#Co2 and fiber laser

Explore tagged Tumblr posts

Text

S400 Laser Engraver

The flagship model for laser engraving solutions

40” X 24” X 11” extra large working area

140 IPS high speed DC servo motor for precise and rapid movement of the laser carriage

GCC SmartFLOW technology provides outstanding dust protection

GCC SmartLID invention makes maintenance a lot easier

Drag and engrave feature assures remarkably easy and fast set ups

Co2 and fiber laser options in one laser machine

0 notes

Link

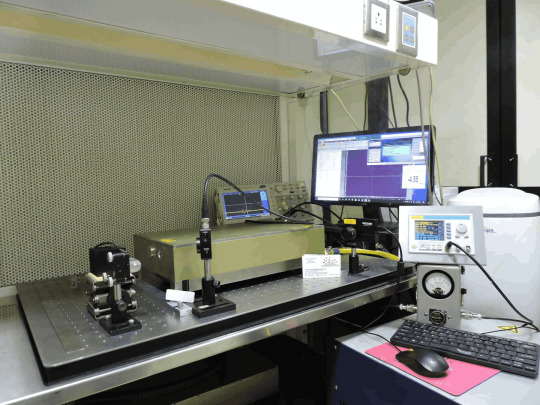

C. And C. Laser Engineering Pvt Ltd. is known for offering all kinds of industrial laser solutions and a range of Scientific and Industrial Laser Products and Services. This includes Industrial Products right from small components, and various spares of laser systems to the installation of complete laser workstations along with maintenance and servicing.

We provide laser workstations with or without material handling systems that are used for laser marking, laser engraving, deep engraving, laser welding, laser cutting, nanosecond micro-machining, and ultra-micro-machining.

We also offer laser-based solutions using Nano–Pico – Femtosecond, IR, Green, UV and DUV lasers.

We have more than 30 years of experience in the laser industry and with this vast experience and range of laser technology available, we are able to provide high-quality laser services and laser systems in the industry.

We provided lasers and services as well for our principal namely –

Control Laser Corporation,

Iradion MegaWatt Lasers QPC Lasers Amplitude Lasers (Continuum), PhotoScribe Uptek

The Scientific range of products from C. And C. Laser Engineering have various applications and some of them are LIDAR, Macromolecules research, Laser microprobes analysis, Fiber Bragg grating diagnostics, Laser-Induced Breakdown Spectroscopy (LIBS), laser flash photolysis, Synchronized pumping of other lasers, Interferometry, Biological imaging, Materials process research.

Our laser marking job work and laser engraving job work is acknowledged and appreciated for their precision, details, and uniformity on any metals and non-metals.

Our prime goal is to offer the best and excellent services and quality products to our customers and always put in our best efforts to achieve that objective.

#lasers#laser technology#laser applications#laser marking#laser welding#laser cutting#laser engraving#micromachining#lidar#iradion lasers#co2 lasers#fiber laser#uv laser#laser systems#laser machines

4 notes

·

View notes

Text

We are Direct Manufacturer & Supplier Of Fiber Laser Cutting Machines. Order Now . Email Us [email protected]

#Fiber Laser Cutting Machine#Laser Pipe Cutting Machine#Fiber Cutting Machine#Fiber Laser Cutter for Metal#Cnc Fiber Laser Cutting Machine Price#Fiber Optic Laser Cutting Machine#Co2 Fiber Laser#Fiber Laser Equipment#Fiber Laser Cutting Machine for Sale#Cnc Fiber Laser Cutting Machine

2 notes

·

View notes

Text

Fiber Laser Marking Machine:- There has been a sharp increase in demand for digital textile printer in UAE. To satisfy each customer's unique needs, Fortune Seven provides the whole line of industrial and commercial printing equipment. Our sales team is equipped to handle any kind of breakdown. https://fortune7.ae/product/fiber-laser-marking-machine/

0 notes

Text

Tech Marvels: Explore MadBytes' CNC Machinery Collection

In an era where precision, speed, and innovation reign supreme, the realm of manufacturing and fabrication has been significantly revolutionised by CNC (computer numerical control) machinery. MadBytes, a trailblazing technological hub, stands at the forefront of this revolution, offering an impressive collection of CNC routers and laser cutting machines. Among their standout offerings are the CNC Router Machine, Co2 Laser CNC Machine, and Fiber Laser Cutting Machine, each representing the pinnacle of technological advancement and efficiency.

