable refrigerants that are less harmful to the environment As technology continues to advance, we can expect refrigerated van technology to become even more efficient, sustainable, and cost-effective. Stay tuned for more exciting developments in the future! In conclusion, refrigerated vans are a must-have for businesses that require the transportation of perishable goods. With temperature control, these vans ensure that your products remain fresh and safe for consumption. They are also versatile, with different sizes and features to suit your needs. Investing in a refrigerated van can save you money in the long run by reducing spoilage and increasing the shelf life of your products. It also gives you the flexibility to transport your goods at any time, without worrying about the weather conditions. So, if you're in the business of delivering fresh produce, dairy products, or pharmaceuticals, a refrigerated van is a wise investment. 🚛❄️ https://van-squad.co.uk/refrigerated-van-keeping-your-products-fresh/?_unique_id=6498e506da9e6

#Uncategorised#coldchainlogistics#perishablegoods#Refrigeratedvan#refrigerationsystem#Temperaturecontrolledtransport#aiomatic_0

0 notes

Text

Seamless Reverse Logistics | Logistics Solution Provider - DahNAY Logistics

As the e-commerce landscape evolves, Seamless Reverse Logistics has become crucial for handling the increasing volume of product returns efficiently. Businesses need to ensure that returns are processed swiftly to maintain customer satisfaction and minimize costs. DahNAY addresses this need by offering tailored reverse logistics solutions that streamline the returns process, featuring real-time tracking and optimized workflows, ultimately enhancing the customer experience while reducing operational burdens.

Explore our blog: dahnay.com/the-impact-of-e-commerce-surge-on-indian-logistics/

Explore DahNAY’s Logistics Services: dahnay.com/services/

#dahnaylogistics#logisticsserviceprovider#supplychainmanagement#freightforwarders#seamelessreverselogistics#timecriticalmanagement#customclearanceservice#logisticssolutionprovider#samedayairfreightservice#coldchainlogistics#endtoendlogistics#doortodoorlogistics#import#export

0 notes

Text

Brazil’s Rigid Polyurethane Foam Market Is Booming – Here’s What You Need to Know

Brazil Rigid Polyurethane Foam Market is set for substantial growth, expanding at a CAGR of 7.2% over the next decade. This surge is fueled by rising demand across construction, automotive, and refrigeration sectors, with polyurethane foam’s superior thermal insulation, structural integrity, and energy efficiency making it indispensable for sustainable development.

To Request Sample Report : https://www.globalinsightservices.com/request-sample/?id=GIS10555 &utm_source=SnehaPatil&utm_medium=Article

Market Growth Drivers & Trends

✔ Construction Boom: The construction segment leads with a 45% market share, driven by urbanization and energy-efficient building initiatives. ✔ Automotive Innovations: The automotive sector (30%) is adopting lightweight materials to enhance fuel efficiency and performance. ✔ Refrigeration Demand: 25% of the market is driven by thermal insulation advancements in refrigeration and cold storage.

Key Segments

🔹 By Type: Flexible Foam, Rigid Foam, Spray Foam 🔹 By Product: Blocks, Slabs, Sheets, Panels 🔹 By Technology: Blowing Agent, Polyol, Isocyanate Technologies 🔹 By Application: Construction, Automotive, Furniture & Bedding, Refrigeration, Packaging 🔹 By Process: Molding, Spraying, Pouring 🔹 By Functionality: Insulation, Structural Support, Vibration Dampening

Regional Insights

🌎 Southeast Brazil dominates, led by São Paulo, an industrial hub driving demand across multiple sectors. 🌎 South Brazil follows, with Porto Alegre & Curitiba fostering innovation and sustainability in manufacturing. 🌎 Northeast Brazil is an emerging hotspot, supported by urban growth and infrastructure investments.

Market Leaders

🏢 Key Players: BASF, Dow Chemical, Huntsman Corporation

📈 By 2028, the market is projected to reach 500 million cubic meters, reflecting strong demand for energy-efficient and sustainable materials.

#polyurethanefoam #rigidfoam #constructionmaterials #energyefficiency #thermalinsulation #lightweightmaterials #automotiveinnovation #refrigerationtech #sustainableconstruction #urbanization #infrastructuredevelopment #foaminsulation #buildingmaterials #smartconstruction #ecofriendlysolutions #industrialgrowth #housingprojects #commercialrealestate #greenbuilding #heatresistant #brazilindustry #manufacturingtrends #automotiveengineering #coldstorage #packagingindustry #foamsolutions #highperformancecoatings #materialscience #advancedinsulation #polyurethaneindustry #sustainabledevelopment #constructionboom #industrialinnovation #manufacturingprocess #smartmaterials #lightweightconstruction #housingdevelopment #constructiontech #buildinginnovation #coldchainlogistics #climatecontrol #insulationtechnology #energyconservation #foaminsulationtech #durablematerials #nextgenmaterials #smartcoatings

0 notes

Text

You own a refrigerated transport business specializing in renting out refrigerated trucks and vans for transporting food, grocery goods, frozen items, vegetables, fruits, and meat. You're focused on growing and expanding your business online.

#refrigeratedtransport#Refrigeratedtrucks#logistics#ColdChainLogistics#Refrigeratedtrucks#coldchain#trucks#truck#reefertruck#Refrigerated#refrigeratedvan#coldstorage#frozenfood#temperaturecontrol#chilledtransport#chilled#melbournecoldtransport#chilledairfreight#boxfreezer#boxpendinginn#RefrigeratedVans

0 notes