#Cold Storage Warehousing PA

Explore tagged Tumblr posts

Text

What are the mechanisms behind the cold storage warehouse?

Cold storage warehouses play a crucial role in preservation of arrival perishable products like Foods, Pharmaceutical products, and any other delicate product that requires low temperature for its conservation. They work on intricate protocols that determine stability and accuracy such as temperature regulation, humidity control, and energy use. To improve the knowledge of the various persons involved in the supply chain of perishable goods these types of Ambiebnt - Dry Warehousing GA mechanisms should be explored fully.

1. Temperature Control Systems

From a basic perspective, the main responsibility of cold storage warehouse is to ensure that the products stored within have an appropriate temperature. By utilizing refrigeration systems and insulation structures, as well as monitoring devices, this outcome is reached.

a. Refrigeration Systems

Cold storage ware houses rely on the refrigeration system as the backbone or the core in regulating the temperatures. These systems typically involve:

Compressor: Compresses refrigerant gas, raising its pressure and temperature.

Condenser: Releases the heat from the compressed gas to the outside environment, cooling the gas into a liquid.

Expansion Valve: Reduces the pressure of the liquid refrigerant, causing it to cool rapidly.

Evaporator: Absorbs heat from the warehouse, causing the liquid refrigerant to evaporate back into a gas, thereby cooling the air inside the warehouse.

b. Insulation

Effective insulation is crucial to minimize heat gain from the external environment. Common materials include:

Polyurethane Foam: Offers excellent thermal resistance.

Expanded Polystyrene (EPS): Lightweight and cost-effective.

Extruded Polystyrene (XPS): Provides high compressive strength and moisture resistance.

c. Temperature Monitoring and Control

Advanced temperature monitoring systems use sensors placed throughout the warehouse to track and maintain the desired temperature. These systems can include:

Thermistors and Thermocouples: For precise temperature measurements.

Automated Control Systems: To adjust the refrigeration output in real-time based on sensor data.

Alarm Systems: To alert staff of any temperature deviations.

2. Humidity Control

Maintaining optimal humidity levels is essential to prevent spoilage and maintain product quality. Excessive humidity can lead to mold growth, while too little can cause products to dry out.

a. Dehumidification

Dehumidifiers remove excess moisture from the air. Common types Cold Storage Warehousing FL include:

Refrigerative Dehumidifiers: Use cooling coils to condense moisture out of the air.

Desiccant Dehumidifiers: Use materials like silica gel to absorb moisture.

b. Humidification

In some cases, it is necessary to add moisture to the air to maintain product quality. This can be done using:

Steam Humidifiers: Introduce steam into the air.

Evaporative Humidifiers: Use a fan to blow air through a wet wick or filter.

3. Airflow and Ventilation

Proper airflow is vital to ensure even temperature and humidity distribution throughout the warehouse. Poor airflow can result in hot or cold spots, leading to uneven cooling or heating of products.

a. Air Circulation Systems

Air circulation systems ensure a constant flow of air throughout the warehouse. Components include:

Fans and Blowers: To circulate air and prevent stratification.

Ductwork: To direct airflow to specific areas.

b. Ventilation

Ventilation systems bring in fresh air from the outside to maintain air quality and remove excess heat, moisture, and contaminants. This can be achieved through:

Mechanical Ventilation: Using fans to force air exchange.

Natural Ventilation: Utilizing openings like vents and windows to facilitate air exchange.

4. Energy Efficiency

Operating a cold storage warehouse can be energy-intensive. Therefore, energy efficiency is a key consideration to reduce operating costs and environmental impact.

a. Energy-Efficient Equipment

Using energy-efficient equipment can significantly reduce energy consumption. This includes:

Variable Speed Drives (VSDs): For compressors and fans to adjust their speed based on demand.

