#Clinker Production

Explore tagged Tumblr posts

Text

Cement Grinding Aids Market is driven by growing construction activities

The cement grinding aids market is crucial for optimizing the cement production process. Cement grinding aids help improve the grinding efficiency of finished cement. Grinding aids improve the grindability of cement clinker and reduce electricity consumption. Some key functions of cement grinding aids include enhancing grinding efficiency, improving powder flowability and rheology, reducing power consumption, and preventing agglomeration and coating of the grinded particles over the mill surfaces.

The Global Cement Grinding Aids Market is estimated to be valued at US$ 3336.4 Mn in 2024 and is expected to exhibit a CAGR of 8.1% over the forecast period 2024 to 2031. Key Takeaways Key players operating in the cement grinding aids market are Hiwin Corporation, Bosch Rexroth AG, The Timken Company, Schneeberger Group, Rockwell Automation Inc., Ewellix AB, THK Co. Ltd, Thomson Industries Inc., Parker Hannifin Corporation, Nippon Bearing Co. Ltd, HepcoMotion Inc., Lintech Corporation and NSK Ltd. The Cement Grinding Aids Market Growth is expected to witness strong growth in demand due to increasing construction activities across the globe. Rapid urbanization and infrastructure development projects are driving the demand for cement. Cement grinding aids help optimize cement production and meet the rising demand. Globally, the cement industry is expanding to new regions and countries. Growing construction activities in developing nations of Asia and Africa are contributing to the global cement demand. Key players in the cement grinding aids market are expanding their geographical footprint to leverage growth opportunities in emerging markets. Market key trends One of the major trends in the cement grinding aids market is the development of bio-based and environment-friendly grinding aid products. With growing environment concerns, cement producers are focusing on reducing carbon footprint and adopting sustainable manufacturing practices. Bio-based grinding aids help improve grinding efficiency as well as offer environmental benefits. These aids are derived from renewable plant sources and enable greener cement production. Their adoption is expected to rise significantly over the forecast period.

Porter's Analysis Threat of new entrants: The threat of new entrants is low due to high capital investment requirements and established presence of existing players. Bargaining power of buyers: The bargaining power of buyers is high due to availability of substitutes and presence of many regional players. Bargaining power of suppliers: The bargaining power of suppliers is moderate due to availability of substitutes. Threat of new substitutes: The threat of new substitutes is moderate due to availability of grinding aids from other industries. Competitive rivalry: The competitive rivalry is high due to presence of many regional players. Geographical Regions Currently, Asia Pacific region accounts for around 40% of the global cement grinding aids market value mainly due to high cement production and consumption in countries like China, India. The region will continue dominating the market during the forecast period due to rapid infrastructure development and urbanization. The fastest growing region for cement grinding aids market is expected to be Middle East & Africa region driven by ongoing and planned infrastructure projects across countries. The demand is projected to increase at a CAGR of over 10% until 2031 led by rising construction activities in GCC countries and investments towards community development in Africa.

Get more insights on Cement Grinding Aids Market

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

#Coherent Market Insights#Cement Grinding Aids Market#Cement Grinding Aids#Cement Additives#Grinding Aids#Cement Production#Clinker Grinding#Cement Processing#Cement Manufacturing#Chemical Additives#Milling Efficiency

0 notes

Text

Gabare

The gabare or gabarre is a type of vessel that has been used since the 17th century on the western French rivers Garonne, Dordogne, Charente, Sèvre Niortaise and Loire as a transport ship. Gabare were also built for use at sea.

It is a shallow-draught boat that was built either in clinker construction (overlapping planks) or in caravel construction (planks next to each other, butted). The bow is pointed, the stern usually in mirror image. The planks were fastened with wooden nails. In some regions, additional planks were added to increase the freeboard height. The boats had a mast with a square sail, and smaller boats were also rowed.

Different goods were transported depending on the region. For example, the Dordogne was used mainly to transport agricultural products, the Loire stones, the Charente wine and Cognac, the Sèvre metal goods such as cannons and anchors, and the Auvergne timber. Around 1850, around 60 per cent of the goods traffic between Bergerac and Bordeaux was carried out by these ships.

Today, replicas can be found on the Dordogne, the Charente and the Loire for tourist purposes.

Fleur de Lampaul, a Breton gabare

As already mentioned, however, there were also seaworthy gabarren that could transport between 120 and 450 tonnes of cargo and had one to three masts. From 1715, these ships were used mainly for transporting timber to the royal arsenals. Some of them were armed with 10 to 20 cannons. Because of their sturdiness and good seakeeping, they were also used as expedition ships in the 18th and 19th centuries.

The Astrolabe in antarctica

Louis Aleno de Saint-Aloüarn (1738-1772) discovered the Crozet Islands with the gabarre Gros Ventre, and Jules Dumont d'Urville rounded the world with the Astrolabe between 1825 and 1829. Notre Dame de Rumengol, a replica built in 1945, was added to France's list of historic monuments in 1990.

A Dictionary of the World's Watercraft: From Aak to Zumbra

#naval history#ship types#gabare#french#coastal and sea vessel#17th -19th century#age of sail#age of steam

64 notes

·

View notes

Text

💥 Fast Crushing – High Efficiency – Cost Savings! 💥

🔹 Hammer Crusher efficiently crushes limestone, coal, and cement clinker with outstanding performance.

✅ Key Benefits: ✔ Simple structure, easy operation ✔ Low investment, high efficiency ✔ Ideal for soft materials: limestone, coal, clay ✔ Produces small, uniform-sized output

🏗 Applications: Construction, cement production, mining

🔗 Learn more: https://thegioimaynghienda.com/may-nghien-bua-trong-day-chuyen-nghien-da-xay-dung/

📞 Contact us for expert advice!

