#wood cnc machine price

Explore tagged Tumblr posts

Text

https://aaradhanatech.com/product/fiber-welding-machine/

Get your hands on the ultimate Fiber Welding Machine, designed to provide precision and efficiency in welding and cutting applications.

#wood cnc machine price#co2 laser machine price in india#cnc router machine price#cnc wood carving machine price in india

0 notes

Text

Best CNC laser cutting services providers in Manesar

CNC laser cutting services refer to the professional cutting services provided by companies equipped with CNC (Computer Numerical Control) laser cutting machines. These services offer precise and efficient cutting of various materials using laser technology.

Here are some key aspects of CNC laser cutting services:

Material Versatility: CNC laser cutting services can handle a wide range of materials, including metals (such as steel, stainless steel, aluminum, brass, copper), plastics, acrylics, wood, fabric, leather, and more. Different types and thicknesses of materials can be accommodated.

Precision and Accuracy: CNC laser cutting machines are known for their high precision and accuracy. They can create intricate and detailed cuts with tight tolerances, allowing for complex shapes and designs. The use of computer-controlled systems ensures consistency and repeatability in the cutting process.

Speed and Efficiency: Laser cutting is a fast and efficient cutting method. CNC laser cutting machines can rapidly cut through materials, reducing production time and increasing productivity. The automation capabilities of these machines enable high-speed cutting while maintaining accuracy.

Customization and Flexibility: CNC laser cutting services offer customization options to meet specific client requirements. They can work with designs provided by clients or assist in creating custom designs. This flexibility allows for the production of unique and tailored products.

Minimal Material Waste: CNC laser cutting machines have narrow kerf widths, resulting in minimal material waste. The precise cuts and tight nesting of parts optimize material utilization, reducing costs and minimizing environmental impact.

Prototyping and Production: CNC laser cutting services cater to both prototyping and large-scale production needs. Whether you need a single prototype or a large batch of parts, these services can accommodate varying order sizes.

Additional Services: Some CNC laser cutting service providers offer additional services such as design assistance, material sourcing, finishing (deburring, polishing), and assembly. This can provide a comprehensive solution for your cutting and fabrication needs.

When looking for CNC laser cutting services, consider factors such as the company's experience, expertise, equipment capabilities, turnaround time, pricing, and customer reviews. It's important to communicate your specific project requirements and ensure that the service provider can deliver the desired results.

4 notes

·

View notes

Text

The boss’s latest business destroying idea; replacing the stocks and blowpipes on the blackwood sets with plastic ones so that only the fringe bodies and tops are made of wood. He said he��s doing this to save him work at the factory... the factory where everything’s done by CNC machine and all he needs to do is hit the run button.

Since making this the standard he’s already had one trade order cancelled over it because when people buy a blackwood instrument they want a complete instrument in blackwood. He’s even put the price way up because the manager suggested doing that instead of making this Black and Tan monstrosity of an instrument... so the boss has just done both?

Every American who comes into the shop to buy only wants blackwood, and pretty much turns around and walks back out when all we have is full delryn sets.

He’s even tried this before and it failed! Apparently a few years ago he made “less than ten” sets like this and it took nearly a year before they were all sold.

He’s doing this again after but making any widen wooden sets at all for months because he couldn’t be bothered.

How in the fuck is this place still in business?!

4 notes

·

View notes

Text

CNC Laser Cutting Machine Manufacturers

Fine Cutting Solution is the top CNC Laser Cutting Machine Manufacturers in India. It has Omni Mat Combo, Omni Mat Fiber, Fiber Blade V and Swift Blade. CNC Laser Cutting Machine Manufacturers. We offer CNC Laser Cutting Machines Manufacturer at the best price. We offer precision-engineered machines suitable for intricate designs like gates and tubes. This is what motivates our nearly 700 experienced employees in 4 main locations with production sites every day. Altogether, we are active in all over India. Whether you need a CNC laser cutting machine for wood or a small-sized laser cutting machine, we have the perfect fit. Explore the best CNC laser cutting machines in India, including fiber and gold laser models. For businesses, our CNC laser cutting services near me and affordable price list in India ensure top-quality and cost-effective solutions. Contact us today!

Website: https://finecuttingsolution.in/cnc-laser-cutting-machine-manufacturers/

#CNC Laser Cutting#Laser Cutting Machine#CNC Laser Cutting Machine#Laser Cutting Machine Manufacturers#CNC Laser Cutting Machine Manufacturers#CNC Laser Cutting Machine supplier#CNC Laser Cutting Machine Manufacturers in India

0 notes

Text

A step-by-step Guide on Buying Second-hand milling Machines for Sale

Milling is the process of machining by forming and cutting, drilling all kinds of materials with greater accuracy and milling machines are essential in manufacturing. Getting the whole setup can be massive, especially for those running on smaller and moderate capacity levels. That is why the used milling machines market in sales presents well since they carry only top-of-the-line models for nearly a penny at times. If you want to extend your workshop or wish to replace some aged machinery and you don’t want to invest much in the process; then definitely used milling machines for sale will be appropriate for you.

While buying, you may have doubts about what to look out for and how to identify whether the used machinery is good for you in the long run or not. If you want the answers to your questions this post is the ultimate guide on milling machines.

The milling machine

A milling machine is a versatile tool used in the cutting and shaping of material, be it metal, wood, or plastic. Rotary cutters give manufacturers the capability to draw out material from a workpiece to obtain certain shapes, slots, and holes. This type of machine is used at massive levels in aerospace, automotive, or small hobby workshops.

Types of Milling Machines

Before you go out looking for used milling machines for sale, it will be helpful first to know the types of milling machines so that you do not buy the wrong one for your work:

Vertical Milling Machines: The spindle axis in this machine is vertical and it is best suited for jobs requiring precision, such as die-sinking and mold-making.