The CNC Router Machine: Precision Redefined

MadBytes' CNC Router Machine embodies the epitome of precision and versatility in material cutting and carving. Crafted to cater to various industries, from woodworking to sign making and metalworking, this machine executes designs with unparalleled accuracy. Its computer-controlled system meticulously translates digital designs into tangible creations, ensuring consistency and intricate detailing. With MadBytes' CNC Router, artisans and industrialists alike can explore limitless possibilities, transforming raw materials into exquisite masterpieces with finesse.

Co2 Laser CNC Machine: Powering Creativity with Precision

For those seeking precision cutting and engraving capabilities, MadBytes' Co2 Laser CNC Machine stands as an unrivalled marvel. Harnessing the power of laser technology, this machine delivers immaculate cuts across various materials, including wood, acrylic, and even metal. The precision and speed offered by this cutting-edge device empower creators to fashion intricate designs and prototypes with remarkable intricacy and efficiency. From intricate filigree patterns to detailed engraving, the Co2 Laser CNC Machine is a beacon of innovation, elevating craftsmanship to unprecedented levels.

Fiber Laser Cutting Machine: Efficiency Redefined

MadBytes' Fiber Laser Cutting Machine represents the pinnacle of efficiency in industrial cutting. Designed to tackle diverse materials with unmatched precision, this machine utilises high-powered lasers to swiftly and accurately slice through metals, plastics, and composites. Its speed and precision make it an indispensable asset in industries demanding high-volume production without compromising on quality. The Fiber Laser Cutting Machine from MadBytes exemplifies the convergence of technology and productivity, setting new benchmarks in industrial manufacturing.

Why choose Madbytes Industry Pty Ltd?

Amidst a myriad of options, MadBytes emerges as a beacon of reliability and innovation in the realm of CNC machinery. Their commitment to technological excellence, coupled with a penchant for customer satisfaction, distinguishes them in the market. Offering a range of cutting-edge CNC solutions, MadBytes caters to the diverse needs of industries and individual creators alike. Moreover, their dedication to providing top-notch customer support and after-sales service ensures a seamless experience for every client, from procurement to operation.

Embracing the Future with Madbytes Industry Pty Ltd

As technology continues to evolve, MadBytes remains at the forefront, propelling industries and creative endeavours forward with its remarkable CNC machinery collection. Whether it's precision carving with the CNC Router Machine, intricate detailing with the Co2 Laser CNC Machine, or swift, high-volume production with the Fiber Laser Cutting Machine, MadBytes offers a gateway to unparalleled craftsmanship and industrial efficiency.

In conclusion, MadBytes' CNC machinery collection stands as a testament to the fusion of technology and innovation, enabling individuals and industries to embark on a journey of limitless possibilities. With their state-of-the-art equipment and unwavering commitment to excellence, MadBytes invites all enthusiasts and professionals to embrace the future of manufacturing and fabrication.

Visit https://madbytes.com.au/ today and witness the marvels of CNC technology redefining precision, creativity, and efficiency.

#CNC Router Machine#Co2 Laser CNC Machine#Fiber Laser Cutting Machine#CNC Machine Manufacturer#CNC Machine Suppliers

1 note

·

View note

Text

Fiber laser marking machine contact Grace Qian

This fiber laser cutter includes a 11×11 cm (4.3×4.3 inch) bed with a built-in workspace grid; the grid dots facilitate positioning bars that can be used to hold your material in just the right spot every time This laser cutting and engraving tool uses EzCad2 software compatible with Windows 7, 8 and 10 and a variety of graphic formats; red dot locator keeps focus fast and easy; scanner provides…

View On WordPress

0 notes

Text

What is the marking principle of fiber laser marking machine

The so-called fiber laser marking machine means that this marking machine uses a fiber laser generator. The fiber laser generator has the characteristics of small size (no water cooling device, using air cooling), good beam quality (basic mode), and maintenance-free. Now the fiber laser equipment can not only reduce the maintenance cost, but also greatly extend the service life, the marking effect is more fine and clear than the original. The application field of fiber laser marking machine is very wide,it can be applied to integrated circuit chips, computer accessories, industrial bearings, watches, electronics and communication products, aerospace devices, various auto parts, home appliances, hardware tools, molds, wires and cables, Marking of graphics and text in many fields such as food packaging, jewelry, tobacco and military affairs, etc.