2 notes

·

View notes

Note

There's good news on the climate impacts from steel! A Swedish company is working on replacing the coke (coal) with hydrogen, so that the only emission is water. Separately, another group has found that they can replace the limestone in steel arc furnaces with cement clinker that needs to be recycled, meaning that there's no CO2 emissions from turning raw limestone into clinker and old cement can be essentially "reacticated" and reused in concrete!

I am fucking ECSTATIC to hear this, it bodes really well for the continued future of body safe surgical steel as an implement for medical procedural tools and body modifications of both a medical and a recreational nature.

There's also a lot to be said for the resource redistribution opportunity that is public works projects, like for example, paying to have every steel manufacturer completely rennovate to meet the new sustainable/ethical model of production.

10 notes

·

View notes

Note

I’ve only known you for a short while, but in that time, you’ve made me belly laugh multiple times. I love your big squishy brain and listening to your ridiculous and serious ideas. 🐀

Now that we’ve gotten the sincerity out of that way - I would like you to name 3 facts about anything that tickle you. (Philosophy, history, stages of human decomposition, etc etc)

thank you! this means a lot to hear. its really kind of you to reach out. the asks were genuinely funny at first bc it felt so silly, but now im just : /

blood is like, weirdly good in concrete. it makes the concrete weather resistant (to an extent) bc the way the blood combines makes these little pockets of air. this is great bc it gives the concrete room to expand and shrink with weather changes. BUT i also hear it may make it brittle.

speaking of my beloved concrete, concrete/cement as it is mass produced today is unfortunately Not Good for the environment. its easy to use, durable, malleable, and theres ten billion cool things that can be done with it, but it uses a LOT of water and emits a LOT of co2. as in, 4-8% of the worlds co2 emissions are from concrete production. however, theres some really, really cool stuff being worked on to combat that! there are numerous less-co2-emitting kinds of concrete being invented. theres also carbon NEGATIVE concrete being made - concrete that during production takes co2 OUT of the atmosphere and traps it inside the concrete, making the sky a cleaner place and making the concrete tougher. also theyre making concrete with carrots.

speaking of both sustainability AND concrete. theres also self healing concrete. concrete that can heal itself (re: when stressors crack the concrete, the concrete "heals" itself and fixes the crack) means longer lasting, more durable concrete, which heavily cuts down on concrete production and keeps the air cleaner. some concrete heals when water is present bc of how it reacts to the clinker or carbonizes the lime. there are a few other ways, all of them cool, but my favorite is the addition of bacteria. bacteria in the concrete that, due to cracks, comes into contact with air/water, produces limestone and this fills in the cracks.

8 notes

·

View notes

Note

You may have already made a post about this so sorry if so, but what are your headcanons regarding how Matt and Katya met? And how they kept touch over the years?

Love your content btw!!

Thank you! And actually, somehow, no one has asked me that on any of the blogs! I had to think and coalesce some thoughts. This got long so I am going to split it into two parts but their meeting!

The Trans-Canada railway was completed in the 1880s and finally opened up what was called the ‘last best west.’ Between the Canadian Rockies in the far west and the western edge of the woodlands that define eastern Canada in Manitoba, the prairies stretch out in what looks to a child of the eastern woodlands like a vast treeless void. Grasslands and steppes are incredibly ecologically important, but I am ethnically a clinker-built canoe lover, and they scare the shit out of me. Judging by settlement patterns, most French Canadians agreed. As the American West closed, some Americans were willing to join Canadians and take land ripped from indigenous peoples too. Alberta was a result. Concerned about American settlement, in 1896, the Dominion of Canada’s federal government coordinated with the foreign office of the British Empire to look for more settlers. At the same time, in what was then the Austro-Hungarian empire, Galicia was likely the poorest place in continental Europe, with the only other comparable example being famine-era Ireland. The other Ukrainian-speaking areas of the Austro-Hungarian empire (75-80 of that territory was held by the Russian Empire) weren’t much better off. Each government found a solution in the other. Britain, representing Anglo-dominated Canada, and the Austrians shook hands, and the flow began. The US saw the largest share of Eastern European immigration in this period, but the majority who sailed to Canada were Ukrainians. And even before immigration, the region's international ties were based on Canadian financial interests. So, what does this mean for Katya and Matt?

The scene I imagine is that while the powerful wheel and deal, two products of empire crossed paths. One of these meetings may have taken place during a summer folk festival. Girls wove wreaths of flowers into their hair and floated others down the river. Songs were sung, vodka and wine flowed, and dancers joined hands. While the Austrians and the British bargained, a young man not so far removed from his peasant roots and his own saint’s day celebrated with fire and river wandered into the edge of a valley clearing at the end of the longest day of the northern year. As a maple or spruce was decorated, the sun sank, and the last light of day fell like fire light onto a Carpathian river valley. Bonfires were lit. Against a world on fire, a child of the woodlands looked upon the silhouette of his future, crowned with birchwood silver woven into her braids. Katya sensed him, a being like herself from across the world and turned. She looked at him a long moment, with eyes belonging to a world since passed set in the face that would one day be the image that sprang into Matthew’s mind when he needed to summon a memory of home that would not cleave him in two. She bid him to approach and, with one gesture, changed their fates.

Later, he would find out she spoke the court French of his earliest years, but this night, there is only Katya’s outstretched hand and burning blue eyes reflecting fire and Matt’s fingers lacing into hers to spin in the dance of all the other young men and women. There is no discussion of soil and wheat, nor opportunity and affection. There is only alcohol, laughter, music, fire and spinning, his mouth full of her language, unknown but already familiar. There is only a lightening of her eyes as she enjoys herself, her head flung back in laughter as he chokes on pear horilka stronger and sweeter than any whiskey he’s ever made. Her wreath topples out of her hair, and she bursts into laughter as he snatches it up and runs, calling over his shoulder, and she hikes up her skirts and follows, hand outstretched, only to grasp onto him and run, stride long and confident as they leap together to make it over the bonfire.