Energy-Efficient Lighting: Such as LED lights, which produce less heat and use less electricity.

b. Renewable Energy Integration

Incorporating renewable energy sources, such as solar panels, can offset some of the energy consumption. Solar energy can be used to power lighting, cooling systems, and other electrical needs.

c. Insulation and Building Design

Cold Storage Warehousing PA services is building design and insulation can reduce the heat load on the refrigeration system. This includes:

High-Performance Insulation Materials: To minimize heat transfer.

Cool Roofing Materials: To reflect more sunlight and absorb less heat.

Strategic Building Orientation: To reduce direct sunlight exposure.

5. Safety and Compliance

Ensuring safety and compliance with regulatory standards is paramount in cold storage warehouses, particularly those storing food and pharmaceuticals.

a. Safety Measures

Emergency Power Systems: Such as backup generators to maintain refrigeration during power outages.

Fire Suppression Systems: Designed to operate in cold environments, like dry chemical or inert gas systems.

Pest Control: Measures to prevent infestations that can compromise product safety.

b. Compliance

Compliance with regulatory standards involves:

Regular Inspections and Audits: To ensure all systems are functioning correctly and meeting legal requirements.

Documentation and Record-Keeping: For traceability and accountability.

6. Automation and Smart Technology

Advancements in technology have led to increased automation and the use of smart systems in cold storage warehouses.

a. Automated Storage and Retrieval Systems (AS/RS)

These systems use robotic systems to automatically store and retrieve products, enhancing efficiency and reducing human error.

b. Internet of Things (IoT) and Smart Sensors

IoT devices and smart sensors provide real-time data on temperature, humidity, and equipment performance. This data can be used for:

Predictive Maintenance: Identifying potential issues before they result in equipment failure.

Optimizing Operations: Adjusting conditions based on real-time data to improve efficiency.

c. Remote Monitoring and Control

Remote monitoring and control systems allow managers to oversee and manage warehouse conditions from anywhere, improving response times and operational flexibility.

Conclusion

Cold storage warehouses rely on a combination of advanced refrigeration systems, precise temperature and humidity control, efficient airflow, energy-efficient technologies, stringent safety measures, and smart automation to preserve the quality of perishable goods. Understanding these mechanisms is essential for optimizing operations, reducing costs, and ensuring compliance with regulatory standards. As technology continues to advance, cold storage warehouses will become even more efficient and capable of meeting the growing demands of global supply chains.

0 notes

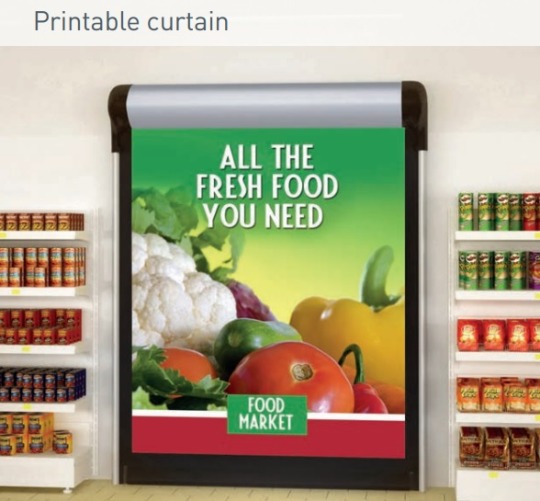

Photo

Ways to Ensure Clean and Controlled Door Access for Food Production in King of Prussia, PA

There is so much we can learn from Philadelphia’s success in the food production industry. Considering its achievements and attainments to be recognized such as:

· National leader in the importation of perishable goods

· Regionally it is one of the leading gateways for food products in the United States

· It has the largest contiguous refrigerated produce terminal in North America - Philadelphia Wholesale Produce Market

Strategic location, access to market, regional snapshots, talented workforce, innovation and entrepreneurship, and quality of life, that makes Philadelphia a haven for many who are in search of a clean and controlled door specifically in the food production business.