Fiber laser equipment uses a high energy density laser beam to act on the surface of the processed product. Under the action of high energy, the marked surface quickly vaporizes or chemical reactions occur, thereby leaving traces on the product surface. The processed surface is not only smooth and natural, but also does not damage the material near the marked surface. Laser processing is different from traditional processing methods. Laser processing requires that the surface of the processed material itself can absorb the laser beam of this wavelength before it can be processed, but traditional processing does not have this requirement. However, laser processing does not require consumables and will not cause deformation of the product. The computer is used to control and operate flexibly during processing.

It is these excellent performances that make the application range of fiber laser equipment increasingly widespread, and have begun to replace traditional processing methods in many fields. Continuously improving and upgrading technologies are constantly striking the market occupied by traditional industries. In terms of price, the price of fiber laser marking machine is much more expensive than traditional equipment, but the excellent performance and lower maintenance cost have won the favor of many industries. Especially for marking materials with high hardness, high melting point and brittleness, it is more advantageous.

DOTSLASER is a highly integrated enterprise which specializes in laser products, laser cutting machine, laser engraving machine, laser welding machine, etc. Manufacturer and processing international sales and domestic sales. As a modernized enterprise with high technology and mature sales channel, we have solid financial base and great capability for production, research and development.

Our products include: laser cutting machine, laser marking machine, all kinds of laser parts, laser cleaning machine, laser welding machine and so on.

We have over 10 years of laser experience. Personalized products and services to provide customers with a significant advantage. Due to the high quality of our products and reliable performance, they are widely used in metal processing, electronics, hardware, model-making, clothing, advertising, printing and packaging, as well as more other industries. Visit our website for more details https://www.dotslaser.com

0 notes

Text

Our F-fiber laser cutting machines are equipped with advanced features such as high-precision cutting, high-speed cutting, and high-quality engraving, making it easy to achieve accurate and high-quality cuts on various metal materials.

#F-Fiber Laser Cutting Machine#wood cnc machine price#co2 laser machine price in india#Laser Cutting Machine Price in Delhi#CNC Machine Manufacturers#8x4 Laser Cutting Machine Price in India

1 note

·

View note

Video

youtube

Dotslaser galvo laser for bamboo engraving , US map

#youtube#WWW.DOTSLASER.COM#Are you Searching CO2 and Fiber Laser Engraving Marking Machine Manufacturer in China? Here we are! Leveraging on advanced laser equipment p

1 note

·

View note

Text

Laser Marking Solutions for the Energy Industry.

Looking for high-quality laser marking solutions for the energy industry? Look no further than our expert services! Our cutting-edge technology and experienced team ensure precise, efficient, and durable laser marking for all your energy industry needs. From pipes to turbines, we have the expertise to handle any project with speed and accuracy. Contact us today to learn more!

0 notes

Text

Engraved Hockey Puck

1 note

·

View note

Text

Effective Acne Scar Removal Treatment at Skin and Laser Clinic

Are you tired of dealing with stubborn acne scars that affect your confidence and overall appearance? At Skin and Laser Clinic, we offer advanced and professional acne scar removal treatments designed to rejuvenate your skin and restore its natural beauty.

Understanding Acne Scars

Acne scars result from the inflammation of acne blemishes. When the acne pore swells, a breakdown occurs in the wall of the pore. Some acne blemishes are small, and the scars created are shallow and heal quickly. However, sometimes the contents of blemishes spill into the surrounding tissue, causing deeper scars. Your skin forms new collagen fibers to repair these scars, but they may not look as smooth and flawless as the original skin.