Still, together, hands clasped, his right her and left and left touching the laurel wreath, the last symbol she indulges from her Varangian roots. Eye contact, a significance, a weight that will one day balance the heaviness of history. She will press his heart into the shape of hers with that weight. He will give it back in every way he can, the ballast of whatever love she’ll let him give. But for now, in the last light of day, there is only a young man and a young woman hand in hand, circling a fire under a night sky. Here, they are under a star-streaked Milky Way that gives way to a mead moon rising over the mountains. Someday, save them; that moon will be the only witness to this night when mortality leaves alive only a man, a woman, and their most human memory.

#the ask box || probis pateo#canukr#katya || бо лишало на серці сліди#matthew || my country is winter#katya and matt || the soil of our souls#hws ukraine#hws canada

51 notes

·

View notes

Text

Low Carbon Cement Market Growing Business Factors, Industry Trends, Share, Size, Growth, Opportunity And Forecast 2034

The size of the global low carbon cement market has been estimated at a value of US$ 2.03 billion for the year 2024 and is anticipated to grow at a CAGR of 11.2% to reach a value of US$ 5.88 billion by the end of the year 2034.

Green energy stocks are going to rise as utmost importance is given to finding alternatives to fossil fuels that are eco-friendly. The environmental footprint of concrete, even with a heavy carbon hit as a building material, can be lessened in many different ways. Technologies that can greatly reduce emissions while still providing products with the same performance capabilities as regular concrete are being developed by the concrete industry. Presently, cement and concrete manufacturers have access to a variety of new and established high-tech options.

For More Insights into the Market, Request a Sample of this Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=5044

Why is Demand for Low Carbon Cement Increasing So Fast?

"Population Growth Attributing to Rising Demand for Low Carbon Cement in Construction Operations"

International Energy Agency states that global cement production is the second-largest industrial source of CO2 emissions and the third-largest industrial user of energy. Cement and concrete are highly demanded because of the increasing population globally and the urbanization trends, along with the demand for infrastructure development, which further compels the industry to minimize its carbon footprint as early as possible.

If nations honor their pledges to cut carbon emissions and enhance energy efficiency, the world's global direct CO2 emissions from the green cement industry will increase by only 4% by 2050, which will lead to a 12% boost in cement output, according to the International Energy Agency. Country-wise Analysis

The United States, a dominant player in the North American market, is to command 73.5% of the market size by 2034. The increasing construction activity is driving sales of low carbon cement in China.

China has always been one of the crucial destinations with regards to the construction sector, beginning with the rapid development of infrastructure and the building boom in the early 2000s. Construction activities growing in the western region of the country are driving up the demand for cement. In the large-scale constructions carried out in China are using belite clinkers. Additionally, the trend towards sustainability is further increasing the demand for low carbon cement in China.

Intense emphasis on cement sustainability and availability of major market players is driving the growth of the market in Germany. Germans are leaders in innovations and rising popularity of built environment is accelerating the sales of green cement. Reuse and recycling goals in the construction industry of Germany are driving the demand for sustainable building materials.

Category-wise Analysis

Among all types of cement which have been under the scope of research, Portland cement is the market favorite with most companies adopting it as base cement and later introducing innovation to formulate their own low carbon cement.

Portland cement is the cement based of preference for the green cement producers due to its easier availability geographically at quite competitive prices compared to other types of cements. Firms are associating with end users and commercial and residential property developers for long-term supply of their cement.

Competitive Landscape

The major players in low carbon cement industry are always emphasizing innovation to gain more. They are implementing multiple organic and inorganic strategies to expand their market share and position. Mergers, collaborations, partnerships, and expansion worldwide are some of the strategic measures undertaken by them.

Heidelberg Materials launched evoZero brand in 2023 to offer carbon neutral cement.

Browse Full Report: https://www.factmr.com/report/5044/low-carbon-cement-market

Key Segments of Low Carbon Cement Market Research

By Cement Type:

Portland Cement

High Alumina Cement

Quick Settling Cement

Others

By Technology:

Fly-ash-based

Slag-based

Others

By Reduction Potential:

Less than 50% Reduction

50 to 70% Reduction

Above 70% Reduction

By End Use:

Residential Construction

Commercial Construction

Industrial Construction

By Region:

North America

Latin America

Europe

East Asia

South Asia & Oceania

Middle East & Africa

𝐂𝐨𝐧𝐭𝐚𝐜𝐭:

US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

Harmony

HARMONY by Barry Manilow and Bruce Sussman directed by Warren Carlyle: It seems distressingly timely in the current political climate to see a musical about the real-life vocal group The Comedian Harmonists, who were suppressed by the Nazis in the early 1930s because half of them were Jewish (and in this production, two are gay or bi) and they performed Jewish music. It’s not that we don’t need to repeat history’s lessons about bigotry until none exists. It’s that the reflection of the play’s action in the current world can leave one a little shell-shocked. Fortunately, the play and production are worth it. Narrated by the incomparable Chip Zien as “Rabbi” Josef Roman Cycowski, the last of the group to die, the production deals with a great deal of regret as Zien looks back on the mistakes he made in dealing with the growing Nazi threat and, by extension, the guilt of people who stand by and do nothing while evil takes over a country. Zien is both funny (he plays a variety of other characters the group encounters) and intensely moving. As his younger self, Danny Kornfeld deserves particular credit for developing a character that really does look as if he could grow up to become the older actor. And Julie Benko is quite powerful as Ruth Stern, the anti-Fascist agitator who marries one of the group’s non-Jewish members. The dialog has the occasional clinker and there are some simplistic lyrics, but Barry Manilow’s score is a surprise. There’s only one number — the Josephine Baker fantasy “We’re Goin’ Loco!” — that mirrors his pop hits. For the rest, he moves effortlessly through a variety of musical styles, including the operetta “Your Son Is Becoming a Singer, the musical joke “Hungarian Rhapsody #20” (which would be great for a men’s chorus) and the beautiful anthem “Stars in the Night.”