Horizontal milling machine: The machine is mounted horizontally. This is excellent for heavy-duty operation and cuts large workpieces.

CNC Milling Machines: Computer numerically controlled milling machine uses computer-controlled millings and is very précised. It is perfect for mass production and complicated designs.

Hand Milling Machines: These are hand-operated, flexible, and under the owner's control. They can be used in small shops or for simpler applications

Multi-Purpose Milling Machines: These machines are a combination of vertical and horizontal machining operations. They are flexible and applicable to a wide variety of applications.

Benefits of Buying Used Milling Machines

For price-sensitive buyers, the advantages of buying a used milling machine are many:

Cost-Effective: Used machines are relatively cheaper compared to the new ones, and you can save money elsewhere.

Performance: Most of the used milling machines are kept well and outperform the newer ones.

Fast Return on Investment: Since the price is cheaper, you will receive a quick return on your investment.

More Choice: There is a vast market for used machinery in the markets today. With numerous models and brands, you get a vast choice to pick the most suitable machinery under budget.

Environment Friendly: The acquisition of second-hand machinery reduces waste and promotes sustainability due to extending the lifespan of industrial equipment.

Things to look for when buying used milling machines

Several things must be checked when buying used milling machines for sale

to ensure that an investment worth making is made:

Machine Condition: Check the machine for signs of wear and tear.

Check for signs of rust, damage, or excessive use.

Brand Reputation: Select quality brands that have a reputation for dependability and performance.

Age and Usage History: The age of the machine as well as the amount of usage of that particular machine.

Spindle and Motor Health: Check the spindle for good running, and check the motor for balanced power.

Capabilities and Features: The machine must be of a specific specification that suits your work; it may be for spindle speed, table size, or cutting capacity.

Availability of Spare Parts: Replace and assure that replacement parts are in readily supply.

Service Records: Get maintenance logs to know how well the machine has been cared for.

Compare Price: Compare prices across different sellers to ensure you’re getting a fair deal.

Warranty or Support: Some of the used machines are under warranty or supported by the seller. Buying such machinery ensures the durability of the machines.

Consult A Professional

If in doubt, call a professional to check the condition of your milling machine.

MachineSpotter.com has been an excellent resource when it comes to searching for quality second-hand milling machines for sale. Here, you'll find the best way to upgrade your workshop without compromising on quality with used milling machines for sale. Additionally, you will come across reliable, high-performance equipment meeting specific needs. A used milling machine is a good option for business if properly evaluated and maintained, which will give years of exceptional value and productivity. Begin researching these options today, taking your steps toward optimization of the machining process!

#used milling machine#hand laser cutting machine#used milling machines for sale#cnc mill for sale#used cnc mill

0 notes

Text

CO2 Metal and Non-Metal Laser Machine in Madhya Pradesh

Success Technologies is a trusted Manufacturer, Exporter, and Supplier of CO2 Metal and Non-Metal Laser Machines in Madhya Pradesh. Our manufacturing unit is located in Ahmedabad, Gujarat, India. Success Technologies is dedicated to empowering businesses with state-of-the-art equipment, providing the tools necessary for success in today's competitive market. Over time, Success Technologies has earned a reputation for its unwavering commitment to quality, precision, and innovation. We offer an extensive selection of industrial machines, from mini tabletop CNC routers to advanced vacuum forming machines, designed to meet the specific needs of various industries. Our products are engineered to deliver the highest levels of precision, efficiency, and reliability across a range of industries. Features of Our CO2 Metal and Non-Metal Laser Machines: High-Speed Engraving and Cutting: Achieve fast and precise results, even with complex designs. Long-Lasting Performance: Built with high-quality components for durability and a longer machine life. Automatic Focus: The machine automatically adjusts to different materials for optimal cutting or engraving. Versatile Materials: Cut or engrave a wide range of materials, including metal, acrylic, wood, leather, fabric, and more. Advanced Control System: Offers precise control over speed, power, and direction for a variety of applications. Low Maintenance: The design requires minimal maintenance and ensures easy servicing to minimize downtime. Applications of CO2 Metal and Non-Metal Laser Machines: Metal Engraving and Cutting Wood and Acrylic Cutting Leather and Fabric Engraving Plastic and Rubber Marking Advertising and Signage CNC Router Machine What materials can CO2 Laser Machines cut and engrave? CO2 laser machines are highly versatile and can cut and engrave both metal and non-metal materials, including stainless steel, aluminum, acrylic, wood, leather, plastic, and fabric. Are Success Technologies' laser machines easy to operate? Yes, our CO2 laser machines feature an easy-to-use interface with intuitive software, making them simple to operate for both beginners and experienced users. What industries benefit from CO2 Metal and Non-Metal Laser Machines? Various industries, including manufacturing, advertising, automotive, textiles, jewelry, architecture, and sign-making, widely use these laser machines. Do you offer after-sales service for your laser machines? Yes, Success Technologies offers full after-sales support, including installation, training, and ongoing maintenance to ensure that your CO2 laser machine operates efficiently. Success Technologies is a Supplier of CO2 Metal and Non-Metal Laser Machines in Madhya Pradesh, including locations: Indore, Bhopal, Jabalpur, Gwalior, Ujjain, Sagar, Dewas, Satna, Ratlam, Rewa, Katni, Singrauli, Burhanpur, Khandwa, Bhind, Chhindwara, Guna, Shivpuri, Vidisha, Chhatarpur, Damoh, Mandsaur, Khargone, Neemuch, Pithampur, Narmadapuram, Itarsi, Sehore, Morena, Betul, Seoni, Datia, Nagda, Dindori. Contact us today for more information, pricing, and availability. View Product: Click Here Read the full article

0 notes

Text

CNC Router Machine Suppliers in Mumbai

In today’s fast-paced world of manufacturing, the demand for precision, efficiency, and advanced technology has skyrocketed. CNC (Computer Numerical Control) router machines are at the forefront of this technological evolution, playing a crucial role in industries like furniture manufacturing, signage, automotive, aerospace, and more. If you’re in Mumbai and looking for reliable CNC router machine suppliers, GK Laser Enterprises stands out as a trusted name in the industry.