Our Advanced Acne Scar Removal Treatments

At Skin and Laser Clinic, we utilize cutting-edge technology and innovative techniques to effectively reduce and remove acne scars. Our comprehensive range of treatments includes:

1. Laser Therapy: Laser treatments are one of the most effective methods for acne scar removal. The laser targets the scar tissue and stimulates the production of new, healthy skin cells. Our state-of-the-art laser systems, such as fractional CO2 lasers and erbium lasers, offer precision and excellent results with minimal downtime.

2. Microneedling: Microneedling involves using fine needles to create micro-injuries in the skin, stimulating the body’s natural healing process and collagen production. This treatment is highly effective in reducing the appearance of acne scars and improving skin texture.

3. Chemical Peels: Chemical peels involve applying a chemical solution to the skin, which exfoliates the top layer and promotes the growth of new skin. This treatment can help reduce the appearance of shallow acne scars and improve overall skin tone and texture.

4. Dermal Fillers: For deep, pitted scars, dermal fillers can be an excellent solution. Fillers are injected into the scars to raise the depressed areas, making them less noticeable and smoothing out the skin’s surface.

5. PRP Therapy: Platelet-Rich Plasma (PRP) therapy involves using a concentration of your own platelets to promote healing and rejuvenation. When applied to acne scars, PRP can accelerate the healing process and enhance the results of other treatments like microneedling.

Why Choose Skin and Laser Clinic?

1. Expertise and Experience: Our team of dermatologists and skincare specialists are highly trained and experienced in acne scar removal treatments. We customize each treatment plan to suit your specific skin type and scar severity.

2. State-of-the-Art Technology: We invest in the latest technology and equipment to provide the most effective and safest treatments for our clients.

3. Personalized Care: We understand that every individual’s skin is unique. Our personalized approach ensures that you receive the best possible care and achieve optimal results.

4. Comfortable Environment: Our clinic provides a welcoming and comfortable environment where you can relax and feel confident in the care you receive.

Book Your Consultation Today

Don’t let acne scars hold you back any longer. At Skin and Laser Clinic, we are dedicated to helping you achieve clear, smooth, and beautiful skin. Contact us today to schedule your consultation and learn more about our acne scar removal treatments.

Website: www.skinandlaserclinic.co.in

Call Us At: +91 81305 30591

Your journey to flawless skin starts here!

3 notes

·

View notes

Text

Shaping the Road Ahead: 30 kW Lasers in Automotive Innovation

In recent years, 30 kW fiber laser cutting machines have emerged as a revolutionary technology in the automotive manufacturing industry. These machines utilize advanced fiber laser technology to achieve high-power cutting capabilities, enabling precise and efficient fabrication of automotive components. The impact of these machines on the industry has been profound, leading to improved productivity, cost-saving benefits, and enhanced customization opportunities.

Understanding Fiber Laser Cutting Machines

Fiber laser cutting machines are state-of-the-art tools that use fiber lasers to cut through various materials, including metals, with remarkable precision. The core of these machines is the fiber laser source, which generates an intense laser beam guided through an optical fiber. This highly focused and coherent laser beam is then directed onto the material to be cut, melting and vaporizing it with exceptional accuracy.

Advantages of fiber laser cutting machines over traditional cutting methods are numerous. Firstly, they offer higher cutting speeds and increased productivity, making them ideal for mass production in the automotive industry. Secondly, fiber lasers consume significantly less energy compared to CO2 lasers, reducing operating costs and environmental impact. Additionally, these machines are known for their excellent beam quality, resulting in smooth, burr-free cuts and minimizing post-processing requirements.

The key components of a fiber laser cutting machine include the laser source, optical fiber, cutting head, and CNC (Computer Numerical Control) system. The CNC system allows for precise control of the cutting process, ensuring accurate and repeatable results. The machine's software plays a crucial role in generating cutting patterns and nesting layouts to optimize material usage and minimize waste.

Transformation

The adoption of 30 kW fiber laser cutting machines has brought about a transformative impact on automotive manufacturing processes. One of the most significant advantages is the improved precision and speed of cutting operations. These machines can cut complex shapes and intricate patterns with unparalleled accuracy, leading to tighter tolerances and higher quality components. The enhanced speed allows for faster production cycles, reducing lead times and increasing overall manufacturing efficiency.