17 notes

·

View notes

Text

Global Regenerative Cement Market to Witness Unprecedented Growth by 2032

The global regenerative cement market is undergoing a seismic shift, transitioning from conventional practices to sustainable and carbon-conscious solutions. With an expected Compound Annual Growth Rate (CAGR) of 36.8% from 2024 to 2031, the regenerative cement market is projected to surge from $34.10 billion in 2023 to $562.97 billion by 2031, driven by innovation in green construction technologies and increasing global commitment to decarbonization.

This dynamic growth trajectory underscores the transformative impact of regenerative cement technologies, especially in a post-pandemic landscape where climate resilience and circular economy initiatives are accelerating infrastructure investments worldwide.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40429-global-regenerative-cement-market

🌍 Regional Regenerative Cement Market Dynamics: Leading Geographies Shaping the Regenerative Cement Landscape

North America

North America is emerging as a key adopter, with the United States spearheading investments in low-carbon building practices. Federal initiatives, such as the Inflation Reduction Act, are reinforcing carbon reduction mandates, accelerating the shift toward carbon-negative materials in public infrastructure projects.

Europe

Europe remains at the forefront of regenerative cement innovation, bolstered by the European Green Deal and stringent EU Emissions Trading System (ETS) regulations. Countries like Germany, France, and the UK are fostering research in bio-cement and geopolymer technologies, setting ambitious sustainability benchmarks for the global industry.

Asia-Pacific

Rapid urbanization in China, India, Japan, and ASEAN countries is driving exponential demand for regenerative construction materials. The region is investing heavily in recycled content cement to mitigate waste, supported by government-led smart city projects and infrastructure modernization.

Middle East and Africa

Driven by megaprojects in the UAE, Saudi Arabia (e.g., NEOM), and African nations seeking resilient infrastructure, regenerative cement is gaining traction. The scarcity of natural resources is pushing the regenerative cement market toward alternative cementitious solutions.

South America

Brazil leads the adoption of low-carbon cement in Latin America, backed by national climate action plans and increasing alignment with UN Sustainable Development Goals.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40429-global-regenerative-cement-market

🔍 Product Segmentation and Innovation Insights

Recycled Content Cement

This category leverages industrial waste—fly ash, slag, and recycled aggregates—to create high-performance cement with reduced environmental burdens. Innovations in material sorting, treatment, and admixture integration are enhancing durability and structural integrity in civil and commercial applications.

Low-Carbon Cement

Low-carbon formulations prioritize alternative clinker materials, renewable fuels, and energy-efficient calcination methods. These cements emit significantly less CO₂ per ton compared to traditional Portland cement, making them pivotal for countries with net-zero emissions targets.

Bio-Cement

A frontier innovation, bio-cement employs microorganisms like Sporosarcina pasteurii to precipitate calcite, enabling self-healing, carbon-sequestering, and low-energy concrete systems. These solutions are particularly relevant for marine structures and low-impact development zones.

⚙️ Cutting-Edge Technologies Driving Market Disruption

Carbon Capture and Utilization (CCU) Cement

CCU cement integrates real-time carbon capture processes within manufacturing operations. By transforming captured CO₂ into stable mineral carbonates within the cement matrix, it both mitigates emissions and improves the compressive strength of the material. Companies are increasingly implementing direct air capture (DAC) and post-combustion capture techniques to scale this innovation.

Geopolymer Cement

Manufactured from alumino-silicate rich materials, such as fly ash and metakaolin, geopolymer cements require no limestone and operate at significantly lower temperatures, reducing energy consumption. Their chemical resistance, fireproofing qualities, and lifecycle performance make them ideal for industrial, military, and infrastructure applications.

🏗️ End-Use Sectors: Driving Adoption at Scale

Construction Companies

Construction firms are integrating regenerative cement into building foundations, structural walls, and precast elements to meet regulatory requirements and ESG goals. Collaborations with green certification bodies (e.g., LEED, BREEAM) are accelerating this shift.

Infrastructure Developers

Megaprojects in transportation, water systems, and energy grids are leveraging regenerative cement to increase lifespan, performance, and carbon neutrality of structures. Governments are issuing green procurement mandates to ensure compliance with international sustainability standards.

🏢 Applications Across Key Building Segments

Infrastructure

Highway bridges, tunnels, wastewater systems, and public transit hubs are increasingly constructed using low-carbon or geopolymer cements. These applications demand resilience, durability, and reduced lifecycle costs, aligning perfectly with regenerative solutions.

Residential Buildings

Builders are incorporating bio-cement and recycled content cement into homes to meet consumer demand for sustainable living spaces. Improved indoor air quality, thermal insulation, and structural longevity contribute to enhanced building performance.

Commercial Buildings

Office towers, retail complexes, and institutional facilities are adopting regenerative cement to achieve net-zero carbon architecture, reduce maintenance overheads, and ensure compliance with evolving zoning and environmental codes.