Whether you are finding a door for food industry application in Philadelphia, planning to invest in another high-performance roll-up door, or you want to upgrade all your roll-up doors to a more advanced state of the art high-performance roll-up door, then you are in the right place. But before we discuss high-performance roll-up doors, here is some basic overview of food production and high-performance roll-up doors.

What is food production?

Food production is a complex process of converting raw ingredients into prepared food products. Food production takes raw food products and transforms them into marketable food items which include different food industry sectors such as:

· Agriculture

· Foodservice

· Manufacturing

· Food processing

· Wholesale and food distribution

· Grocery, markets, and other retailing

· Research and development

Why is food production important?

Basically, as humans, we need to eat food. Without food, we die. We have long been challenged on how to process our food production in the most efficient way to sustain our most vital essential need.

For many thousands of years, where people collect their food from the wild to the present age of biotechnology with genetic manipulation of crops, humans have made rapid advancements in the food production industry.

Nowadays, modern, organized, and efficient food production is the backbone of population growth and the development of cities and towns, trade, and other essential elements of human progress. In short, without food production, our human existence would cease to exist.

Overhead Door Company of Philadelphia a division of DuraServ, its employees with over 40 years of experience represents some of the most knowledgeable people you’ll find in the loading dock and door industry offers one of their latest high performance roll-up commercial doors for the food production industry- Dynaco the Streamline model.

How to choose doors for the food processing business?

As compared to any ordinary door in the food production business, our top-notch high-quality doors have specific standards and specifications meeting certain hygiene and sanitation requirements ensuring optimum operating efficiency and performance.

Here are some of the key considerations in more detail:

1. High Protection Against Contaminants and Pests.

First, contamination from bacteria and other external elements are the top priorities in food processing facilities. To lessen bacterial contamination, it is important to have a seamless and impervious door that prevents germ build-up on cracks in the door's surface or any of its hard-to-clean gaps.

Secondly, door surfaces should be waterproof and smooth to allow easy cleaning and disinfection thoroughly and regularly.

Third, they should be durable enough to endure impact from traffic and vigorous cleaning procedures such as aggressive cleaning chemicals, very hot water, and steams.

Lastly, another important consideration is its temperature levels. Keeping the temperature levels balanced, and easy accessibility for goods and workers while minimizing air exchange should be implemented.

Doors should be automated and airtight offering a higher degree of air management to improve temperature control and reduce cross-contamination.

Our high performance doors Philadelphia service office offers our Dynaco the Streamline model, ‘The World's Slimmest Interior High Performance Door’, a high performance door for outstanding environmental control through the use of its state of the art technology. Designed for applications where cleanliness and/or aesthetics are critical features such as:

· Keep contaminants and airborne particles out-superior seal/full perimeter of the door

· Minimize open time: 120 in/s opening speed - 24 in/s closing speed

· Energy savings and limited air leakage- excellent seal and patented side guides

Ideally, best for applications like food processing, general warehousing, and refrigeration & cold storage where hygiene, cleanliness, and sanitation are top priorities.

2. Enhanced Safety and Productivity

Standardized door size for food production facilities should be installed to allow easy access to workers, vehicles, and equipment.

Fast doors or automatic doors can be beneficial for high traffic areas where food items and products are being transferred. They minimize exposure from dust, contamination, and draughts while also increasing production efficiency and saving energy costs. Additionally, automated doors help keeps the workers safe and prevents door damage due to collisions from vehicles or forklifts.

Our Dynaco Streamline model is designed to increase the safety and productivity of the workers:

· fast door: Opening Speed- 48 in/s and closing speed- 24 in/s

· built Standard Dimensions: 12′ W x 12′ H

· flexible curtain without rigid elements avoids injuries and damages

· wireless DYNACO detector with reversing edge on the bottom of the door

· built-in infrared sensors inside guide 12” from floor

· anti-roll off detector ensure proper closing

· no coil cords

3. Type of Materials

High performance and long-lifespan durability can be achieved by using the most ideal door materials.