Why Choose CNC Router Machines?

CNC router machines offer unmatched precision and automation, making them an essential tool for manufacturers. These machines are designed to cut, carve, and engrave a wide range of materials, including wood, acrylic, aluminum, plastic, and even composites. Their key benefits include:

High Precision: With computer-controlled operations, CNC routers deliver consistent, accurate cuts every time.

Cost Efficiency: Reduce material wastage and labor costs through automated processes.

Versatility: Handle various materials and projects, from intricate designs to large-scale productions.

Speed: High-speed operations ensure faster project completion, meeting tight deadlines.

Ease of Use: User-friendly interfaces make these machines accessible to operators of all skill levels.

About GK Laser Enterprises

Based in Mumbai, GK Laser Enterprises is a leading supplier of CNC router machines, offering high-quality products and exceptional customer service. With a strong commitment to innovation and client satisfaction, we cater to businesses of all sizes, from small workshops to large-scale manufacturing units.

Our portfolio includes a diverse range of CNC router machines tailored to meet specific industry needs. We focus on delivering cutting-edge technology that enhances productivity while maintaining cost-efficiency for our clients.

Key Features of Our CNC Router Machines

At GK Laser Enterprises, we pride ourselves on providing CNC router machines equipped with the latest advancements. Here are some key features that set our products apart:

Robust Build Quality: Built with durable materials to ensure longevity and performance.

Advanced Control Systems: User-friendly interfaces with high-performance controllers for precise operations.

Customizable Options: Machines can be tailored to meet specific operational requirements.

High-Speed Spindles: Capable of handling both soft and hard materials with ease.

Safety Features: Integrated systems for operator safety and machine reliability.

Low Maintenance: Designed for minimal downtime and easy maintenance.

Industries We Serve

CNC router machines from GK Laser Enterprises are versatile and can be applied across various industries, including:

Furniture Manufacturing: Create intricate woodwork designs with precision.

Signage and Advertising: Cut and engrave acrylics, plastics, and metals for high-quality signage.

Automotive: Design and fabricate parts with accuracy.

Aerospace: Ensure precision in manufacturing components for aircraft.

Education: Equip institutions with CNC routers for technical training and prototyping.

Why GK Laser Enterprises?

Choosing the right supplier is crucial when investing in CNC router machines. GK Laser Enterprises stands out for several reasons:

Quality Assurance: We offer only the best-in-class machines sourced from reputed manufacturers.

Expert Consultation: Our team of experts guides you in selecting the right machine based on your business needs.

Competitive Pricing: Get the best value for your investment with affordable pricing.

After-Sales Support: We provide comprehensive maintenance and support to ensure your machine operates seamlessly.

Training and Installation: We assist with on-site installation and operator training for a smooth transition.

Our Product Range

GK Laser Enterprises offers a wide range of CNC router machines to meet diverse manufacturing requirements:

3-Axis CNC Routers: Perfect for basic cutting and engraving tasks.

4-Axis CNC Routers: Ideal for intricate designs and complex shapes.

5-Axis CNC Routers: Best suited for advanced machining and multi-dimensional operations.

Custom CNC Routers: Tailored to your unique specifications for maximum efficiency.

Customer Success Stories

We have served numerous clients in Mumbai and beyond, helping them elevate their production capabilities. Here are a few success stories:

A leading signage company streamlined its production line using our high-speed CNC router, reducing turnaround time by 40%.

A furniture manufacturer in Mumbai leveraged our 4-axis CNC router to produce intricate designs, gaining a competitive edge in the market.

An educational institution integrated our CNC router into their curriculum, providing students hands-on experience with industry-grade machinery.

How to Choose the Right CNC Router Machine

When investing in a CNC router machine, consider the following factors:

Material Compatibility: Ensure the machine can handle the materials you work with.

Size and Work Area: Choose a machine with a work area suitable for your projects.

Power and Speed: Opt for a machine that balances power with efficiency.

Software Compatibility: Check for compatibility with your existing design software.

Budget: Consider the total cost, including installation, maintenance, and training.

Our Commitment to Sustainability

At GK Laser Enterprises, we are committed to sustainability. Our CNC router machines are designed to minimize material wastage, reduce energy consumption, and support eco-friendly manufacturing processes.

Contact GK Laser Enterprises Today!

If you’re looking for CNC router machine suppliers in Mumbai, look no further than GK Laser Enterprises. We are dedicated to providing top-quality machines, unmatched service, and ongoing support to help your business thrive.

Get in touch with us today to explore our range of CNC router machines and discover how we can transform your manufacturing process. Call us at [Your Contact Number] or email us at [Your Email Address]. Visit our website [Your Website URL] for more information.

Transform your business with cutting-edge CNC technology from GK Laser Enterprises!