👨💼 Competitive Landscape: Global Leaders and Innovators

Major regenerative cement market players are shaping the future of regenerative cement through strategic R&D, partnerships, and acquisitions. Key companies include:

LafargeHolcim

HeidelbergCement AG

CEMEX

CRH plc

UltraTech Cement Ltd.

Buzzi Unicem

Taiheiyo Cement Corporation

Dalmia Cement (Bharat) Limited

Titan Cement Group

Holcim Philippines, Inc.

These entities are investing in carbon-neutral portfolios, leveraging AI-driven production optimization, and enhancing regional circular economy models.

📈 Regenerative Cement Market Forecast: Growth Outlook to 2031

The trajectory for regenerative cement remains robust through 2031, underpinned by escalating climate policy enforcement, investor focus on ESG, and technological maturation.

🌐 Strategic Imperatives for Stakeholders

Policy Makers: Mandate regenerative cement adoption through incentives and emissions regulations.

Developers: Integrate low-carbon materials early in design to unlock funding and regulatory benefits.

Investors: Prioritize companies with clear regenerative material roadmaps and third-party verifications.

Academia: Foster multidisciplinary R&D to accelerate bio-cement and geopolymer breakthroughs.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40429-global-regenerative-cement-market

Conclusion: Cementing a Carbon-Free Future

The regenerative cement market represents more than just a sustainable alternative—it is the foundation of tomorrow's infrastructure, resilient against climate risk and tailored for long-term environmental stewardship. As urban development and ecological accountability converge, regenerative cement will become the bedrock of global construction.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Text

OCs as obscure references—bonus round lolll

ANIMAL: horse, elephant, falcon

COLOURS: gold, pale yellow, light blue, mustard green

MONTH: may

SONGS: it takes a muscle to fall in love, spectral display | because, the clinkers | jonathan, fiona apple | safer waters, chevelle | veslefrikk, karin krog | the suburbs, the arcade fire | roseate, ionna gika | eg veit i himmerik ei borg, helene bøksle

NUMBER: 3, 6, 8

PLANTS: grass, monstera

SMELLS: sweat, moist earth, chlorine, snow

GEMSTONE: amber

TIME OF DAY: noon

SEASON: early summer

PLACES: Hallingdal, Oslo, the jungle (DRC), hiking trails

FOOD: medisterkaker

DRINKS: beer, rum, akvavit

ELEMENT: earth; light

ASTROLOGICAL SIGNS: Taurus❂ Virgo❍ Scorpio↑ (apparently!)

SEASONINGS: dill, mustard, butter

SKY: blue with fluffy clouds

WEATHER: freezing day with brilliant sun

MAGICAL POWER: self-destruct

WEAPONS: M1921, bare hands

SOCIAL MEDIA: probably a stupid tumblr blog that makes no sense tbh

MAKEUP PRODUCT: (someone else's) lipstick

CANDY: kitkat

METHOD OF LONG DISTANCE TRAVEL: car that hopefully someone else is driving

ART STYLE: Stig Eklund

FEAR: failing his loved ones; weakness

MYTHOLOGICAL CREATURE: griffin

PIECE OF STATIONARY: lined paper

THREE EMOJIS: 😳💪🫡

CELESTIAL BODY: red dwarf

#roland#hes technically not an OC but#memecomradeoriginal#jungle work#thats one of kadokura's old colleagues btw for anyone who doesnt know#along with van owen and the rest. and if you get it im kissing you on the hand!! sensually

7 notes

·

View notes

Text

Aside from water, concrete is the most-used material in the world, with about 14 billion cubic metres being used every year. Of that, 40% of that is used to build places for people to live.

If you were to pour that amount of concrete to make a paving slab ten centimetres thick, it would cover all of England and about half of Wales. In the US, the same amount would cover the state of New York.

But concrete production releases carbon dioxide (CO₂), one of the greenhouse gases that drives climate change. About 90% of emissions associated with concrete come from the production of Portland cement – this fine grey powder, the part that binds concrete ingredients together, was named after its resemblence to stone from the Isle of Portland, Dorset. Portland cement accounts for 7%-8% of the world’s direct CO₂ emissions.

Production of a more sustainable and cost-effective low-carbon cement, often nicknamed “green” cement, is scaling up. A new plant next to an existing cement plant in Redding, California, will produce about 15,000 tonnes of low-carbon cement every year. This could be used to make about 50,000 cubic metres of concrete, which is less than 0.0004% of the world’s concrete production.

At Redding, materials technology company Fortera turns CO₂ captured during conventional cement production into ready-to-use green cement, a form of calcium carbonate. This could reduce carbon emissions of cement by 70% on a tonne-for-tonne basis, according to Fortera.

A concrete issue

People have been using concrete for more than 2,000 years, by blending gravel, sand, cement, water and, sometimes, synthetic chemicals. It’s used to create everything from paths and bridges to buildings and pipes.

Currently, the EU uses more than two tonnes of concrete per person per year – 325kg of that is cement. That’s equivalent to the amount of food the average European person eats in five months.

Cement production is an energy-intensive process and the greenhouse gas emissions are hard to cut. When limestone is heated in a kiln, often fuelled by coal, nearly half that limestone is lost as CO₂ emissions.

This happens because limestone (calcium carbonate) breaks down in heat to form clinker, a mix of calcium oxide and CO₂. For every tonne of ordinary Portland cement made, 0.6-0.9 tonnes of CO₂ are released into the atmosphere.

So many industries rely on this material. The main challenge facing the cement industry is reducing CO₂ emissions at the same time as meeting global demand.

So as well as developing new technologies, low-carbon cement production must be established on a global scale to meet infrastructural needs required of economically developing nations.

Low-carbon alternatives

Other ways to reduce the carbon footprint of concrete include using fly ash (a by-product from burning coal in power plants) or slag (a by-product from steel production) to partially replace Portland cement.