Moreover, fiber laser cutting machines offer exceptional versatility, capable of cutting a wide range of materials used in automotive manufacturing. From steel and aluminum to composites and plastics, these machines can handle various automotive-grade materials with ease, expanding the possibilities for design and innovation.

youtube

Benefits for Automotive Manufacturers

The utilization of 30 kW fiber laser cutting machines provides several compelling benefits for automotive manufacturers. One of the most notable advantages is cost-saving. Due to their high cutting speeds and reduced energy consumption, these machines lead to lower production costs, making them cost-effective for large-scale manufacturing.

Furthermore, fiber laser cutting machines result in minimal material waste. Their precise cutting abilities allow for optimized nesting layouts, maximizing material utilization and minimizing scrap. This reduction in waste not only saves costs but also contributes to a more sustainable and environmentally-friendly manufacturing process.

Another advantage is the level of customization and flexibility these machines offer. With their ability to cut intricate shapes and patterns, automotive manufacturers can cater to customer demands more effectively. Additionally, the adaptability of these machines enables rapid prototyping and quick design iterations, accelerating the product development cycle.

Several leading automotive manufacturers have successfully implemented 30 kW fiber laser cutting machines in their production processes. Hyundai Motor Company for instance, increased their production output by 40% after integrating fiber laser cutting machines into their assembly line. This efficiency gain allowed them to meet rising market demands while maintaining high product quality.

Another example is Volkswagen Group, which achieved significant cost savings by minimizing material waste through precise cutting patterns generated by fiber laser cutting machines. This reduced their overall material expenses and made their operations more sustainable.

In conclusion, 30 kW fiber laser cutting machines have revolutionized automotive manufacturing, offering increased precision, speed, and material versatility. These machines are driving the industry towards enhanced productivity, cost-effectiveness, and customization opportunities, making them a pivotal technology for automotive manufacturers in the 21st century.

2 notes

·

View notes

Text

Laser Cutting Machine in Thane

In today’s world, businesses across various industries require highly precise cutting tools to create products that meet exacting standards. From intricate designs to industrial-grade cuts, laser cutting technology has revolutionized the way we work with materials like metal, wood, plastic, and more. At GK Laser Enterprises, we are proud to be your go-to provider for laser cutting machines in Thane, catering to a wide range of industries and applications.

This article will guide you through the benefits, applications, and reasons why GK Laser Enterprises is the trusted name for laser cutting solutions in Thane.

What is Laser Cutting?

Laser cutting is a technology that uses a high-powered laser beam to cut or engrave materials with exceptional precision. The laser beam melts, burns, or vaporizes the material to create clean, accurate edges. With computer-controlled operations, this technology ensures repeatability and perfection in every cut.

The technique is widely used in industries such as automotive, aerospace, electronics, signage, jewelry, and construction, making it indispensable for modern manufacturing.

Why Choose Laser Cutting Machines?

1. High Precision and Accuracy

Laser cutting machines offer unparalleled precision, capable of creating intricate designs and cuts that would be impossible with traditional tools. The accuracy ensures minimal wastage, saving both material and cost.

2. Versatility

From metals like stainless steel and aluminum to non-metals like acrylic and wood, laser cutting machines handle a wide variety of materials with ease. This versatility makes them suitable for diverse industries.

3. Efficiency

Laser cutting machines are faster than conventional cutting methods, enabling high-speed production. Automation further enhances efficiency, reducing labor costs and improving turnaround time.

4. Minimal Material Wastage

Laser cutting ensures clean edges with minimal burrs or debris. This precision reduces material waste, making it an environmentally friendly option for businesses.

5. Customization

Whether you need unique patterns for jewelry or precise cuts for industrial components, laser cutting allows for endless customization, adapting to any design requirement.

Applications of Laser Cutting Machine in Thane

As a bustling industrial and commercial hub, Thane is home to businesses that demand cutting-edge technology. At GK Laser Enterprises, we cater to a variety of industries, including:

1. Automotive Industry

Laser cutting is ideal for creating precise automotive components, such as gears, brackets, and panels. Its high precision ensures that parts fit perfectly, enhancing vehicle performance.