0 notes

Text

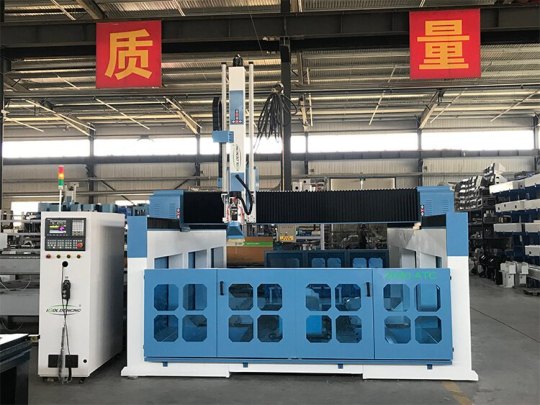

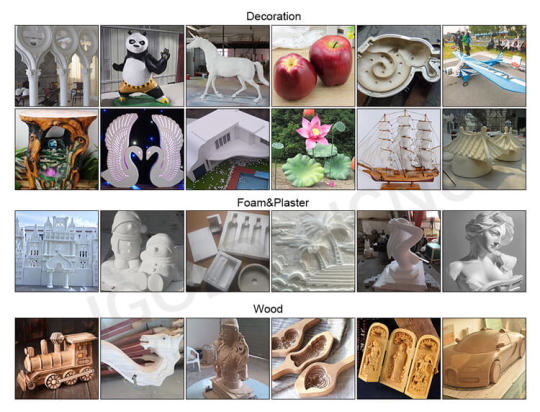

Get Accurate 5 Axis CNC Router Quotes for Your Business Needs

https://www.igoldencncrouter.com/get-accurate-5-axis-cnc-router-quotes-for-your-business-needs/ When it comes to investing in a 5-axis CNC router for your business, obtaining accurate and detailed quotes is crucial to making an informed decision. Whether you're in the stone, metal, woodworking, or aerospace industry, a 5-axis CNC router can offer your business unparalleled precision, versatility, and efficiency. However, with many factors influencing the final price, it’s important to understand the various components that make up a comprehensive quote.

In this article, we’ll walk you through the process of obtaining accurate 5-axis CNC router quotes, including factors that affect cost, common pricing structures, and how to ensure you’re getting the best value for your investment.

Why Are 5-Axis CNC Routers Essential for Business?

Industries that benefit from 5-axis CNC routers include:

Woodworking: Creating custom furniture, carvings, and decorative elements.

Metalworking: Manufacturing aerospace components, molds, and parts for automotive industries.

Signage and Art: Detailed carvings, custom signs, and artistic sculptures.

Prototyping and Product Development: Designing and manufacturing complex prototypes for various industries.

Key Factors That Affect 5 Axis CNC Router Machining

When requesting a quote for a 5-axis CNC router, there are several important factors that will determine the overall cost. Understanding these elements helps ensure you get an accurate quote tailored to your needs.

1. Machine Specifications

The specifications of the 5-axis CNC router play a large role in determining its price. The more advanced the machine’s capabilities, the higher the cost. Key specifications to consider include:

Worktable Size: A larger working area provides more flexibility for large projects, but it also increases the price. A typical 5-axis CNC router ranges from small (1.2m x 1.2m) to large (3m x 5m) worktable sizes.

Spindle Power and Speed: The power of the spindle determines how well the machine can cut through tough materials like granite or metal. A more powerful spindle will generally cost more.

Axes Movement and Range: A 5-axis CNC router can have different configurations of axis movement (e.g., 3+2, 5-axis simultaneous). The more sophisticated the axes' movement, the higher the cost.

Material Compatibility: Machines that can handle a variety of materials—stone, metal, wood, and composites—will usually come at a premium compared to single-material machines.

2. Customization and Features

Many 5-axis CNC routers offer customizable options and add-ons, such as:

Tool Changers: Automatic tool changers increase productivity by reducing downtime between tool swaps.

Vacuum Systems: These help hold the material in place, especially for large or thin sheets, providing greater stability during cutting.

Rotary Axis: Additional rotary axes can increase the machine’s versatility, enabling operations such as engraving cylindrical objects.

Cooling Systems: High-end routers often come with advanced cooling systems to prevent overheating when cutting through dense materials, which is particularly important for metal and stone cutting.

Customizations can be priced separately and will significantly influence the final quote.

3. Material Types and Intended Use

The type of materials you intend to cut or engrave with the 5-axis CNC router will influence both the choice of machine and its cost. For example:

Stone CNC Routers: Machines used for stone cutting tend to be larger, more powerful, and require specialized tooling. The price may range significantly based on the type of stone the machine can handle (e.g., granite, marble).

Woodworking CNC Routers: A router meant for woodworking is generally more affordable than one intended for stone or metal, as the materials are softer and easier to cut.

Metalworking CNC Routers: Machines designed to cut metals like aluminum or steel require more robust spindles and greater torque, which will increase the cost.

If you need a machine that can handle multiple materials, expect the quote to be higher due to the additional capabilities and features required.

4. Software Compatibility and Integration

The software integrated with the CNC router plays a critical role in its performance. Some CNC routers come with proprietary software, while others are compatible with third-party CAD/CAM software like Rhino, SolidWorks, or ArtCAM.

Proprietary Software: This software is often built specifically for the machine, optimizing its performance and capabilities. However, it may add to the overall cost of the machine.

Third-Party Software Compatibility: If you already use a particular CAD/CAM software, make sure that the CNC router you are quoting for can seamlessly integrate with it.

Software pricing can be an additional cost, depending on the license and features you choose.

Common Pricing Structures for 5 axis CNC machining center

The cost of a 5-axis CNC router is typically determined by the machine’s complexity and specifications. Here’s how pricing is generally structured:

1. Base Machine Price

This includes the fundamental features of the CNC router—basic specifications, spindle, and the standard working area. For a basic 5-axis CNC router, the price can range from $50,000 to $150,000. Machines designed for more complex work or larger scale operations can reach $200,000 to $500,000 or more.

2. Add-ons and Custom Features

Add-ons such as advanced cooling systems, rotary axes, tool changers, or vacuum systems will increase the price. The cost of these add-ons can range from $5,000 to $50,000 depending on the complexity.

3. Software Licensing

Software used to control the CNC router can also come with licensing costs. Typically, licensing for CAD/CAM software may range from $2,000 to $10,000 or more, depending on the software package.