However, sources of these materials will reduce as other industries decarbonise. Over time, less iron ore will be used to produce steel as more steel is produced from recycling existing steel, so there’ll be less available slag.

Current strategies for decarbonising cement and concrete rely heavily on using carbon capture and storage technology to capture unavoidable process emissions from cement plants.

So low-carbon cement production doesn’t have to involve replacing every cement production plant in operation. Low-carbon cement facilities can be retrofitted to capture CO₂ emissions released from manufacturing conventional cement. Plants can also use that captured CO₂ within the cement that they are producing or as a product for the food and chemical industries.

In Norway, Heidelberg Materials are building an industrial-scale carbon capture and storage plant at a cement facility that could capture and store an estimated 400,000 tonnes of CO₂ per year – that’s half the existing plant’s emissions.

However, this technology has a high investment cost for cement producers. Captured CO₂ can be stored underground, but this requires specific geological characteristics that aren’t guaranteed at cement production sites.

Greenhouse gas emissions in the cement sector are regulated by the EU’s emissions trading system. This was established to make polluters pay for their greenhouse gas emissions, reduce emissions and generate revenues to finance the green transition.

This legislation has not significantly reduced carbon emissions in the cement sector over the past decade, according to the International Energy Agency, mainly due to free emissions allowances being granted to cement manufacturers.

Despite sustained healthy profits in the cement industry, there hasn’t been enough investment in the widespread uptake of cleaner technologies and the sustainable use of materials. Greater financial incentives could help whereby companies have to pay for emissions associated with the production of cement.

As a design engineer, I appreciate that material choice and good design play a major role in the sustainability credentials of construction. Before low-carbon cement technology becomes more widespread, engineers, designers and builders can use construction materials more efficiently and choose products with lower embodied carbon – that’s carbon emissions released during the life cycle of building materials, from extraction through to disposal.

This approach could easily save 20% in embodied emissions associated with new building design.

Some governments could move towards only permitting the use of low-carbon cement. In Ireland, the Climate Action Plan 2024 requires that low-carbon construction methods and low-carbon cement are specified where possible for government-procured or government-supported construction projects.

Could all cement in the future be low-carbon or “green”? How “low-carbon” is defined will play a very important part in how this is translated into practice in the industry.

Retrofitting technology to large-scale existing cement production plants will prove that it’s technically possible to produce low-carbon cement efficiently at scale. With the right incentives in place by governments and the construction sector, almost all cement produced around the world could be low-carbon.

2 notes

·

View notes

Text

How Quick Lime Is Used in Steel, Cement, and Chemical Industries

Quick lime, also known as calcium oxide (CaO), is one of the most widely used industrial chemicals across the globe. Derived from limestone through a high-temperature calcination process, quick lime has unique properties that make it essential in various heavy industries. Among the most prominent users of this material are the steel, cement, and chemical industries.

In this blog, we’ll explore how quick lime is used in each of these sectors, why it’s so valuable, and how quick lime supplier support the demand with various forms like quick lime powder to suit different processes.

Quick Lime in the Steel Industry

The steel industry is perhaps one of the largest consumers of quick lime. In steel manufacturing, quick lime is used for several purposes—especially in removing impurities during the production process.

1. Purification and Slag Formation

When iron is converted to steel, it contains impurities like sulfur, phosphorus, and silica. Quick lime acts as a fluxing agent, combining with these unwanted elements to form slag, which floats on top of the molten steel and is easily removed. This not only improves the purity of the steel but also enhances its strength and quality.

2. pH Control and Refining

Quick lime is also used to control pH levels in wastewater generated during steel processing. Its alkaline nature helps neutralize acidic wastes, ensuring safer discharge and environmental compliance.

Additionally, quick lime powder is often preferred in automated steel plants where dust-free application and rapid reactivity are essential.

Quick Lime in the Cement Industry

Quick lime plays a pivotal role in cement manufacturing, both as a raw material and a functional additive.

1. Ingredient in Clinker Formation

Cement production begins with heating a mixture of limestone, clay, and other materials in a rotary kiln. Here, limestone breaks down into calcium oxide (quick lime) and carbon dioxide. This quick lime then reacts with other components like silica and alumina to form clinker—the basic building block of cement.

2. Controlling Setting Time and Strength

In some types of cement, a controlled amount of quick lime powder is added to adjust the setting time and improve long-term strength. The fine powder ensures even mixing and reactivity, especially in specialty cements like white cement and oil well cement.

Leading quick lime manufacturers supply high-purity lime products to cement plants to maintain consistent chemical composition, ensuring quality output batch after batch.

Quick Lime in the Chemical Industry

In the chemical industry, quick lime is a fundamental raw material used to manufacture a wide range of essential products.

1. Producing Calcium Compounds

One of the major uses of quick lime is in producing other calcium-based chemicals. When it is treated with water, it forms slaked lime (calcium hydroxide), which is then used to produce compounds like calcium carbonate, calcium chloride, and bleaching powder. These chemicals are widely used in paper manufacturing, plastics, water purification, and even food processing.

2. pH Regulation and Neutralization

Quick lime is also heavily used in chemical processing plants to adjust pH levels, neutralize acidic waste streams, and support chemical reactions that require a basic environment. For example, in the manufacture of alkalis and sodium carbonate, It plays a key role in maintaining reaction efficiency.

3. Gas Treatment

Certain chemical industries use quick lime to remove acidic gases like sulfur dioxide from emissions, making it a part of environmental control strategies.

Choosing the Right Quick Lime Product

The choice of lime form—lumps, granules, or quick lime powder—depends on the specific application. For instance, powder is ideal for high-speed automated systems, while lump lime is commonly used in large kilns and furnaces.