2. Architectural and Interior Design

From intricate metal screens to wooden panels, laser cutting machines enable designers to create stunning architectural and interior elements. The technology also supports custom signage and decorative pieces.

3. Jewelry and Art

For artisans and jewelers in Thane, laser cutting is a game-changer. It allows for delicate cuts and engravings on precious metals, ensuring unique and intricate designs.

4. Electronics

The electronics industry relies on laser cutting for creating intricate circuits and components. Its precision ensures that even the smallest parts are manufactured flawlessly.

5. Manufacturing and Engineering

In industrial manufacturing, laser cutting machines are indispensable for creating machine parts, prototypes, and other components with exact specifications.

Why Choose GK Laser Enterprises in Thane?

At GK Laser Enterprises, we bring years of expertise and a commitment to delivering the best laser cutting machines to businesses in Thane. Here’s what sets us apart:

1. Wide Range of Machines

We offer a comprehensive range of laser cutting machines, including CO2 lasers, fiber lasers, and hybrid systems. Whether you need a compact machine for small-scale projects or a high-capacity system for industrial use, we have you covered.

2. Quality Assurance

Our laser cutting machines are sourced from leading manufacturers, ensuring durability, reliability, and top-notch performance. Each machine undergoes rigorous testing to meet global standards.

3. Customization and Support

We understand that every business has unique needs. That’s why we provide tailored solutions to match your specific requirements. Our team also offers installation, training, and ongoing technical support to ensure seamless operation.

4. Competitive Pricing

At GK Laser Enterprises, we believe that cutting-edge technology should be accessible to all businesses. Our laser cutting machines are competitively priced, offering excellent value for money.

5. Local Expertise

As a Thane-based business, we understand the local market and are committed to helping businesses in our community thrive. We’re just a call away for consultations, demonstrations, and support.

Advantages of Partnering with GK Laser Enterprises

Comprehensive Training We provide training to help your team maximize the potential of your laser cutting machine.

After-Sales Support Our dedicated customer service team ensures that your operations run smoothly with minimal downtime.

Upgrades and Maintenance Stay ahead with the latest technology. We offer upgrades and maintenance services to keep your machine in top condition.

Custom Solutions From bespoke machine configurations to specialized cutting needs, we deliver solutions tailored to your business.

Testimonials from Our Clients

“Our experience with GK Laser Enterprises has been exceptional. Their laser cutting machine has transformed our production process, saving us time and costs. The team’s support and expertise made the transition seamless.” – Ramesh Gupta, Automotive Parts Manufacturer

“Thanks to GK Laser Enterprises, we’ve been able to offer custom metal designs that have delighted our customers. Their machine’s precision is unmatched.” – Sneha Patel, Interior Designer

Contact GK Laser Enterprises Today

If you’re looking for laser cutting machines in Thane, look no further than GK Laser Enterprises. Our cutting-edge technology, exceptional customer service, and competitive pricing make us the ideal partner for your business.

Get in touch with us today to learn more about our laser cutting solutions and how they can benefit your business. Whether you’re starting a new venture or upgrading your existing setup, GK Laser Enterprises is here to support your growth.

0 notes

Text

Choose CO2 laser marking machine or fiber laser marking machine?

Regarding co2 laser marking machine and fiber laser marking machine, which is better? First of all, this should be determined according to the materials and customer needs. Some materials are suitable for CO2 carbon dioxide laser marking machines, some materials are suitable for fiber laser marking machines, and some are general-purpose laser marking machines. Although the application range of fiber laser marking machine is wide, the materials used for co2 laser marking machine are not necessarily suitable for fiber laser marking machine, and each has its advantages and disadvantages.

What are the differences between CO2 laser marking machine and fiber laser marking machine?

The carbon dioxide laser marking machine is mainly for marking non-metallic materials, such as plastic, glass, etc., but after a period of use, it needs to be filled (carbon dioxide). The fiber laser marking machine can mark metal and non-metal materials. Simply put, it combines the functions of a carbon dioxide laser marking machine and a semiconductor laser marking machine, and the speed is more than 3 times that of a semiconductor, and there is no need to change parts for 100,000 hours. , High-power, high-brightness, high-precision, is currently more advanced laser marking equipment.