4. Installation and Training

Most quotes will include the cost of installation and training. This is important for ensuring that your team is fully capable of operating the router. These services typically range from $5,000 to $15,000 depending on the provider and the level of training required.

5. Ongoing Maintenance and Service

Maintenance packages can either be purchased upfront or as part of a service contract. Regular maintenance helps ensure the longevity and efficiency of your CNC router, and service contracts usually range from $2,000 to $10,000 per year depending on the machine's complexity.

How to Get Accurate CNC Router

To ensure you receive the most accurate and relevant quotes for your business needs, follow these steps:

Define Your Requirements:Before requesting quotes, make sure to have a clear understanding of your business requirements, including material types, production volume, and the types of projects you’ll be working on.

Request Multiple Quotes:Approach multiple CNC router suppliers and ask for detailed, itemized quotes. This will allow you to compare different machines, features, and pricing to ensure you’re getting the best deal.

Ask About After-Sales Support:Ensure that the supplier provides after-sales support, including installation, training, and ongoing maintenance. Good customer support is essential for machine longevity.

Factor in Hidden Costs:Always ask about any hidden or additional costs, such as software upgrades, installation fees, or extended warranties. Having a complete understanding of the pricing structure will help prevent surprises down the line.

Conclusion

Obtaining accurate 5-axis CNC router quotes is a crucial step in making an informed investment for your business. By understanding the factors that influence the pricing and comparing different quotes, you can ensure that you get the right machine for your needs at a competitive price.

Whether you're in stone fabrication, metalworking, or woodworking, a 5-axis CNC router can significantly improve your production efficiency, precision, and ability to handle complex projects. Take the time to assess your needs, gather accurate quotes, and choose the machine that will best serve your long-term business goals.

0 notes

Text

The E High-Speed Fiber Laser Cutting Machine by Aaradhana Technology Systems is a cutting-edge solution for precision cutting and engraving on a variety of materials, including metal, wood, and acrylics.

#wood cnc machine price#co2 laser machine price in india#cnc router machine price#cnc wood carving machine price in india#Laser Cutting Machine Manufacturers in India#Laser Engraving Machine Price in India

1 note

·

View note

Text

Everything You Need to Know About Laser Cutting Machines

The world of manufacturing and fabrication has been revolutionized by laser cutting machines. From precise metal cutting to creating intricate designs, these machines have become indispensable in industries such as automotive, aerospace, electronics, and more. SLTL Group, a global leader in laser technology, offers a wide range of fiber laser cutting machines, CNC laser cutting machines, and metal laser cutters to cater to diverse industrial needs.

What is a Laser Cutting Machine?

A laser cutting machine uses a focused laser beam to cut or engrave materials with high precision. The laser melts, burns, or vaporizes the material, leaving smooth and accurate edges. These machines are widely used for cutting metals like steel, aluminum, and titanium, as well as non-metals such as plastics and ceramics.

Types of Laser Cutting Machines

SLTL Group specializes in advanced laser cutting machines tailored to meet various industrial requirements:

1. Fiber Laser Cutting Machines

Ideal for cutting metals like stainless steel, aluminum, and brass.

Known for high energy efficiency and minimal maintenance.

Delivers faster and cleaner cuts compared to traditional methods.

2. CNC Laser Cutting Machines

Combines laser technology with CNC (Computer Numerical Control) systems for automated and precise operations.

Perfect for industries that require intricate designs and repetitive cutting tasks.

Reduces human error and increases production efficiency.

3. Metal Laser Cutting Machines

Specifically designed for cutting and shaping metal sheets and plates.

Features high-powered lasers that handle thick and hard metals effortlessly.

Used extensively in automotive, construction, and heavy machinery manufacturing.

Applications of Laser Cutting Machines

Automotive Industry: For cutting and shaping car parts, including body panels and chassis components.

Aerospace: Precision cutting of lightweight materials like aluminum and titanium.

Electronics: Creating intricate circuit boards and enclosures.

Signage and Advertising: Cutting custom designs, letters, and logos.

Jewelry: Crafting delicate designs with unmatched precision.

Benefits of Using SLTL’s Laser Cutting Machines

1. Unmatched Precision

SLTL’s fiber laser cutting machines offer unparalleled accuracy, enabling intricate designs and fine details even in thick materials.

2. Speed and Efficiency

Compared to traditional methods, laser cutting is faster and more efficient, significantly reducing production time.

3. Versatility

Whether it’s metal, wood, plastic, or glass, SLTL’s laser cutting machines can handle a variety of materials and thicknesses.

4. Cost-Effective

With minimal material wastage and reduced maintenance costs, these machines offer long-term savings.

5. Automation and Integration

Our CNC laser cutting machines are equipped with IoT features and advanced automation, ensuring seamless operation and monitoring.

Factors Affecting Laser Cutting Machine Price

If you’re considering investing in a laser cutting sysyem, it’s essential to understand the factors influencing its price:

Laser Power: Machines with higher wattage offer greater cutting capabilities but come at a higher cost.

Machine Size: Larger machines capable of handling bigger materials tend to be more expensive.

Automation Features: IoT integration and smart features increase the price but add significant operational value.

Material Compatibility: Machines designed for specialized materials may cost more.

Brand Value: Trusted brands like SLTL Group ensure quality and support, making their machines a worthwhile investment.

Why Choose SLTL Group?

At SLTL Group, we are committed to delivering world-class laser cutting machines that cater to the ever-evolving needs of industries. Here’s why customers around the globe trust us:

Innovative Technology: We constantly innovate to offer cutting-edge solutions, such as IoT-enabled fiber laser cutting machines and automated systems.

Global Presence: With decades of experience, we have established a strong presence in over 30 countries.

Customizable Solutions: Our machines can be tailored to meet specific industry requirements.

Exceptional Support: We provide comprehensive after-sales support, including training and maintenance services.