Reliable quick lime manufacturer offer customized solutions for different industries, ensuring the right purity levels, reactivity, and packaging to meet operational needs.

Final Thoughts

From purifying molten steel to forming cement clinker and enabling chemical reactions, quick lime proves to be a truly versatile industrial material. Its chemical stability, high reactivity, and environmental benefits make it indispensable in modern manufacturing.

As industries evolve, so does the demand for high-quality lime products. Partnering with experienced quick lime suppliers ensures not only product reliability but also technical support and sustainable supply chains.

Whether you’re in the steel, cement, or chemical business, understanding how to use quick lime effectively can significantly improve your production processes—and your bottom line.

Also Read: How Slaked Lime Purifies Water: A Look Into Its Role in Water Treatment

0 notes

Text

Buy Weed Online In Woonsocket, RI, Rhode Island USA

Cannabis Travel Guide

Smoking Tolerance Level

[1= very illegal 5=virtually legal]: 4.8

Marijuana Laws & Legislation for Woonsocket

Rhode Island has legalized both recreational and medical marijuana. Adults aged 21 and over can possess up to one ounce of cannabis and up to 10 ounces within their residence. Home cultivation of up to six plants, with no more than three being mature, is allowed. Medical marijuana patients may possess up to 2.5 ounces and cultivate up to 12 mature plants. CBD products are legal in Rhode Island. This summary provides up-to-date marijuana laws for Rhode Island as of 2025.

Please note that marijuana laws are subject to change. For the most current information, consult your state’s official resources or legal counsel.

Law Enforcement

When you smoke the police might have something to say about it, but as long as you’re not selling it and only have a little on you they will let you off with a warning.. If you get caught and it’s bagged up, IT’S OVER FOR YA…. you will be in the clinker and most likely face the judge in the morning….

Where to buy marijuana in Woonsocket, Rhode Island

: Usually, you need to know one person.. you can talk to people in parks, or near the projects and other public housing complexes. You’ll know what parts too ask and who not to ask.

Woonsocket, Rhode Island marijuana prices

:

Schwag – Dime 10$ – 3 grams

1/4 – 20$-25$ 1/2 – 40$ – 50$

Ounce 80$ -90$ QP 250$ Pound $700

Mid-Grades – 1/4 – 40$ 1/2 – 80$

Ounce 140$

Hydro – 1/8 35$-40$ 1/4 70$ – 75$ 1/2 130$ – 140$

Ounce 230$ – 240$

a more recent report we have is: ”

It all depends who you know…

Schwag (garbo,dirt) : 20-25 for a quater 40-50 for a half 80-90 for a ounce 200-250 for a quater pound 600-800 a pound

Mid-grades (aight,decent) : 35-45 for a quater 65-80 for a half 130-150 for a ounce 450 – 500 a quater pound

Hydro (BOMB) 35-45 for a eighth 70-90 for a quater 130-150 for a half 230-260 for a ounce

Headies (BOMB) 45-60 for a eighth 90-120 a quater 180-210 for a half

Haze (BOMB) same as Headies, 20-30 for a gram, maybe .8 for about 15

Exotic Strands (White widow,Northern Lights,Yellow Haired Hydro,Orange Crush, Kush) Expensive, gotta be a baller. 25-30 a gram all day

Woonsocket, Rhode Island Marijuana Brands

:

Schwag

Mid-Grades

Hydro

Haze

KB

CatPiss

Canadian Weed

More Information

#rhodeislandweed#cannabiscommunity#washingtonweed#dc#florida#georgiaweed#utahweed#massachusettsweed#bostonweed#montanaweed#maineweed#cali#floridaweed#texasweed#bostonstoners#caliweed#southcarolinaweed#massgas#canadianweed#westvirginiaweed#oregonweed#kentuckyweed#alabamaweed#californiaweed#tennesseeweed#delawareweed#miami#rhodehighland#marylandweed#growyourown

0 notes

Text

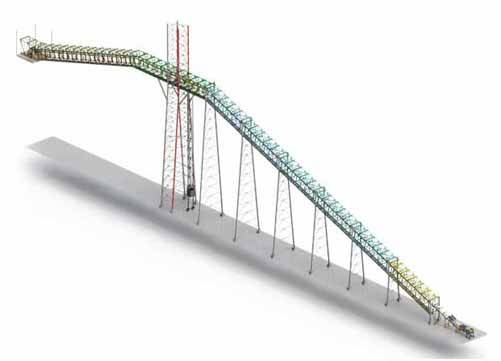

Top-Quality Material Handling Solutions by Reliable Belt Conveyor Suppliers

In the fast-paced world of bulk material handling, belt conveyors have emerged as a dependable and cost-effective solution. These systems streamline transportation processes across industries such as cement, mining, fertilizer, power plants, and metallurgy by ensuring smooth movement of materials over long distances with minimal energy consumption.

The need for efficient belt conveyor suppliers is growing as industries demand increased automation, reduced downtime, and better handling of varied material types. These suppliers provide customized systems that align with production targets, load capacities, and environmental factors.

As industries scale operations, the demand for specialized conveyor systems increases. Reliable belt conveyor suppliers understand that durability, modularity, and maintenance ease are central to long-term performance. With options for troughed, flat, and closed-type conveyors, suppliers cater to a wide array of process requirements—delivering systems that reduce manual handling and ensure safety on the shop floor.

In India, Chanderpur Group has established a solid reputation for designing and manufacturing industrial-grade conveyor systems tailored for high-capacity applications. With over six decades of engineering legacy, CPG integrates modern fabrication technology and design precision to develop belt conveyors that meet rigorous performance standards across diverse sectors.