Performance characteristics of CO2 laser marking machine:

1. The marking accuracy is high, the speed is fast, and the engraving depth can be controlled at will;

2. The laser power is large and can be used for engraving and cutting a variety of non-metal products;

3. No consumables, low processing cost, laser operating life up to 20,000 to 30,000 hours;

4. Clear marking, not easy to wear, fast engraving and cutting efficiency, environmental protection and energy saving;

5. Use the 10.64nm laser beam to expand, focus, and finally control the deflection of the galvanometer;

6. Act on the work surface according to the predetermined trajectory to vaporize the work surface to achieve the marking effect;

7. Good beam pattern, stable system performance, low maintenance, suitable for industrial processing sites with large batches, multiple varieties, high speed and high precision continuous production;

8. The most advanced optical path optimization design and unique graphics path optimization technology, coupled with the unique super pulse function of the laser, make the cutting speed faster.

Industry application and applicable materials of CO2 laser marking machine:

Suitable for paper, leather, cloth, plexiglass, epoxy resin, woolen products, plastics, ceramics, crystal, jade, bamboo and wood products. It is widely used in all kinds of consumer goods, food packaging, beverage packaging, pharmaceutical packaging, architectural ceramics, clothing accessories, leather, textile cutting, craft gifts, rubber products, shell brands, denim, furniture and other industries.

Performance of fiber laser marking machine:

1. The marking software is very powerful, compatible with application software such as Coreldraw, AutoCAD, Photoshop, etc.; supports PLT, PCX, DXF, BMP, etc., and can use SHX and TTF fonts; supports automatic encoding, printing serial numbers, batch numbers, dates, bar codes , QR code, automatic number skipping, etc.;

2. Adopt an integrated structure, equipped with an automatic focusing system, and the operation process is humanized;

3. Use the original imported isolator to protect the fiber laser window, increase the stability and laser life;

4. No maintenance required, long service life, small size, suitable for working in harsh environments;

5. The processing speed is fast, 2-3 times of the traditional marking machine;

6. The electro-optical conversion rate is high, the power consumption of the whole machine is less than 500W, which is 1/10 of the lamp pumped solid laser marking machine, which greatly saves energy consumption;

7. The beam quality is much better than the traditional solid laser marking machine. It is the basic mode, TEM00, and the output focused spot diameter is less than 20um. The divergence angle is 1/4 of the semiconductor pump laser. Especially suitable for fine and close marking.

Applicable materials used in fiber laser marking machine industry:

Metal and various non-metal materials, high-hardness alloys, oxides, electroplating, coating, ABS, epoxy resin, ink, engineering plastics, etc. Widely used in plastic translucent buttons, ic chips, digital product components, compact machinery, jewelry, sanitary ware, measuring tools, clocks and glasses, electrical appliances, electronic components, hardware accessories, hardware tools, mobile phone communication components, automobile and motorcycle accessories, Plastic products, medical equipment, building materials, pipes and other industries.

DOTSLASER has 10 years experience in industrial laser equipment, we are a professional laser equipment production base, all equipment are researched,developed,assembled by ourselves.Our products mainly include fiber laser cutting machine, fiber laser marking machine, fiber laser welding machine, UV laser marking machine, CO2 laser marking machine, CO2 laser cutting machine, etc.

#Fiber Laser Marking Machine Manufacturer China#CO2 Laser Marking Machine Manufacturer China#Fiber Laser Engraving Machine Manufacturer China

0 notes

Text

How Effective are Laser Treatments for Acne Scars? All you need to know

Are you tired of dealing with stubborn acne? Are you thinking of going the laser way?

Well, acne scars may be a sign of past skin problems, but thanks to the recent advancements in dermatology, people can now achieve clear skin. For all those looking for a safe and effective solution, laser treatment is one of the best procedures you can opt for your scar removal. Further in this blog, we’ll be discussing how laser acne scar treatment can change your skin for the better and why it is necessary to choose the right acne scar treatment clinic in Delhi. Read on!