How to Choose the Right Laser Cutting Machine?

When selecting a laser cutting machine, consider the following:

Material Type: Ensure the machine is compatible with the materials you work with.

Cutting Thickness: Check the maximum thickness the machine can handle.

Power and Speed: Higher power and speed improve productivity.

Automation Needs: For large-scale operations, opt for CNC laser cutting machines with automation.

Budget: Understand your budget while considering long-term savings.

Future of Laser Cutting Technology

As industries move towards automation and smart manufacturing, laser cutting machines are set to play a pivotal role. Advancements in fiber lasers, AI integration, and green technologies are making these machines more efficient and eco-friendly. SLTL Group is at the forefront of this transformation, offering innovative solutions that not only enhance productivity but also contribute to sustainability.

Conclusion

A laser cutting machine is a valuable investment for any industry looking to improve precision, efficiency, and productivity. Whether you need a high-powered metal laser cutter or an advanced CNC laser cutting machine, SLTL Group offers solutions that cater to diverse needs. With our focus on innovation and customer satisfaction, we help businesses stay ahead in a competitive market.

Explore SLTL’s range of fiber laser cutting machines today and elevate your manufacturing capabilities! For more information or to get a quote on the laser cutting machine price, contact us now.

0 notes

Text

Automatic Tool Change Foam Router EPS CNC Carving Machine

CNC Router Foam Cutting Machine

Automatic Tool Change Foam Router, also known as an EPS CNC Carving Machine with Automatic Tool Change, is a specialized computer-controlled machine designed for cutting, carving, and shaping Expanded Polystyrene (EPS) foam materials. These machines are equipped with an automatic tool change system that allows for the seamless swapping of cutting tools during the CNC routing process.The 3d CNC router milling machine can be seamlessly spliced, suitable for various shapes.This CNC router foam machine also can be used in embossing, lettering, hollowing, cutting, vertical carving, round carving, etc.

This 4 axis cnc foam router is a little special when compared with the ordinary four axis machine. The conventional 4-axis construction has two types: one is that the spindle can swing ±90 degrees; the other refers to the rotary axis. Either of the two can be called the ordinary 4-axis cnc machine. What makes this machine special is that it is actually a 2 in 1 cnc foam router as it has the two types 4 axis construction stated above. Based on this design, there is no doubt that it has more possibilities than a normal 4-axis machine. The 4 axis cnc foam router here is perfect for 3D polystyrene shapes making.

4 Axis 3d CNC Router Milling Machine

EPS/foam CNC router usually comes with a big working dimension for carving and cutting large-size workpieces of wood, aluminum, and styrofoam. It can also be equipped with an ATC spindle and a rotary device for complex, heavy-duty, and long-term work. It is widely used to process and carve wood and styrofoam automotive, ship or other molds, and GRG or GRC decorations, and architecture models.

Automatic Tool Change Foam Routers are specifically designed to work with EPS foam materials. EPS foam is commonly used in various industries for insulation, packaging, and creative applications due to its lightweight and easy-to-cut properties.Like other CNC machines, EPS CNC carving machines with automatic tool change offer high precision and accuracy. The CNC technology ensures that complex designs, intricate patterns, and 3D shapes can be executed with precision.

Foam Router EPS CNC Carving Machine

Packaging: Creating custom foam inserts for protecting fragile items during shipping.

Sculpture and Art: Carving intricate sculptures and art pieces from EPS foam.

Architectural Design: Crafting decorative elements and architectural details.

Set Design: Producing props and scenery for theater, film, and events.

Sign Making: Crafting 3D signs, logos, and lettering.

This cnc router foam cutter is designed especially for custom EPS expanded polystyrene foam moldings. The molded foam is usually used for casting & founding. Three-axis construction with 1500x3000mm machining size (5×10 in English); (need 4th rotary? please check out foam milling machine with rotary axis) Dirt guard is designed on X Y Z axes particular for cnc foam machining, which keeps the precise transmission parts away from the machining debris. The table is made of aluminum profiles. It is ideal for EPS EVA foam machining as well as wood machining. CNC router foam cutter for custom EPS EVA molding for sale at a reasonable price now!

Application Scope

How Many Kinds of CNC Foam Router Are There?

Well, this need to see from which perspective. From a motion axis quantity perspective, there are 3 axis, 4 axis and 5 axis cnc foam router; from application point of view, there are cnc foam router for polystyrene, for woods and for aluminum.

0 notes

Text

CNC Laser Cutting Machine Manufacturers

fine cutting solution, We are Manufacturer and Supplier of CNC Laser Cutting Machine from Faridabad, Haryana, India. We offer CNC Laser Cutting Machines Manufacturer at the best price. We offer precision-engineered machines suitable for intricate designs like gates and tubes. Whether you need a CNC laser cutting machine for wood or a small-sized laser cutting machine, we have the perfect fit. Explore the best CNC laser cutting machines in India, including fiber and gold laser models. For businesses, our CNC laser cutting services near me and affordable price list in India ensure top-quality and cost-effective solutions. Contact us today!

Website: https://finecuttingsolution.in/cnc-laser-cutting-machine-manufacturers/

#CNC Laser Cutting Machine#CNC Laser Cutting Machine manufacturer#CNC Laser Cutting Machine supplier#CNC Laser Cutting Machine manufacturer in India

0 notes

Text

Screw Suppliers in India: Building a Global Reputation

India has emerged as a significant player in the global screw manufacturing and supply industry, thanks to its skilled workforce, advanced production technologies, and competitive pricing. Indian screw suppliers cater to a wide range of industries, including automotive, construction, electronics, and aerospace, offering products that meet international quality standards. With a focus on precision engineering, durability, and customization, Indian suppliers have earned the trust of clients worldwide. Government initiatives like Make in India and incentives for exports have further fueled the sector’s growth. By adopting sustainable practices and embracing innovation, Indian screw suppliers are solidifying their position in global markets, proving themselves as reliable partners for industrial and commercial needs.