FRP doors, use these types of materials: steel, laminate or glass-reinforced plastic (GRP), and timber.

GRP doors, provide high quality hygienic performance much better than its steel or timber counterparts.

The DYNACO Streamline high-performance door incorporates:

· smooth composite materials: virtually free of exposed fasteners

· side guides (outer) formed galvanized structural channels: 2 1/16”x 1 ½” x 1/8”

· curved composite drum cover and lateral side cover (standard type)

· inner side guides: extruded low friction polyethylene PE-UHMW 1000. 10” composite drive drum

4. Lifecycle Costs

Hygienically speaking, GRP doors are better valued as compared to their competitors.

Hygienic GRP doors are required to comply with all the latest manufacturing practice (GMP) requirements in the food industry. They should be designed and engineered to have seamless, smooth construction, making cleaning easy, convenient, and bacteria free.

Additionally, the GRP door surface and core should be water-resistant, warp rust, and rot free, when exposed to disinfectants. Doors should be flexible and can be supplied and installed with several options for automation, access control, and airtight sealing alternatives to suit each opening.

The Streamline model is hygienically engineered to perform seamlessly, totally clean-free, and with fully smooth construction:

· Side Guide: made of structural channels of 2 1/16″ x 1 1/2″ x 1/8″ in galvanized steel

· Inner Side Guide: polyethylene (PE-UHMW 1000); outer section 9/16” x 9/16”

· Side Guide Covers: composite

5. Aesthetically look and Unique Design

Attractive doors project company character and helps marketing strategies by promoting company products and its services. Besides, a good-looking door creates a positive ambient-working environment that increases employee productivity and saves a lot of money.

Additionally, Streamline’s sleek, attractive, and unobtrusive profile minimizes clearance and projection requirements at the same time simplifying cleaning procedures. Sharp angles and exposed fasteners are virtually eliminated:

· Door Curtain: reinforced PVC (27 oz/sq.yd)/Continuous Sealing Bead

· Design: flexible weighted soft bottom edge

· Colors: available in different colors

Let our Dynaco Streamline Philadelphia team of door specialists help you in choosing and making that decision with your high-speed and high-performance commercial doors for your food production facility in Philadelphia. We sell, design, install, and service everything we provide – and do it better than most. Our mission is “to be the most trusted sales and service distributor in our market” and we live by it!

At Overhead Door Company of Philadelphia, a division of DuraServ Corp, we are a division of the largest distributor in the world for the leading manufacturers of loading dock equipment and hi-speed doors:

· Most trusted in the Market

· Over 35 years of experience

· Fully trained and certified technicians

· One customer-one contact’ for all service needs

· 24/7/365 Availability

· Large Retails

To learn more about us, you may contact us at 215-352-4805, or through our website.

Contact High Speed Doors Team Philadelphia for your service requests, or visit us at our Service Areas: Philadelphia, Bensalem, Allentown, Reading, King of Prussia, Levittown, Langhorne, Doylestown, PA and surrounding cities in Pennsylvania.

0 notes

Text

TN Ward Company - Yards Brewing

Rendering credit: DIGSAU

Yards Brewing Company maintains its commitment to Philadelphia.

Yards Brewing Company is “Philadelphia’s Brewery.” So when owners Tom Kehoe and Trevor Prichett decided it was time to expand, they chose a new location in Philadelphia’s growing Northern Liberties section, even though Yards received lucrative offers to move outside the city. In the spirit of its “Brew Unto Others” philosophy, an approach established with the firm in 1994, Yards also insisted the new brewery be neighborhood and eco-friendly and involve the Philadelphia community. Green energy resources, self-contained and closed cycle systems and repurposed materials – such as bar tops made from old bowling alley wooden lanes – all would be integrated into the design and operations.