What is Laser Acne Scar Treatment?

Laser acne scar treatment is one treatment technique that is widely used in the treatment of scars that are a result of acne. This skin treatment is non-surgical and employs the use of a laser to promote the production of collagen and improve the skin texture. Lasers work by targeting the outer skin layer as well as deeper skin tissues to minimize the appearance of scars gradually.

How Does It Work?

Laser treatments involve the use of light energy on the scarred skin tissues of the patients. This energy is used to heat the skin and stimulate the formation of new collagen and elastin dermal fibers which are vital for young skin. There are several types of laser treatments available, each designed to target different types of acne scars. Read more to find out!

Fractional Laser Therapy: This technique uses a laser to create tiny columns of heat in the skin, encouraging the body's natural healing process and collagen production.

CO2 Laser Resurfacing: Known for its precision, this laser targets the upper layers of the skin to remove damaged tissue and stimulate new, healthy skin growth.

Erbium Laser: Ideal for treating more superficial scars, this laser focuses on the outer layers of the skin to improve texture and tone.

Why Choose a Specialized Clinic like SkinQure In Delhi?

It is important to choose the best acne scar treatment clinic in Delhi to get the best results. Any clinic where you are going to receive your treatment should be staffed with well-experienced professionals and the best equipment to help you get the right treatment that is safe. When evaluating clinics, consider the following factors before making the final decesion.

Expertise of Practitioners: You need to search for clinics that have experienced dermatologists or cosmetic surgeons in treating acne scars.

Technology and Equipment: Make sure that the clinic adopts the best laser technology in surgeries for the best results.

Patient Reviews and Testimonials: Check online ratings and comments from other patients to see what kind of treatment they got in that hospital.

What are the Benefits of Laser Acne Scar Treatment?

Laser acne scar treatment offers several advantages, making it a preferred choice for many seeking to improve their skin’s appearance. Read on!

It is non-invasive: In contrast to the operations, the laser procedures do not involve incisions, and therefore the recovery time is short.

Effective for Various Scar Types: Lasers can be used to treat a variety of scars such as ice pick, box scar, and rolling scars.

Long-Lasting Results: For patients with multiple sessions, there can be many enhancements of scar characteristics for many years.

Customizable Treatment Plans: Some of the advantages include the fact that dermatologist can easily prescribe remedies for the various types of scars depending on their severity.

What to Expect During and After Treatment?

Before undergoing laser acne scar treatment, a detailed consultation with a dermatologist is essential. During this consultation, he will assess your skin and a treatment plan will be created based on your specific requirements.

During the Procedure: The treatment typically involves minimal discomfort, and most patients describe it as tolerable. A cooling device or topical anesthetic may be used to enhance comfort.

Post-Treatment Care: Your skin may also look red and feel warm as if you have had a mild sunburn after the procedure. The use of gentle skin products and also applying sunscreen on the newly treated skin is important as recommended by the physician.

Why Choose Acne Scar Treatment in Delhi?

Delhi is one of the best places to get treatment for acne scars as there are clinics that offer laser treatment for different skin complications and scars. Choosing a clinic for acne scar treatment in Delhi is advantageous since you will have access to the best facilities and personnel. Several clinics in Delhi offer high-quality treatment for acne scars, with an emphasis on patient satisfaction and the use of the latest technologies.

How to find the right acne scar treatment clinic in Delhi?

When selecting the right clinic, consider the clinics that are recommended by most patients and have positive reviews with successful treatment of acne scars. Consult with as many clinics as possible before making a descion, consider the plans offered by them, and make sure that you are okay with the surroundings of the clinic.

Conclusion

Laser acne scar treatment therefore holds great potential for anyone who wants to attain a better look for their scarred skin. This treatment is highly effective in targeting and minimizing the appearance of scars and its benefits can be enjoyed in the long run with little to no recovery time. Selecting a good acne scar treatment clinic in Delhi will help you get the best treatment and the transformation you deserve.

So, if you're considering laser acne scar treatment, explore the top acne scar treatment clinics in Delhi and take the first step towards clearer, smoother skin. Visit SkinQure Clinics today for a customized treatment plan!

0 notes