Why Choose Indian Screw Suppliers?

Screw suppliers in India offer a wide range of fasteners that cater to industries like automotive, construction, electronics, and machinery. Known for their cost efficiency, Indian suppliers leverage local raw materials and skilled labor to provide high-quality screws at competitive prices. Additionally, Indian suppliers are adapting to global standards with ISO-certified manufacturing processes, making them a preferred choice for domestic and international clients.

Types of Screws Offered by Indian Suppliers

Machine Screws: Commonly used in industrial applications.

Wood Screws: Ideal for carpentry and woodworking.

Self-Tapping Screws: For sheet metal and plastic.

Hex Screws: Designed for heavy-duty machinery.

Specialty Screws: Custom-designed screws tailored for specific industries.

This diversity ensures Indian suppliers can meet the needs of various sectors, making them versatile and reliable partners.

Regions Leading Screw Supply in India

Ludhiana: Known as a hub for fastener manufacturing, producing high-quality screws and bolts.

Pune and Mumbai: Emerging as centers for automotive fasteners.

Delhi-NCR: Specializes in industrial and construction fasteners.

Chennai and Bengaluru: Key exporters of precision screws for the technology and electronics industries.

These regions not only cater to domestic markets but also serve as significant exporters to countries across Europe, the Americas, and the Middle East.

Technological Advancements in Screw Manufacturing and Supply

CNC Machining: For high precision and uniformity.

Heat Treatment: Ensuring screws meet strength and durability standards.

Surface Coating Techniques: Providing corrosion resistance and enhanced aesthetics.

Automation: Improving efficiency and reducing lead times.

By integrating these technologies, Indian suppliers ensure their products meet international standards, catering to diverse industrial requirements.

Challenges Faced by Screw Suppliers in India

Rising Raw Material Costs: Fluctuations in steel prices directly impact production costs.

Global Competition: Competing with countries like China, which dominate the fastener market.

Skilled Labor Shortage: The need for a workforce trained in advanced manufacturing techniques.

Logistical Barriers: Delays in supply chains affecting delivery schedules.

Addressing these issues through innovation and government support is essential for the industry's sustained growth.

Opportunities for Screw Suppliers in India

The increasing demand for screws in industries like renewable energy, aerospace, and infrastructure development offers significant opportunities. Government initiatives like Make in India and the focus on local sourcing present further growth avenues. Additionally, the rising preference for sustainable and recyclable materials opens doors for eco-friendly screw production.

Export markets also provide tremendous potential. With India gaining recognition for its quality products, suppliers can expand their reach globally, especially in regions seeking cost-effective alternatives to European and Chinese manufacturers.

How to Choose the Best Screw Supplier in India?

Certifications and Standards Compliance: Look for suppliers adhering to ISO and other international standards.

Product Range: Ensure the supplier offers screws suited to your industry’s specific needs.

Customization Options: Check if they can design and produce specialty screws.

Reputation and Experience: Research reviews and track records of suppliers.

Delivery Timelines and Logistics: Ensure they can meet your deadlines efficiently.

A thorough evaluation will help you identify a reliable partner for your screw requirements.

Conclusion

Screw suppliers in India are becoming global leaders due to their ability to provide high-quality, cost-effective solutions across industries. With advancements in technology, increasing demand from domestic and export markets, and support from government policies, the industry is poised for significant growth. However, overcoming challenges like raw material costs and global competition is critical to unlocking the sector’s full potential. By focusing on quality, innovation, and sustainability, screw suppliers in India can secure a stronger foothold in the global market and continue contributing to India's industrial growth.

0 notes

Text

The Role of Liquidation Auctions in the Woodworking Machinery Market

In the dynamic world of woodworking, where innovation meets craftsmanship, the machinery used is essential for both efficiency and quality. However, changes in business conditions, technology, and market demands often necessitate the disposal of equipment. This is where liquidation auctions come into play, especially in the woodworking machinery market. Among the various methods of selling machinery, wood tool auctions have become a vital component in facilitating these transactions.

Understanding Liquidation Auctions

Liquidation auctions are processes through which businesses sell off their assets—often due to downsizing, bankruptcy, or restructuring. For woodworking companies, this can include everything from saws and sanders to more specialized CNC machines. Auctions allow sellers to recover some of their investment while providing buyers an opportunity to acquire high-quality equipment at potentially lower prices.

The Benefits of Wood Tool Auctions

1. Cost-Effective Purchases: One of the most significant advantages of participating in wood tool auctions is the potential for cost savings. Buyers can often acquire machinery for a fraction of its original cost, making it an attractive option for startups and smaller woodworking shops that may be operating on tight budgets.

2. Access to High-Quality Equipment: Liquidation auctions often feature well-maintained equipment from established businesses. For buyers, this translates to the opportunity to invest in quality machinery that may no longer be in production or is hard to find elsewhere.

3. Diverse Inventory: Auctions typically offer a wide range of tools and machines. This variety is beneficial for woodworkers looking to expand their capabilities or replace older equipment. From basic hand tools to advanced automated systems, the assortment available at wood tool auctions can meet various needs.

4. Quick Transactions: The auction format facilitates rapid sales. Sellers can clear out inventory quickly, while buyers can make decisions on the spot. This efficiency is crucial in a fast-paced industry where time is money.

The Auction Process

For those new to liquidation auctions, the process can seem daunting. However, understanding the steps can demystify the experience:

- Registration: Interested bidders typically need to register in advance, often online. This involves providing contact information and, in some cases, a deposit to ensure serious bidding.

- Inspection: Before the auction, bidders are usually allowed to inspect the equipment. This step is vital for assessing the condition of the tools and making informed decisions.