Belt conveyors not only improve operational flow but also support sustainability goals by minimizing energy losses and material wastage. Automation-enabled models allow for real-time monitoring and consistent throughput, supporting production continuity and reducing labour dependency.

As projects get more complex, the role of expert conveyor suppliers becomes pivotal. Whether it's transporting limestone, fly ash, clinker, or biomass, high-performance conveyor systems enhance productivity and ensure system reliability.

Manufacturers like Chanderpur Group are helping industries evolve with robust conveying solutions built on a foundation of proven expertise and engineered precision, ensuring smooth movement, project success, and long-term value.

#Belt Conveyor Manufacturer in India#Belt Conveyor Supplier in India#Belt Conveyor Manufacturer#Belt Conveyor Supplier#Belt Conveyor

0 notes

Text

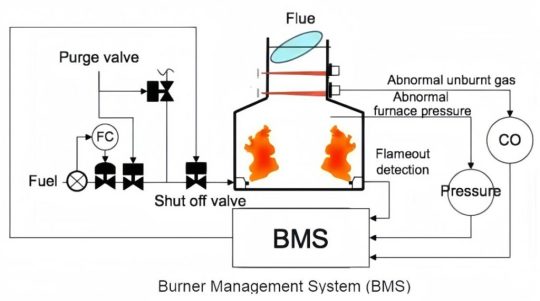

Why Every Industrial Furnace Needs a Zirconia Oxygen Analyzer for Precision Burner Control

In industries like steel, glass, cement, and petrochemicals, industrial furnaces are the beating heart of production. But without tight burner control, they bleed energy, raise emissions, and put safety at risk. The solution? Real-time oxygen insight from zirconia oxygen analyzers.

What’s at Stake with Burner Control?

Poor combustion control = wasted fuel, unstable flame temperatures, and higher CO/NOₓ emissions. To combat this, manufacturers often use excess air—but that comes at a cost: cooler flames, inefficiencies, and more energy up the stack.

This is where zirconia oxygen analyzers become game changers. Installed directly into the flue gas stream, they deliver real-time, accurate O₂ data. Operators or automation systems can immediately adjust the air–fuel ratio, optimizing combustion dynamically—not hours or days later.

How Do Zirconia Oxygen Analyzers Actually Work?

At their core, zirconia sensors use a heated ceramic probe made of zirconium dioxide. When exposed to differing oxygen concentrations, the probe generates a voltage based on the Nernst equation. This voltage reflects the exact oxygen content in the combustion gases.

Thanks to their extreme temperature resistance and wide measurement range (0.1% to 25% O₂), zirconia analyzers provide consistent, high-precision readings—even in the harshest furnace environments.

Big Benefits of Using Zirconia Analyzers in Furnaces

1. Instant Air-Fuel Optimization: Live data means your burner control system can auto-tune air input to match fuel needs—improving energy use and flame stability.

2. Lower Fuel Costs: Eliminate unnecessary excess air and boost heat transfer. Many users report fuel savings of 3–5% or more.

3. Reduced Emissions: Minimize CO and NOₓ formation by burning cleaner and more completely. Stay within compliance limits easily.

4. High Durability in Harsh Conditions: Built to endure up to 1,000°C, zirconia sensors thrive in extreme heat, corrosion, and dust-heavy zones.

5. Less Maintenance, More Uptime: Self-calibrating designs and robust construction reduce the need for frequent service—freeing up your maintenance crew.

Where Are These Analyzers Used?

Zirconia oxygen analyzers are found in:

Steel reheating and annealing furnaces

Glass melting tanks

Cement kilns

Petrochemical cracker furnaces

Ceramic sintering ovens

Wherever flame control, fuel efficiency, and product consistency matter—zirconia delivers .

Real Results from the Field

A steel plant cut excess air by 15%, saving 5% on fuel while reducing CO emissions.

A cement facility saw more consistent clinker quality and less downtime by stabilizing burner conditions.

A glass factory extended refractory life by reducing flame impingement through tighter O₂ control.

Take Control of Your Furnace Today

Don’t let poor combustion eat into your margins. With a zirconia oxygen analyzer, you're not just installing a sensor—you’re unlocking a smarter, cleaner, and more profitable furnace operation.

Request a consultation, Download the spec sheet, Or schedule a pilot test and see the technology in action.

Contact Us : 0086–15071131907

Email Us : [email protected]

0 notes

Text

Rhino 5538EV: The Perfect Truck for Cement Logistics | IPLTech Electric

The industrial world is evolving fast, and the cement industry is no exception. To tackle high fuel costs and carbon emissions, companies are looking at reliable electric trucks.

IPLTech Electric’s Rhino 5538EV tractor head is built specifically for heavy cement inbound and outbound transport. Major cement brands like Ultratech, JSW, Dalmia, JK, Shree, and Mangalam have already integrated these powerful EV trucks into their fleets.

Key Raw Materials Covered: Limestone, clinker, flyash, and other critical commodities. Range & Efficiency: The Rhino 5538EV delivers ~189 km per charge under real-world conditions. Multi-Trailer Compatibility: Skeleton, flatbed, sidewall, bulker, and tip trailers — all supported. Faster Loading & Unloading: Its 3-minute trailer coupling/decoupling saves time & boosts productivity. 70% Lower Running Costs: Compared to diesel trucks, operating costs drop massively.

With zero tailpipe emissions, the Rhino 5538EV helps cement brands hit their ESG goals while improving profitability and sustainability.

Looking Ahead: As India’s only OEM serving the full cement value chain with electric trucks, IPLTech Electric is leading the way toward a cleaner, smarter logistics future.

0 notes