Yards chose the former Destination Maternity building, just 10 blocks from its existing facility, as its new home - knowing it would require architectural genius to transform the stark brick veneered steel structure into the sleek industrial look Kehoe and Prichett envisioned. Philadelphia based architect DIGSAU was chosen for the task. Bohler Engineering, Chestnut Engineering and Conn Shaffer Consulting were added to the design team to provide site/civil engineering, mechanical, electrical and plumbing engineering, and structural engineering, respectively.

Project Phases

A phased project was planned to maintain product availability, consistency and quality during the expansion. Phase 1 would entail designing, constructing and opening the new tasting and banquet rooms and kitchen; designing, constructing and commissioning the new brewery and packaging operations would be completed during Phase 2; and the existing brewery operations would be shut down, select brewing and packaging equipment would be moved to the new location, and the new and relocated operations would be integrated during Phase 3. Becker and Frondorf, a Philadelphia institution, was selected to facilitate all three phases and to represent the owner throughout the project.

Finally, TN Ward Company, headquartered in Ardmore, Pa., was chosen as the construction manager and general contractor for all three phases to complete the team. “With this project we were betting our future on the build out of the new brewery in Philadelphia, and needed a partner that had the scope of experience and local knowledge to execute a complex project, including a retail and manufacturing facility, in downtown Philadelphia,” Pritchett says. “TN Ward was that partner.”

TN Ward provided design assistance and pre-construction estimating throughout the design of the facility. The design process for the 70,000 square-foot facility began with the gathering of the design and construction team in late 2016. The age and high bay design of the destination building presented a challenge for the team.

“There wasn’t a lot of existing information for the building, and we had a very short time to design the Yards facility and get it commercially operational,” TN Ward Vice President John Marks says. “The design team was very supportive throughout the project.” Marks also credits Kehoe, Prichett and Head Brewer Tim Roberts for the project’s success. “They were heavily engaged in each step of the design and construction and made decisions quickly,” he adds.

The building’s exterior and interior are designed to have an industrial look while also being eye-catching. “With a unique entrance and outdoor seating area among the fermenting tanks, this is now not a bland building by any means,” Marks says. “DIGSAU did a remarkable job of capturing the essence of Philadelphia. The Philadelphia skyline lights up the background and the fermenting tanks are striking in the foreground as you approach the entrance.”

The interior design is equally impressive. Guests will have an up-close view of Yards’ operations. “When in the tasting or banquet rooms, patrons will be in a beer hall atmosphere but will also feel like they’re surrounded by the processing area. They will be able to view every part of the operation from brewing to packaging through large glass panels,” Marks adds. The high bay tasting room and mezzanine level banquet room, each with its own bar connected by a beer python to the brewery, are the primary features of the building fit out. A full service kitchen, designed and operated by renowned chef Jim Burke, is getting rave reviews. A lounge area, game room and retail product and merchandise areas fill the remainder of the public space.

TN Ward began construction of the $20 million facility in March 2017. The tasting room and banquet room opened to capacity crowds enjoying more than 20 brews on tap and a full lunch and dinner menu in November 2017. Offices, the laboratory and support areas also opened at the same time.

The building layout was used to its fullest extent to accommodate both the dry and wet process areas and cold storage warehousing found in a modern brewery. A new mill room, control room and mechanical and electrical support rooms were constructed. In addition, the building structure itself was modified. For example, grain feed and spent grain conveyors that span the roof required precise placement of supports in the light industrial building. Utility service pipe bridges required reinforcement of the building structure. After the slab on grade was reinforced to support the equipment and sloped to allow wet area drainage, the floor was coated with a specialty topping typical for breweries. The entire process area was redesigned to maintain cleanliness.

The fully automated and integrated brewery and bottling, canning and kegging lines are anticipated to be commissioned by February and start commercial production in March 2018, including all of the relocated equipment. The 100,000-barrel facility will more than double the existing facility capacity and is designed for future expansion as well. The brewery utilizes internationally proclaimed Ziemann Holvrieka and Alfa Laval-designed and furnished stainless steel process systems.