- Bidding: Once the auction begins, participants place bids on the items they are interested in. Many auctions now utilize online platforms, allowing bidders to participate from anywhere.

- Payment and Pickup: Winning bidders are responsible for payment and must arrange for the transportation of the equipment. Some auctions may offer assistance with logistics, which can be a significant advantage.

The Impact on the Market

Liquidation auctions play a critical role in maintaining a healthy woodworking machinery market. They create a secondary market for equipment that might otherwise remain idle or be discarded. This not only promotes sustainability by reusing tools but also keeps prices competitive, which is essential for businesses trying to thrive in a challenging economic landscape.

Furthermore, these auctions can help to stimulate innovation. By making advanced machinery more accessible, smaller companies can adopt new technologies and processes, contributing to the overall growth of the woodworking sector.

Conclusion

The importance of liquidation auctions in the woodworking machinery market cannot be overstated. They provide an efficient, cost-effective means for both buyers and sellers to navigate the complexities of asset disposal and acquisition. As wood tool auctions continue to evolve, they will likely remain a cornerstone of the industry, enabling craftsmen and entrepreneurs to access the tools they need to succeed. Whether you’re a seasoned woodworker or just starting, keeping an eye on upcoming auctions could lead to your next great investment.

0 notes

Text

Why use CNC machines in woodworking

One of the reasons to choose a CNC machine for wood is the ability to create intricate patterns and complex designs. It’s possible to carve detailed inlays and craft complicated architectural elements with ease. For the best-quality machines, trust the team of Premier Plasma CNC. They offer a wide selection of CNC tables at the best prices. Visit this link to explore the options: https://premierplasmacnc.com/.

1 note

·

View note

Text

The Art and Industry of Bathroom Vanity Manufacturing

The Evolution of Bathroom Vanity Design

The concept of bathroom vanities has come a long way since their humble beginnings. Originally simple washstands, these fixtures have evolved into complex pieces of furniture that combine storage, style, and practicality. Today's manufacturers are at the forefront of this evolution, constantly innovating to meet changing consumer preferences and lifestyle needs.

Modern vanity designs range from sleek, minimalist floating units to ornate, furniture-style pieces that make bold statements. Manufacturers now offer an array of styles to suit various tastes, from contemporary and industrial to rustic and traditional. This diversity reflects the growing recognition of bathrooms as personal sanctuaries rather than merely utilitarian spaces.

Materials and Craftsmanship

The choice of materials is paramount in vanity manufacturing. While traditional wooden vanities remain popular, manufacturers are increasingly experimenting with alternative materials. High-quality MDF (Medium Density Fiberboard), thermofoil, and even recycled materials are being used to create durable and eco-friendly options.

For higher-end products, manufacturers often employ skilled artisans who work with luxury materials such as marble, quartz, and exotic woods. These craftsmen combine traditional woodworking techniques with modern manufacturing processes to create unique, high-quality pieces.

Water-resistant finishes and treatments are another area where manufacturers invest heavily in research and development. These innovations help extend the lifespan of vanities, ensuring they can withstand the humid bathroom environment.

Technology in Manufacturing

The integration of technology has revolutionized the vanity manufacturing process. Computer-aided design (CAD) software allows for precise planning and customization, while Computer Numerical Control (CNC) machines ensure accuracy in cutting and shaping materials.

Some forward-thinking manufacturers are also incorporating smart technology into their vanities. Features like built-in charging stations, Bluetooth-enabled speakers, and LED-illuminated mirrors are becoming increasingly common, catering to tech-savvy consumers.

Customization and Flexibility

Recognizing that no two bathrooms are alike, many manufacturers now offer customizable options. This flexibility allows consumers to tailor vanities to their specific space constraints and personal preferences. Options might include adjustable heights, modular components, or a choice of finishes and hardware.

Some manufacturers have even adopted a made-to-order approach, producing vanities only after receiving specific customer requests. This model reduces waste and allows for greater personalization, albeit often at a higher price point.

For More Information Click Here:bathroom vanity manufacturer

Sustainability in Vanity Manufacturing

As environmental concerns grow, many vanity manufacturers are adopting more sustainable practices. This shift includes using responsibly sourced materials, implementing energy-efficient manufacturing processes, and designing products with longevity in mind.

Some manufacturers are going a step further by creating vanities from reclaimed wood or recycled materials, appealing to environmentally conscious consumers. Water-saving faucets and low-flow systems are also being integrated into vanity designs to promote water conservation.

The Global Market and Competition

The bathroom vanity manufacturing industry is highly competitive and global. While some manufacturers focus on mass-producing affordable options, others carve out niches in luxury or eco-friendly markets. Asian manufacturers, particularly from China, dominate in terms of volume, but high-end European and North American brands often lead in design innovation and quality.

E-commerce has significantly impacted the industry, allowing smaller manufacturers to reach a global audience. However, it has also increased competition and put pressure on traditional brick-and-mortar distribution channels.

Challenges and Future Outlook

Bathroom vanity manufacturers face several challenges, including fluctuating raw material costs, changing import/export regulations, and the need to continually innovate to stay relevant. The COVID-19 pandemic has also disrupted supply chains and shifted consumer behaviors, forcing manufacturers to adapt quickly.

Looking ahead, the industry is likely to see continued emphasis on customization, sustainability, and smart technology integration. As bathrooms increasingly become personalized retreats, manufacturers who can balance functionality, aesthetics, and innovation will be well-positioned to thrive in this dynamic market.

In conclusion, bathroom vanity manufacturers play a vital role in shaping our daily lives and living spaces. Through a combination of craftsmanship, technology, and responsiveness to consumer needs, these companies continue to transform the humble bathroom into a space of comfort, style, and personal expression.

0 notes