Overcoming Challenges

Installation of the equipment presented additional challenges to Yards and TN Ward.

“Given the orientation of the building relative to street access, limited laydown areas, ongoing construction of the tasting room, configuration of the equipment inside the building and size and weight of the equipment, the only practical way to rig the equipment was through a new full bay roof hatch,” Marks explains. “The largest piece weighs almost 100,000 pounds and is nearly as tall as the high bay. It had to be carefully skated in place between process and utility piping.”

Yards, Ziemann Holvrieka, Alfa Laval, TN Ward and TN Ward subcontractors pre-planned every step of the equipment delivery and installation so that equipment arrived from port and was set that day. Thousands of feet of stainless steel pipe and fittings and miles of power and control wiring interconnect the brewing equipment and the brewery with the packaging lines. Specialty stainless steel pipe welding techniques to produce a food-grade material distribution system were needed. “Many of the field welds were in tight spaces and were intricate in nature,” Marks says. “All of the welds were inspected visually by Ziemann Holvrieka, Alfa Laval and Roberts, and were tested by a third party firm. The quality of welds required and provided demonstrates the skill of the tradesmen we have in Philadelphia.”

Conversion of the documented control schemes from a European format to a US format was required. “Cooperation and communication between the electricians and the equipment supplier representatives was essential for installing the systems in an efficient manner,” Marks adds.

TN Ward subcontractors routinely suggested cost effective and time saving construction means and methods. “We appreciate the value our subcontractors added to the team,” Marks says. “Philadelphia’s Brewery was built in Philadelphia by tradesmen from Philadelphia, making this a true ‘Brew Unto Others’ success story.”

0 notes

Text

Lynca Meats: Leader in Pork

From its humble beginnings in 1988, Lynca Meats has grown to become one of the major contributors to the pork landscape in South Africa, processing over 230 000 pigs annually.

As South African as you can hope for with processed meat products being 100% manufactured in SA, at the heart of Lynca Meats is a passion to inspire people from all walks of life with industry innovation and world-class meat products. To underpin this passion and purpose and to always ensure consistent quality for peace of mind, Lynca Meats applies and is accredited by the highest quality management system worldwide, FSSC22000.

Food safety is an increasingly complex undertaking, and producing safe, high quality and nourishing food is fundamental to Lynca Meats’ very existence. All quality certifications, highlighting that Lynca Meats systems rate amongst the best in the world to ensure food safety and consistent quality, includes; Pork360 Abattoir Registration; SANS 10330: 2007 HACCP (SABS); PAS 220 (SABS); Woolworths Proof of Audits; Food Safety Assessment Audits and Export Status Certificate (ZA14).

Through its principal production facility, 20 minutes south of Johannesburg, situated outside Meyerton South Africa, Lynca Meats supplies frozen primal cuts to the food service, wholesale, butchery and retail industries and includes; Legs, Loins, Neck, Shoulder, Belly, Ribs and Trimmings. A dedicated department that focusses solely on short notice fit for purpose innovation, including primal cuts, ensures Lynca Meats consistently matches its customers’ and market needs.

An experienced management team with a proven track record has ensured that the complete service offering has continuously grown and evolved whilst always providing consistent quality and currently includes Carcasses, Primal Cuts, Offal, Contract Slaughter and Deboning Services and Processed Products (Bacon, hams, sausages, cooked marinated ribs, smoked products and many more). Lynca Meats has also recently commissioned a cold storage facility that provides it with the value-added service capability to offer multi-principle cold storage warehousing and logistical solutions to a range of clients.

Further information on Lynca Meats can be found by visiting their website at www.lyncameats.co.za, liking its Facebook page at www.facebook.com/LyncaMeats, or by simply phoning them at +27 016 360 4600.

#lynca meats#meat#pork#pigs#abattoir#factory#south africa#south african chefs association#sa chef#sa chef magazine#sa chef issue 4#red meat

0 notes